Abstract

In recent years, the detrimental impact of traditional gas–liquid refrigerants on the environment has prompted a shift towards sustainable solid-state refrigeration technology. The elastocaloric effect, particularly in NiTi-based shape memory alloys (SMAs), presents a promising alternative due to its high coefficient of performance. However, conventional methods for alloy development are inefficient, often failing to meet the stringent requirements for practical applications. This study employed machine learning (ML) to accelerate the design of NiTi-based SMAs with an enhanced elastocaloric effect. Through active learning across four iterations, we identified nine novel NiTi-based SMAs exhibiting phase-transformation-induced entropy changes (ΔS) greater than 90 J/kg·K−1, surpassing most existing alloys. Our ML model demonstrates robust interpretability, revealing key relationships between material features and performance. This work not only establishes a more efficient pathway for alloy discovery but also aims to contribute significantly to the advancement of sustainable refrigeration technologies.

1. Introduction

Traditional refrigeration systems predominantly rely on gas–liquid compression technology, utilizing refrigerants such as chlorofluorocarbon (CFC) and hydrochlorofluorocarbon (HCFC), which significantly harm the ozone layer. While some refrigerants like hydrofluorocarbon (HFC) do not deplete the ozone layer, they still contribute to the greenhouse effect, exacerbating climate change [1]. Moreover, these conventional refrigeration systems are plagued by issues such as excessive noise levels and high energy consumption. Refrigeration alone consumes over 15% of global electricity, a figure anticipated to escalate with economic growth [2]. In response, researchers are actively exploring alternative cooling materials and technologies.

Among the promising solutions are solid-state refrigeration technologies based on various mechanisms, including the magnetocaloric effect [3,4], electrocaloric effect [5], and elastocaloric effect [6], which have been proposed as alternatives due to their environmentally friendly nature. Particularly, the elastocaloric effect, specifically based on shape memory alloys (SMAs), has shown its unique promise [7] on account of a coefficient of performance (COP) exceeding 80% [8]. Notably, NiTi-based SMAs outperform Cu-based, Fe-based, and ferromagnetic SMAs in terms of the latent heat of phase change and elastomeric effects. As a result, prototype chillers utilizing NiTi-based SMAs have been successfully reported [9,10].

The composition [11,12,13,14,15,16,17,18] and preparative process [19,20] of NiTi-based SMAs wield a significant influence on the phase transition temperature, precipitation, and microstructure. These factors, consequently, play a crucial role in affecting the ΔS of the elastocaloric effect. In the case of multielement NiTi alloys, the variables concerning the type and content of the alloying elements span a wide range. Moreover, common heat treatment processes for NiTi-based SMAs encompass homogenization, solution, and aging treatments [21]. Each step in these processes has a broad range of selectable heating temperatures, times, and cooling methods. Wang et al. [22] and Mevada et al. [23] published review papers that summarized and commented on the latest research progress related to elastocaloric refrigeration and elastocaloric materials.

Given the extensive search space involved in combined composition and process parameters, machine learning (ML) has proven to be a highly effective tool in materials research and engineering practice [24,25,26,27,28,29,30,31,32,33]. For example, Yang et al. [34] proposed a machine learning workflow to design and optimize the elastocaloric properties of NiMn-based SMAs. An XGB Regressor model was trained and utilized to predict the adiabatic temperature change. Tang et al. [35] developed a non-isothermal phase-field model and machine learning to accelerate the prediction and optimization of magneto-elastocaloric materials. Raji et al. [36] employed various ML algorithms to predict the austenite finish temperature of NiTiHfPd SMAs and then validated them through experiments. Tian et al. [37] provided a potential selection of narrow thermal hysteresis TiNi-based SMAs screened using an effective strategy combining XGBoost and DFT calculation. Zhao et al. [38] showed an adaptive design strategy that tightly coupled ML with theoretical calculations to accelerate the process of the discovery of multi-component Cu-Al-based SMAs with high ΔS.

