Abstract

The paper presents the financial potential of recycling waste electronic equipment (WEE) in the form of printed circuit boards, hard drives, and lithium-ion batteries. Metal contents in selected types of WEE were presented, as well as their price and importance from an environmental, economic, and geopolitical perspective using indicators of relative supply risk and abiotic depletion potential (ADP). The potential benefits that recycling can bring to the company and the environment were presented. Furthermore, the mass balance and value of recovered metals were estimated for southern Poland, and potential possibilities for the management of the remaining separation products were presented. Finally, verified physical recycling methods for the presented WEE were described.

1. Introduction

Waste electronic equipment (WEE) represents a group of wastes whose quantity is growing dynamically from year to year and, due to the presence of metals, which are often critical, and plastics, constitutes a global environmental, economic, and even political problem. Such a rapid rise in end-of-life electronic equipment poses a challenge both for companies seeking to recover valuable raw materials and for authorities striving to reduce the environmental impact of this waste stream.

From a global economic perspective, the dynamic increase in WEE is closely related to the growth of the world’s population and the escalating consumption of electronic devices, which together amplify the demand for the metals required to manufacture them. Modern electronic devices are highly dependent on critical raw materials, including rare earth elements (REEs), cobalt, nickel, lithium, and precious metals [1]. The demand for these metals is driven not only by consumer electronics but also by ongoing digital and energy transformations. The digital transition stimulates the development of information and communication technologies (ICTs), widespread use of mobile devices, data centres, and the Internet of Things (IoT) [2]. Meanwhile, the energy transition requires the implementation of low-emission power sources (e.g., wind turbines, photovoltaic cells) and supports the development of electromobility [3]. For example, lithium, cobalt, and REEs are crucial in the manufacturing of batteries for electric vehicles, whereas copper is indispensable for power grids and wind turbine components.

The most commonly used methods for recovering metals from small-sized WEE are chemical methods that involve their dissolution in acids or incineration. In addition to the high complexity of these methods and the high emissions to the environment, there is a loss of non-metallic parts that could be used for other production or manufacturing processes. Furthermore, the process costs and installation costs of these methods are often very high. Alternative methods for processing WEE are mineral engineering methods. They allow for the separation of various materials, including plastics, which can then be reused to create the same or other products without creating excess emissions into the environment. We can then say that this is an eco-efficient WEE recycling technology that is in line with the idea of a circular economy and sustainable production.

It should be noted that products obtained by purely physical methods typically do not achieve elemental purity but rather are metal-rich concentrates. Nevertheless, the authors’ research demonstrated exceptions, such as obtaining a high-purity neodymium alloy concentrate directly from HDDs, which was successfully processed into fully functional magnets without chemical treatments, and producing economically valuable metal-rich concentrates from WPCBs suitable for further metallurgical refining.

This article focusses on the financial and technological potential of eco-efficient WEE recycling. Three groups of small-sized WEE were analysed: printed circuit boards (WPCBs), computer hard drives (WHDs), and lithium-ion batteries (WLIBs). The subsequent sections present the following:

- The content and price of metals in selected types of WEE, along with an overview of indicators that evaluate their importance from environmental, economic, and geopolitical perspectives, particularly relative supply risk and abiotic depletion potential (ADP);

- Price trends of metals used to create electronic equipment from 2000 to 2024;

- The mass balance and estimated value of recoverable metals in WEE collected in southern Poland, illustrating the economic and environmental potential of recycling;

- Review of the research on eco-efficient recycling of WEE conducted by the authors of the article against the background of other methods of recovering valuable substances.

WPCBs, WHDs, and WLIBs were selected due to their high content of critical and valuable metals and diverse material composition, and because they represent three technologically distinct recycling challenges for which the authors have developed and experimentally verified dedicated recovery processes.

2. Methods

The literature analysis method was used to determine the prices of metals used in the construction of electronic equipment and their average content in the WEE, as well as to analyse the indicators of relative supply risk and abiotic depletion potential (ADP). Based on the metal prices in March 2025 and the average metal content in the relevant WEE, the estimated metal prices in 1 Mg of waste were then calculated.

To assess the importance of metals present in WEE from a geographical, geological, environmental, economic, and political perspective, two indicators were used: relative supply risk and abiotic depletion potential (ADP). The second parameter is used to assess the impact of resource depletion. It focusses specifically on abiotic resources, which are non-living materials such as minerals and metals. ADP describes the ratio of the annual production of a resource to its ultimate reserves (based on the crustal content). It allows an assessment of the extent to which the use of a particular material contributes to the depletion of its resources. The higher the ADP value for a particular resource, the greater the potential for the resource to deplete [4]. Just as the global warming potential (GWP) of various pollutants is converted to CO2 equivalents, ADP values are commonly converted into antimony equivalents (Sb eq.). The other indicator is the relative supply risk developed by the Royal Society of Chemistry, which assesses future raw material availability issues. The indicator is based on factors such as crustal abundance, distribution and quantity of reserves, production concentration, substitutability, recycling rates, and political stability [5]. The relative supply risk ranges from 1 (very low risk) to 10 (very high risk).

In order to determine the mass balance of WEE and the estimated value of metals in them for the Silesian Voivodeship and, on this basis, for the whole of Poland, data were obtained from three anonymous companies located in the Silesian Voivodeship dealing with WEE collection.

Finally, the results of research conducted by the authors of the article on the recycling of WEE in accordance with the principles of circular economy and sustainable production were presented.

