Evaluation of Hot Deformation Behaviour of UNS S32750 Super Duplex Stainless Steel (SDSS) Alloy

Abstract

1. Introduction

2. Materials and Methods

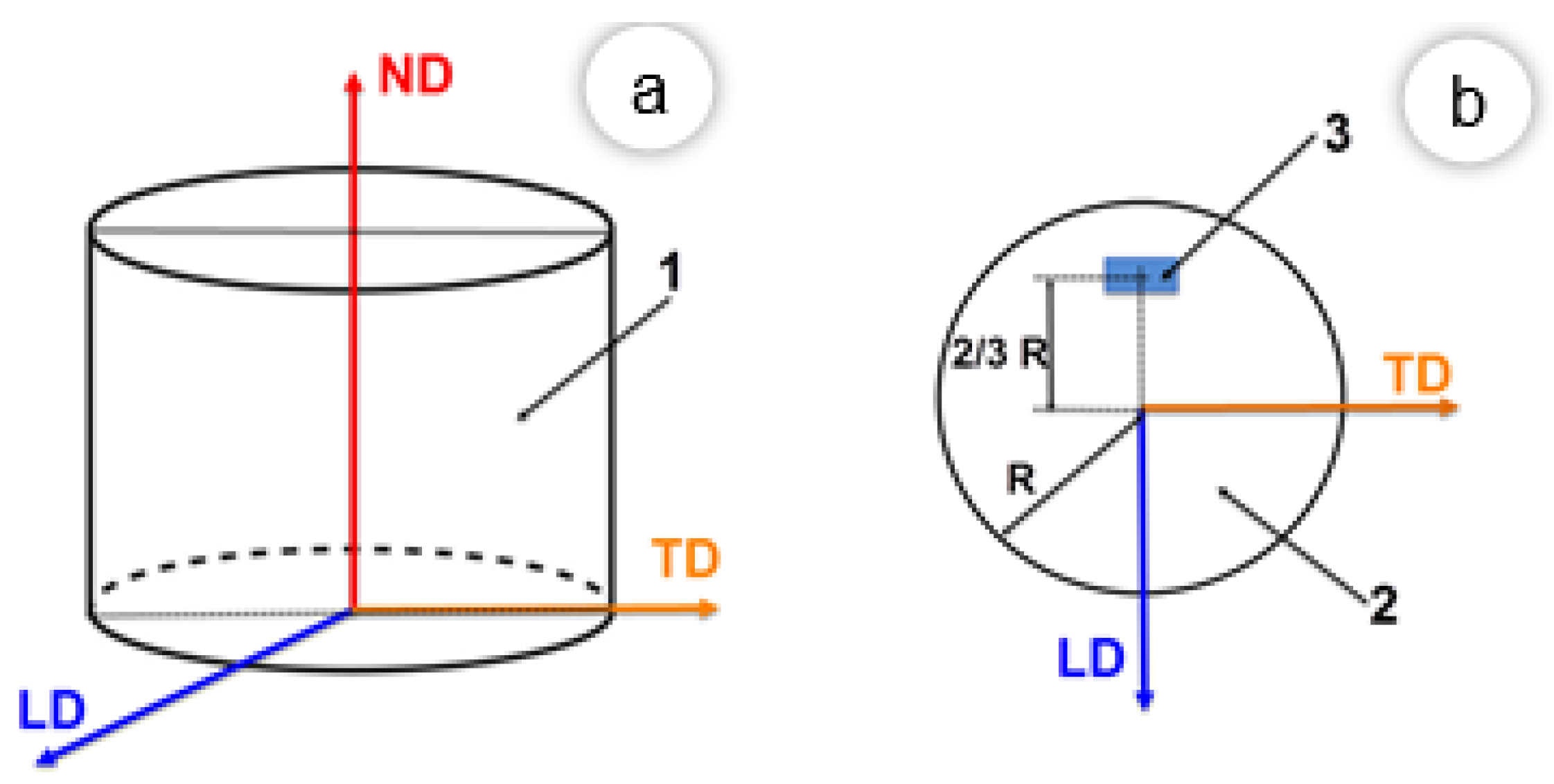

2.1. Thermomechanical Processing Route

