Abstract

The Statistical Process Control (SPC) approach using mathematical modeling proves effective for correlated data, with applications in healthcare, finance, and technology to enhance quality and efficiency. Here, we provide a novel SPC method using mathematical modeling and discuss its use in simulation tests to assess its applicability for tracking processes containing correlated data operating on sophisticated control charts. Particularly, an approach for detecting small shifts in the mean of a process running on the double-modified exponentially weighted moving average (DMEWMA) control chart, which is symmetric about the center line with upper and lower control limits, is of special interest. The computations showed exceptional accuracy, with ARL from the explicit formula closely matching that from the NIE method. Simulation tests assess its applicability in detecting small mean shifts and compare its performance with exponentially weighted moving average (EWMA) and modified exponentially weighted moving average (MEWMA) control charts across various scenarios. For several values of the design parameters, the performances of these three control charts are also compared in terms of the relative average index and relative standard deviation index. The results show that the DMEWMA chart outperforms others for several process mean shifts. The method’s practical use is demonstrated with stock data, highlighting its superior effectiveness in enhancing process monitoring.

1. Introduction

Statistical Process Control (SPC) is a methodological framework that employs statistical techniques to monitor and control manufacturing processes, ensuring efficiency and quality. Symmetry is essential in SPC, especially for designing and interpreting control charts. Control charts are fundamental instruments in SPC for monitoring process stability and variability across time. The development of these charts is underpinned by the assumption of symmetry, which is frequently based on the normal distribution of process data. The concept of SPC was pioneered by Shewhart [] in 1926 and has since evolved into a critical aspect of operational excellence. Its notable application in the manufacturing sector has significantly reduced variability, enhanced product quality, and minimized waste. The methodology’s versatility extends beyond manufacturing, finding utility in healthcare, where it aids in managing patient care processes, and in financial services, where it improves compliance and service delivery []. A comprehensive review of research on the limitations and advantages of Statistical Process Control (SPC) in enhancing healthcare system quality is available in [,]. Additionally, Saravanan and Nagaragan [] provide a comparative analysis of SPC and various control charts employed in the manufacturing industry.

There are two techniques to describe symmetry in control charts. First, control limits are symmetrically positioned around the process mean in traditional Shewhart control charts, like the -chart. The process data are assumed to have a normal distribution in this design, meaning that departures from the mean are equally likely to occur. Process shifts or anomalies can be easily detected thanks to its symmetry. Second, the assumption that process data are regularly distributed is necessary for symmetrical control limits to be effective. Effective monitoring and quality control are made possible when this assumption is true because the control limits appropriately represent the anticipated process variability [,].

Control charts, also known as Shewhart charts, are fundamental tools in SPC that visualize how a process changes over time. They consist of data points representing a statistic from a process, plotted in chronological order, with three key components: a central line (average), an upper control limit (UCL), and a lower control limit (LCL) []. These charts are used to monitor process stability, detect out-of-control conditions, and investigate variations that may affect quality []. The Shewhart chart is a memoryless chart that only considers the most current process observations, ignoring any previous outcomes. In looking for modest fluctuations in process parameters, the cumulative sum (CUSUM) control chart recommended by Page [] and the exponentially weighted moving average (EWMA) control chart suggested by Roberts [] outperform the Shewhart-type control chart. Since then, numerous studies have been conducted to improve the performance of EWMA charts for minor process changes. For example, Shamma [] proposed double exponentially weighted moving average (DEWMA); adaptive exponentially weighted moving average (AEWMA) was introduced by Capizzi and Masarotto []; Zhou et al. developed the weighted exponentially weighted moving average (WEWMA) chart for identifying changes in a Poisson incidence rate []; Patel and Divecha suggested the modified exponentially weighted moving average (MEWMA) []; and Naveed et al. devised extended exponentially weighted moving average (EEWMA) []. Alevizakos et al. proposed a triple exponentially weighted moving average (TEWMA), a hybrid of EWMA in 2021, and reported that it was more efficient than the EWMA control chart []. They also proposed a double-modified exponentially weighted moving average (DMEWMA), which is a hybrid of the two MEWMA control charts [].

