Autonomous Multirotor UAV Docking and Charging: A Comprehensive Review of Systems, Mechanisms, and Emerging Technologies

Abstract

1. Introduction

2. Categorization of Multirotor UAV Docking Systems

2.1. Fixed Docking Systems

2.2. Mobile Docking Systems

3. Positioning and Landing Mechanisms

3.1. Mechanical Positioning

3.2. Passive Positioning

3.3. Vision-Based Approaches

3.4. Sensor Fusion Methods

3.5. Precision and Modular Docking Solutions

3.6. Summary and Trade-Offs in Positioning and Landing Mechanisms

4. Charging Mechanisms and Technologies

4.1. Physical Contact Charging

4.2. Wireless Power Transfer

5. Battery Swapping Approaches

5.1. Swapping Mechanisms on Fixed Platforms

5.2. Swapping Mechanisms Using Mobile Platforms

6. Discussion and Future Directions

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| UAV | Unmanned Aerial Vehicle |

| MEMS | Microelectromechanical Systems |

| UGV | Unmanned Ground Vehicle |

| USV | Unmanned Surface Vehicle |

| GNSS | Global Navigation Satellite System |

| WPT | Wireless Power Transfer |

| EM | Electromagnetic |

| CC-CV | Constant-Current Constant-Voltage |

| PV | Photovoltaic |

| AI | Artificial Intelligence |

References

- Zhukov, I.; Dolintse, B. Enhancing Accuracy of Information Processing in Onboard Subsystems of UAVs. Technol. Audit Prod. Reserv. 2023, 5, 6–10. [Google Scholar] [CrossRef]

- Nieuwoudt, H.; Welgemoed, J.; van Niekerk, T.; Phillips, R. Automated Charging and Docking Station for Security UAVs. In Proceedings of the 2023 14th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 3–5 May 2023; pp. 32–38. [Google Scholar] [CrossRef]

- Jain, K.P.; Mueller, M.W. Flying Batteries: In-Flight Battery Switching to Increase Multirotor Flight Time. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 3510–3516. [Google Scholar] [CrossRef]

- Lai, C.; Paliwal, A.; Loo, M.; Tran, N.; Khong, H. Methods of Automating Power Swapping Mechanisms for Extending UAV Flight Missions. In Proceedings of the 2023 Wireless Telecommunications Symposium (WTS), Boston, MA, USA, 19–21 April 2023; pp. 1–10. [Google Scholar] [CrossRef]

- Omar, B.; Al Savvaris, O.; Rahil, O.; Abdulhadi; Afdhol, M.K.; Hasibuan, M.Y. Saving Hydrogen Fuel Consumption and Operating at High Efficiency of Fuel Cell in a Hybrid System to Power UAV. J. Earth Energy Eng. 2021, 10, 32–42. [Google Scholar] [CrossRef]

- Almesafri, N.; Alhammadi, M.; Zafar, S.; Santos, G. Power System Analysis of Solar and Hydrogen Fuel Cell Powered EVTOL UAV. In Proceedings of the ASME 2024 International Mechanical Engineering Congress and Exposition; Volume 3: Advanced Materials: Design, Processing, Characterization and Applications; Advances in Aerospace Technology, Portland, OR, USA, 17–21 November 2024; V003T05A006. ASME: New York, NY, USA, 2024. [Google Scholar] [CrossRef]

- An, J.-H.; Kwon, D.-Y.; Jeon, K.-S.; Tyan, M.; Lee, J.-W. Advanced Sizing Methodology for a Multi-Mode eVTOL UAV Powered by a Hydrogen Fuel Cell and Battery. Aerospace 2022, 9, 71. [Google Scholar] [CrossRef]

- Bhaad, M.S.; Pai, A.; Mahalank, S.; Mirza, K.; Azmi, D.; Deshmukh, V.; Sharma, C. Ariel Symphony: Nature-Inspired Docking and Battery Swapping for UAV. Innov. Emerg. Technol. 2024, 11, 2440015. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, T.; Liu, P.; Lu, X. Outdoor Independent Charging Platform System for Power Patrol UAV. In Proceedings of the 2020 12th IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Nanjing, China, 20–23 September 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Ambroziak, L.; Kownacki, C.; Bożko, A. Hybrid VTOL UAV Autonomous Operations from Mobile Landing Pad. In Proceedings of the 2022 26th International Conference on Methods and Models in Automation and Robotics (MMAR), Międzyzdroje, Poland, 22–25 August 2022; pp. 270–275. [Google Scholar] [CrossRef]