2.2. Microstructural Characterization

3. Results and Discussion

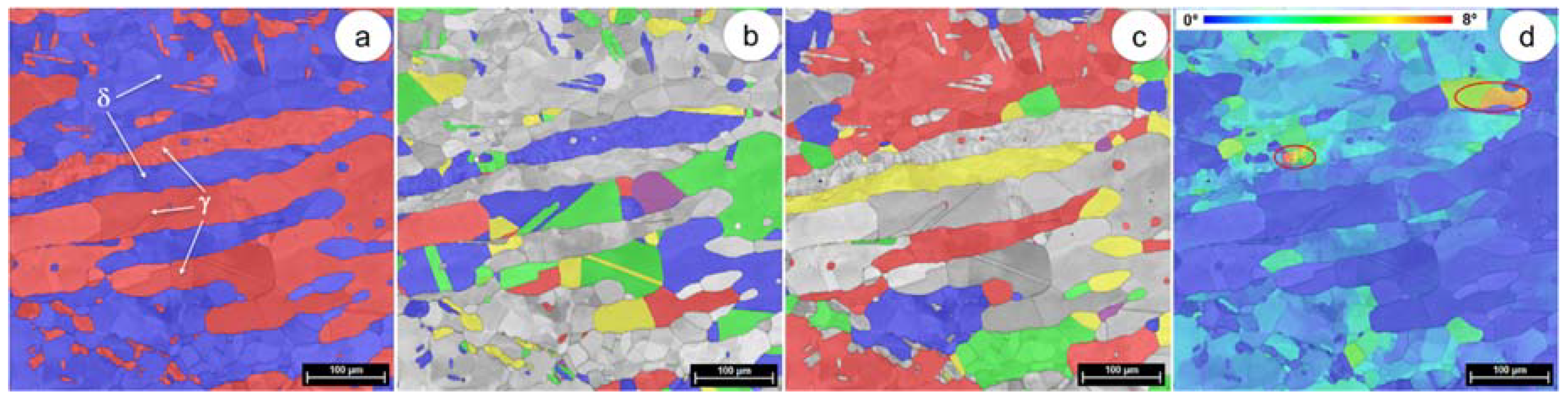

3.1. SEM-EBSD Microstructural Analysis of As-Received UNS S32750 Alloy

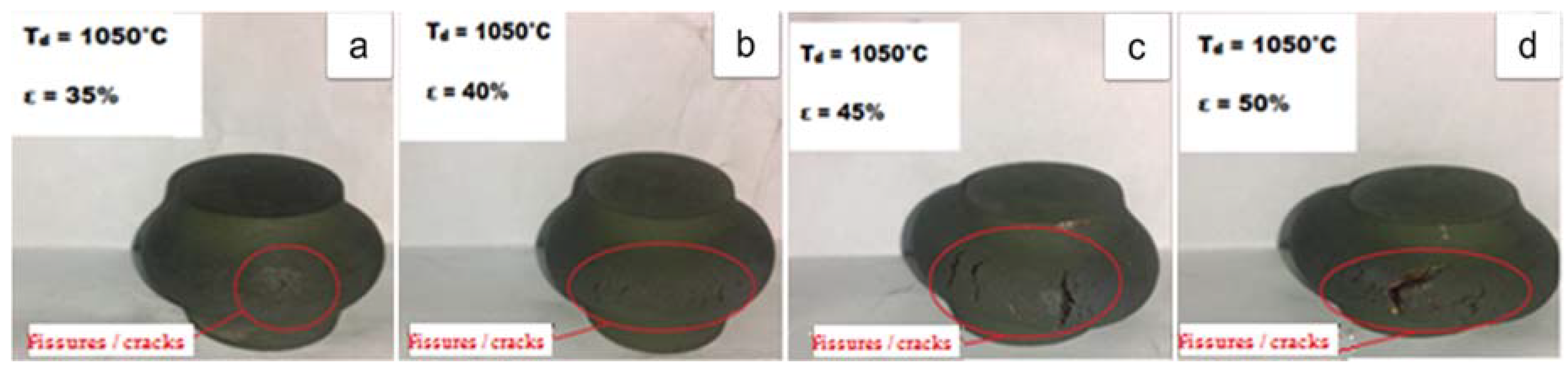

3.2. Hot Deformation, by Upsetting, of As-Received UNS S32750 Alloy.