3. Results

3.1. Content, Price, and Environmental, Economic, and Geopolitical Importance of the Metals Present in the WEE

3.1.1. Waste Printed Circuit Boards (WPCBs)

One of the most common types of WEE is waste printed circuit boards (WPCBs), which are made of a composite material with embedded metal tracks as the base. The most commonly used PCBs are of type FR-4, whose composite is made of glass fibre in an epoxy resin matrix with flame-retardant additives. Copper is the most abundant metal in PCBs, but metals such as aluminium, lead, nickel, tin, and zinc are also present, as well as small amounts of precious metals such as gold, silver, platinum, and palladium [6,7] (Table 1). The metal content in PCBs is tens or even hundreds of times higher than that of ores [8]. As shown in Table 1, the WPCBs consist of metals with medium (Cu, Al, Zn, Au), increased (Pb, Ni, Sn, Ag), and high (Pd, Pt) relative supply risk. For example, lead (Pb) has a relative supply risk value of 6.2, according to the Royal Society of Chemistry. Although Pb is widely recycled and geologically abundant, its risk level is elevated due to its dependence on byproduct extraction (mainly from zinc ores), declining primary production, and regulatory constraints.

In terms of abiotic depletion potential (ADP), the values are very high for Au, Pd, and Pt; medium for Ag; and low or very low for Cu, Al, Pb, Zn, Ni, and Sn. This means that resources of some metals such as Au, Pd, and Pt are particularly limited, and that their availability is further threatened by geopolitical or production factors.

Both indicators show that the key metals from an economic, environmental, and political perspective are Pd, Pt, Au, and Ag. This is reflected in their market value. Therefore, the most valuable metals in WPCBs—considering both their content and price—are gold, silver, palladium, and, due to high abundance, copper (Table 1). The recovery of these metals can generate significant economic benefits for recycling companies [9]. The estimated value of metals in 1 Mg (1000 kg) of WPCBs is nearly USD 92,000, with gold accounting for the largest portion. Metals are treated as target concentrates, whereas plastics are treated as residual materials for which downstream applications are sought.

Table 1.

Estimated metal content of type FR-4 WPCBs and related indicators of relative supply risk and abiotic depletion potential [4,5,7] and estimated value of metals in WPCBs [10,11,12].

Table 1.

Estimated metal content of type FR-4 WPCBs and related indicators of relative supply risk and abiotic depletion potential [4,5,7] and estimated value of metals in WPCBs [10,11,12].

| Metal | Average Metal Content in WPCB, % | Relative Supply Risk | ADP, kg Sb eq/kg | Estimated Value of Metal in 1 Mg, USD |

|---|---|---|---|---|

| Cu | 20 | 4.3 | 2.1 × 10−2 | 1821.6 |

| Al | 2 | 4.8 | 2.5 × 10−8 | 49.5 |

| Pb | 2 | 6.2 | 1.9 × 10−2 | 39.3 |

| Zn | 1 | 4.8 | 2.8 × 10−3 | 32.2 |

| Ni | 2 | 6.2 | 8.1 × 10−4 | 303.6 |

| Sn | 4 | 6.7 | 8.1 × 10−2 | 1194.1 |

| Ag | 0.20 | 6.2 | 8.6 × 10 | 128.4 |

| Au | 0.10 | 5.7 | 1.4 × 103 | 84,556.5 |

| Pd | 0.0050 | 7.6 | 9.7 × 102 | 1532.0 |

| Pt | 0.0015 | 7.6 | 9.7 × 102 | 454.3 |

| Total | 31.31 | - | - | 91,910.9 |

3.1.2. Waste Hard Drives (WHDs)

Another type of WEE is waste hard drives (WHDs), which have an average weight of 509.8 g and consist of several elements [13]. These include aluminium, steel, plastic, printed circuit boards, and neodymium magnets. Most of the mass share belongs to the HDD casing, which consists of two parts: the main part and its cover. Typically, this casing is made of an Al-Si alloy. The HDD also consists of a disc stack assembly, which includes platters with a spacer and a spindle cover. The platters are made of an Al core with a thin layer of metal alloy providing magnetic properties. This alloy contains Co, Ni, Fe, and Zn [14]. The HDD also contains a PCB that is mounted on the bottom of the case. The HDD also consists of a Voice Coil Assembly (VCA), which is made up of neodymium magnets, ferrous metal holders, and other mechanical parts. The VCA contains metals such as Fe, Nd, Pr, Dy, and Co [15]. An HDD is composed of about 83% (by weight) metals and about 17% non-metallic assemblies such as PCBs and plastic parts. The Al content is the highest because the HDD casing is made of this metal.

HDD consists of metals with medium (Al, Fe, Cu, Ti, Zn, Au), increased (Ni, Sn, Ta, Ag), high (Co, Pd, Pd, Pt), and extremely high (Nd, Ce, Pr, Dy, Sb) relative supply risk (Table 2), while the ADP is very high for Au and Pd, medium for Ag and Sb, low for Cu, Ni, Sn, Zn, and Pr, and very low for Ce, Nd, Dy Co, Al, Si, Fe, Ti, and Ta (Table 2), meaning that the resources of metals used in HDD production, apart from those from which PCBs are made, are large, but the availability risk, especially of Nd, Pr, Dy, Ce, and Sb due to production concentration, substitutability, recycling rates, and political stability, is extremely high. The most important metals from an economic, environmental, and political perspective that drive the need for WHD recycling are Nd, Pr, Ce, and Dy, which make up neodymium magnets, and Pd, Au, and Ag, which are found in PCBs that control HDD.

