Deformation Behavior and Experiments on a Light Alloy Seamless Tube via a Tandem Skew Rolling Process

Abstract

1. Introduction

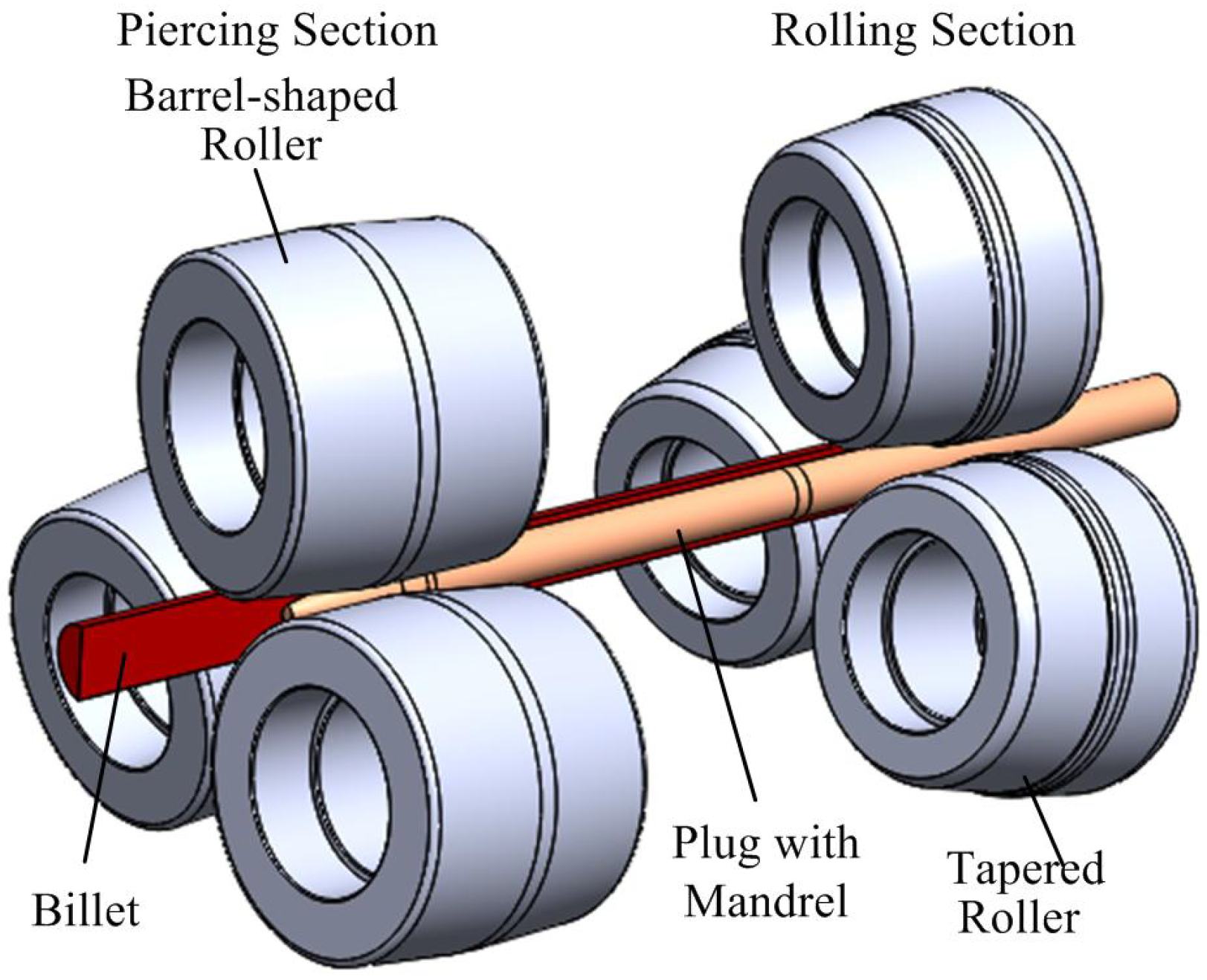