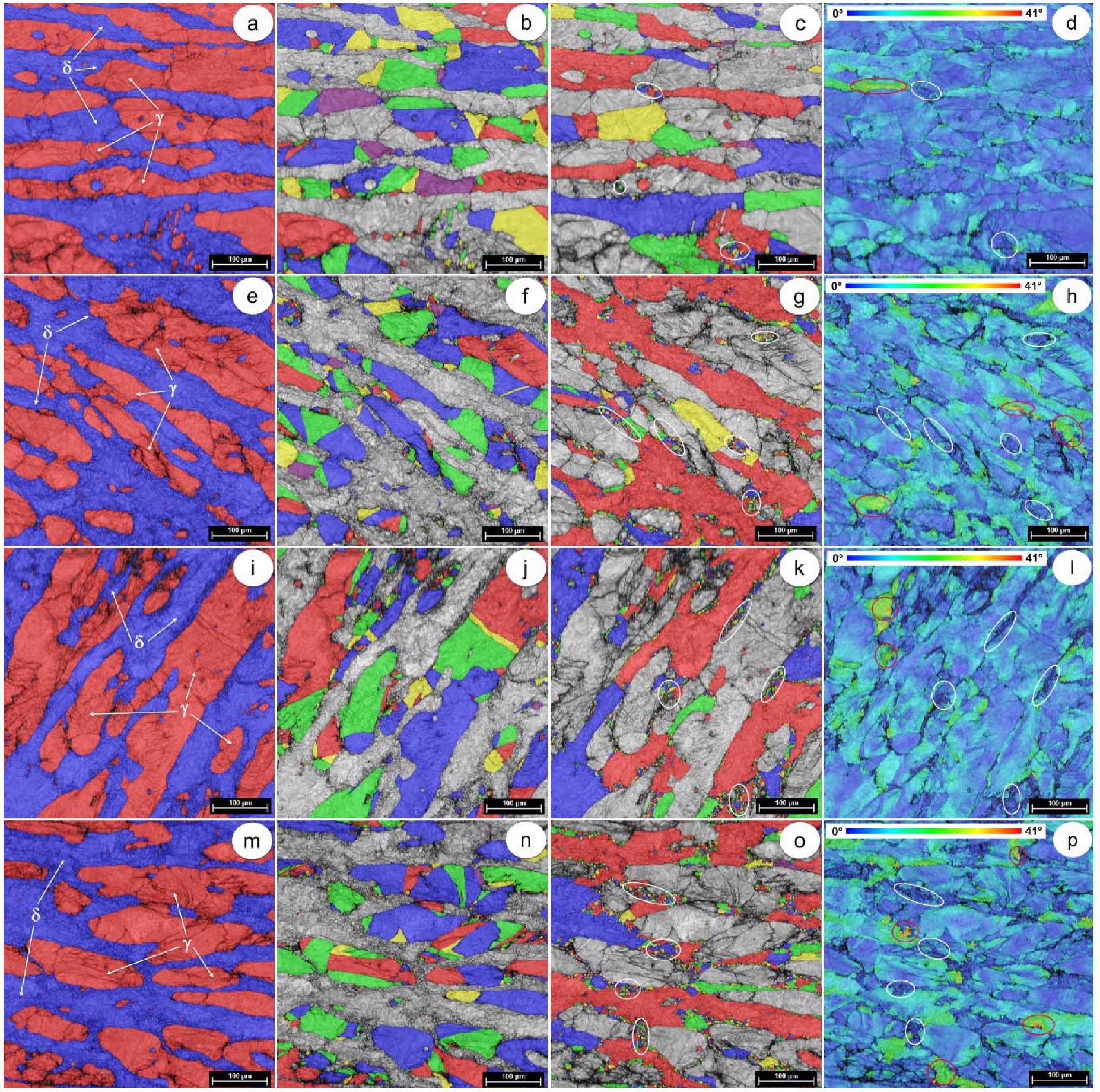

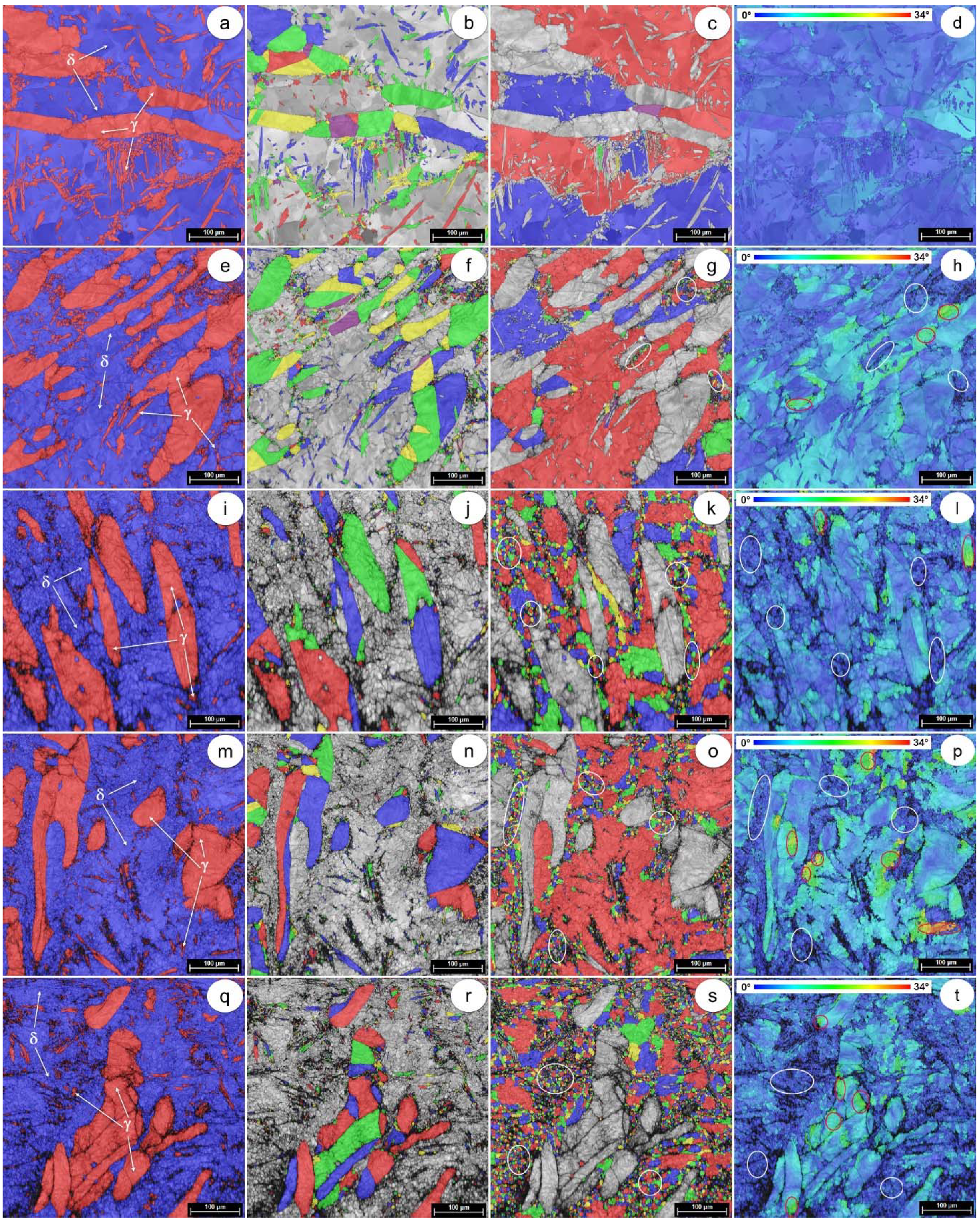

3.3. SEM-EBSD Microstructural Analysis

4. Conclusions

- (1).

- After hot deformation, by upsetting, at 1050 °C the microstructure of the UNS S32750 SDSS alloy consists of approximately equal proportions of the γ-phase and δ-phase. However, after deformation at 1300 °C, the weight fraction of δ-phase increases up to about 65%, due to the initiation of γ → δ phase transition;

- (2).

