Abstract

This study first assessed the friction and wear properties of two polytetrafluoroethylene materials sliding against electroplated chrome and high-velocity oxy-fuel-sprayed WC-10Co-4Cr coatings. Subsequently, the sealing performance of three different structure seals made from these two polytetrafluoroethylene materials was investigated on both electroplated chrome and high-velocity oxy-fuel-sprayed WC-10Co-4Cr coatings. The study results indicate the following: in terms of changes in the counter-face surface roughness, both the electroplated chrome and high-velocity oxy-fuel-sprayed WC-10Co-4Cr surfaces exhibited an increase in surface roughness after sliding, demonstrating the phenomenon of “soft material wearing hard material.” Moreover, the changes in surface roughness were greater after sliding against wollastonite mineral-filled polytetrafluoroethylene than against polyether ether ketone-filled polytetrafluoroethylene, indicating that wollastonite mineral-filled polytetrafluoroethylene was more likely to cause damage to the metal surface. Regarding the friction coefficient and wear amount, under dry friction conditions, both materials exhibited higher friction coefficients but lower wear rates on high-velocity oxy-fuel-sprayed WC-10Co-4Cr surfaces, while showing lower friction coefficients but higher wear rates on electroplated chrome surfaces. This behavior was related to the ease of transfer film formation and the stability of the transfer films formed by polytetrafluoroethylene materials on the two surfaces. In terms of the products’ sealing performance, test results showed that, for composite seals with polytetrafluoroethylene as the counter-face, sealing performance was better on high-velocity oxy-fuel-sprayed WC-10Co-4Cr surfaces than on electroplated chrome surfaces. For seals with rubber as the counter-face, there was little difference in sealing performance between high-velocity oxy-fuel-sprayed WC-10Co-4Cr and electroplated chrome surfaces.

1. Introduction

The functionality of sealing components depends not only on the seals themselves and their operating conditions, but also on other factors, such as the surface quality of the mating surfaces, which is closely related to their surface treatment processes. Electrolytic hard chrome (EHC) is a commercially available technology that has been in use for over 50 years. It is used both for applying hard coatings to various aircraft components during manufacturing and for general refurbishment of worn or corroded parts removed from aircraft during overhauls. However, electroplated chrome baths contain chromic acid, in which chromium exists in the hexavalent state (Cr6+). Hexavalent chromium is a known carcinogen. Due to environmental concerns, as early as 1996 researchers established the Hard Chrome Alternatives Team (HCAT) to conduct research on replacing electroplated chrome with high-velocity oxygen fuel (hereafter referred to as HVOF) thermal spraying. From 1996 to early 1998, the HCAT installed HVOF thermal spray systems at the Naval Air Station in Cherry Point, North Carolina (NADEP-CP), and the Corpus Christi Army Depot (CCAD), respectively, and conducted related tests on fatigue resistance, corrosion resistance, and other properties [1,2,3,4,5]. At this stage, this research primarily focused on the aircraft components themselves and had not yet explored the compatibility between aircraft components and sealing elements. In 2003, the U.S. Navy began validating the matching relationship between HVOF-coated rods and seals, discovering that the sealing performance of HVOF-treated surfaces was significantly superior to that of electroplated chrome surfaces.

In 2007, the U.S. Department of Defense conducted validation work on HVOF thermal spray coatings as a replacement for electroplated chrome in hydraulic/pneumatic actuators [6,7,8,9,10,11]. Regarding the verification of sealing performance, studies were carried out on the sealing characteristics of nitrile rubber O-rings with backup rings, nitrile rubber double-triangle seals, fluorosilicone rubber double-triangle seals, and spring-energized seals under different surface treatments. The results showed that except for the O-rings with backup ring configuration, which exhibited identical leakage levels on both electroplated chrome and HVOF surfaces, all other cases demonstrated lower leakage on HVOF-treated surfaces compared to electroplated chrome ones. Specifically for double-triangle seals, nitrile rubber performed better on HVOF surfaces while fluorosilicone rubber showed superior performance on electroplated chrome surfaces. Additionally, ground surfaces demonstrated lower leakage than superfinished surfaces. Post-test examinations revealed significant scratches on the electroplated chrome surfaces along with severe damage to the sealing components.

In 2008, K.J. Monaghan [12] compared the sealing friction performance of electroplated chrome piston rods and HVOF-coated piston rods under short-stroke reciprocating conditions. This study investigated the sealing performance of seals under different surface treatments as well as the changes in surface quality of the mating surfaces before and after testing. It found that the average friction force of HVOF-treated surfaces was consistently lower than that of electroplated chrome surfaces. Additionally, the friction force of HVOF surfaces showed little variation between the run-in period and stable operation, whereas electroplated chrome surfaces exhibited a sharp increase in friction during the run-in phase, followed by a reduction upon reaching stable operation.

In 2014, R.M. Castro et al. [13,14] conducted a study on the frictional performance of seals with electroplated chrome and WC-CoCr (HVOF) surface treatments. This research revealed that, compared to electroplated chrome surfaces, HVOF-sprayed WC surfaces exhibited a longer run-in period (the friction coefficient of electroplated chrome surfaces stabilized around at 50 s, followed by a slight increase during subsequent testing, while the friction coefficient of WC-CoCr (HVOF) surfaces stabilized at around 200 s, followed by a slight decrease). Additionally, the electroplated chrome surfaces showed significant changes in surface roughness before and after testing, particularly a notable increase in Rmr. The post-test examination of the electroplated chrome rod surfaces revealed the presence of “micro-scratches” and “micro-grooves,” which created leakage paths. This study found that Rmr was the most critical parameter for characterizing shaft surface wear (while Ra was not the primary factor affecting leakage).

W. Fang et al. [15] investigated the surface properties of WC-CrC-Ni coatings, including the microstructure, crystalline phases, hardness, and porosity. They also conducted a comparative study on the friction and wear performance of WC-CrC-Ni coatings and electrolytic hard chromium (EHC) plating on IN718 substrates. Ilhan Celik [16] investigates the application of tungsten carbide and chromium carbide–nickel chromium coatings to St37 steel surfaces using the HVOF method. The results indicate the formation of phases such as Cr3C2, NiCr, and W2C on the low-alloy steel surface after the tungsten carbide and chromium carbide–nickel chromium coating processes. Coating thicknesses of 204 and 239 µm were achieved for tungsten carbide and chromium carbide–nickel chromium, respectively. These coatings contributed to improved mechanical and tribological properties. The WC-12Co-coated sample exhibited the highest hardness value (1304 HV0.1), while the CrC-NiCr-coated sample recorded the highest critical load value in the scratch test (48 N). The WC-12Co-coated samples showed the best wear resistance. Sun Jiyong [17] compared the wear characteristics of tungsten carbide–cobalt alloy coatings deposited by high-velocity oxygen fuel (HVOF) spraying with traditional cyanide-containing electroplated chrome when sliding against rubber seals through run-in tests. The results demonstrated that HVOF-sprayed tungsten carbide–cobalt alloy coatings exhibited excellent wear resistance and densification.

The aforementioned research landscape indicates that both the surface treatment and quality of mating surfaces significantly influence sealing performance. While international studies have partially investigated the effects of electroplated chrome and HVOF coating on sealing, their scope has been limited to a few seal types such as double-triangle seals, spring-energized seals, and O-rings with backup rings. Notably, no research has been conducted on the performance of aeronautically prevalent VL seals and T seals under varying surface conditions. Furthermore, the existing evaluations of sealing performance were performed either under non-pressurized or low-pressure conditions, leaving the high-pressure regime of 35 MPa unexplored.

The new generation of aircraft hydraulic systems imposes extreme demands on the performance of sealing materials. Single rubber O-rings are unsuitable for high-pressure, long-stroke, and long-life reciprocating sealing applications due to their high friction coefficient, poor wear resistance, and low anti-extrusion capability. Therefore, to meet the stringent operational requirements of aircraft hydraulic systems, combination seals composed of a rubber elastomer and a PTFE sliding ring are currently widely adopted for reciprocating sealing [18]. Pure PTFE exhibits unstable friction coefficients and significant wear, which may lead to seal failure and equipment malfunctions in hydraulic systems with extremely high demands for sealing performance and operational stability, making it difficult to meet reliability and durability requirements. To overcome these shortcomings, numerous researchers have conducted diverse modification studies on PTFE by incorporating various fillers; the composite effect can be leveraged to mitigate and overcome its drawbacks, thereby enhancing its overall performance. In recent years, wollastonite fiber has attracted attention due to its unique advantages. Incorporating wollastonite fiber with PTFE can significantly improve its mechanical properties and dry friction wear resistance [19]. Additionally, polyether ether ketone (PEEK) is a thermoplastic polymer composed of aromatic backbone molecular chains interconnected via ketone and ether functional groups. It is widely used as a filler for PTFE modification due to its high mechanical strength, excellent wear resistance, and good compatibility with PTFE [20], enabling it to meet the high-pressure, long-stroke, and long-life requirements of aircraft hydraulic system seals. Given the excellent mechanical and tribological properties of wollastonite fiber and PEEK-filled PTFE composites, which can fulfill the high-reliability demands of aircraft hydraulic systems, this study selects these two filler-modified PTFE materials to investigate their friction, wear, and sealing performance against electroplated chrome surfaces and HVOF-sprayed WC-10Co-4Cr coatings.

This study investigates the differences in the sealing performance of two materials and three types of seals, commonly used in high-pressure aviation hydraulic systems, on electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces.

The study results can provide certain guidance for the selection and design of mating surfaces for 35 MPa high-pressure composite sealing products. First, the friction and wear properties of the two materials on electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces were studied. Second, the leakage characteristics of three typical aerospace hydraulic system composite sealing products made from these two materials were investigated on both electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces.

2. Materials and Methods

2.1. Material Experiment

This study investigated the friction and wear properties of two materials on both electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces through standardized friction and wear tests (testing is based on the standard ISO 6601:2002 [21]).

2.1.1. Dimensions and Material Properties of Test Specimens

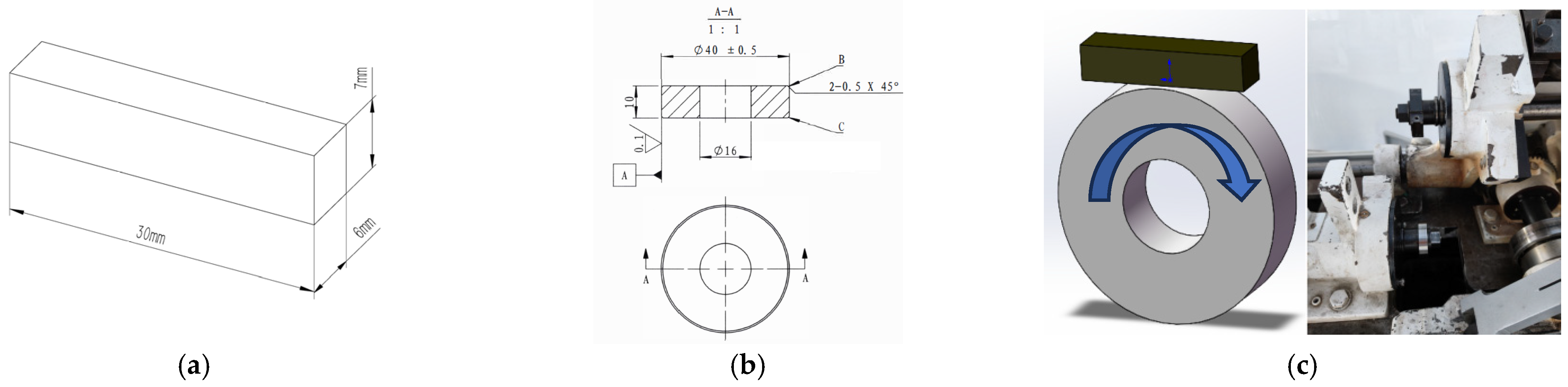

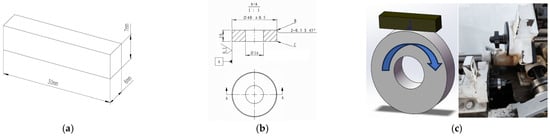

Specimen dimensions: 30 mm × 7 mm × 6 mm (a rectangular block; Figure 1a).

Figure 1.

Material friction and wear test specimens and schematic diagram of tribological test: (a) schematic diagram of the test specimen dimensions, (b) dimensions of the counter-wear ring, and (c) schematic diagram of the tribological test (The arrow represents the direction of rotation of the counter-wear ring).

The filler descriptions and key performance of the two filled PTFE materials are presented in Table 1. Among them, the polyether ether ketone (PEEK)-filled PTFE material contains 12% PEEK powder (at this content, the comprehensive performance of the composite material is optimal) with a particle size of 20–23 μm, an irregular powder shape, and a granularity of 650 mesh. The wollastonite fiber-filled PTFE material contains 18% fibers (at this content, the comprehensive performance of the composite material is optimal) in their original state as discrete short-cut fibers, with geometric shape parameters including an aspect ratio of 5:1 to 10:1 and a fiber diameter of 8 μm.

Table 1.

Material characteristics and properties.

The friction and wear specimens for both materials were prepared using an identical process, as detailed below.

