Abstract

To address the technical challenges in exploring concealed high-grade iron deposits in China, this study focuses on Banded Iron Formation, BIF, which represents the largest reserves and hosts the greatest number of large-scale deposits in the country. The Gongchangling iron deposit, a typical high-grade iron deposit in the Anben region, was selected as the main study area. In situ measurements and statistical analysis of the geophysical parameters of rocks and ores were conducted, with an emphasis on evaluating their sensitivity to high-grade magnetite mineralization. Based on this analysis, an integrated gravity, magnetic, and electrical survey method was identified as the optimal exploration approach. Building on this foundation, high-precision gravity and magnetic surveys were performed to investigate the geophysical anomaly response mechanisms of the Gongchangling-type high-grade ores. Forward and inverse modeling were applied to identify deep-seated concealed iron ore bodies, with results further validated by audio-frequency magnetotellurics. This study enhances the methodological framework for mineral exploration, improves prospecting efficiency, and provides practical insights to support new breakthroughs in exploration initiatives.

1. Introduction

With the continuous development of society and ongoing advancements in science and technology, the significance of mineral resources has become increasingly pronounced. As a key player in the global steel industry, China is recognized as the world’s largest producer of pig iron and crude steel. Correspondingly, it also holds the position of being the largest importer and consumer of iron ore globally, with its iron ore imports ranking first worldwide [1]. However, China’s excessive reliance on foreign iron ore resources has placed its steel industry in a passive position. This dependency has rendered iron ore one of the most critically scarce strategic bulk mineral resources within the country [2]. Although China possesses substantial iron ore reserves—estimated at approximately 85 billion tons—over 97% of these reserves are classified as low-grade ores, exhibiting an average iron content of only about 33% [3]. Consequently, this situation leads to poor ore-forming characteristics and significant processing challenges for domestic iron ore resources in China. In light of this, addressing the developmental bottleneck posed by China’s challenges in achieving self-sufficiency in iron ore necessitates a focused approach. Consequently, targeted research and predictive modeling for high-grade iron ore deposits have emerged as critical avenues for facilitating breakthroughs in iron ore exploration.

Regarding iron deposit types, the main categories of high-grade iron deposits in China comprise sedimentary–metamorphic, skarn, volcanic–rock, and magmatic types [4]. Among these, sedimentary–metamorphic iron deposits in China possess the largest reserves and the greatest number of large-scale deposits. This distribution is consistent with global patterns of iron ore reserve types. However, a key distinction exists: internationally, high-grade sedimentary–metamorphic ores are predominantly rich hematite. In contrast, most sedimentary–metamorphic ores in China are low-grade, with high-grade ores representing only a minor proportion [5]. Therefore, effectively utilizing these sedimentary–metamorphic resources and exploring their potential for high-grade ore discovery is crucial for enhancing China’s iron ore resource base.

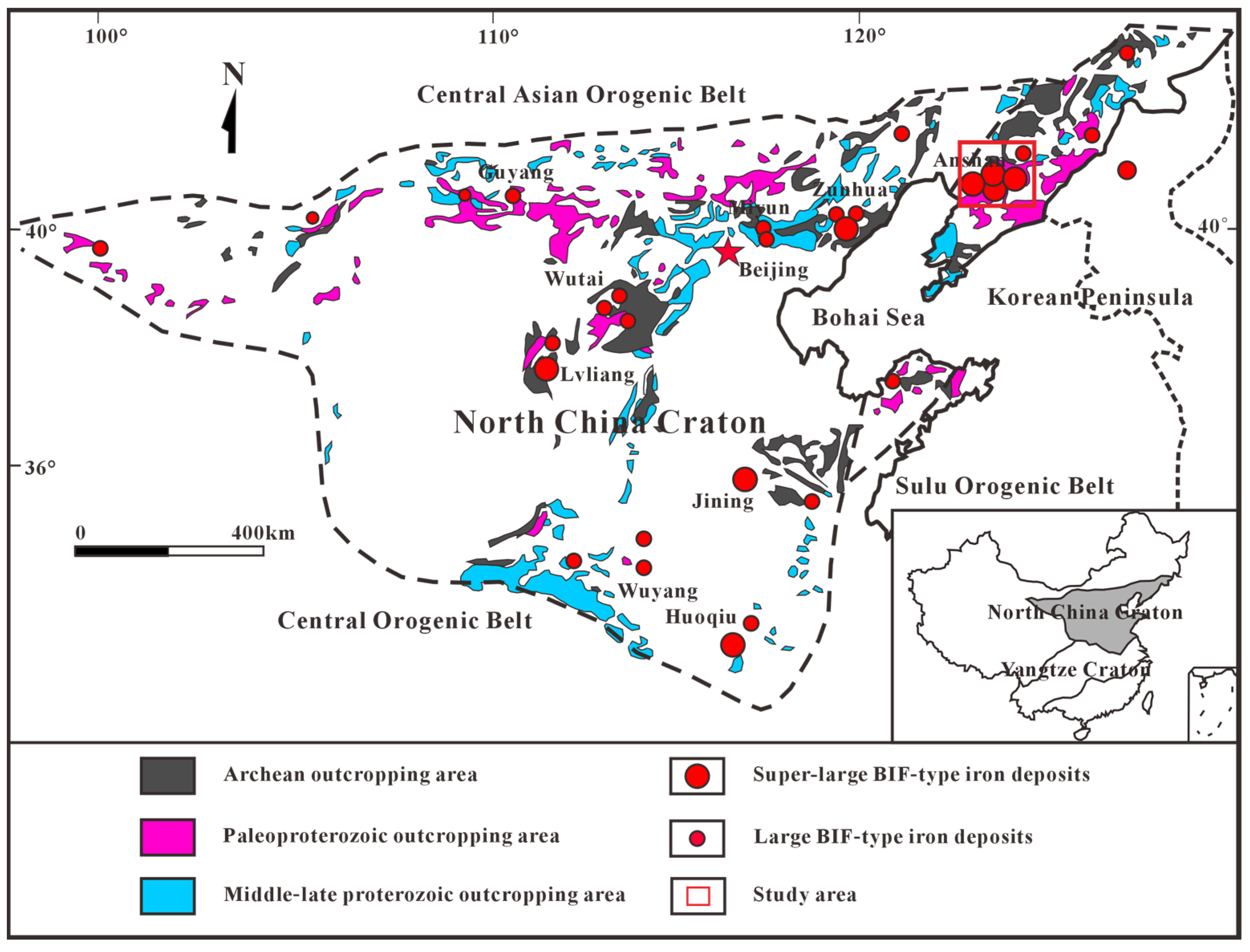

Sedimentary–metamorphic iron deposits, primarily represented by Banded Iron Formations (BIFs), constitute the most significant iron ore type in China, accounting for approximately 57.7% of the nation’s total iron ore resources. These deposits were mainly formed through the metamorphism of Precambrian BIF. They are predominantly distributed along the northern margin of the North China Craton and its basement uplift zones [6]. This distribution has led to the formation of several major iron ore clusters, including the Anshan–Benxi area in Liaoning, eastern Hebei, Lüliang in Shanxi, western Shandong, Wuyang in Henan, and Huoqiu in Anhui. Among these, the Anshan–Benxi region stands as the largest iron ore cluster in China, containing approximately 24% of the nation’s total iron ore reserves. The BIF in this region is primarily distributed across several key areas, including Anshan, Gongchangling, Waitoushan–Beitai, Nanfen, and Dataigou [7]. Although BIF iron deposits are widely distributed, known high-grade ores of this type remain limited in total volume. Most known high-grade BIF deposits are small in scale, with the mining area II of the Gongchangling iron deposit being a rare large-scale example, representative of the Gongchangling-type high-grade ore [8]. Previous studies have examined its geological features and genesis. However, the extreme complexity of mineralization and ore-forming processes has resulted in high-grade ores being hosted within low-grade BIFs. Prolonged mining has further altered orebody geometry and reserve estimates, constraining further exploitation and sustainable development. Consequently, developing effective exploration methods for deep-seated high-grade ores is urgently required.

Therefore, this study focuses on the mining area II of the Gongchangling iron deposit. Systematic measurements of density, magnetic susceptibility, resistivity, and chargeability were performed. Sensitive physical parameters for high-grade ore bodies were identified through multivariate statistical analysis, and the corresponding geophysical anomaly responses were investigated. An optimized geophysical method combination was subsequently proposed for exploring concealed high-grade ores. This work provides theoretical and technical support for identifying deep-seated, high-grade ore bodies in sedimentary–metamorphic iron deposits.