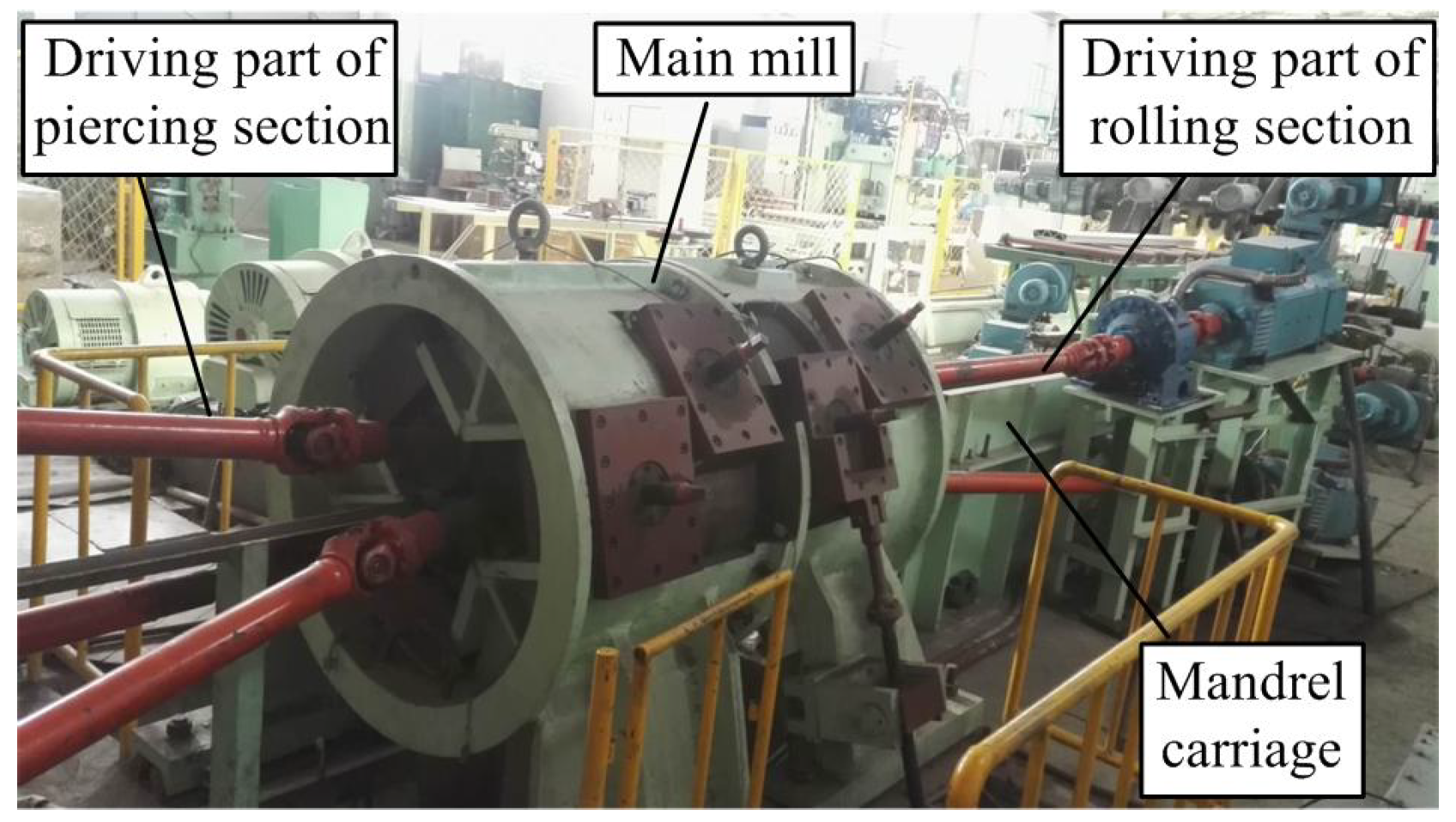

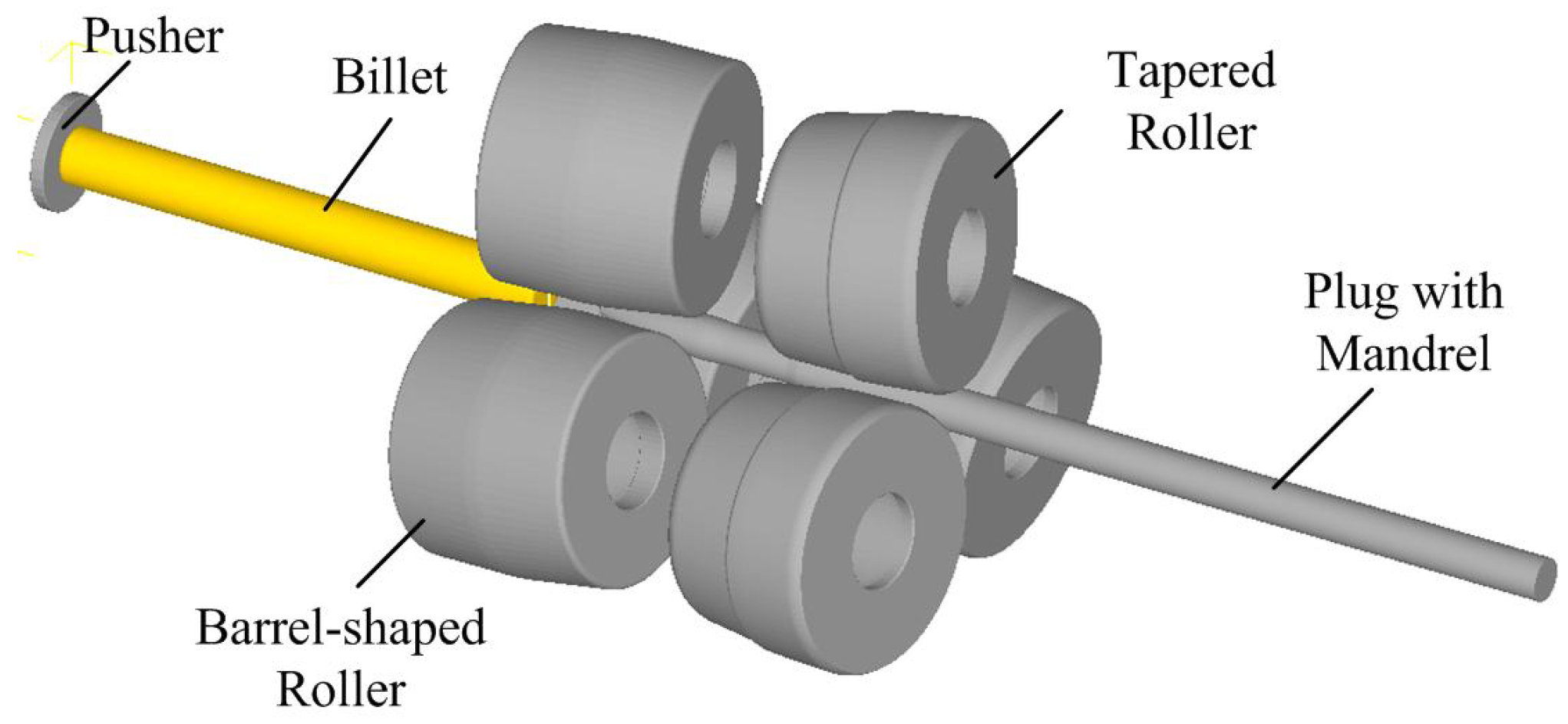

2. Materials and Methods

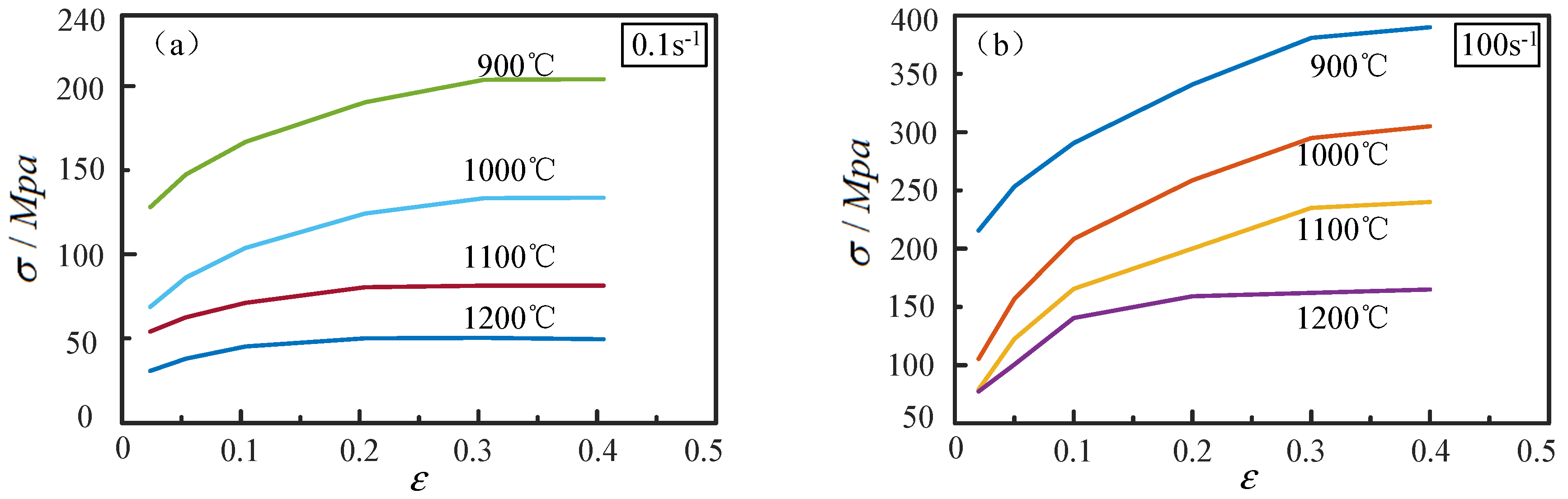

