The Significance of Central Segregation of Continuously Cast Billet on Banded Microstructure and Mechanical Properties of Section Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results

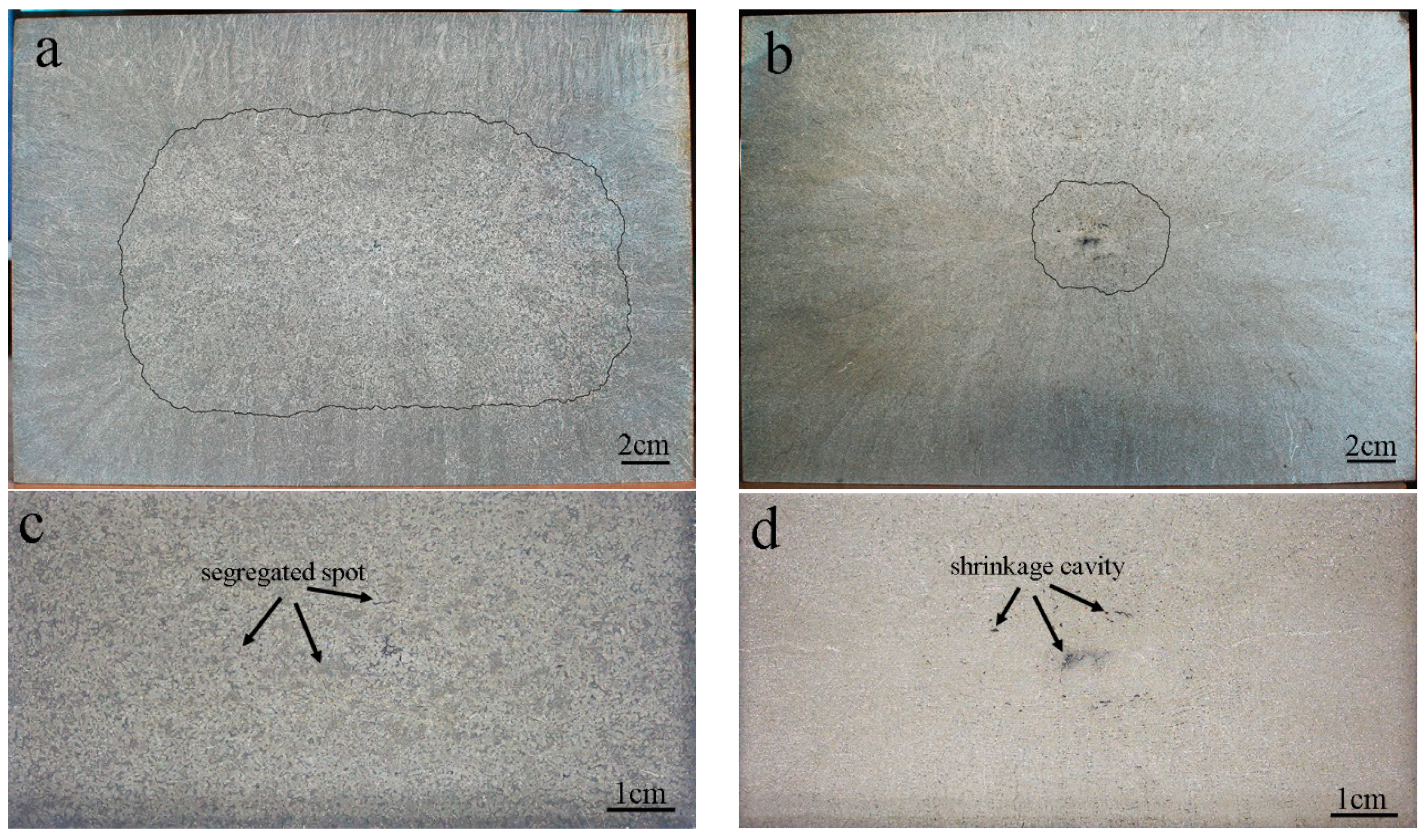

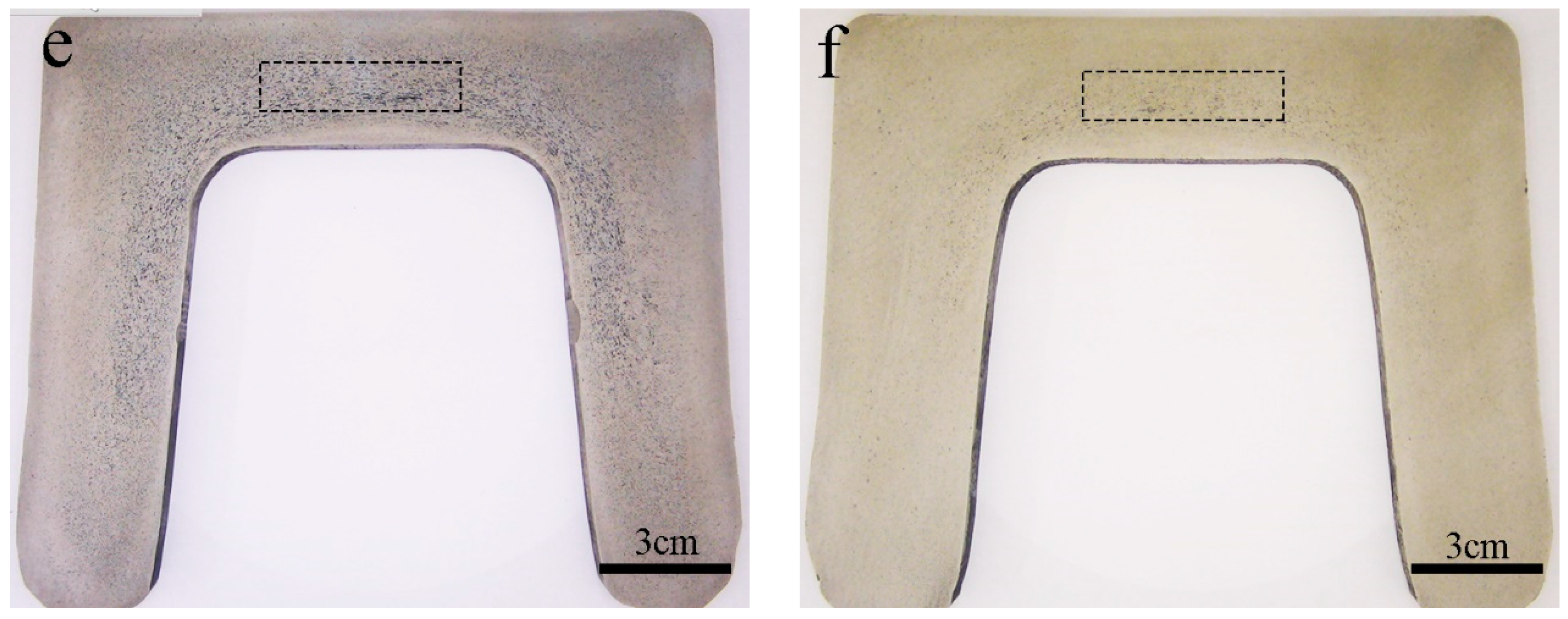

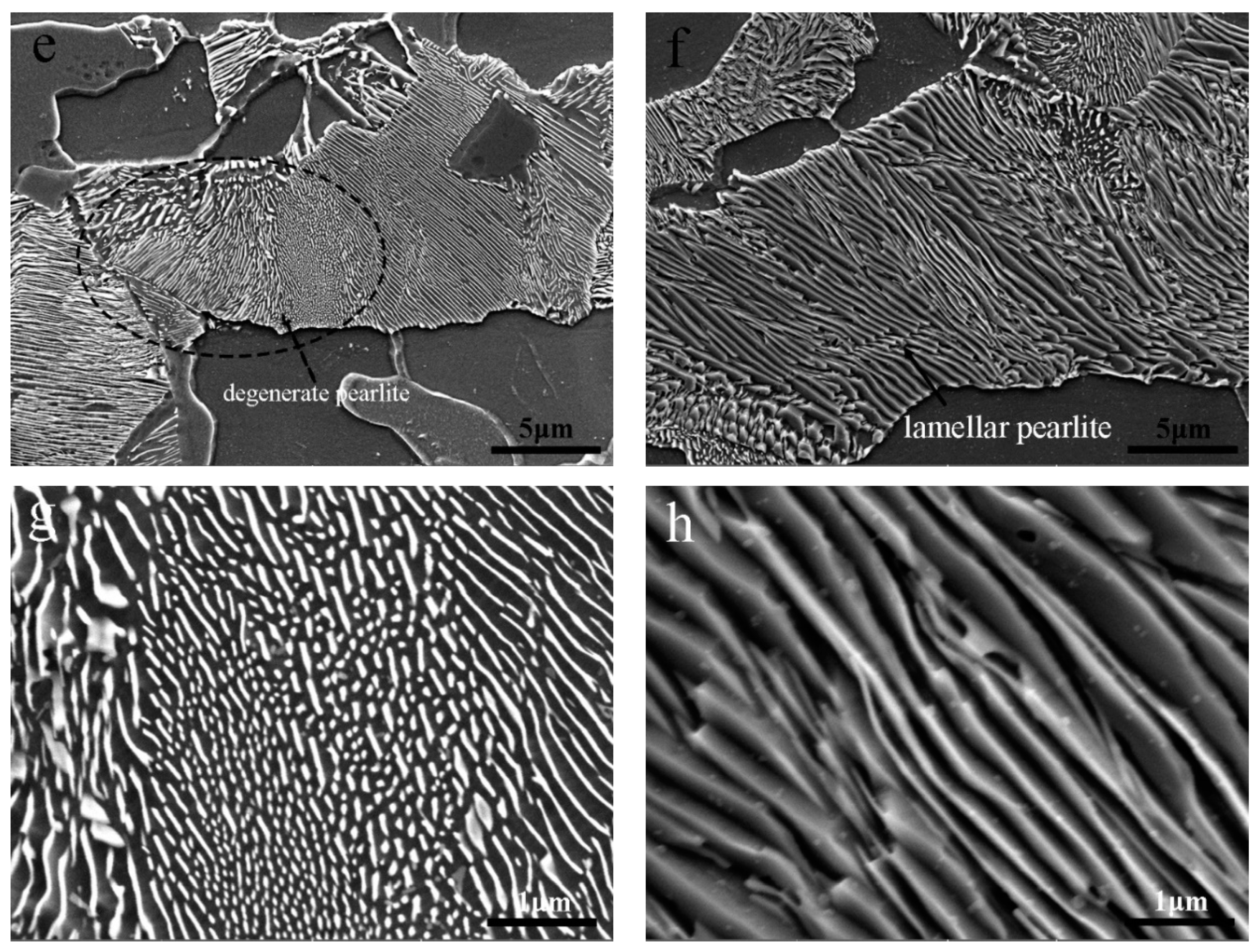

3.1. Macro-Etching Results of Billets and U-Section Steels

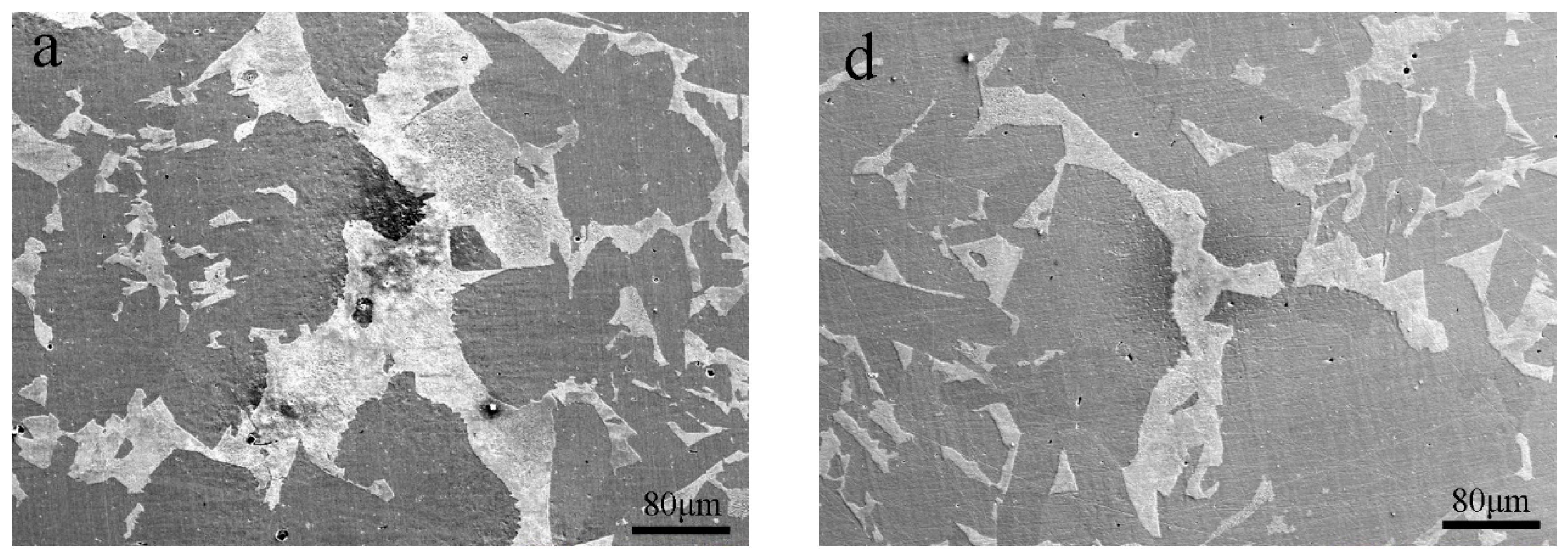

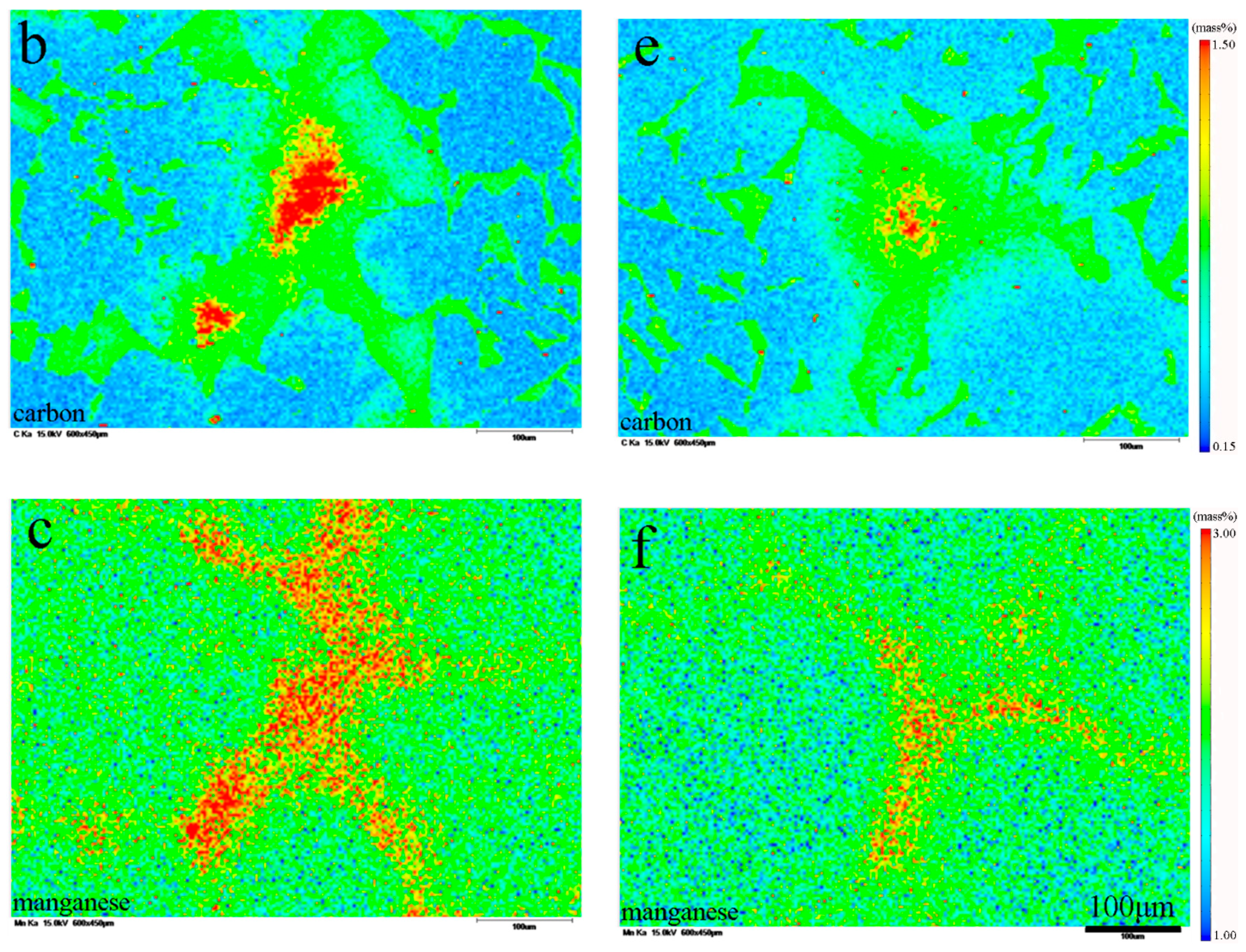

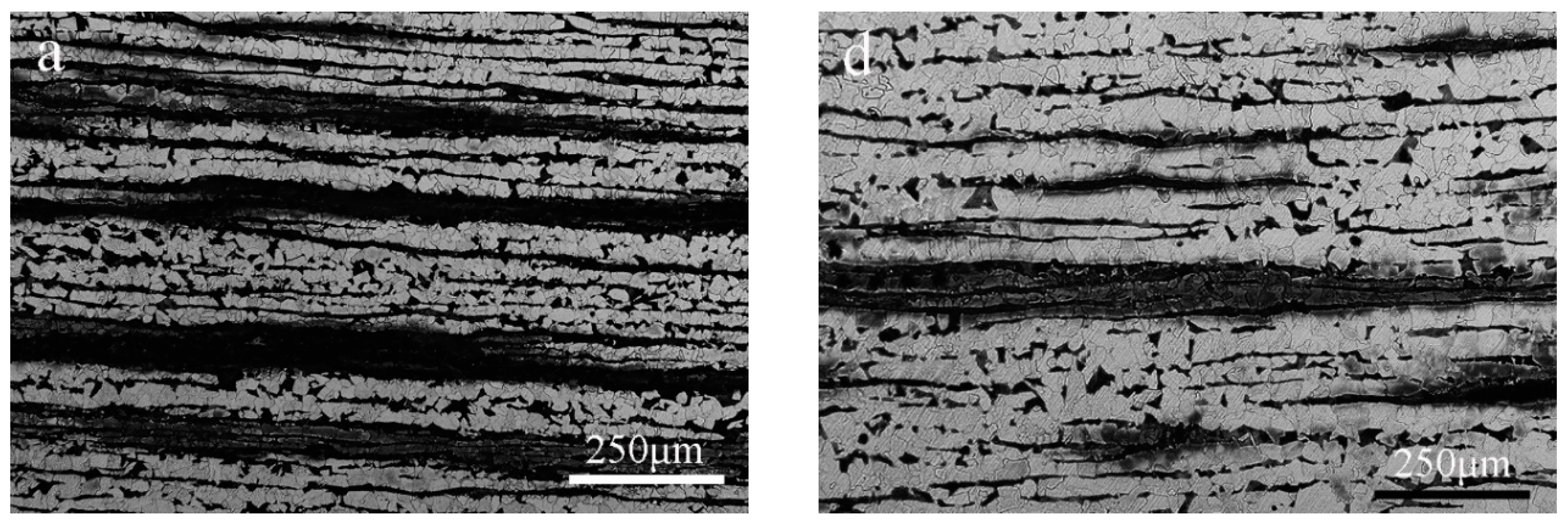

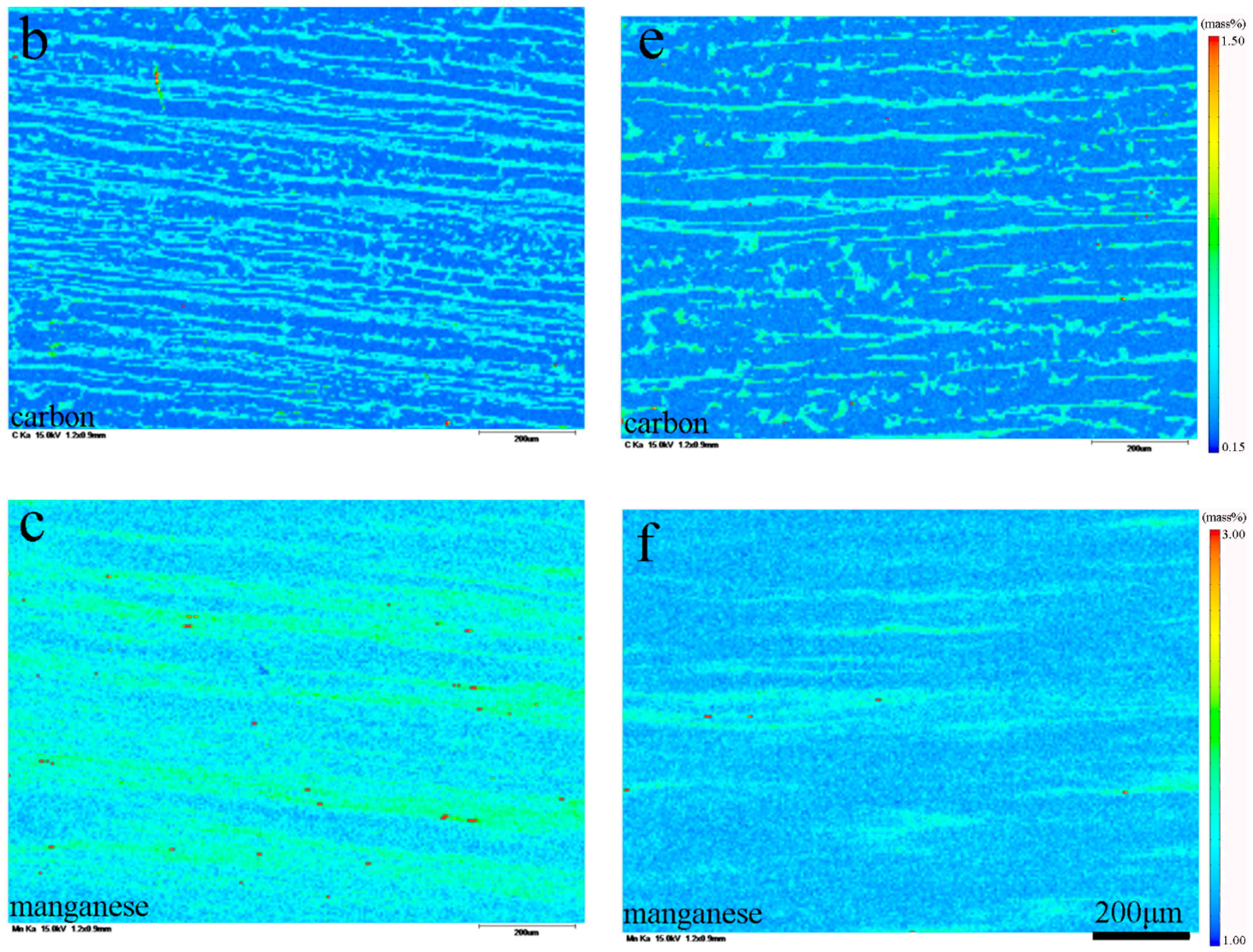

