Microstructure Characteristics of Porous NiTi Shape Memory Alloy Synthesized by Powder Metallurgy during Compressive Deformation at Room Temperature

Abstract

:1. Introduction

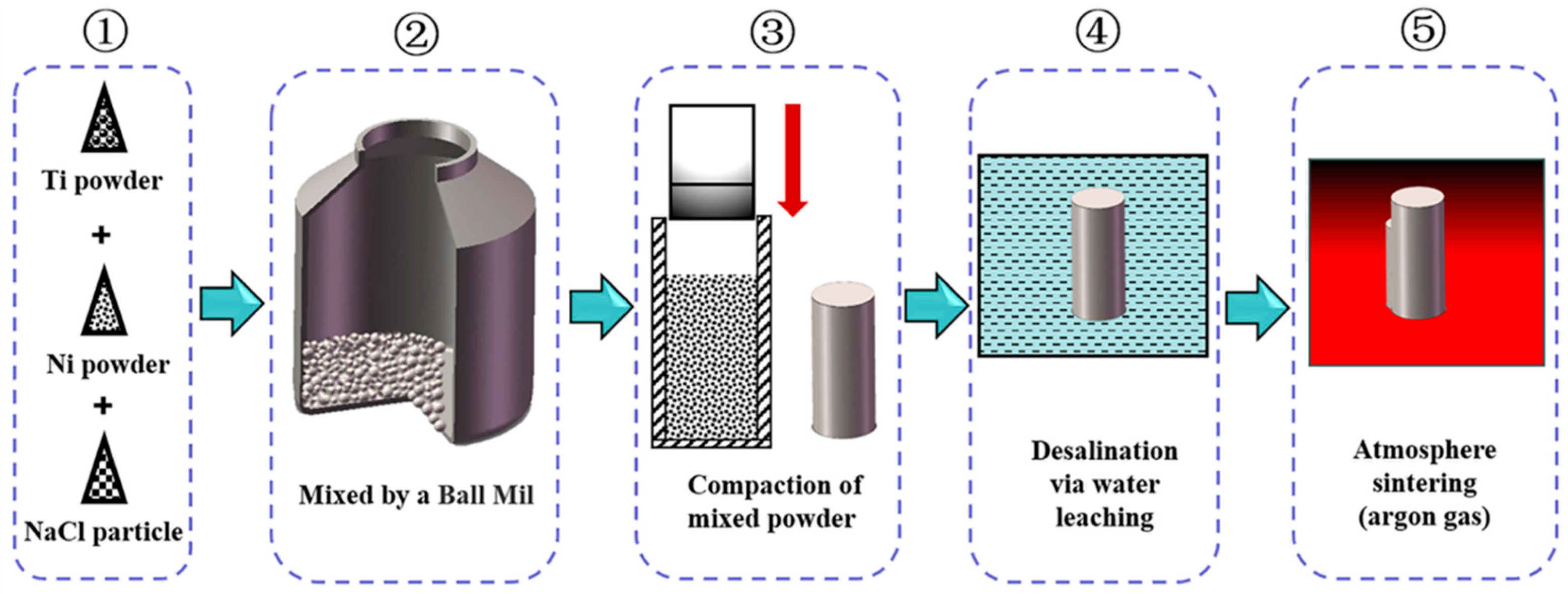

2. Material and Methods

2.1. Preparation of Porous NiTi SMA

2.2. Experimental Characterization Procedures

3. Results and Discussion

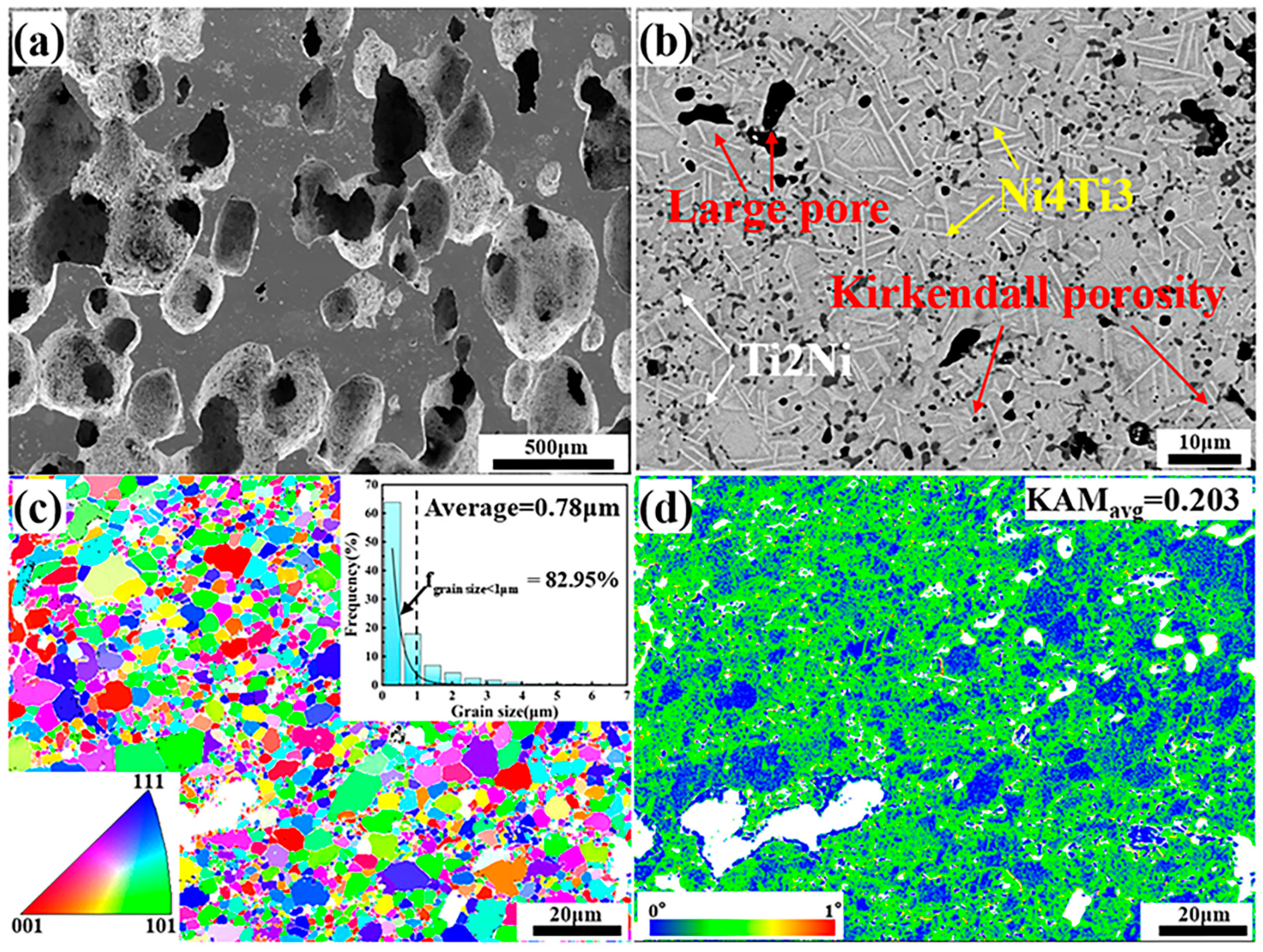