- Nadig, N.; Minde, P.; Gautam, A.; Asokan, A.B.; Malhi, G.S. Conceptual Design of Aerostat-Based Autonomous Docking and Battery Swapping System for Extended Airborne Operation. Drones Auton. Veh. 2024, 1, 10013. [Google Scholar] [CrossRef]

- Nelson, B.; Preez, J.D.; van Niekerk, T.; Phillips, R.; Stopforth, R. Autonomous Landing of a Multirotor Aircraft on a Docking Station. In Proceedings of the 2020 International SAUPEC/RobMech/PRASA Conference, Cape Town, South Africa, 29–31 January 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Aikins, G.; Jagtap, S.; Nguyen, K.-D. A Robust Strategy for UAV Autonomous Landing on a Moving Platform under Partial Observability. Drones 2024, 8, 232. [Google Scholar] [CrossRef]

- Al-Obaidi, M.R.; Wan Hasan, W.Z.; Mustafa, M.A.; Azis, N. Charging Platform of Chess-Pad Configuration for Unmanned Aerial Vehicle (UAV). Appl. Sci. 2020, 10, 8365. [Google Scholar] [CrossRef]

- Moreira, M.; Azevedo, F.; Ferreira, A.; Pedro, D.; Matos-Carvalho, J.; Ramos, Á.; Loureiro, R.; Campos, L. Precision Landing for Low-Maintenance Remote Operations with UAVs. Drones 2021, 5, 103. [Google Scholar] [CrossRef]

- Thuan, P.N.; Tomi, W.; Jorge, P.Q. Vision-based safe autonomous UAV docking with panoramic sensors. Front. Robot. AI 2023, 10, 1223157. [Google Scholar] [CrossRef]

- Wang, B.; Ma, R.; Zhu, H.; Sha, Y.; Yang, T. An Autonomous Tracking and Landing Method for Unmanned Aerial Vehicles Based on Visual Navigation. Drones 2023, 7, 703. [Google Scholar] [CrossRef]

- Liao, M.; Yang, G.; Liu, C. A method for obtaining fixed-point positions by precision landing of unmanned aerial vehicles. In Proceedings of the Fourth International Conference on Geology, Mapping, and Remote Sensing (ICGMRS), Wuhan, China, 14–16 April 2023. [Google Scholar] [CrossRef]

- Tsapparellas, K.; Jelev, N.; Waters, J.; Shrikhande, A.; Brunswicker, S.; Mihaylova, L. A versatile real-time vision-led runway localisation system for enhanced autonomy. Front. Robot. AI 2024, 11, 1490812. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Du, W.; Lin, J.; Borhan, U.M.; Lin, Y.; Du, B.; Li, X.; Li, J. Emergency UAV Landing on Unknown Field Using Depth-Enhanced Graph Structure. IEEE Trans. Autom. Sci. Eng. 2025, 22, 4434–4445. [Google Scholar] [CrossRef]

- Sanjukumar, N.T.; Meghashyam, A.V.V.; Bhuvanesh; Rajalakshmi, P. TDMBPLD: A Dataset Focusing on Marker Scene for UAV Landing. IEEE Geosci. Remote Sens. Lett. 2025, 22, 8500105. [Google Scholar] [CrossRef]

- Houichime, T.; Amrani, Y.E. Reinforcement Learning-Based Monocular Vision Approach for Autonomous UAV Landing. arXiv 2025. [Google Scholar] [CrossRef]

- Schroder, S.; Deng, Y.; James, A.; Seth, A.; Morton, K.; Mukhopadhyay, S.C.; Han, R.; Zheng, X. Towards Robust Autonomous Landing Systems: Iterative Solutions and Key Lessons Learned. In Proceedings of the 2025 55th Annual IEEE/IFIP International Conference on Dependable Systems and Networks-Supplemental Volume (DSN-S), Naples, Italy, 23–26 June 2025; pp. 167–173. [Google Scholar] [CrossRef]