2.1. Experimental Test

2.2. Finite Element Model

3. Results and Discussion

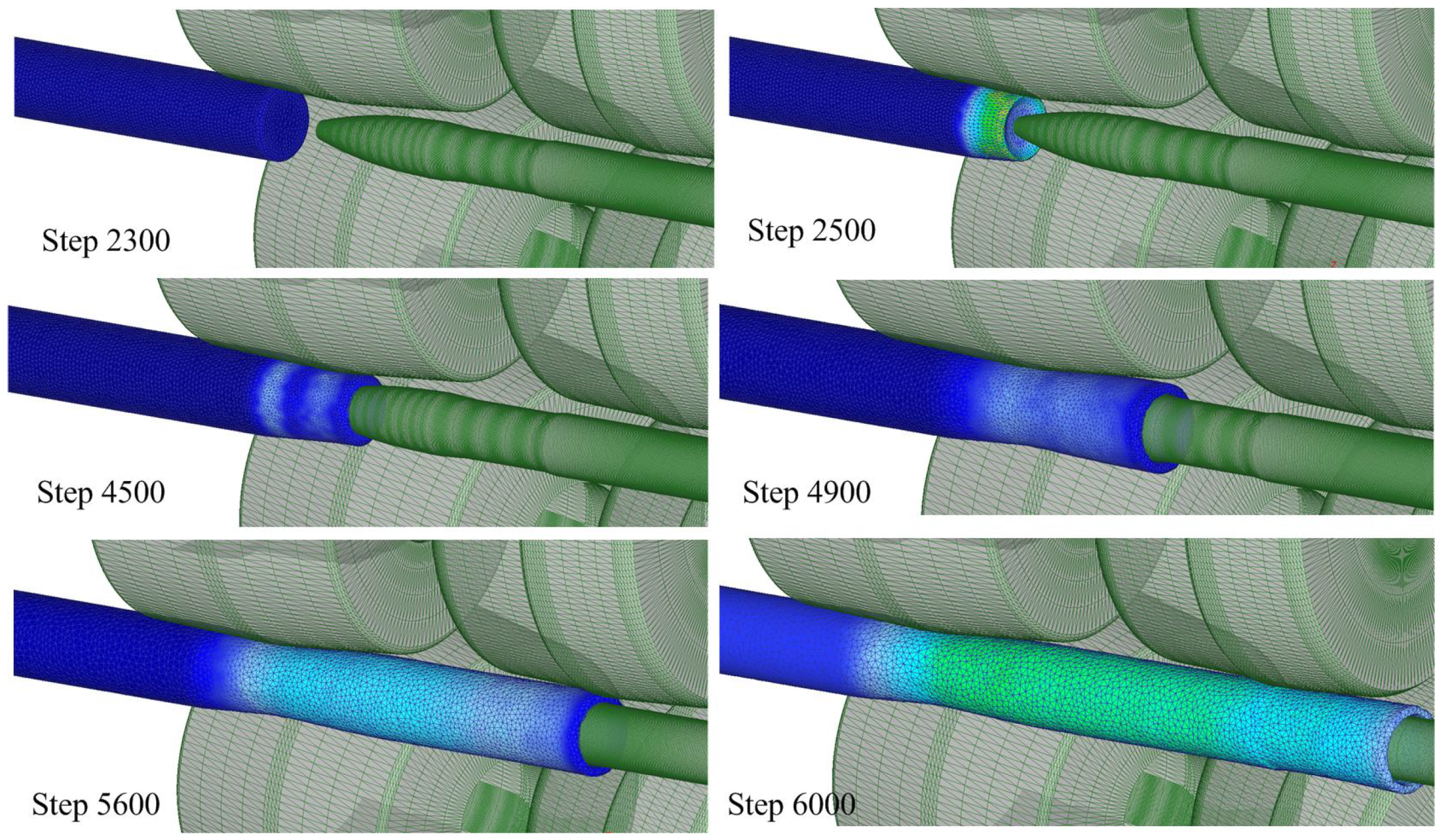

3.1. Numerical Modeling