Abstract

In this study, a novel process was established for extraction of Fe and Al from a complex high aluminum iron ore (33.43% Fetotal and 19.09% Al2O3). The main steps in the proposed process included pre-reducing high alumina iron ore and subsequent smelting to produce pig iron and rich-alumina slag, followed by alkaline leaching of the slag to obtain sodium aluminate solution and a clean slag. When smelting the pre-reduced high alumina iron ore pellets at 1625 °C for 30 min with a slag basicity of 0.40, the pig iron yielded 97.08% Fe and extracted 0.13% Al2O3, together with an iron recovery of 94.54%. In addition, more than 68.93% Al2O3 was recovered by leaching the slag, which was achieved by firstly roasted the slag at 900 °C for 2 h and then alkaline leaching at 95 °C for 2 h with a liquid-to-solid ratio of 10 mL/g. In addition, the alkaline leaching slag could potentially be used as raw material for construction purpose, which mainly consisted of SiO2 and CaO.

1. Introduction

With the rapid increasing in demand for metals, the global reserves of high-grade ores are shrinking at an alarming rate. Therefore, it is urgent to develop a novel process to upgrade the complex iron resources [1,2]. High aluminum iron ore (HAIO), a kind of polymetallic complex resources, is widely distributed in nature, which has a high comprehensive utilization value. Moreover, it is abundantly found in China, Australian, India and Indonesia [3]. Typically, it contains 5–20% Al2O3 and 30–60% Fe, indicating that it is difficult to be used as a raw material for ironmaking [4,5]. Thus, it is important to remove alumina from HAIO.

The recovery of valuable metals, such as Fe and Al, from HAIO has attracted increasing attention. Many technologies have been reported in previous literature, including physical beneficiation, biological leaching, and smelting. The beneficiation methods include both physical [6,7,8] and chemical [9] processes. Thella et al. [7] adopted flotation process to treat HAIO slime (4.0% Al2O3 and 61.99% Fe), and the findings demonstrated that the iron recovery is only 70% and the content of Al2O3 in final concentrate remained as high as 2.66%. Generally, it is difficult to effectively remove aluminum by the using the conventional beneficiation process, due to the dissemination of aluminum minerals is complex and micro-grained [10]. Pradhan et al. [2] used Bacillus circulars and Aspergillus niger to remove aluminum from iron ore containing Fetotal 52.94%, 9.95% Al2O3 and 6.1% SiO2, and only 40% alumina was removed after 6 or 15 days of in situ leaching at 10% pulp density. Biological method could play a certain role in the separation of iron from alumina, but its effect may be poorer, especially the period is too lengthy compared to smelting processes.

Smelting processes consist of coal-based direct reduction-magnetic separation, roasting-magnetic separation, and smelting separation [11,12,13]. It is effective to recover iron from low-grade refractory iron ore through coal-based direct reduction-magnetic separation. However, there is a problem that exists in this process, low reduction rate [14,15]. Zhou et al. [13] proposed a high temperature reduction followed by magnetic separation for high aluminum hematite-limonite ore treatment. Their findings indicated that approximately 90.25% of iron recovery was obtained, but the recovery of Al2O3 was not considered. Sellaeg et al. [16] adopted a direct smelting reduction process to recover iron from red mud, and the result showed that only 70% of iron was recovered and an Al2O3-containing slag was obtained. He et al. [17] proposed a slag-iron bath smelting reduction process for the treatment of alumina-rich iron ore, and more than 90% iron was recovered using this method. It is worth noting that the smelting separation process can achieve the separation of iron and alumina. However, the slag could not be effectively used, resulting in a difficulty of extracting aluminum.

Considering that the existing processes for HAIO treatment have highly energy consumption and are economically impractical, it is urgent to develop a more economical and valid process. In this work, a new process was developed through the pre-reduction of high alumina iron ore and subsequent smelting to produce pig iron and rich-alumina slag, followed by alkali leaching to extract aluminum and generate a clean slag for cement industry.

2. Materials and Methods

2.1. Materials

2.1.1. High Aluminum Iron Ore

The HAIO used in this study was supplied by Guang Xi Province, China. To remove all free moisture, the sample was pre-dried for 10 h at 100 °C prior to chemical analysis, and the findings are shown in Table 1. The major ingredients of HAIO included 33.43 wt. % Fe, 19.09 wt. % Al2O3 and 18.36% SiO2.

Table 1.

Chemical compositions of high aluminum iron ore (HAIO) (wt. %).

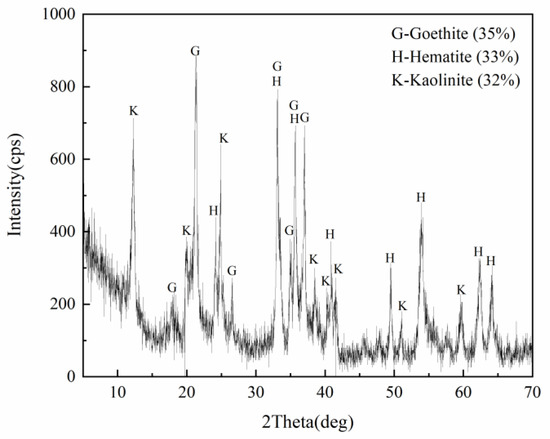

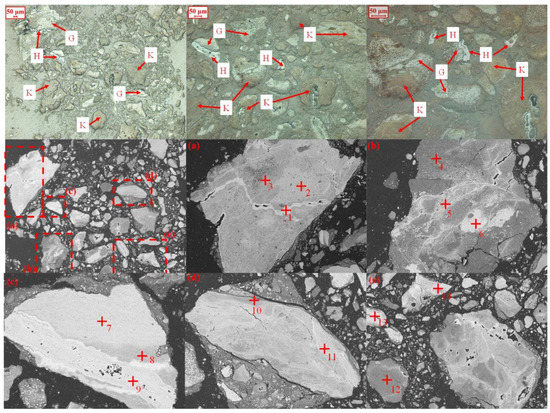

As shown in Figure 1, the minerals compositions of the main phases of the iron ore cover goethite (35%), hematite (33%) and kaolinite (32%). The distributions of iron and aluminum in the ore are summarized in Table 2 and Table 3, showing that the iron is predominantly found in the form of hematite and goethite, while aluminum is dominantly presented in the form of kaolinite. Figure 2 reveals the microstructure of HAIO. The results of EDS analysis for the areas in Figure 2 is demonstrated in Table 4. It was observed that the main iron minerals existed within 10 μm and embedded closely with gangue minerals, which in turn could impart a great challenge for the removal of aluminum from HAIO through physical beneficiation processes.