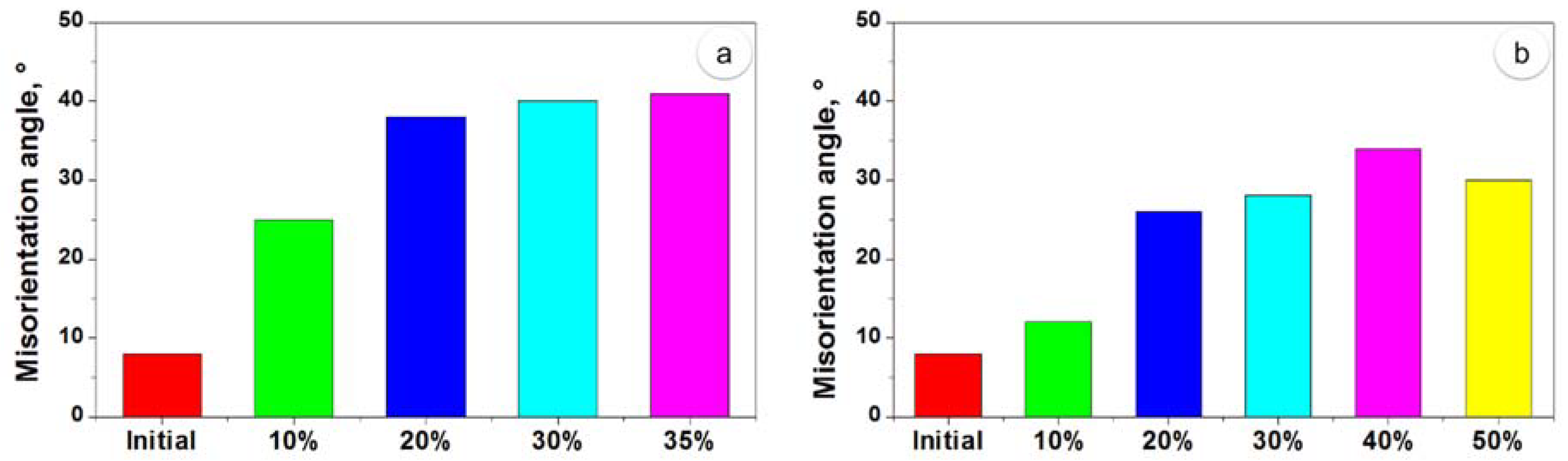

- Development of cracks/fissures, on the lateral surface of UNS S32750 SDSS alloy samples, were observed only in the case of hot deformation, by upsetting, at 1050 °C with a deformation degree exceeding 30%, being related to the limited plasticity of the δ-phase at 1050 °C;

- (3).

- Grain Reference Orientation Deviation (GROD) analysis showed a limit/critical value, close to (38–40°), must be reached in order to develop cracks/fissure on lateral surface of UNS S32750 SDSS alloy samples; and,

- (4).