Results of the Steel 1045 during the TSR Process

3.2. Experimental Analysis

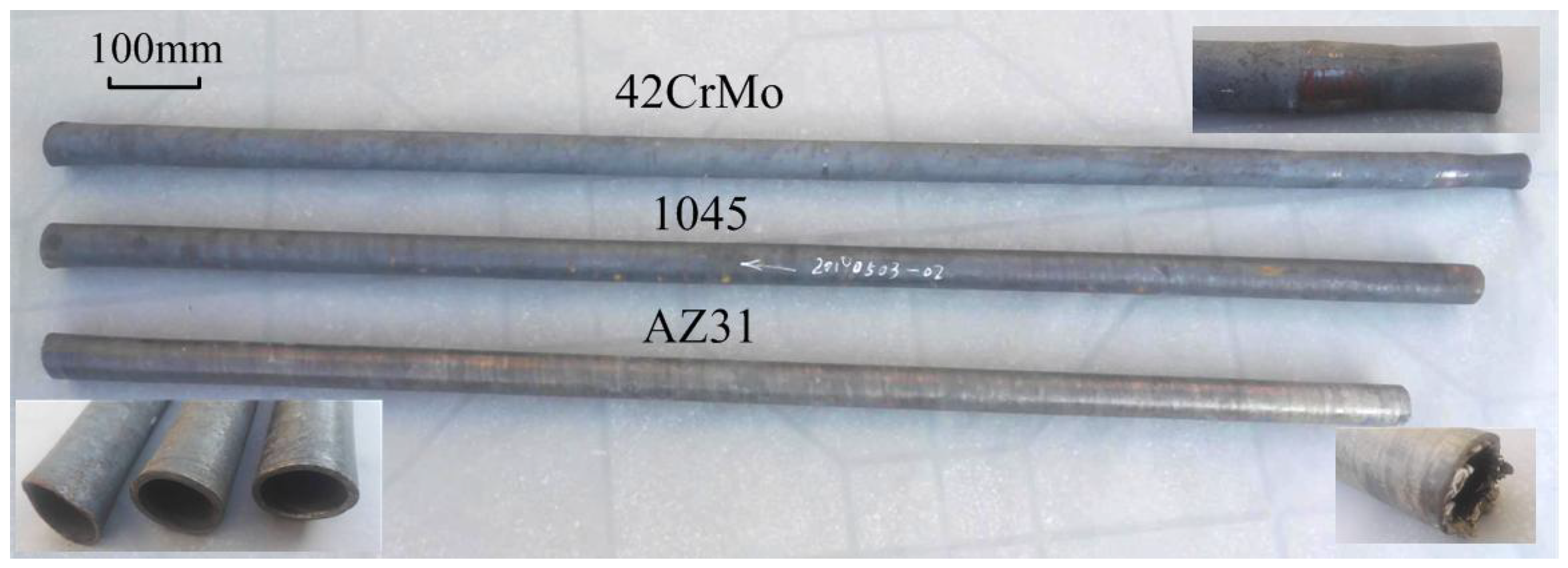

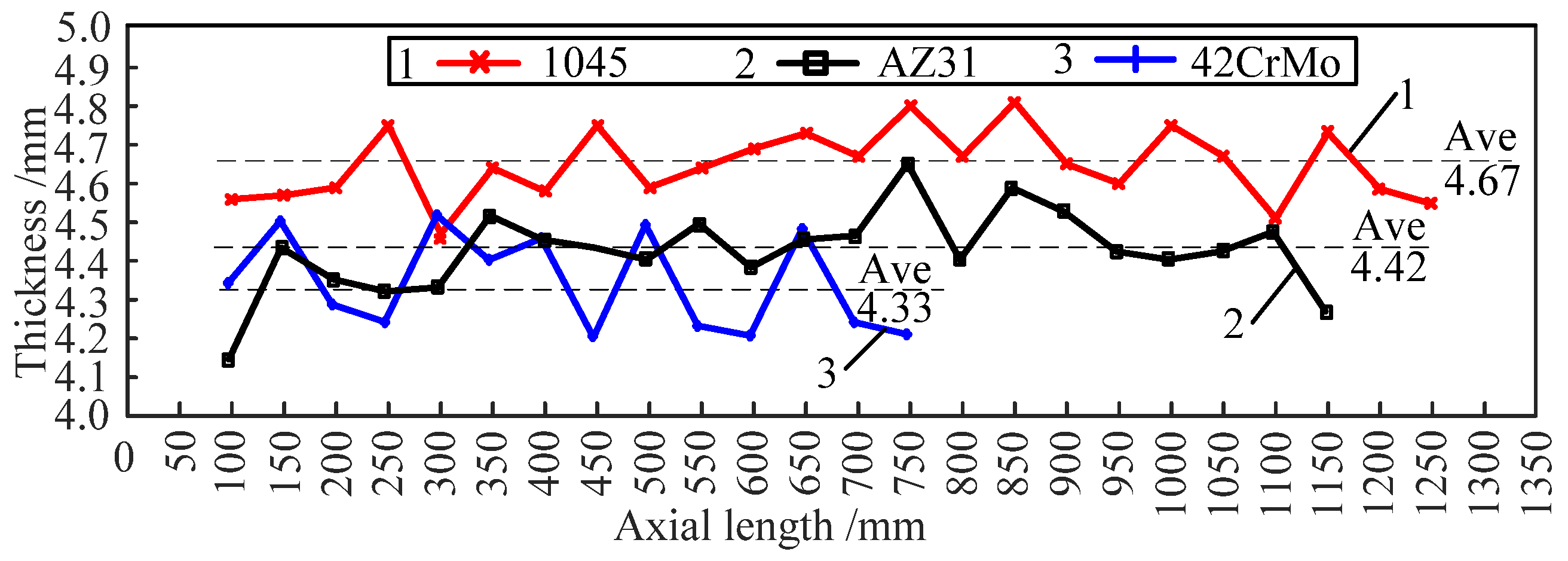