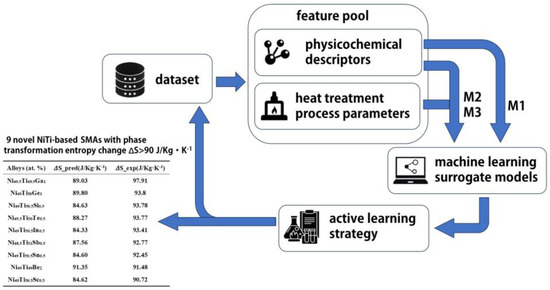

Despite the potential of NiTi-based SMAs, the traditional trial-and-error approach in alloy development is inefficient and often leads to suboptimal materials. The development of rapid and effective design methods is essential to address the growing environmental concerns associated with conventional refrigeration technologies. Therefore, this study aimed to leverage machine learning techniques to accelerate the discovery and optimization of NiTi-based SMAs with enhanced elastocaloric effects. By integrating machine learning into the alloy design process, we seek to not only improve the efficiency of material discovery but also to provide a deeper understanding of the relationships between compositional and processing parameters and elastocaloric performance. In this study, we developed machine learning models to predict the entropy change in phase transition (ΔS) in NiTi-based SMAs using both physical characteristics and heat treatment process parameters as shown in Figure 1. For comparison, three ML models were trained. The first model (M1) was constructed using only physicochemical characteristics. The second model (M2) was constructed using combined features including physicochemical characteristics and heat treatment process parameters. Based on M2, a segmentation fitting method was introduced and yielded the third model (M3), which showed superior results. Subsequently, adopting an active learning strategy [39,40,41], we iteratively optimized new materials, that is, nine new NiTi-based SMAs with ΔS values greater than 90 J/Kg·K−1 after four iterations. We further optimized the corresponding heat treatment process parameters for these new alloys and conducted experimental verification. Finally, we delved into the physical interpretability of our ML models.

Figure 1.

A schematic of the machine-learning-based iterative design loop for accelerated design of high-elastocaloric NiTi-based SMAs.

2. Methods

2.1. Datasets

The data used in present work were taken from published papers. M1 used 137 data samples including compositions and ΔS values. M2 and M3 used 200 additional data samples including heat treatment process parameters besides compositions and ΔS values.

For ΔS values, one part could be directly extracted from papers using text mining. The other part was obtained by measurement based on latent heat of phase transformation (ΔH) and martensitic transformation temperatures according to Equation (1)

Here, T0 = and and are the starting temperature of martensite phase transformation and the end temperature of reverse transformation, respectively.

2.2. Features

The original feature set for M1 included 60 physicochemical characteristics. M2 was constructed using 20 physical features and 9 heat treatment process parameters as shown in Table S1 in Supplementary Materials. These physicochemical characteristics encompassed information at the electron, atomic, and lattice levels. For NiTi-based SMAs, generally, there are three heat treatment stages: homogenization treatment (I), solution treatment (II) and aging treatment (III). Common cooling methods include water quenching (WQ), oil quenching (OQ), air cooling (AC), and cooling in the furnace (FC). To enable the ML models to handle string-type data [42], we used label encoding to encode WQ, OQ, AC, and FC as 4, 3, 2, and 1, respectively. Some of the data samples had only one or two of the three ways of heat treatment for the SMAs. To make more efficient use of the limited dataset, for some samples that had not undergone solution or/and age heat treatment, to align the data, a temperature of 293 K and a time of 0 min with air cooling were used as the temperature and time of heat treatment, as shown in Table 1.

Table 1.

Filling data for missing values of heat treatment process parameters.

2.3. Experiments

In this work, our experiments focused on the exploration and extrapolation of the compositions and processes of NiTi-based binary and ternary SMAs, which are guided by machine learning models and are used for model validation and iterative learning. Ingots of SMAs, each with a weight of about 100 g, were prepared using 99.99% pure nickel, titanium, and other alloying metals by arc melting at 1723 K under argon atmosphere using a WK-II-type non-consumable vacuum arc melting furnace. The specimens corresponding to the predicted results from M1 were not heat-treated, and the specimens corresponding to the predicted results of M2 were heat-treated according to the predicted process parameters. Specimens with the size of 5 mm × 5 mm × 3 mm and Φ3 mm × 1.5 mm, cut from the ingots by electrospark cutting, were ground and polished. Elemental contents were verified using an energy-dispersive spectrometer (EDS) embedded in a field-emission scanning electron microscope (FE-SEM, ZEISS Sigma 300, Zeiss Greater China headquarters, Shanghai, China) using square specimens. Phase transformation temperatures and latent heat ΔH were measured using differential scanning calorimetry (DSC, Q2000 V24.11 Build 124, TA Instruments, New Castle, DE, USA) at heating and cooling rates of 10 K/min in the temperature range of 188 K~573 K using circular specimens.