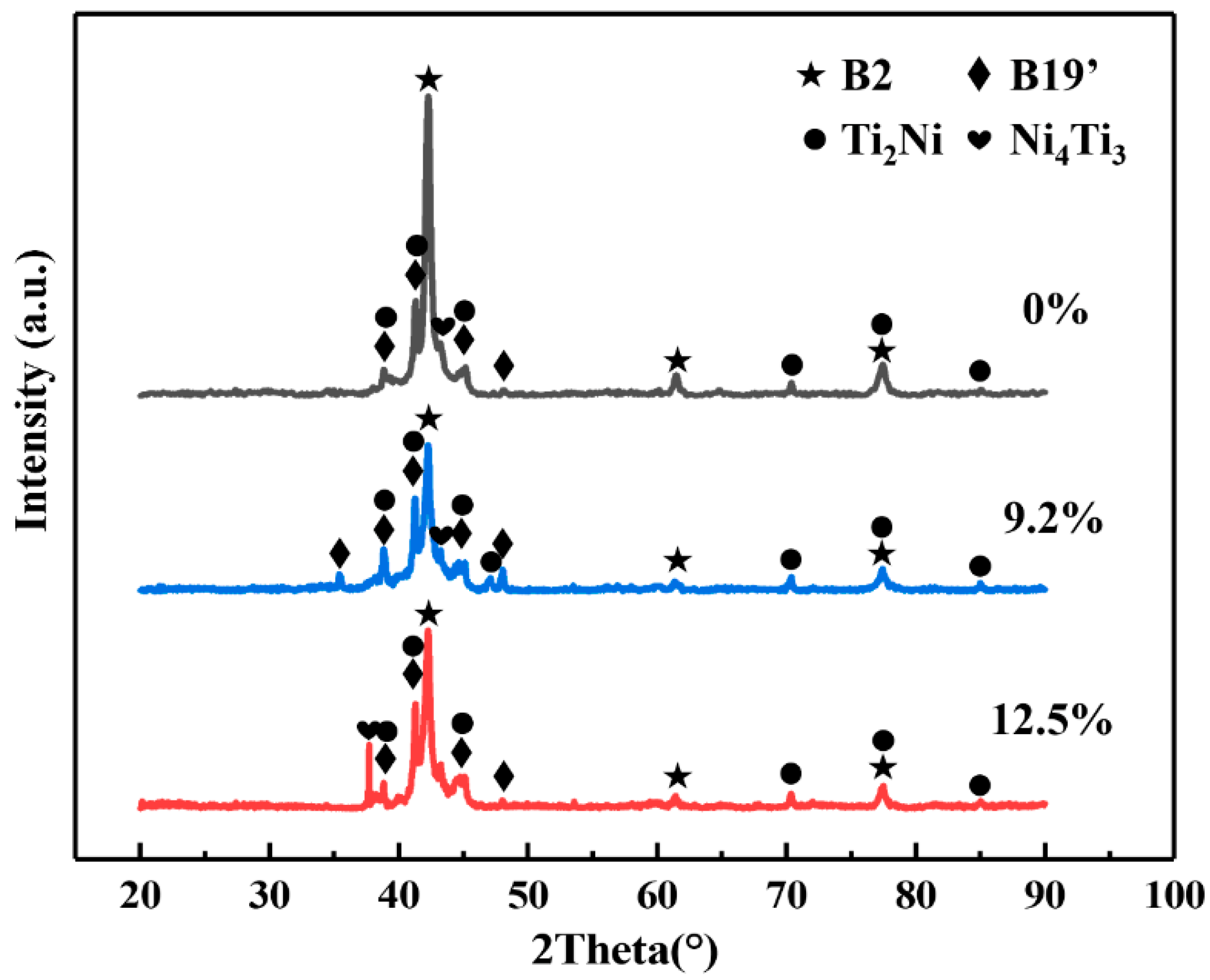

3.1. Microstructure Characteristics of Fabricated Porous NiTi SMA Samples

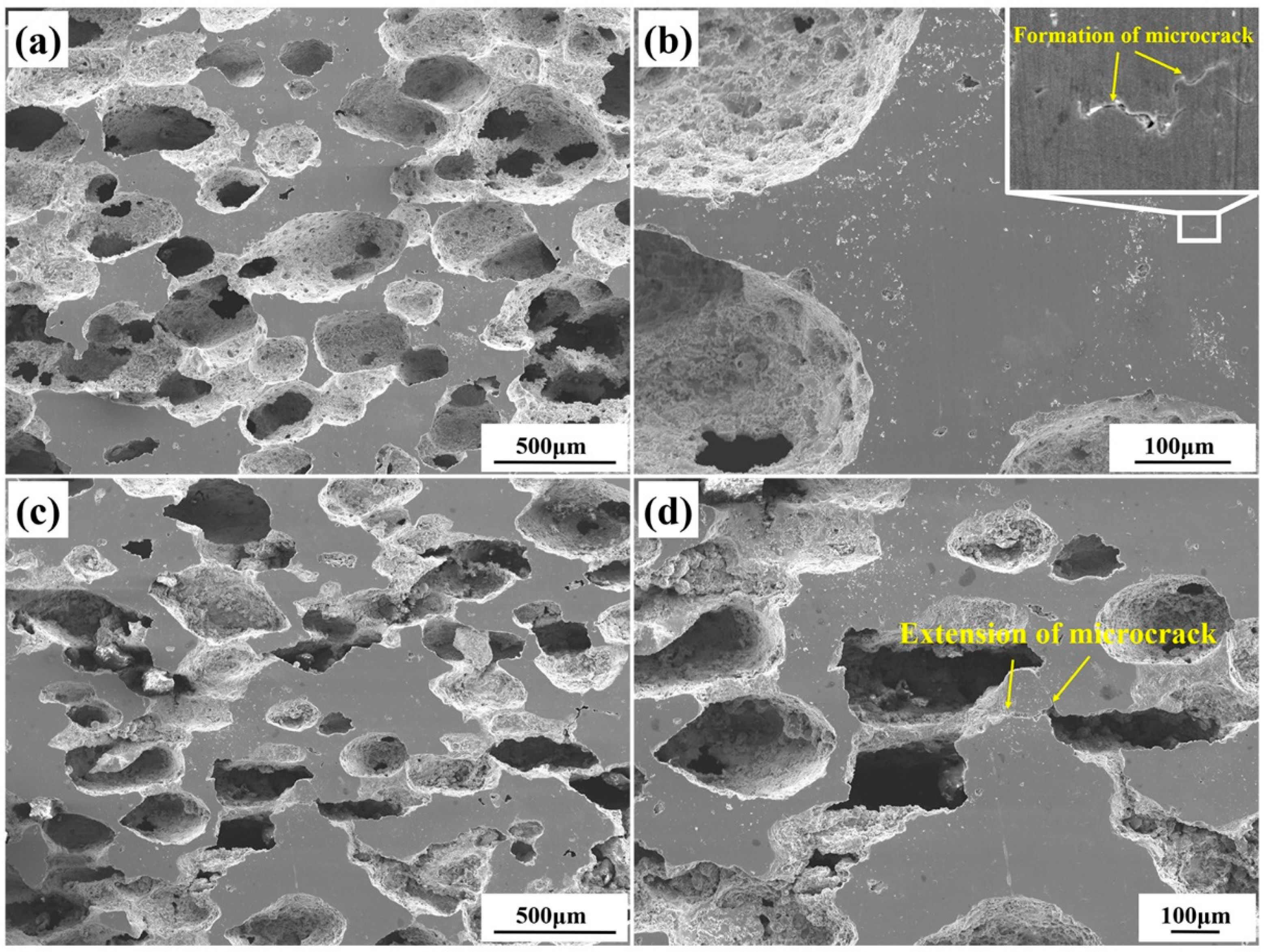

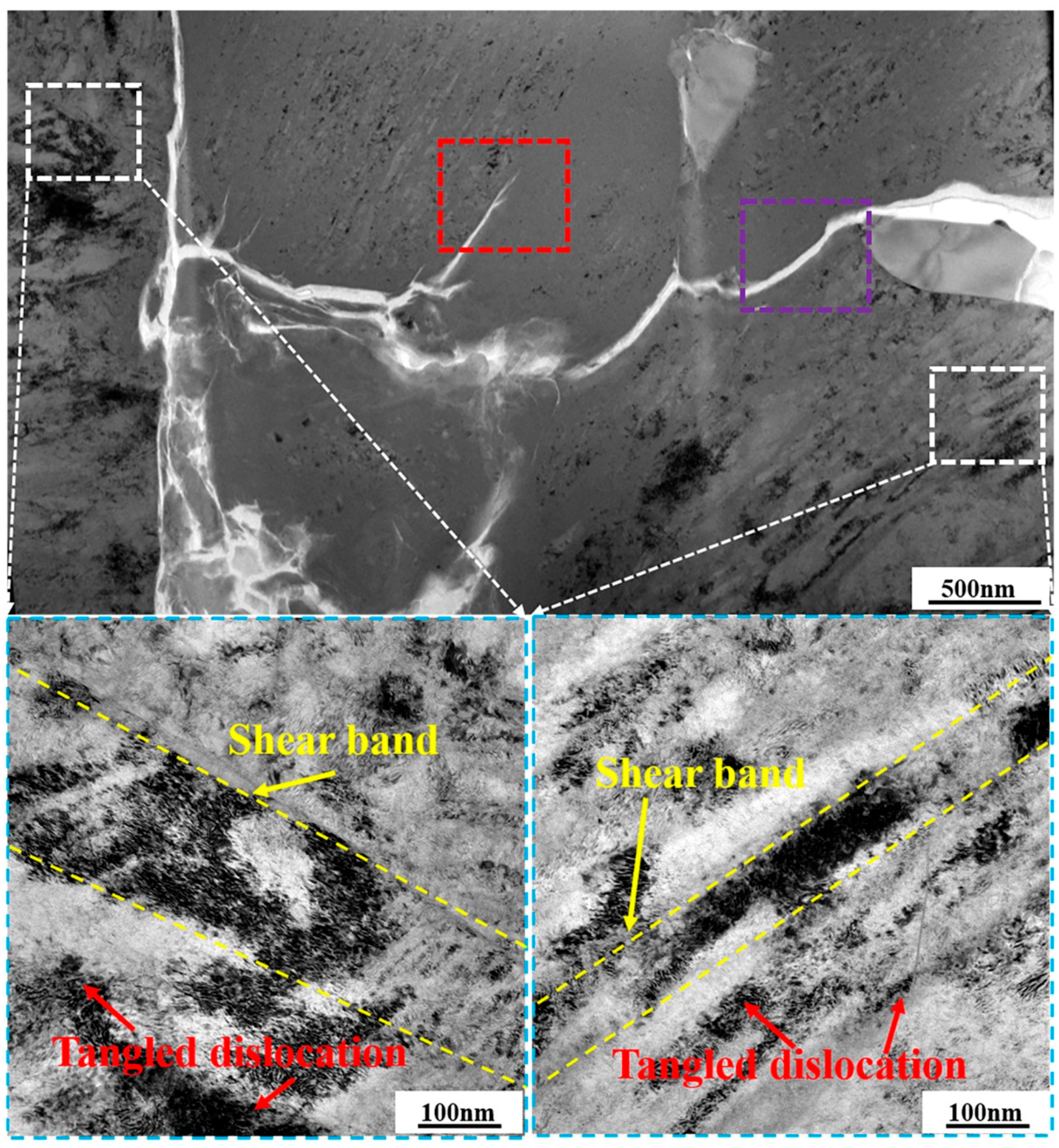

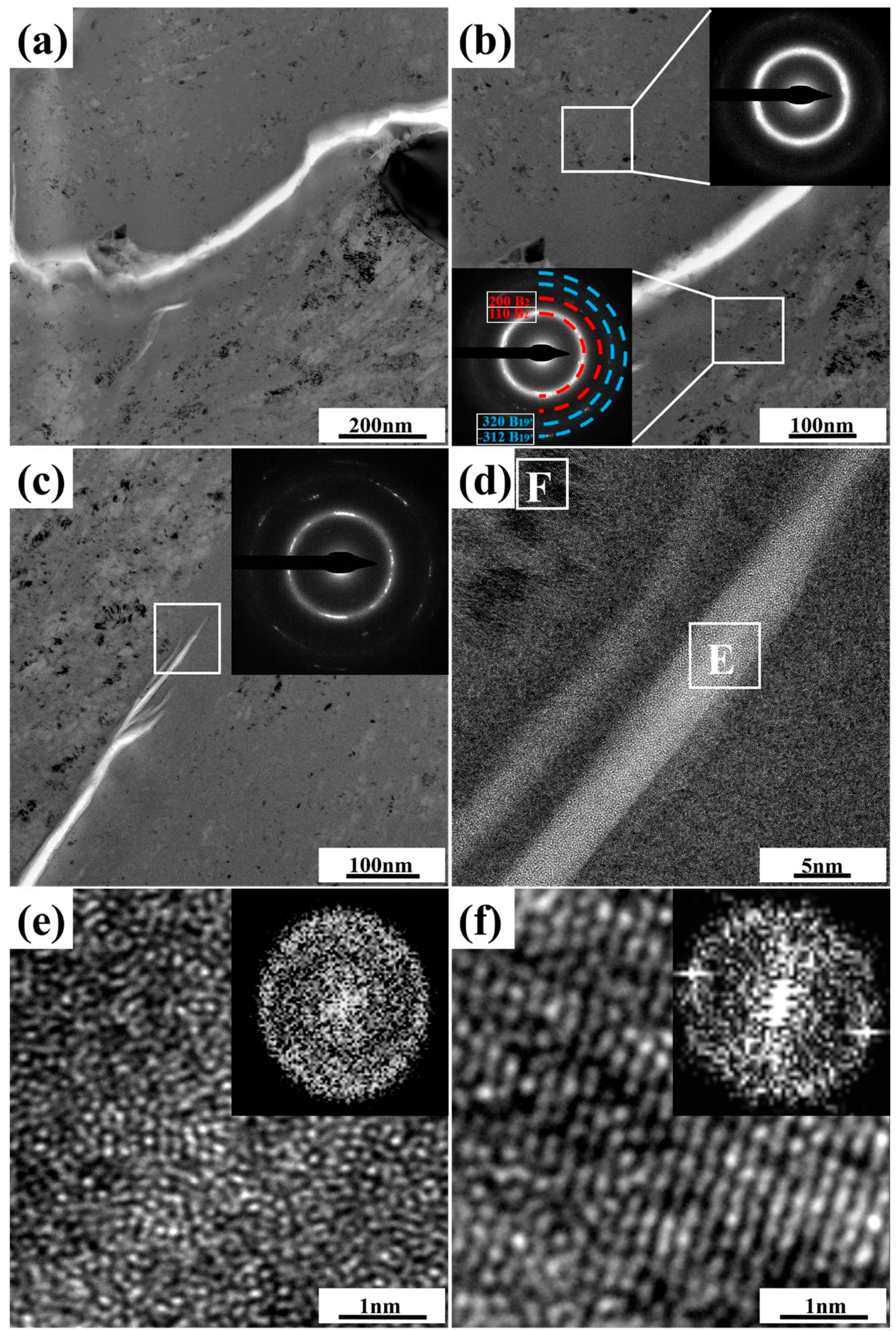

3.2. Microstructure Characteristics of Deformed Porous NiTi SMA Samples

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, H.; Ma, H.; Luo, X.; Wang, Y.; Wang, J.; Lupoi, R.; Yin, S.; Yang, C. Microstructure, shape