3.2.1. Quality of Tubes

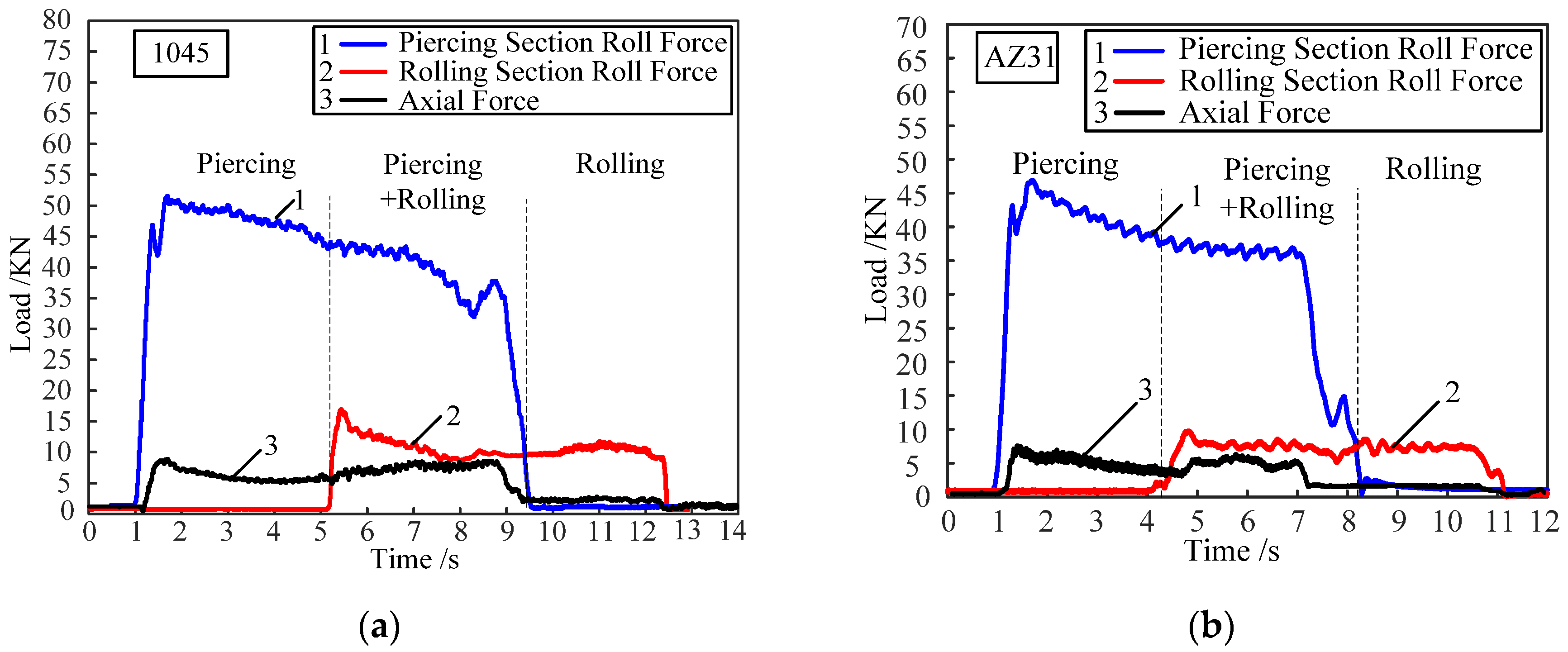

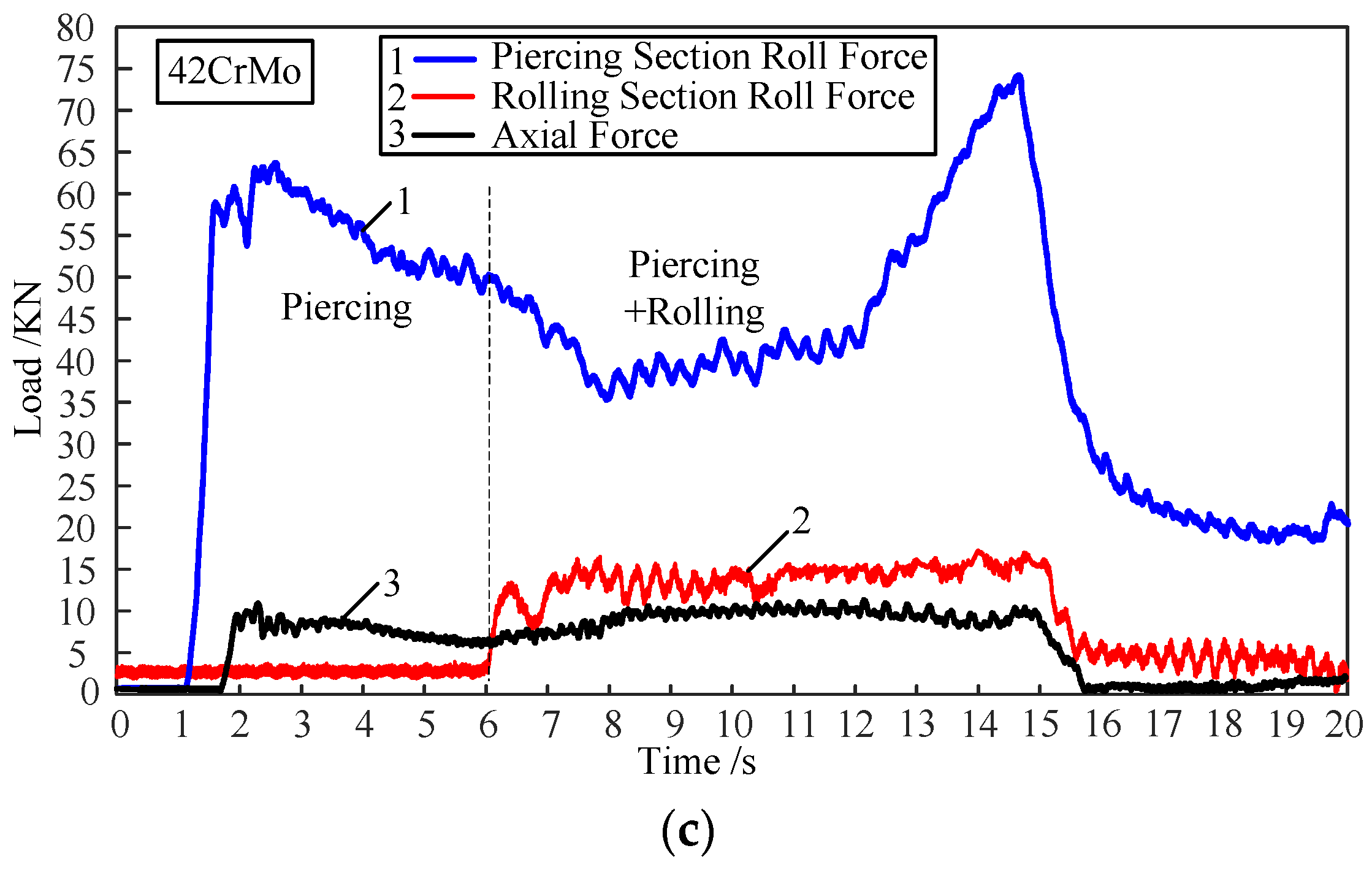

3.2.2. Roll Force

4. Conclusions

- (1)