Table 2.

Estimated metal content in WHDs and related indicators of relative supply risk and abiotic depletion potential [4,5,14,15] and estimated metal value in WHDs [10,11,12,16].

The most valuable metals in WHD, based on their content, are gold, cerium, copper, neodymium, palladium, dysprosium, silver, and praseodymium, which are contained in neodymium magnets and PCBs (Table 2). Aluminium and quartz are also of great value due to their high content in HDD. The HDD casing is made of aluminium with a steel cover. The estimated value of metals contained in a ton of WHD is around USD 9908, with the highest-value metals found in neodymium magnets, PCBs, and HDD casings. Therefore, they are treated as concentrates in the recycling process.

Over the past decade, there has been a marked transition from HDDs to solid-state drives (SSDs) in both consumer and enterprise storage markets. According to a study of the global storage market, total HDD shipments decreased from approximately 650 million units in 2010 to approximately 260 million units in 2020 [17]. Despite the continued surge in SSD adoption, market analyses from 2023 and early 2024 indicate that HDDs remain relevant in specific niches. According to a recent IDC report, worldwide HDD shipments dropped from around 260 million units in 2020 to approximately 180 million units in 2023, while SSD shipments exceeded 400 million units during the same period [17]. However, HDDs continue to be deployed in cost-sensitive environments and in applications requiring high-capacity storage with less stringent input/output performance, such as long-term data archiving, near-line backups, and certain big data analytics platforms where throughput needs can be met by high-density HDD arrays [18]. Additionally, large-scale cloud providers still integrate HDDs for data storage purposes to balance capital expenditures with operational efficiency. Although the price gap between SSDs and HDDs continues to narrow, magnetic disc technology is likely to retain a share of the enterprise storage market for at least the next five years, particularly where massive storage capacity remains a priority. As a result, a dual-market model is expected to persist, with SSDs dominating performance-centric segments and HDDs occupying high-capacity, lower-cost storage roles.

3.1.3. Waste Lithium-Ion Batteries (WLIBs)

The last example of WEE presented is waste lithium-ion batteries (WLIBs). LIBs are now the dominant portable power source in smartphones, laptops, cameras, handheld devices, and other high-tech devices. The structure of LIBs is not homogeneous, and multimetallic compounds can be found in them. Lithium cobalt oxide (LCO) and lithium nickel manganese cobalt oxide (NMC) are examples of the types of active cathode materials (CAM) used in these batteries [19]. They typically contain approximately 21.31% Mn, 16.54% Co, 2.56% Ni, 2.22% Li, 5.93%–14% Cu, 4.7%–9.12% Al, 0.04%–25% Fe, and approximately 15% organic materials and 7% plastics [20,21]. Organics include electrolytes, binders, and separators [19,20]. LIBs consist of metals with medium (Mn, Cu, Al, Fe), elevated (Ni, Li), and high (Co) relative supply risk, while the ADP is low or very low for Cu and Ni and Mn, Co, Li, Al, and Fe (Table 3), respectively, which means that the resources of metals used for battery production are large, but the availability risk, especially of Co, Li, and Ni, due to production concentration, substitutability, recycling rates, and political stability, is quite high. The last indicator makes the value of the metals Li, Ni, and Co significant (Table 3).

Table 3.

Estimated metal content in WLIBs and related indicators of relative supply risk and abiotic depletion potential [4,5,20,21] and estimated metal value in WLIBs [10,12].

WLIB recycling can also provide significant financial benefits to the recycler. Considering the current metal prices on the exchanges and the average metal content in WLIBs, it is estimated that in one tonne of WLIBs, the value of the metals contained is over USD 6350. Note that cobalt is the key metal determining the profitability of WLIB recycling, although copper, nickel, lithium, and manganese are also high-value metals.