Figure 1.

XRD diffraction pattern of HAIO.

Table 2.

Distributions of iron in mineral phases of the HAIO (wt. %).

Table 3.

Distributions of aluminum in mineral phases of the HAIO (wt. %).

Figure 2.

Microstructure of the HAIO (G-Goethite, H-Hematite, K-Kaolinite).

Table 4.

The EDS analysis results for areas in Figure 2.

2.1.2. Flux and Additive

In this study, limestone was employed as a flux to modify the binary basicity of pre-reduced-smelting separation process, which contains 55.73% of CaO and 41.52% of loss on ignition.

Analytical grade Na2CO3 was used as the additive in this study for reconstructing the mineral phases of smelting separation slag by modifying the firing process.

2.1.3. Reductant

Soft coal was selected as a reductant in this study, which was crushed and screened to a size of 1–5 mm. A proximate analyzer (SDTGA5000, Hunan Sundy, Changsha, China) was used for the proximate analysis of soft coal, while the chemical compositions of ash were evaluated by chemical titration method [18,19]. Table 5 summarizes the results of proximate analysis and the major chemical compositions of ash.

Table 5.

Proximate analysis of soft coal and its ash chemical compositions (wt. %).

2.2. Experimental Methods

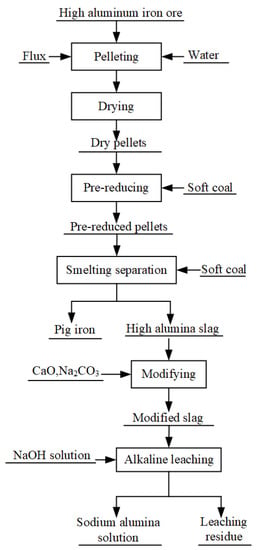

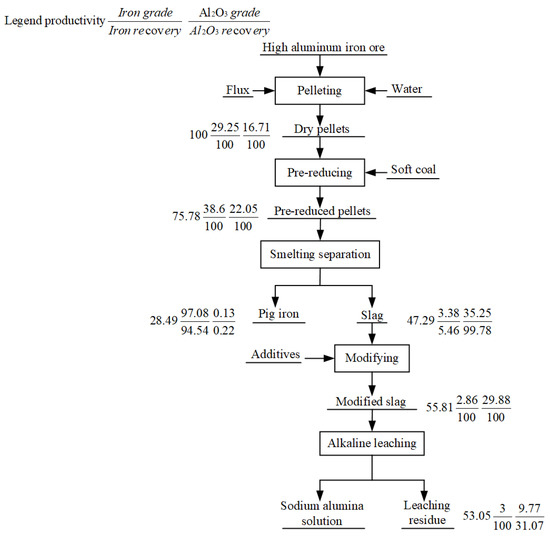

A schematic flow diagram for the treatment process of the proposed HAIO is illustrated in Figure 3, which was established based on the following steps: (1) pre-reduction of the HAIO pellets followed by smelting separation to recover Fe; (2) modification the smelting slag-alkaline leaching to extract Al.

Figure 3.

Experiment flow sheet of the proposed HAIO treatment process.

2.2.1. Pre-Reduction-Smelting Separation Process

HAIO was sufficiently mixed with a ratio of flux. The mixture was pelletized into 12–16 mm green balls using a disc pelletizer (diameter: 800 mm and depth: 200 mm), and then dried in a vacuum oven at 110 °C for 4 h until their weight remained constant. The dried pellets (50 g) with 75 g coals were loaded into a corundum crucible (diameter: 80 mm and height: 80 mm) and roasted in a muffle furnace (model: KSY-12-18, Hefei Kejing Material Technology Co., Ltd., Hefei, China) at pre-set temperature (800–1100 °C) for a specific period of time (15–120 min) [20]. Afterwards, the reduced pellets were cooled down to room temperature under nitrogen atmosphere, and then prepared for the subsequent smelting separation process. The metallization rates of iron were determined as the following:

where ηFe is the metallization rate of iron; TFe is the content of total iron in the pre-reduced, which was determined as the equation: w(TFe) = w(MFe) + w(Fe content in “FeO”); MFe is the content of metallic iron in the pre-reduced pellets.

Due to the lower metallization rates of pre-reduced pellets and the main iron-containing phases are fayalite and hercynite, a massive amount of reductant should be added into the smelting separation process, which is favorable for the separation of iron and aluminum. The pre-reduced pellets (~100 g) with 5–20 wt. % of coals were loaded into a corundum crucible (diameter: 80 mm and height: 90 mm), and then transferred into a smelting furnace (model KSl-1700X-A4, Hefei Kejing Material Technology Co., Ltd., Hefei, China) at pre-set temperature (1550–1625 °C) for a definite period of time (10–40 min). After smelting separation, the pig iron and slag were cooled down to room temperature under nitrogen atmosphere. The smelting separation indexes include the recovery rates of iron and the content of total iron in the pig iron. The recovery rates of iron were determined by the following formula:

where εFe is the recovery rate of iron; TFe0 is the content of total iron in pig iron; y is the yield of pig iron; TFe is the content of total iron in the pre-reduced pellets

