1. Introduction

In recent years, cemented tailings backfill (CTB) technology has emerged as a vital strategy in metal mining, aligning with the principles of green mining and sustainable resource development [

1,

2,

3]. CTB plays a crucial role not only in stabilizing mined-out voids and controlling ground pressure but also in mitigating surface subsidence, which ultimately enhances mining safety and operational efficiency. As the primary aggregate in CTB mixtures, tailings significantly influence the overall performance of the backfill. The physical properties and particle size distribution of tailings are particularly critical, as they directly affect the workability and strength of the hardened backfill [

4,

5].

With the growing emphasis on resource recycling, both classified and unclassified tailings are increasingly being utilized in backfill operations [

6,

7,

8,

9]. Previous research by Fall et al. demonstrated the impact of tailing particle size on the water demand of fresh cemented paste backfill (CPB) and the strength of hardened CPB [

10]. Ke et al. explored how tailing gradation affects both fresh and hardened CPB properties [

11]. Their findings indicated that increasing the fineness of tailings reduces the flowability of CPB. Qiu et al. [

12] highlighted that the fineness of tailings has a significant impact on the fluidity and uniaxial compressive strength (UCS) of CPB. Zhang [

13] further explored how the particle size distribution of tailings influences the fresh slurry’s settlement behavior, bleeding rate, slump, and rheological properties, as well as the effect of tailing gradation on the UCS of hardened CTB. Li [

14] studied the influence of gangue particle size gradation on cemented backfill using uniaxial compression, acoustic emission, digital image correlation, and SEM analysis. They found that compressive strength peaked at 4.28 MPa at a gradation coefficient of 0.5, and variations in pore and crack distribution caused differences in acoustic emission behavior and backfill strength.

Among the various factors influencing CTB performance, the cement-to-tailings (C/T) ratio and slurry concentration are considered particularly critical [

15,

16,

17]. Studies have shown that increasing these parameters typically enhances hydration reactions, facilitates the formation of binding products, and results in a denser microstructure, ultimately improving the compressive strength of CTB [

18,

19,

20,

21]. Li et al. [

22] investigated the effects of solid content, C/T ratio, and curing time on the rheological properties and mechanical performance of CTB slurry. The results showed that slurry concentration and the C/T ratio significantly influenced the rheological behavior and compressive strength of CTB. Wang [

23] explored the coupling effects of the C/T ratio and solid content on the early strength of cemented coarse tailings backfill. This study found that increases in both the C/T ratio and solid content enhanced the compressive strength of CTB, with a synergistic interaction between the two factors. Cai [

24] investigated the effects of curing age and the cement–sand ratio on the strength and energy evolution of cemented whole-tailings backfill through uniaxial compression tests. They found that both strength and energy parameters increased exponentially with curing age and the cement–sand ratio. The results revealed that crack initiation and propagation consumed significant energy, and the energy storage limit effectively reflected the internal damage evolution of the backfill body. Zhu [

25] used superfine cement to improve the fluidity, strength, and pore structure of superfine tailings cemented paste backfill (STCPB) and analyzed the influence of water film thickness (WFT) on its performance. The results showed that superfine cement significantly enhanced the compactness and strength of STCPB, while the cement-to-tailings ratio, solid content, and WFT had notable effects on its spread diameter and compressive strength. Ru [

26] investigated the uniaxial compressive behavior and failure mechanisms of cemented tailings backfill (CTB) with varying cement-to-tailings ratios. They found that lower ratios reduced strength and energy accumulation while promoting coarser particles and more pronounced shear failure and developed a modified damage constitutive model that accurately simulates the full compression process.

While many studies have focused on individual factors such as binder type, curing conditions, and tailing gradation, a systematic understanding of how the differences between classified and unclassified tailings affect CTB behavior under identical mix conditions remains limited. Moreover, research has not sufficiently addressed the microstructure-to-failure mechanism perspective, which is essential for a comprehensive understanding of CTB performance.

To address this gap, we conduct a multi-scale investigation of cemented tailings backfill (CTB) using classified and unclassified tailings as aggregates. Specimens with cement-to-tailings (C/T) ratios of 1:8, 1:6, and 1:4 and slurry concentrations of 60%, 65%, and 70% were prepared and subjected to uniaxial compression (UCS) testing, failure mode observation, and scanning electron microscopy (SEM). By jointly examining mechanical response, failure patterns, and microstructural evolution, we clarify how mix design governs CTB performance and reveal the mechanisms underlying strength development and failure. These findings provide practical guidance for optimizing mix designs and improving the safety and efficiency of underground backfilling. In addition, viewed through a symmetry lens, CTB deformation can be interpreted as a process of symmetry formation and subsequent breaking: the early-age distributions of hydration products and internal stress are approximately symmetric, whereas loading promotes microcrack initiation and defect growth, breaking symmetry and culminating in localized deformation and macroscopic failure.