2. Geological and Geophysical Characteristics of Gongchangling High-Grade Magnetite Deposit

2.1. Geological Characteristics of Mineralization

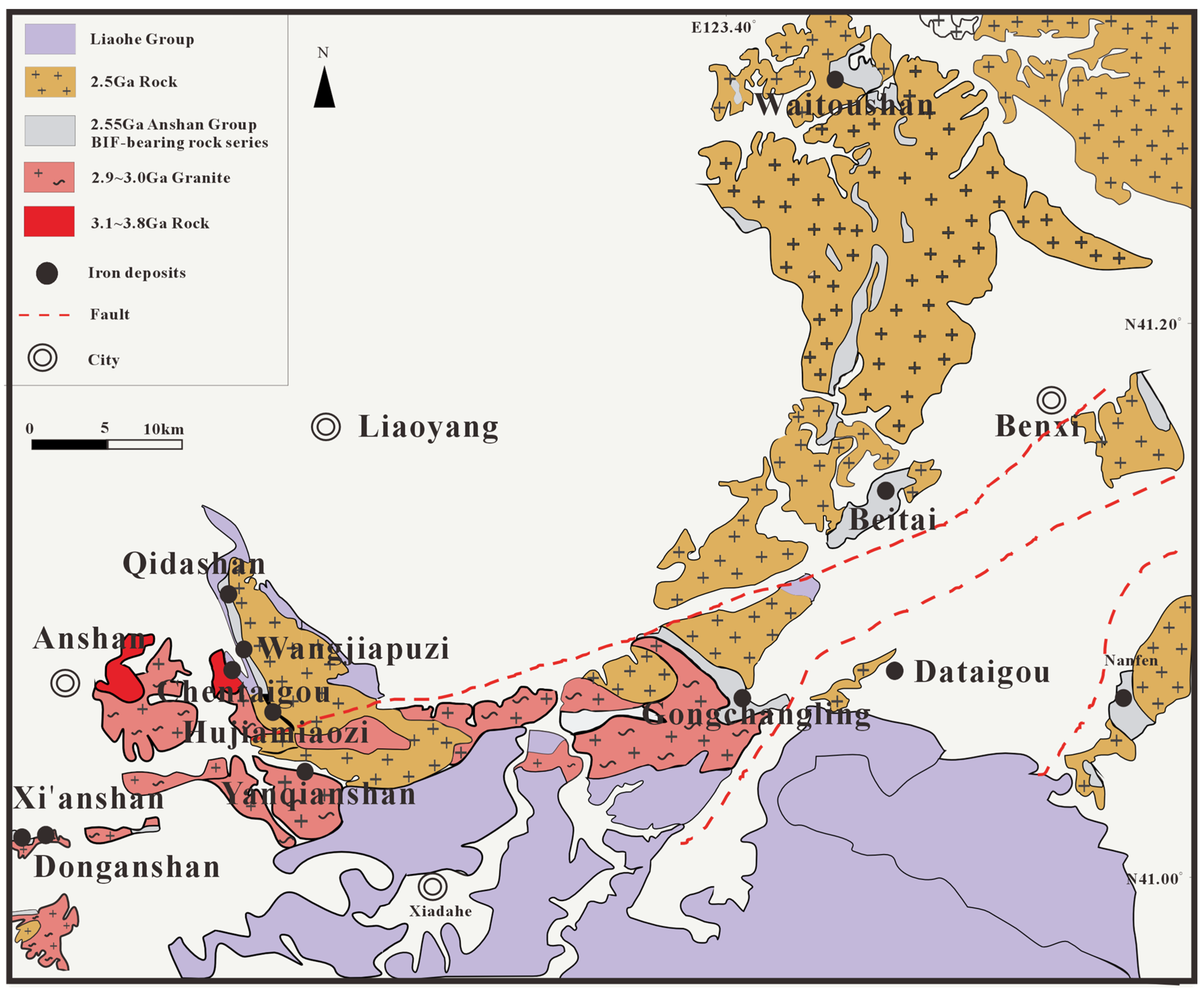

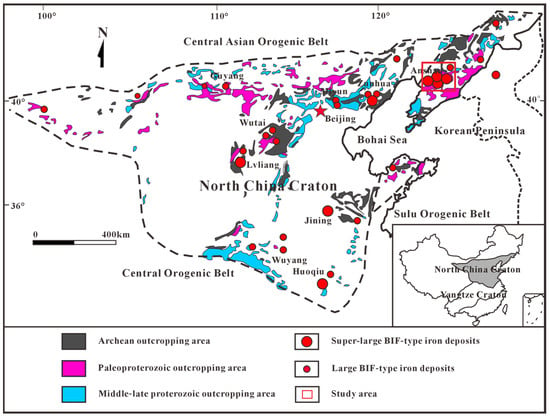

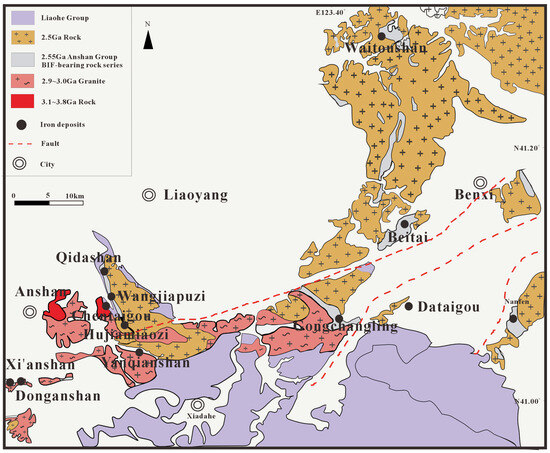

The Anben region is situated in the Liaodong area along the northeastern margin of the North China Craton (Figure 1). Tectonically, it lies within the western part of the Liaodong Anticline on the North China Platform, spanning the southwestern edge of the Tieling–Jingyu Uplift, the western extremity of the Taizihe Depression, and the northwestern section of the Yingkou–Kuandian Uplift [9]. The region exhibits a dual-layer structure comprising an Archean crystalline basement and a Neoproterozoic–Palaeozoic sedimentary cover. The Archean granite–greenstone terrane serves as the sedimentary basement of the area, while the sedimentary cover consists of Late Proterozoic to Mesozoic strata developed within fault-depressed basins of the basement. The Archean geological units in the region generally trend east–west. The northern part is dominated by an Archean oval structural domain composed mainly of tonalite–trondhjemite–granodiorite (TTG) and biotite granite, whereas the southern part belongs to the early Paleoproterozoic Liaoji Paleoproterozoic Orogenic Belt. The Anshan Group, as supracrustal rocks, occurs as enclaves within extensive Late Archean granites [10]. Fault structures are well developed within the region and can be categorized into four principal groups based on their strikes: EW-trending, NE-trending, NNE-trending, and NW-trending. Among these, the NNE-trending Tanlu Fault, the NE-trending Hanling–Pianling Fault, and the NW-trending Shiqiaozi Fault are considered to have played significant roles in controlling the stratigraphic distribution, magmatic activities, volcanic eruptions across different geological periods in the Anben region, and are particularly crucial for the exploration of BIF-type iron deposits [11]. Magnatic rocks in the region mainly include Pre-Sinian ultramafic and mafic rocks, as well as Yanshanian intermediate-acid intrusive rocks. Currently, proven sedimentary–metamorphic banded iron deposits in the Anben area include extra-large, large, and medium-to-small sized deposits such as East Anshan, West Anshan, Yanqianshan, Gongchangling, Waitoushan, Nanfen, Qidashan, Beitai, and Dagushan (Figure 2).

Figure 1.

A geological map showing the distribution of Precambrian BIF-type iron deposits in the North China Craton (modified from Jia et al., 2026) [12].

Figure 2.

A geological map showing the distribution of BIF-related high-grade magnetite deposits in the Anshan–Benxi area, Liaoning Province, China (modified from Li et al., 2015) [13].

The Gongchangling iron deposit is situated in the central-eastern Anshan Uplift of the Anben region and is a typical BIF-type deposit. The mining field is bounded by the Hanling Fault to the northwest and the Bianling Fault to the southwest [14]. It consists of four mining districts: the mining area I, II, and III of the Gongchangling iron deposit, and the Laoling–Bapanling area. The mining area II, located in the northwestern section, is large in scale, with well-exposed strata containing both low-grade and high-grade magnetite ores.

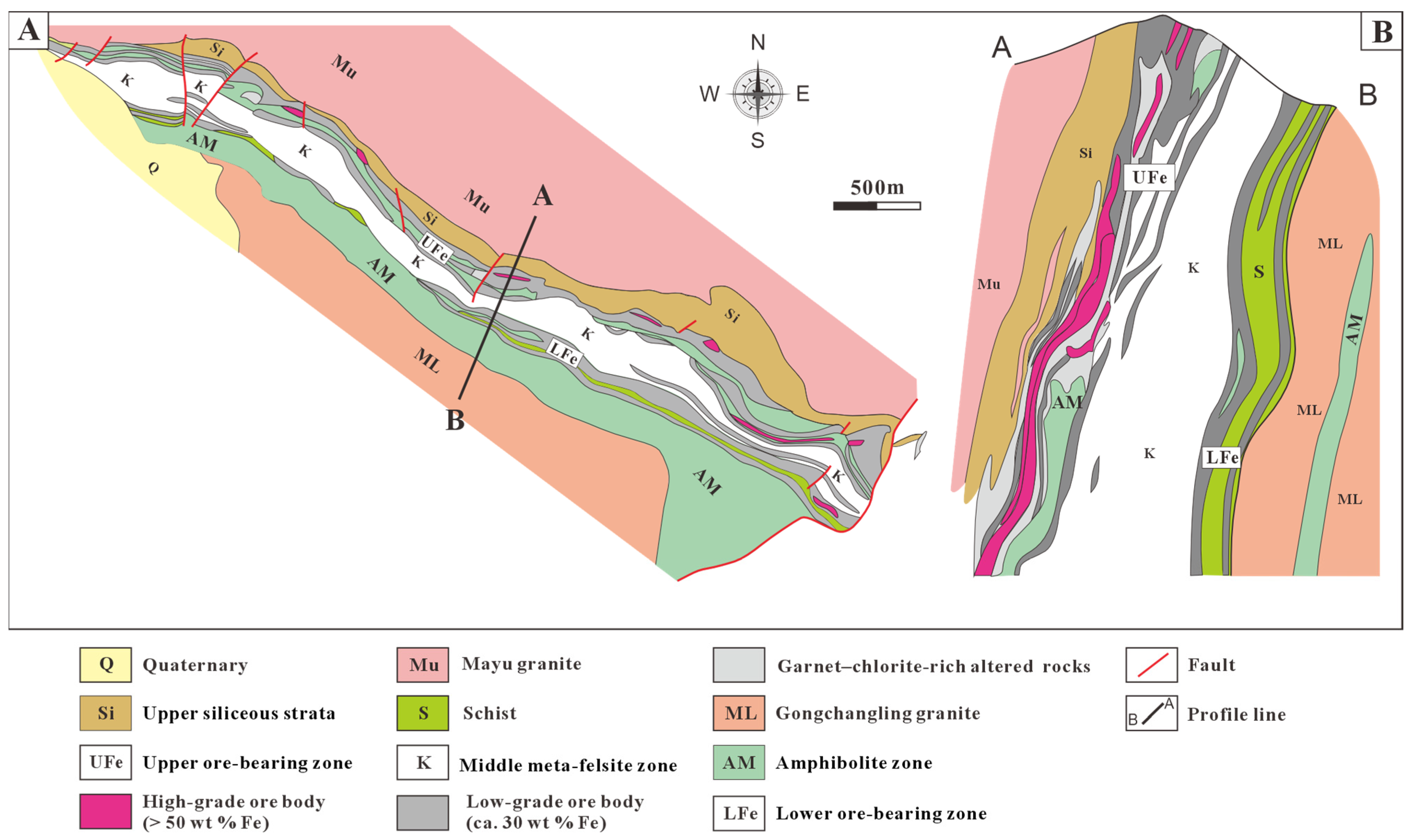

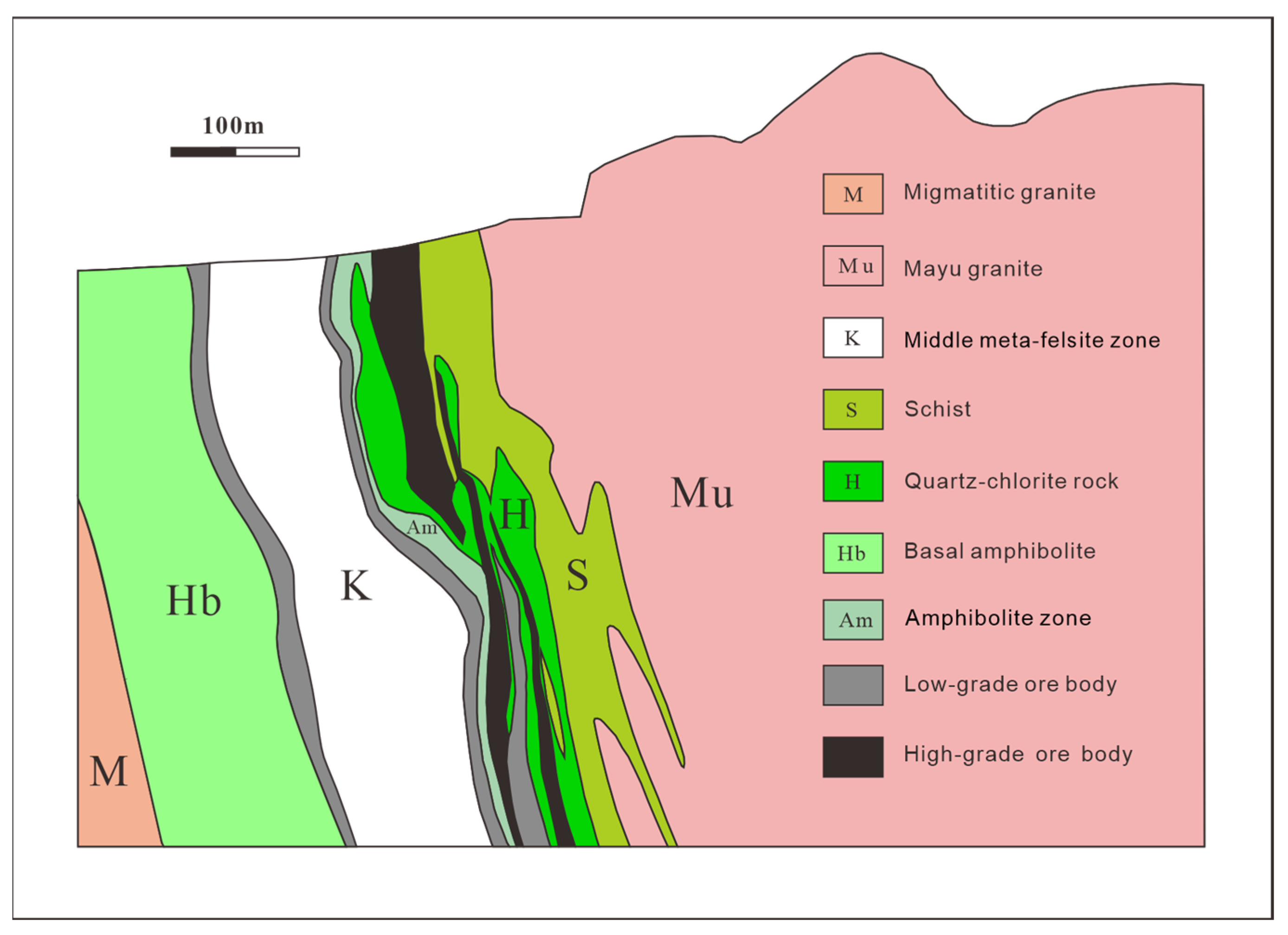

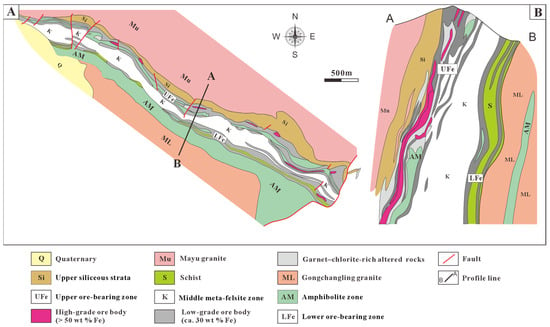

The mining area II of the Gongchangling iron deposit primarily exposes the Archean Anshan Group’s Cigou Formation, with local outcrops of Ordovician and Quaternary strata (Figure 3). It is situated between the Hanling Fault and the Laoling Fault. The iron-bearing rock series occurs as single-layered remnants surrounded by extensive migmatite. The strata strike NW 20–60°, dip NE, with dips ranging from 60° to 90°. It extends over 4800 m in length and varies from 100 to 700 m in width [15]. The Anshan Group’s Cigou Formation, which hosts the BIF iron ore, consists of a metamorphosed volcanic-sedimentary sequence. From the base upward, it is divided into six units [16]:

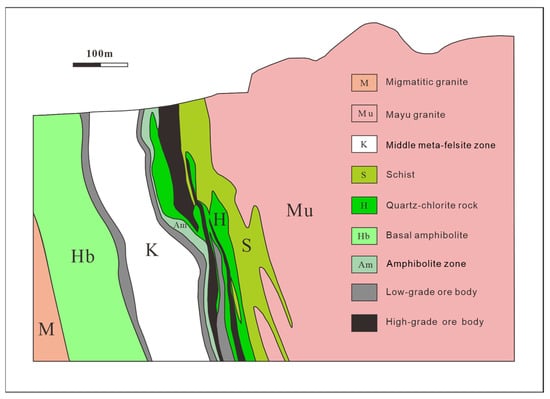

Figure 3.