3.2. Enrichment of Elements in Continuous Casting Billets and U-Section Steel

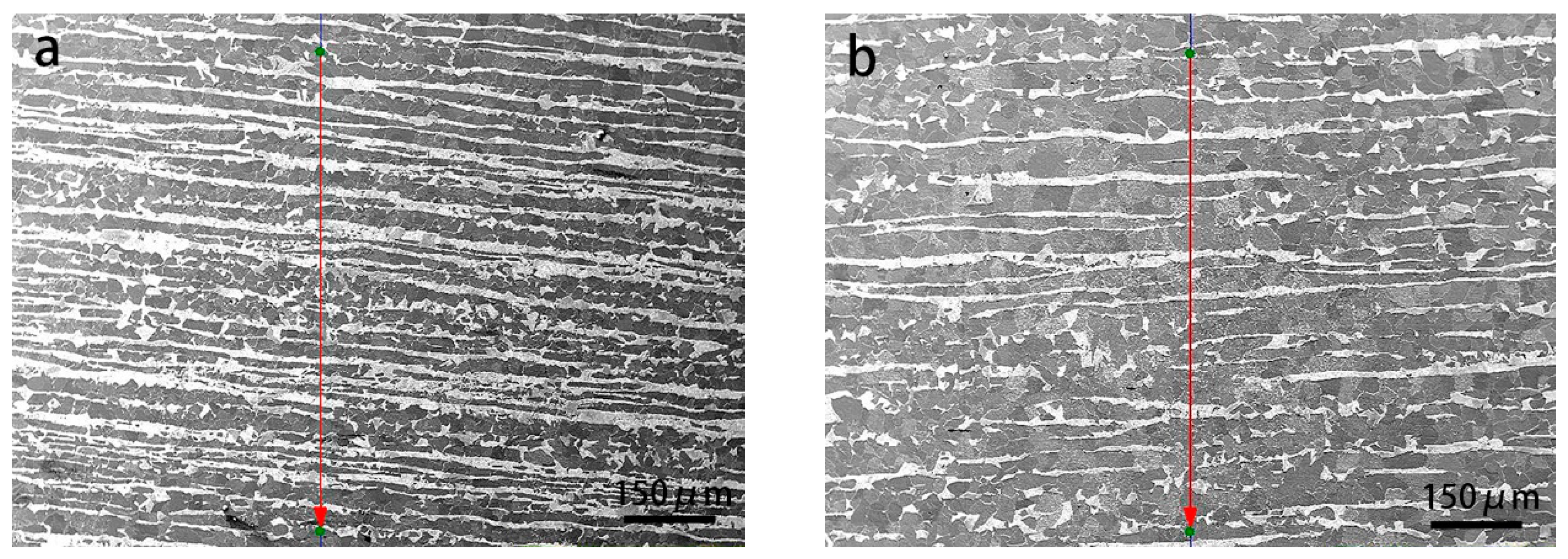

3.3. Microstructure in U-Section Steel

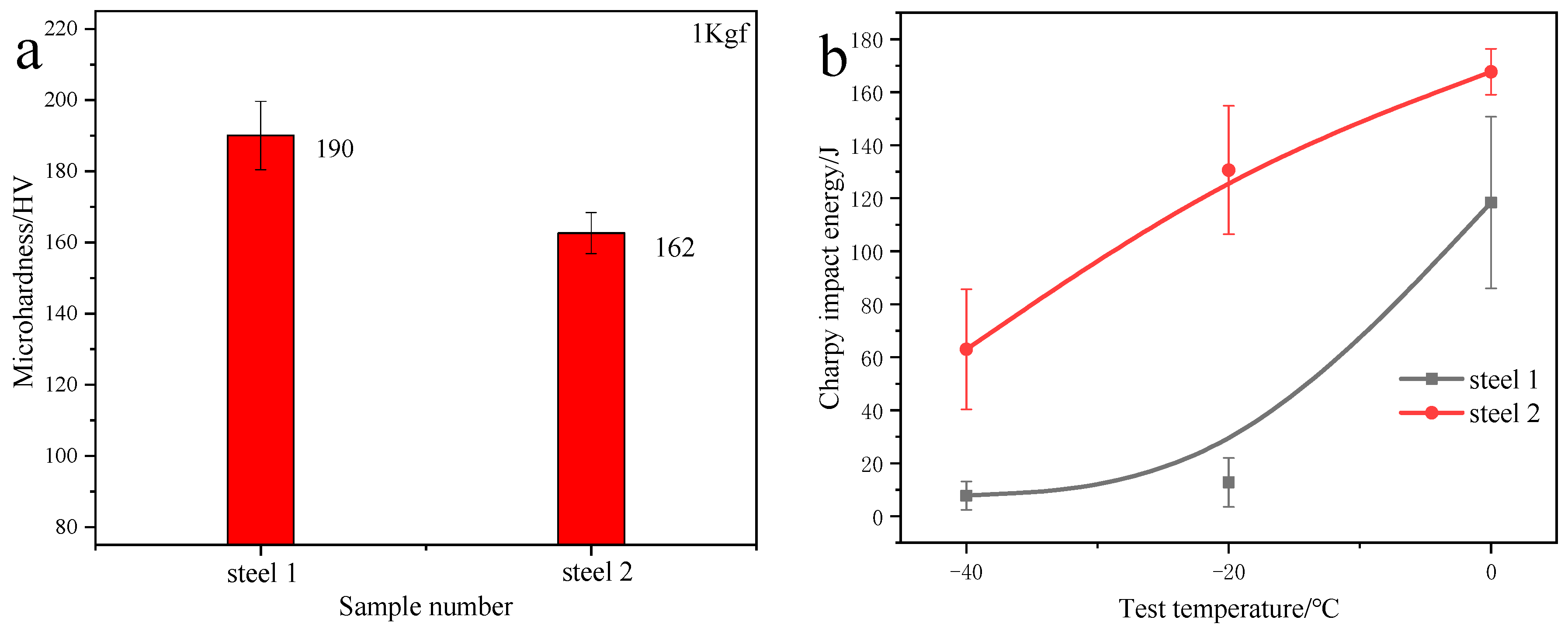

3.4. Mechanical Properties

4. Discussion

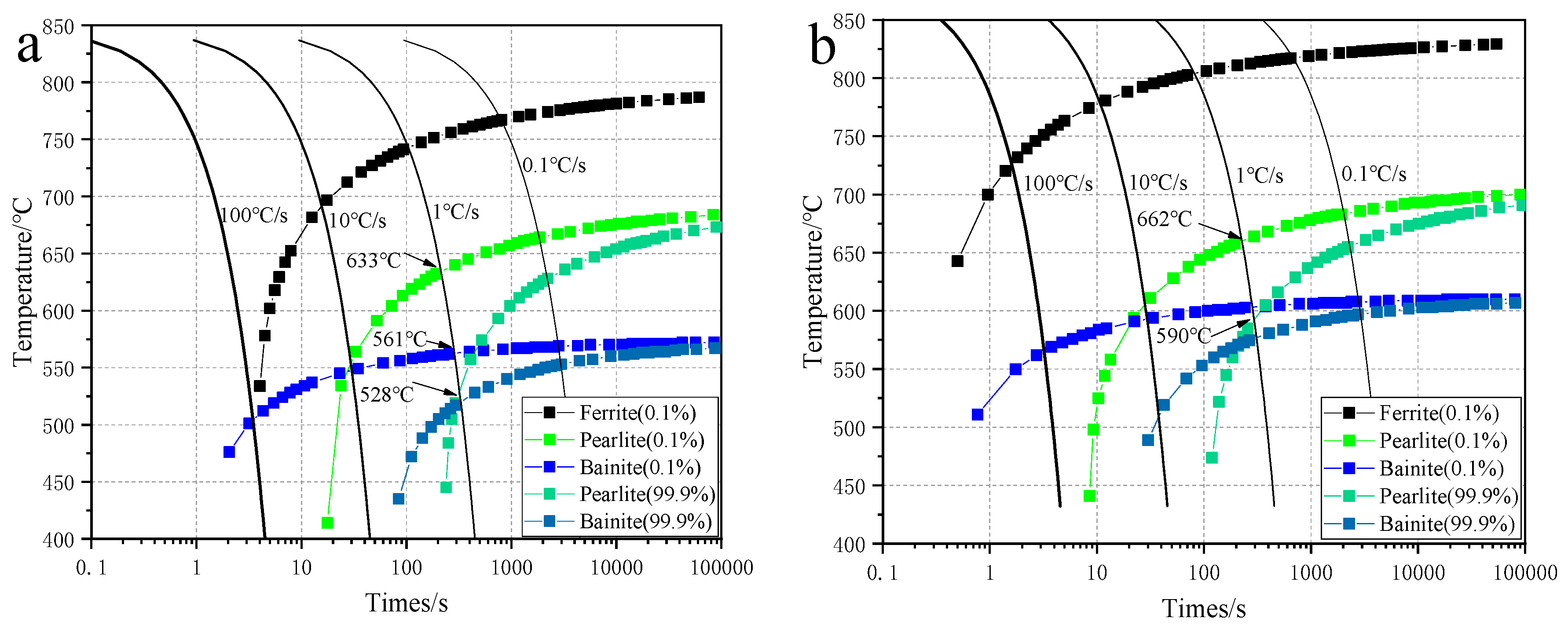

4.1. Occurrence of Degenerate Pearlite and Its Influence on Mechanical Properties

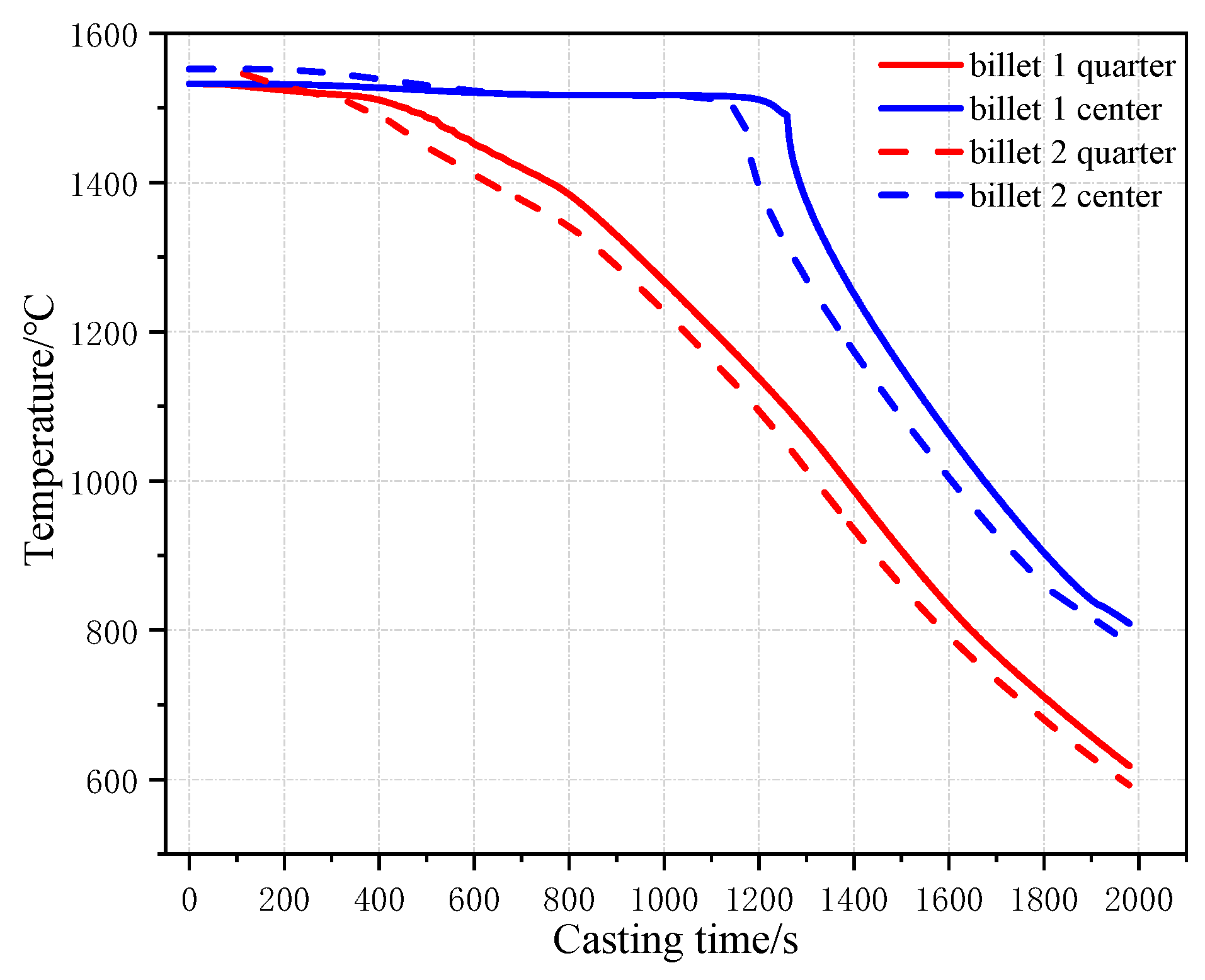

4.2. Effect of Continuous Casting Process on Solidification Structure and Central Segregation of Billet

5. Conclusions

- (1)