2. Materials and Methods

2.1. Materials

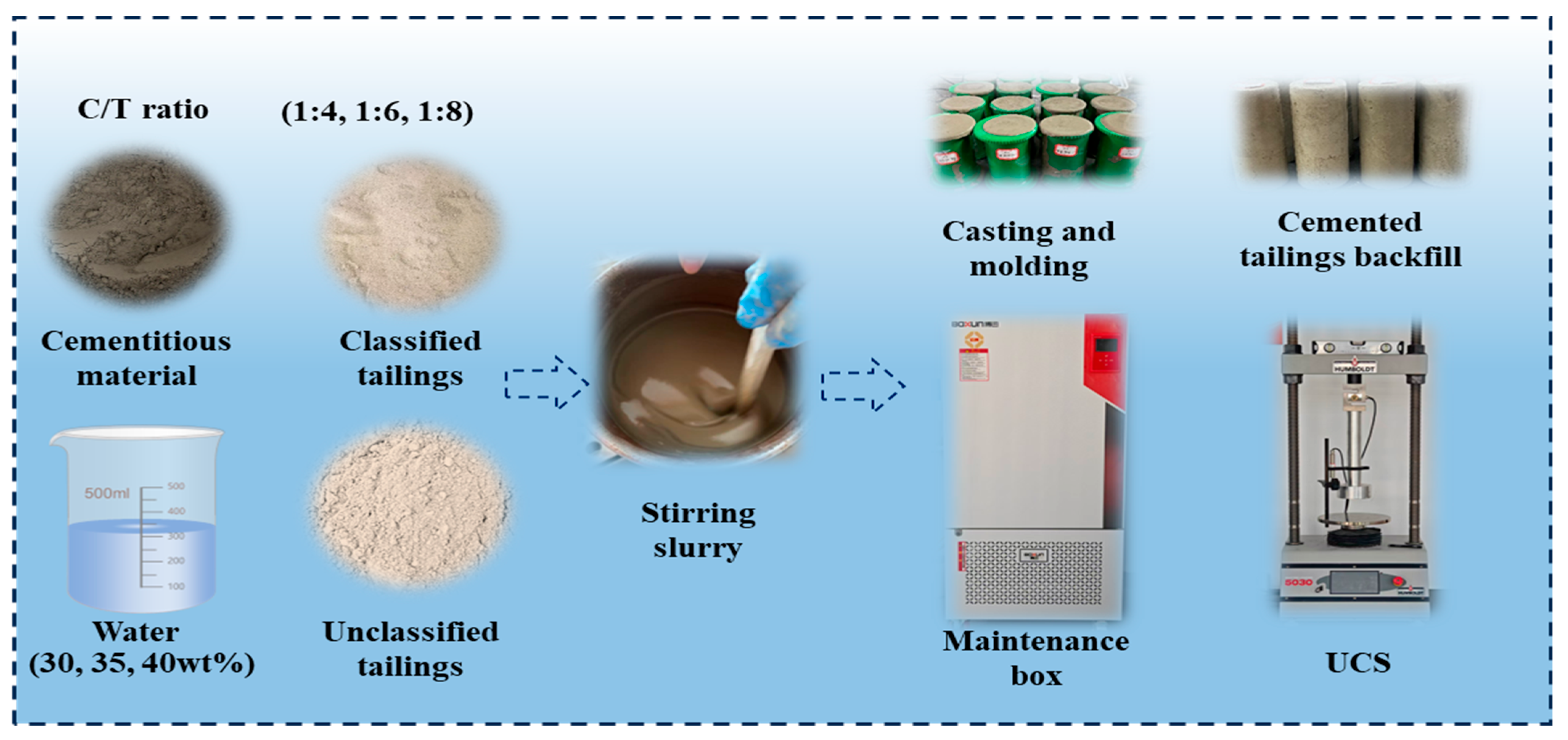

The tailings were oven-dried and used as unclassified tailings for the experiments. After sieving, graded tailings were obtained and air-dried under natural conditions (

Figure 1). The main chemical composition was analyzed using X-ray fluorescence (XRF), as shown in

Table 1. The tailings mainly consisted of SiO

2, MgO, Fe

2O

3, and Al

2O

3. The binder used was a slag-based alkali-activated material. The mixing water was industrial tap water with a pH of 7.3, a SO

42− concentration of 414.32 mg/L, and a Cl

− concentration of 5.41 × 10

3 mg/L. The chemical composition of the cementing material is shown in

Table 2.

2.2. Methods

The primary objective of this study is to investigate the strength development patterns of cemented backfills prepared from classified tailings and unclassified tailings under varying mix proportions. To this end, cemented backfill specimens were prepared separately using classified tailings and unclassified tailings, with slurries formulated at different cement-to-tailings ratios (1:4, 1:6, and 1:8) and solid concentrations (60%, 65%, and 70%). The mixtures were poured into 50 × 100 mm molds pre-coated with lubricant and gently tapped for 5 min to release entrapped air bubbles. After standing for 48 h, the specimens were demolded and cured in a controlled environment chamber at 18 °C and 96% relative humidity for curing durations of 3, 7, and 28 days. Uniaxial compression tests were conducted using a pressure testing machine to obtain stress–strain curves. Additionally, scanning electron microscopy (SEM) was employed to analyze the failure modes and microstructural strength mechanisms of the backfills. The experimental procedure and analysis methods are illustrated in

Figure 2, and the detailed experimental design is summarized in

Table 3.