3. Results and Discussion

3.1. ML Model Selection and Evaluation

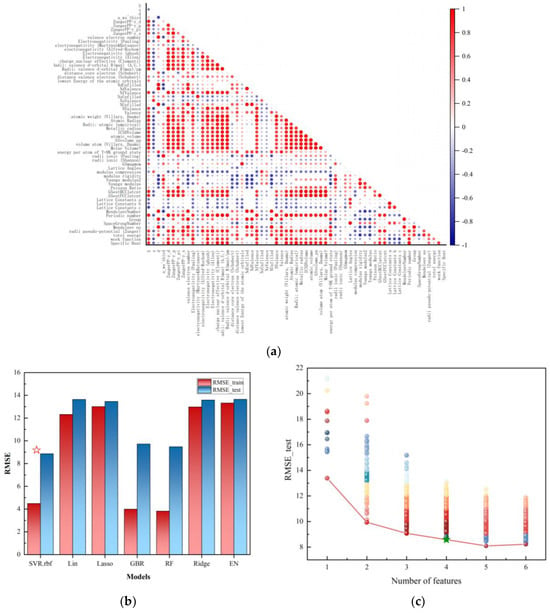

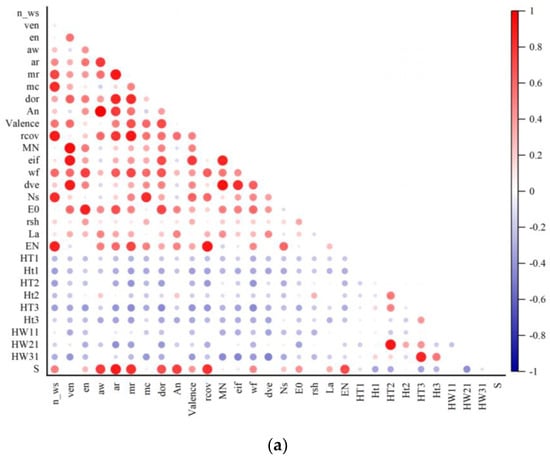

Figure 2a and Figure 3a illustrate the Pearson correction between features for M1 and M2, respectively. After removing the strongly correlated features with a Pearson correlation coefficient threshold of 0.8 for M1, we retained 13 features (Table S2) for details. Similarly, ten physicochemical features and nine heat treatment process features were preserved for M2 (pink-marked in Table S1).

Figure 2.

Characterization and model selection for the physical and chemical characteristic model (M1). (a) Pearson correlation matrix for the initial 60 descriptors. (b) Model selection based on leave-out cross-validation. (c) Cross-validation error from SVR.rbf model containing a subset of the retained descriptors. (d) The prediction performance of M1. (e) Results of 4 iterations of active learning based on M1.

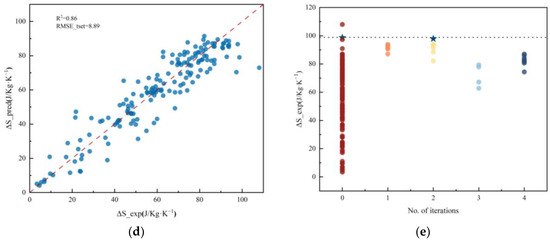

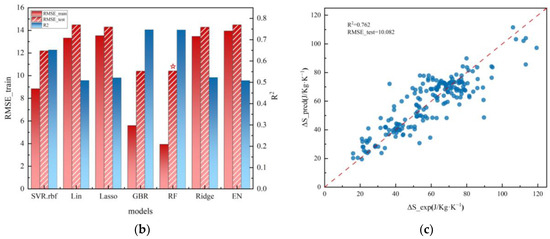

Figure 3.

Characteristics and model selection for physical and chemical characteristics combined with heat treatment process characteristic model (M2). (a) Pearson correlation matrix for the initial 29 descriptors. (b) Model selection based on leave-out cross-validation. (c) The prediction performance of M2.

Notably, the temperatures, times, and quenching methods of the three heat treatment processes were independent and only related to the experimenter’s setup. Consequently, these factors were not considered in the feature screening process.

Subsequently, we evaluated the R2 and RMSE of various regression models using the standardized and pre-screened dataset. The optimal model, selected based on the largest R2 and smallest RMSE, was drawn from a Support Vector Machine with a radial kernel (SVR.rbf), a Random Forest (RF), Gradient Boosting (GBR), Ridge Regression (Ridge), a least absolute shrinkage and selection operator (LASSO), an Elastic Network (EN), and a linear regression model (Lin). We finetuned the hyperparameters of these models using leave-out cross-validation [43] and Grid Search or Random Search.

As shown in Figure 2b,c, for M1, the top performer was SVR.rbf. After a screening of more exhaustive features, we identified four key physical features for constructing M1: ΔS = f1(aven, en, Nsvalence, Modulus, compression). The resulting R2 for M1 was 0.860, and the RMSE was 8.472, and these were obtained according to Equations (1) and (2).

Here, is the predicted value of the output of each cluster, yi represents the experimental data, and is the mean value of y.

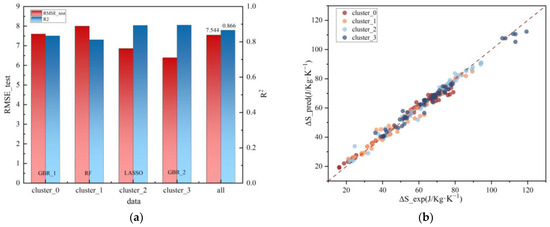

Similarly, for M2, the best-performing model was RF, with ΔS = f2(aw, dor, rcov, Valence, HTI,II,III, HtI,II,III, WI,II,III). The R2 of M2 was 0.746 and the RMSE was 10.422. However, the generally accepted threshold for better interpretability in regression models is an R2 value over 0.8. Therefore, to enhance the R2 of M2, we explored ensemble learning [44,45,46] (Boosting, Bagging, and Stacking), cluster learning (K-Means [47] and DBSCAN [48]), and Neural Networks [49]. The segmentation fitting method showed superior results and was designated as M3. Using M1 as a reference, we clustered points with similar heat treatment process parameters into four clusters with 45, 50, 49, and 56 data points. The R2 and RMSE values of the optimal models for these clusters are showcased in Figure 4 and Table 2. The final R2 for M3 was 0.866, with an RMSE of 7.544. The divide-and-conquer approach demonstrated better fitness and model performance compared to the traditional RF model M2.