- •

- The PTFE and filler powders were uniformly mixed according to the specified ratio and mixing procedure, as follows: mixing equipment: SHR-100A; mixing process parameters: ambient temperature ≤ 20 °C, humidity ≤ 60%, mixing speed 1500–2000 rpm, mixing time 30 s; mixing program: ① PTFE freezing for ≥ 12 h, ② filler drying for ≥ 4 h at 150 °C, ③ filler sieving, ④ addition of ingredients, ⑤ mixing.

- •

- The mixing powder was cold pressed under specific pressing parameters, as follows: pressing equipment: 25 t CNC press, gauge pressure 2 MPa, holding time 5 min, pressing speed 1.2 mm/s.

- •

- The resulting green compacts were sintered following a defined thermal profile as follows: sintering equipment: sintering furnace (Ningbo Zhisheng Oven Co., Ltd., Ningbo, China); and sintering process parameters: heating rate of 50 °C/h, to 370 °C, and insulation for 140 min.

- •

- The sintered billets were finally machined to the required dimensions for testing, as follows: the cutting tool was made of hard alloy steel, the turning speed was 200 m/min, the feed rate was 0.2 mm/r for rough turning and 0.06 mm/r for precision turning, and the lathe speed was 1200 r/min.

2.1.2. Testing Equipment and Counter-Wear Ring Parameters

The dimensions and configuration of the counter-wear ring are as follows: a ring with an inner diameter of 16 mm, an outer diameter of 40 mm, and a thickness of 10 mm (Figure 1b).

Figure 1c shows schematic and physical images of the friction and wear testing machine used in this study (machine model: M-2000).

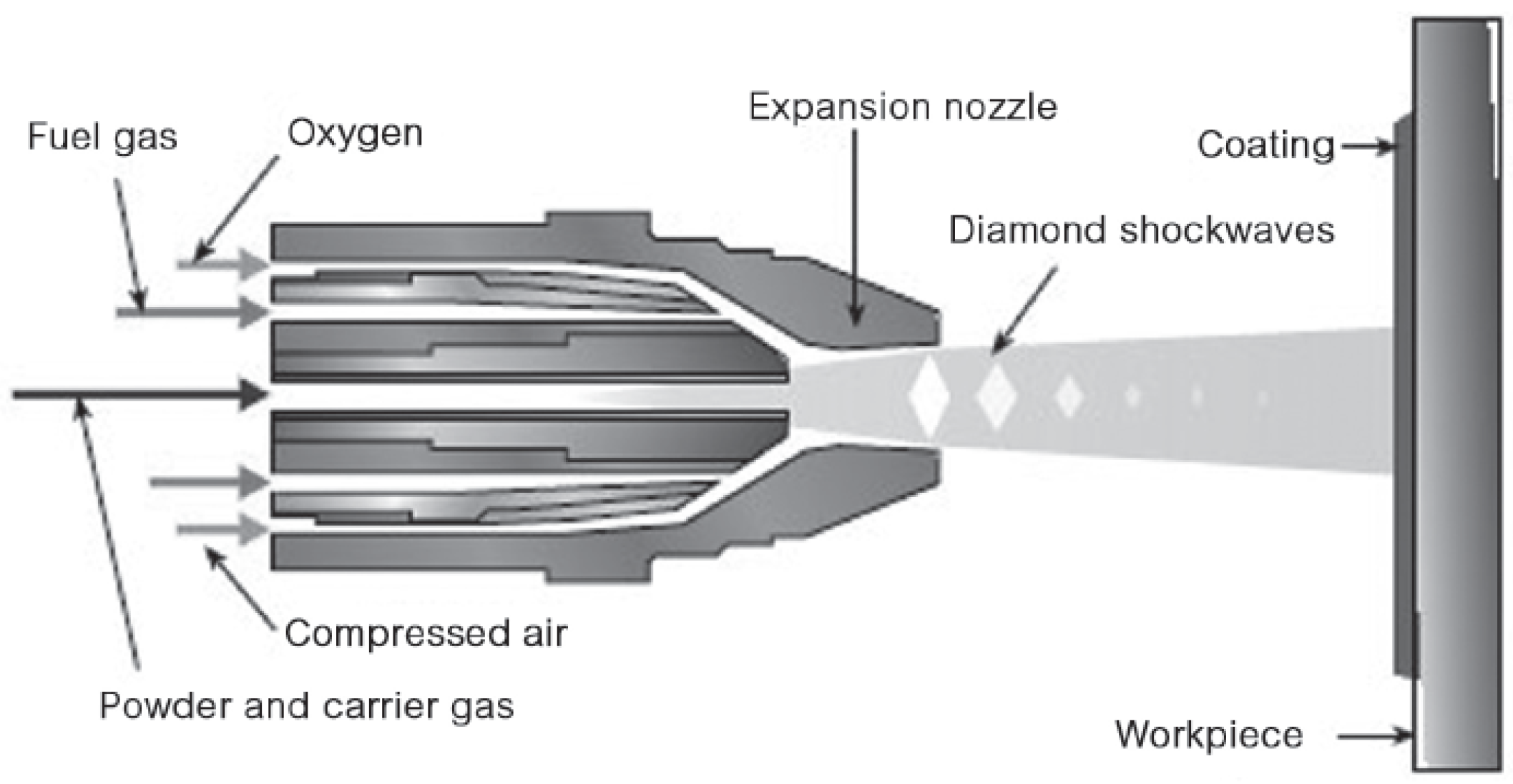

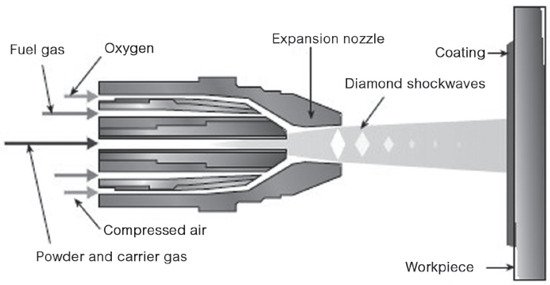

Counter-wear ring surface treatment: electroplated chrome or HVOF-sprayed WC-10Co4Cr. The core of the high-velocity oxygen fuel (HVOF) thermal spray system is the spray gun, which consists of a combustion chamber, a nozzle, and a constant-section long barrel. Figure 2 shows a typical cross-section of an HVOF spray gun. Table 2 presents the key process parameters for spraying, which include fuel and oxygen pressures, spray distance, powder feed rate, workpiece rotational speed, and spray gun movement speed.

Figure 2.

A schematic of the HVOF process from Bob Flitney [22].

Table 2.

Spray coating process parameters.

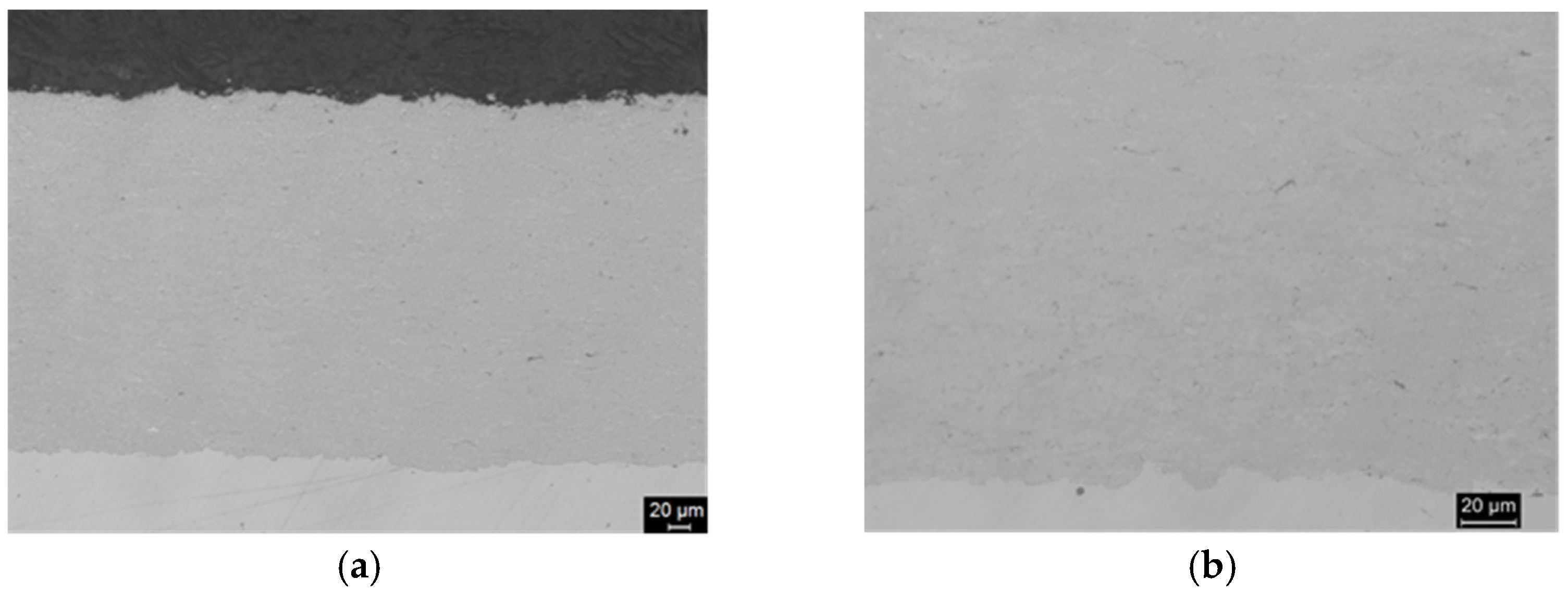

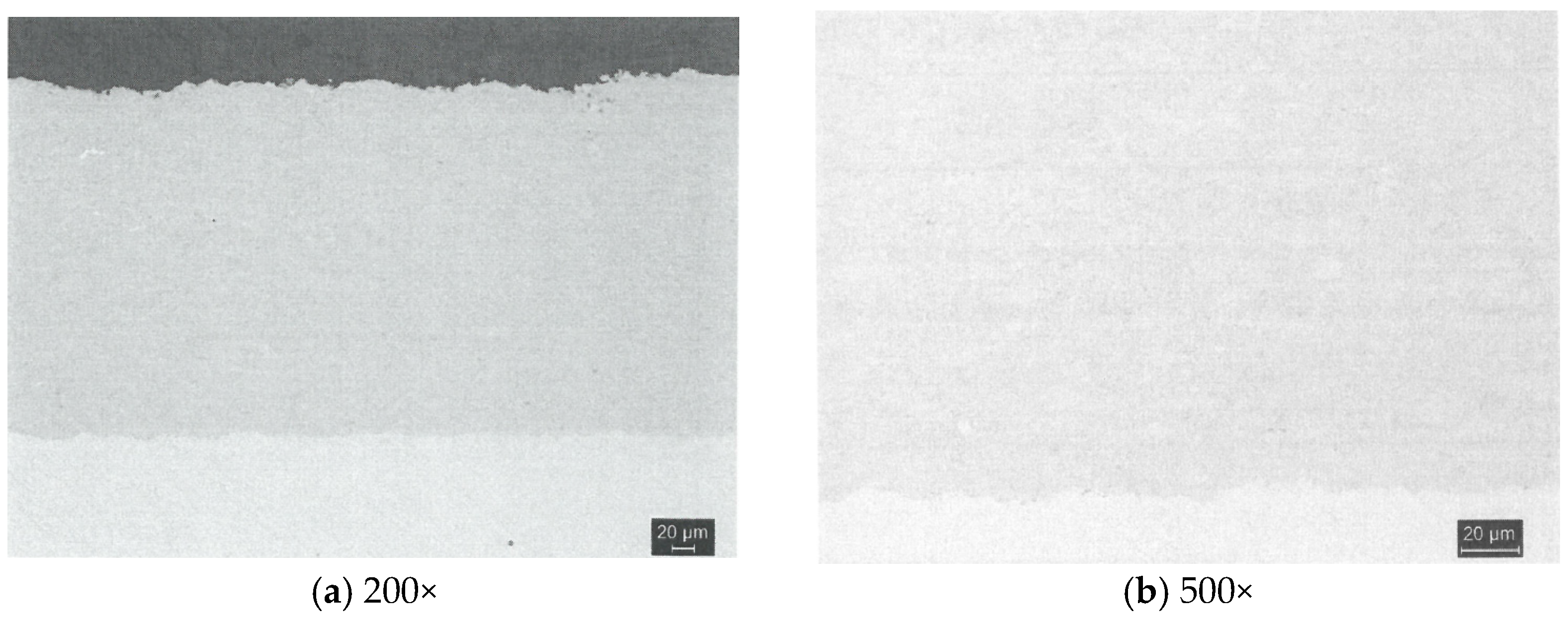

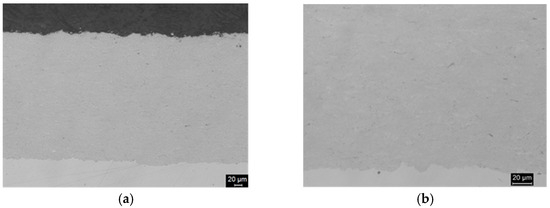

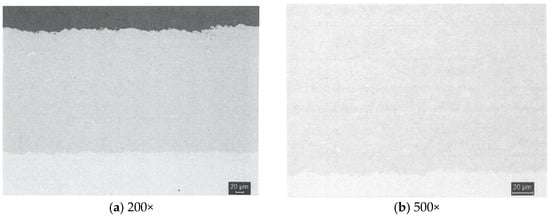

Figure 3 shows a cross-sectional view of a WC-10Co-4Cr coating sprayed by HVOF. As shown in Figure 3, the coating thickness is uniform, approximately 0.2–0.27 mm. The average porosity measured by image analysis is 0.5%. The surface roughness after grinding reached Ra 0.02–0.04 μm. The bond strength of the coating, measured using a tensile testing machine, is 89 MPa. Micro-Vickers hardness tests indicate an average microhardness value of 1184 HV0.3.