3. Results

3.1. Stress–Strain Response Characteristics

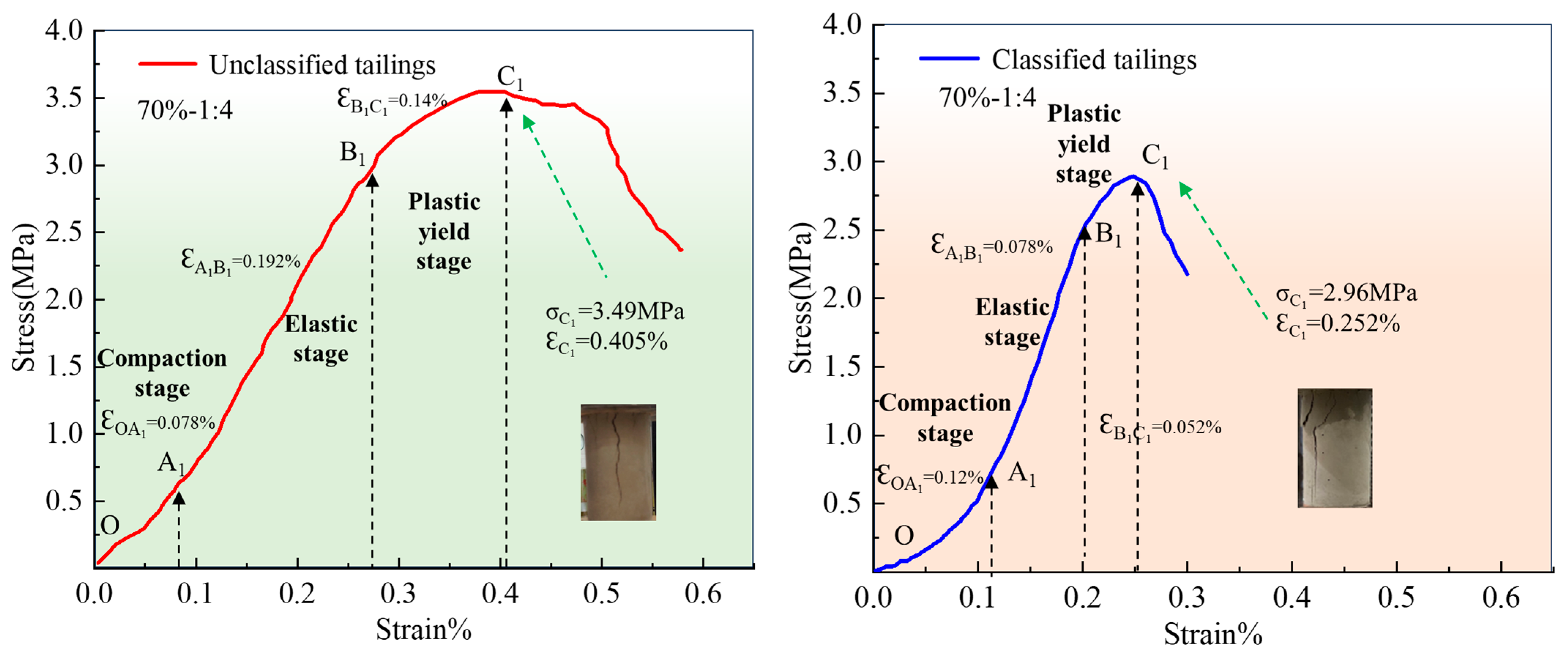

Although the stress–strain curves of specimens prepared with different binder–sand ratios and slurry concentrations exhibit similar overall trends, notable differences still exist between the responses of the unclassified and classified tailings. To highlight these differences, representative samples with a binder–sand ratio of 1:4 and a slurry concentration of 70%, cured for 7 days, were selected for comparative analysis. The results are presented in

Figure 3.

As shown in

Figure 3, under the same cement-to-tailings ratio (1:4) and slurry concentration (70%), the stress–strain curves of both unclassified and classified tailings specimens undergo four stages: pore compaction, linear elasticity, plastic yielding, and post-peak failure. However, their deformation characteristics and failure behaviors differ significantly [

27].

Firstly, during the pore compaction stage (OA1), the classified tailings specimens complete compaction at a strain of 0.12%, notably higher than the 0.078% observed for unclassified tailings. This indicates that classified tailings, with a more optimized particle size distribution, have larger initial voids and undergo more pronounced particle rearrangement and pore closure, resulting in a longer compaction phase (OA1 segment) and stronger microstructural accommodation.

Secondly, in the linear elastic and plastic yielding stages (A1B1, B1C1), the unclassified tailings exhibit longer strain intervals of 0.192% and 0.14%, respectively, whereas the classified tailings complete these stages at shorter strains of 0.078% and 0.052%. This suggests that unclassified tailings experience a more gradual deformation process before peak stress, with more stable strain accumulation and energy release, while classified tailings deform more rapidly, exhibiting a “quick rise and sharp drop” behavior.