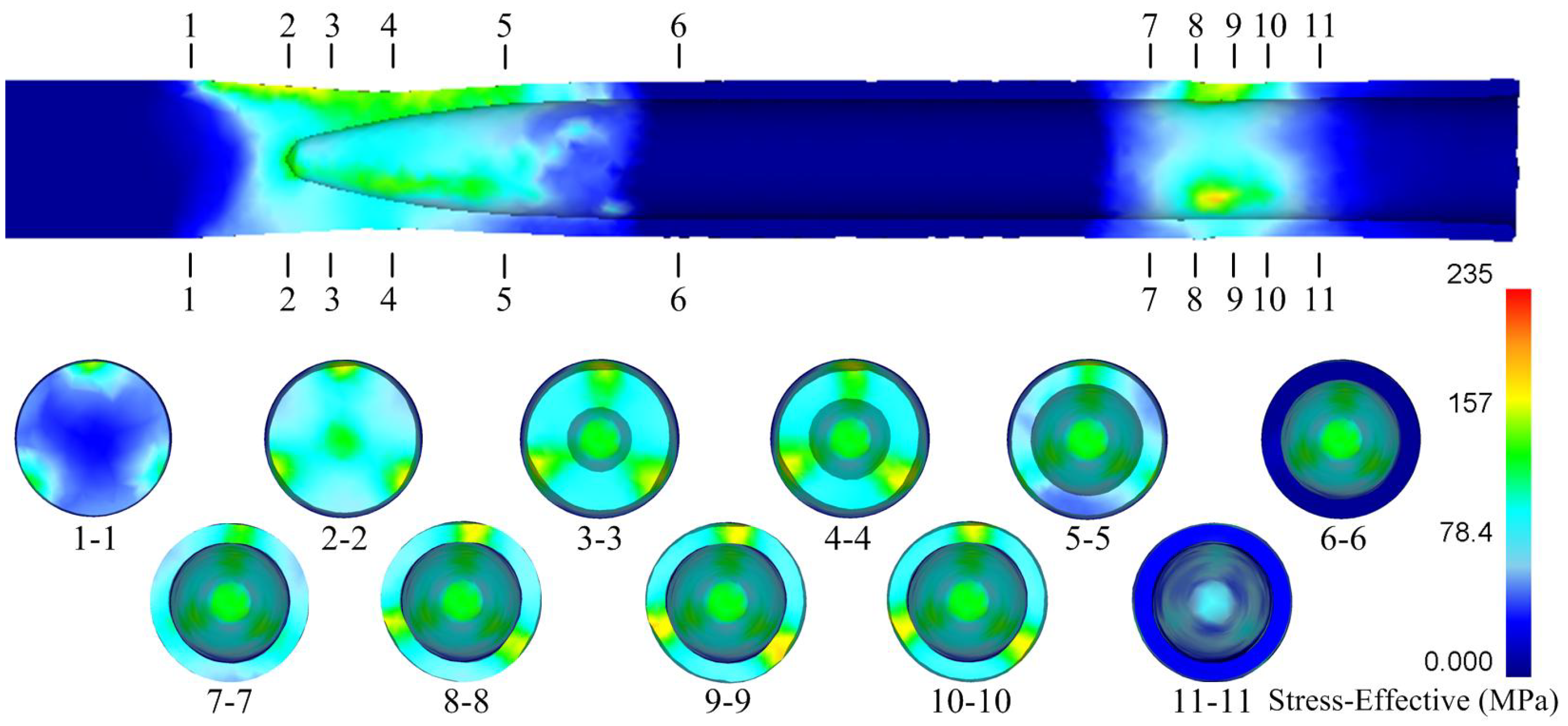

- The distribution of stress presented higher stress intensity magnitudes on outside surfaces contacting with the rollers.

- (2)

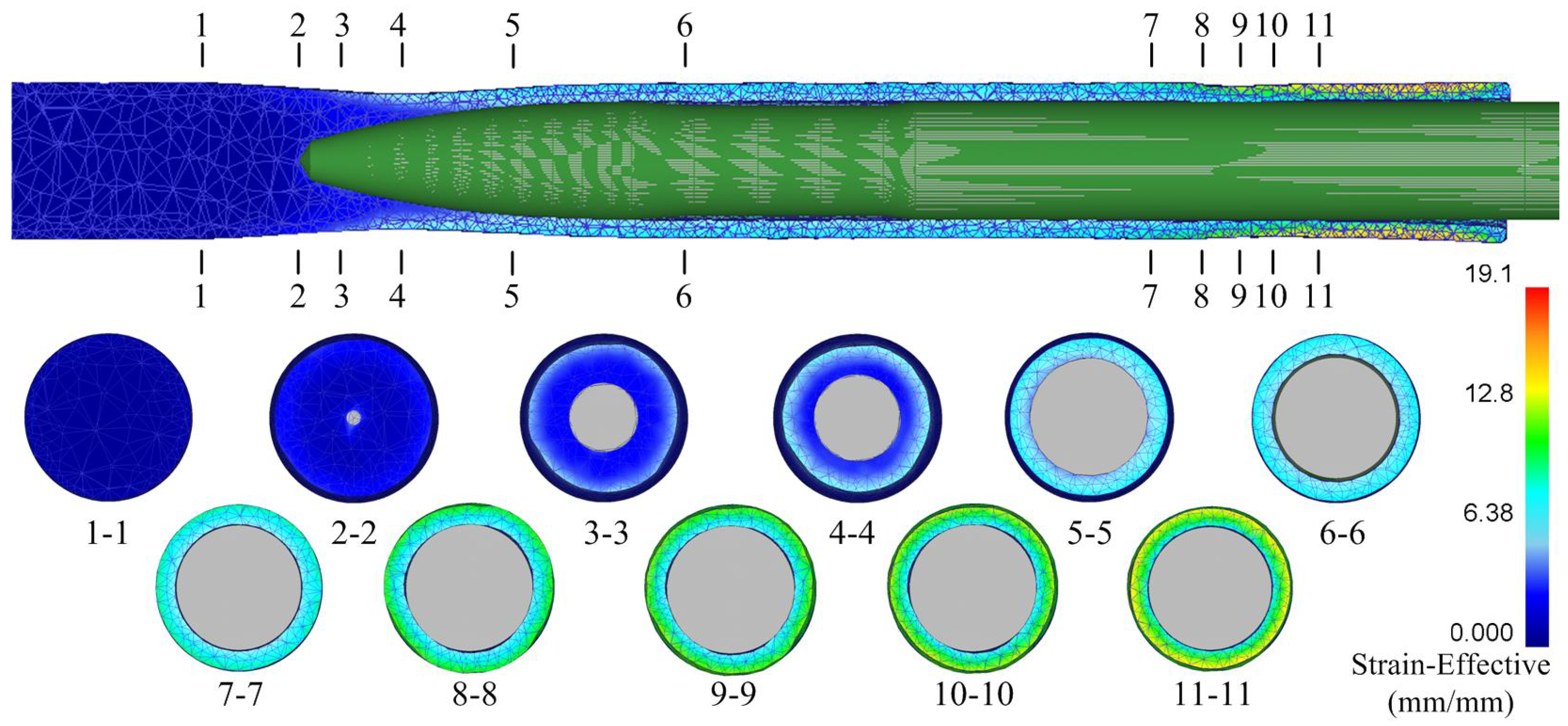

- The distribution of strain was presented in a laminar way, with higher strain intensity magnitudes occurring at the external layers of the formed tube. The cross profile varied from a circle to a triangular circle and then to another circle in the piercing section, and again, continuously, in the rolling section.