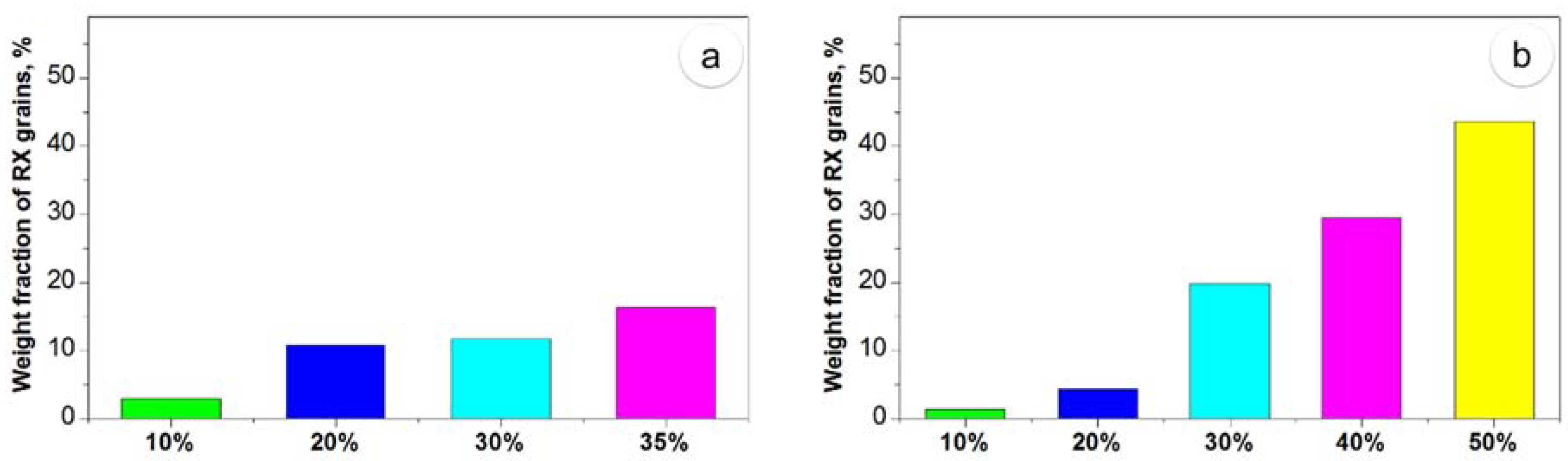

- Recrystallization (RX) of δ-phase grains is observed for all UNS S32750 SDSS alloy processed samples, both at 1050 °C and 1300 °C; a higher weight fraction of RX δ-phase grains is noticed in the case of hot deformation at 1300 °C in comparison 1050 °C; maximum weight fraction of RX δ-phase grains, close to 43.7%, was recorded for an applied deformation degree of 50% at 1300 °C.

Author Contributions

Funding

Conflicts of Interest

References

- Zanotto, F.; Grassi, V.; Balbo, A.; Monticelli, C.; Zucchi, F. Stress corrosion cracking of LDX 2101® duplex stainless steel in chloride solutions in the presence of thiosulphate. Corros. Sci. 2014, 80, 205–212. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; Silva, V.G.; Pardal, J.M.; Corte, J.S. Investigation of stress corrosion cracks in a UNS S32750 superduplex stainless steel. Eng. Fail. Anal. 2013, 35, 88–94. [Google Scholar] [CrossRef]

- Xiong, J.; Tan, M.Y.; Forsyth, M. The corrosion behaviors of stainless steel weldments in sodium chloride solution observed using a novel electrochemical measurement approach. Desalination 2013, 327, 39–45. [Google Scholar] [CrossRef]

- Zanotto, F.; Grassi, V.; Balbo, A.; Zucchi, F.; Monticelli, C. Investigation on the Corrosion Behavior of Lean Duplex Stainless Steel 2404 after Aging within the 650–850 °C Temperature Range. Metals 2019, 9, 529. [Google Scholar] [CrossRef]

- Nilsson, J.O. Super Duplex Stainless Steels. J. Mater. Sci. Technol. 1992, 8, 685–700. [Google Scholar] [CrossRef]

- Hoseinpoor, M.; Momeni, M.; Moayed, M.H.; Davoodi, A. EIS assessment of critical pitting temperature of 2205 duplex stainless steel in acidified ferric chloride solution. Corros. Sci. 2014, 80, 197–204. [Google Scholar] [CrossRef]

- Gutierrez, I.; Iza-Mendia, A. Process: Hot Workability. In Duplex Stainless Steels; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Martin, G. Hot Workability of Duplex Stainless Steels. Ph.D. Thesis, Autre. Université de Grenoble, Cities of Grenoble, France, 04 November 2011. [Google Scholar]

- Kang, J.H.; Heo, S.J.; Yoo, J.; Kwon, Y.C. Hot working characteristics of S32760 super duplex stainless steel. J. Mech. Sci. Technol. 2019, 33, 2633–2640. [Google Scholar] [CrossRef]

- Cojocaru, V.D.; Serban, N.; Angelescu, M.L.; Cotrut, M.C.; Cojocaru, E.M.; Vintila, A.N. Influence of Solution Treatment Temperature on Microstructural Properties of an Industrially Forged UNS S32750/1.4410/F53 Super Duplex Stainless Steel (SDSS) Alloy. Metals 2017, 7, 210. [Google Scholar] [CrossRef]

- Cojocaru, V.D.; Raducanu, D.; Angelescu, M.L.; Vintila, A.N.; Serban, N.; Dan, I.; Cojocaru, E.M.; Cinca, I. Influence of Solution Treatment Duration on Microstructural Features of an Industrial Forged UNS S32750/1.4410/F53 Super Duplex Stainless Steel (SDSS) Alloy. JOM 2017, 69, 1439–1445. [Google Scholar] [CrossRef]