Finally, during the post-peak failure stage, the unclassified tailings show a gradual stress decline, indicating ductile failure characteristics, with crack propagation occurring progressively while retaining some load-bearing capacity. In contrast, classified tailings undergo a sharp stress drop accompanied by rapid crack coalescence and sudden structural instability, reflecting a typical brittle failure mode.

In summary, although both tailings types share similar stages in their stress–strain evolution, their curve morphologies and mechanical responses differ substantially. Classified tailings, with fewer fine particles and a looser skeletal framework lacking fine particle filling support and strong interparticle locking, exhibit sufficient pre-peak compaction but rapid post-peak instability with brittle failure traits. Conversely, unclassified tailings, enriched with fines that fill the voids and create a denser matrix, demonstrate greater ductility, better deformation coordination, and enhanced energy absorption. These differences underscore the dominant influence of particle size distribution on the deformation mechanisms and failure modes of cemented tailings backfill.

3.2. Mechanical Strength Characteristics of CTB

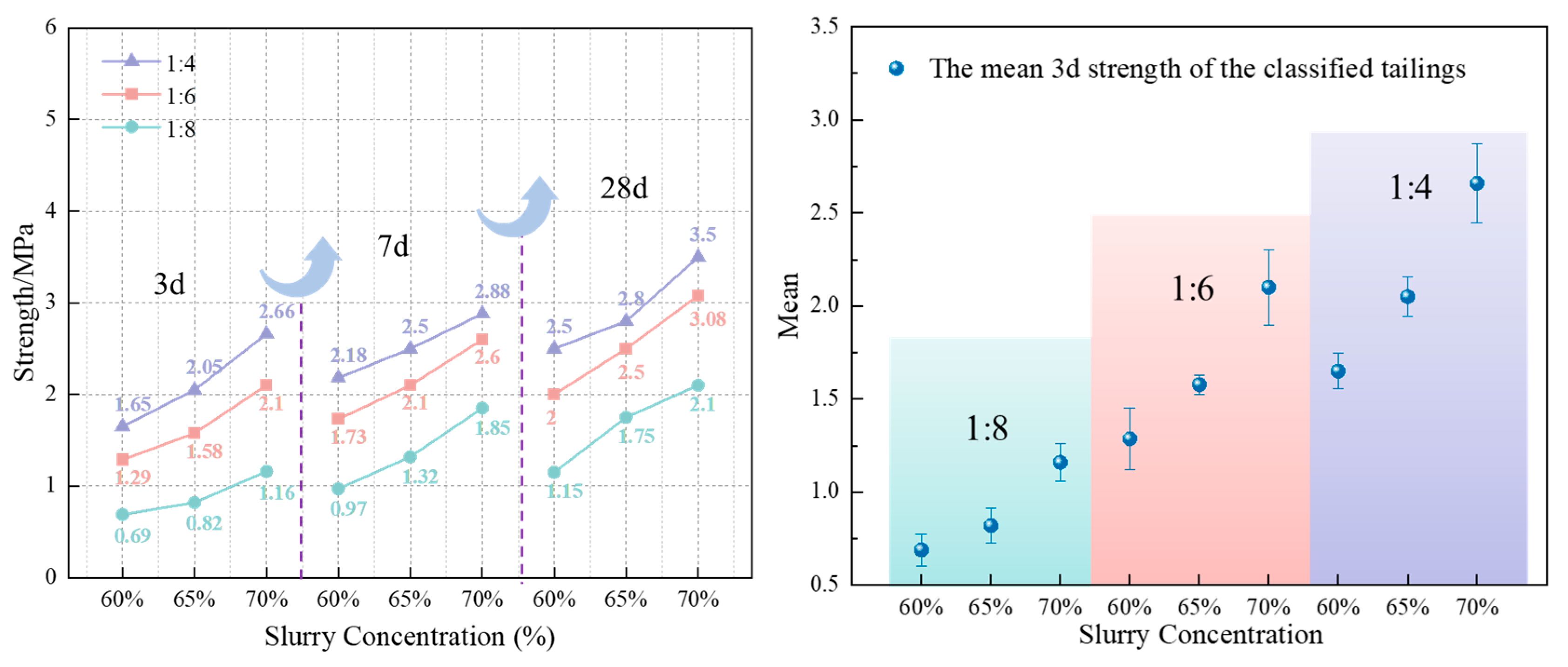

Based on an in-depth analysis of the representative stress–strain curve differences between classified and unclassified tailings cemented backfill, 54 sets of uniaxial compressive strength test data at curing ages of 3, 7, and 28 days were collected and compiled to systematically investigate the strength evolution of both tailings types under varying cement-to-tailings ratios and slurry concentrations, as presented in

Table 3 and

Table 4.

The uniaxial compressive strength (UCS) of cemented tailings backfill (CTB) is significantly influenced by slurry concentration, cement-to-tailings ratio, and curing time. Across all specimens, extended curing periods generally enhance strength due to progressive hydration reactions, which promote cementitious bonding and matrix densification. However, notable differences emerge between classified and unclassified tailings in terms of response magnitude and strength development patterns under varying mix conditions [

28].

Based on the data presented in

Figure 4 and

Figure 5, factors such as slurry concentration, the cement-to-tailings ratio, and curing time significantly influence the mechanical properties of both unclassified tailings and classified tailings, showing notable differences and patterns.