2.2.2. The Slag Modification-Alkaline Leaching

The main compositions of the pre-reduced pellets are hercynite, fayalite, quartz, and gehlenite, which can be used to reconstruct the mineral phases by adding Na2CO3 and limestone. The slag from the smelting separation process was first ground below −0.074 mm, and then sufficiently mixed with specific amounts of additives (10 wt. % limestone and 20 wt. % Na2CO3). The mixture containing 5% moisture was prepared in the form of briquettes (diameter: 10mm and height: 10mm), and then dried in a vacuum oven at 110 °C for 4 h. After drying, the dried briquettes (30 g) were charged into a corundum crucible (length: 30 mm and height: 20 mm), and then fired in a pipe furnace (model: KSY-12-18, Hefei Kejing Material Technology Co., Ltd., Hefei, China) at 900 °C for 120 min for the purpose of modification. Subsequently, the modified slag was cooled down to room temperature.

The alkaline leaching tests were performed by mixing the modified slag with 2 mol/L alkaline solution at a liquid-to-solid (L/S) ratio of 10 mL/g and a rotation speed of 300 rpm. The mixture was heated at 95 °C in a thermostatic water bath (HH-12468, Changzhou Yuexin Instrument Manufacturing Co., Ltd., Changzhou, China) for 2 h. After filtration, the leach residues were rinsed with deionized water. The recovery rates of Al2O3 were calculated by the following:

where is the recovery rate of Al2O3; y1 is the yield of leaching residue; w0 and w1 are the content of Al2O3 in the modified slag and leaching residue, respectively.

2.3. Characterization of Raw Materials and Products

To determine the chemical compositions of HAIO, X-ray fluorescence (XRF, PANalytical Axios; RIGAKU ZSX Priums, PANalytical B.V., Almelo, The Netherlands) was carried out. Mineral compositions and distributions of aluminum and iron in HAIO at various phases were evaluated by chemical phase analysis as described previously [21,22]. The concentrations of metallic iron were determined by chemical titration method according to the national standards (GB/T 24194-2009) [23]. The microstructures of HAIO and smelting separation slag were examined using Leica DMLP optical microscopy, FEI Quata-200 (Leica, Weztlar, Germany) scanning electron microscope (SEM), energy-dispersive spectrometry (EDS; XMAX20, FEI, Eindhoven, The Netherlands), EDAX32 genesis spectrometer (FEI, Eindhoven, The Netherlands) and TESCAN MIRA-3, LMH SEM(FEI, Eindhoven, The Netherlands) The mineral phases were measured by X-ray powder diffraction (XRD, RIGAKU, D/Max-2500, Bruker corporation, Madison, WI, USA) with a 2θ scan range from 10°–70°, operating at 40 KV and 40 mA with Cu Kα radiation (λ = 0.15418 nm) at 25 °C The contents of main mineral of raw material, pre-reduced pellets and slag were calculated by the following formula [24]:

where and are the content of determined mineral and reference substance, respectively; and are the diffraction peak intensity of determined mineral and reference substance, respectively; is the reference intensity (diffraction peak intensity is the result of the collective action of all the atoms in the unit cell).

3. Results and Discussion

3.1. Recover Iron from HAIO by Pre-Reduction-Smelting Separation Process

3.1.1. Pre-Reduction of High Alumina Iron Ore Pellets

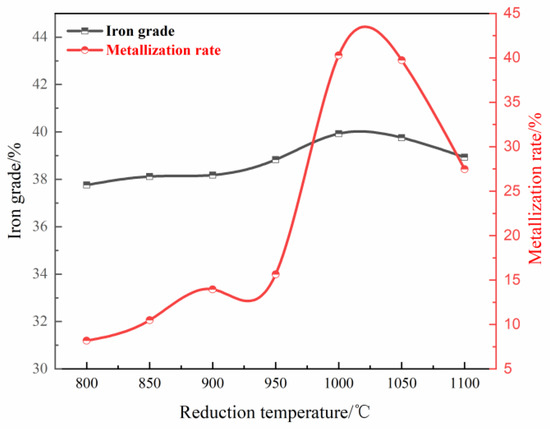

As shown in Figure 4, the metallization rates of iron were elevated from 8.18% to 40.27% with increasing reduction temperature (800 °C–1000 °C). Meanwhile, the content of iron was changed slightly. At an elevated temperature, the metallization rate of iron was reduced. This is probably due to the fact that rising temperature is beneficial to enhance the reduction of fayalite (Fe2SiO4) and hercynite (FeAl2O4), but more liquid phase would be formed if the reduction temperature is too high, which may be detrimental for diffusion of the reduction gas [13]. Therefore, the reduction temperature of 1000 °C was selected for subsequent experiments.

Figure 4.

Effects of reduction temperature on the pre-reduction indices. (Reducing for 60 min, with a C/Fe mass ratio of 1.50, natural basicity of 0.0020).

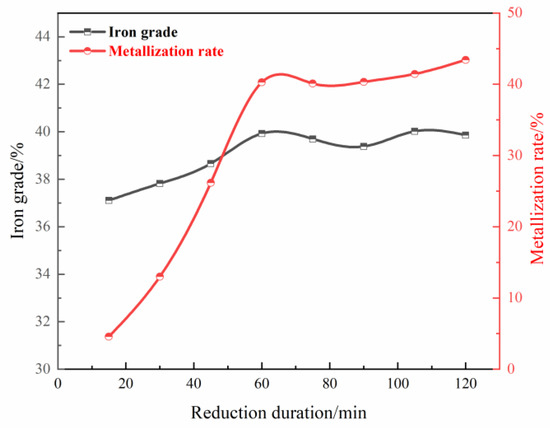

Figure 5 reveals the effects of reduction duration on the iron grade and metallization rate of the pre-reduced pellets. The metallization rates were increased by prolonging the reducing duration from 15 to 60 min. Further extending the reduction duration could slightly affect the two indices, indicating that the reductant is nearly exhausted and the reduction atmosphere is diminished due to a lengthy period of reduction. Based on these finding, a reduction time of 60 min was selected. As a result, the pre-reduced pellets were manufactured with 39.93% of iron grade and 40.27% of metallization rate.