Figure 4.

Results of K-Means clustering model M3. (a) The best models for each clustering subset and their R2 and RMSE values. (b) The prediction performance of M3.

Table 2.

The best models for four clustering subsets, their R2 and RMSE values, and comprehensive results for K-Means clustering model M3.

In physics, entropy is commonly understood as the degree of disorder within a system. The entropy ΔS of an alloy is influenced by various factors, as expressed in Equation (3) [45].

Here, represents the entropy change caused by atomic vibration, represents the entropy change caused by electrons, represents the entropy change caused by the magnetic properties of the material, and represents the entropy change caused by structural alteration.

Given that the NiTi-based SMAs in this study were non-magnetic, we have . Additionally, since the martensitic phase change was a non-diffusive phase transformation, .

While the highest-scoring four features for M1 differed from those for M2 and M3, all three models encapsulated information about the alloys at the electronic, atomic, and lattice levels. Electronegativity (en), for instance, denotes an atom’s ability to attract electrons. Electronegativity, the valence electron number (ven), and the covalent radius (rcov) exhibited periodic trends, with main group elements of the same period witnessing an increase in en and a decrease in rcov as ven increased. In the same main group, as periodicity increased, en decreased while rcov increased.

The average electron concentration (aven) and the s orbital electron filling number (NsValence) are related to an element’s position in the periodic table. In addition, the compression modulus has a relationship, as per Equation (4), with the elastic modulus.

Here, represents the modulus of elasticity, represents the modulus of compression, and is the Poisson’s ratio of the alloys, signifying the lateral shrinkage capacity. The elastic modulus indicates the ease of atoms leaving their equilibrium positions, characterizing the strength of interatomic bonding. Crystals with strong interatomic bonding, such as covalently bonded crystals like diamonds, have a high elastic modulus.

Features like the aven, en, Nsvalence, compression modulus, rcov, and ven all directly or indirectly reflect information about at the electronic level. Additionally, the effect of atomic mass (am) on vibrational entropy shows that a larger atomic mass in a compound leads to less violent vibration under the same conditions, resulting in a smaller . Despite the non-identical feature sets, both provide a reasonable explanation for the phase transformation entropy change S in terms of electron, atomic, and lattice aspects.

In terms of the generalization ability of the model, the machine learning framework and methodology that we have developed can be adapted to other elastocaloric materials directly. The core principles of feature selection, model training, and active learning can be transferred to other caloric materials, e.g., magnetocaloric and electrocaloric materials. However, each type of caloric material may require specific features relevant to its mechanisms. For instance, magnetocaloric materials would involve magnetic properties while electrocaloric materials would focus on dielectric properties.

3.2. Validation

To evaluate each machine learning model, we not only assessed its performance on the training data but also prioritized examining its extrapolation ability. For this purpose, we collected five new data points that were not present in the training dataset to assess the extrapolation ability of M1. Similarly, 30 new data points were gathered for validating M2 and M3. For the M3 segmented-fit model, a preliminary step involved assigning each data point to the relevant cluster before entering it into the prediction model. Here, we computed the clustering center of each cluster model Ci (i = 1, 2, 3, 4), where Ci represented a sequence of 13 × 1. The next step involved calculating the Euclidean distance () of each data point (D1, …, Dj, …, D30) from the four clustering centers separately. We considered a data point to belong to cluster when the distance was minimal.

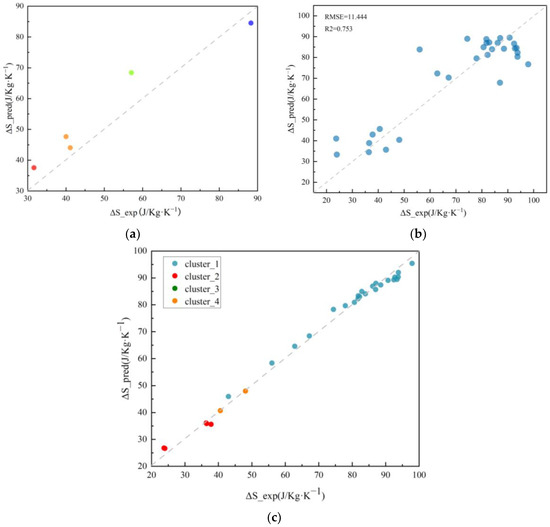

The validation results for the new data of M1, M2, and M3 are shown in Figure 5a–c, respectively, with average errors of 13.84%, 13.51%, and 2.91%. Notably, the incorporation of heat treatment process features led to a significant reduction in the extrapolation error for the models. Moreover, the segmented fitting model proved to be even more effective in minimizing the extrapolation error, providing clear evidence of the improved extrapolation ability of the model.