- The central crystal zone of a continuously cast billet presented segregated spots that were caused by the concentration of Mn.

- (2)

- With the application of high superheating and secondary cooling temperatures without EMS (electro magnetic stirring), the fraction of the equiaxed crystal zone effectively decreased. The columnar crystal structure was more effective to control central segregation in the continuously casting billet.

- (3)

- The microstructure of the steel that was rolled from the billet with severe segregation consisted of ferrite and degenerate pearlite, while the microstructure of the steel that was rolled from the optimized billet was dominated by ferrite and lamellar pearlite. The fraction of pearlite in Steel 1 (41%) was obviously higher than that of Steel 2 (14%).

- (4)

- Controlling the degree of central segregation could achieve an excellent low temperature toughness, as the DBTT decreased from −10 to −40 °C, and the elongation increased by ~10%.

Author Contributions

Funding

Conflicts of Interest

References

- Miao, C.L.; Shang, C.J.; Zhang, G.D. Recrystallization and strain accumulation behaviors of high Nb-bearing line pipe steel in plate and strip rolling. Mater. Sci. Eng. A 2010, 527, 4985–4992. [Google Scholar] [CrossRef]

- Nie, Y.; Shang, C.; You, Y. 960 MPa grade high performance weldable structural steel plate processed by using TMCP. J. Iron Steel Res. Int. 2010, 17, 63–66. [Google Scholar] [CrossRef]

- Nie, Y.; Shang, C.; Song, X. Properties and homogeneity of 550-MPa grade TMCP steel for ship hull. Int. J. Min. Metall. Mater. 2010, 17, 179–184. [Google Scholar] [CrossRef]