Figure 5.

Effect of reduction duration on the pre-reduction indices. (Reduction at 1000 °C, with a C/Fe mass ratio of 1.50, natural basicity of 0.0020).

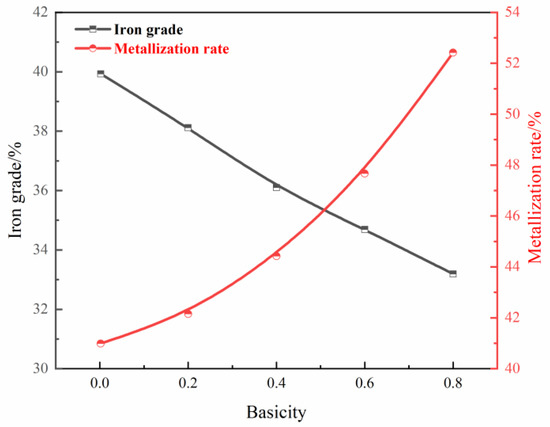

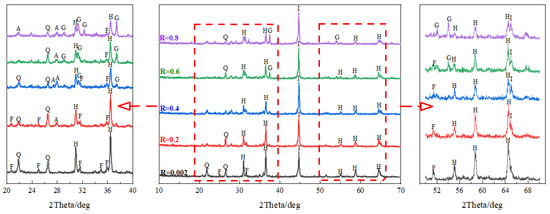

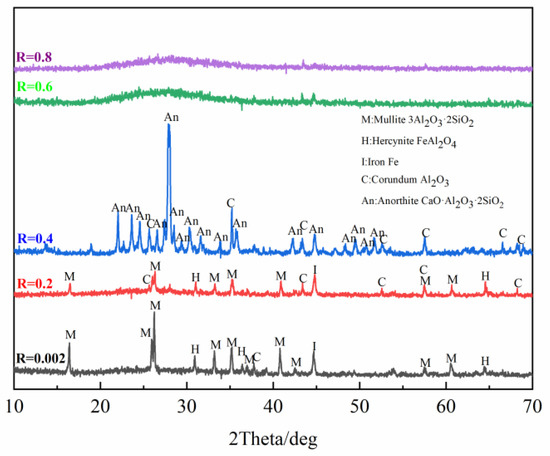

Figure 6 shows the effects of basicity on the iron grade and metallization rate of the pre-reduced pellets. The metallization rates were elevated from 40.99% to 52.42% when the basicity levels were increased from 0.002 (natural basicity) to 0.8. The XRD patterns of pre-reduced pellets at different binary basicity (w(CaO)/w(SiO2)) levels are presented in Figure 7. The mineral compositions of the pre-reduced pellets of natural basicity are element iron, fayalite, hercynite, and quartz. The contents of fayalite and hercynite decreased with increasing basicity levels from 0.002 to 0.8. On the contrary, the contents of gehlenite increased with increasing basicity levels (as shown in Table 6). These results provide compelling evidence that CaO could enhance the decomposition of fayalite and hercynite, which in turn leads to the improved activity of FeO. And ultimately increased the rates of metallization.

Figure 6.

Effects of binary basicity (w(CaO)/w(SiO2)) on the pre-reduction indices (Reduction at 1000 °C for 60 min, with a C/Fe mass ratio of 1.50).

Figure 7.

XRD pattern of the pre-reduced pellets at different binary basicity (w(CaO)/w(SiO2)) (A: Albite (Na,Ca)Al(Si,Al)3O8; Q: Quartz SiO2; G: Gehlenite Ca2Al2SiO7;H: Hercynite FeAl2O4; F: Fayalite Fe2SiO4; I: element Iron;).

Table 6.

The content of main minerals in the Figure 7 (wt. %).

3.1.2. Smelting Separation Process

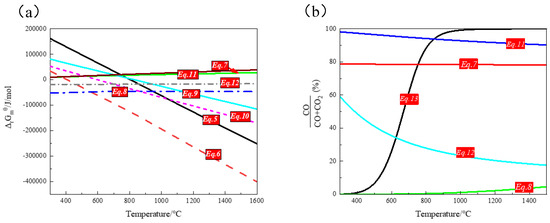

Thermodynamic Analysis

As shown in Figure 7, the main iron minerals in the pre-reduced pellets are fayalite and hercynite. Equations (5–12) reveals the potential reactions during the smelting process of pre-reduced pellets. FactSage7.0 (Thermfact/CRCT, Montreal, QC, Canda; GTT-Technologies, Herzogenrath, Germany) was adopted to estimate the changes in the Gibbs free energy of the reactions; and the findings are presented in Figure 8. Based on the thermodynamic calculation, both fayalite and hercynite were difficult to be reduced by CO thermodynamically (Equations (7) and (11)), indicating that they are not able to be reduced in pre-reduction process. However, lower CO concentration might be required to reduce fayalite and hercynite when CaO is existed. In the smelting separation process, solid carbon was employed as the reductant, and thus both fayalite and hercynite could be reduced. Additionally, CaO could promote the reduction of fayalite and hercynite by chemically reacting with Al2O3 and SiO2 to form calcium aluminate (CaAl2O4) and larnite (Ca2SiO4), respectively.