- Nugraha, B.; Abidin, Z. QR-Code Based Visual Servoing and Target Recognition to Improve Payload Release Accuracy in Air Delivery Missions using Fully Autonomous Quad-Copter UAV. Recursive J. Inform. 2025, 3, 59–67. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, G.; Zhong, F. Research on UAV Autonomous Recognition and Approach Method for Linear Target Splicing Sleeves Based on Deep Learning and Active Stereo Vision. Electronics 2024, 13, 4872. [Google Scholar] [CrossRef]

- Narváez, E.; Ravankar, A.A.; Ravankar, A.; Emaru, T.; Kobayashi, Y. Autonomous VTOL-UAV Docking System for Heterogeneous Multirobot Team. IEEE Trans. Instrum. Meas. 2021, 70, 5500718. [Google Scholar] [CrossRef]

- Liu, C.; Fang, S.; Li, J.; Gaom, B. An Adaptive Dual-Docking Force Control of Ship-Borne Manipulators for UAV-Assisted Perching. In Proceedings of the 2024 IEEE 14th International Conference on CYBER Technology in Automation, Control, and Intelligent Systems (CYBER), Copenhagen, Denmark, 16–19 July 2024; pp. 394–398. [Google Scholar] [CrossRef]

- Wang, Y.; Paul, H.; Miyazaki, R.; Martinez, R.; Kominami, T.; Ladig, R.; Shimonomura, K. Active Translatory Drive System with Docking Capability for UAV Power Line Inspection. In Proceedings of the 2022 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Sapporo, Japan, 11–15 July 2022; pp. 689–694. [Google Scholar] [CrossRef]

- Zang, Z.; Ma, J.; Li, C.; Wang, H.; Jing, R.; Shi, Y. A Design of Automatic UAV Dock Platform System. J. Phys. Conf. Ser. 2020, 1650, 022068. [Google Scholar] [CrossRef]

- Martin, T.; Blanco, J.R.; Mouret, J.B.; Raharijaona, T. Compact Docking Station for Sub-150g UAV Indoor Precise Landing. In Proceedings of the 2024 International Conference on Unmanned Aircraft Systems (ICUAS), Chania, Greece, 4–7 June 2024; pp. 1267–1274. [Google Scholar] [CrossRef]

- De Silva, S.C.; Phlernjai, M.; Rianmora, S.; Ratsamee, P. Inverted Docking Station: A Conceptual Design for a Battery-Swapping Platform for Quadrotor UAVs. Drones 2022, 6, 56. [Google Scholar] [CrossRef]

- Feng, Z.; Zheng, K.; Ma, T.; Liu, W.; Song, Y.; Liu, X.; Li, Z.; Ma, M. Research on patrol platform of fixed wing UAV for ultra long distance transmission and distribution lines. In Proceedings of the 3rd International Conference on Artificial Intelligence, Automation, and High-Performance Computing (AIAHPC 2023), Wuhan, China, 31 March–2 April 2023. [Google Scholar] [CrossRef]

- Zhan, G.; Niu, S.; Zhang, W.; Zhou, X.; Pang, J.; Li, Y.; Zhan, J. A Docking Mechanism Based on a Stewart Platform and Its Tracking Control Based on Information Fusion Algorithm. Sensors 2022, 22, 770. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, X.; Wang, D.; Wang, L.; Tu, Z.; Ai, J. Research on Aerial Autonomous Docking and Landing Technology of Dual Multi-Rotor UAV. Sensors 2022, 22, 9066. [Google Scholar] [CrossRef]

- Chen, M.; Zeng, F.; Xiong, X.; Zhang, X.; Chen, Z. A Maritime Emergency Search and Rescue System Based on Unmanned Aerial Vehicle and Its Landing Platform. In Proceedings of the 2021 IEEE International Conference on Electrical Engineering and Mechatronics Technology (ICEEMT), Qingdao, China, 2–4 July 2021; pp. 758–761. [Google Scholar] [CrossRef]

- Liu, Y.; Li, H.; Wang, L.; Ai, J. Deep Learning Approach to Drogue Detection for Fixed-Wing UAV Autonomous Aerial Refueling with Visual Camera. In Proceedings of the 2023 International Conference on Unmanned Aircraft Systems (ICUAS), Warsaw, Poland, 6–9 June 2023; pp. 827–834. [Google Scholar] [CrossRef]