Figure 5.

Fitting results of M1 (a), M2 (b), and M3 (c) on new validation data.

3.3. Material Design Toward High-Elastocaloric SMA

In pursuit of NiTi-based SMAs with heightened elastocaloric effects, we applied the machine learning models M1, M2, and M3 to an adaptive design approach. The exploration encompassed the search space for binary and ternary SMAs, comprised of 51 NiTi-based SMAs. The third group of elemental predictions excluded gases, radioactive elements, toxic elements, alkali metal elements, and halogens, with lanthanum representing the lanthanide system. The elemental concentration ranges are detailed in Table 3, with a step of 0.5 at.% for each element. In addition, we defined the search space for heat treatment process parameters for M2 and M3 as outlined in Table 4. Notably, we constrained the parameters for homogenization heat treatment to 1323 K, 4320 min, and water quenching, optimizing for computational efficiency and cost-effectiveness. Additionally, for solution and aging heat treatment, we not only introduced values from Table 4 but also used the heat treatment process parameters with a temperature of 293 K, time of 0 min, and cooling method of air cooling to complete the missing process parameters.

Table 3.

Types and concentration ranges of third group elements in NiTi-based SMA for M1, M2, and M3.

Table 4.

Range and steps of 9 heat treatment process parameters for M2 and M3. HT1, Ht1, and CQ1 indicate the temperature, time, and way of cooling of homogenization; HT2, Ht2, and CQ2 indicate the parameter of solution; and HT3, Ht3, and CQ3 indicate the parameter of aging.

For M3, candidate alloys within the search space were selected based on the maximum expected improvement EI (μ, σ) as defined by Equation (6). Active learning was used as shown in Figure 2e.

Here, , where is the maximum value in the training set, is the mean value of the predicted data, and is the standard deviation of and , representing the standard normal density and distribution function, respectively.

The element space to be predicted involved all elements in the periodic table except gases, halogen elements, alkali metal elements, radioactive elements, and toxic elements. This element space was too large. Therefore, based on domain knowledge and the time cost of model running, the alloys of the third component such as Cu, V, Mn, Fe, Hf, Pd, and Zr were limited to the range of 0~5 at.%, and the other alloys were limited to the range of 0~2 at.% near the NiTi-based SMAs. The selected prediction material included about 300,000 compositions.

3.4. Experimental Validation

We conducted experiments to validate the prediction results and provide feedback to each next iteration. At least four compositions were experimentally validated for each iteration. In four iterations, we found nine new NiTi-based SMAs with ΔS > 90 J/Kg·K−1, as detailed in Table 5. As shown in the third column in Table 5, a small amount of Ge, Ga, In, Te, Sb, Sc, Si, Sn, and Be can improve the elastocaloric effect of NiTi-based SMAs. These third group elements are mainly meta-metals and poor metals, which generally have higher electronegativity, greater atomic masses, and larger covalent radii.

Table 5.

SMAs designed with ΔS greater than 90 J/Kg·K−1 in 4 iterations.

The above validation results showcase the efficacy of machine learning in accelerating material discovery, significantly reducing the time and resources typically required in traditional experimental methods.

However, the datasets for the tree models were relatively small, which may have limited the generalizability of the models. Although the introduction of active learning and cluster learning improved the performance of the models and assisted us in finding new materials, the dependence of the prediction reliability on the dataset volume and data quality cannot be ignored. In addition, the performance of M2 did not significantly improve despite incorporating heat treatment parameters; the main reason could be attributed to the dimensional disaster problem. That is, the introduction of process parameters led to an increase in the feature dimension, but the incrementation of process data was not enough to match it, indicating that the further exploration of additional features or methods may be necessary for enhanced prediction.

4. Conclusions

In this work, we focused on the application of machine learning to accelerate the discovery of novel NiTi-based shape memory alloys (SMAs) with enhanced elastocaloric effect. Three models were compared and validated. The following conclusions were drawn:

- (1)

- The SVR.rbf model (M1) utilized four physicochemical features (aven, en, Nsvalence, modulus compression) exhibited superior performance with an R2 = 0.860 and an RMSE = 8.472.

- (2)

- The RF model (M2), incorporating four physicochemical features (aw, dor, rcov, Valence) along with nine heat treatment parameters, achieved R² = 0.746 and RMSE = 10.422.

- (3)

- Combining the M2 model and K-Means clustering, we formulated the model M3, which achieved improved prediction performance with an R2 = 0.866 and an RMSE = 7.544.

- (4)

- Based on the M3 model, leveraging an active learning strategy through four iterations, we identified nine new NiTi-based SMAs with phase transformation entropy changes ΔS > 90 J/Kg·K−1, surpassing the majority of alloys in the original dataset.