One tool that is frequently used in control chart measurement is Average Run Length (ARL). The Average Run Length (ARL) is the average number of observations or samples collected before a control chart indicates a potential shift in the process. When discussing symmetry, the focus is frequently on how symmetric and asymmetric alterations in process parameters (e.g., mean or variance) affect ARL and the comparative performance of various control charts []. Several common control charts, such as Shewhart charts, make the assumption that the process data are distributed symmetrically, much like the normal distribution. Both in-control (IC) and out-of-control (OOC) statuses are used to compute ARL. Consistent ARL performance for equal-sized deviations in both directions is guaranteed by symmetry []. Numerous techniques can be used to calculate the ARL; in particular, numerical integration equations (NIE) based on different quadrature methods can be used []. The solution of second-order Fredholm IEs is necessary to determine the explicit form of the ARL []. One benefit of using quadrature rules with the NIE technique is that it offers an accurate and computationally efficient means of estimating the ARL []. As a result, it can be used for the comparative analysis of exact solutions.

While traditional control charts like EWMA, MEWMA, and DMEWMA are typically designed with symmetric two-sided control limits, real-world applications may require one-sided limits. Additionally, processes exhibiting autocorrelation, where past data points influence current values, can undermine the effectiveness of standard control charts. In such cases, specialized charts or adjustments are necessary to accurately monitor and analyze these processes.

Stochastic processes that rely on time-space or time series are frequently the source of observations or data used in real-world scenarios. In other words, the models developed using econometric models are sometimes expressed in time-series models. The observations in an econometrics time-series model are made up of autoregressive (AR) and moving average (MA) elements. Identifying movement patterns of time-series observations in MA models is simple, and seasonal factors can easily be treated as seasonal moving averages (SMAs). Modeling should take into the difference between the exact and approximated values, often known as error. A smaller inaccuracy indicates higher accuracy. A smaller inaccuracy indicates higher accuracy. The error of a time-series model, known as white noise, often follows a normal distribution; however, another type of time-series model with auto-correlated observations is exponential white noise [,,,].

According to the literature review, DMEWMA charts have not been provided in any method other than the AR process []. Recently, Neammai et al. [] compared DMEAMA on the MA(q) process utilizing only the NIE approach. However, no exact solution has been discovered and compared to other charts. As a result, the primary focus of this study was on constructing an ARL for monitoring change in a time series using an MA model order q. In various circumstances, this approach is based on the DMEWMA control chart with underlying exponential white noise. An explicit formula was used to calculate the ARL. The control charts for EWMA and MEWMA continue for comparison. Furthermore, their ARL is extended to compare processes with the AMC entertainment stock datasets.

2. Materials and Methods

2.1. Exponentially Weighted Moving Average, EWMA

The exponentially weighted moving average (EWMA) is a statistical analysis technique that progressively averages data, assigning less weight to observations as they move further from the current measurement in time []. The EWMA statistic is calculated recursively using individual data points providing a dynamic and responsive measure of process behavior.

where is the EWMA statistic at time t, is an exponential smoothing parameter such that and is the observation at time t. The mean is , and the variance of the EWMA control chart is . The center line (CL) for the control chart is the average of historical data. The upper (UCL) and lower (LCL) control limits of the EWMA control charts are determined by

where and are the mean and standard deviation, respectively, and is the width of the control limit.

2.2. Modified Exponentially Weighted Moving Average, MEWMA

The MEWMA control chart is an attempt to improve the conventional EWMA chart’s performance. The constant case is taken into account in a revised MEWMA control chart []. The following is a description of the MEWMA statistic control chart:

where is an exponential smoothing parameter such that , is a MEWMA statistic at time t, with as the initial value and as the observation at time t; is an additional parameter in case turns to an EWMA control chart. The mean of is , and for large values of t, the variance of the statistic is approximately equal to . The center line (CL) for the control chart is the average of historical data. The upper (UCL) and lower (LCL) control limits of the EWMA control charts are determined by

where and are the mean and standard deviation, respectively, and is the width of the control limit.

2.3. Double-Modified EWMA Control Chart, DMEWMA

The DMEWMA control chart is a smoothed variant of the modified EWMA control chart, which allows the control chart to detect small shifts more easily []. The system of Equation (3) can be used to calculate the DMEWMA statistics.

where are DMEWMA and MEWMA statistics at time , is the observed value of the process at time are the smoothing parameters, are constants, and the starting values The calculations for the proposed DMEWMA chart are too complex because it includes four parameters, and To enhance the implementation and decrease the computational complexity, we take into account and The control chart performs best when and are configured [].

For a DMEWMA chart, the mean value is generally assumed to be the process mean in the absence of shifts. This is because the chart is designed to detect shifts from a stable process, so in the normal state, the chart’s value should be centered around the mean of the process. The mean is equal to .

For a DMEWMA chart, the variance can be more complex and will generally be a function of both the smoothing constant and the time horizon over which the control chart is monitored. However, for large values of t, the variance can be approximated as

Following (1), the centerline (CL), the upper control limit (UCL), and the lower control limit (LCL) of the proposed DMEWMA control chart are given by

where and are the mean and standard deviation of the process, and is the width of the control limit.