- Xu, Y.; Han, P.; Zhao, Z.; Zhang, W. The Stable Method of UAV Landing on the Moving Platform. In Proceedings of the 2023 35th Chinese Control and Decision Conference (CCDC), Yichang, China, 20–22 May 2023; pp. 2809–2814. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, M.; Li, D.; Li, M. A mobile UAV hangar design for transmission line inspection. In Proceedings of the 2024 3rd International Conference on Smart Grids and Energy Systems (SGES), Zhengzhou, China, 25–27 October 2024; pp. 234–238. [Google Scholar] [CrossRef]

- Wu, L.; Wang, C.; Zhang, P.; Wei, C. Deep Reinforcement Learning with Corrective Feedback for Autonomous UAV Landing on a Mobile Platform. Drones 2022, 6, 238. [Google Scholar] [CrossRef]

- Shriki, U.; Gal, O.; Doytsher, Y. Drone Autonomous Landing on a Moving Maritime Platform Using Machine Learning Classifiers. Int. J. Data Sci. Adv. Anal. 2020, 2, 30–35. [Google Scholar] [CrossRef]

- Choi, A.J.; Park, J.; Han, J.H. Development of mid-air autonomous aerial docking system using onboard machine learning computations. In Proceedings of the Active and Passive Smart Structures and Integrated Systems XV, Online, 22–26 March 2021. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Liu, Y.; Li, J. Neural Adaptive Coordinated Docking Control with Improved Prescribed Performance for UAV Aerial Recovery. IEEE Trans. Ind. Electron. 2024, 71, 16546–16557. [Google Scholar] [CrossRef]

- Laffita van den Hove d’Ertsenryck, J.J.E.; Smeur, E.J.J.; Remes, B.D.W. Rigid Airborne docking between a fixed-wing UAV and an over-actuated multicopter. In Proceedings of the 14th Annual International Micro Air Vehicle Conference and Competition, Aachen, Germany, 11–15 September 2023; pp. 231–239. Available online: https://resolver.tudelft.nl/uuid:706644d1-4f28-482a-8add-65d7be4d4e68 (accessed on 3 November 2025).

- Keipour, A.; Pereira, G.A.S.; Bonatti, R.; Garg, R.; Rastogi, P.; Dubey, G.; Scherer, S. Visual Servoing Approach to Autonomous UAV Landing on a Moving Vehicle. Sensors 2022, 22, 6549. [Google Scholar] [CrossRef]

- Morales, J.; Castelo, I.; Serra, R.; Lima, P.U.; Basiri, M. Vision-Based Autonomous Following of a Moving Platform and Landing for an Unmanned Aerial Vehicle. Sensors 2023, 23, 829. [Google Scholar] [CrossRef]

- Cheng, C.; Li, X.; Xie, L.; Li, L. A Unmanned Aerial Vehicle (UAV)/Unmanned Ground Vehicle (UGV) Dynamic Autonomous Docking Scheme in GPS-Denied Environments. Drones 2023, 7, 613. [Google Scholar] [CrossRef]

- Dong, X.; Gao, Y.; Guo, J.; Zuo, S.; Xiang, J.; Li, D.; Tu, Z. An Integrated UWB-IMU-Vision Framework for Autonomous Approaching and Landing of UAVs. Aerospace 2022, 9, 797. [Google Scholar] [CrossRef]

- He, C.; Zhang, Z.; He, C.; Yang, L.; Wan, F. Research on vision-based autonomous precise landing of unmanned aerial vehicles and adaptive inspection software for UAVs. In Proceedings of the International Conference on Physics, Photonics, and Optical Engineering (ICPPOE 2024), Singapore, 8–10 November 2024. [Google Scholar] [CrossRef]

- Livingston, J.R.; Pilskalns, O.J. Battery Exchange and Charging System for Drones. U.S. Patent US20210380019A1, 7 November 2023. [Google Scholar]

- Ali, E.; Fanni, M.; Mohamed, A.M. A New Battery Selection System and Charging Control of a Movable Solar-Powered Charging Station for Endless Flying Killing Drones. Sustainability 2022, 14, 2071. [Google Scholar] [CrossRef]