A geologic map ((A) modified from Zhou, 1994 [17]) and profile ((B) modified from Li et al., 1983 [18]) of the Gongchangling iron deposit, showing the distribution of high-grade magnetite ore bodies.

- Hornblendic rock formation (Hb): Composed mainly of plagioclase amphibolite, accompanied by biotite amphibolite, chlorite amphibolite, quartz amphibolite, and quartz–chlorite amphibolite. Thin magnetite quartzite layers are locally intercalated. The unit thickens from northwest to southeast, with a total thickness ranging from 20 to 385 m.

- Schist bed below the first iron ore bed (Sch1): Consists of chlorite–mica schist, quartz–mica schist, mica–chlorite schist, chlorite schist, and quartz–chlorite schist, with a thickness of 0–40 m. The schist often contains biotite or chlorite and is occasionally interlayered with thin talc schist or magnetite quartzite.

- Lower iron-bearing zone: Comprises two iron ore layers (Fe1, Fe2) intercalated with intermediate schist composed of albite amphibolite, chlorite–mica schist, and chlorite–amphibole schist. Thickness varies from 0 to 88 m due to structural discontinuities or original sedimentary breaks.

- Middle marker zone (K): This layer is laterally continuous across the area and serves as a marker bed separating the upper and lower iron-bearing zones. It is dominated by biotite leptynite and occasionally contains thin magnetite quartzite layers (0–20 m thick), corresponding to the third iron ore layer (Fe3).

- Lower siliceous rocks (Su): Contains two plagioclase amphibolite layers (AM) and three iron ore layers (Fe4, Fe5, Fe6). This zone is the main host for high-grade magnetite ore.

- Upper siliceous rocks (Su): Located at the top of the upper iron-bearing zone, this unit exhibits significant lithofacies variation. It is primarily composed of quartzite and quartz schist, often interbedded with mica–quartz schist, mica schist, tremolite quartzite, actinolite quartzite, talc schist, and chlorite schist. Thin iron ore and high-grade ore layers are locally present.

A total of 138 high-grade iron ore bodies have been identified in the mining area [19]. They are primarily hosted in the sixth iron layer (Fe6), accounting for 77.1% of the total high-grade reserves, followed by the siliceous rock layer (S) at 13.5%. The remaining layers each contribute less than 6.5%. The high-grade ore averages 70% TFe and typically occurs as stratiform, stratoid, or vein-like bodies within or adjacent to banded magnetite quartzite, with an attitude generally conformable to the host rocks.

Altered wall rocks are widely developed in the mining area II of the Gongchangling iron deposit and show close spatial association with high-grade ores. These wall rocks, occurring as lenses or bands, consist mainly of amphibolite, amphibole schist, chlorite–amphibole rocks, plagioclase amphibolite, biotite leptynite, and siliceous rocks. They are typically located at the roof, floor, interior, or structural gaps of the high-grade ore bodies, exhibiting sharp contacts and variable thicknesses from meters to tens of meters [20]. This spatial relationship indicates significant hydrothermal modification, suggesting that the high-grade ores were formed from low-grade iron formations through desilicification and iron enrichment.

2.2. Geophysical Characteristics

Given that magnetite is the dominant ore mineral in the Gongchangling iron deposit, reduction-to-the-pole aeromagnetic data reveal a prominent high-amplitude positive magnetic anomaly over the deposit cluster. Specifically, the mining area II of the Gongchangling iron deposit exhibits a NW-striking, band-shaped anomaly that closely corresponds to the distribution of the ore bodies. The anomaly intensity here is exceptionally high, exceeding 10,000 nT. In contrast, anomalies in other sectors of the deposit are mostly near-elliptical, with intensities on the order of several thousand nanotesla.

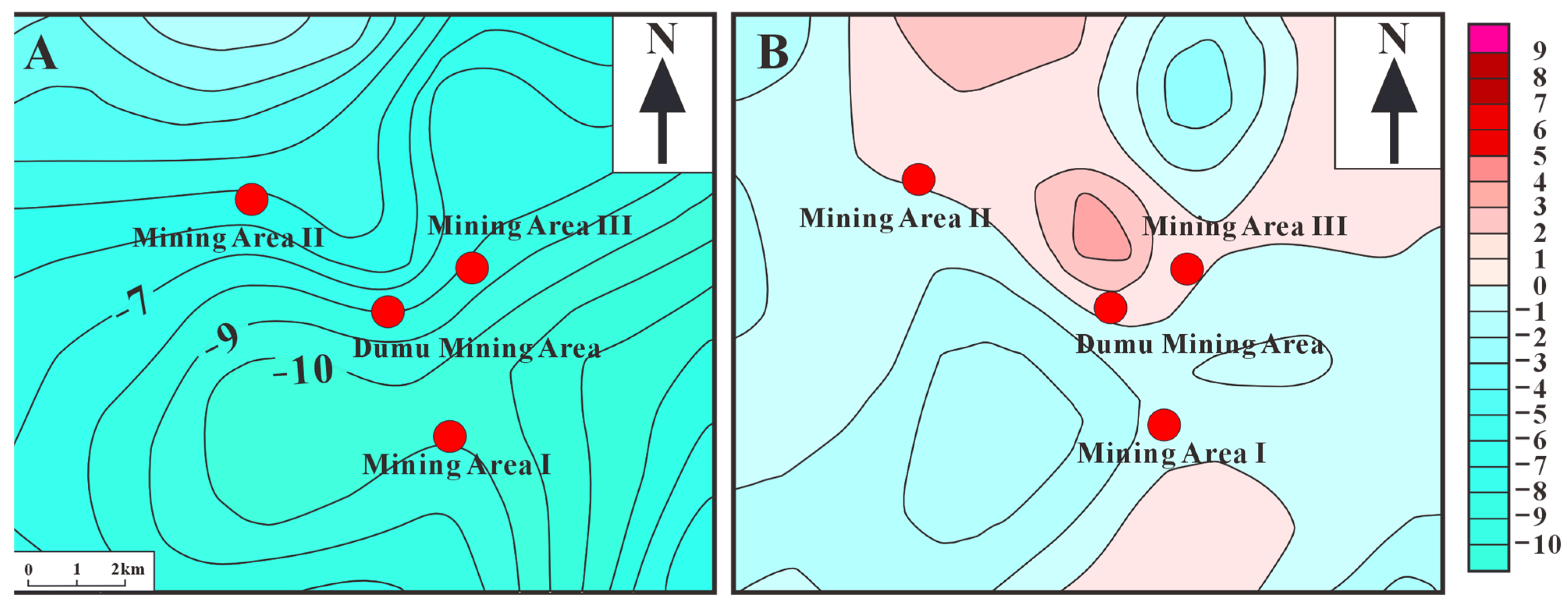

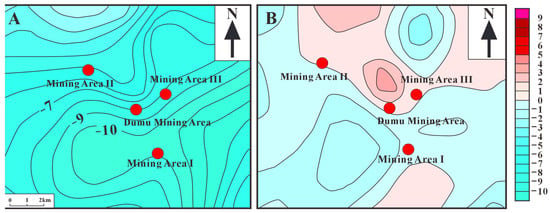

In terms of gravity anomalies, according to 1:200,000 aerogravity survey results, the Gongchangling iron deposit is located within a regional negative Bouguer gravity anomaly (Figure 4). However, it corresponds to a local NW-trending high-residual-gravity anomaly. A local NW-striking gravity high is observed within the mining area, appearing as a nose-like protrusion on a NE-trending gravity gradient zone, causing deflection of the contours with an anomaly amplitude of approximately 3 mGal. Nevertheless, due to the relatively small scale of the aerogravity data, it is difficult to effectively delineate medium and small-sized ore bodies within the area [21].

Figure 4.

Schematic diagram of Bouguer gravity contour in Gongchangling area [22] (modified from Cui, 2014): (A) Bouguer gravity anomaly map; (B) residual gravity anomaly map.

3. Physical Property Characteristics of the Gongchangling-Type High-Grade Iron Ores

The physical properties of rocks are a key focus in geophysical exploration. Differences in physical properties among various rock types form the basis for geophysical field variations and are crucial for identifying geophysical anomalies. To better investigate the physical characteristics of the rocks and ores in the Gongchangling iron deposit, in situ physical property measurements were conducted on the subsurface rocks and ores from the mining area II of the Gongchangling iron deposit. In situ physical property measurements were conducted at nine crosscuts within the +38 m, +26 m, −10 m, and −70 m levels of the northwestern mining area. A total of 890 rock and ore samples were collected, including high-grade and low-grade magnetite ores, as well as altered wall rocks closely associated with the high-grade mineralization, such as plagioclase amphibolite, quartz–chlorite rock, chlorite schist, and granitic migmatite. To analyze the physical property characteristics, density, magnetic susceptibility, resistivity, and polarizability of the samples were measured, along with their Fe content.

Sample density was measured using an electronic density meter based on the water displacement method. Magnetic susceptibility was determined directly with an MCH-1 magnetic susceptibility meter manufactured by Zhongke Dingfeng Intelligent Technology (Chongqing) Co., Ltd, Chongqing, China. Resistivity and polarizability were measured using an EDYC rock specimen electrical property tester manufactured by Zhongke Dingfeng Intelligent Technology (Chongqing) Co., Ltd, Chongqing, China. Fe content was qualitatively assessed with a handheld X-ray fluorescence (XRF) analyzer, Niton XL3T-500, manufactured by Thermo Fisher Scientific Inc. (Waltham, MA, USA), considering the sample’s geological context. The measured density, magnetic susceptibility, resistivity, and polarizability data were statistically analyzed. Based on the classification into high-grade magnetite ore, low-grade magnetite ore, and wall rock, statistical tables and distribution charts for each physical parameter were subsequently generated.