The DMEWMA control chart’s stopping time is represented as follows:

where the constant parameter represents the upper control limit and is the initial value of

2.4. Analytical Explicit Formula of ARL for the MA Model

In the case of exponential white noise, the observations equation for the moving average for the order q model () where q is the number of lags, or past values is specified as

where is the mean of the MA process, are the coefficients of the process, and is the exponential white noise. The DMEWMA statistics based on can be written as

Consider with initial value and define and

Thus, the DMEWMA statistics for at can be described as

In the control process, the interval of between the lower and upper bound control limits is expressed as and as shown below.

Subsequently, the control limit is moved to the exponential residual term in the following form:

The integral equation representing the ARL of the DMEWMA control chart (denoted by )

Let ; then, It can be rewritten as follows when the variable in (6) is changed:

Since so . Then,

After that, we define and . We obtain

Additionally, the solution to is as follows:

Then,

Ultimately, the explicit ARL formula on a two-sided DMEWMA control chart for the MA(q) model can be found by substituting Equation (8) into Equation (7).

The process is in control () when the exponential parameter but out of control () when the exponential parameter which where is the shift size in the mean.

2.5. The Existence and Uniqueness of Explicit Formula via Banach’s Fixed Point Theorem and Hölder Inequality

To verify that the ARL solution illustrates that the integral equation for an exact formula appears only once. To demonstrate the proof, we will use Banach’s fixed point theorem and Hölder inequality. The connection between Banach’s fixed-point theorem and Hölder’s inequality lies in their combined utility in solving problems involving the existence and uniqueness of solutions. The Banach fixed-point theorem is often applied to demonstrate the existence of solutions to integral equations, while Hölder’s inequality aids in establishing bounds necessary for these proofs [,].

For each class of continuous functions described by, let represent a function operation.

Theorem 1.

(Banach’s Fixed-point): Suppose that is a continuous function and satisfying the following assumption:

(H0): for with . If where and ; then, the formula has a unique solution.

Proof of Theorem 1.

Let be the contraction mapping for and for each ; then,

□

Theorem 2.

(Hölder’s inequality) Let be the measure space, and let with Then, for all measurable real-valued function and on Hölder’s inequality is

Proof of Theorem 2.

Given Hölder’s inequality, we have

It follows that is a contraction mapping. Hence, Banach’s fixed point theorem implies that has a unique point, which is the unique solution to problem (10). This completes the proof. □

2.6. Approximate Numerical Integral Equation of ARL for the MA Model

The explicit formula’s accuracy is verified using the ARL’s numerical integral equation approach (NIE method). The midpoint quadrature rule, designated , are used to determine the estimated ARL using the NIE approach.

A form that represents the solution to an integral equation for calculating the ARL is provided as

The approximation for an integral is evaluated using the quadrature rule as follows:

where is a point, and is a weight that is determined by the midpoint quadrature rule.

Using the midpoint quadrature formula, the result of the system of linear equations is as follows:

The system of m linear equations can be shown as If the inverse exists, the distinct resolution appears as

where and is a matrix. The elements of the R matrix are defined as

Finally, an approximation of the numerical integral for the function is

where and are a point and a weight that is determined by the midpoint quadrature rules, respectively.

3. Evaluation of Performance

Statistical performance was evaluated using simulation. All computations are repeated 1000 times. There are some criteria for evaluating the performance of a control chart. The most popular ARL has been chosen as the performance indicator for our suggestions. To determine the accuracy of the ARL solution between the proposed explicit form and the NIE method, the relative percentage change (RPC) [] is used to compare the results of the two techniques, as seen below.

Several researchers also defend other criteria, such as the median run length (MRL), which relates to the run length at the middle, and the standard deviation of run length (SDRL), which is a beneficial statistic used to examine the spreading []. Thus, the MRL and SDRL are estimated for the schemes described.

The in-control ARL, MRL, and SDRL are defined as

for where is the result of the process, and is the mean. While the out-of-control are given by

for where is the shifted mean proportion parameter.