- Chang, C.-W.; Lo, L.-Y.; Cheung, H.C.; Feng, Y.; Yang, A.-S.; Wen, C.-Y.; Zhou, W. Proactive Guidance for Accurate UAV Landing on a Dynamic Platform: A Visual–Inertial Approach. Sensors 2022, 22, 404. [Google Scholar] [CrossRef]

- Taner, B.; Subbarao, K. Modeling of Cooperative Robotic Systems and Predictive Control Applied to Biped Robots and UAV-UGV Docking with Task Prioritization. Sensors 2024, 24, 3189. [Google Scholar] [CrossRef]

- Ochoa-de-Eribe-Landaberea, A.; Zamora-Cadenas, L.; Peñagaricano-Muñoa, O.; Velez, I. UWB and IMU-Based UAV’s Assistance System for Autonomous Landing on a Platform. Sensors 2022, 22, 2347. [Google Scholar] [CrossRef] [PubMed]

- Xuan-Mung, N.; Hong, S.K.; Nguyen, N.P.; Ha, L.N.N.T.; Le, T.L. Autonomous quadcopter precision landing onto a heaving platform: New method and experiment. IEEE Access 2020, 8, 167192–167202. [Google Scholar] [CrossRef]

- Pereira, P.; Campilho, R.; Pinto, A. An Inverse Kinematics Approach for the Analysis and Active Control of a Four-UPR Motion-Compensated Platform for UAV–ASV Cooperation. Machines 2023, 11, 478. [Google Scholar] [CrossRef]

- Liu, X.; Shao, M.; Zhang, T.; Zhou, H.; Song, L.; Jia, F.; Sun, C.; Yang, Z. Research on Motion Control and Compensation of UAV Shipborne Autonomous Landing Platform. World Electr. Veh. J. 2024, 15, 388. [Google Scholar] [CrossRef]

- Jianming, Z.; Kanyao, J.; Rui, C.; Yi, Y.; Kejia, L. A Tethered Aerial Recovery System for UAV Landing on USV. In Proceedings of the 2024 9th International Conference on Automation, Control and Robotics Engineering (CACRE), Jeju Island, Republic of Korea, 18–20 July 2024; pp. 321–328. [Google Scholar] [CrossRef]

- Lo, T.-Y.; Chang, J.-Y.; Wei, T.-Z.; Chen, P.-Y.; Huang, S.-P.; Tsai, W.-T.; Liou, C.-Y.; Lin, C.-C.; Mao, S.-G. GPS-Free Wireless Precise Positioning System for Automatic Flying and Landing Application of Shipborne Unmanned Aerial Vehicle. Sensors 2024, 24, 550. [Google Scholar] [CrossRef]

- Deng, L.; Yang, B.; Dong, X.; Cui, Y.; Gao, Y.; Li, D.; Tu, Z. Self-Spin Enabled Docking and Detaching of a UAV-UGV System for Aerial-Terrestrial Amphibious and Independent Locomotion. IEEE Robot. Autom. Lett. 2023, 8, 2454–2461. [Google Scholar] [CrossRef]

- Infanti, J.; Pegg, A.; Kanninen, T. Landing Systems and Methods for Unmanned Aerial Vehicles. U.S. Patent US12214902B2, 4 February 2025. [Google Scholar]

- Nguyen, M.T.; Nguyen, C.V.; Truong, L.H.; Le, A.M.; Quyen, T.V.; Masaracchia, A.; Teague, K.A. Electromagnetic Field Based WPT Technologies for UAVs: A Comprehensive Survey. Electronics 2020, 9, 461. [Google Scholar] [CrossRef]

- Cai, C.; Liu, X.; Wu, S.; Chen, X.; Chai, W.; Yang, S. A misalignment tolerance and lightweight wireless charging system via reconfigurable capacitive coupling for unmanned aerial vehicle applications. IEEE Trans. Power Electron. 2023, 38, 22–26. [Google Scholar] [CrossRef]

- Lozano-Hernández, Y.; Martínez de la Cruz, I.; Gutiérrez-Frías, O.; Lozada-Castillo, N.; Luviano-Juárez, A. Design Procedure of a Low-Cost System for Energy Replenishment in a Quadrotor UAV through a Battery Exchange Mechanism. Drones 2023, 7, 270. [Google Scholar] [CrossRef]