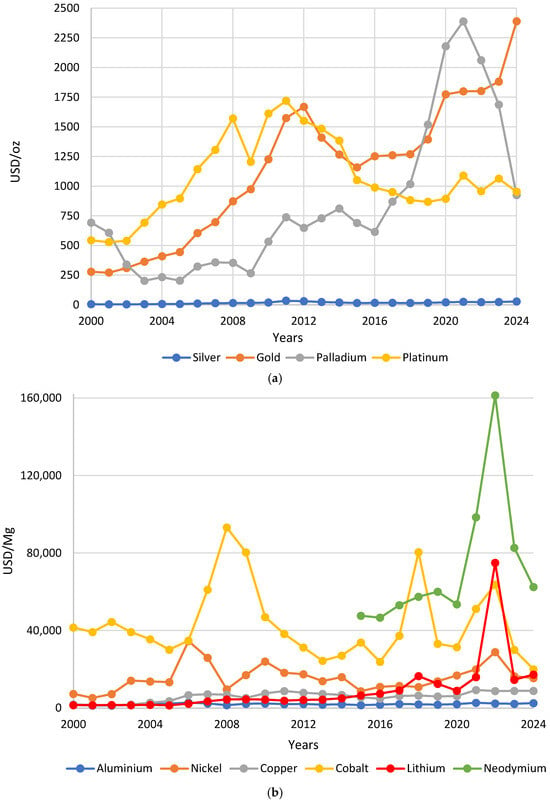

3.2. Metal Price Volatility 2000–2024

Due to digital transformation and the development of information and communication technologies, but also the geopolitical situation, the demand for metals is increasing. Higher demand causes their prices to rise. Therefore, since the beginning of the 21st century, there has been an increase or fluctuation in the prices of many metals on world markets (Figure 1). Price fluctuations are usually due to geopolitical, economic, or technological factors [22]. For example, in the case of cobalt, production in the Congo accounts for 70% of the world market, while the shares of the three largest producers of lithium and REEs were, in 2024, 92% and 90%, respectively. For lithium, these were Australia, Chile, and China, and for REEs, China, the US, and Myanmar [3,23]. Additionally, prices fluctuate according to global economic cycles. In general, since 2000 (for Nd since 2015), there has been an increase in the prices of platinum, palladium, gold, and silver by 75, 33, 756, and 471%, respectively, as well as nickel, aluminium, copper, lithium, and neodymium by 112, 62, 380, 1015, and 31%, respectively. Among the metals analysed, only the price of cobalt dropped by 61%, from around USD 41,000 to USD 20,000, mainly due to geopolitical reasons.

Figure 1.

Historical price trends of (a) silver, gold, palladium, and platinum [10] and (b) nickel, copper, cobalt, lithium, aluminium [10,11], and neodymium [16] between 2000 and 2024.

All of these factors, such as the growth of WEE volumes, the increase in metal demand, and volatility, underscore the importance of effective recycling as a means of reducing the pressure on primary resources, mitigating supply risks, and minimising environmental impact [24]. WEE recycling can provide significant financial benefits by stabilising metal supply chains and reducing vulnerability to price fluctuations [25], as well as environmental benefits through lower energy consumption and a reduced environmental footprint compared to traditional mining and smelting [26].

3.3. Mass Balance and Estimated Value of Metals in WEE for Southern Poland

Eco-efficient recycling of WEE can bring significant economic benefits. The mass balance and estimated value of metals in WPCBs, WHDs and WLIBs — both per 1 million inhabitants and extrapolated to the national scale — are summarised in Table 4. In Poland, with a population of 38.4 million, it is estimated that approximately 1045 Mg of WPCBs, 522 Mg of WHDs, and 1742 Mg of WLIBs are collected annually. The estimated value of the metals contained in these waste streams amounts to approximately USD 96 million for WPCBs, USD 5.1 million for WHDs, and USD 11 million for WLIBs.

Table 4.

Mass balance and estimated value of metals in WEE (WPCBs, WHDs, and WLIBs) for southern Poland in 2024. Data based on averages from three collection companies in the Silesian Voivodeship. Values are provided per 1 million inhabitants (top rows) and extrapolated to the entire Polish population (bottom rows).

In addition to regional estimates, it is important to place the value and quantity of waste electronic equipment (WEE) in a global context. According to the Global E-waste Monitor 2024, a record 62 million tonnes of e-waste was generated worldwide in 2022, representing an 82% increase since 2010 and averaging 7.8 kg per person. This figure is projected to rise by another 32%, reaching 82 million tonnes by 2030. However, only 22.3% of the 2022 e-waste mass was formally collected and recycled in an environmentally sound manner, leading to significant losses of secondary resources. The estimated value of metals embedded in the 2022 e-waste stream was approximately USD 91 billion, including USD 19 billion in copper, USD 15 billion in gold, and USD 16 billion in iron [27].

Among the countries generating the largest volumes of e-waste in 2024 were China (10.1 Mt), the United States (6.9 Mt), and India (3.2 Mt). Despite their contribution to the global total, recycling rates in these countries remain low: approximately 16% in China, 15% in the USA, and just 1% in India. By contrast, Germany and the United Kingdom have achieved significantly higher formal collection rates of 52% and 57%, respectively [28]. These disparities underscore the need for harmonised and enforced recycling frameworks as well as the implementation of efficient recovery methods, such as those analysed in this study.

3.4. Research on Recycling of WEE

Currently, WEE recycling is carried out by chemical methods, i.e., hydrometallurgy, pyrometallurgy, and biohydrometallurgy, or by physical methods. Where physical methods can be used in recycling, they should be used in preference to chemical methods, as the use of the latter usually requires special permits and increased work to prevent environmental degradation. It should also be remembered that chemical changes occurring during WEE recycling processes cause the destruction or severe contamination of non-metal parts, which in turn creates additional waste. In the case of physical methods, no hazardous substances or devices that cause emissions into the atmosphere are used, so these methods can be considered more environmentally friendly. Proper recycling using these methods allows for high yields at relatively low costs. Furthermore, plastics obtained as a byproduct of recycling remain chemically unchanged, which significantly increases the potential for further use, e.g., in the production of resin-based composite materials. Note that physical methods often result in the creation of a mixture of metals that must be further chemically processed to isolate the individual metals.

The following section presents an overview of the research conducted by the authors of the paper in the field of WPCB, WHD, and WLIB recycling.

In WPCB recycling, one of the most effective physical methods is electrostatic separation [8,29]. To do this properly, disintegration and grinding are required, preferably using a shredder and a knife mill at cryogenic temperatures. Separation occurs as a result of differences in the surface charge accumulation capacity of the grains and is carried out without the use of process water. Separation results in a mixture of metals and separately ground composite parts. Due to the high purity of the products, the valuable metal mixture can be sold to local metal smelters, while the product consisting of non-metallic parts can be used as a filler in the production of composite materials (Table 5) [8]. Due to this, recycling carried out in this way is relatively simple to implement and does not require the use of complicated technical equipment.

Table 5.

Amount of separation products and method of using them for WEE recycling.