Figure 3.

Typical microstructure of the counter-wear ring coating—a WC-10Co-4Cr coating sprayed by HVOF: (a) magnification factor 200× and (b) magnification factor 500×.

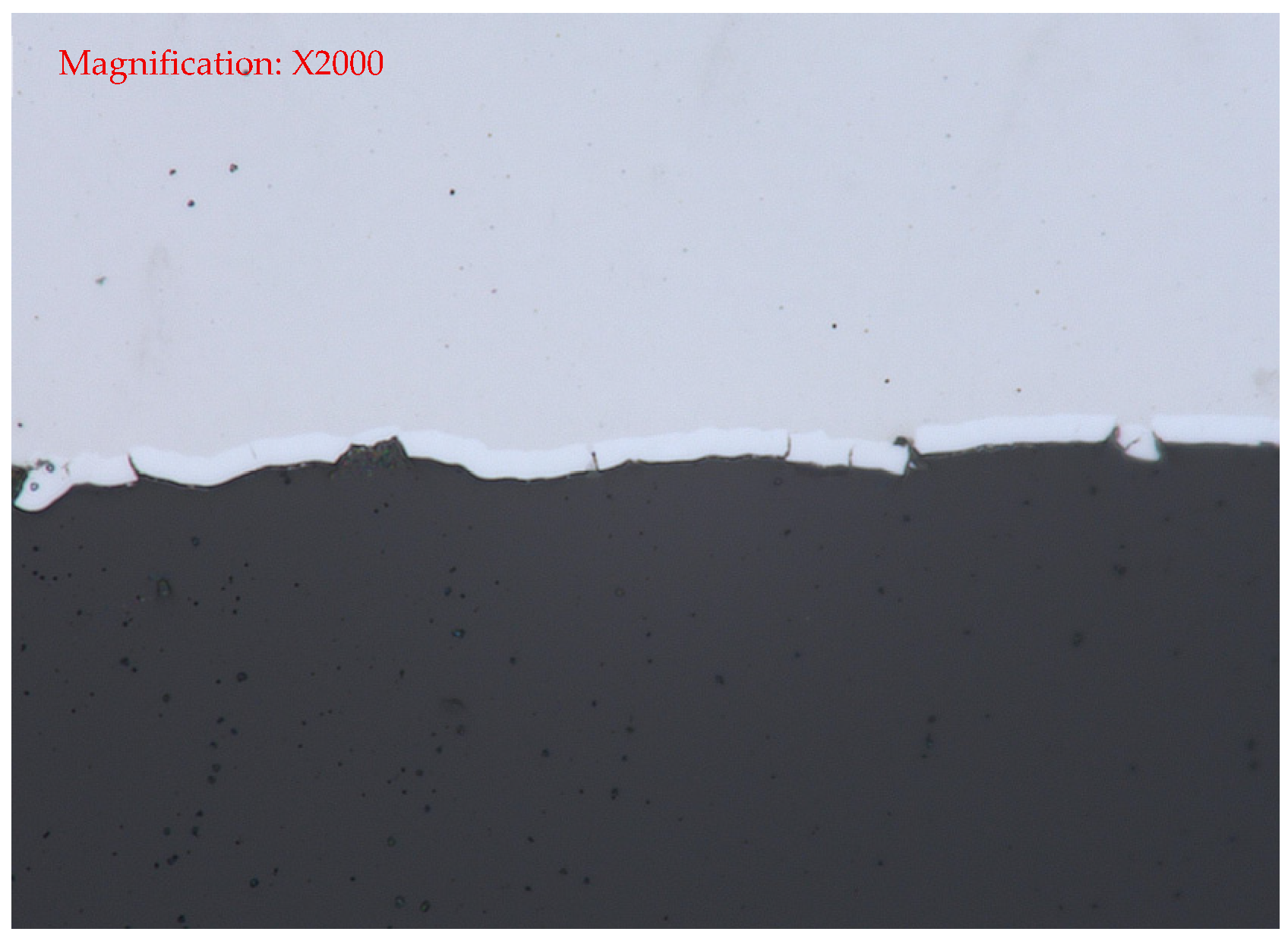

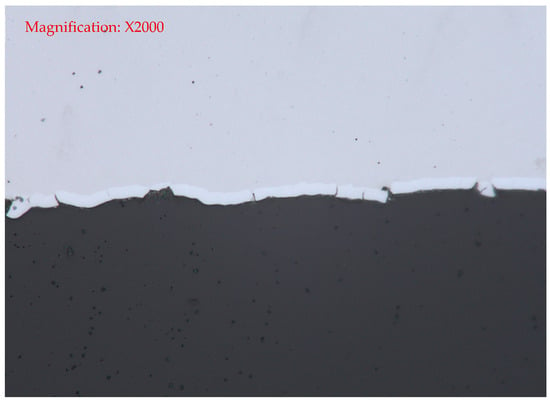

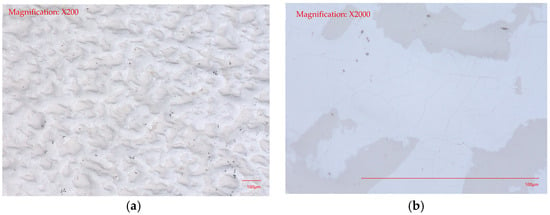

The counter-wear ring surface was electroplated with hard chromium in accordance with the requirements of AMS 2406 [23]. Figure 4 shows a cross-sectional view of electroplated chrome. Figure 5 shows a magnified view of the porosity in the electroplated chrome coating. The coating exhibited a thickness of 0.24 mm, an average porosity of 0.03%, and a surface roughness of Ra 0.02–0.04. The average bonding force is 20.15 N, with a microhardness of 986 HV0.3.

Figure 4.

Typical microstructure of the counter-wear ring coating—electroplated chrome.

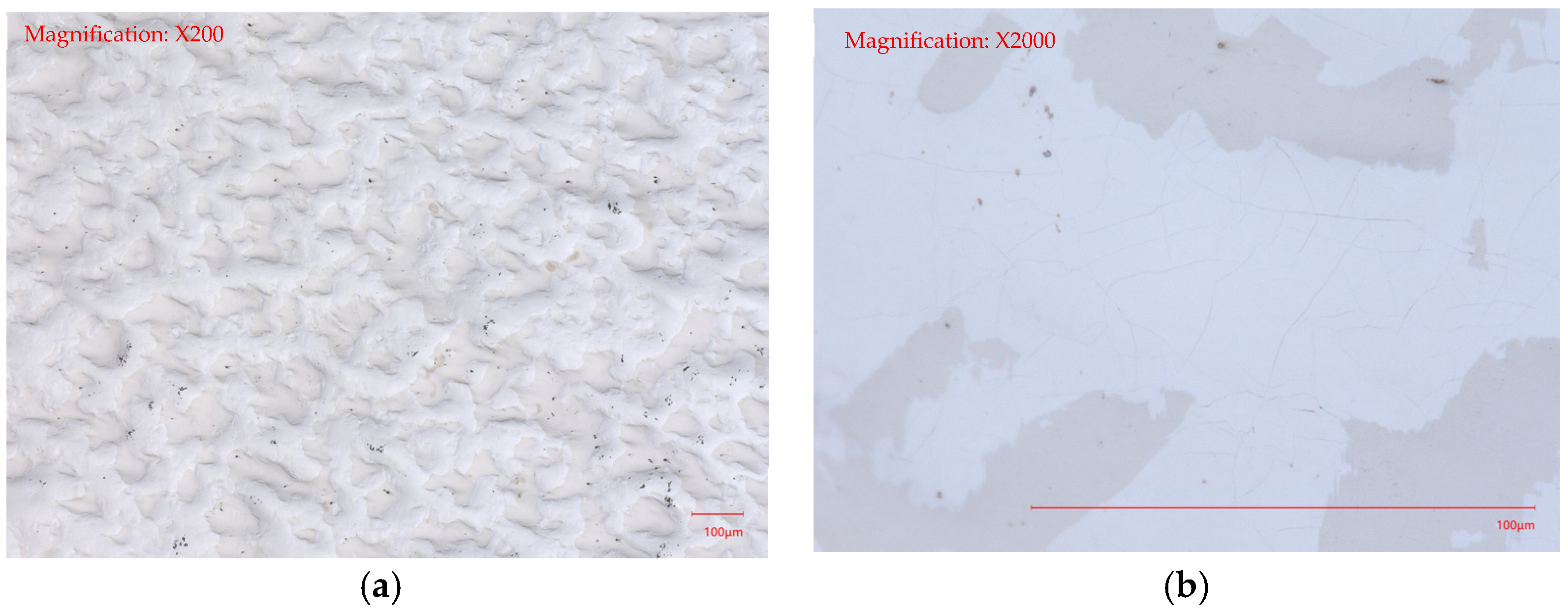

Figure 5.

Magnified view of the porosity in the electroplated chrome coating: (a) magnification factor 200× and (b) magnification factor 2000×.

2.1.3. Material Test Conditions

The specific test conditions were as follows: a load of 196 N, a counter-wear ring rotation speed of 200 rpm (linear velocity 0.42 m/s), and a test duration of 5 h under both dry friction and 46# hydraulic oil lubrication conditions.

2.1.4. Result Calculation

The friction coefficient is calculated according to Equation (1)

The volume wear amount is calculated according to Equation (2)

2.2. Product Experiment

Based on the material friction and wear tests, this study assessed the sealing performance of VL seals with wollastonite mineral-filled PTFE and polyether ether ketone-filled PTFE rings, double-triangle seals, and T seals with wollastonite mineral-filled PTFE backup rings on both electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces.

2.2.1. Tested Seals

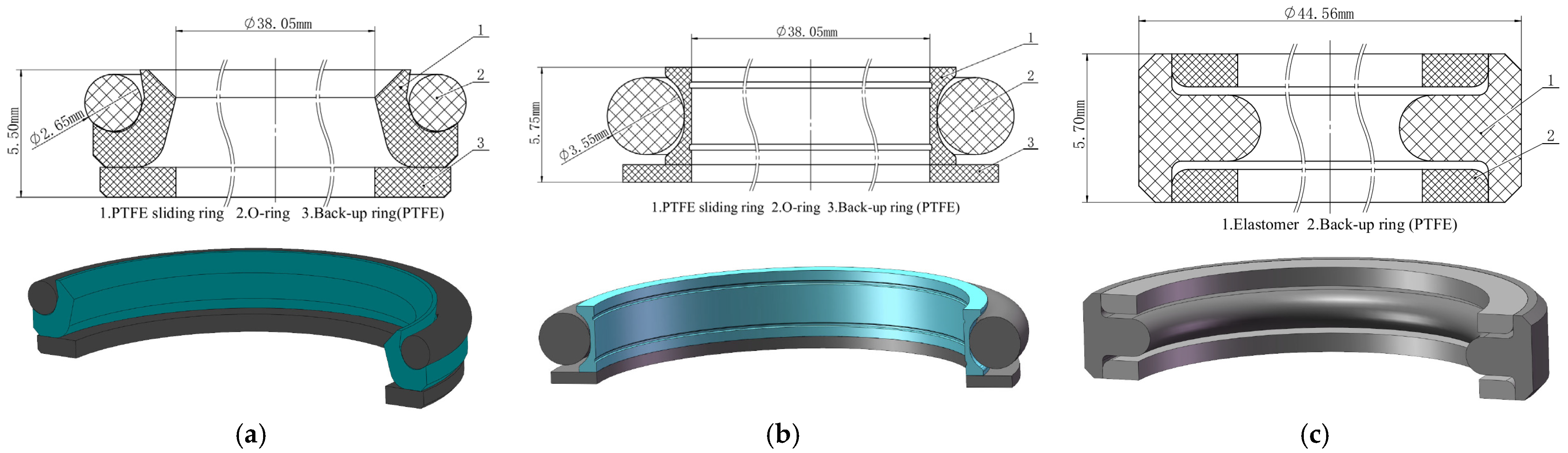

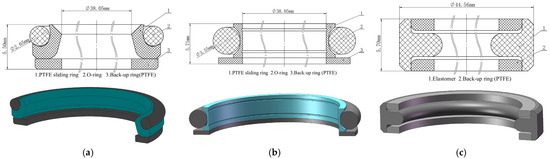

The cross-sectional and 3D diagrams of the test seals are shown in Figure 6. For VL and double-triangle seals, the number 1 designates the PTFE sliding ring, 2 the O-ring, and 3 the backup ring (Figure 6a,b). For the T seal, the number 1 designates the elastomer and 2 the backup ring (Figure 6c).

Figure 6.

Cross-sectional and 3D diagrams of the specimens; (a) VL seal, 1—PTFE sliding ring, 2—O-ring, 3—Backup ring (PTFE); (b) double-triangle seals, 1—PTFE sliding ring, 2—O-ring, 3—Backup ring (PTFE); and (c) T seal, 1—Elastomer, 2—Back-up ring (PTFE).