- Hoang, M.; Ov, A.; Chen, S.; Huynh, D.; Vega, J.; Kim, N.; Karwal, Y.; Dobbs, S.; Yu, Z. Design of Autonomous Battery Swapping for UAVs. In Proceedings of the 2024 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Boston, MA, USA, 15–19 July 2024; pp. 353–358. [Google Scholar] [CrossRef]

- Kodeeswaran, S.; Kannabhiran, A.; Elangovan, D. A comparative study of energy sources, docking stations and wireless charging technologies for certain quadrotor unmanned aerial vehicles. Aerosp. Sci. Technol. 2025, 166, 110628. [Google Scholar] [CrossRef]

- Gil, J.; Cooper, J. Methods for Parcel Delivery and Pickup via an Unmanned Aerial Vehicle. U.S. Patent US10860971B2, 8 December 2020. [Google Scholar]

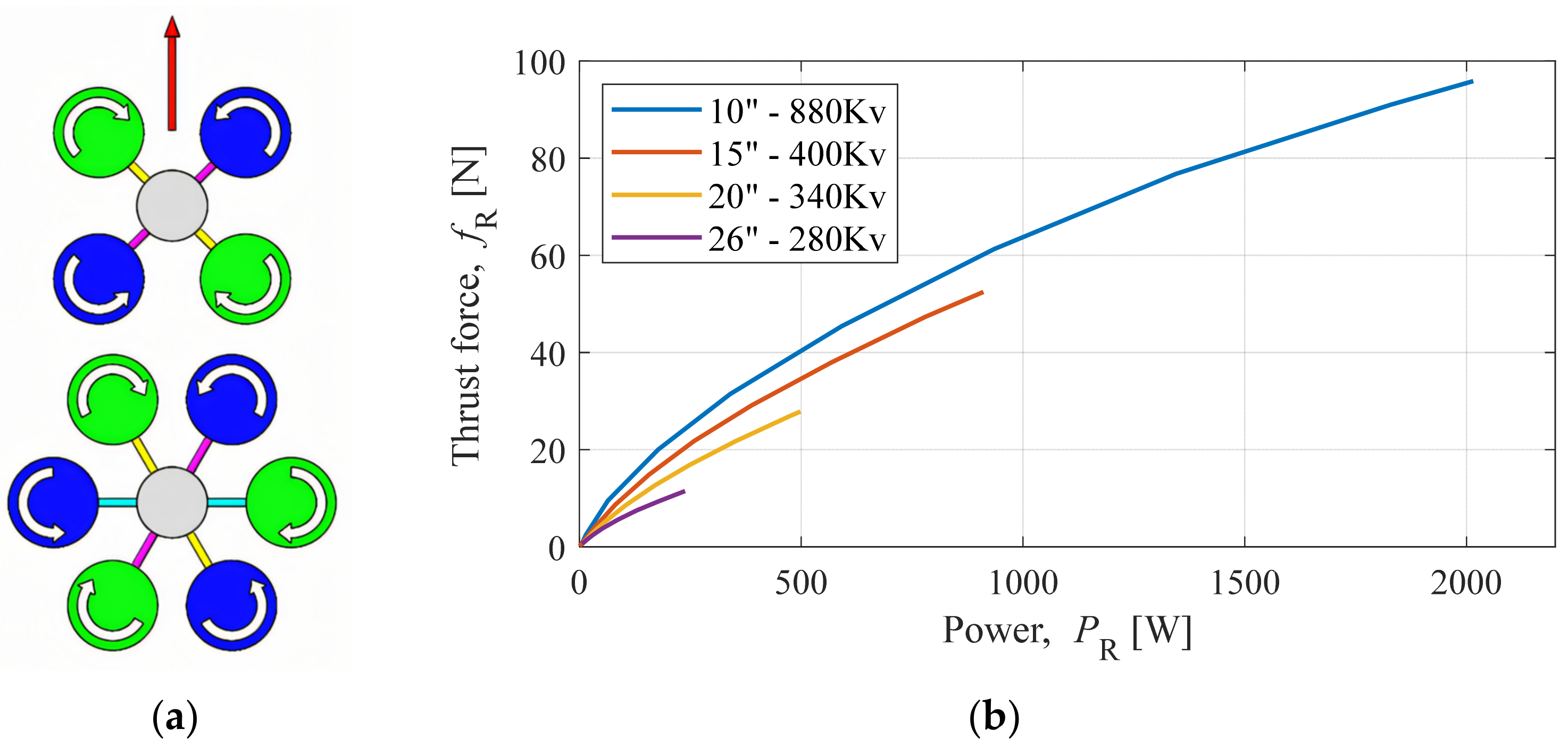

- Song, Y.; Kim, H.; Byun, J.; Park, K.; Kim, M.; Lee, S.J. Aerial Dockable Multirotor UAVs: Design, Control, and Flight Time Extension Through In-Flight Battery Replacement. IEEE Access 2025, 13, 96782–96799. [Google Scholar] [CrossRef]

- Xu, R.; Liu, C.; Cao, Z.; Wang, Y.; Qian, H. A Manipulator-Assisted Multiple UAV Landing System for USV Subject to Disturbance. Ocean Eng. 2024, 299, 117306. [Google Scholar] [CrossRef]

- Mirza, K.Z.; Bohrey, A.; Bangera, S.; Agrawal, H.; Shukla, D.; Pant, R.S. A Robotic Solution for Autonomous Battery Swapping of Unmanned Aerial Vehicles. In Proceedings of the AIAA AVIATION 2023 Forum, San Diego, CA, USA, 12–16 June 2023. [Google Scholar] [CrossRef]

- Chen, J.; Li, W.; Sha, Y.; Yinchuan, W.; Zhang, Z.; Li, S.; Wang, C.; Ma, S. Autonomous battery-changing system for UAV’s lifelong flight. Biomim. Intell. Robot. 2023, 3, 100104. [Google Scholar] [CrossRef]

- Bláha, L.; Severa, O.; Goubej, M.; Myslivec, T.; Reitinger, J. Automated Drone Battery Management System—Droneport: Technical Overview. Drones 2023, 7, 234. [Google Scholar] [CrossRef]