Recent studies have also demonstrated innovative approaches for the recovery of aluminium and iron from WEE using integrated mechanical and thermal techniques, further confirming the potential for sustainable valorisation of these metals [34,35].

In the investigated WHD recycling technology, both the initial mechanical shredding and the subsequent selective separation processes play a key role [36]. These steps enable the recovery of several fractions of material with different compositions and industrial applications, namely aluminium, steel, neodymium alloy (NdFeB), printed circuit boards (PCBs), and plastics (Table 5). The metal recovery process of hard drives begins with mechanical shredding, which enables the disintegration of components and the release of embedded metals. This is followed by a two-stage magnetic separation process: in the first stage, using a stationary steel plate, NdFeB magnet fragments are separated along with accompanying ferromagnetic contaminants, whereas in the second stage, a strong permanent magnet is employed to separate the remaining ferromagnetic metals, primarily structural steel. The next step involves the granulometric classification of the shredded material, resulting in division into four particle size classes, >25 mm, 25–10 mm, 10–3.15 mm, and 3.15–0 mm, facilitating its selective further processing. The >25 mm particle size class, composed only of stainless steel, is considered a final product and directed to metallurgical recycling. The 25–10 mm fraction undergoes gravity separation on a concentration table, where aluminium is recovered as a product, while the remaining material is subjected to optical separation to extract printed circuit board (PCB) fragments and plastics as distinct products. The 10 to 3.15 mm fraction is subjected to cyclofluidic gravity enrichment in air, resulting in aluminium recovery, after which the remaining material is directed to optical separation for further separation of PCB grains from plastic grains. The finest particle size class, 3.15 to 0 mm, undergoes electrostatic separation, where differences in electrical conductivity allow the recovery of metals and plastics. The method of hard drive recycling has been submitted to the Polish Patent Office [37].

The pretreatment process of WLIBs, which is divided into various steps such as discharge, disintegration/dismantling, comminution, classification, separation, dissolution, and thermal treatment, is of essential importance, particularly in the cases of hydrometallurgical extraction and direct recycling of spent LIBs. The pretreatment process has been shown to improve recovery efficiency and reduce energy consumption in subsequent recycling processes similar to mineral processing for extractive metallurgy [38,39]. The primary objective of the pretreatment is to separate the various components, such as separators, current collectors, etc., from the black mass of the LIBs in a safe and effective manner [40].

The process begins with the discharge of the batteries to eliminate any residual electrical charge, thereby preventing thermal runaways, gas emissions, or fires during further processing. This is followed by dismantling/disintegration, either manually for lab-scale precision or mechanically for industrial throughput, to separate casings, electrodes, and internal modules. Mechanical disintegration often incorporates cryogenic shredding or crushing to fragment battery structures, liberating embedded components such as anode/cathode materials and current collectors. This is followed by further comminution, which includes cryogenic grinding to detach electrode powders from aluminium or copper foils, thereby increasing liberation efficiency. Subsequent to comminution, the material undergoes classification, typically via sieving or air separation, to sort particles based on size and density. Fine particles (often < 0.25 mm) typically contain black mass rich in Li, Co, Ni, Mn, and graphite, while coarser fractions include metallic foils and casings. Additional separation techniques such as magnetic and eddy current separation are employed to isolate ferrous and non-ferrous metals, respectively. In some advanced setups, flotation or pneumatic separation is used to refine electrode fractions. To further detach electrode coatings from current collectors, thermal treatment or chemical dissolution methods are applied. Thermal treatment at approximately 450 °C is particularly effective in removing PVDF binders and residual electrolytes while avoiding contamination of active materials if optimised carefully. Alternatives such as organic solvents, deep eutectic solvents, and ionic liquids are also used to selectively dissolve binders [40,41,42].

The key output of the pretreatment stage is the black mass, a fine ground mixture of active materials from anodes and cathodes (Table 5). This fraction serves as the feedstock for hydrometallurgical or direct regeneration methods. Alongside black mass, several byproduct streams are recovered: Al foil (~5%–7% of total mass), Cu foil (~5%–10%), steel casings (~3%–5%), and plastic–organic residues (~30%–35%). Aluminium and copper are redirected to secondary metal recovery facilities, while steel is commonly recycled via standard remelting [19].

4. Conclusions and Discussion

The growing stream of WEE, driven by global demand for critical metals and concurrent digital and energy transitions, highlights both the urgency and the potential of eco-efficient recycling solutions. As demonstrated in this study, WEE such as printed circuit boards (WPCBs), hard disc drives (WHDs), and lithium-ion batteries (WLIBs) contains valuable metals ranging from copper and precious metals (Au, Ag, Pd) to critical elements (Co, Nd, Li) that can be recovered with substantial economic and environmental gains. Metals with the highest relative supply risk and ADP are Au, Pd, and Pt for WPCBs, Nd, Pr, Ce, Dy, Pd, and Au for WHDs, and Co, Li, and Ni for WLIBs. It should be noted that the estimated value of metals in 1 Mg of WPCBs could be almost USD 92000, while 1 Mg of WHDs could give recoverable metals worth approximately USD 9908, and 1 Mg of WLIBs could give a potential metal value exceeding USD 6351. To assess the profitability of recycling, investment and process costs must also be considered.

The annual mass of WPCBs, WHDs, and WLIBs collected per 1 million inhabitants of southern Poland is approximately 27.2, 13.6, and 45.3 Mg, respectively, and the estimated value of metals in them is approximately 2499, 135, and 288 thousand USD/year, respectively, indicating a large financial potential for companies involved in WEE recycling.