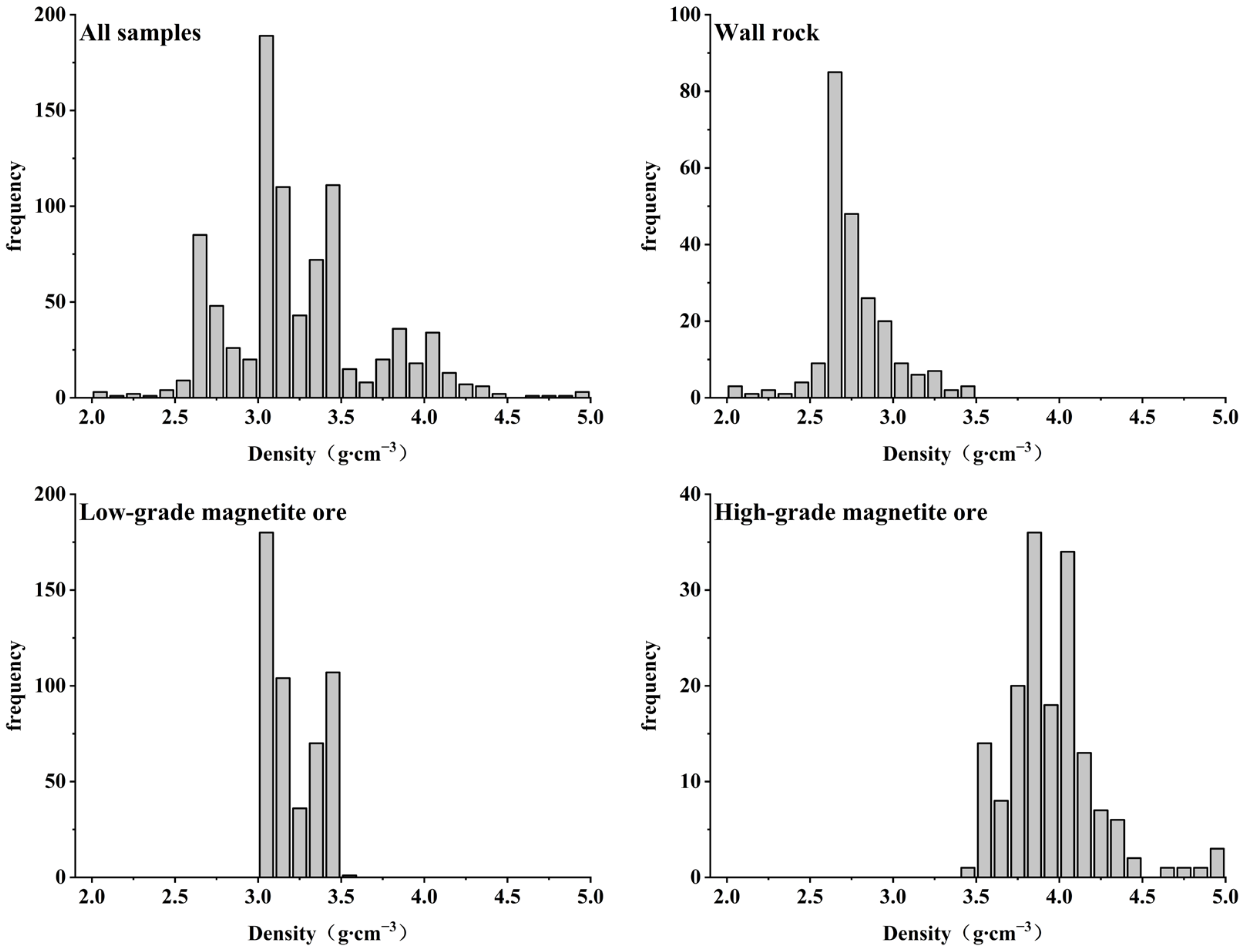

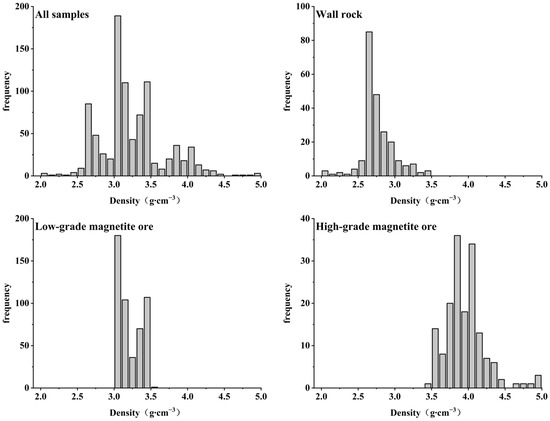

3.1. Statistical Results of Density

The statistical analysis of density is summarized in Table 1 and illustrated in Figure 5. Rock and ore densities range from 2.03 to 4.93 g/cm3, with most values clustering within 2.5–4.3 g/cm3. The distribution is approximately normal and shows a three-peak pattern, indicating clear differences among rock types. Wall rocks have the lowest density, averaging 2.77 g/cm3 and mainly ranging from 2.5 to 3.0 g/cm3. Low-grade ore shows moderate density, averaging 3.21 g/cm3 and concentrating between 3.0 and 3.51 g/cm3. High-grade ore has the highest density, averaging 4.15 g/cm3 and predominantly above 3.5 g/cm3. These results show that high-grade ore is significantly denser than low-grade ore and wall rocks. The clear density contrast among these units can produce detectable high-gravity anomalies at the surface.

Table 1.

Rock and ore density parameter statistical table.

Figure 5.

Rock and ore density parameter distribution map.

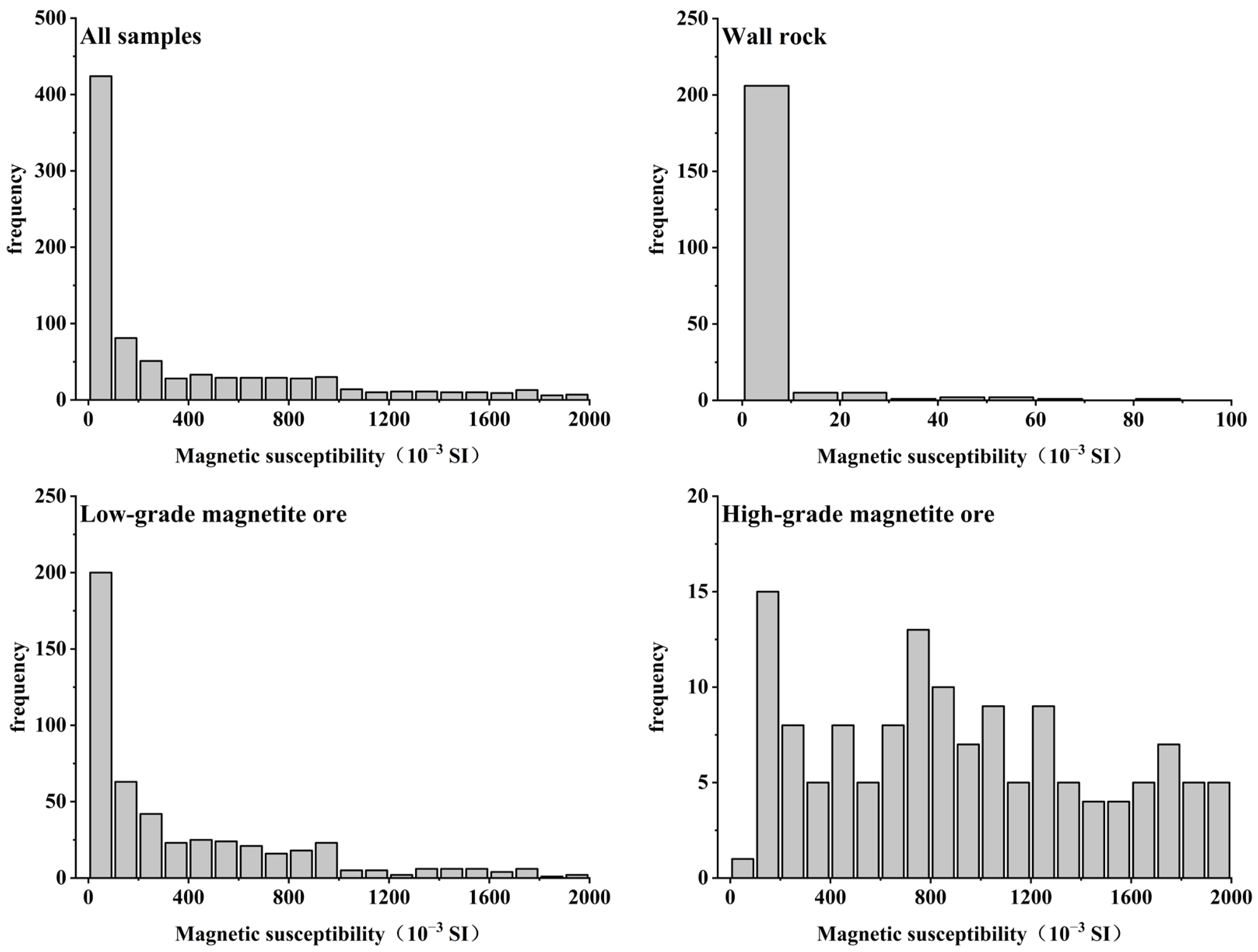

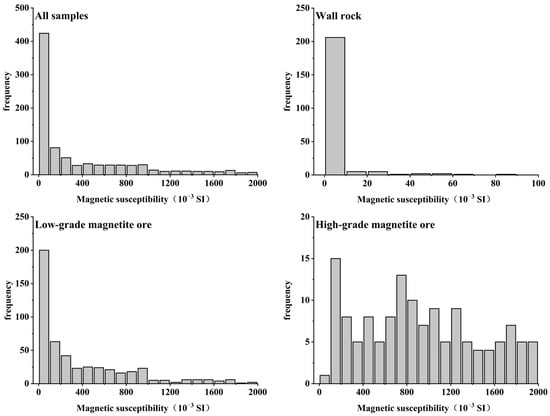

3.2. Statistical Results of Magnetic Susceptibility

The statistical analysis of magnetic susceptibility is summarized in Table 2 and illustrated in Figure 6. The measured values span a wide range from 0.18 × 10−3 to 2000 × 10−3 SI. Wall rocks near the ore are weakly magnetic to non-magnetic, averaging 7.24 × 10−3 SI. Low-grade magnetite ore exhibits moderate susceptibility (average 374.14 × 10−3 SI), mainly distributed between 100 and 1000 × 10−3 SI. High-grade ore possesses the strongest magnetism, with an average of 1101.16 × 10−3 SI and a range of 96.10 × 10−3 to 2000 × 10−3 SI. The results demonstrate a significant magnetic contrast among wall rocks, low-grade ore, and high-grade ore. This pronounced difference indicates that the high-grade ore bodies can generate strong magnetic anomalies, forming the basis for their detection via magnetic surveys.

Table 2.

Rock and ore magnetic susceptibility parameter statistical table.

Figure 6.

Rock and ore magnetic susceptibility parameter distribution map.

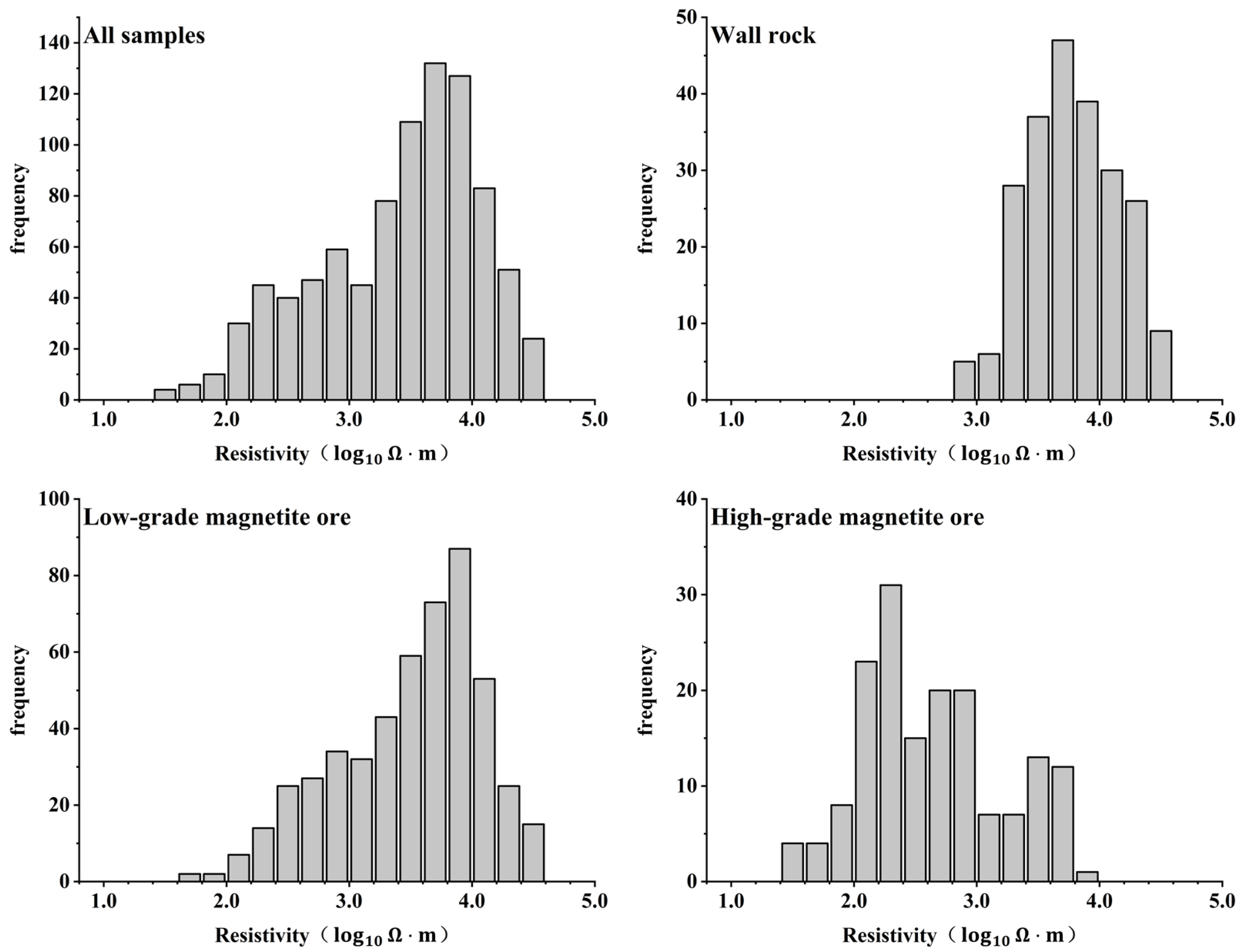

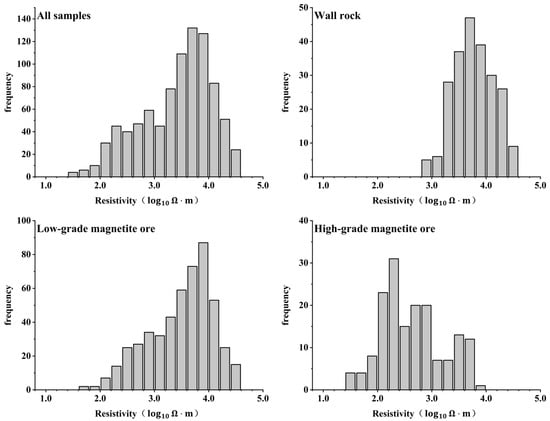

3.3. Statistical Results of Resistivity

The statistical analysis of resistivity is summarized in Table 3 and illustrated in Figure 7. The overall resistivity of the rocks and ores ranges from 34 to 67,187 Ω·m, primarily concentrated between 200 and 15,000 Ω·m. The wall rocks exhibit the highest resistivity, with an average value of 8351.42 Ω·m, mainly varying between 2000 and 25,000 Ω·m. The resistivity of low-grade magnetite ore is slightly lower, averaging 6153.00 Ω·m and distributed mostly between 500 and 20,000 Ω·m, which aligns closely with the overall distribution. In contrast, high-grade magnetite ore shows the lowest resistivity, averaging 1041.31 Ω·m and ranging predominantly from 100 to 10,000 Ω·m. The results indicate that the Fe content of the rocks and ores influences their resistivity, with a particularly significant contrast observed between high-grade magnetite ore and other rock types.