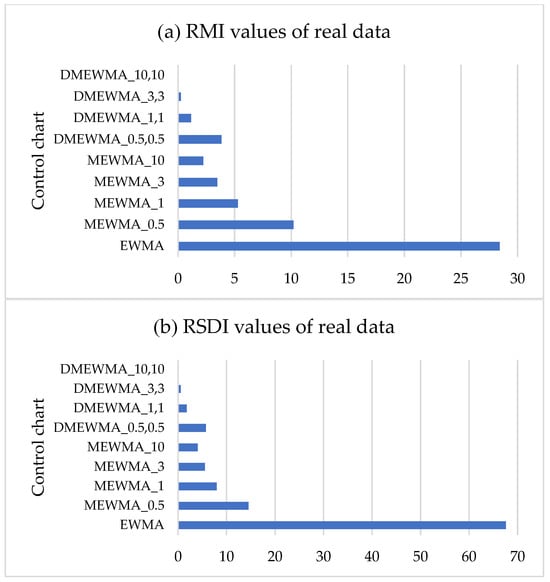

However, these criteria measure the performance of a control chart for a specific shift. To measure the overall performance, the relative mean index (RMI) and relative standard deviation index (RSDI) were proposed by Han and Tsung [].

The RMI and RSDI measures are calculated as

where is an amount of shift size considered, and are the and values of control charts for the specific shift , and and are the smallest of and values found in all of the charts proposed to detect the shift , receptively. Control schemes with the lowest RMI and RSDI values detect shifts more swiftly and robustly. It should be noted that in this article, SDRL values equal to zero are not considered in the computation of RSDI, and this index is calculated by the range of shifts with SDRL greater than zero. To start the monitoring action, we consider a specific in-control ARL. The control chart methods in this article have been developed to have an in-control ARL of around 370.

3.1. Simulation Results

The study is divided into two parts: comparing the proposed approach to numerical methods and determining whether the proposed method performs better. The criteria utilized is the relative percentage change. The other part is to look at the performance of the proposed method by comparing it with previously studied charts, namely the EWMA chart and the DMEWMA chart. This analysis was carried out using simulations in Wolfram Mathematica 8, which were conducted 1000 times each. The relative standard deviation index (RSDI) and relative mean index (RMI) are used to compare how well these three approaches perform. The selection of the optimal method is determined by two crucial factors minimizing the values of indicators RSDI and RMI. In this research, we study the performance of the control chart to detect only the mean by fixing the variation. Therefore, the performance of the proposed control chart will challenge only detecting the mean. The process mean shifts from to where indicating an out-of-control condition. The in-control condition is characterized by exponential white noise with mean . The results are as follows: = 0.001, 0.003, 0.005, 0.01, 0.03, 0.05, 0.1, 0.3, 0.5, and 1, where and, respectively, imply that the process is under control and out of control, respectively. These processes are denoted as and

We performed simulation research to assess the efficacy of explicit formulas, and NIE approaches for the ARL of an MA(q) process running on the DMEWMA control chart using the steps detailed below.

Step 1: Setting up the control limit for the MA(q) process:

- i.

- Define the exponential white noise () and smoothing parameters for the in-control process.

- ii.

- Define the initial values for the MA(q) process and the DMEWMA statistic.

- iii.

- Select acceptable values for ARLout and the shift sizes ().

- iv.

- Compute the upper control limit (b) that gives the desired ARL for the control process by using (9).

Step 2: For the in-control ARL:

- i.

- Compute ARLin using (9) when given the upper control limit (b) from Step 1.

- ii.

- Approximate the value of ARLin Via the NIE method by using (11).

- iii.

- If necessary, change the value of b according to the desired ARLin value (Here, we set ARL0 = 370).

Step 3: For the out-of-control ARL:

- i.

- Compute ARLout for various shift sizes and using (9) and the value of b from Step 1.

- ii.

- Approximate ARLout Via the NIE method by using (6).

- iii.

- Compare the ARL values obtained using the explicit formulas and NIE methods.

When examining the exact and numerical approaches’ relative percentage change (RPC) values. Table 1 and Table 2 present the results of the simulation, which show that the relative percentage change (RPC) produces relatively modest numbers. This indicates that there is no difference between the two approaches’ average values. This is relevant even though the value adjusts, and the process mean shifts grow.

Table 1.

The ARL values for MA(q) models on the DMEWMA control chart with the initial and , where with .

Table 2.

The ARL values for MA(q) models on the DMEWMA control chart with the initial and , where with .

Table 3 compares lambda values on the DMEWMA chart in and processes for and . In this case, giving the lower values is used in the control chart comparison phase. The results demonstrate that produces a lower value (the bold fonts indicate the lower values for a specific shift, and each value of ) in the case of being small (lower than 5), obviously, but when is large, gives a lower value, but when considered carefully in this situation, the values are not much different. So, in this study, we put to compare the charts in the following step.

Table 3.

Comparison of ARL values for DMEWMA control charts under varying . Conditions and .