Physical recycling methods such as shredding, milling, electrostatic, magnetic, and gravity separation, complemented in the next step by hydrometallurgical or pyrometallurgical processes, enable the recovery of high-value metals at low process costs, lower energy consumption, and limited emissions of pollutants into the environment, compared to traditional mining. Such multi-step approaches are supported by continuous innovation in selective metal separation techniques and the application of new methods for the recovery of plastics and their use in the production of new consumer goods.

Furthermore, regional mass balance analysis demonstrates how improved collection and processing infrastructures can significantly increase the volume of recoverable metals. Converting end-of-life materials into secondary resources promotes regional economic development by creating jobs in recycling, metallurgy, and related industries and simultaneously mitigates the environmental damage associated with raw material extraction. In particular, recovering critical raw materials, such as cobalt and REEs, increases the resilience of the supply chain for industries dependent on these scarce inputs.

Beyond economic benefits, eco-efficient WEE recycling aligns with broader sustainability goals. Reduced landfill use, lower greenhouse gas emissions, and conservation of finite resources are key outcomes of developing recycling technologies aligned with the principles of a circular economy. Supporting research and development in key areas (e.g., advanced material sorting, optimised shredding, and selective separation) will further increase recycling efficiencies and contribute to global carbon neutrality targets.

It should also be noted that WEE, particularly WPCBs, contain metals at concentrations far exceeding those in geogenic ores. For example, based on the values in Table 1, the gold content in WPCBs is approximately 1000 g/t, whereas conventional gold ores often contain less than 5 g/t. Moreover, under optimised physical and metallurgical processing, the recovery efficiency of such metals from WEE can be comparable to—or even exceed—that of primary raw materials, which further supports the importance of WEE as a strategic secondary resource.

Implementing these solutions on a larger scale will be essential for sustainable resource management, resilient supply chains, and the protection of natural resources for future generations. By viewing WEE as a reservoir of high-value secondary raw materials rather than a waste problem, societies can capitalise on emerging market opportunities while adhering to responsible environmental stewardship in an increasingly resource-constrained world.

Beyond annual generation figures, it is essential to acknowledge that electronic waste is accumulating continuously at the global level. Most devices are not recycled promptly after use, resulting in growing stockpiles of unmanaged WEE. This long-term build-up not only increases the risk of environmental contamination from hazardous substances but also leads to the permanent loss of valuable secondary raw materials such as copper, gold, cobalt, and rare earth elements. These materials, once landfilled or processed using informal methods, are often no longer recoverable at scale.

In parallel, the accumulation of e-waste contributes to missed economic opportunities. According to recent global assessments, the embedded value of metals in e-waste exceeded USD 90 billion in 2022, much of which remains unrecovered. This inefficiency perpetuates reliance on primary extraction, increasing environmental degradation and geopolitical supply risks. Moreover, uncontrolled stockpiling of e-waste—whether in households, warehouses, or landfills—poses growing health threats in regions where informal dismantling and burning occur without proper protection.

Tackling the accumulation of e-waste calls for a coordinated and structural transformation across the entire management chain. Progress in recycling technology alone is insufficient without parallel advancements in collection efficiency, access to authorised treatment facilities, and the enforcement of extended producer responsibility (EPR) frameworks. Furthermore, effective policies must enable the gradual integration of informal recyclers into the formal economy by providing targeted support, regulatory clarity, and capacity-building programmes. Such a multidimensional approach is essential to mitigate the environmental and economic risks posed by unchecked e-waste growth and to move decisively toward a functioning circular economy aligned with long-term sustainability targets.

Although the global use of traditional HDDs and some lithium-ion battery types may have peaked, the accumulation of waste containing these components remains significant. Legacy equipment that has already been phased out still poses an environmental burden due to stockpiling or improper disposal. Moreover, the transition to SSDs and emerging battery chemistries such as silicon–carbon (Si-C) and lithium–sulphur (Li-S) technologies will soon create new streams of end-of-life products. Future studies should therefore address the recyclability and resource content of these innovative components to ensure preparedness for upcoming challenges in electronic waste management.

However, it must also be noted that metal price volatility—such as the decline observed in 2024—may discourage some companies from investing in recycling infrastructure, especially in cases where the recovered metals are of lower value. In this context, the consistently high market value of gold remains a major economic driver for recycling certain waste streams. Such risks underline the importance of developing integrated recovery systems that combine both high- and low-value materials to achieve overall profitability.

Author Contributions

Conceptualisation and formulation of theses, T.S.; formal analysis and conclusions, T.S.; methodology, T.S. and D.M.F.; analysis of metal price trends, T.S., P.F., U.K. and P.G.; analysis of content, price, and environmental, economic, and geopolitical importance of metals, T.S., P.F., U.K. and D.M.F.; analysis of economic and environmental potential of WEE recycling, T.S.; review of recycling research, P.F., U.K. and D.M.F.; investigation, T.S., P.F., U.K., D.M.F. and P.G.; writing—original draft preparation, T.S., P.F., U.K. and D.M.F.; writing—review and editing, T.S.; visualisation, T.S., P.F., U.K. and P.G. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by the KOMAG Institute of Mining Technology and the Silesian University of Technology.