- Guetta, Y.; Shapiro, A. On-Board Physical Battery Replacement System and Procedure for Drones During Flight. IEEE Robot. Autom. Lett. 2022, 7, 9755–9762. [Google Scholar] [CrossRef]

- Fox, Y.; Kliner, M.; Krauss, R. Positioning and Locking System and Method for Unmanned Vehicles. U.S. Patent US20190202578A1, 4 July 2019. [Google Scholar]

- Stamatovski, I. Unmanned Aerial Vehicle Charging Station with Centering Mechanism. U.S. Patent US20180148170A1, 31 May 2018. [Google Scholar]

- Zhao, T.; Currier, C.; Bonnin, A.; Mellos, G.; Martinez, N.; Chen, Y. Low Cost Autonomous Battery Replacement System for Quadrotor Small Unmanned Aerial Systems (sUAS) using 3D Printing Components. In Proceedings of the 2018 International Conference on Unmanned Aircraft Systems (ICUAS), Dallas, TX, USA, 12–15 June 2018; pp. 103–107. [Google Scholar] [CrossRef]

- Embention—Precision Landing for Autonomous Battery Replacement. Available online: https://www.embention.com/drones-unmaneed-vehicles/precision-landing-for-autonomous-battery-replacement/ (accessed on 17 September 2025).

- Kim, J.; Song, C.-U. Three-Phase Wireless Power Transfer System and Three-Phase Wireless Chargeable Un-Manned Aerial Vehicle System Based on the Same. U.S. Patent US20180056794A1, 25 September 2018. [Google Scholar]

- Wang, Z.; Liu, C. Unmanned Aerial Vehicle Airport, Unmanned Aerial Vehicle System, Tour Inspection System and Unmanned Aerial Vehicle Cruise System. U.S. Patent US12091194B2, 17 September 2024. [Google Scholar]

- Gu, Y.; Wang, J.; Liang, Z.; Zhang, Z. Mutual-inductance-dynamic-predicted constant current control of LCC-P compensation network for drone wireless Inflight charging. IEEE Trans. Ind. Electron. 2022, 69, 12710–12719. [Google Scholar] [CrossRef]