memory properties, and in vitro biocompatibility of porous NiTi scaffolds fabricated via selective laser melting. J. Mater. Res. Technol. 2021, 15, 6797–6812. [Google Scholar] [CrossRef]

- Lai, T.; Xu, J.-L.; Xiao, Q.-F.; Tong, Y.-X.; Huang, J.; Zhang, J.-P.; Luo, J.-M.; Liu, Y. Preparation and characterization of porous NiTi alloys synthesized by microwave sintering using Mg space holder. Trans. Nonferrous Met. Soc. China 2021, 31, 485–498. [Google Scholar] [CrossRef]

- Marchenko, E.; Baigonakova, G.; Dubovikov, K.; Kokorev, O.; Yasenchuk, Y.; Vorozhtsov, A. In Vitro Bio-Testing Comparative Analysis of NiTi Porous Alloys Modified by Heat Treatment. Metals 2022, 12, 1006. [Google Scholar] [CrossRef]

- Marchenko, E.S.; Kozulin, A.A.; Yasenchuk, Y.F.; Vetrova, A.V.; Volinsky, A.A.; Zhang, Y. Numerical and experimental study of porous NiTi anisotropy under compression. J. Mater. Res. Technol. 2023, 22, 3502–3510. [Google Scholar] [CrossRef]

- Zhao, M.; Qing, H.; Wang, Y.; Liang, J.; Zhao, M.; Geng, Y.; Liang, J.; Lu, B. Superelastic behaviors of additively manufactured porous NiTi shape memory alloys designed with Menger sponge-like fractal structures. Mater. Des. 2021, 200, 109448. [Google Scholar] [CrossRef]

- Li, D.; Du, C.; He, Z.; Li, Y.; Luo, F.; He, H. High-strength porous NiTi shape memory alloys with stable cyclic recovery properties fabricated using elemental powders. Mater. Sci. Eng. A 2023, 886, 145682. [Google Scholar] [CrossRef]

- Li, J.; Yang, H.; Wang, H.; Ruan, J. Low elastic modulus titanium–nickel scaffolds for bone implants. Mater. Sci. Eng. C 2014, 34, 110–114. [Google Scholar] [CrossRef]