3.2.1. Influence of Slurry Concentration on Strength Growth

Increasing slurry concentration enhances the mechanical strength of both tailings types by promoting a denser solid skeleton. Nevertheless, unclassified tailings exhibit a more pronounced sensitivity to slurry concentration changes. For instance, at a cement-to-tailings ratio of 1:4 and 7-day curing age, increasing the slurry concentration from 60% to 70% increases the UCS of unclassified tailings from 2.41 MPa to 3.55 MPa, a 47.3% rise. In contrast, classified tailings under the same conditions improve from 2.18 MPa to 2.88 MPa, representing a more modest 32.1% increase. This disparity is attributed to the higher fines content in unclassified tailings, which better fills voids and supports denser particle packing at elevated concentrations.

3.2.2. Effect of Cement-to-Tailings Ratio on Strength Enhancement

Strength increases with higher binder content for both tailings types, yet the degree and efficiency of strength gain differ. At 70% slurry concentration and 28-day curing age, increasing the cement-to-tailings ratio from 1:8 to 1:4 boosts UCS for unclassified tailings from 3.51 MPa to 5.38 MPa (a 53.3% increase), whereas that for classified tailings increases from 2.10 MPa to 3.50 MPa (a 66.7% increase). Although classified tailings show a higher relative improvement, unclassified tailings consistently exhibit higher absolute strength values under identical conditions, indicating the more efficient utilization of cementitious materials due to enhanced particle packing and contact surfaces.

3.2.3. Curing Time and Strength Evolution Patterns

Curing time has a substantial effect on UCS development, with distinct temporal trends between the two tailings types. Classified tailings exhibit higher early-age strength, owing to their optimized particle size distribution that facilitates rapid early skeleton formation. For example, at 3 days with 70% slurry concentration and a 1:6 cement-to-tailings ratio, classified tailings reach a UCS of 2.10 MPa, nearly twice that of unclassified tailings (1.03 MPa). However, unclassified tailings display greater long-term strength potential. At 28 days under the same conditions, unclassified tailings reach 3.85 MPa, exceeding the 3.33 MPa of classified tailings.

This trend of late-age outperformance is evident across multiple mix proportions. Under 65% slurry concentration and a 1:6 cement-to-tailings ratio, unclassified tailings show a UCS increase from 1.07 MPa (3 days) to 3.68 MPa (28 days), representing a 244.9% gain. In contrast, classified tailings under the same conditions increase from 1.82 MPa to 2.89 MPa, a 58.5% improvement. The substantial late-stage gain in unclassified tailings is attributed to their higher fine content and specific surface area, which sustain hydration and cementation over time, promoting the development of a more integrated and robust microstructure.

In summary, classified tailings provide superior early-age strength and rapid scaffold formation—useful when early stability is required—because of their coarse skeleton. Unclassified tailings, however, exhibit superior long-term strength potential, especially at high slurry concentrations, moderate to low C/T ratios, and extended curing, due to better fines-driven packing, sustained hydration, and the more effective development of a continuous, load-bearing microstructure.

As shown in

Table 4, the growth of uniaxial compressive strength (UCS) in cemented tailings backfill (CTB) made with unclassified and classified tailings was evaluated across cement-to-tailings ratios (C/T = 1:4, 1:6, 1:8) and slurry concentrations (60–70%). The data reveal distinct, mix-dependent trajectories governed jointly by tailings type, binder dosage, and curing duration.

At C/T = 1:4 and 60–65% concentration, unclassified mixes systematically outpace classified mixes. At 60%, UCS growth over 3–7 d is 47.0% for unclassified versus 32.0% for classified; over 7–28 d, it is 73.0% versus 51.0%, respectively. When C/T is reduced to 1:8, the contrast widens: at 65%, unclassified achieves 100% (3–7 d) and 91.7% (7–28 d), compared with 61.0% and 32.6% for classified. At 70% concentration, the advantage persists: for C/T = 1:4, unclassified records 69.0% (3–7 d) versus 8.3% for classified; for C/T = 1:8, the corresponding values are 94.1% versus 8.3%. Collectively, these patterns are consistent with a more reactive matrix and fines-assisted packing in unclassified tailings, which translate into faster early-to-mid-age densification and continued later-age gains.

Across curing stages and mix windows, unclassified tailings exhibit more pronounced and accelerated strength evolution—especially at lower binder doses (1:8) and higher concentrations (≥65–70%)—and demonstrate later-age outperformance (7–28 d) relative to classified mixes. Classified tailings, while showing lower growth rates, may confer benefits in early structural stability due to their narrower particle size distribution. These grouped trends provide an evidence-based basis for tailoring CTB mix designs to balance rapid early support against long-term durability.