2.2.2. Experimental Setup: Shaft Surface Treatment and Product Installation

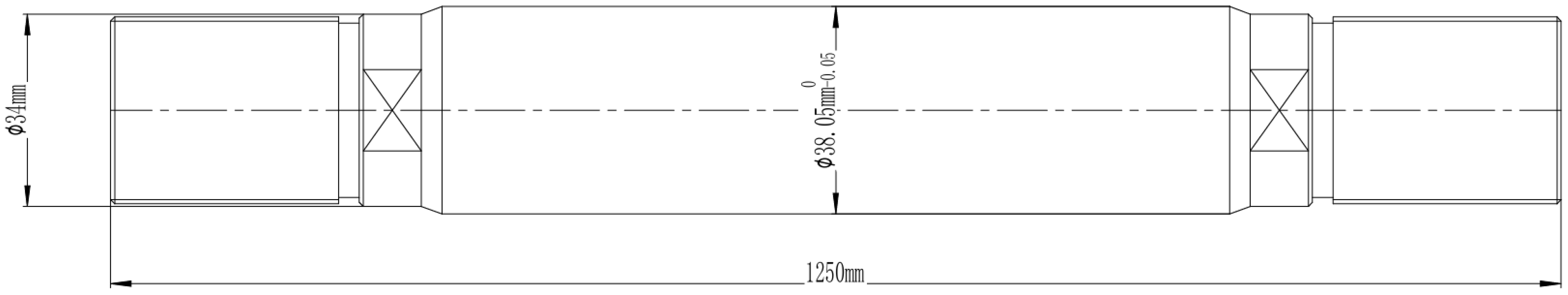

Figure 7 shows the rod of hydraulic cylinders; the rod surface employs two coatings: one is electroplated chromium, and the other is HVOF-WC-10Co-4Cr. The manufacturing processes for the electroplated chrome and HVOF-sprayed WC-10Co-4Cr coatings are described in Section 2.1.

Figure 7.

Rod of hydraulic cylinders.

Figure 8 shows the cross-sectional view of the WC-10Co-4Cr coating of the hydraulic rod sprayed by HVOF. As shown in Figure 8, the coating thickness is uniform, approximately 0.24 mm. The average porosity measured by image analysis is 0.3%. The surface roughness after grinding reached Ra 0.02–0.04 μm. The bond strength of the coating, measured using a tensile testing machine, is 89 MPa. Micro-Vickers hardness tests indicate an average microhardness value of 1197 HV0.3.

Figure 8.

Typical microstructure of the hydraulic rod coating.

The parameters of the electroplated chrome coating on the hydraulic rod are closely aligned with those on the counter-wear ring.

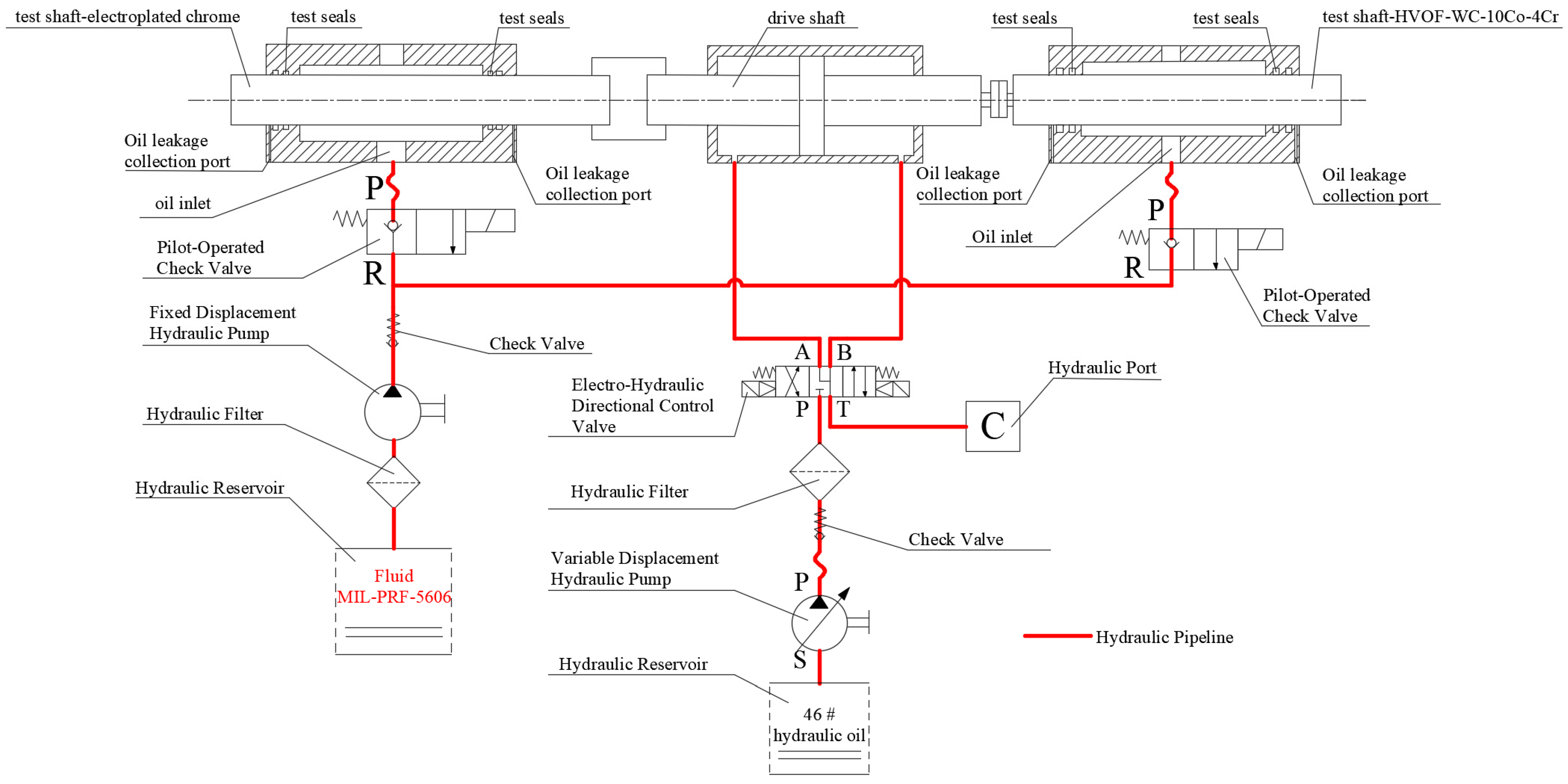

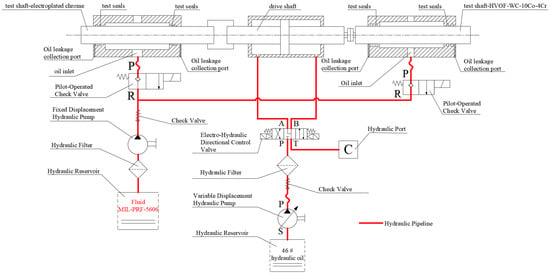

The schematic diagram of the test setup is shown in Figure 9. The central unit is a driving hydraulic cylinder, which actuates the left and right test hydraulic cylinders to perform reciprocating motion. Lubricating oil is pressurized by an oil supply system (tank-pump) independent of the driving hydraulic cylinder and then introduced from the central oil port of the test hydraulic cylinders. The piston rod of the left test hydraulic cylinder is coated with electroplated chromium, while the piston rod of the right test hydraulic cylinder is coated with HVOF-sprayed WC-10Co-4Cr. One test seal product is installed on each side of the test hydraulic cylinder and leakage collection ports are machined outside the test seal products to collect oil leakage (the test method for leakage is in accordance with ISO7986 [24]).

Figure 9.

Schematic diagram of testing system.

2.2.3. Products Tested Conditions

The product test conditions are provided in Table 3; the test pressure is set to the maximum pressure of new-generation aircraft, the test speed is set to the maximum reciprocating speed of the flight control system, and the stroke is set to the maximum test stroke of the test bench.

Table 3.

Product test conditions.

3. Results

3.1. Material Experimental Results’ Analysis

3.1.1. Analysis of Surface Roughness Changes on Metal Counter-Faces Before and After Sliding Against Two Different Materials

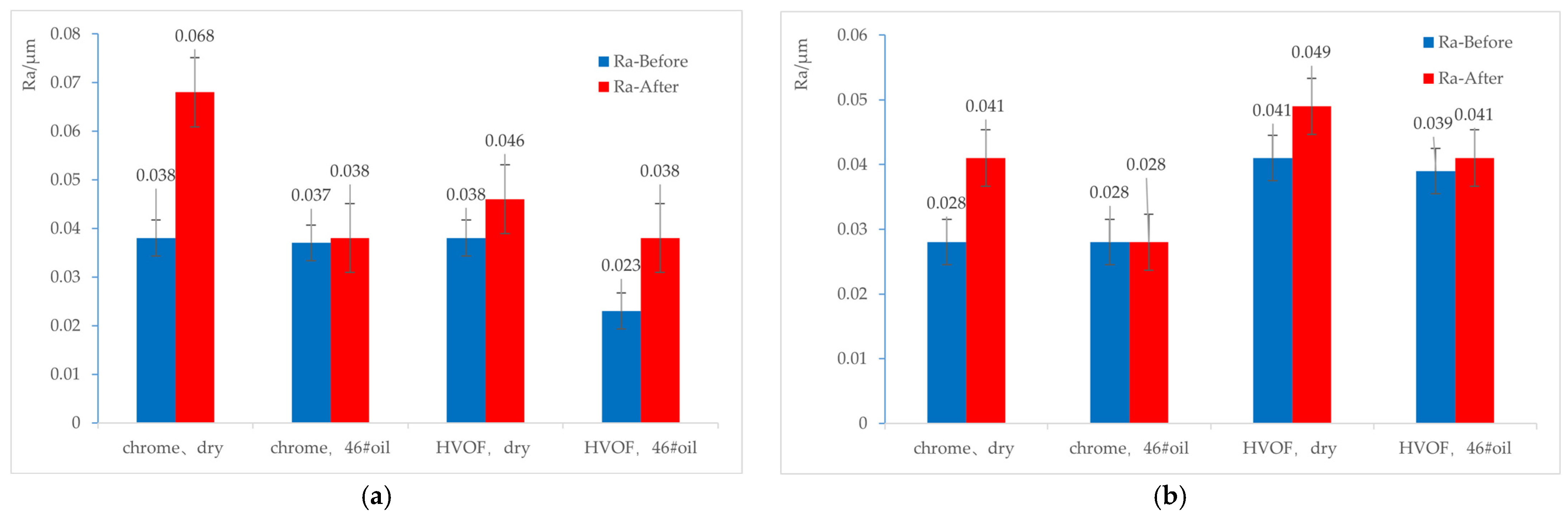

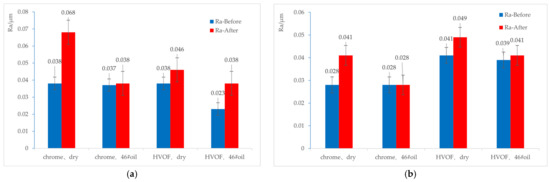

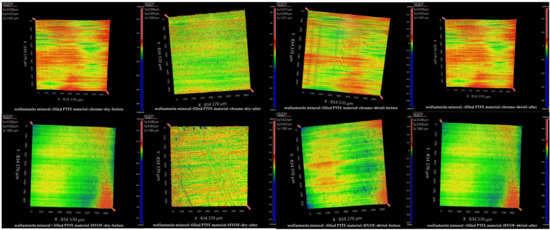

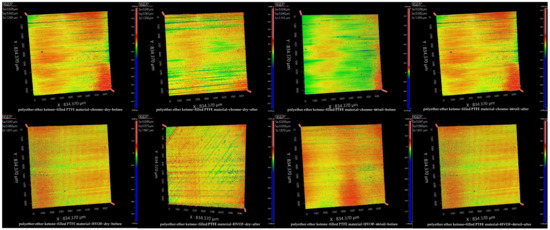

The friction and wear properties of two materials against both electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces were analyzed under various conditions. Figure 10 shows the changes in metal surface roughness before and after sliding tests for different material combinations and surface treatments under various testing conditions (the definition of surface roughness and the test instruments are defined by ISO 25178-2 [25] and covered by ISO 25178-604, respectively [26].). Figure 11 and Figure 12 show the surface morphology variations in electroplated chrome and HVOF-WC-10Co-4Cr surfaces before and after sliding against two different PTFE materials.

Figure 10.

Changes in metal surface roughness before and after sliding contact between two materials and differently surface-treated metals: (a) surface roughness variations in different counter-faces before and after sliding against wollastonite mineral-filled PTFE material under various test conditions; (b) surface roughness variations in different counter-faces before and after sliding against polyether ether ketone-filled PTFE material under various test conditions.