Table 3.

Rock and ore resistivity parameter statistical table.

Figure 7.

Rock and ore resistivity parameter distribution map.

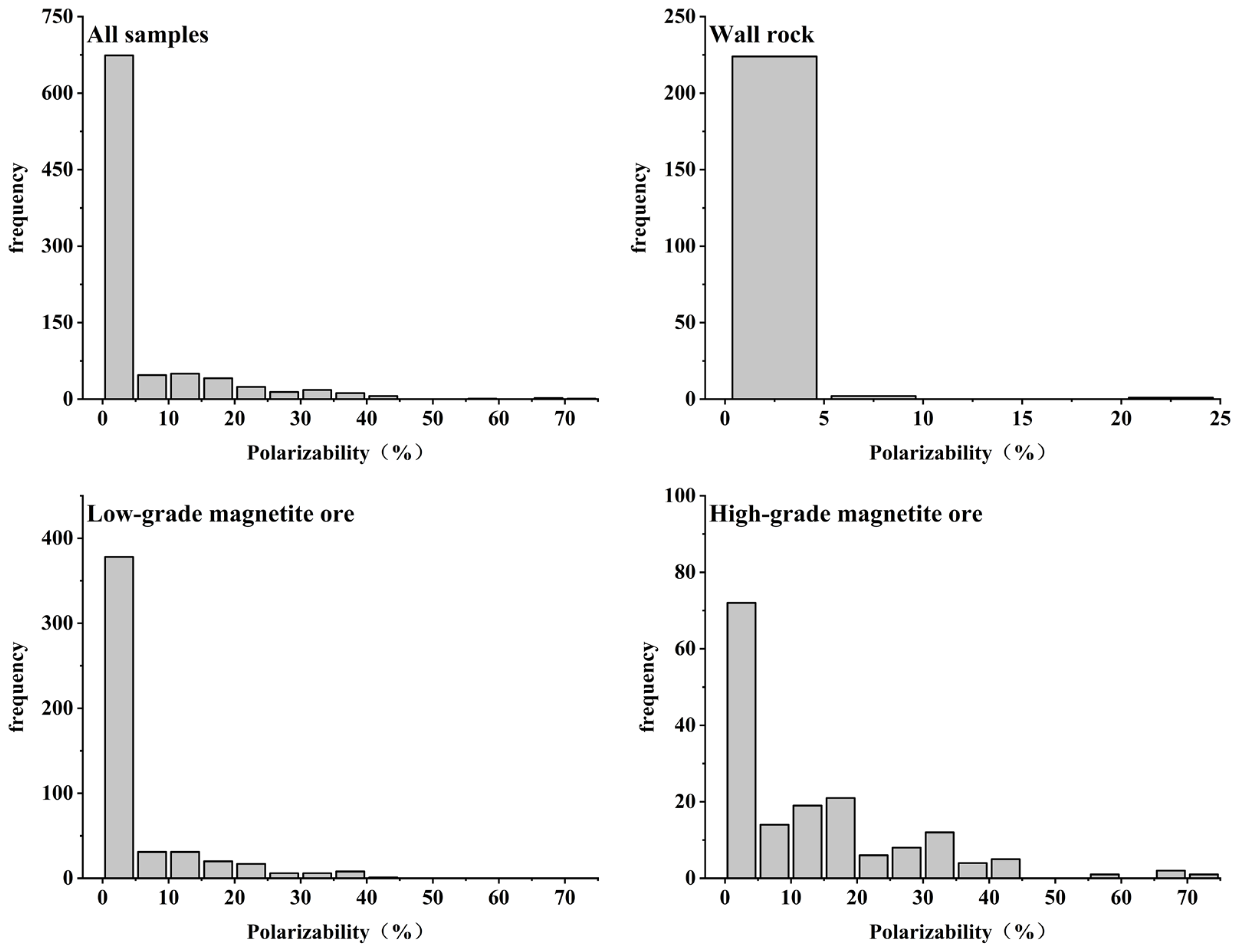

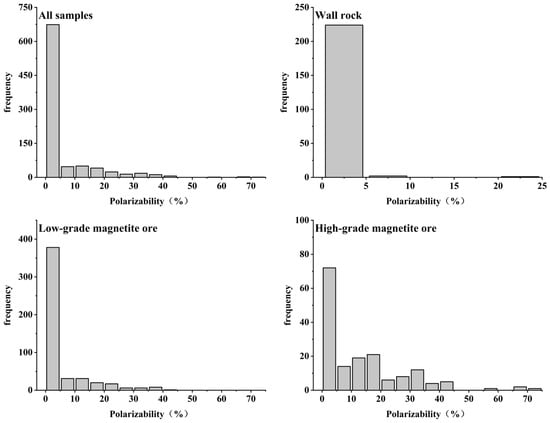

3.4. Statistical Results of Polarizability

The statistical analysis of polarizability is summarized in Table 4 and illustrated in Figure 8. The polarizability values for the rocks and ores range from 0.08% to 73.95%, with a predominant number of samples exhibiting values below 10%, indicating an overall classification of medium to low polarizability. High-grade magnetite ore demonstrates relatively elevated polarizability, with an average value of 13.23%; however, there is considerable variability among individual samples, some of which display markedly low readings. In contrast, low-grade ore presents a lower average polarizability at 5.28%, while wall rocks exhibit the lowest average at merely 2.03%. Despite observable differences in polarizability among wall rocks, low-grade ore, and high-grade ore, the extensive distribution and poor stability of polarizability values associated with high-grade ore imply that it may not serve as a reliable indicator for identifying high-grade mineralization.

Table 4.

Rock and ore polarizability parameter statistical table.

Figure 8.

Rock and ore polarizability parameter distribution map.

4. Sensitivity Analysis of Physical Properties of Gongchangling-Type High-Grade Iron Ores

To address the lack of effective integrated geophysical methods for locating and identifying deep-seated, high-grade magnetite ore bodies, a sensitivity analysis of various physical property parameters was conducted based on the completed measurements and statistics of rocks and ores from the mining area II of the Gongchangling deposit. Correlation and cluster analysis methods were employed to evaluate the sensitivity of these parameters to the Gongchangling-type high-grade mineralization. The aim is to screen for an optimal combination of geophysical exploration methods to facilitate the identification and targeting of high-grade magnetite ores.

4.1. Correlation Analysis

Correlation analysis is a statistical method that investigates the relationships among two or more random variables of equal status. It employs correlation coefficients to quantify both the degree and direction of their interdependent variation. Conducting correlation analysis on various physical property parameters can elucidate their interrelationships and reveal linear dependencies among them. In geoscientific applications, the strength of linear correlation is typically evaluated as follows: an absolute correlation coefficient |r| ≤ 0.3 indicates no linear correlation; 0.3 < |r| ≤ 0.5 suggests a weak linear correlation; 0.5 < |r| ≤ 0.8 signifies a moderate linear correlation; and |r| > 0.8 denotes a strong linear correlation [23].

Table 5 presents the results of the correlation analysis for all rock and ore samples concerning their physical property parameters. As illustrated in Table 5, combinations of parameters exhibiting a moderate positive linear correlation include magnetic susceptibility and polarizability (0.632), magnetic susceptibility and density (0.661), density and Fe content (0.616), and magnetic susceptibility and Fe content (0.702). Weak positive linear correlations are observed between polarizability and density (0.474) as well as between polarizability and Fe content (0.379). Additionally, resistivity demonstrates a moderate negative linear correlation with magnetic susceptibility (−0.644), density (−0.572), and Fe content (−0.597). A weak negative linear correlation exists between resistivity and polarizability (−0.496).

Table 5.

Correlation coefficient table of physical property parameters of all samples.

To further qualitatively assess the sensitivity of each physical property parameter in delineating high-grade ores within low-grade iron formations, a correlation analysis was conducted on the physical property parameters of the tested iron ore samples (excluding wall rock samples). The results are presented in Table 6. As indicated in Table 6, there exists a moderate positive linear correlation between density and Fe content (0.507), as well as between magnetic susceptibility and Fe content (0.562). In contrast, resistivity exhibits a moderate negative linear correlation with Fe content (−0.650).

Table 6.

Correlation coefficient table of physical property parameters of iron ore samples.

Comparing the outcomes of the two correlation analyses reveals that density, magnetic susceptibility, and resistivity all demonstrate significant correlations with Fe content across both analyses. Notably, density and magnetic susceptibility exhibit particularly strong correlations with Fe content throughout the entire sample set; conversely, resistivity shows a more pronounced correlation specifically within the iron ore samples. Based on these correlation analysis results, it can be reasonably inferred that among various physical property parameters of rocks and ores in the Gongchangling iron deposit, density and magnetic susceptibility display high sensitivity in distinguishing wall rock from ore bodies. Conversely, resistivity demonstrates superior sensitivity for further differentiating between low-grade and high-grade magnetite ores. This provides a robust foundation based on physical properties for conducting gravity, magnetic, and electrical surveys in the Gongchangling iron deposit area.