- Kim, J.Y.; Sanchez, J.; Kim, J. Base Station for Drone Battery Swap. U.S. Patent US12286252B2, 29 April 2025. [Google Scholar]

- Shengdong, D. Unmanned Aerial Vehicle Charging System. China Patent CN215972166U, 8 March 2022. [Google Scholar]

- Kodeeswaran, S.; Julius Fusic, S.; Kannabhiran, A.; Nandhini Gayathri, M.; Padmanaban, S. Design of dual transmitter and single receiver coil to improve misalignment performance in inductive wireless power transfer system for electric vehicle charging applications. Results Eng. 2024, 24, 103602. [Google Scholar] [CrossRef]

- Jevtuševski, A.; Ihnatiev, Y.; Lillerand, T.; Virro, I.; Olt, J. Constructive solution of battery swapping unit in service station for unmanned agricultural robot. Agron. Res. 2025, 23, 415–435. [Google Scholar] [CrossRef]

- Zheng, B.; Wu, Y.; Li, H.; Chen, Z. Adaptive Sliding Mode Attitude Control of Quadrotor UAVs Based on the Delta Operator Framework. Symmetry 2022, 14, 498. [Google Scholar] [CrossRef]

- Takaoğlu, F.; Alshahrani, A.; Ajlouni, N.; Ajlouni, F.; Al Kasasbah, B.; Özyavaş, A. Robust Nonlinear Non-Referenced Inertial Frame Multi-Stage PID Controller for Symmetrical Structured UAV. Symmetry 2022, 14, 689. [Google Scholar] [CrossRef]

| Platform | Fixed | UGV | UAV | USV | |

|---|---|---|---|---|---|

| Docking | Mechanical | 14 (40%) | 5 (25%) | 7 (87.5%) | 3 (37.5%) |

| Passive | 21 (60%) | 12 (60%) | 0 | 5 (62.5%) | |

| Landing navigation | Machine vision | 18 (51.4%) | 10 (50%) | 5 (62.5%) | 2 (25%) |

| Sensor fusion | 7 (20%) | 6 (30%) | 0 | 3 (37.5%) | |

| Other | 2 (5.7%) | 1 (5%) | 0 | 2 (25%) | |

| Charging | Direct contact | 3 (8.6%) | 1 (5%) | 0 | 1 (12.5%) |

| Wireless | 5 (14.3%) | 3 (15%) | 1 (12.5%) | 0 | |

| Other | 10 (28.6%) | 3 (15%) | 3 (37.5%) | 1 (12.5%) | |

| Mechanical Positioning | Passive Positioning | Machine Vision | Sensor Fusion | |

|---|---|---|---|---|

| Accuracy | High | Medium | High | Very high |

| Cost | High | Low | Very high | High |

| Complexity | High | Low | High | High |

| Adaptability | Medium | Low | Medium | High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šćuric, A.; Krznar, N.; Penđer, A.; Štedul, I.; Kotarski, D. Autonomous Multirotor UAV Docking and Charging: A Comprehensive Review of Systems, Mechanisms, and Emerging Technologies. Symmetry 2025, 17, 1988. https://doi.org/10.3390/sym17111988

Šćuric A, Krznar N, Penđer A, Štedul I, Kotarski D. Autonomous Multirotor UAV Docking and Charging: A Comprehensive Review of Systems, Mechanisms, and Emerging Technologies. Symmetry. 2025; 17(11):1988. https://doi.org/10.3390/sym17111988

Chicago/Turabian StyleŠćuric, Alen, Nino Krznar, Antonia Penđer, Ivan Štedul, and Denis Kotarski. 2025. "Autonomous Multirotor UAV Docking and Charging: A Comprehensive Review of Systems, Mechanisms, and Emerging Technologies" Symmetry 17, no. 11: 1988. https://doi.org/10.3390/sym17111988

APA StyleŠćuric, A., Krznar, N., Penđer, A., Štedul, I., & Kotarski, D. (2025). Autonomous Multirotor UAV Docking and Charging: A Comprehensive Review of Systems, Mechanisms, and Emerging Technologies. Symmetry, 17(11), 1988. https://doi.org/10.3390/sym17111988