Fe2SiO4 + 2C = 2CO +2Fe + SiO2

Fe2SiO4 + 2C + 2CaO = 2Fe + 2CO + Ca2SiO4

1/2Fe2SiO4 + CO = CO2 + Fe + 1/2SiO2

1/2Fe2SiO4 + CO + CaO = CO2 + Fe + 1/2Ca2SiO4

FeAl2O4 + C = Fe + Al2O3 + CO

FeAl2O4 + C + CaO = Fe + CO + CaAl2O4

FeAl2O4 + CO = CO2 + Fe + Al2O3

FeAl2O4 + CO + CaO = Fe + CO2 + CaAl2O4

C + CO2 = 2CO

Figure 8.

The correlation of the standard free energy (ΔrGmθ) with reaction temperature for Equations (5–12). (a): The standard free energy versus reaction temperature; (b): Gas-phase equilibrium of Equations (7,8,11,12) reduced by CO).

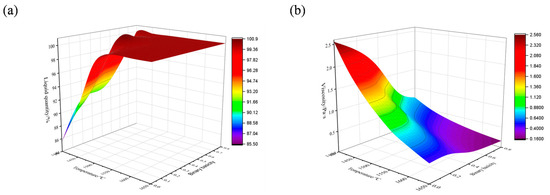

According to the chemical composition of pre-reduced pellets, the liquid phase quantity and viscosity at different temperature were calculated by FactSage7.2 (Thermfact/CRCT, Montreal, QC, Canda; GTT-Technologies, Herzogenrath, Germany), and the results are shown in Figure 9. As can be seen from that the figure, the liquid phase quantity increased from 85.53% to 100% with elevating smelting temperature from 1400 °C to 1550 °C under natural basicity. Meanwhile, the viscosity decreased from 2.56 Pa·s to 0.92 Pa·s. The smelting separation process required the slag to have lower viscosity, and its value for ferroalloy production is generally between 0.20 Pa·s and 0.50 Pa·s. When the viscosity of the slag is higher than 1 Pa·s, it is hard to separate the iron from the slag [25]. Nevertheless, the viscosity of the slag decreased from 0.92 Pa·s to 0.28 Pa·s when the binary basicity (w(CaO)/w(SiO2)) level of the slag was increased from natural basicity to 0.80, indicating that addition of CaO can improve the fluidity and viscosity of the slag.

Figure 9.

Effects of temperature on the mass fraction of liquid phase and viscosity. (a) Effects of temperature on the liquid quantity; (b) Effects of temperature on the viscosity (liquid phase quantity represents the mass fraction of liquid phase).

Smelting Separation of the Pre-Reduced Pellets

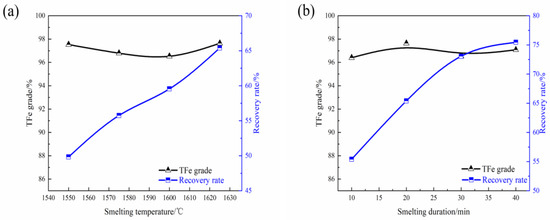

Figure 10 shows the effect of the process parameters on the smelting separation indices. It was found that the grades of pig iron changed slightly with elevating smelting temperature from 1550 °C to 1625 °C However, the recovery rates of iron increased from 49.83% to 65.40% (as shown in Figure 10a). Compared to the viscosity of 0.92 Pa·s at 1550 °C, it was only 0.47 Pa·s at 1625 °C Indeed, the lower viscosity at higher temperature is favorable for the separation of iron and slag, thus the optimum smelting temperature of 1625 °C was selected.

Figure 10.

Effects of smelting separation parameters on the smelting separation of pre-reduced pellets. (a) Smelting at various temperature for 20 min with 10% soft coal, under natural basicity; (b) Smelting at 1625 °C with 10% soft coal, under natural basicity. (The yields of pig iron obtained at different smelting temperature were 20.56%, 22.97%, 24.94%, and 26.99%, respectively; The yields of pig iron obtained at different smelting duration were 23.09%, 26.96%. 30.45%, and 30.99%, respectively).

Figure 10b reveals the effects of smelting duration on the indices. Notably, the recovery rates of iron increased from 55.39% to 73.06% by prolonging the smelting duration from 10 min to 30 min. With a further extension of the time, the recovery rates were increased slightly. In addition, the iron grade changed slightly throughout the smelting duration. Based on the above results, smelting at 1625 °C for 30 min with natural basicity (0.002) was selected. As a result, the pig iron could be generated from 96.53% of iron grade and 73.06% of iron recovery rate.

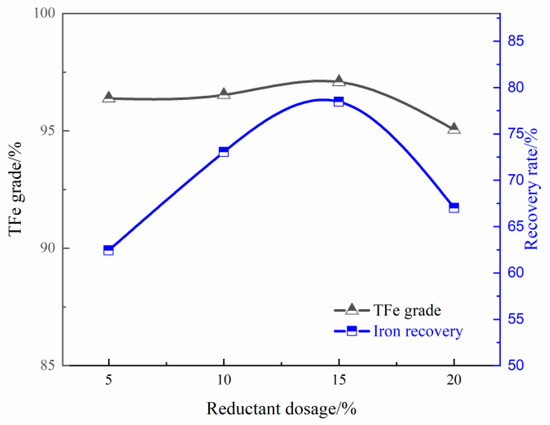

The effects of reductant dosage on the smelting separation process indices are depicted in Figure 11. The grades of the pig iron changed slightly with increasing doses (5–15%) of the reductant. However, the iron recovery rates of pig iron were obviously increased from 62.44% to 78.47%. Further increasing the reductant doses could negatively affect the values of the indices, probably due to fact that the excessive reductant may cause serious carburizing and lower basicity levels of the slag, leading to the decreased iron grade and higher viscosity of the slag. Considering these indices, the optimal reductant dosage was recommended as 15%.

Figure 11.

Effects of reductant dosage on the smelting separation of pre-reduced pellets. (Smelting at 1625 °C for 30 min, under natural basicity). (The yields of pig iron obtained at different reductant doses were 26.03%, 26.96%, 32.48%, and 28.17%, respectively).