Table 4 presents a comparison of the scenarios for equal and unequal Zeta values. In the case of , when the ARL value is slightly lower, particularly when the mean undergoes small to moderate changes. Similarly, for results in a noticeably lower ARL value under small to moderate mean shifts. However, the difference is not substantial enough to impact the analysis significantly. Hence, for chart comparisons, the scenario where values are equal is selected for simulation.

Table 4.

Comparison of ARL values for DMEWMA control charts under varying . Conditions and .

The performance comparison of the EWMA, MEWMA, and DMEWMA control charts with varying and utilizing the ARL at for the and models, respectively, is displayed in Table 5 and Table 6. When the shift in the process means becomes bigger, these ARL data clearly demonstrate that the average run length of the DMEWMA approach is less than that of MEWMA and EWMA. If the values are the same, the MEWMA and DMEWMA approaches are comparable. Table 5 and Table 6 demonstrate that the additional parameters in the DMEWMA chart enhance detection speed, resulting in lower ARL values. Notably, when c is set to match the MEWMA, the chart achieves reduced ARL values. Similarly, keeping in the DMEWMA equal to in the MEWMA ensures that in the DMEWMA also yields lower ARL values. For example, In Table 5, at , the EWMA chart yields an ARLout of 364.6455. When is applied in the MEWMA chart, the ARLout reduces to 335.9040. Further, in the DMEWMA chart, with fixed and set , the ARLout decreases to 308.9601, demonstrating a consistent trend across all cases. This clearly shows that the DMEWMA chart is superior.

Table 5.

The ARL, SDRL, and MRL values for two-sided control charts on when and with .

Table 6.

The ARL, SDRL, and MRL values for two-sided control charts on when and with .

Additionally, Table 7’s summarized findings for each control chart are compared using the RMI and RSDI values, which were calculated so that the DMEWMA control chart’s RMI and RSDI values are lower than those of the EMMA and MEWMA at the same and . Furthermore, greater capacity and lower ARL and RMI values are shown by the DMEWMA control charts with large and values.

3.2. Empirical Applications

In this section, the ARL formula has been applied to real data using the following steps.

- Estimate parameters from relevant data, such as stock prices, ensuring the inclusion of an MA mode by using the SPSS program.

- Estimate the parameter of exponentially distributed residuals using the one-sample Kolmogorov–Smirnov goodness-of-fit test.

- Use the parameter values from steps 1 and 2 to calculate the ARL using Equation (9).

- Compare performance by evaluating the ARL obtained in step 3 with the EWMA and MEWMA control charts.

- Detect changes in the process mean by determining the UCL value using the equation in (9) and applying it to data for computation.

To accomplish the primary goal of this study, we present experiments with real data to observe how the results align with the results of synthetic data. The real data used is the stock of AMC Entertainment (AMC), an American entertainment corporation provided by https://th.investing.com/equities/amc-entertat-hld (accessed on 10 October 2024). From these data, we have 52 total weekly price histories ranging from 17 September 2023 to 8 September 2024.

Before comparing the performance of EWMA, MEWMA, and DMEWMA control charts, we check the compatibility between the real data and the MA models, namely and , by taking into account the following values: R-squared, Root Mean Squared Error (RMSE), Mean Absolute Percentage Error (MAPE), and Mean Absolute Error (MAE), as shown in Table 8. The following shows the parameter values and Kolmogorov–Smirnov goodness-of-fit test that were obtained by fitting the model using SPSS. For dataset, it was fitted to the because, as a result, the has the highest R-square and the lowest RMSE, MAPE, and MAE, indicating that it is the best model, as illustrated in bold letters in Table 8. Apply the Kolmogorov–Smirnov Test to ensure that white noise conforms to the exponential mean presented in Table 9. The parameters of this prediction model can be assigned as follows:

Table 8.

The MA estimates for AMC Entertainment stock price and model fit.

Table 9.

Exponential white noise of residual using the one-sample Kolmogorov–Smirnov goodness of fit test.