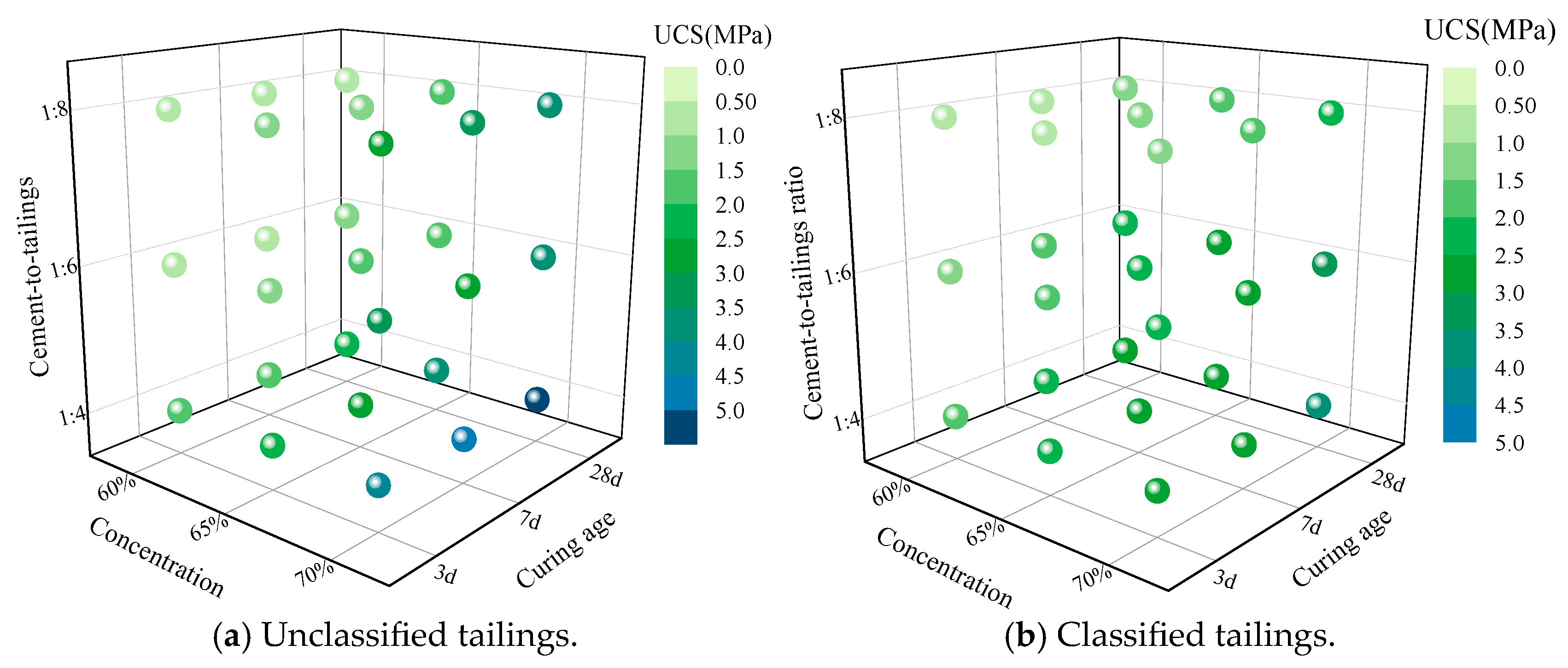

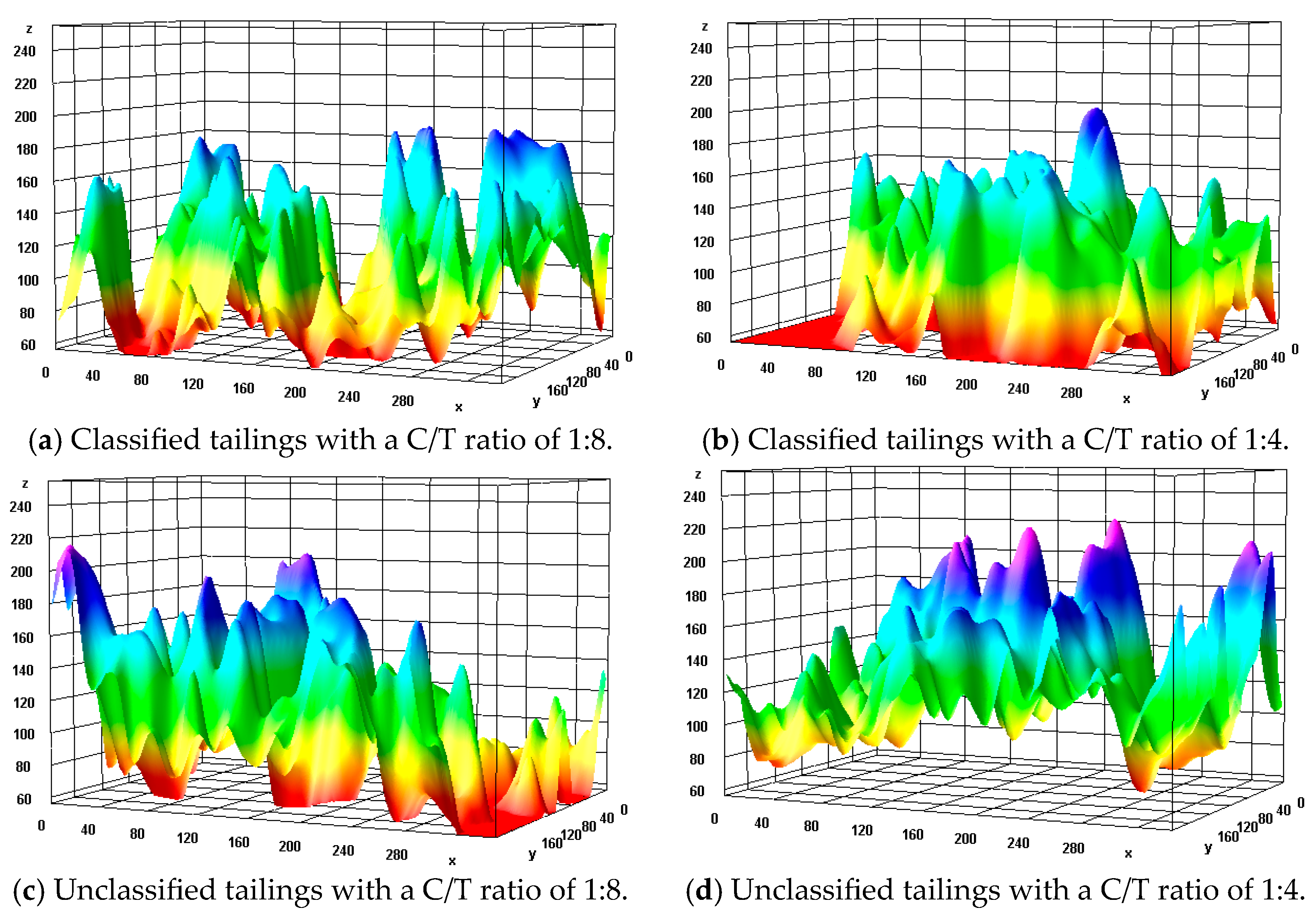

3.3. Influence of Three-Factor Coupling on CTB Strength

Figure 6 shows the strength distribution patterns of unclassified and classified tailings backfill under the coupling effect of three factors. It reveals how the interaction of slurry concentration, cement-to-tailings ratio, and curing age affects the mechanical strength of the two types of tailings backfills.

Figure 6a shows the uniaxial compressive strength (UCS) distribution of unclassified tailings backfill under different slurry concentrations, cement-to-tailings ratios, and curing ages. Darker colors (toward blue) represent higher strength. Curing age has a clear leading effect on strength growth [

20]. As curing time increases from 3 to 28 days, most data points become much darker, especially at a cement-to-tailings ratio of 1:4 and a concentration of 70%, where UCS exceeds 5.0 MPa. Increasing slurry concentration (from 60% to 70%) and lowering the cement-to-tailings ratio (from 1:8 to 1:4) work together to rapidly improve strength. The combined effect of high concentration, high cement ratio, and long curing age produces a nonlinear increase in strength that is greater than the sum of individual effects.

Figure 6b shows the UCS distribution of classified tailings backfill under the same conditions. The colors are generally lighter, indicating lower strength. The effect of curing age on strength is weaker than in unclassified tailings. At cement-to-tailings ratios of 1:4 and 1:6, strength growth slows, and color changes are less noticeable. Increasing the slurry concentration from 65% to 70% results in little improvement in UCS in some areas. The three-factor coupling effect is weaker, suggesting that particle size distribution limits compactness and cementation efficiency.

In summary, unclassified tailings show better strength development through the combined action of the three factors. It is easier to achieve high strength by using high slurry concentration and a reasonable cement-to-tailings ratio. Classified tailings have a delayed strength response and limited growth potential under the same conditions. These results provide important guidance for designing high-performance cemented backfill.