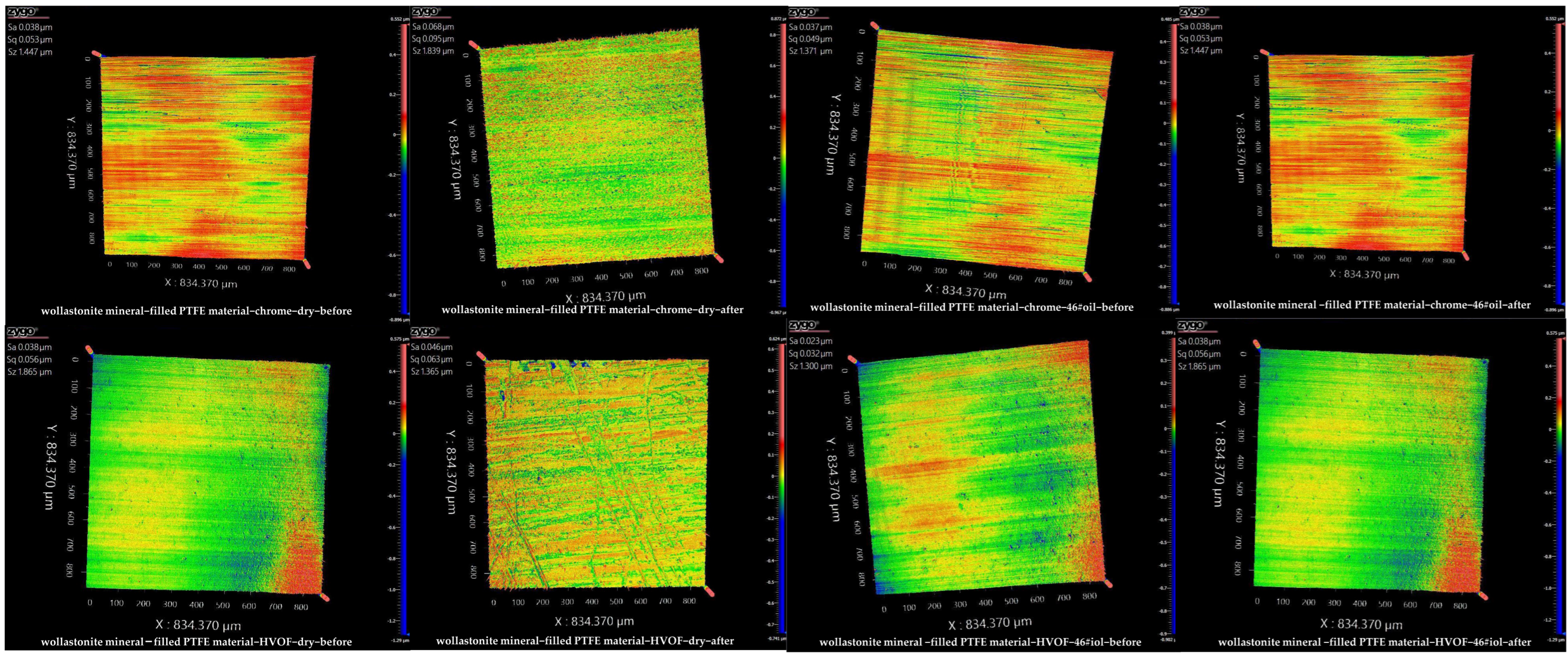

Figure 11.

Surface morphology variations in electroplated chrome and HVOF-WC-10Co-4Cr surfaces before and after sliding against wollastonite mineral-filled PTFE material under various test conditions.

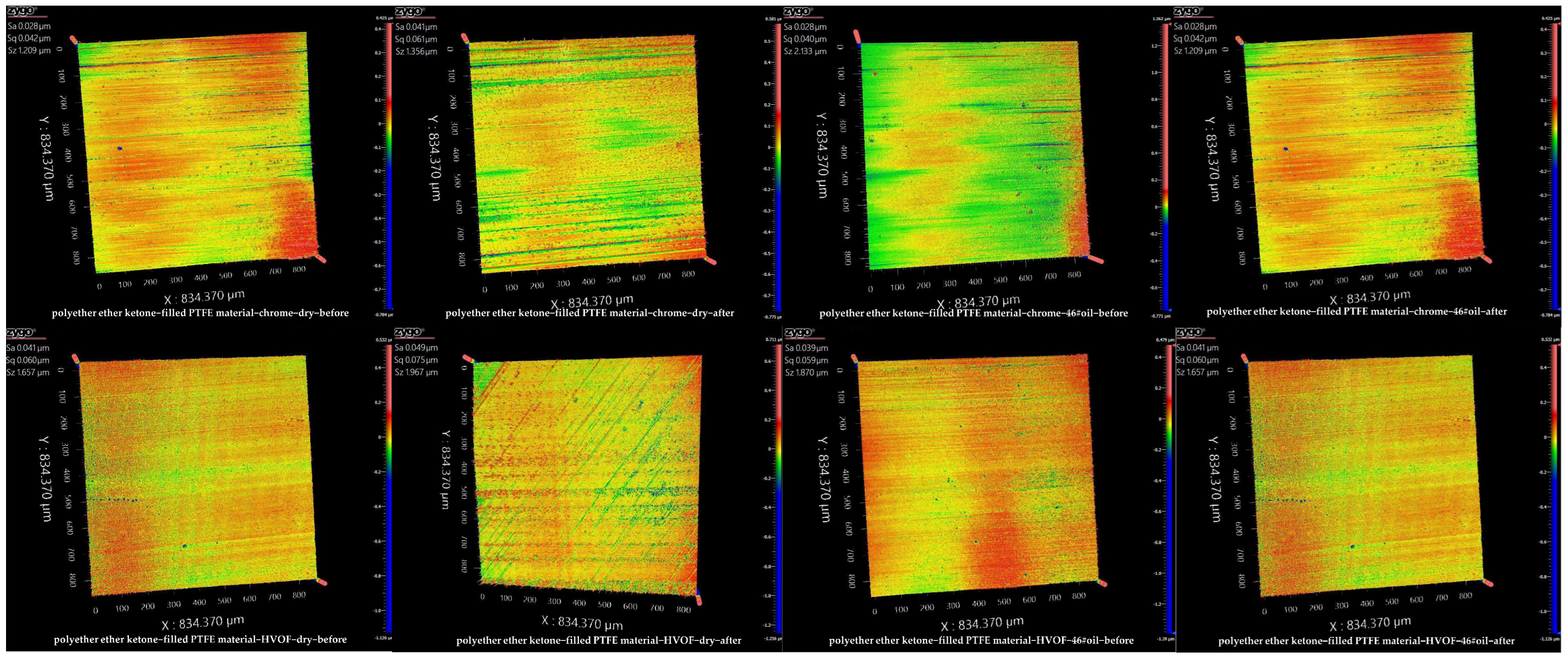

Figure 12.

Surface morphology variations in electroplated chrome and HVOF-WC-10Co-4Cr surfaces before and after sliding against polyether ether ketone-filled PTFE material under various test conditions.

It is evident from Figure 10, Figure 11 and Figure 12 that, for both the wollastonite mineral-filled PTFE and polyether ether ketone-filled PTFE materials, under either dry or lubricated conditions, the surface roughness of the metal counter-faces increased after sliding contact. Regardless of whether the surface was electroplated chrome or HVOF-WC-coated, and whether the test condition was dry or lubricated, the variations in surface roughness were consistently greater after sliding against the wollastonite mineral-filled PTFE material than after sliding against the polyether ether ketone-filled PTFE material, indicating that wollastonite mineral-filled PTFE caused more significant surface damage to metals than polyether ether ketone-filled PTFE. This difference originates from their filler compositions: the mineral fibers are harder and have sharper morphologies and are more likely to damage metal surfaces than the softer, more rounded polymeric fillers.

Furthermore, under dry sliding conditions, both materials produced greater surface roughness changes on electroplated chrome surfaces than on HVOF-sprayed WC-10Co-4Cr surfaces, demonstrating the superior wear resistance of HVOF-sprayed WC-10Co-4Cr coatings. Under oil-lubricated conditions, the changes in surface roughness before and after sliding were relatively minor for both counter-face materials. However, compared to electroplated chrome surfaces, HVOF-sprayed WC-10Co-4Cr surfaces exhibited slightly more pronounced roughness changes after sliding in lubricated conditions.

3.1.2. Analysis of the Tribological Properties of Two Materials Against Different Surfaces

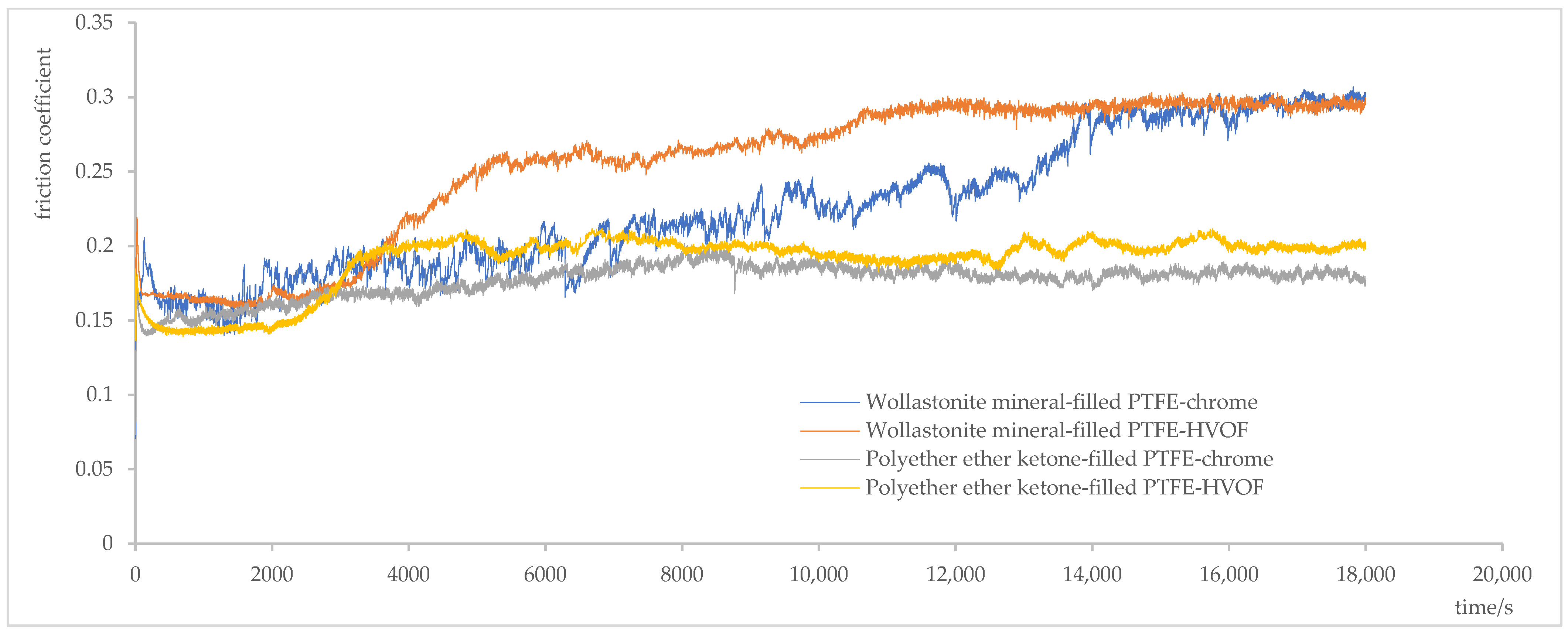

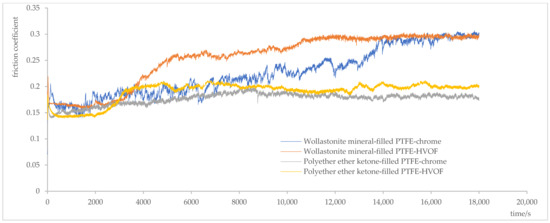

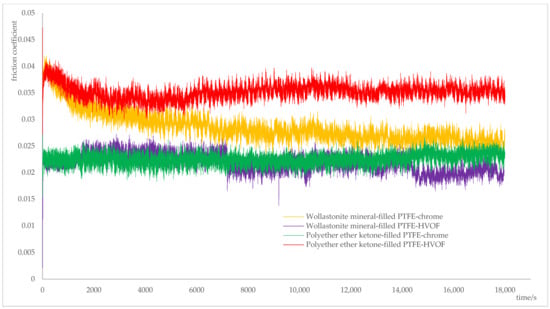

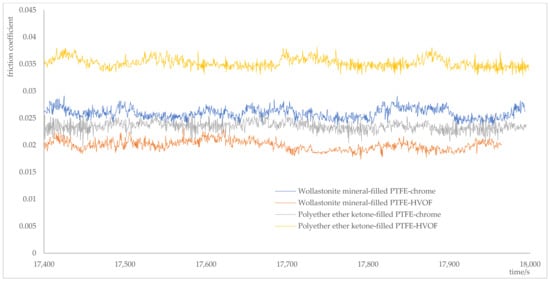

The friction coefficients of both materials under dry and lubricated sliding conditions against electroplated chrome and HVOF-coated surfaces are shown in Figure 13, Figure 14 and Figure 15.

Figure 13.

Comparison of dry friction coefficients between two materials on electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces.