From the above result, it can be concluded that the separation of iron from the high alumina slag is not so efficient due to the low recovery of iron. Therefore, some measures should be taken to increase the recovery rates.

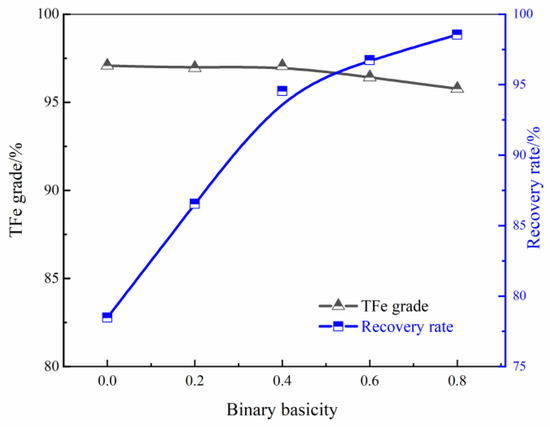

The effects of binary basicity (w(CaO)/w(SiO2)) of the slag on the smelting process indices are shown in Figure 12. Increasing the basicity from natural value of 0.0020–0.80 exerted a little impact on the iron grade. In contrast, it exhibited a significant positive impact on the recovery rates of iron with a large increase from 78.47% to 98.55%. The addition of CaO could enhance the decomposition of fayalite and hercynite and induce the activity of FeO, leading to increase rates of iron recovery, which are consistent with the previous thermodynamic calculation.

Figure 12.

Effects of binary basicity (w(CaO)/w(SiO2)) levels on the smelting separation indices of the pre-reduced pellets. (Reducing at 1625 °C for 30 min and with 15% soft coal). (The yields of pig iron obtained at different binary basicity levels were 32.61%, 33.80%, 35.14%, 35.18%, and 34.20%, respectively).

The XRD patterns of the slag obtained from smelting separation at different basicity levels are demonstrated in Figure 13. The main mineral composition of the slag obtained from smelting separation at natural basicity is mullite. By increasing the basicity to 0.20, the content of mullite decreased, while that of corundum increased (as shown in Table 7). The peak of mullite disappeared, and the anorthite was generated when the basicity reached 0.4. Further elevating the basicity to 0.60, the XRD pattern tended to be amorphous. This is probably the reason that lots of liquid phase with lower viscosity were formed and the amorphous phase is observed after rapid cooling.

Figure 13.

XRD patterns of the slag obtained from smelting separation at different basicity levels.

Table 7.

The content of main compositions in the slag of Figure 13 (wt. %).

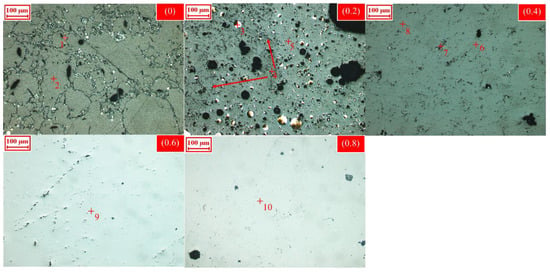

The microstructures of the slags obtained from smelting separation at different binary basicity (w(CaO)/w(SiO2)) levels are presented in Figure 14 and the EDS analysis of Figure 14 is presented in Table 8. It is obvious that the main phases are metallic iron and mullite at the basicity of 0.002 (natural basicity). By increasing the basicity to 0.20, flake alumina could also can be observed, in addition to metallic iron and mullite, indicating that the separation of iron from the slag is not efficient. Further elevating the basicity to 0.40, the metallic iron disappeared and the anorthite was observed. However, there was no crystalline phase observed in the slag at basicity of 0.60 and 0.80, and the uniformity was found in the slag phase. This indicates that CaO can improve the fluidity and viscosity of slag, which are consistent with the results presented in Figure 9. All these findings agree with those of Figure 13, in which an excellent separation of iron from the slag can be achieved at 0.40–0.80 basicity.

Figure 14.

Microstructures of the slags obtained from smelting separation at different basicity levels.

Table 8.

The EDS analysis of Figure 14 (wt. %).

3.2. Extracting Al2O3 from Smelting Separation Slag by Modifying-Alkaline Leaching

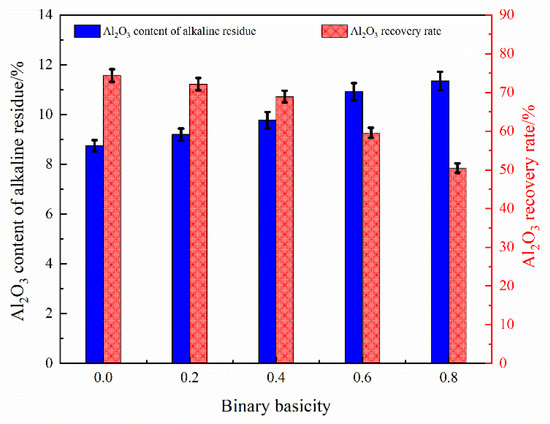

The slags obtained from smelting separation at various basicity levels can be used as the burden for extracting Al2O3. The dry briquettes were fired at 900 °C for 120 min followed by alkaline leaching at 95 °C for 2 h with a liquid-to-solid ratio of 10 mL/g for the purpose of modification.

Figure 15 shows the effects of the slags obtained from smelting separation at different basicity levels on the extraction yields of Al2O3. The recovery rates of Al2O3 decreased from 74.38% to 50.43% with increasing slag basicity levels from 0.0020 to 0.80. In addition, the content of Al2O3 in alkaline leaching residue increased from 8.74% to 11.35%. It can be concluded that increasing the basicity of the slag is not a suitable option for the extraction of alumina. Considering the separation of iron and extraction of alumina from the slag, the optimum basicity of the slag is recommended as 0.40.

Figure 15.