- (3)

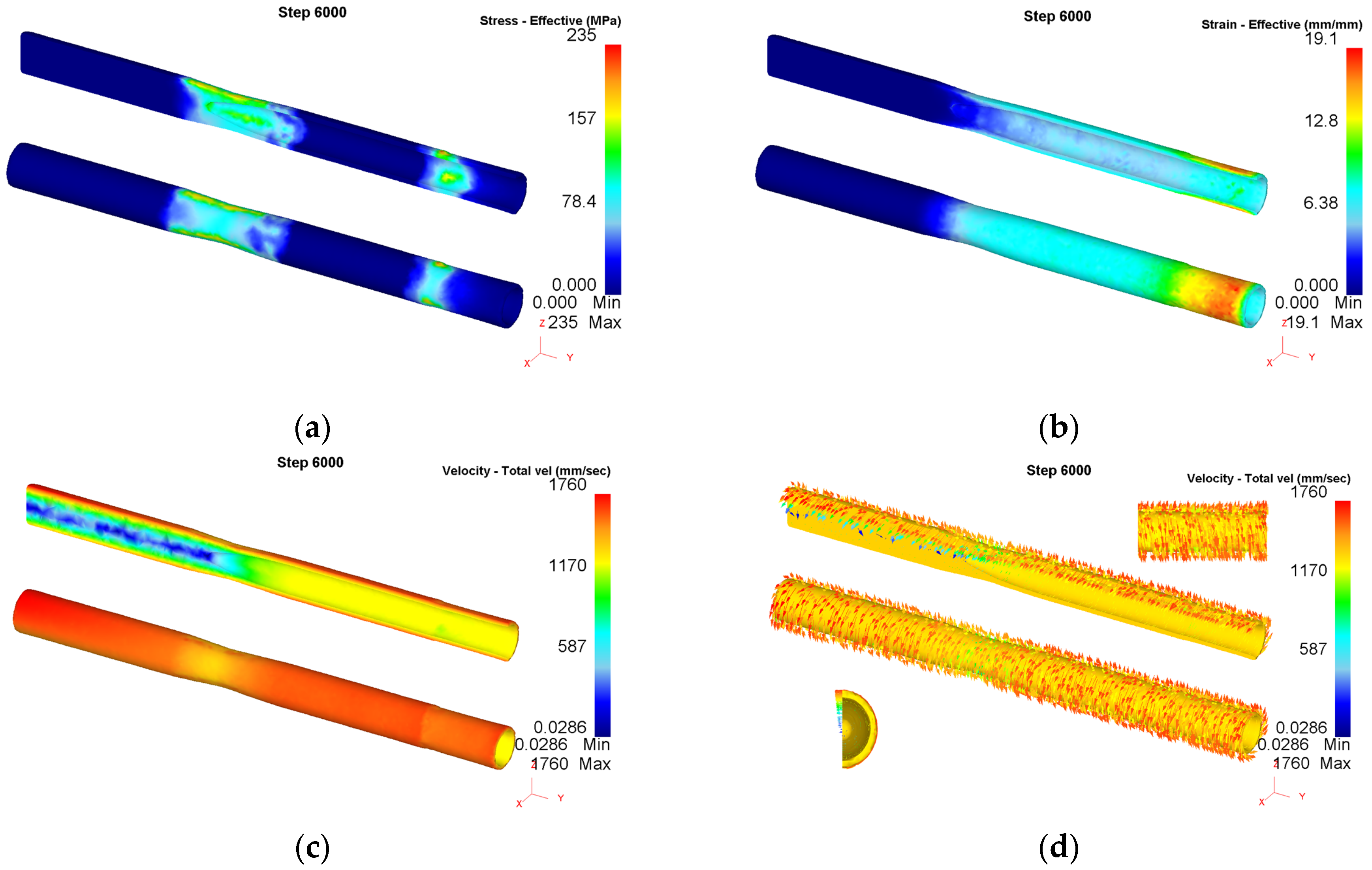

- The distribution of velocity was also arranged in layers with a higher magnitude at the outside surface and the lowest one at the central axial zone in front of the plug.

- (4)

- Based on experiments in a TSR testing mill, the desired seamless tubes of carbon steel 1045, HSS 42CrMo, and the AZ31 alloy were obtained, with an accuracy of ± 0.2 mm in wall thickness and a diameter of ±0.35 mm.

- (5)

- The TSR process is suitable for manufacturing seamless tubes that are difficult to deform or that are deformed in a narrow temperature range.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, F.J.; Shuang, Y.H.; Zhang, G.Q. A new type of seamless steel pipe production process-tandem skew rolling process. Steel Pipe 2014, 43, 54–58. [Google Scholar]

- Wang, F.-J.; Shuang, Y.-H.; Hu, J.-H.; Wang, Q.-H.; Sun, J.-C. Explorative study of tandem skew rolling process for producing seamless steel tubes. J. Mater. Process. Technol. 2014, 214, 1597–1604. [Google Scholar] [CrossRef]

- Wang, F.J.; Shuang, Y.H. Tandem skew rolling process for compact producing seamless steel tubes. Iron Steel 2016, 21, 44–48. [Google Scholar]

- Shuang, Y.H.; Wang, F.J.; Wang, Q.H. Explorative study of tandem skew rolling process and equipment for producing seamless steel tubes. J. Mech. Eng. 2017, 53, 18–24. [Google Scholar] [CrossRef]

- Mao, F.L.; Shuang, Y.H.; Wang, Q.H.; Wang, F.J.; Gou, Y.J.; Zhao, C.J. Theoretical and Experimental Study of the Tandem Skew Rolling Process. Steel Res. Int. 2018, 89, 1800022. [Google Scholar] [CrossRef]