Data Availability Statement

The data supporting the findings of this study are not publicly available due to commercial confidentiality agreements with the collaborating recycling companies.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Graedel, T.E.; Harper, E.M.; Nassar, N.T.; Nuss, P.; Reck, B.K. Criticality of Metals and Metalloids. Proc. Natl. Acad. Sci. USA 2015, 112, 4257–4262. [Google Scholar] [CrossRef] [PubMed]

- United Nations Digital Library System. The Impact of Digital Technologies. Available online: https://www.un.org/en/un75/impact-digital-technologies (accessed on 28 March 2025).

- International Energy Agency Low-Emissions Sources of Electricity-Analysis. Available online: https://www.iea.org/reports/low-emissions-sources-of-electricity (accessed on 28 March 2025).

- Van Oers, L.; Guinée, J.B.; Heijungs, R. Abiotic Resource Depletion Potentials (ADPs) for Elements Revisited—Updating Ultimate Reserve Estimates and Introducing Time Series for Production Data. Int. J. Life Cycle Assess. 2020, 25, 294–308. [Google Scholar] [CrossRef]

- Royal Society of Chemistry Periodic Table–Relative Supply Risk. Available online: https://periodic-table.rsc.org/ (accessed on 28 March 2025).

- Franke, D.M.; Suponik, T.; Siudyga, T.; Kar, U. Evaluation of the Use of Flotation for the Separation of Ground Printed Circuit Boards. Gospod. Surowcami Miner.-Miner. Resour. Manag. 2022, 38, 171–188. [Google Scholar]

- Mir, S.; Dhawan, N. Recycling of Metallic Values from Discarded Tantalum Capacitors. Miner. Process. Extr. Metall. 2023, 132, 87–98. [Google Scholar] [CrossRef]

- Kaya, M. Recovery of Metals and Nonmetals from Waste Printed Circuit Boards (PCBs) by Physical Recycling Techniques. In Energy Technology 2017; Zhang, L., Drelich, J.W., Neelameggham, N.R., Guillen, D.P., Haque, N., Zhu, J., Sun, Z., Wang, T., Howarter, J.A., et al., Eds.; The Minerals, Metals & Materials Series; Springer International Publishing: Cham, Switzerland, 2017; pp. 433–451. ISBN 978-3-319-52191-6. [Google Scholar]

- Macrotrens LLC Macrotrends|The Long Term Perspective on Markets. Available online: https://macrotrends.net (accessed on 28 March 2025).

- IndexMundi LCC Commodity Prices. Available online: https://www.indexmundi.com/commodities/ (accessed on 28 March 2025).

- London Metal Exchange, T.L.M. Metals. Available online: https://www.lme.com/ (accessed on 18 March 2025).

- Manhart, A.; Buchert, M.; Degreif, S.; Mehlhart, G.; Meinel, J. Recycling of Hard Disk Drives–Analysing the Optimal Dismantling Depth for Recyclers in Developing Countries and Emerging Economies; Oko-Institut: Freiburg, Germany, 2015. [Google Scholar]

- Habib, K.; Parajuly, K.; Wenzel, H. Tracking the Flow of Resources in Electronic Waste-the Case of End-of-Life Computer Hard Disk Drives. Environ. Sci. Technol. 2015, 49, 12441–12449. [Google Scholar] [CrossRef] [PubMed]

- Ueberschaar, M.; Rotter, V.S. Enabling the Recycling of Rare Earth Elements through Product Design and Trend Analyses of Hard Disk Drives. J. Mater. Cycles Waste Manag. 2015, 17, 266–281. [Google Scholar] [CrossRef]

- Trading Economics LCC Neodymium. Available online: https://tradingeconomics.com/commodity/neodymium (accessed on 9 April 2025).

- IDC Global Worldwide Hard Disk Drive Forecast Update, 2023–2027. Available online: https://www.idc.com/getdoc.jsp?containerId=US51423423 (accessed on 28 March 2025).

- Trendfocus Inc. The Data Storage Industry’s Most Trusted Market Intelligence. Pioneering Analysis in SSDs, HDDs, NAND in Cloud, Enterprise, and Cloud Markets. Available online: https://trendfocus.com/ (accessed on 28 March 2025).

- Kaya, M. State-of-the-Art Lithium-Ion Battery Recycling Technologies. Circ. Econ. 2022, 1, 100015. [Google Scholar] [CrossRef]

- An, L. (Ed.) Recycling of Spent Lithium-Ion Batteries: Processing Methods and Environmental Impacts; Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-030-31833-8. [Google Scholar]

- Horeh, N.B.; Mousavi, S.M.; Shojaosadati, S.A. Bioleaching of Valuable Metals from Spent Lithium-Ion Mobile Phone Batteries Using Aspergillus Niger. J. Power Sources 2016, 320, 257–266. [Google Scholar] [CrossRef]

- World Bank Group Commodity Prices Revised Down as Global Growth Weakens and Supplies Remain Ample. Available online: https://www.worldbank.org/en/news/press-release/2019/10/29/commodity-prices-revised-down-as-global-growth-weakens-and-supplies-remain-ample (accessed on 28 March 2025).

- Statista Ltd. Mine Production of Rare Earths Worldwide in 2024, by Leading Country. Available online: https://www.statista.com/statistics/268011/top-countries-in-rare-earth-mine-production/ (accessed on 10 April 2025).