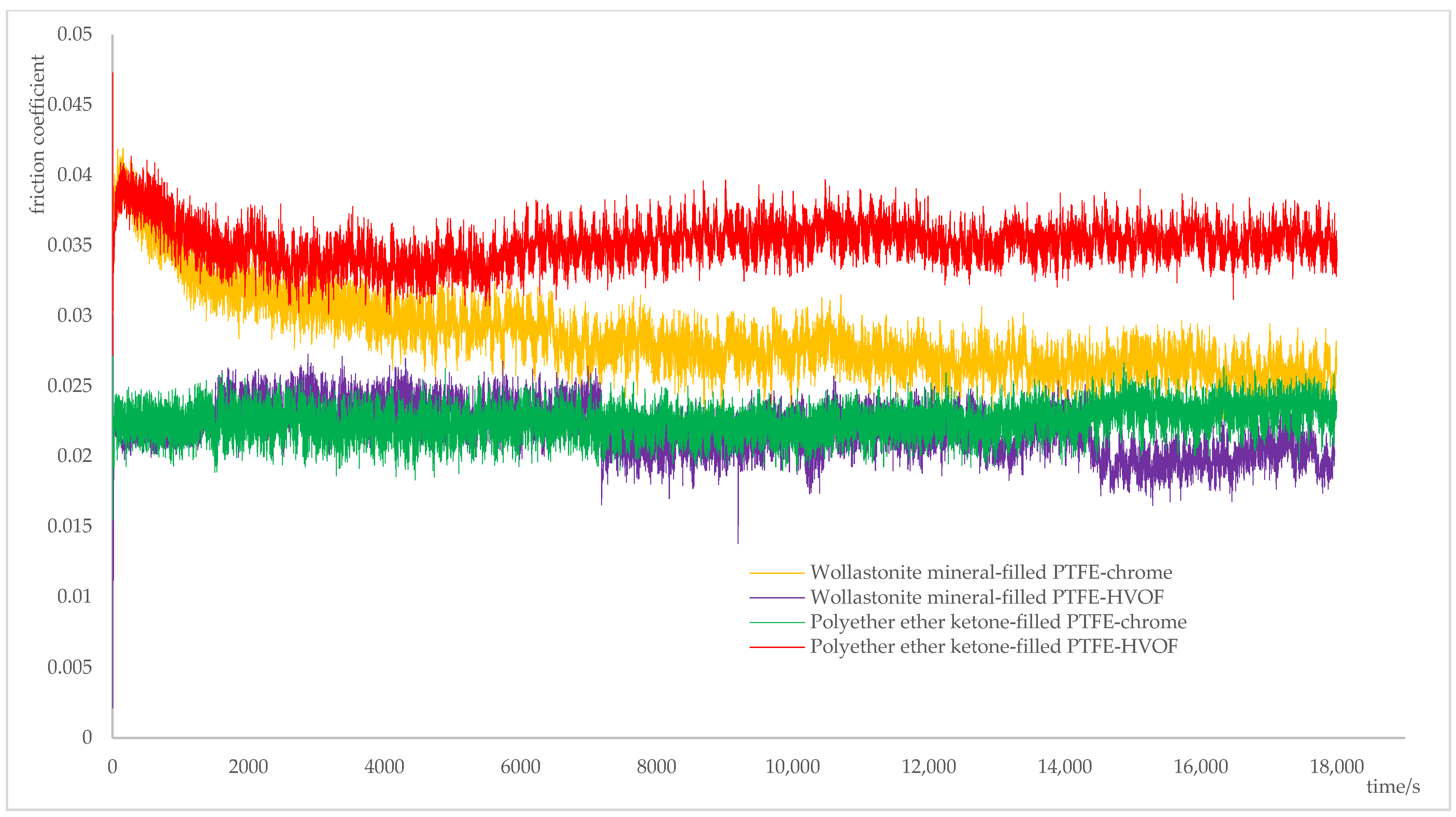

Figure 14.

Comparison of lubricated friction coefficients between two materials on electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces.

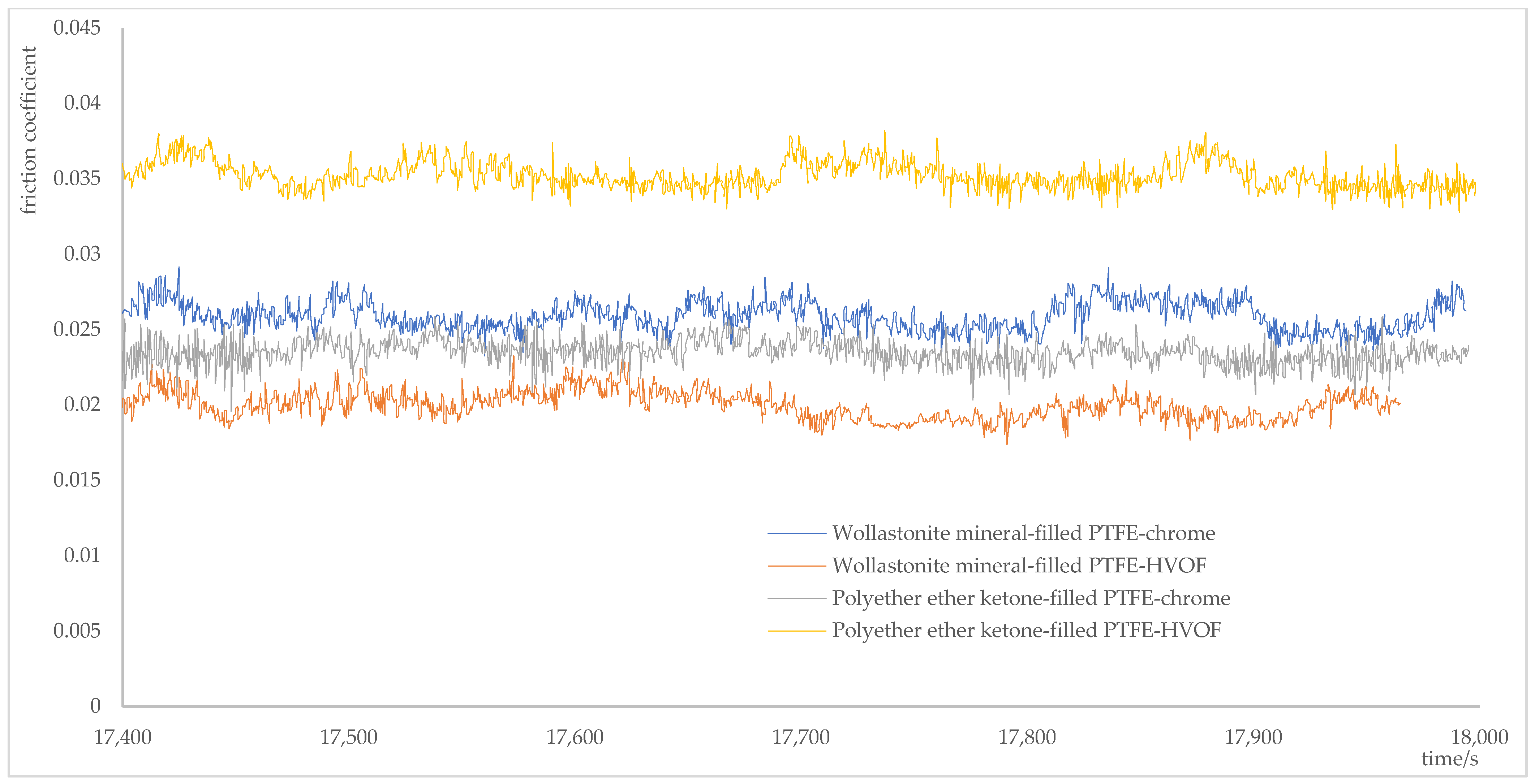

Figure 15.

Comparison of lubricated friction coefficients during the final 600 s sliding period for two materials on electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces.

As shown in Figure 13, under dry sliding conditions, the friction coefficients of the two materials on different surfaces followed the following descending order: wollastonite mineral-filled PTFE-HVOF-sprayed WC-10Co-4Cr coating > wollastonite mineral-filled PTFE-electroplated chrome > polyether ether ketone-filled PTFE-HVOF-sprayed WC-10Co-4Cr coating > polyether ether ketone-filled PTFE-electroplated chrome. As shown in Figure 14 and Figure 15, under oil-lubricated conditions, after reaching a steady state, the ranking of the friction coefficients was as follows: polyether ether ketone-filled PTFE-HVOF-sprayed WC-10Co-4Cr > wollastonite mineral-filled PTFE-electroplated chrome > polyether ether ketone-filled PTFE-electroplated chrome > wollastonite mineral-filled PTFE-HVOF-sprayed WC-10Co-4Cr.

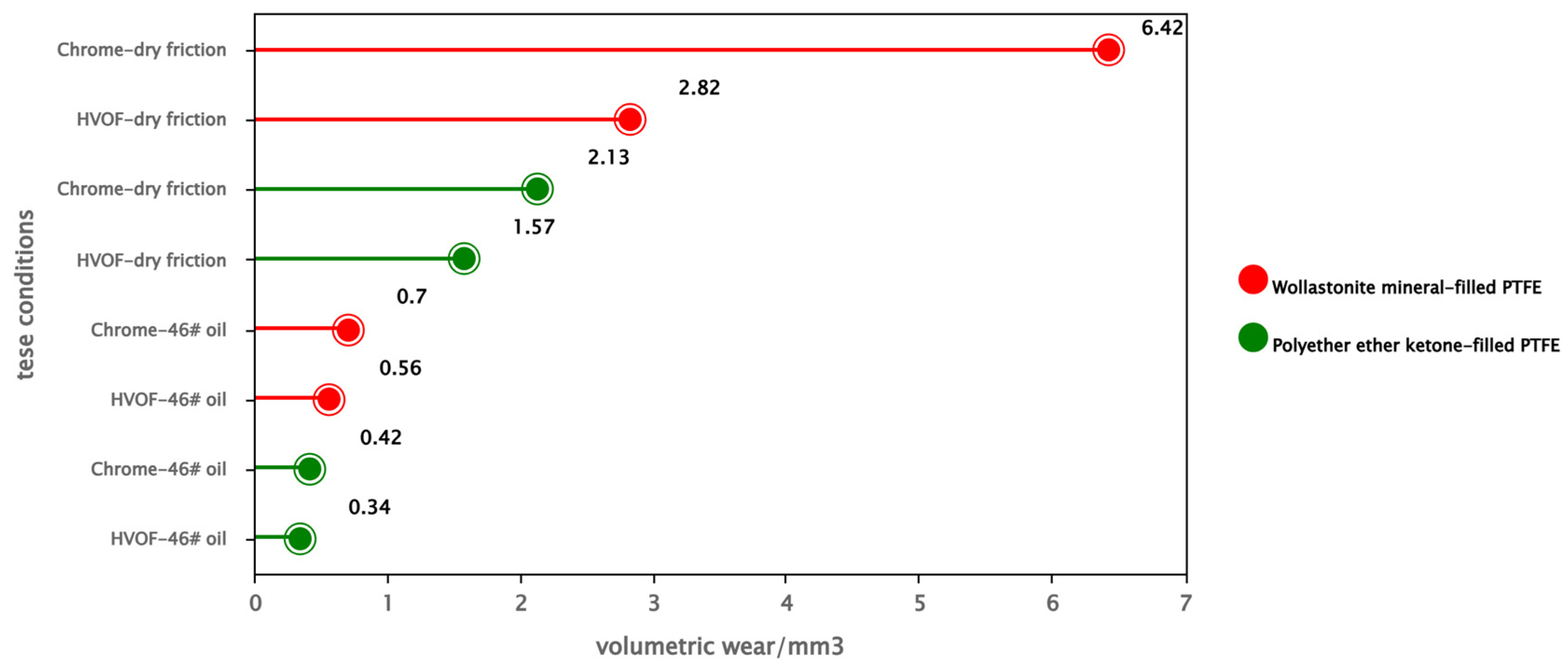

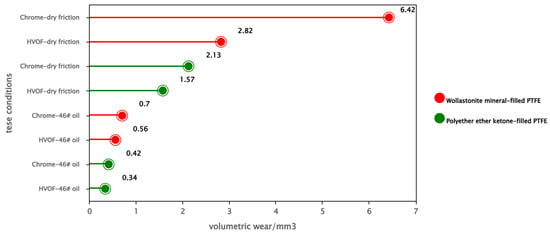

The volumetric wear amounts of the two PTFE materials after rubbing against an electroplated chrome surface and a HVOF-WC-10Co-4Cr surface under different lubrication conditions was measured using the method in Section 2.1, Equation (2), the test results were shown in Figure 16.

Figure 16.

Volumetric wear measurements of two materials under different test conditions.

As evident from Figure 16, the volumetric wear rate under dry sliding conditions was significantly greater than that under lubricated conditions. Regardless of whether testing occurred under dry or lubricated sliding, both materials exhibited lower volumetric wear when sliding against HVOF-sprayed WC-10Co-4Cr surfaces than when sliding against electroplated chrome surfaces. This demonstrates that HVOF-sprayed WC-10Co-4Cr surfaces cause less material wear than electroplated chrome surfaces. Furthermore, under all test conditions—whether dry or lubricated, and whether sliding against electroplated chrome or HVOF-sprayed WC-10Co-4Cr surfaces—wollastonite mineral-filled PTFE consistently showed higher volumetric wear rates than polyether ether ketone-filled PTFE. This indicates that the wollastonite mineral-filled PTFE material was more prone to wear compared to the polyether ether ketone-filled PTFE material.

Additionally, under dry friction conditions, both materials showed higher friction coefficients but lower wear rates on HVOF-sprayed WC-10Co-4Cr surfaces compared to electroplated chrome surfaces. This occurs for the following reasons: (a) the extreme hardness of HVOF-sprayed WC-10Co-4Cr coatings makes it difficult for PTFE to form continuous transfer films and the hard WC particles “plow” through PTFE during friction, increasing shear resistance; (b) once formed, the transfer films adhere firmly to WC surfaces and resist detachment, reducing PTFE loss; and (c) WC itself is nearly unwearable by PTFE, and the coating’s rough surface helps distribute load, further decreasing localized stress and PTFE wear. Electroplated chrome surfaces exhibited the opposite behavior—transfer films form easily but detach readily, resulting in lower friction coefficients but higher wear rates.