- Chen, S.; An, Y.G.; Lahaije, C. Toughness improvement in hot rolled HSLA steel plates through asymmetric rolling. J. Mater. Sci. Eng. A 2015, 625, 374–379. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Raghupathy, Y.; Srinivasan, D.; Suwas, S.; Srivastava, C. Microstructural evolution of cold-sprayed Inconel 625 superalloy coatings on low alloy steel substrate. J. Acta Mater. 2017, 129, 11–25. [Google Scholar] [CrossRef]

- Ronevich, J.A.; Somerday, B.P.; San Marchi, C.W. Effects of microstructure banding on hydrogen assisted fatigue crack growth in X65 pipeline steels. Int. J. Fatigue 2016, 82, 497–504. [Google Scholar] [CrossRef]

- Krauss, G. Solidification, segregation, and banding in carbon and alloy steels. Metall. Mater. Trans. B 2003, 34, 781–792. [Google Scholar] [CrossRef]

- Shibanuma, K.; Nemoto, Y.; Hiraide, T.; Suzuki, K.; Sadamatsu, S.; Adachi, Y.; Aihara, S. A strategy to predict the fracture toughness of steels with a banded ferrite–pearlite structure based on the micromechanics of brittle fracture initiation. Acta Mater. 2018, 144, 386–399. [Google Scholar] [CrossRef]