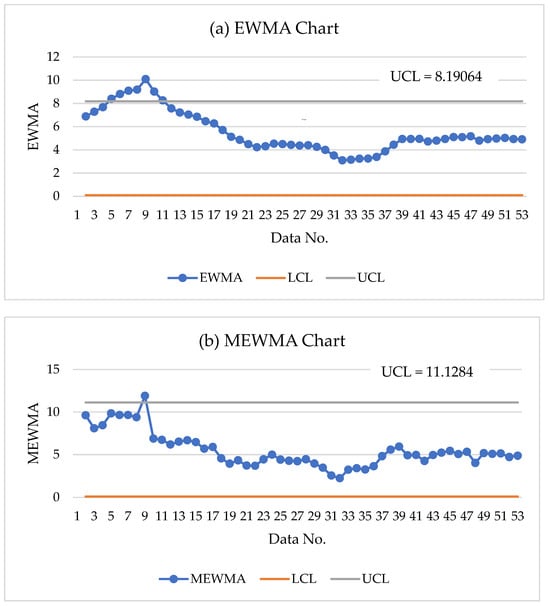

Table 10 summarizes the results of the explicit formula technique used to compare the ARL, SDRL, and MRL values for on the EWMA, MEWMA, and DMEWMA control charts. It can be seen that the results are clearly consistent with Table 5. The table shows that the DMEWMA control chart has lower ARL, SDRL, and MRL values than EWMA and MEWMA, as shown in Figure 1. Here, we compare MEWMA and DMEWMA in terms of looking at the c value (i.e., the c value in MEWMA is equal to the c1 value in DMEWMA is compared), and if we look at the trend of ARL values when c in MEWMA increases, the ARL value decreases. At the same time, when c1 in DMEWMA increases, the ARL value decreases significantly. Overall, when all the models are compared in terms of each process mean shifts, DMEWMA has the lowest value. This also resulted in the lowest RMI and RSDI of all mean process changes, as shown in Figure 2.

Table 10.

The ARL, SDRL, and MRL values for two-sided control charts on when and .

Figure 1.

Graphical display of out-of-control ARL values of each control chart occur when the shift size values vary.

Figure 2.

Comparing (a) RMI and (b) RSDI values across EWMA, MEWMA, and DMEWMA control charts.

Figure 3 has been applied to real data through the following steps:

Figure 3.

The AMC Entertainment stock price fitted to an process running on (a) EWMA chart, (b) MEWMA chart, and (c) DMEWMA chart.

- Import AMC Entertainment () stock price data.

- Set initial values and parameters.

- Calculate the statistics for the three control charts using Equations (1)–(3) with the data from step 1.

- Set the upper control limit (UCL) to 0.1.

- Determine the lower control limit (LCL) using Equation (9).

- Plot the graph using the results from steps 3, 4, and 5, and identify any values that exceed the control limits.

Control charts for stock prices as a statistical tool used to monitor fluctuations and identify atypical trends based on Statistical Process Control (SPC) methodologies. While traditional SPC charts are designed for stable industrial processes, applying them to stock prices can still provide insights, particularly for detecting unusual price movements or volatility spikes. This chart enables traders and analysts to detect significant deviations from expected price movements, facilitating informed decision-making and risk management. Figure 3, the EWMA, MEWMA, and DMEWMA statistics for AMC Entertainment’s stock price are analyzed to assess variability and detection efficiency, determining which control chart identifies changes most rapidly. The findings indicate that the DMEWMA control chart detects the change at the first observation, whereas the EWMA and MEWMA charts identify changes at the fifth and ninth observations, respectively. This suggests that, for this real dataset, the DMEWMA control chart exhibits a shorter initial detection time compared to the other two methods. Consequently, the results highlight the superior detection speed of the DMEWMA control chart, demonstrating its enhanced performance in adapting to process variations relative to the EWMA and MEWMA control charts.

4. Discussion and Conclusions

The theoretical computations revealed exceptional accuracy, with the ARL calculated from the explicit formula closely matching the ARL obtained using the NIE method, indicating a relative percentage error of less than 0.00001. Furthermore, the existence and uniqueness of the ARL derivation based on the explicit formulas were proved. The explicit formula and NIE method were applied to derive and evaluate ARL values for an MA process with exponential white noise operating under the DMEWMA control chart that features symmetric two-sided control limits. While the literature highlights the EWMA and MEWMA control charts for their similarities to the DMEWMA chart, the DMEWMA chart—an advanced iteration of the MEWMA—was chosen for comparative analysis. Its performance against EWMA and MEWMA charts underscores its refined design and superior efficacy. Our analysis of the DMEWMA chart focused on the critical parameter , revealing that assigning greater weight to compared to (the parameter of MEWMA) results in a lower ARL value. The proposed method evaluated the ARL, SDRL, and MRL values for MA processes on EWMA, MEWMA, and DMEWMA control charts, comparing their performances across varying mean shift sizes. Additionally, these charts were assessed using RMIs and RSDIs for different design parameter values. Experimental results using AMC stock price data aligned closely with theoretical computations, affirming the DMEWMA control chart’s superior ability to detect small process shifts. This validates the assertion that while MEWMA, an enhancement of EWMA, is highly effective at detecting small changes, DMEWMA, built upon MEWMA, achieves even greater performance. Notably, the DMEWMA chart identified out-of-control values faster than both the EWMA and MEWMA charts. The findings of this study align with the research of Phanthuna et al. [], who analyzed the DMEWMA chart in the context of the AR model and similarly concluded that the DMEWMA control chart outperformed the comparison chart.