3.4. Differences in Failure Modes of CTB

Since the failure modes of specimens cured for different durations in this experiment are generally similar, the analysis focuses on the failure patterns of specimens cured for 28d under varying cement-to-tailings ratios and slurry concentrations.

The failure modes of unclassified tailings backfill are primarily characterized by splitting–tensile cracks, as observed in

Figure 7. Wherein the solid line represents the main crack and the dotted line represents the secondary crack. Among the influencing factors, a low cement-to-tailings (C/T) ratio often results in the insufficient encapsulation of aggregate particles by the cement, leading to weaker interparticle bonding interfaces. This can cause the main fracture to develop along more tortuous paths. Under low slurry concentration, moisture evaporation during curing produces numerous microvoids, which in turn generate more microcracks during loading. The accumulation and interaction of these microcracks can alter the evolution of the main fracture and ultimately affect the overall failure pattern [

29].

At a C/T ratio of 1:8, unclassified tailings specimens under low slurry concentration exhibit both tensile and splitting features, along with localized spalling at the specimen ends. As slurry concentration increases, the failure transitions from multiple tortuous main cracks to a dominant splitting–tensile crack, with a noticeable reduction in microcrack formation and the disappearance of spalling. As the C/T ratio increases from 1:6 to 1:4, the failure mode progressively shifts toward a more typical splitting–tensile pattern. Secondary cracks decrease in number, and the main fracture tends to evolve into a single dominant crack. Specimens with a 1:6 C/T ratio show two slightly curved splitting cracks, while those with a 1:4 ratio typically present one straight crack. This trend becomes more distinct with increasing slurry concentration.