- Putra, N.; Mirzaali, M.; Apachitei, I.; Zhou, J.; Zadpoor, A. Multi-material additive manufacturing technologies for Ti-, Mg-, and Fe-based biomaterials for bone substitution. Acta Biomater. 2020, 109, 1–20. [Google Scholar] [CrossRef]

- Li, D.; Zhang, Y.; Eggeler, G.; Zhang, X. High porosity and high-strength porous NiTi shape memory alloys with controllable pore characteristics. J. Alloys Compd. 2009, 470, L1–L5. [Google Scholar] [CrossRef]

- Liu, S.F.; Liu, J.B.; Wang, L.Q.; Ma, R.L.; Zhong, Y.S.; Lu, W.J.; Zhang, L.C. Superelastic behavior of in-situ eutectic-reaction manufactured high strength 3D porous NiTi-Nb scaffold. Scr. Mater. 2020, 181, 121–126. [Google Scholar] [CrossRef]

- Wu, S.; Chung, C.; Liu, X.; Chu, P.K.; Ho, J.; Chu, C.; Chan, Y.; Yeung, K.; Lu, W.; Cheung, K.; et al. Pore formation mechanism and characterization of porous NiTi shape memory alloys synthesized by capsule-free hot isostatic pressing. Acta Mater. 2007, 55, 3437–3451. [Google Scholar] [CrossRef]

- Yuan, B.; Chung, C.; Zhu, M. Microstructure and martensitic transformation behavior of porous NiTi shape memory alloy prepared by hot isostatic pressing processing. Mater. Sci. Eng. A 2004, 382, 181–187. [Google Scholar] [CrossRef]

- Saadati, A.; Aghajani, H. Fabrication of porous NiTi biomedical alloy by SHS method. J. Mater. Sci. Mater. Med. 2019, 30, 92. [Google Scholar] [CrossRef] [PubMed]

- Resnina, N.; Rubanik, V., Jr.; Rubanik, V.; Kulak, M.; Belyaev, S.; Liulchak, P.; Chepela, D.; Kalganov, V. Influence of the Ar pressure on the structure of the NiTi foams produced by self-propagating high-temperature synthesis. Mater. Lett. 2021, 299, 130047. [Google Scholar] [CrossRef]

- Tang, C.; Zhang, L.; Wong, C.; Chan, K.; Yue, T. Fabrication and characteristics of porous NiTi shape memory alloy synthesized by microwave sintering. Mater. Sci. Eng. A 2011, 528, 6006–6011. [Google Scholar] [CrossRef]

- Xu, J.; Bao, L.; Liu, A.; Jin, X.; Luo, J.; Zhong, Z.; Zheng, Y. Effect of pore sizes on the microstructure and properties of the biomedical porous NiTi alloys prepared by microwave sintering. J. Alloys Compd. 2015, 645, 137–142. [Google Scholar] [CrossRef]

- Yang, Q.; Sun, Y.K.; Yang, C.; Sun, M.; Peng, H.; Shen, X.; Huang, S.; Chen, J. Compression and superelasticity behaviors of NiTi porous structures with tiny strut fabricated by selective laser melting. J. Alloys Compd. 2021, 858, 157674. [Google Scholar] [CrossRef]

- Khademzadeh, S.; Carmignato, S.; Parvin, N.; Zanini, F.; Bariani, P.F. Micro porosity analysis in additive manufactured NiTi parts using micro computed tomography and electron microscopy. Mater. Des. 2016, 90, 745–752. [Google Scholar] [CrossRef]

- Guoxin, H.; Lixiang, Z.; Yunliang, F.; Yanhong, L. Fabrication of high porous NiTi shape memory alloy by metal injection molding. J. Mater. Process. Technol. 2008, 206, 395–399. [Google Scholar] [CrossRef]

- Zhao, D.; Chang, K.; Ebel, T.; Nie, H.; Willumeit, R.; Pyczak, F. Sintering behavior and mechanical properties of a metal injection molded Ti–Nb binary alloy as biomaterial. J. Alloys Compd. 2015, 640, 393–400. [Google Scholar] [CrossRef]

- Bansiddhi, A.; Dunand, D. Shape-memory NiTi foams produced by replication of NaCl space-holders. Acta Biomater. 2008, 4, 1996–2007. [Google Scholar] [CrossRef] [PubMed]