This research demonstrates the efficacy of machine learning in material discovery, offering improved model performance and the potential for practical applications in engineering. Practitioners can select from different models based on their specific requirements, allowing for informed decision making in alloy design.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/met14101193/s1, Table S1: List of features used in M2 and M3. Pink represents the remaining features after filtering by Pearson correlation coefficient; Table S2. Thirteen features after Pearson correlation selection for M1. References [50,51,52,53] were cited in the supplementary.

Author Contributions

Data collection, modeling, validation, formal analysis, investigation, and writing—original draft preparation, Y.G. and Y.H.; methodology and validation, X.Z. and Y.L.; conceptualization, writing—review and editing, and supervision, H.H.; resources, project administration, funding acquisition, H.H. and Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Guangdong Major Project of Basic and Applied Basic Research, grant number No. 2019B030302011, from Department of Science and Technology of Guangdong Province, China.

Data Availability Statement

The raw/processed data required to reproduce these findings can be obtained by contacting the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Secretariat, O. The Montreal Protocol on Substances that Deplete the Ozone Layer; United Nations Environment Programme: Nairobi, Kenya, 2000; p. 54. [Google Scholar]

- Coulomb, D.; Dupont, J.-L.; Pichard, A. The Role of Refrigeration in the Global Economy—29 Informatory Note on Refrigeration Technologies; Instut International du Froid (IIF)-Internation Institute of Refrigeration (IIR): Paris, France, 2015. [Google Scholar]

- Franco, V.; Blázquez, J.S.; Ingale, B.; Conde, A. The magnetocaloric effect and magnetic refrigeration near room temperature: Materials and models. Annu. Rev. Mater. Res. 2012, 42, 305–342. [Google Scholar] [CrossRef]

- Zhang, N.; Shen, H.; Luo, L.; Liu, J.; Zhao, Z.; Zhang, L.; Sun, J.; Phan, M.H. Magnetocaloric properties of melt-extracted medium entropy gd33co33al34 microfibers. Metals 2024, 14, 880. [Google Scholar] [CrossRef]

- Valant, M. Electrocaloric materials for future solid-state refrigeration technologies. Prog. Mater. Sci. 2012, 57, 980–1009. [Google Scholar] [CrossRef]

- Qian, S.; Geng, Y.; Wang, Y.; Ling, J.; Hwang, Y.; Radermacher, R.; Takeuchi, I.; Cui, J. A review of elastocaloric cooling: Materials, cycles and system integrations. Int. J. Refrig. 2016, 64, 1–19. [Google Scholar] [CrossRef]

- Goetzler, W.; Shandross, R.; Young, J.; Petritchenko, O.; Ringo, D.; McClive, S. Energy Savings Potential and RD&D Opportunities for Commercial Building HVAC Systems; Navigant Consulting: Burlington, MA, USA, 2017. [Google Scholar]

- Cui, J.; Wu, Y.; Muehlbauer, J.; Hwang, Y.; Radermacher, R.; Fackler, S.; Wuttig, M.; Takeuchi, I. Demonstration of high efficiency elastocaloric cooling with large ΔT using NiTi wires. Appl. Phys. Lett. 2012, 101, 073904. [Google Scholar] [CrossRef]

- Ossmer, H.; Miyazaki, S.; Kohl, M. Elastocaloric heat pumping using a shape memory alloy foil device// Elastocaloric heat pumping using a shape memory alloy foil device. In Proceedings of the 2015 Transducers–2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 726–729. [Google Scholar]

- Schmidt, M.; Kirsch, S.-M.; Seelecke, S.; Schütze, A. Elastocaloric cooling: From fundamental thermodynamics to solid state air conditioning. Sci. Technol. Built Environ. 2016, 22, 475–488. [Google Scholar] [CrossRef]

- Tušek, J.; Engelbrecht, K.; Millán-Solsona, R.; Manosa, L.; Vives, E.; Mikkelsen, L.P.; Pryds, N. The elastocaloric effect: A way to cool efficiently. Adv. Energy Mater. 2015, 5, 1500361. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, M.-X.; Eggeler, G. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2010, 58, 3444–3458. [Google Scholar] [CrossRef]

- Ma, J.; Karaman, I.; Noebe, R.D. High temperature shape memory alloys. Int. Mater. Rev. 2010, 55, 257–315. [Google Scholar] [CrossRef]

- Zhou, Y.; Xue, D.; Ding, X.; Wang, Y.; Zhang, J.; Zhang, Z.; Wang, D.; Otsuka, K.; Sun, J.; Ren, X. Strain glass in doped Ti50(Ni50−xDx) (D=Co, Cr, Mn) alloys: Implication for the generality of strain glass in defect-containing ferroelastic systems. Acta Mater. 2010, 58, 5433–5442. [Google Scholar] [CrossRef]

- Ossmer, H.; Miyazaki, S.; Kohl, M. The Elastocaloric Effect in TiNi-based Foils. Mater. Today: Proc. 2015, 2, S971–S974. [Google Scholar] [CrossRef]