4.2. Q-Mode Cluster Analysis

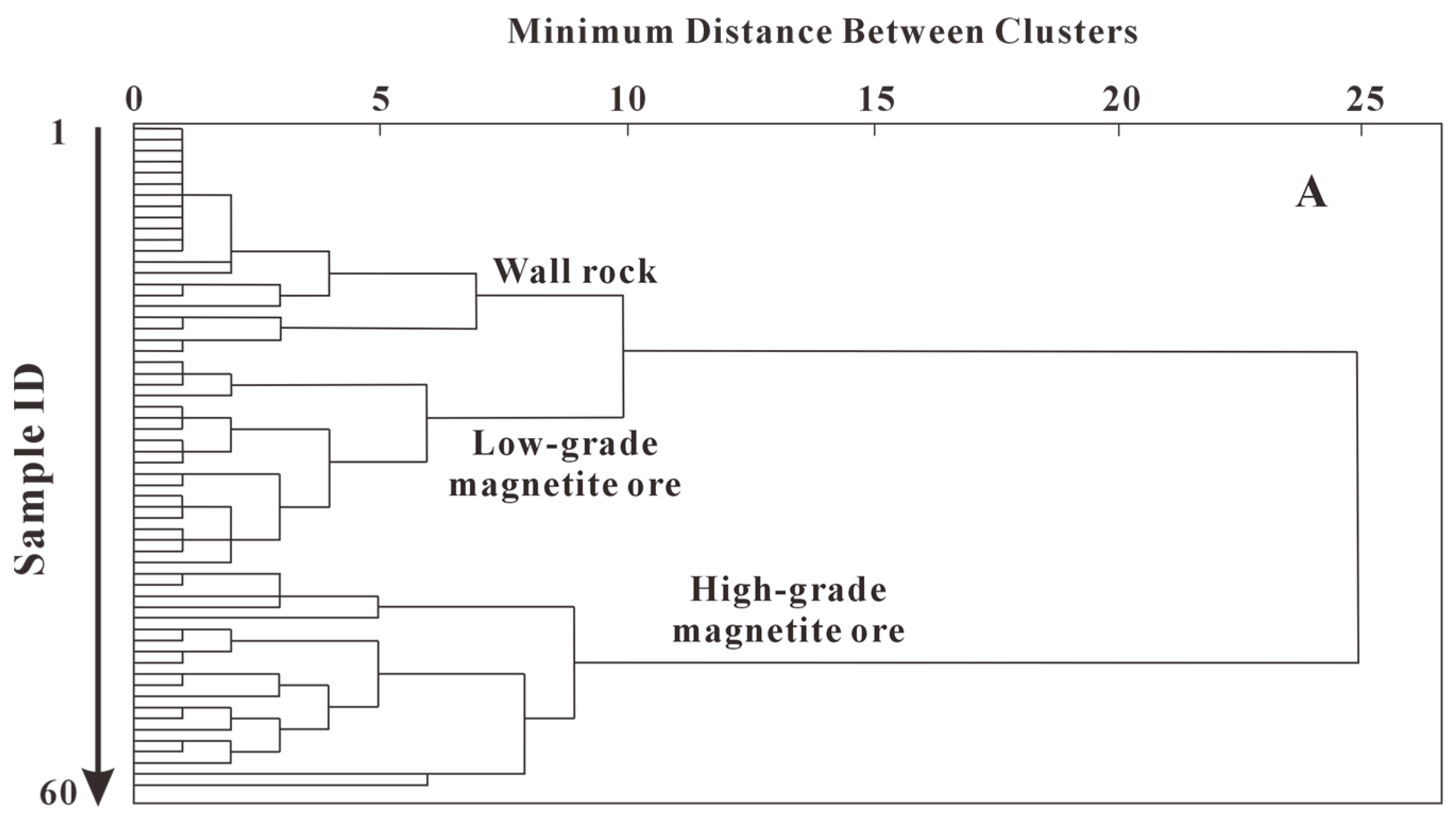

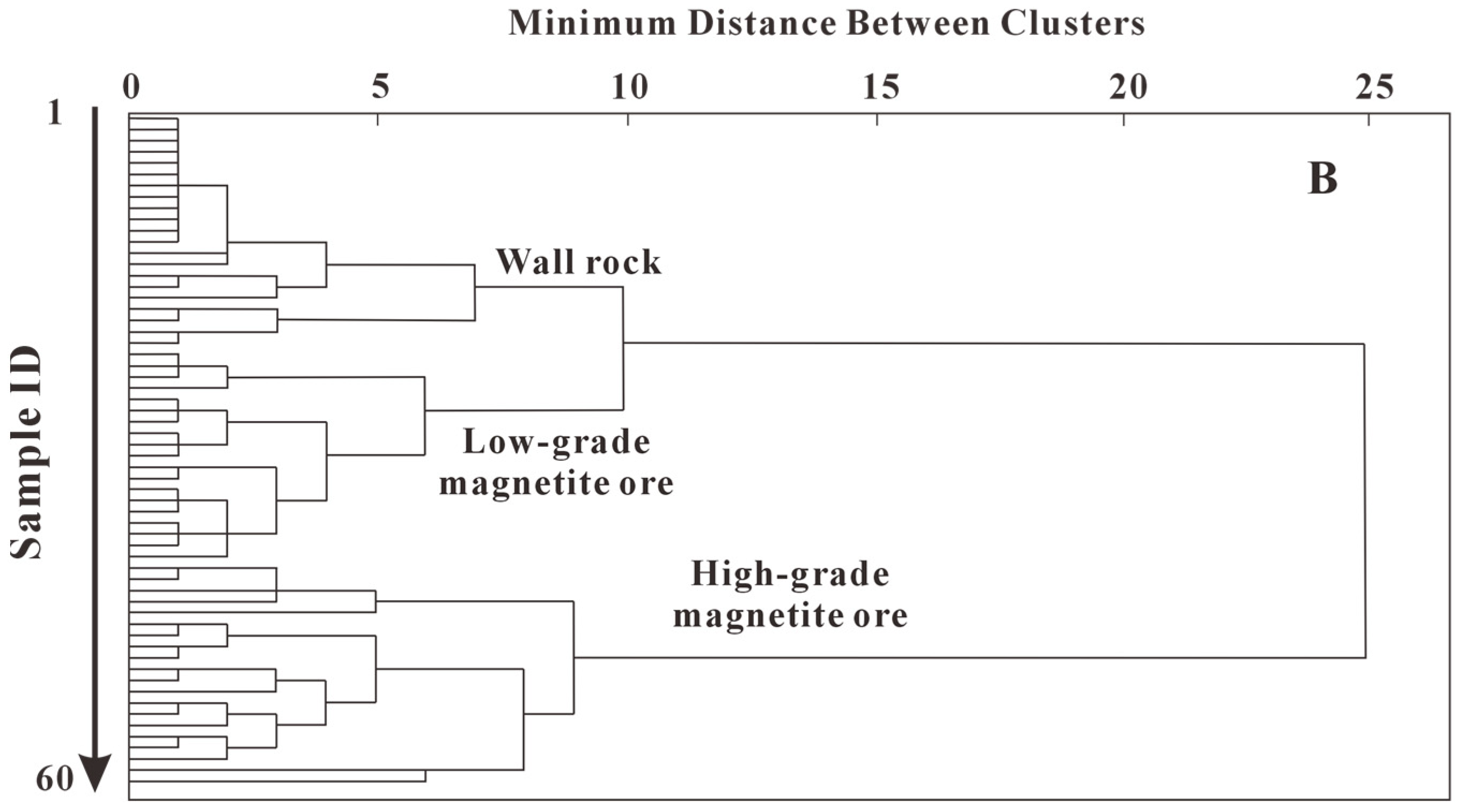

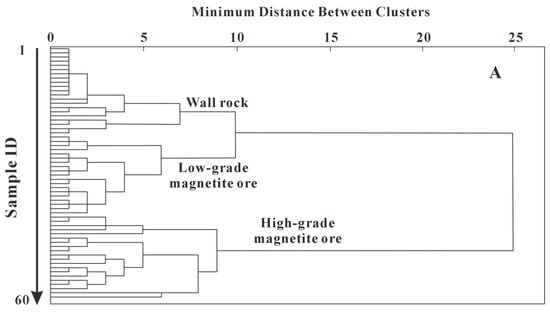

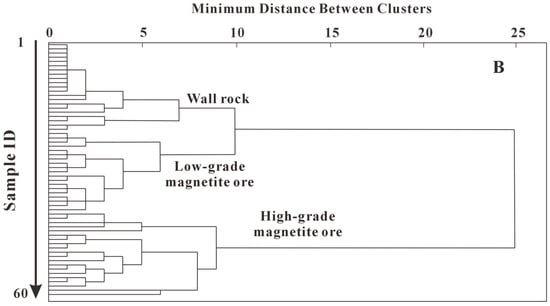

To validate the sensitivity of physical property parameters in distinguishing low-grade ore, high-grade ore, and wall rock as inferred from correlation analysis, a Q-mode cluster analysis was conducted based on the in situ measured data. Cluster analysis is a multivariate statistical method that classifies data into groups based on inherent similarities, without prior assumptions. It aims to maximize the similarity of data within the same group while ensuring discernible differences between different groups.

Due to significant differences among the rock and ore samples, stratified sampling was conducted for statistical analysis. Twenty samples each were selected from low-grade magnetite ore, high-grade magnetite ore, and wall rock, resulting in a total of 60 samples. Sample numbers 1–20 represent wall rock, 21–40 represent low-grade magnetite ore, and 41–60 represent high-grade magnetite ore. Cluster analysis was first performed based on density and magnetic susceptibility parameters. The results, shown in Figure 9A, indicate that all 20 wall rock samples were accurately classified into a distinct group. Among the iron ore samples, six were misclassified, yielding an overall classification accuracy of 90.0%. Subsequently, resistivity was included as an additional variable in the cluster analysis. The results, presented in Figure 9B, show that all 20 wall rock samples were again correctly classified. Among the iron ore samples, only 2 were misclassified, increasing the overall accuracy to 96.7%. Repeated stratified sampling and cluster analysis consistently yielded results consistent with these findings. The results of Q-mode cluster analysis indicate that density and magnetic susceptibility parameters exhibit good sensitivity in distinguishing wall rock from low-grade and high-grade magnetite ores in the Gongchangling mining area. The discrimination accuracy between low-grade and high-grade ores is further improved after incorporating resistivity parameters, which aligns with the findings from the correlation analysis.

Figure 9.

Dendrogram of Q-mode cluster analysis. (A) Dendrogram of cluster analysis based on density and magnetic susceptibility. (B) Dendrogram of cluster analysis based on density, magnetic susceptibility, and resistivity.

In summary, the sensitivity analysis of the physical properties of rocks and ores in the Gongchangling mining area demonstrates clear differences in density, magnetic susceptibility, and resistivity between ore bodies and wall rocks, as well as between high-grade and low-grade magnetite ore bodies. These parameters exhibit excellent sensitivity for detecting high-grade magnetite ores in this region. The integrated gravity, magnetic, and electrical survey method, which synthesizes these three physical properties, represents the optimal combination of geophysical exploration techniques for targeting Gongchangling-type high-grade iron deposits.

5. Methods

Based on the analysis of metallogenic geological characteristics and the sensitivity of physical property parameters of rocks and ores in the Gongchangling mining area, an integrated prospecting methodology combining gravity, magnetic, and electrical surveys was determined. This study first conducted ground high-precision gravity and magnetic surveys over selected iron deposits to delineate the spatial distribution of low-grade and high-grade ore bodies. Subsequently, within the anomalous areas, audio-frequency magnetotellurics (AMT) was employed to investigate the burial scale and morphological features of concealed high-grade magnetite ore bodies in the deep parts of the deposits. This approach also verified the forward modeling results of the ground high-precision gravity and magnetic data, enabling precise identification and localization of high-grade ore bodies within low-grade magnetite deposits. This methodology not only ensures exploration accuracy but also improves the efficiency of high-grade magnetite ore prospecting, demonstrating considerable potential.

5.1. Magnetic Survey

The magnetic survey method exploits magnetic variations among geological bodies by measuring magnetic field values to identify subsurface geological features. The ground high-precision magnetic method, known for its high resolution, is commonly employed in detailed geophysical investigations [24]. In this study, to accurately characterize the magnetic anomalies associated with iron ore bodies, a ground high-precision magnetic survey was conducted at a scale of 1:2000. Survey lines were oriented mainly perpendicular to the strike of known ore bodies, with a line spacing of 200 m and a station interval of 10 m.

The primary instrument used was the GEM-19T proton precession magnetometer manufactured by GEM Systems, Markham, ON, Canada. It has a measurement range of 20,000 to 120,000 nT, an accuracy of ±0.2 nT at a 1 s sampling rate, a resolution of 0.01 nT, and a gradient tolerance greater than 7000 nT/m. Prior to data acquisition, instrument performance was verified through noise tests, consistency tests, and sensor height tests. Base stations and check points were subsequently established. During the survey, diurnal variation was monitored at a fixed station concurrently with field measurements. Data collection followed strict operational protocols to ensure reliability and accuracy, with 10% of the readings repeated for quality control.

Data processing was carried out using GeoIPAS geoscience software version 4.7 developed by Urumqi Jinwei Graphics & Information Technology Co., Ltd, Urumqi, China. Corrections for diurnal variation, elevation, and the normal geomagnetic field were applied to remove external influences and obtain the residual ΔT anomalies. Subsequent processing included reduction-to-the-pole (RTP), analytical continuation, and derivative transformations to support the interpretation of magnetic anomalies in the study area [25].

5.2. Gravity Survey

The gravity survey method is a geophysical exploration technique based on the density contrast between the target bodies and the surrounding rocks. The ground high-precision gravity survey, a detailed and precise measurement method with high accuracy, has achieved significant results in solid mineral exploration [26]. In this study, a ground high-precision gravity survey was conducted at a scale of 1:2000, with a station spacing of 50 m. The survey lines coincided with those of the magnetic survey.

The primary instrument used was the CG-5 Autograv relative gravimeter manufactured by Scintrex Ltd., Concord, ON, Canada. It has a resolution of 0.01 g.u., a specified accuracy of 0.05 g.u., and a measurement range of 80,000 g.u. Following the gravity data acquisition protocols, static and dynamic tests of the gravimeter were performed prior to the formal survey. During the high-precision gravity data acquisition, base stations were established within the study area for observations at the beginning and end of each measurement day.

For data processing, the GeoIPAS geoscience software version 4.7. The collated gravity data underwent terrain correction, elevation correction, Bouguer slab correction, and normal gravity field correction to obtain the complete Bouguer gravity anomaly (Δg) at each measurement point.

5.3. Audio-Frequency Magnetotellurics

Audio-frequency magnetotellurics (AMT) is a geophysical detection method that involves collecting electric and magnetic fields on the ground surface to study their relationship with subsurface electrical information, thereby achieving exploration objectives. In this study, AMT survey lines were laid out based on the results of ground high-precision gravity and magnetic surveys, with a station spacing of 50 m [27]. This approach first enables the identification and delineation of deep-seated high-grade iron ore bodies and, second, provides mutual verification with the depth-derived results from gravity and magnetic data.

This research employed the EH4 Audio-frequency Magnetotelluric Sounding System, jointly produced by the American companies EMI and Geometrics, to conduct the measurements. A cross-shaped electrode configuration was used, and the observed data were processed in full-frequency domain tensor mode. The fundamental parameters of AMT observation are the time series of orthogonal electric field components (Ex, Ey) and magnetic field components (Hx, Hy). Through Fourier transformation, the time-domain electromagnetic signals are converted into spectral signals to obtain Ex, Ey, Hx, and Hy, ultimately allowing for the calculation of the Cagniard apparent resistivity [28].

For the time-series data collected by the AMT method, data preprocessing was first conducted. Subsequently, the Fast Fourier Transform (FFT) was applied to obtain the real and imaginary components and the phase data of the electric and magnetic fields. Finally, one-dimensional and two-dimensional inversions were performed using the software provided with the equipment. The results of AMT data processing provide two-dimensional resistivity profiles that can be used for geological interpretation and inference.

6. Results

Based on the geological plan map and typical cross-section of the iron deposit (Figure 3) from the mining area II of the Gongchangling deposit, the iron-bearing rock series in the area is divided into six layers from top to bottom, dipping northeast with dip angles of 60–80° [11]. Due to this stratification, the high-grade magnetite mineralization in the mining area II exhibits distinct spatial zoning. The ore bodies occur as stratiform and lenticular units hosted within the upper and lower iron-bearing zones. The lower iron zone includes the first and second iron layers, while the upper iron zone comprises the fourth, fifth, and sixth iron layers. The high-grade ore bodies are strictly controlled by the low-grade iron formations and are mainly concentrated in the sixth and fourth iron layers of the upper iron zone. Their attitude is generally consistent with that of the low-grade magnetite layers [29].