- Örnek, C.; Engelberg, D.L. Towards understanding the effect of deformation mode on stress corrosion cracking susceptibility of grade 2205 duplex stainless steel. Mater. Sci. Eng. A 2016, 666, 269–279. [Google Scholar] [CrossRef]

- Serban, N.; Cojocaru, V.D.; Angelescu, M.L.; Raducanu, D.; Cinca, I.; Vintila, A.N.; Cojocaru, E.M. High temperature deformation behaviour of an industrial S32760/1.4501/F55 super duplex stainless steel (SDSS) alloy. Metall. Ital. 2019, 111, 41–48. [Google Scholar]

- Rys, J.; Cempura, G. Microstructure and deformation behavior of metastable duplex stainless steel at high rolling reductions. Mater. Sci. Eng. A 2017, 700, 656–666. [Google Scholar] [CrossRef]

- Primig, S.; Ragger, K.S.; Buchmayr, B. EBSD Study of the Microstructural Evolution during Hot Compression Testing of a Superduplex Steel. Mat. Sci. Forum 2013, 783, 973–979. [Google Scholar] [CrossRef]

- Kim, S.K.; Kang, K.Y.; Kim, M.S.; Lee, J.M. Low-Temperature Mechanical Behavior of Super Duplex Stainless Steel with Sigma Precipitation. Metals 2015, 5, 1732–1745. [Google Scholar] [CrossRef]

- Pettersson, N.; Wessman, S.; Thuvander, M.; Hedström, P.; Odqvist, J.; Pettersson, R.F.A.; Hertzman, S. Nanostructure evolution and mechanical property changes during aging of a super duplex stainless steel at 300 °C. Mater. Sci. Eng. A 2015, 647, 241–248. [Google Scholar] [CrossRef]

- Liu, G.; Wang, Y.; Li, S.; Du, K.; Wang, X. Deformation behavior of thermal aged duplex stainless steels studied by nanoindentation, EBSD and TEM. Mater. High. Temp. 2016, 33, 15–23. [Google Scholar] [CrossRef]

- Wroński, S.; Tarasiuk, J.; Bacroix, B.; Baczmański, A.; Braham, C. Investigation of plastic deformation heterogeneities in duplexsteel by EBSD. Mater. Charact. 2012, 73, 52–60. [Google Scholar] [CrossRef]

- Dakhlaoui, R.; Baczmański, A.; Braham, C.; Wroński, S.; Wierzbanowski, K.; Oliver, E.C. Effect of residual stresses onindividual phase mechanical properties of austeno-ferriticduplex stainless steel. Acta Mater. 2006, 54, 5027–5039. [Google Scholar] [CrossRef]

- Fargas, G.; Anglada, M.; Mateo, A. Effect of the annealing temperature on the mechanical properties, formability and corrosion resistance of hot-rolled duplex stainless steels. J. Mater. Process. Technol. 2009, 209, 1770–1782. [Google Scholar] [CrossRef]

- Maki, T.; Furuhara, T.; Tsuzaki, K. Microstructure Development by Thermomechanical Processing in Duplex Stainless Steel. ISIJ Int. 2001, 41, 571–579. [Google Scholar] [CrossRef]

- Moverare, J.J.; Odén, M. Deformation behaviour of a prestrained duplex stainless steel. Mater. Sci. Eng. A 2002, 337, 25–38. [Google Scholar] [CrossRef]

- Kleber, S.; Hafok, M. Multiaxial Forging of Super Duplex Steel. Mater. Sci. Forum 2010, 638, 2998–3003. [Google Scholar] [CrossRef]

- Angelescu, M.L.; Cojocaru, V.D.; Serban, N.; Cojocaru, E.M. Evaluation of Optimal Forging Temperature Range for an Industrial UNS S32750 SDSS Alloy Using SEM-EBSD Analysis. Metals 2018, 8, 496. [Google Scholar] [CrossRef]

- Schayes, C.; Bouquerel, J.; Vogt, J.B.; Palleschi, F.; Zaefferer, S. A comparison of EBSD based strain indicators for the study of Fe-3Si steel subjected to cyclic loading. Mater. Charact. 2016, 115, 61–70. [Google Scholar] [CrossRef]