- Schmidt, M.; Schütze, A.; Seelecke, S. Scientific test setup for investigation of shape memory alloy based elastocaloric cooling processes. Int. J. Refrig. 2015, 54, 88–97. [Google Scholar] [CrossRef]

- Chen, H.; Xiao, F.; Li, Z.; Jin, X.; Mañosa, L.; Planes, A. Elastocaloric effect with a broad temperature window and low energy loss in a nanograin Ti-44Ni-5Cu-1Al Ti-44Ni-5Cu-1Al (at·%) shape memory alloy. Phys. Rev. Mater. 2021, 5, 015201. [Google Scholar] [CrossRef]

- Xu, B.; Wang, C.; Wang, Q.; Yu, C.; Kan, Q.; Kang, G. Enhancing elastocaloric effect of NiTi alloy by concentration-gradient engineering. Int. J. Mech. Sci. 2023, 246, 108140. [Google Scholar] [CrossRef]

- Yeung KW, K.; Cheung KM, C.; Lu, W.W.; Chung, C.Y. Optimization of thermal treatment parameters to alter austenitic phase transition temperature of NiTi alloy for medical implant. Mater. Sci. Eng. A 2004, 383, 213–218. [Google Scholar] [CrossRef]

- Deng, Z.; Huang, K.; Yin, H.; Sun, Q. Temperature-dependent mechanical properties and elastocaloric effects of multiphase nanocrystalline NiTi alloys. J. Alloys Compd. 2023, 938, 168547. [Google Scholar] [CrossRef]

- Wang, S.; Shi, Y.; Li, Y.; Lin, H.; Fan, K.; Teng, X. Solid-state refrigeration of shape memory alloy-based elastocaloric materials: A review focusing on preparation methods, properties and development. Renew. Sustain. Energy Rev. 2023, 187, 113762. [Google Scholar] [CrossRef]

- Mevada, H.; Liu, B.; Gao, L.; Hwang, Y.; Takeuchi, I.; Radermacher, R. Elastocaloric cooling: A pathway towards future cooling technology. Int. J. Refrig. 2024, 162, 86–98. [Google Scholar] [CrossRef]

- Liu, S.; Kappes, B.B.; Amin-ahmadi, B.; Benafan, O.; Zhang, X.; Stebner, A.P. Physics-informed machine learning for composition–process–property design: Shape memory alloy demonstration. Appl. Mater. Today 2021, 22, 100898. [Google Scholar] [CrossRef]

- Malinov, S.; Sha, W.; McKeown, J.J. Modelling the correlation between processing parameters and properties in titanium alloys using artificial neural network. Comput. Mater. Sci. 2001, 21, 375–394. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, Y.; Wang, C.; Xue, D.; Bai, Y.; Antonov, S.; Dai, L.; Lookman, T.; Su, Y. Machine learning assisted design of high entropy alloys with desired property. Acta Mater. 2019, 170, 109–117. [Google Scholar] [CrossRef]

- Liu, P.; Huang, H.; Antonov, S.; Wen, C.; Xue, D.; Chen, H.; Li, L.; Feng, Q.; Omori, T.; Su, Y. Machine learning assisted design of γ′-strengthened Co-base superalloys with multi-performance optimization. npj Comput. Mater. 2020, 6, 62. [Google Scholar] [CrossRef]

- Ohno, H. Training data augmentation: An empirical study using generative adversarial net-based approach with normalizing flow models for materials informatics. Appl. Soft Comput. 2020, 86, 105932. [Google Scholar] [CrossRef]

- Chanda, B.; Jana, P.P.; Das, J. A tool to predict the evolution of phase and Young’s modulus in high entropy alloys using artificial neural network. Comput. Mater. Sci. 2021, 197, 110619. [Google Scholar] [CrossRef]

- Lee, J.; Asahi, R. Transfer learning for materials informatics using crystal graph convolutional neural network. Comput. Mater. Sci. 2021, 190, 110314. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, C.; Zhu, H.; Chen, Q. A supervised data augmentation strategy based on random combinations of key features. Inf. Sci. 2023, 632, 678–697. [Google Scholar] [CrossRef]

- He, S.; Wang, Y.; Zhang, Z.; Xiao, F.; Zuo, S.; Zhou, Y.; Cai, X.; Jin, X. Interpretable machine learning workflow for evaluation of the transformation temperatures of TiZrHfNiCoCu high entropy shape memory alloys. Mater. Des. 2023, 225, 111513. [Google Scholar] [CrossRef]

- Yang, Z.; Li, S.; Li, S.; Yang, J.; Liu, D. A two-step data augmentation method based on generative adversarial network for hardness prediction of high entropy alloy. Comput. Mater. Sci. 2023, 220, 112064. [Google Scholar] [CrossRef]