- Niu, X.; Shuang, Y.H.; Wang, Q.H.; Wang, F.J. Discussion on velocity coordination between roll units of tandem skew rolling process. Steel Pipe 2016, 45, 54–58. [Google Scholar]

- Mao, F.L.; Shuang, Y.H.; Wang, Q.H.; Liu, Q.Z. Tension detecting device and its experimental study of a steel tube skew tandem rolling mill. Hot Work. Technol. 2017, 46, 150–155. [Google Scholar]

- Mao, F.L.; Shuang, Y.H.; Wang, Q.H.; Wang, F.J. Effect of process parameters on rolling force and dimensional precision of tubes rolled by tandem skew rolling process. J. Plast. Eng. 2018, 25, 108–114. [Google Scholar]

- Wang, Q.H.; Shuang, Y.H. Research on the speed setting model and control of the tandem skew rolling mill. Process Auto. Instrum. 2017, 38, 13–18. [Google Scholar]

- Wang, Q.H.; Shuang, Y.H.; Mao, F.L. Predictive control for speed and tension system of tandem skew rolling mill. J. Taiyuan Univ. Tech. 2017, 48, 991–995, 1028. [Google Scholar]

- Wang, F.J.; Shuang, Y.H.; Hu, J.H.; Sun, J.C.; Wang, Q.H. Numerical simulation and experimental analysis of three-roll cross piercing process. Hot Work. Technol. 2014, 43, 95–98, 105. [Google Scholar]

- Bogatov, A.A.; Nukhov, D.S.; Toporov, V.A. Simulation of rotary piercing process. Metallurgist 2017, 61, 101–105. [Google Scholar] [CrossRef]

- Pater, Z.; Tomczak, J.; Bulzak, T. Numerical analysis of the skew rolling process for main shafts. Metalurgija 2015, 54, 627–630. [Google Scholar]

- Pater, Z.; Kazanecki, J.; Bartnicki, J. Three dimensional thermo-mechanical simulation of the tube forming process in Diescher’s mill. J. Mater. Process. Technol. 2006, 177, 167–170. [Google Scholar] [CrossRef]

- Pater, Z.; Kazanecki, J. thermo-mechanical analysis of piercing plug loads in the skew rolling process of thick-walled tube shell. Met. Foundry Eng. 2006, 32, 31–40. [Google Scholar] [CrossRef][Green Version]

- Stefanik, A.; Morel, A.; Mróz, S.; Szota, P. Theoretical And Experimental Analysis Of Aluminium Bars Rolling Process In Three-High Skew Rolling Mill. Arch. Met. Mater. 2015, 60, 809–813. [Google Scholar] [CrossRef]

- Romantsev, B.A.; Skripalenko, M.M.; Huy, T.B.; Skripalenko, M.N.; Gladkov, Y.A.; Gartvig, A.A. Computer Simulation of Piercing in a Four-High Screw Rolling Mill. Metallurgist 2018, 61, 729–735. [Google Scholar] [CrossRef]

- Toporov, V.A.; Chepurin, M.V.; Parfenov, V.A.; Stepanov, A.I. Skew rolling in the piercing of blanks. Steel Transl. 2014, 44, 452–455. [Google Scholar] [CrossRef]

- Murillo-Marrodán, A.; García, E.; Cortés, F. Study of Friction Model Effect on A Skew Hot Rolling Numerical Analysis. In The World Congress on Engineering; Springer: Singapore, 2017; pp. 377–387. [Google Scholar]

- Ding, X.F.; Shuang, Y.H.; Wang, Q.H.; Zhou, Y.; Gou, Y.J.; Wang, J.; Lin, W.L. New Rotary Piercing Technique of AZ31 Magnesium Alloy Seamless Tube. Rare Metal. Mat. Eng. 2018, 47, 357–362. [Google Scholar]

- Ding, X.F.; Shuang, Y.H.; Liu, Q.Z.; Zhao, C.J. New rotary piercing process for an AZ31 magnesium alloy seamless tube. Mater. Sci. Technol. 2018, 34, 408–418. [Google Scholar] [CrossRef]

| Item | Piercing Section | Rolling Section | ||||||

|---|---|---|---|---|---|---|---|---|

| Process Parameter | Feed Angle (deg) | Entrance Face Angle (deg) | Roll Gap (mm) | Plug Advance (mm) | Feed Angle (deg) | Entrance Face Angle (deg) | Roll Gap (mm) | Roll Rotational Speed/rpm |

| Adjustable rang | 0–15 | 0–9 | 30–48 | 0–35 | 0–15 | 0–9 | 35–48 | 0–200 |

| Reasonable rang | 7–9 | 0 | 34–36 | 20–25 | 7–9 | 4 | 37–39 | 174–190 |

| Experimental values | 8 | 0 | 35 | 23 | 9 | 4 | 39 | 186 |

| Material | Diameter (mm) | Thickness (mm) | Length (mm) | Extension Coefficient |

|---|---|---|---|---|

| Carbon steel 1045 | 39.14 ± 0.35 | 4.67 ± 0.20 | 1360 | 2.72 |

| HSS 42CrMo | 38.22 ± 0.4 | 4.33 ± 0.30 | 1400 | 2.80 |

| AZ31 alloy | 39.85 ± 0.35 | 4.42 ± 0.25 | 1200 | 2.40 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, F.; Wang, F.; Shuang, Y.; Hu, J.; Chen, J. Deformation Behavior and Experiments on a Light Alloy Seamless Tube via a Tandem Skew Rolling Process. Metals 2020, 10, 59. https://doi.org/10.3390/met10010059

Mao F, Wang F, Shuang Y, Hu J, Chen J. Deformation Behavior and Experiments on a Light Alloy Seamless Tube via a Tandem Skew Rolling Process. Metals. 2020; 10(1):59. https://doi.org/10.3390/met10010059

Chicago/Turabian StyleMao, Feilong, Fujie Wang, Yuanhua Shuang, Jianhua Hu, and Jianxun Chen. 2020. "Deformation Behavior and Experiments on a Light Alloy Seamless Tube via a Tandem Skew Rolling Process" Metals 10, no. 1: 59. https://doi.org/10.3390/met10010059

APA StyleMao, F., Wang, F., Shuang, Y., Hu, J., & Chen, J. (2020). Deformation Behavior and Experiments on a Light Alloy Seamless Tube via a Tandem Skew Rolling Process. Metals, 10(1), 59. https://doi.org/10.3390/met10010059