3.2. Product Experimental Results’ Analysis

3.2.1. VL Seal Experimental Results Analysis

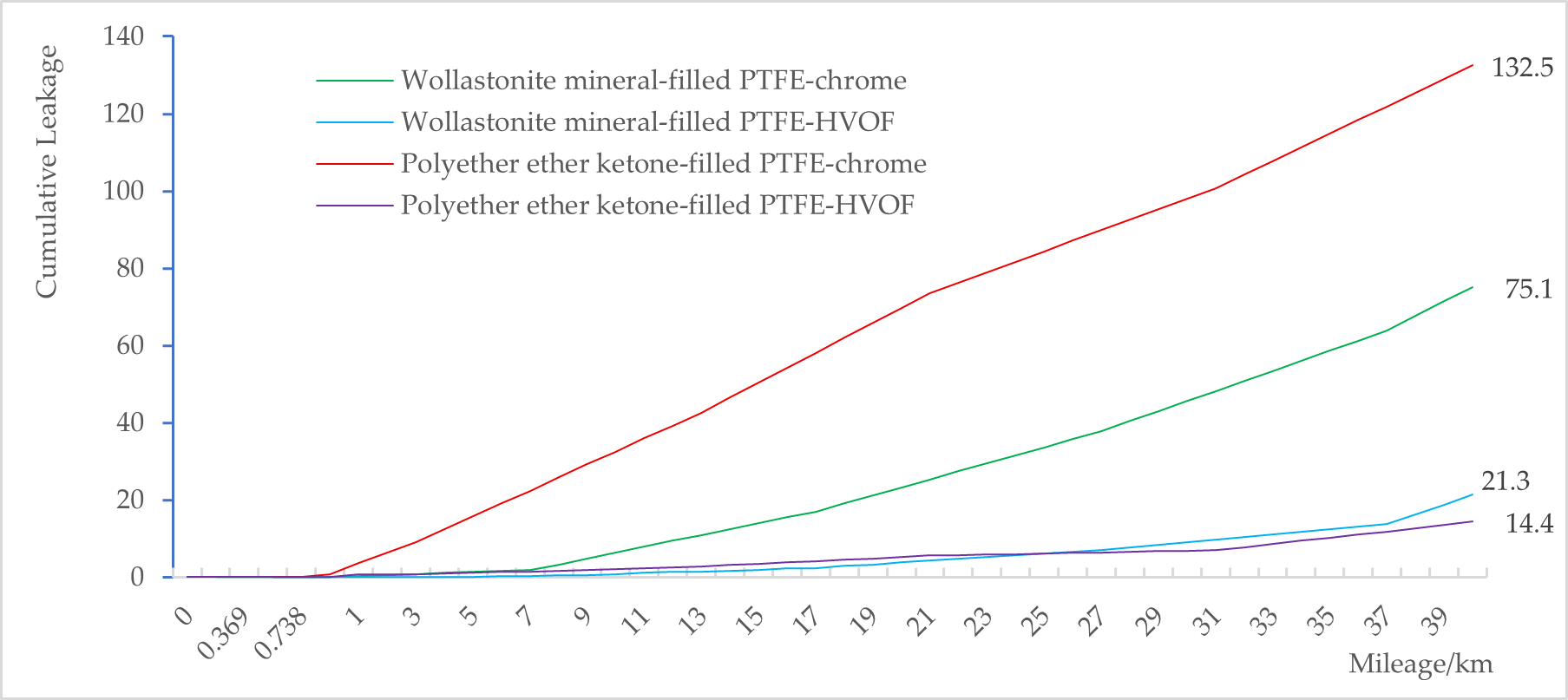

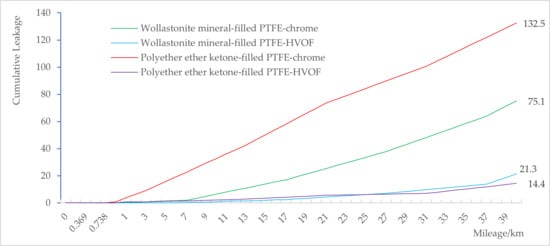

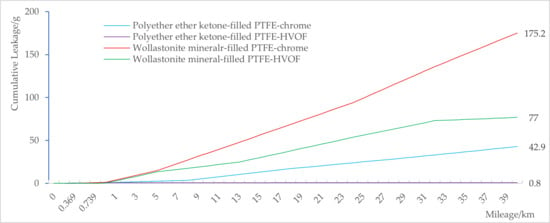

Cumulative leakage volumes of VL seals made from both materials over a 40 km sliding distance on electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces are shown in Figure 17.

Figure 17.

Leakage performance of VL seals made from both materials on different counter-face surfaces.

As shown in Figure 17, the leakage volumes for both wollastonite mineral-filled PTFE and polyether ether ketone-filled PTFE VL seals were consistently lower on HVOF-sprayed WC-10Co-4Cr surfaces than on electroplated chrome surfaces. This was for the following reasons: (a) the WC coatings’ micron-scale asperities and pores from thermal spraying allow PTFE transfer films to be embed firmly, forming stable solid lubrication layers that minimize leakage paths, and (b) on electroplated chrome surfaces, PTFE films shear off easily, leaving microscopic leakage channels. For VL seals on electroplated chrome surfaces, the wollastonite mineral-filled PTFE material demonstrated superior sealing performance to the polyether ether ketone-filled PTFE material. In contrast, on HVOF-sprayed WC-10Co-4Cr surfaces, the sealing performance difference between wollastonite mineral-filled PTFE and polyether ether ketone-filled PTFE was negligible. Therefore, for VL sealing products, the wollastonite mineral-filled PTFE material is preferred on electroplated chrome surfaces and the polyether ether ketone-filled PTFE material was preferred on HVOF-sprayed WC-10Co-4Cr surfaces.

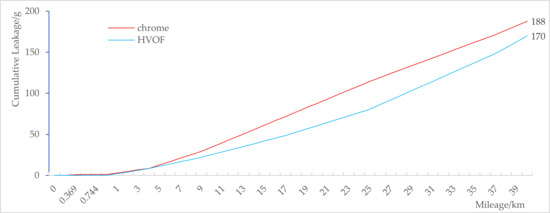

3.2.2. T Seal Experimental Results Analysis

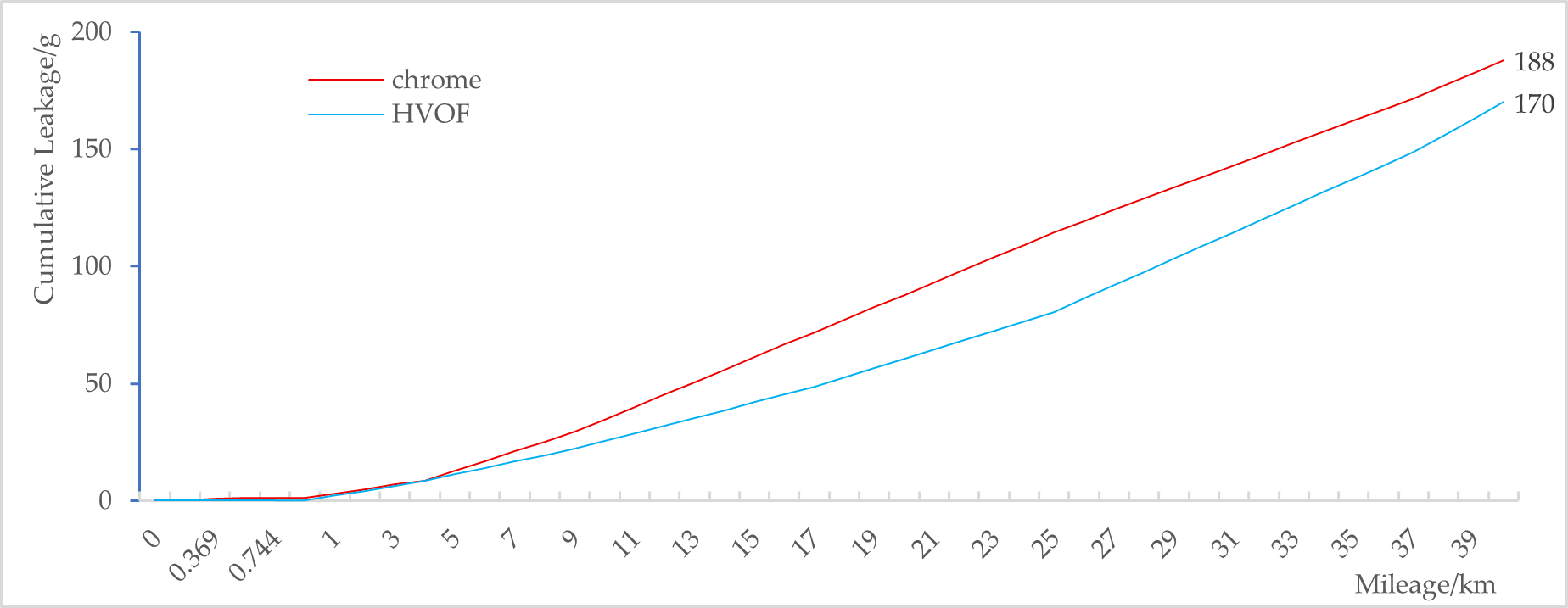

Cumulative leakage volumes of wollastonite mineral-filled PTFE T seals over a 40 km sliding distance on electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces are shown in Figure 18.

Figure 18.

Leakage performance of T seals made from wollastonite mineral-filled PTFE on different counter-face surfaces.

As shown in Figure 18, for T seals the sealing performance difference between electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces was negligible. This finding aligns with the U.S. Department of Defense’s verification tests for HVOF thermal spray coatings as replacements for electroplated chrome in hydraulic/pneumatic actuators, which concluded that for rubber-faced sealing products, surface treatment (chrome plating vs. HVOF-sprayed WC-10Co-4Cr) has minimal impact on sealing performance.

3.2.3. Double-Triangle Seal Experimental Results’ Analysis

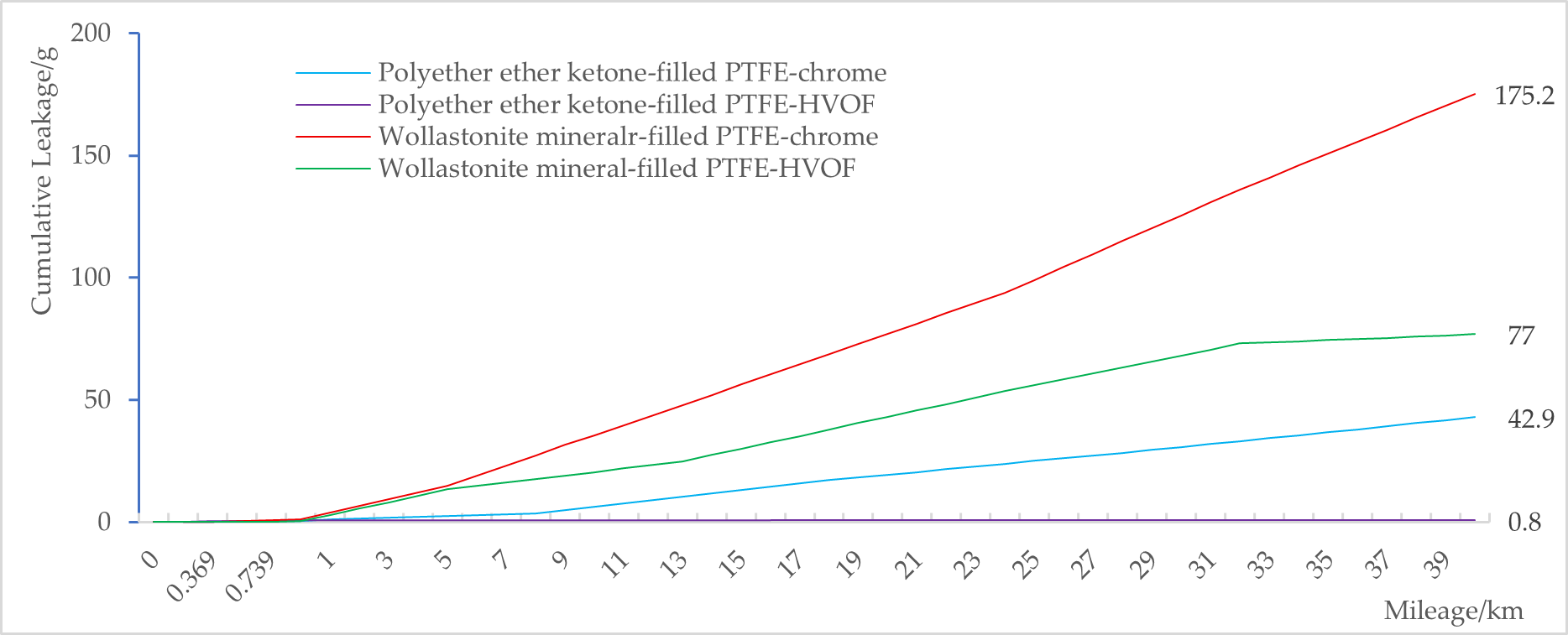

Cumulative leakage volumes of double-triangle seals made from both materials over a 40 km sliding distance on electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces are shown in Figure 19.

Figure 19.

Leakage performance of double-triangle seals made from both materials on different counter-face surfaces.