Effects of the slags obtained from smelting separation at different basicity levels on the recovery rates of Al2O3. (The slag was subjected to firing at 900 °C for 120 min and leaching at 95 °C for 120 min, with a liquid-to-solid ratio of 10 mL/g at 300 rpm). (The Al2O3 contents of modified slag obtained at different basicity levels were 17.11%, 17.88%, 18.51%, 19.27%, 19.72%, respectively. The yields of leaching residues obtained at different basicity levels were 50.16%, 54.16%, 58.86%, 71.32%, and 86.13%, respectively).

3.3. Fe and Al Balance in the Full Flow Sheet

As a whole, the following conditions were optimized: pre-reduction at 1000 °C for 60 min with a C/Fe mass ratio of 1.5, smelting the pre-reduced pellets to recover iron at 1625 °C for 30 min with 15% soft coal at 0.4 binary basicity (w(CaO)/w(SiO2)), then roasting the slag at 900 °C for 120 min and alkaline leaching the slag to extract alumina at 95 °C for 120 min with a liquid-to-solid of 10 mL/g. A full flow sheet of the exergy balance of Fe and Al elements is illustrated in Figure 16.

Figure 16.

A complete flow sheet for the exergy balance of Fe and Al elements.

Table 9 summarizes the chemical compositions of pig iron and alkaline leaching residue. It can be seen that the pig iron yielded 97.08% Fetotal with an overall iron recovery of 94.54%, and the extraction rate of Al2O3 by alkaline leaching was 68.93%. The pig iron can be applied as the burden for steelmaking by an electric arc furnace, while the pure Al2O3 can be manufactural from leaching solution and the alkaline leaching residue can be used to produce cement [26,27]. Effective utilization of HAIO could be achieved through the proposed method.

Table 9.

Chemical compositions of pig iron and alkaline leaching tailing (wt. %).

Baev et al. [28] investigated the heat exchange and reduction in high-alumina charges in the Blast furnace. The results showed that, due to the lower reducibility of HAIO, the coke and energy consumption were up to 1200 kg/(ton of pig iron) and 460 kWh/(ton of pig iron) in the blast furnace smelting process, respectively. He et al. [29] also reported that the coke and energy consumption of the direct slag-iron smelting reduction were 1463.30 kg/(ton of pig iron) and 432.29 kWh/(ton of pig iron), respectively. The energy and reductant consumption of the pre-reduction-smelting separation of HAIO treatment were decreased with increasing metallization rates of pre-reduced pellets [30]. According to a previous report [30], it can be calculated that the energy and reductant consumption of this process is 380 kWh/(ton of pig iron) and 1014 kg/(ton of pig iron), respectively.

4. Conclusions

In this study, an innovative technique, consisting of pelleting-pre-reducing-smelting reduction-modifying-alkaline leaching steps, was developed for extraction of Fe and Al2O3 from HAIO. Conclusions can be drawn as follows:

- HAIO, assaying 33.43% Fetotal, 19.09% Al2O3, and 18.36% SiO2, was defined as a refractory iron ore and employed as the raw materials to yield pig iron and extract Al2O3. In addition, the major iron minerals of HAIO are hematite and goethite, while the main aluminum minerals are kaolinite, and all of them are closely associated at superfine size.

- Approximately 94.54% of Fe was recovered in the pig iron when smelting the pre-reduced high aluminum iron pellets at 1625 °C for 30 min with a slag basicity of 0.40, while approximately 68.93% Al2O3 was extracted from the slag by roasting the smelting separation slag at 900 °C for 2 h and alkaline leaching at 95 °C for 2 h with a L/S ratio of 10 mL/g, and the leaching residue is suitable for cement industry.

- The developed process can provide an alternative for effective and green utilization of HAIO.

Author Contributions

Funding acquisition, J.P. and Z.G.; investigation, S.L., Y.S., J.C., and J.X.; methodology, J.P. and D.Z.; supervision, J.P., D.Z., and Z.G.; writing—original draft, S.L.; writing—review and editing, S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Nation Natural Science Foundation of China (grant number NO. 51574281), the Youth natural science foundation China (grant number NO. 51904347) and Innovation-driven Project of Guangxi Zhuang Autonomous Region (grant number No. AA18242003, No. AA148242003).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, K.Y.; Kleit, A.N. Mining rate optimization considering the stockpiling: A theoretical economics and real option model. Resour. Policy 2016, 47, 87–94. [Google Scholar] [CrossRef]

- Pradhan, N.; Das, B.; Gahan, C.S.; Kar, R.N.; Sukla, L.B. Beneficiation of iron ore slime using aspergillus niger and bacillus circulans. Bioresour. Technol. 2006, 97, 1876–1879. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Sahoo, H.; Rath, S.S.; Sahu, A.K.; Das, B. Recovery of iron minerals from Indian iron ore slimes using colloidal magnetic coating. Powder Technol. 2015, 269, 38–45. [Google Scholar] [CrossRef]

- Lu, L.; Holmes, R.J.; Manuel, J.R. Effects of alumina on sintering performance of hematite iron ores. ISIJ Int. 2007, 47, 349–358. [Google Scholar] [CrossRef]

- Umadevi, T.; Prakash, S.; Bandopadhyay, U.K.; Mahapatra, P.C.; Prabhu, M.; Ranjan, M. Influence of alumina on iron ore sinter quality and productivity. World Iron Steel 2010, 10, 12–18. [Google Scholar]

- Rocha, L.; Cançado, R.L.; Peres, A.C. Iron ore slimes flotation. Miner. Eng. 2010, 23, 842–845. [Google Scholar] [CrossRef]

- Thella, J.S.; Mukherjee, A.K.; Srikakulapu, N.G. Processing of high alumina iron ore slimes using classification and flotation. Powder Technol. 2012, 217, 418–426. [Google Scholar] [CrossRef]