- Cucchiella, F.; D’Adamo, I.; Lenny Koh, S.C.; Rosa, P. Recycling of WEEEs: An Economic Assessment of Present and Future e-Waste Streams. Renew. Sustain. Energy Rev. 2015, 51, 263–272. [Google Scholar] [CrossRef]

- De Oliveira Neto, G.C.; De Jesus Cardoso Correia, A.; Schroeder, A.M. Economic and Environmental Assessment of Recycling and Reuse of Electronic Waste: Multiple Case Studies in Brazil and Switzerland. Resour. Conserv. Recycl. 2017, 127, 42–55. [Google Scholar] [CrossRef]

- Luo, X.; Ding, N.; Yang, J.; Lu, B.; Ma, J. Potential Environmental Benefits Assessment of Recycling Based on Multi-LCA and SFA. J. Clean. Prod. 2024, 457, 142370. [Google Scholar] [CrossRef]

- E-Waste Monitor. The Global E-Waste Monitor 2024; E-Waste Monitor: Bonn, Germany, 2024. [Google Scholar]

- Valdez, M. The Biggest E-Waste Facts of 2024; Reboot Tech LLC: ITAD & eWaste Recycling: Montclair, CA, USA, 2024. [Google Scholar]

- Franke, D.; Suponik, T.; Nuckowski, P.; Dubaj, J. Evaluation of the Efficiency of Metal Recovery from Printed Circuit Boards Using Gravity Processes. Physicochem. Probl. Miner. Process. 2021, 57, 63–77. [Google Scholar] [CrossRef]

- Hyra, K.; Nuckowski, P.M.; Willner, J.; Suponik, T.; Franke, D.; Pawlyta, M.; Matus, K.; Kwaśny, W. Morphology, Phase and Chemical Analysis of Leachate after Bioleaching Metals from Printed Circuit Boards. Materials 2022, 15, 4373. [Google Scholar] [CrossRef]

- Jin, H.; Afiuny, P.; Dove, S.; Furlan, G.; Zakotnik, M.; Yih, Y.; Sutherland, J.W. Life Cycle Assessment of Neodymium-Iron-Boron Magnet-to-Magnet Recycling for Electric Vehicle Motors. Environ. Sci. Technol. 2018, 52, 3796–3802. [Google Scholar] [CrossRef] [PubMed]

- Klemettinen, A.; Adamski, Z.; Chojnacka, I.; Leśniewicz, A.; Rycerz, L. Recovery of Rare Earth Elements from the Leaching Solutions of Spent NdFeB Permanent Magnets by Selective Precipitation of Rare Earth Oxalates. Minerals 2023, 13, 846. [Google Scholar] [CrossRef]

- European Aluminium Environmental Profile Report 2018-Executive Summary. Available online: https://european-aluminium.eu/news_events/environmental-profile-report-2018-executive-summary/ (accessed on 10 April 2025).

- Park, I.; Ito, M.; Jeon, S.; Tabelin, C.B.; Phengsaart, T.; Silwamba, M.; Hiroyoshi, N. A Novel Recycling Route for Aluminum Alloys: Synthesis of Fe/Al Bimetallic Materials and Magnetic Separation. Miner. Eng. 2023, 201, 108202. [Google Scholar] [CrossRef]

- Sun, B.; Sun, N.; Wang, L.; Zhang, S.; Guo, Z. A New Process for Efficient Purification of 6061 Aluminum Alloy Scrap under Semi-Solid and Super-Gravity Conditions. J. Clean. Prod. 2023, 402, 136825. [Google Scholar] [CrossRef]

- Friebe, P. Development of a Prototype Shredder for WEEE Equipped with NdFeB Magnets. Min. Mach. 2023, 41, 143–157. [Google Scholar] [CrossRef]

- Friebe, P.; Suponik, T.; Nuckowski, P.M.; Matusiak, P.; Kowol, D. A Method of Recovering Metals from Used Hard Drives. Poland Patent P.452083, 19 May 2025. [Google Scholar]

- Al-Thyabat, S.; Nakamura, T.; Shibata, E.; Iizuka, A. Adaptation of Minerals Processing Operations for Lithium-Ion (LiBs) and Nickel Metal Hydride (NiMH) Batteries Recycling: Critical Review. Miner. Eng. 2013, 45, 4–17. [Google Scholar] [CrossRef]

- Zhao, Y.; Yuan, X.; Jiang, L.; Wen, J.; Wang, H.; Guan, R.; Zhang, J.; Zeng, G. Regeneration and Reutilization of Cathode Materials from Spent Lithium-Ion Batteries. Chem. Eng. J. 2020, 383, 123089. [Google Scholar] [CrossRef]

- Kim, S.; Bang, J.; Yoo, J.; Shin, Y.; Bae, J.; Jeong, J.; Kim, K.; Dong, P.; Kwon, K. A Comprehensive Review on the Pretreatment Process in Lithium-Ion Battery Recycling. J. Clean. Prod. 2021, 294, 126329. [Google Scholar] [CrossRef]

- Kar, U.; Nili, S.; Mends, E.; Vahidi, E.; Chu, P. A Review and Environmental Impact Analysis on the Current State of Froth Flotation on Recycling of E-Wastes. Resour. Conserv. Recycl. 2025, 212, 107967. [Google Scholar] [CrossRef]

- Gao, T.; Dai, T.; Fan, N.; Han, Z.; Gao, X. Comprehensive Review and Comparison on Pretreatment of Spent Lithium-Ion Battery. J. Environ. Manag. 2024, 363, 121314. [Google Scholar] [CrossRef] [PubMed]

- Sommerville, R.; Shaw-Stewart, J.; Goodship, V.; Rowson, N.; Kendrick, E. A Review of Physical Processes Used in the Safe Recycling of Lithium Ion Batteries. Sustain. Mater. Technol. 2020, 25, e00197. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).