This research not only validates the DMEWMA control chart’s efficacy but also highlights its practical utility in financial strategies, enabling the detection of shifts in stock price movements because the DMEWMA control chart is a variant of the EWMA control chart that is well-suited for monitoring systems that exhibit dynamic or non-stationary behavior. Its application to stock data has important consequences because financial markets are inherently unpredictable and non-stationary []. Such detections can serve as actionable buy or sell signals for investors, underscoring the chart’s potential in optimizing investment decisions. In summary, the DMEWMA control chart outperformed EWMA and MEWMA charts for all change magnitudes, with results validated using AMC Entertainment stock data. However, the proposed explicit formula derivation for the ARL can be applied to other scenarios.

The limitations of this research are that it only considers scenarios using exponential white noise and the MA(q) model. To increase detection efficiency, we can differentiate between detected changes for real shifts and random variations. For data with other white noise patterns, alternative approaches, such as the Markov Chain Method, may be required to calculate the ARL value. Furthermore, using other models such as ARMA, ARIMA, or ARFIMA in conjunction with the DMEW-MA control chart may result in more comprehensive solutions for real-world applications.

Author Contributions

Conceptualization, J.N., Y.A. and S.S.; methodology, J.N. and Y.A.; software, J.N.; validation, J.N. and S.S.; formal analysis, J.N.; investigation, J.N.; writing—original draft preparation, J.N.; writing—review and editing, J.N. and Y.A.; visualization, Y.A. and S.S.; supervision, Y.A.; funding acquisition, Y.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Thailand Science Research and Innovation Fund (NSRF) and King Mongkut’s University of Technology North Bangkok under contract no. KMUTNB-FF-68-B-08.

Data Availability Statement

The data can be found at [https://th.investing.com/equities/amc-entertat-hld (accessed on 10 September 2024)].

Acknowledgments

The authors are grateful to the editor and referees for their valuable time and efforts on our manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shewhart, W.A. Quality control charts. Bell Syst. Tech. J. 1926, 5, 593–603. [Google Scholar] [CrossRef]

- Pozzi, R.; Cannas, V.G.; Rossi, T. Data Science Supporting Lean Production: Evidence from Manufacturing Companies. Systems 2024, 12, 100. [Google Scholar] [CrossRef]

- Carrey, R.G.; Stake, L.V. Improving Healthcare with Control Charts: Basic and Advanced SPC Methods and Case Studies; ASQ Quality Press: Milwaukee, WI, USA, 2003. [Google Scholar]

- Johan, T.; Jonas, L.; Jakob, A.; Jesper, O.; Cheryl, C.; Karin, P.H.; Mats, B. Application of statistical process control in healthcare improvement: Systematic review. Qual. Saf. Health Care 2007, 16, 387–399. Available online: https://qualitysafety.bmj.com/content/16/5/387 (accessed on 5 November 2024).

- Saravanan, A.; Nagarajan, P. Implementation of quality control charts in bottles manufacturing industry. Int. J. Eng. Sci. Technol. 2013, 5, 335–340. Available online: https://www.semanticscholar.org/paper/IMPLEMENTATION-OF-QUALITY-CONTROL-CHARTS-IN-BOTTLE-Saravanan/a40f7d24bc412debb145f5c3709f6bfe214cdeef#citing-papers (accessed on 20 October 2024).

- Yang, Z. Monitoring Process Variability with Symmetric Control Limits. Research Collection School of Economics, 2020. Available online: https://ink.library.smu.edu.sg/soe_research/2064/ (accessed on 17 December 2024).

- Montgomery, D.C. Introduction to Statistical Quality Control, 8th ed.; Wiley: Hoboken, NJ, USA, 2020. [Google Scholar]

- Page, E.S. Continuous inspection schemes. Biometrika 1954, 41, 100–115. [Google Scholar] [CrossRef]

- Roberts, S.W. Control chart tests based on geometric moving averages. Technometrics 1959, 1, 239–250. [Google Scholar] [CrossRef]

- Shamma, S.E.; Shamma, A.K. Development and evaluation of control charts using double exponentially weighted moving averages. Int. J. Qual. Reliab. Manag. 1992, 9, 18–25. [Google Scholar] [CrossRef]

- Capizzi, G.; Masarotto, G. An adaptive exponentially weighted moving average control chart. Technometrics 2003, 45, 199–207. [Google Scholar] [CrossRef]

- Zhou, Q.; Zou, C.; Wang, Z.; Jiang, W. Likelihoodbased EWMA charts for monitoring poisson count data with time-varying sample sizes. J. Am. Stat. Assoc. 2012, 107, 1049–1062. [Google Scholar] [CrossRef]

- Patel, A.K.; Divecha, J. Modified exponentially weighted moving average (EWMA) control chart for an analytical process data. J. Chem. Eng. Mater. Sci. 2011, 2, 12–20. Available online: https://iopscience.iop.org/article/10.1088/1742-6596/979/1/012097 (accessed on 20 October 2024).