- Shobhana, D.; Santosh, P.; Ratnakar, S.; Gayna, M.P. Response of process parameters for processing of iron ore slime using column flotation. Int. J. Miner. Process 2015, 140, 58–65. [Google Scholar]

- Mahiuddin, S.; Bondyopadhway, S.; Baruah, J.N. A study on the beneficiation of indian iron-ore fines and slime using chemical additives. Int. J. Miner. Process 1989, 26, 285–296. [Google Scholar] [CrossRef]

- Shu, C.W.; Tang, Y.; Wang, Z.Q.; Zhang, Q. Research on sodium salt roasting-acid leaching technology for high-alumina and high-silicon refractory limonite. Min. Metall. Eng. 2012, 32, 62–65. [Google Scholar]

- Zhu, D.Q.; Chun, T.J.; Pan, J. Recovery of Iron from High-Iron Red Mud by Reduction Roasting with Adding Sodium Salt. J. Iron. Steel Res. Int. 2012, 19, 1–5. [Google Scholar] [CrossRef]

- Chun, T.J.; Zhu, D.Q.; Pan, J. Preparation of metallic iron powder from red mud by sodium salt roasting and magnetic separation. Can. Metall. Q. 2014, 53, 183–189. [Google Scholar] [CrossRef]

- Zhou, X.L.; Zhu, D.Q.; Pan, J.; Luo, Y.H.; Liu, X.Q. Upgrading of High-Aluminum Hematite-Limonite Ore by High Temperature Reduction-Wet Magnetic Separation Process. Metals 2016, 6, 57. [Google Scholar] [CrossRef]

- Liu, Y.; Zuo, K.; Yang, G.; Shang, Z.; Zhang, J. Recovery of ferric oxide from bayer red mud by reduction roasting-magnetic separation process. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2016, 31, 404–407. [Google Scholar] [CrossRef]

- Chun, T.J.; Long, H.M.; Li, J.X. Alumina-Iron Separation of High Alumina Iron Ore by Carbothermic Reduction and Magnetic Separation. Sep. Sci. Technol. 2015, 50, 760–766. [Google Scholar] [CrossRef]

- Sellaeg, H.; Kolbeinsen, L.; Safarian, J. Iron separation from bauxite through smelting-reduction process. Light Metals. 2017, 127–135. [Google Scholar]

- He, Y.B.; Tang, B.; Li, Q.; Zou, Z.S. A comprehensive static model of an iron bath smelting reduction process for alumina-rich iron ore. ISIJ Int. 2015, 55, 2135–2144. [Google Scholar] [CrossRef]

- Guo, Z.Q.; Zhu, D.Q.; Pan, J.; Zhang, F. Innovative methodology for comprehensive and harmless utilization of waste copper slag via selective reduction-magnetic separation process. J. Clean. Prod. 2018, 187, 910–922. [Google Scholar] [CrossRef]

- Yang, C.C.; Zhu, D.Q.; Pan, J.; Lu, L.M. Simultaneous Recovery of Iron and Phosphorus from a High-Phosphorus Oolitic Iron Ore to Prepare Fe-P Alloy for High-Phosphorus Steel Production. JOM 2017, 69, 1663–1668. [Google Scholar] [CrossRef]

- Li, S.W.; Pan, J.; Zhu, D.Q.; Guo, Z.Q.; Xu, J.W.; Chou, J.L. A novel process to upgrade the copper slag by direct reduction-magnetic separation with the addition of Na2CO3 and CaO. Powder Technol. 2019, 347, 159–169. [Google Scholar] [CrossRef]

- Qin, S.C.; Jiang, K.X.; Zhang, B.S.; Wang, H.B. Study on phase form and content of sulfur and iron in oxygen pressure acidic leaching residue of sphalerites. Chin. J. Inorg. Anal. Chem. 2016, 6, 57–61. [Google Scholar]

- Wang, W.H.; Wang, D.; Li, X.Y. Phase analysis on aluminum metal and aluminum trioxide in aluminium ash. Resour. Environ. Eng. 2009, 23, 33–334. [Google Scholar]

- Iron Ores—Determination of Metallic Iron Content—Sulfosalicylic Acid Spectrophotometric Method; GB/T 24194-2009; Wuhan lron and Steel Company: Wuhan, China, 2010.

- Yang, Y.X.; Qi, X. X-ray Diffraction Analysis; Shanghai Jiaotong University Press: Shanghai, China, 1989; pp. 270–278. [Google Scholar]

- Zhang, F.; Zhu, D.Q.; Pan, J.; Guo, Z.Q. Effect of basicity on the structure characteristics of chromium-nickel bearing iron ore pellets. Powder Technol. 2019, 342, 409–417. [Google Scholar] [CrossRef]

- Gu, X.; Dong, W.; Chen, Y.; Li, Y. Investigation on the glass-anorthite insulating composites with low dielectric constant and low sintering temperature. Rare Metal Mater. Eng. 2007, 36, 464–467. [Google Scholar]

- Liu, Q.; Pan, Z.; Li, Q.; Ruan, Y. Preparation of anorthite lightweight thermal insulating brick and the formation process of anorthite. Bull. Chin. Ceram. Soc. 2010, 29, 1269–1274. [Google Scholar]

- Baev, S.V.; Uryavin, G.A.; Leont’ev, L.N. Heat exchange and reduction in high-alumina charges in the blast furnace. Metallurgist 1975, 19, 351–354. [Google Scholar] [CrossRef]

- He, Y.B. Study on Slag-Iron Bath Smelting Reduction Process for Alumina-Rich Iron Ore Processing; Northeastern University: Shenyang, China, 2016; pp. 24–34. [Google Scholar]

- Gao, J.J.; Wang, X.Y.; Qi, Y.H.; Wang, F. Technical analysis on ironmaking process of rotary kiln pre-reduction and smelting by coal and oxygen. J. Iron Steel Res. 2018, 30, 91–96. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).