- Bo, L.; Zhonghua, Z.; Huasong, L. Characteristics and Evolution of the Spot Segregations and Banded Defects in High Strength Corrosion Resistant Tube Steel. Acta Metall. Sin. 2019, 55, 762–772. [Google Scholar]

- Guo, F.; Wang, X.; Liu, W. The Influence of Centerline Segregation on the Mechanical Performance and Microstructure of X70 Pipeline Steel. Steel Res. Int. 2018, 89, 1800407. [Google Scholar] [CrossRef]

- Guo, F.; Liu, W.; Wang, X. Controlling Variability in Mechanical Properties of Plates by Reducing Centerline Segregation to Meet Strain-Based Design of Pipeline Steel. Metals 2019, 9, 749. [Google Scholar] [CrossRef]

- Sahoo, P.P.; Kumar, A.; Halder, J. Optimisation of electromagnetic stirring in steel billet caster by using image processing technique for improvement in billet quality. ISIJ Int. 2009, 49, 521–528. [Google Scholar] [CrossRef]

- Nakata, H.; Inoue, T.; Mori, H.; Lshiguro, S.; Nakata, H.; Murakami, T.; Kominami, T. Improvement of billet surface quality by ultra-high-frequency electromagnetic casting. J. ISIJ Int. 2002, 42, 264–272. [Google Scholar] [CrossRef]

- An, H.; Bao, Y.P.; Wang, M.; Zhao, L.H. Reducing macro segregation of high carbon steel in continuous casting bloom by final electromagnetic stirring and mechanical soft reduction integrated process. Metall. Res. Technol. 2017, 114, 405. [Google Scholar] [CrossRef]

- Choudhary, S.K.; Ganguly, S. Morphology and segregation in continuously cast high carbon steel billets. ISIJ Int. 2007, 47, 1759–1766. [Google Scholar] [CrossRef]

- Choudhary, S.K.; Ganguly, S.; Sengupta, A. Solidification morphology and segregation in continuously cast steel slab. J. Mater. Process. Tech. 2017, 243, 312–321. [Google Scholar] [CrossRef]

- Xiu, Z.G.; Wang, X.H. Effect of superheat on the center segregation in continuous casting slab of X65 steel. Steel Mak. 2014, 30, 36–44. [Google Scholar]

- Mukherjee, M.; Chintha, A.R.; Kundu, S. Development of stretch flangeable ferrite–bainite grades through thin slab casting and rolling. Mater. Sci. Technol. 2016, 32, 348–355. [Google Scholar] [CrossRef]

- Zhang, H.; Cheng, X.; Bai, B. The tempering behavior of granular structure in a Mn-series low carbon steel. Mater. Sci. Eng. A 2011, 528, 920–924. [Google Scholar] [CrossRef]

- Rui, F. Research on Internal Quality and Its Influencing Factors of Ferrite Pearlite Steel Plate. Ph.D. Thesis, Shandong University, Jinan, Shandong, China, 30 October 2013. [Google Scholar]

- Ji, Y.; Lan, P.; Geng, H. Behavior of spot segregation in continuously cast blooms and the resulting segregated band in oil pipe steels. J. Steel Res. Int. 2018, 89, 1700331. [Google Scholar] [CrossRef]

- Aaronson, H.I.; Enomoto, M.; Lee, J.K. Mechanisms of Diffusional Phase Transformations in Metals and Alloys; CRC Press: Boca Raton, FL, USA, 2016; pp. 576–577. ISBN 978-1-4398-8253-5. [Google Scholar]

- Zhang, J.; Chen, D.; Wang, S.; Long, M. Compensation control model of superheat and cooling water temperature for secondary cooling of continuous casting. Steel Res. Int. 2011, 82, 213–221. [Google Scholar] [CrossRef]

- Feng, J.; Cheng, W.Q. Effect of high secondary cooling intensity on solidification structure and center carbon segregation of high carbon steel billet. Spec. Steel 2006, 27, 42–44. [Google Scholar]

| Billet | Superheating/°C | Speed/m/min | Secondary Cooling Kg/L | EMS |

|---|---|---|---|---|

| 1 | 24 | 0.7 | 0.25 | with |

| 2 | 35 | 0.7 | 0.4 | without |

| Steel | YS/MPa | TS/MPa | Agt/% | A/% |

|---|---|---|---|---|

| 1 | 504.5 (±9.2) | 572.0 (±4.2) | 8.53 (±1.05) | 25.36 (±0.79) |

| 2 | 386.0 (±2.8) | 552.5 (±0.7) | 15.04 (±0.30) | 34.40 (±0.10) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, F.; Wang, X.; Wang, J.; Misra, R.D.K.; Shang, C. The Significance of Central Segregation of Continuously Cast Billet on Banded Microstructure and Mechanical Properties of Section Steel. Metals 2020, 10, 76. https://doi.org/10.3390/met10010076

Guo F, Wang X, Wang J, Misra RDK, Shang C. The Significance of Central Segregation of Continuously Cast Billet on Banded Microstructure and Mechanical Properties of Section Steel. Metals. 2020; 10(1):76. https://doi.org/10.3390/met10010076

Chicago/Turabian StyleGuo, Fujian, Xuelin Wang, Jingliang Wang, R. D. K. Misra, and Chengjia Shang. 2020. "The Significance of Central Segregation of Continuously Cast Billet on Banded Microstructure and Mechanical Properties of Section Steel" Metals 10, no. 1: 76. https://doi.org/10.3390/met10010076

APA StyleGuo, F., Wang, X., Wang, J., Misra, R. D. K., & Shang, C. (2020). The Significance of Central Segregation of Continuously Cast Billet on Banded Microstructure and Mechanical Properties of Section Steel. Metals, 10(1), 76. https://doi.org/10.3390/met10010076