- Naveed, M.; Azam, M.; Khan, N.; Aslam, M. Design a control chart using extended EWMA statistics. Technologies 2018, 6, 108. [Google Scholar] [CrossRef]

- Alevizakos, V.; Chatterjee, K.; Koukouvinos, C. The triple exponentially weighted moving average control chart. Qual. Technol. Quant. Manag. 2021, 18, 326–354. [Google Scholar] [CrossRef]

- Alevizakos, V.; Chatterjee, K.; Koukouvinos, C. Modified EWMA and DEWMA control charts for process monitoring. Commun. Stat. -Theory Methods 2021, 51, 7390–7412. [Google Scholar] [CrossRef]

- Woodall, W.H. Controversies and contradictions in statistical process control. J. Qual. Technol. 2000, 32, 341–350. [Google Scholar] [CrossRef]

- Crowder, S.V. A simple method for studying run length distributions of exponentially weighted moving average charts. Technometrics 1987, 29, 401–407. [Google Scholar] [CrossRef]

- Paichit, P.; Peerajit, W. The average run length for continuous distribution process mean shift detection on a modified EWMA control chart. Asia-Pac. J. Sci. Technol. 2022, 27, 109–118. [Google Scholar] [CrossRef]

- Areepong, Y.; Karoon, K. Detection capability of the dewma chart using explicit run length solutions: A case study on data of gross domestic product. Eng. Lett. 2024, 32, 1300–1312. Available online: https://www.engineeringletters.com/issues_v32/issue_7/index.html (accessed on 20 October 2024).

- Andel, J. On AR (1) processes with exponential white noise. Commun. Stat. Theory Methods 1988, 17, 1481–1495. [Google Scholar] [CrossRef]

- Turkman, M.A.A. Bayesian analysis of an autoregressive process with exponential white noise. Statistics 1990, 21, 601–608. [Google Scholar] [CrossRef]

- Ibazizen, M.; Fellag, H. Bayesian estimation of an AR (1) process with exponential white noise. Statistics 2003, 37, 365–372. [Google Scholar] [CrossRef]

- Girón, F.J.; Caro, E.; Domínguez, J.I. A conjugate family for AR (1) processes with exponential errors. Commun. Stat. Theory Methods 1994, 23, 1771–1784. [Google Scholar] [CrossRef]

- Phanthuna, P.; Areepong, Y.; Sukparungsee, S. Performance Measurement of a DMEWMA Control Chart on an AR(p) Model with Exponential White Noise. Appl. Sci. Eng. Prog. 2024, 17, 7088. [Google Scholar] [CrossRef]

- Neammai, J.; Areepong, Y.; Sukparungsee, S. Performance Comparison of Numerical Integral Equation Methods on DMEWMA Control Chart for Moving Average Process Order q. Research, Invention, and Innovation Congress. In Proceedings of the 2023 Innovative Electricals and Electronics (RI2C), Bangkok, Thailand, 24–25 August 2023. [Google Scholar] [CrossRef]

- Banach Fixed-Point Theorem. Available online: https://en.wikipedia.org/wiki/Banach_fixed-point_theorem (accessed on 4 September 2024).

- Hölder’s Inequality. Available online: https://www.wikiwand.com/en/articles/H%C3%B6lder’s_inequality (accessed on 4 September 2024).

- Bualuang, D.; Peerajit, W. Performance of the CUSUM control chart using approximation to ARL for long-memory fractionally integrated autoregressive process with exogenous variable. Appl. Sci. Eng. Prog. 2022, 16, 5917. [Google Scholar] [CrossRef]

- Fonseca, A.; Ferreira, P.H.; Nascimento, D.C.; Fiaccone, R.; Correa, C.U.; Piña, A.G.; Louzada, F. Water Particles Monitoring in the Atacama Desert: SPC approach Based on proportional data. Axioms 2021, 10, 154. [Google Scholar] [CrossRef]

- Han, D.; Tsung, F. A reference-free cuscore chart for dynamic mean change detection and a unified framework for charting performance comparison. Am. Stat. Assoc. 2006, 101, 368–386. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).