- Bram, M.; Köhl, M.; Buchkremer, H.P.; Stöver, D. Mechanical Properties of Highly Porous NiTi Alloys. J. Mater. Eng. Perform. 2011, 20, 522–528. [Google Scholar] [CrossRef]

- Yan, B.; Zhang, Y.; Jiang, S.; Yu, J.; Sun, D.; Tang, M. Mechanical properties and fracture mechanisms of martensitic NiTi shape memory alloy based on various thermomechanical-processing microstructures. J. Alloys Compd. 2021, 883, 160797. [Google Scholar] [CrossRef]

- Zhang, N.; Khosrovabadi, P.B.; Lindenhovius, J.; Kolster, B. TiNi shape memory alloys prepared by normal sintering. Mater. Sci. Eng. A 1992, 150, 263–270. [Google Scholar] [CrossRef]

- Ismail, M.H.; Goodall, R.; Davies, H.A.; Todd, I. Formation of microporous NiTi by transient liquid phase sintering of elemental powders. Mater. Sci. Eng. C 2012, 32, 1480–1485. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Yang, X.; Fu, D.; Zhang, L.; Li, C.; Cui, Z. Stress–strain behavior of porous NiTi alloys prepared by powders sintering. Mater. Sci. Eng. A 2005, 408, 264–268. [Google Scholar] [CrossRef]

- Laeng, J.; Xiu, Z.; Xu, X.; Sun, X.; Ru, H.; Liu, Y. Phase formation of Ni–Ti via solid state reaction. Phys. Scr. 2007, 129, 250–254. [Google Scholar] [CrossRef]

- Pantleon, W. Resolving the geometrically necessary dislocation content by conventional electron backscattering diffraction. Scr. Mater. 2008, 58, 994–997. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Z.; Qin, X.; Wang, C.; Zhou, L. Effect of initial state on hot deformation and dynamic recrystallization of Ni-Fe based alloy GH984G for steam boiler applications. J. Alloys Compd. 2019, 795, 370–384. [Google Scholar] [CrossRef]

- Mentz, J.; Bram, M.; Buchkremer, H.P.; Stöver, D. Improvement of Mechanical Properties of Powder Metallurgical NiTi Shape Memory Alloys. Adv. Eng. Mater. 2006, 8, 247–252. [Google Scholar] [CrossRef]

- Lagoudas, D.C.; Vandygriff, E.L. Processing and Characterization of NiTi Porous SMA by Elevated Pressure Sintering. J. Intell. Mater. Syst. Struct. 2002, 13, 837–850. [Google Scholar] [CrossRef]

- Jiang, S.; Hu, L.; Zhao, Y.; Zhang, Y.; Liang, Y. Multiscale investigation of inhomogeneous plastic deformation of NiTi shape memory alloy based on local canning compression. Mater. Sci. Eng. A 2013, 569, 117–123. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, L.; Shen, Z.; Chen, X.; Hu, K.; Tang, M.; Wang, L. Microstructure Characteristics of Porous NiTi Shape Memory Alloy Synthesized by Powder Metallurgy during Compressive Deformation at Room Temperature. Metals 2023, 13, 1806. https://doi.org/10.3390/met13111806

Hu L, Shen Z, Chen X, Hu K, Tang M, Wang L. Microstructure Characteristics of Porous NiTi Shape Memory Alloy Synthesized by Powder Metallurgy during Compressive Deformation at Room Temperature. Metals. 2023; 13(11):1806. https://doi.org/10.3390/met13111806

Chicago/Turabian StyleHu, Li, Zeyi Shen, Xiaojuan Chen, Keyu Hu, Ming Tang, and Li Wang. 2023. "Microstructure Characteristics of Porous NiTi Shape Memory Alloy Synthesized by Powder Metallurgy during Compressive Deformation at Room Temperature" Metals 13, no. 11: 1806. https://doi.org/10.3390/met13111806

APA StyleHu, L., Shen, Z., Chen, X., Hu, K., Tang, M., & Wang, L. (2023). Microstructure Characteristics of Porous NiTi Shape Memory Alloy Synthesized by Powder Metallurgy during Compressive Deformation at Room Temperature. Metals, 13(11), 1806. https://doi.org/10.3390/met13111806