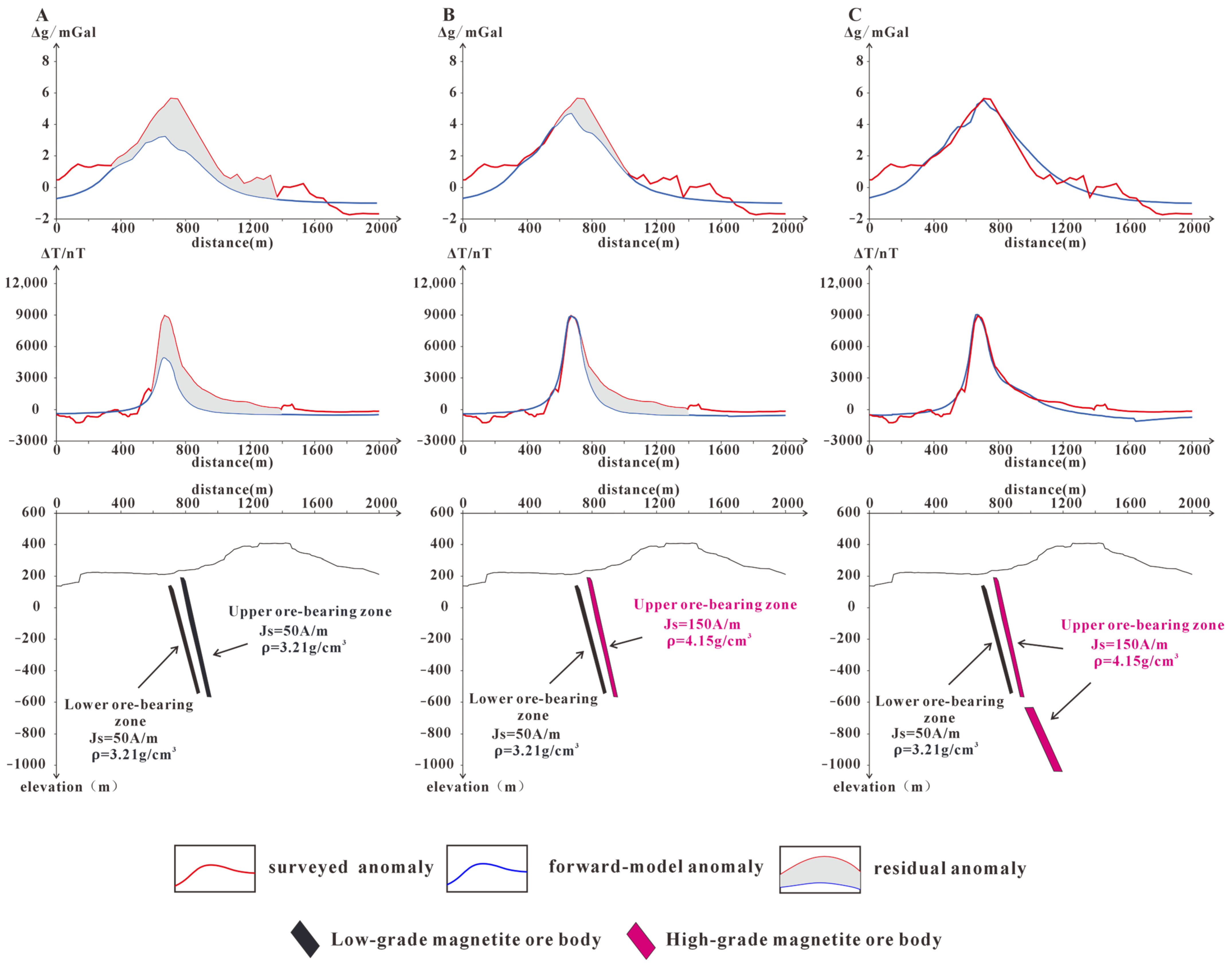

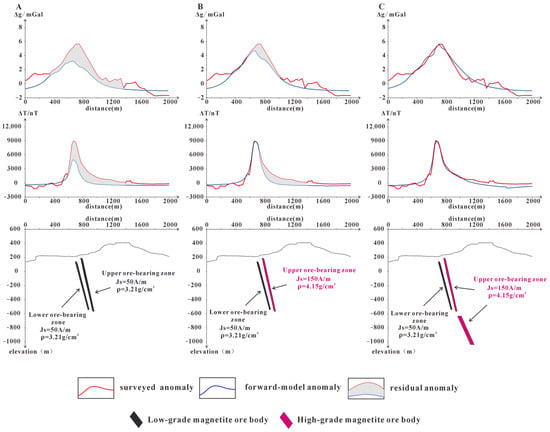

Based on the morphological characteristics of high-grade and low-grade magnetite ore bodies in the study area, this study performed 2.5D forward modeling and integrated interpretation of gravity and magnetic anomaly data acquired from ground high-precision gravity and magnetic surveys. The modeling was constrained by measured in situ physical property data and known geological information, combined with the geological characteristics of the Gongchangling mining area. According to the measurement results, GeoIPAS geoscience software version 4.7 was selected for forward modeling of gravity–magnetic profiles. Based on the in situ physical property data, the following parameters were assigned to the model bodies: low-grade magnetite ore bodies were assigned a density of 3.21 g/cm3 and a magnetization intensity of 50 A/m, while high-grade magnetite ore bodies were assigned a density of 4.15 g/cm3 and a magnetization intensity of 150 A/m; the cell size is 10 m × 10 m.

Through comparative simulation calculations of the low-grade and high-grade magnetite ore bodies, residual gravity and magnetic anomalies are derived to separate and identify the superimposed gravity and magnetic anomaly fields generated by the coexistence of low-grade and high-grade magnetite bodies. This approach enables the identification of deep-seated concealed high-grade magnetite ore bodies. Furthermore, forward modeling profiles were constructed based on the spatial distribution patterns of the low-grade and high-grade ore bodies.

High-precision gravity and magnetic survey profiles were laid out from Duimiangou to Yanjiapu in the Gongchangling area, traversing the mining area II of the Gongchangling deposit. The measured gravity and magnetic anomaly curves are shown in Figure 10. The gravity anomaly curve exhibits a shape similar to that of the magnetic anomaly curve, demonstrating the characteristic “coincident high gravity and magnetic anomalies” indicative of the Gongchangling-type high-grade magnetite ore bodies. The forward modeling results of the gravity magnetic profiles indicate that a single low-grade ore body cannot produce the measured intensity of gravity and magnetic anomalies, with both showing high residual anomaly values. When geological constraints reflecting the occurrence of high-grade ore bodies are applied, the forward modeled anomalies show good agreement with the measured anomalies, although broad and gentle residual gravity and magnetic anomalies persist on the left side of the profile. Figure 10C suggests that a thick high-grade magnetite orebody is likely hosted at depths below −600 m elevation, allowing the forward modeled anomalies to closely match the measured anomaly intensities.

Figure 10.

Calculated residual magnetic anomalies of high-grade magnetite ore in Gongchangling iron deposit. (A) Results of 2.5D forward calculation of magnetite ore bodies. (B) 2.5D forward modeling results of iron ore containing high-grade magnetite ore bodies. (C) 2.5D forward modeling results for iron ores containing deep-seated high-grade magnetite ore bodies.

Combined with the actual geological profile of the study area (Figure 11), the forward modeling-derived low-grade magnetite ore bodies show good correspondence with Fe4 and Fe5 within the upper iron-bearing zone of the mining area II of the Gongchangling deposit. The shallow high-grade magnetite ore bodies align well with Fe6 of the upper iron-bearing zone in the same mining area. The deep high-grade magnetite ore bodies are interpreted as a downward extension of the upper iron-bearing zone in the mining area II of the Gongchangling deposit, representing yet unexplored deep-seated concealed high-grade magnetite ore bodies.

Figure 11.

Geological profile along geophysical survey line.

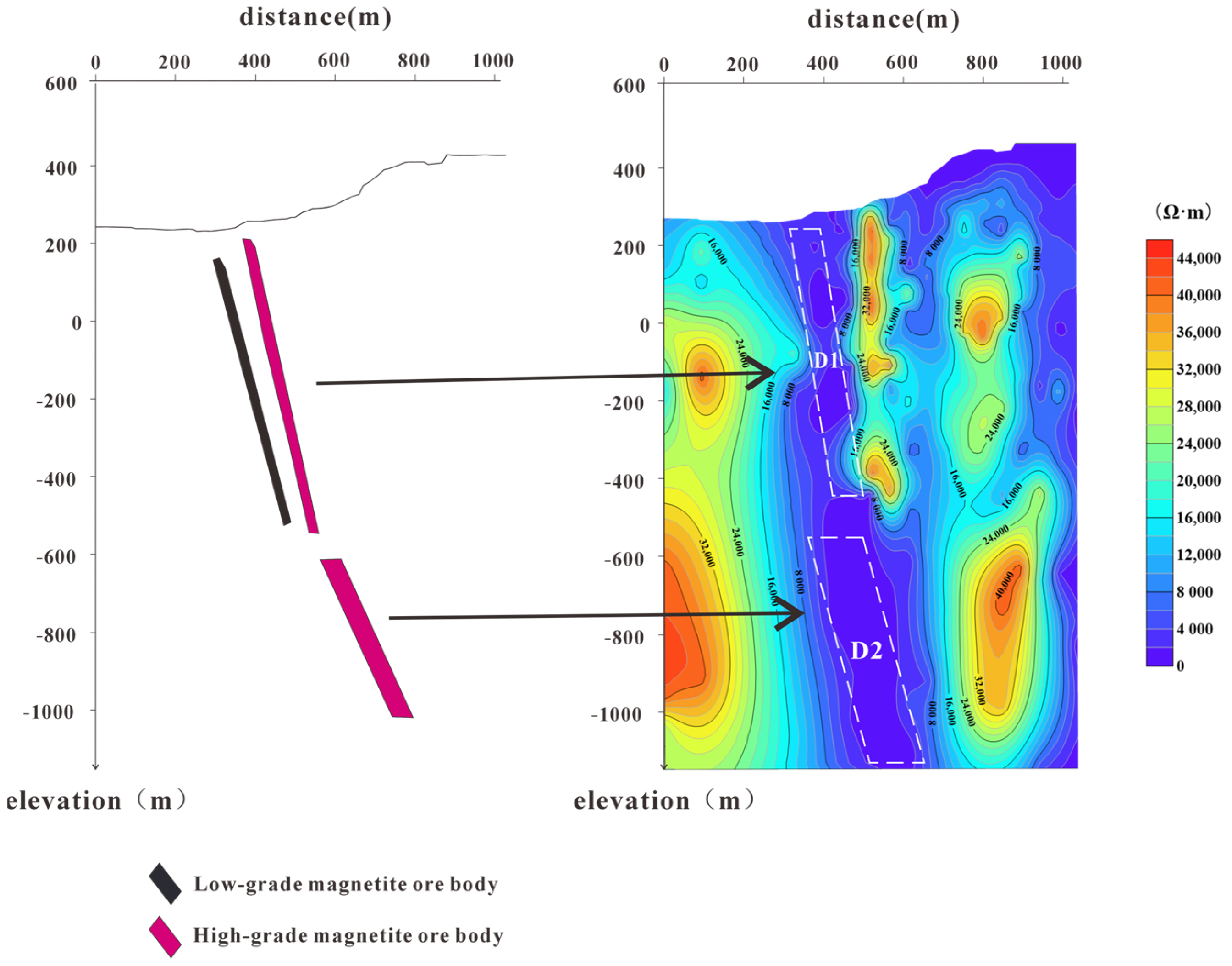

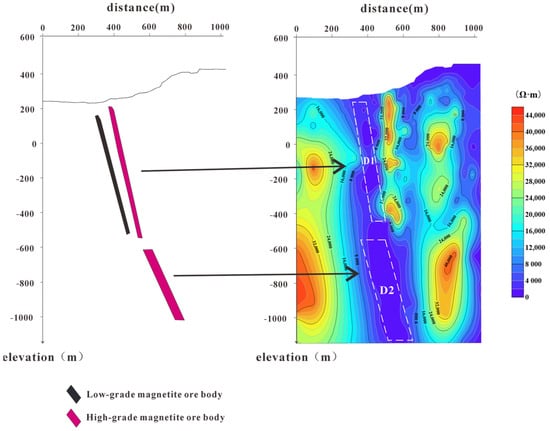

To further verify the accuracy and effectiveness of high precision gravity and magnetic methods in detecting deep-seated high grade magnetite orebodies in the Gongchangling mining area, this study conducted Audio frequency Magnetotelluric (AMT) measurements. The AMT profile, with a total length of 1000 m, was deployed within the gravity magnetic survey line. Based on the AMT resistivity section (Figure 12), low resistivity anomaly zones with resistivity less than 4000 Ω·m were delineated. Low resistivity zone D1 is located at elevations between 200 m and −500 m, while zone D2 extends from −600 m to −1000 m, and continues further downward. It is inferred that the total vertical extent of these low-resistivity bodies may exceed 1000 m, and their overall morphology broadly corresponds with the orebody geometry delineated from the gravity and magnetic forward modeling results. This demonstrates the effectiveness of the integrated approach described above for exploring deep Gongchangling type high grade magnetite ores in the mining area.