- Yang, Y.; Fu, H.; Gao, W.; Su, W.; Sun, B.; Yi, X.; Zheng, T.; Meng, X. Data-driven high elastocaloric NiMn-based shape memory alloy optimization with machine learning. Mater. Lett. 2024, 371, 136948. [Google Scholar] [CrossRef]

- Tang, W.; Wen, S.; Hou, H.; Gong, Q.; Yi, M.; Guo, W. Phase-field simulation and machine learning of low-field magneto-elastocaloric effect in a multiferroic composite. Int. J. Mech. Sci. 2024, 275, 109316. [Google Scholar] [CrossRef]

- Raji, H.; Rad, M.; Acar, E.A.; Karaca, H.; Saedi, S. A machine learning approach to predict austenite finish temperature in quaternary NiTiHfPd SMAs. Mater. Today Commun. 2024, 38, 107847. [Google Scholar] [CrossRef]

- Tian, X.; Zhou, L.; Zhang, K.; Zhao, Q.; Li, H.; Shi, D.; Ma, T.; Wang, C.; Wen, Q.; Tan, C. Screening for shape memory alloys with narrow thermal hysteresis using combined XGBoost and DFT calculation. Comput. Mater. Sci. 2022, 211, 111519. [Google Scholar] [CrossRef]

- Zhao, X.; Huang, H.; Wen, C.; Su, Y.-J.; Qian, P. Accelerating the development of multi-component Cu-Al-based shape memory alloys with high elastocaloric property by machine learning. Comput. Mater. Sci. 2020, 176, 109521. [Google Scholar] [CrossRef]

- Zhang, Y.-F.; Ren, W.; Wang, W.-L.; Li, N.; Zhang, Y.-X.; Li, X.-M.; Li, W.-H. Interpretable hardness prediction of high-entropy alloys through ensemble learning. J. Alloys Compd. 2023, 945, 169329. [Google Scholar] [CrossRef]

- Xue, D.; Balachandran, P.V.; Hogden, J.; Theiler, J.; Xue, D.; Lookman, T. Accelerated search for materials with targeted properties by adaptive design. Nat Commun 2016, 7, 11241. [Google Scholar] [CrossRef]

- Xue, D.; Xue, D.; Yuan, R.; Zhou, Y.; Balachandran, P.V.; Ding, X.; Ding, X.; Lookman, T. An informatics approach to transformation temperatures of NiTi-based shape memory alloys. Acta Mater. 2017, 125, 532–541. [Google Scholar] [CrossRef]

- Maharana, K.; Mondal, S.; Nemade, B. A review: Data pre-processing and data augmentation techniques. Glob. Transit. Proc. 2022, 3, 91–99. [Google Scholar] [CrossRef]

- Gareth, J.; Daniela, W.; Trevor, H.; Robert, T. An Introduction to Statistical Learning: With Applications in R; Spinger: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Schapire, R.E. The boosting approach to machine learning: An overview. Nonlinear Estim. Classif. 2003, 171, 149–171. [Google Scholar]

- Khalil-Allafi, J.; Amin-Ahmadi, B. The effect of chemical composition on enthalpy and entropy changes of martensitic transformations in binary NiTi shape memory alloys. J. Alloys Compd. 2009, 487, 363–366. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, K.; Thé, J.; Yu, H. Accurate prediction of band gap of materials using stacking machine learning model. Comput. Mater. Sci. 2022, 201, 110899. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, J.; Wang, Z.; Lu, X.-G.; Avdeev, M.; Shi, S.; Wang, C.; Yu, T. Predicting creep rupture life of Ni-based single crystal superalloys using divide-and-conquer approach based machine learning. Acta Mater. 2020, 195, 454–467. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, D.; Liu, S.; Zhang, P.; Zhao, W. Aluminum alloy microstructural segmentation method based on simple noniterative clustering and adaptive density-based spatial clustering of applications with noise. J. Electron. Imaging 2019, 28, 033035. [Google Scholar] [CrossRef]

- Waber, J.; Cromer, D.T. Orbital radii of atoms and ions. J. Chem. Phys. 1965, 42, 4116–4123. [Google Scholar] [CrossRef]

- Pauling, L. The nature of the chemical bond. IV. The energy of single bonds and the relative electronegativity of atoms. J. Am. Chem. Soc. 1932, 54, 3570–3582. [Google Scholar] [CrossRef]

- Rabe, K.M.; Phillips, J.C.; Villars, P.; Brown, I.D. Global multinary structural chemistry of stable quasicrystals, high-TC ferroelectrics, and high-Tc superconductors. Phys. Rev. B 1992, 45, 7650–7676. [Google Scholar] [CrossRef]

- Clementi, E.; Raimondi, D.L. Atomic screening constants from SCF functions. J. Chem. Phys. 1963, 38, 2686–2689. [Google Scholar] [CrossRef]

- Pettifor, D.G.; Pettifor, D. Bonding and Structure of Molecules and Solids; Clarendon Press Oxford: Oxford, UK, 1995. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).