- Kamaya, M. Characterization of microstructural damage due to low-cycle-fatigue by EBSD observation. Mater. Charact. 2009, 160, 1454–1462. [Google Scholar] [CrossRef]

- Wright, S.I.; Nowell, M.M.; Field, D.P. A review of strain analysis using electron backscatter diffraction. Microsc. Microanal. 2011, 17, 316–329. [Google Scholar] [CrossRef]

- Kamaya, M. Assessment of local deformation using EBSD: Quantification of local damage at grain boundaries. Mater. Charact. 2012, 66, 56–67. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Liang, Z.Y.; Huang, M.X. Deformation twinning in small-sized face-centred cubic single crystals: Experiments and modelling. J. Mech. Phys. Solids 2015, 85, 128–142. [Google Scholar] [CrossRef]

- Chen, Z.; Cai, H.; Li, S.; Zhang, X.; Wang, F.; Tan, C. Analysis of crystallographic twinning and slip in fcc crystals under plane strain compression. Mater. Sci. Eng. A 2007, 464, 101–109. [Google Scholar] [CrossRef]

- Li, N.; Wang, J.; Misra, A.; Zhang, X.; Huang, J.Y.; Hirth, J.P. Twinning dislocation multiplication at a coherent twin boundary. Acta Mater. 2011, 59, 5989–5996. [Google Scholar] [CrossRef]

| Sample Number | Deformation Temperature, Td (°C) | Heating Temperature, Th (°C) | Maintenance Duration at Th, t (min) | Deformation Degree, ε (%) |

|---|---|---|---|---|

| 0 * | - | - | - | - |

| 1 | 1050 | 1070 | 20 | 5 |

| 2 * | 1050 | 1070 | 20 | 10 |

| 3 | 1050 | 1070 | 20 | 15 |

| 4 * | 1050 | 1070 | 20 | 20 |

| 5 | 1050 | 1070 | 20 | 25 |

| 6 * | 1050 | 1070 | 20 | 30 |

| 7 *# | 1050 | 1070 | 20 | 35 |

| 8 # | 1050 | 1070 | 20 | 40 |

| 9 # | 1050 | 1070 | 20 | 45 |

| 10 # | 1050 | 1070 | 20 | 50 |

| 11 | 1300 | 1320 | 20 | 5 |

| 12 * | 1300 | 1320 | 20 | 10 |

| 13 | 1300 | 1320 | 20 | 15 |

| 14 * | 1300 | 1320 | 20 | 20 |

| 15 | 1300 | 1320 | 20 | 25 |

| 16 * | 1300 | 1320 | 20 | 30 |

| 17 | 1300 | 1320 | 20 | 35 |

| 18 * | 1300 | 1320 | 20 | 40 |

| 19 | 1300 | 1320 | 20 | 45 |

| 20 * | 1300 | 1320 | 20 | 50 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Angelescu, M.L.; Cojocaru, E.M.; Șerban, N.; Cojocaru, V.D. Evaluation of Hot Deformation Behaviour of UNS S32750 Super Duplex Stainless Steel (SDSS) Alloy. Metals 2020, 10, 673. https://doi.org/10.3390/met10050673

Angelescu ML, Cojocaru EM, Șerban N, Cojocaru VD. Evaluation of Hot Deformation Behaviour of UNS S32750 Super Duplex Stainless Steel (SDSS) Alloy. Metals. 2020; 10(5):673. https://doi.org/10.3390/met10050673

Chicago/Turabian StyleAngelescu, Mariana Lucia, Elisabeta Mirela Cojocaru, Nicolae Șerban, and Vasile Dănuț Cojocaru. 2020. "Evaluation of Hot Deformation Behaviour of UNS S32750 Super Duplex Stainless Steel (SDSS) Alloy" Metals 10, no. 5: 673. https://doi.org/10.3390/met10050673

APA StyleAngelescu, M. L., Cojocaru, E. M., Șerban, N., & Cojocaru, V. D. (2020). Evaluation of Hot Deformation Behaviour of UNS S32750 Super Duplex Stainless Steel (SDSS) Alloy. Metals, 10(5), 673. https://doi.org/10.3390/met10050673