Figure 12.

Resistivity sections of AMT profile.

7. Conclusions

The North China Craton, a world-renowned region for Precambrian Banded Iron Formation (BIF)-type iron ore development, hosts numerous large to super-large iron deposits and contains high-grade magnetite ore bodies of varying scales [30]. The Gongchangling iron deposit is a typical representative of BIF-type iron deposits in the Anben area of the North China Craton. Its ore-hosting strata belong to the Neoarchean Anshan Group’s Cigou Formation. The deposit is structurally controlled by two subparallel NE to E trending faults—the Hanling Fault and the Pianling Fault—with the ore bodies extending along monoclines or multi-level fold systems. Magnetite is the dominant ore mineral, and chloritization is the predominant alteration type. The high-grade magnetite ore bodies in the Gongchangling deposit were formed through a desilicification and iron enrichment mechanism. These ore bodies largely retain the typical geological occurrence characteristics of sedimentary–metamorphic iron deposits, mainly occurring as regular veins and stratiform bodies within low-grade iron formations and exhibiting relatively large dimensions. It is noteworthy that most Precambrian BIF-type iron deposits in the North China Craton are large to super-large operating mines. Conventional geological and geophysical methods face challenges in effectively identifying and characterizing the internal high-grade magnetite ore bodies within these deposits, which constrains the efficient exploration and utilization of high-grade magnetite resources.

Based on in situ measurements of the physical properties of rocks and ores in the Gongchangling mining area, this study has comprehensively acquired parameters such as density, magnetic susceptibility, resistivity, and polarizability. Through correlation analysis and cluster analysis, we evaluated the sensitivity of these physical property parameters, confirming that an integrated approach utilizing gravity, magnetic, and electrical surveys represents the optimal geophysical exploration model for Gongchangling-type high-grade magnetite ores. This provides a robust foundation based on physical properties for subsequent investigations. Among these methodologies, the implementation of ground-based high-precision gravity and magnetic surveys significantly enhances the contrast in anomaly intensities related to gravity and magnetism. This enhancement facilitates the identification of critical geophysical anomalies associated with concealed high-grade magnetite ore bodies. Within these key anomaly zones, audio-frequency magnetotellurics (AMT) can be employed for deep detection purposes. This technique not only validates findings from gravity and magnetic surveys but also identifies resistivity anomalies linked to high-grade ore bodies. Such an approach enables effective assessment of burial depth, scale, and morphological characteristics pertaining to high-grade magnetite ore bodies.

Therefore, the integrated application of ground high-precision gravity and magnetic surveys combined with audio-frequency Magnetotellurics (AMT) holds significant practical importance for evaluating the resource potential of high-grade magnetite ores in the North China Craton and for guiding future deep exploration targeting high-grade mineralization within BIF-type iron deposits. This approach not only validates the effectiveness of the method in the Gongchangling area but also provides a transferable technical framework for mineral exploration in similar geological settings across the craton.

Author Contributions

Conceptualization, S.C.; Methodology, S.C.; Software, S.C. and S.J.; Validation, S.C. and S.J.; Formal analysis, S.C.; Investigation, S.C. and J.F.; Resources, J.F., S.J., Y.Z. and S.Z.; Data curation, S.C.; Writing—original draft, S.C.; Writing—review & editing, J.F. and S.J.; Supervision, J.F. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Deep Earth Probe and Mineral Resources Exploration-National Science and Technology Major Project (Grant No. 2025ZD1007200).

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

Conflicts of Interest

Author Yangyang Zhou and Suibo Zhang were employed by the company Liaoning Metallurgical Geological Exploration Research Institute Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Dai, T.; Han, Z.; Chen, W.; Wen, B.; Ouyang, X.; Li, Q.; Pan, Z.; Liu, Q. Uncovering Availability of the Secondary Iron Resources in China: Integrating Material Flow Analysis and Secondary Resources Reserve Assessment. Environ. Sci. Technol. 2024, 58, 15268–15278. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Z.; Li, L.; Zhang, Z.; Chen, J.; Yao, T. Types and general characteristics of the BIF-related iron deposits in China. Ore Geol. Rev. 2014, 57, 264–287. [Google Scholar] [CrossRef]

- Han, Y.X.; Zhang, X.L.; Gao, P.; Li, Y.J.; Sun, Y.S. Development and Prospect of Iron Ore Processing Technologies in China. Met. Mine 2024, 2, 1–24. [Google Scholar] [CrossRef]

- Zhang, Z.; Hou, T.; Santosh, M.; Li, H.; Li, J.; Zhang, Z.; Song, X.; Wang, M. Spatio-temporal distribution and tectonic settings of the major iron deposits in China: An overview. Ore Geol. Rev. 2014, 57, 247–263. [Google Scholar] [CrossRef]

- Zhang, L.C.; Zhai, M.G.; Wan, Y.S.; Quo, J.H.; Dai, Y.P.; Wang, C.L.; Liu, L. Study of the Precambrian BIF-iron deposits in the North China Craton: Progresses and questions. Yanshi Xuebao Acta Petrol. Sin. 2012, 28, 3431–3445. [Google Scholar]

- Shen, B.F. Geological Characters and Resource Prospect of the BIF Type Iron Ore Deposits in China. Acta Geol. Sin. 2012, 86, 1376–1395. [Google Scholar]

- Wang, Q.; Li, Y.; Li, H.; Hou, K.; Zhang, Z. Paleoproterozoic hydrothermal overprinting over Neoarchean banded iron formation produced high-grade iron ores in the giant Gongchangling deposit of North China: Evidence from O–S–B isotopes. Ore Geol. Rev. 2024, 165, 105911. [Google Scholar] [CrossRef]

- Sun, X.-H.; Tang, H.-S.; Luan, Y.; Chen, J.-H. Geochronological constraints on the genesis of high-grade iron ore in the Gongchangling BIFs from the Anshan-Benxi area, North China Craton. Ore Geol. Rev. 2020, 122, 103504. [Google Scholar] [CrossRef]

- Wang, E.-D.; Xia, J.-M.; Fu, J.-F.; Jia, S.-S.; Men, Y.-K. Formation mechanism of Gongchangling high-grade magnetite deposit hosted in Archean BIF, Anshan-Benxi area, Northeastern China. Ore Geol. Rev. 2014, 57, 308–321. [Google Scholar] [CrossRef]

- Dai, C.Q. Structural Characteristics and 3D Modeling of BlF in Anshan-Benxi, Liaoning Province. Ph.D. Thesis, Jilin University, Changchun, China, 2017. [Google Scholar]

- Zhang, J.; Fu, J.; Jia, S.; Wu, Z. Petrological Characteristics of the Altered Rock in No. 2 Mining Area of the Gongchangling Iron Deposit. Acta Geol. Sin.—Engl. Ed. 2014, 88, 138–140. [Google Scholar] [CrossRef]

- Jia, S.; Fu, J.; Leng, W.; Cui, S.; Zhao, B.; Meng, J. Identification and location of high-grade iron deposits in the Anshan-Benxi area, China, using integrated geophysical techniques. Ore Geol. Rev. 2026, 188, 107056. [Google Scholar] [CrossRef]

- Li, H.-M.; Yang, X.-Q.; Li, L.-X.; Zhang, Z.-C.; Liu, M.-J.; Yao, T.; Chen, J. Desilicification and iron activation–reprecipitation in the high-grade magnetite ores in BIFs of the Anshan-Benxi area, China: Evidence from geology, geochemistry and stable isotopic characteristics. J. Asian Earth Sci. 2015, 113, 998–1016. [Google Scholar] [CrossRef]

- Sun, X.; Zhu, X.; Tang, H.; Luan, Y. In situ LA-ICP-MS trace element analysis of magnetite from the late Neoarchean Gongchangling BIFs, NE China: Constraints on the genesis of high-grade iron ore. Geol. J. 2018, 53, 8–20. [Google Scholar] [CrossRef]

- Cheng, Y.Q. Genesis of High-grade Ore in Pre-Sinian Anshan-type Banded Iron Formations in Liaoning, Shandong and Other Provinces of Northeastern China. Acta Geol. Sin. 1957, 2, 153–180+241–250. [Google Scholar] [CrossRef]

- Li, J.P. Characteristics and Genesis of Magnetite in BIF Rich Iron Ore—An Example of Gongchangling Iron Mine. Master’s Thesis, Jilin University, Changchun, China, 2022. [Google Scholar]

- Zhou, S.T. Geology of BIF-Hosted Iron Deposits in Anshan-Benxi District; Geological Publishing House: Beijing, China, 1994; pp. 220–266. [Google Scholar]

- Li, S.; Zhi, X.; Chen, J.; Wang, J.; Deng, Y. Origin of graphites in Early Precambrian banded iron formation in Anshan, China. Geochimica 1983, 3, 162–169. [Google Scholar] [CrossRef]

- Sun, X.-H.; Zhu, X.-Q.; Tang, H.-S.; Zhang, Q.; Luo, T.-Y. The Gongchangling BIFs from the Anshan–Benxi area, NE China: Petrological–geochemical characteristics and genesis of high-grade iron ores. Ore Geol. Rev. 2014, 60, 112–125. [Google Scholar] [CrossRef]

- Dong, C.; Wan, Y.; Xie, H.; Nutman, A.P.; Xie, S.; Liu, S.; Ma, M.; Liu, D. The Mesoarchean Tiejiashan-Gongchangling potassic granite in the Anshan-Benxi area, North China Craton: Origin by recycling of Paleo- to Eoarchean crust from U-Pb-Nd-Hf-O isotopic studies. Lithos 2017, 290–291, 116–135. [Google Scholar] [CrossRef]

- Li, L.-X.; Zi, J.-W.; Li, H.-M.; Rasmussen, B.; Wilde, S.A.; Sheppard, S.; Ma, Y.-B.; Meng, J.; Song, Z. High-Grade Magnetite Mineralization at 1.86 Ga in Neoarchean Banded Iron Formations, Gongchangling, China: In Situ U-Pb Geochronology of Metamorphic-Hydrothermal Zircon and Monazite. Econ. Geol. 2019, 114, 1159–1175. [Google Scholar] [CrossRef]

- Cui, P.L. Metallogenic Tectonic Setting, Metallogenic and Prospecting Models for Precambrian Iron Formations in the Anshan-Benxi Area. Ph.D. Thesis, Jilin University, Changchun, China, 2014. [Google Scholar]

- Xu, L.S.; Lu, H.; Huang, T.T.; Yuan, D.Y. Application of Multivariate Statistical Analysis Thought in Geophysical and Geochemical Exploration. China Manganese Ind. 2022, 40, 29–36. [Google Scholar] [CrossRef]

- Deng, S.S. The Application of High Accuracy Magnetic Survey In TheMagnetite Exploration In Western Australia. Master’s Thesis, China University of Geosciences, Beijing, China, 2016. [Google Scholar]

- Qian, L.H.; Qian, L.P. Geophysical interpretation method and its application of magnetic anomalies. Jilin Geol. 2010, 29, 75–78. [Google Scholar]

- Zhang, D. Application Research of High-Precision Gravity in Mineral Exploration in the Xiaozhuqing Survey Area of Huize Lead-Zinc Mining Area. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2017. [Google Scholar]

- Zeng, Q.; Di, Q.; Liu, T.; Li, G.; Yu, C.; Shen, P.; Liu, H.; Ye, J. Explorations of gold and lead-zinc deposits using a magnetotelluric method: Case studies in the Tianshan-Xingmeng Orogenic Belt of Northern China. Ore Geol. Rev. 2020, 117, 103283. [Google Scholar] [CrossRef]

- Fu, J.; Jia, S.; Wang, E. Combined Magnetic, Transient Electromagnetic, and Magnetotelluric Methods to Detect a BIF-Type Concealed Iron Ore Body: A Case Study in Gongchangling Iron Ore Concentration Area, Southern Liaoning Province, China. Minerals 2020, 10, 1044. [Google Scholar] [CrossRef]

- Han, C.; Xiao, W.; Su, B.-X.; Sakyi, P.A.; Chen, Z.; Zhang, X.; Ao, S.; Zhang, J.; Wan, B.; Zhang, Z.; et al. Formation age and genesis of the Gongchangling Neoarchean banded iron deposit in eastern Liaoning Province: Constraints from geochemistry and SHRIMP zircon U–Pb dating. Precambrian Res. 2014, 254, 306–322. [Google Scholar] [CrossRef]

- Wang, E.; Song, K.; Yao, Y.; Fu, J.; Hao, D.; Ma, S. Hyperspectral and Geochemical Analysis of Chlorites at the Gongchangling High-Grade Magnetite Deposit, NE China: Implications for Alteration Processes. Minerals 2022, 12, 629. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.