As shown in Figure 19, similar to VL seals, the double-triangle seals made from both materials demonstrated superior sealing performance on HVOF-sprayed WC-10Co-4Cr surfaces compared to electroplated chrome surfaces. However, unlike VL seals, the polyether ether ketone-filled PTFE material exhibited better sealing performance than the wollastonite mineral-filled PTFE material on both surface types—whether electroplated chrome or HVOF-sprayed WC-10Co-4Cr.

4. Discussion

Both electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces exhibited an increase in surface roughness during sliding against two types of PTFE materials. This phenomenon, where a softer material abrades a harder material, occurs because metal surfaces contain tiny asperities—even after polishing, micro/nano-scale protrusions remain. When in sliding contact with PTFE, these asperities generate compressive and shear forces at the interface; although PTFE is relatively soft, metal asperities embed into the PTFE surface under pressure; during sliding, PTFE exerts a reverse frictional force on the metal asperities. This continuous shear force causes micro-plastic deformation at the tips of the metal asperities or leads to the detachment of small debris due to fatigue, ultimately resulting in “wear” of the metal surface (manifested as increased roughness).

Furthermore, regardless of the surface treatment method, wollastonite mineral-filled PTFE caused greater wear to the metal surfaces compared to polyether ether ketone-filled PTFE. This difference is related to the inherent hardness and shape of the fillers themselves.

Both PTFE materials showed consistent tribological behavior: lower friction coefficients but higher wear rates on electroplated chrome surfaces and higher friction coefficients but lower wear rates on HVOF-sprayed WC-10Co-4Cr surfaces. This behavior is associated with the ease of transfer film formation and the stability of the transfer film formed by PTFE on the two surfaces. A transfer film forms more easily on electroplated chrome surfaces but lacks stability, whereas on HVOF-sprayed WC-10Co-4Cr surfaces, film formation is more difficult but stable. Regardless of the material (wollastonite mineral-filled or polyether ether ketone-filled PTFE material), the testing condition (dry or lubricated), or the counter-face (electroplated chrome or HVOF-coated), a consistent positive correlation was observed between the friction coefficient and surface roughness. That is, a higher roughness leads to a higher coefficient of friction.

The product test results are consistent with the findings of Bruce D. Sartwel et al. [1]. For composite sealing products using PTFE as the mating friction surface, the sealing performance on HVOF-sprayed WC-10Co-4Cr surfaces is superior to that on electroplated chrome surfaces. However, for composite sealing products using elastomers as the mating friction surface, HVOF-sprayed WC-10Co-4Cr surfaces do not offer a definitive advantage. Additionally, product type is a key factor influencing sealing performance; for example, on electroplated chrome surfaces, wollastonite mineral-filled PTFE is more suitable for VL products but not for double-triangle products. Therefore, during the design of sealing system solutions, comprehensive consideration must be given to product type, material selection, and surface treatment.

While this study investigated the friction and wear properties of the two PTFE materials under two surface treatment conditions, as well as the sealing performance of different product types under these surface treatments, it only provided a preliminary analysis of the underlying causes for the observed results. For instance, no further verification was conducted to confirm why PTFE transfer films form easily but lack stability on electroplated chrome surfaces, while forming with greater difficulty but higher stability on HVOF-sprayed WC-10Co-4Cr surfaces. Moreover, the reasons why electroplated chrome and HVOF-sprayed WC-10Co-4Cr surfaces have little impact on the performance of elastomer-based mating friction surfaces were not explored. In future research, we will further investigate the formation mechanism of PTFE transfer films on these two distinct surfaces, as well as the interaction mechanisms between rubber materials/PTFE materials and electroplated chrome/HVOF-sprayed WC-10Co-4Cr surfaces.

5. Conclusions

This study evaluated the friction and wear properties of two materials on electroplated chrome surfaces and HVOF-sprayed WC-10Co-4Cr surfaces, as well as the leakage performance of three structural types made of the two materials on electroplated chrome surfaces and HVOF-sprayed WC-10Co-4Cr surfaces. The conclusions are as follows:

- For both materials under either dry or lubricated conditions, the surface roughness of metal counter-faces increased after friction tests, demonstrating the phenomenon of “soft material wearing hard material”. Regardless of the surface treatment or lubrication condition, metal surfaces sliding against the wollastonite mineral-filled PTFE material exhibited greater roughness changes than those sliding against the polyether ether ketone-filled PTFE material, indicating that wollastonite mineral-filled PTFE caused more severe surface damage than polyether ether ketone-filled PTFE.

- Under dry friction conditions, both materials showed higher friction coefficients but lower wear rates on HVOF-sprayed WC-10Co-4Cr surfaces than on electroplated chrome surfaces.

- Product tests revealed that for VL seals and double-triangle seals (where plastic rings contact counter-faces), sealing performance was significantly better on HVOF-sprayed WC-10Co-4Cr surfaces than on electroplated chrome surfaces. For T seals (with rubber elastomer contact surfaces), both surface treatments showed similar sealing performance.

- For VL seals (a) on electroplated chrome surfaces, wollastonite mineral-filled PTFE demonstrated better sealing performance than polyether ether ketone-filled PTFE; and (b) on HVOF-sprayed WC-10Co-4Cr surfaces, both materials showed comparable performance. Therefore, wollastonite mineral-filled PTFE was preferred for electroplated chrome surfaces, while polyether ether ketone-filled PTFE was recommended for HVOF-sprayed WC-10Co-4Cr surfaces.

- For double-triangle seals, polyether ether ketone-filled PTFE outperformed wollastonite mineral-filled PTFE on both surface treatments. Thus, polyether ether ketone-filled PTFE should be selected as the sealing ring material regardless of surface treatment.

Author Contributions

Conceptualization, M.Z. and L.H.; methodology, M.Z. and J.W.; validation, M.Z., F.T., and Y.W.; formal analysis, M.Z.; investigation, M.Z.; resources, Y.W.; data curation, M.Z.; writing—original draft preparation, M.Z.; writing—review and editing, J.H.; visualization, M.Z.; supervision, Y.W.; project administration, F.T.; funding acquisition, Y.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All of the data generated or analyzed during this study are included in this published article.

Acknowledgments

The authors thank Jinghu Yu from Jiangnan University for their assistance with the operation of the product performance tester and data collection.

Conflicts of Interest

Authors Minmin Zhao, Le Huang, Feng Tan, Yong Wang and Jinyu Hu were employed by the company Guangzhou Mechanical Engineering Research Institute Co., Ltd. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| HVOF | High-velocity oxygen fuel |

| PTFE | Polytetrafluoroethylene |

| WC | WC-10Co4Cr |

References

- Sartwell, B.D.; Zimmerman, J.; Gribble, J.; Legg, K.O. Validation of HVOF Thermal Spray Coatings as a Replacement for Hard Chrome Plating on Hydraulic/Pneumatic Actuators. 2007. Available online: https://apps.dtic.mil/sti/citations/ADA603509 (accessed on 16 October 2025).

- Sartwell, B.D.; Legg, K.O.; Schell, J.; Sauer, J.; Natishan, P.; Dull, D.E.; Falkowski, J.O.; Bretz, P.; Parker, D.; Edwards, C.; et al. Validation of HVOF WC/Co Thermal Spray Coatings as a Replacement for Hard Chrome Plating on Aircraft Landing Gear. 2004. Available online: http://servidor.demec.ufpr.br/disciplinas/TM734/Material%20de%20AT%20para%20divulgar/HVOF%20WC%20Co.pdf (accessed on 16 October 2025).

- Gent, A.N.; Lin, C.-W. Model Studies of the Effect of Surface Roughness and Mechanical Interlocking on Adhesion. J. Adhes. 1990, 32, 113–125. [Google Scholar] [CrossRef]

- Sartwell, B.D.; Legg, K.O.; Nardi, A.A.; Kestler, R.O.; Assink, W.A.; Schell, J.E. Replacement of Chromium Electroplating on C-2, E-2, P-3, and C-130 Propeller Hub Components Using HVOF Thermal Spray Coatings. 2004. Available online: http://servidor.demec.ufpr.br/disciplinas/EME715/AT%20PGMEC/Artigos%20para%20Semin%C3%A1rio/Replacement%20of%20Chromium.pdf (accessed on 16 October 2025).

- Devereaux, J.L.; Jacksonville, N. HVOF as a Hard Chrome Replacement. In Proceedings of the 26th Replacement of Hard Chrome and Cadmium Plating Program Review Meeting, San Diego, CA, USA, 24–26 January 2006. [Google Scholar]

- Josephson, R.; Martin, B. Hill AFB HVOF Implementation. 2008. Available online: https://apps.dtic.mil/sti/tr/pdf/ADA599947.pdf (accessed on 16 October 2025).

- Luchenta, R.; Guillemette, R. Qualification and Implementation of HVOF Coatings on H-60 Main and Tail Landing Gear. In Proceedings of the 26th Replacement of Hard Chrome and Cadmium Plating Program Review Meeting, San Diego, CA, USA, 24–26 January 2006. [Google Scholar]

- Ngin, T. EA-6B HVOF HVOF-Coated Landing Gear: Post Post-Deployment Inspection Results, Westminster, ASETS Defense 2009: Sustainable Surface Engineering for Aerospace and Defense Workshop, 2009. Available online: https://apps.dtic.mil/sti/tr/pdf/ADA604774.pdf (accessed on 16 October 2025).

- Moorman, J. Navy Qualification Effort for HVOF Wear-Resistant Actuator Rod Coatings. In Proceedings of the 23rd Replacement of Hard Chrome Plating Program Review Meeting, Cape Canaveral, FL, USA, 18–19 November 2003. [Google Scholar]

- Gribble, J. Functional Rod/Seal Testing and Qualification of HVOF Coatings on Navy Actuators. In Proceedings of the 25th Replacement of Hard Chrome and Cadmium Plating Program Review Meeting, Greensboro, NC, USA, 15–17 March 2005. [Google Scholar]

- Sartwell, B.D.; Legg, K.O. Replacement of Chromium Electroplating on Landing Gear Components Using HVOF Thermal Spray Coatings. 2004. Available online: https://apps.dtic.mil/sti/tr/pdf/ADA607046.pdf (accessed on 16 October 2025).

- Monaghan, K.J. Comparison of seal friction on chrome and HVOF coated rods under conditions of short stroke reciprocating motion. Feature 2008, 2008, 9–14. [Google Scholar] [CrossRef]

- Castro, R.M.; Cavaler, L.C.C.; Marques, F.M. Comparative of the Tribological Performance of Hydraulic Cylinders Coated by the Process of Thermal Spray HVOF and Hard Chrome Plating. Tribol. Ind. 2014, 36, 79–89. [Google Scholar]

- SAE International. Use of HVOF Thermal Spray Coatings for Hard Chrome Replacement in Landing Gear Applications: ARP5935. 2013. Available online: https://www.sae.org/standards/arp5935-use-hvof-thermal-spray-coatings-hard-chrome-replacement-landing-gear-applications (accessed on 16 October 2025).

- Fang, W.; Cho, T.Y.; Yoon, J.H.; Song, K.O.; Hur, S.K.; Youn, S.J.; Chun, H.G. Processing optimization, surface properties and wear behavior of HVOF spraying WC-CrC-Ni coating. J. Mater. Process. Technol. 2009, 209, 3561–3567. [Google Scholar] [CrossRef]

- Celik, I.; Benli, B. The effect of WC-12Co and CrC-NiCr hard coatings applied by HVOF method on the microstructure, mechanical, and surface properties of steel. Metall. Res. Technol. 2024, 121, 318. [Google Scholar] [CrossRef]

- Jiyong, S. An Investigation of Rubber Seals Abrasion by Tungsten Carbide Cobalt Coating Sprayed by HVOF. Lubr. Eng. 2009, 34, 100–102. [Google Scholar]

- Yan, X.; Du, X.; Chang, K. Influence of Surface Roughness on Seal Property of Aircraft Actuator. Adv. Aeronaut. Sci. Eng. 2020, 11, 738–745. [Google Scholar]

- Dang, W. Study on the Tribological Properties of PTFE Sealing Materials Filled with Wollastonite Fibers. Shenyang Univ. Technol. 2025. [Google Scholar] [CrossRef]

- Yang, D.; Dong, Y.; Gong, J. The Tribological Behaviors of PEEK Filled PTFE Composites. Lubr. Eng. 2013, 38, 60–63. [Google Scholar]

- ISO 6601:2002; International Organization for Standardization. Plastics—Friction and Wear by Sliding—Identification of Test Parameters. ISO: Geneva, Switzerland, 2002.

- Flitney, B. Alternatives to chrome for hydraulic actuators. Feature 2007, 10, 8–12. [Google Scholar] [CrossRef]

- SAE International. Plating, Chromium Hard Deposit: AMS2406P, 2020. Available online: https://saemobilus.sae.org/standards/ams2406p-plating-chromium-hard-deposit (accessed on 16 October 2025).

- ISO 7986:1997; International Organization for Standardization. Hydraulic Fluid Power—Sealing Devices—Standard Test Methods to Assess the Performance of Seals Used in Oil Hydraulic Reciprocating Applications. ISO: Geneva, Switzerland, 1997.

- ISO 25178-2:2021; International Organization for Standardization. Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2021.

- ISO 25178-604:2025; International Organization for Standardization. Geometrical Product Specifications (GPS)—Surface Texture: Areal Part 604: Design and Characteristics of Non-Contact (Coherence Scanning Interferometry) Instruments. ISO: Geneva, Switzerland, 2025.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.