In contrast, the failure mode of classified tailings specimens is influenced by the absence of fine particles, which reduces the ability to fill voids and form a dense structure. Under axial stress, the loosely packed granular skeleton results in more pronounced block spalling, especially under low slurry concentrations. As shown in the figure, all specimens with a 1:8 C/T ratio display block spalling failure, with the extent of spalling decreasing as slurry concentration increases. As both slurry concentration and the C/T ratio increase, the interface strength between aggregates and cement improves, and the number of evaporation-induced pores declines. Consequently, the failure mode transitions from pure block spalling to a mixed mode of block spalling and splitting and eventually to a typical splitting–tensile failure.

3.5. Microstructural Analysis

To further reveal the differences in failure mechanisms and their microstructural origins for different types of tailings under various mix proportions, it is necessary to analyze the material structure. Scanning electron microscopy (SEM) was used to observe the microstructure of representative backfill specimens, providing a direct view of the distribution of cementation products, interfacial bonding between particles, and the evolution of pore structure. These observations offer essential micro-level insights into the strength development and crack propagation behavior of backfill under the coupled effects of the three factors.

The microstructure of the backfill consists of a skeleton structure formed by tailings particles intertwined with hydration products, and a pore structure composed of micropores and microcracks (citation). Previous studies have confirmed that cement content affects the microstructure of specimens [

30]. In this experiment, both the mechanical strength and failure modes of the two types of tailings showed similar trends with changing cement-to-tailings ratios under different slurry concentrations. Therefore, SEM analysis was conducted on specimens prepared with 70% slurry concentration and cement-to-tailings ratios of 1:8 and 1:4, using both classified and unclassified tailings.

Comparing

Figure 8a,c, both classified and unclassified tailings specimens showed large tailing particles not fully wrapped by hydration products (such as C-S-H gel and needle-like ettringite). In the early curing stage, the voids between large particles were filled with water and hydration products. However, as curing time increased, water evaporated, leaving behind pores between particles and hydration products. These micropores weakened the overall strength. In unclassified tailings, the presence of fine particles filled the voids between coarse particles and allowed for better contact with hydration products. This resulted in a denser structure and reduced the formation of pores caused by water evaporation.

Comparing

Figure 8a,b, an increase in the cement-to-tailings ratio led to more hydration products coating the surface of coarse particles. However, the voids between particles could not be completely filled by hydration products alone. This explains why, in classified tailings, increasing the cement content did not significantly improve strength as it did in unclassified tailings.

From

Figure 8c,d, it is clear that in unclassified tailings, the fine particles had more contact with hydration products, which enhanced the cementation effect. This made the overall structure denser. However, more fine particles meant a larger surface area, requiring more cement. At a low cement-to-tailings ratio, the cement was not sufficient to coat all particles. In the high-cement-to-tailings-ratio specimen (

Figure 8d), more needle-like ettringite and interwoven C-S-H gel were observed. These hydration products helped bond the large surface area of the particles, reducing voids between particles, between particles and hydration products, and among hydration products themselves.

SEM micrographs were processed in ImageJ v1.52p to obtain grayscale–intensity distributions.

Figure 9 shows that increasing the C/T ratio from 1:8 to 1:4 lowers the apparent porosity, consistent with progressive densification. At a fixed C/T ratio, the unclassified tailings (with fines present) exhibit a substantially higher apparent porosity than the classified tailings, with the contrast most pronounced at C/T = 1:4.

At low C/T, more voids persist between particles. These voids promote local debonding under load; once they interconnect, they act as nucleation sites for microcracks, which then propagate and reduce strength, ultimately triggering failure.

In classified tailings, the deficit of fines limits void filling between coarse particles. Consequently, more pores remain, and the effective contact/bonding area available for hydration products is reduced. Under low C/T, this yields weaker interparticle interfaces and, therefore, a lower compressive strength of the backfill.

4. Discussion

The experimental results highlight the intricate, multi-scale interactions among particle size distribution, cement-to-tailings ratio (C/T), and slurry concentration in governing the mechanical behavior of cemented tailings backfill (CTB). At the particle scale, classified tailings, with fewer fines, present a coarser mean particle size, leading to larger interparticle voids and a skeletal structure requiring substantial densification during early loading. This explains the pronounced compaction stage observed in classified specimens, where the coarser grading creates additional voids that must collapse before a stable load-bearing framework forms. In contrast, unclassified tailings, being finer and more heterogeneous, show limited compaction and exhibit more plastic deformation, reflecting a structure where internal friction and localized yielding dominate the early response.

From a mechanistic perspective, the primary reasons for the strength reduction in classified mixes can be summarized in four key steps. First, at the particle scale, the lack of fines results in a coarser skeleton with larger voids, which negatively impacts the overall density of the material. Second, in the packing and interfacial transition zone (ITZ), the coarser skeleton has a lower packing density and reduced grain-to-grain contact area, thereby decreasing the effective surface area available for the formation of load-bearing bridges by hydration products. Third, the poor filling of voids leads to a more connected porosity network, with localized stress concentrations at the contacts between coarse particles. Finally, these stress concentrations, combined with insufficient binder bridges, promote early crack nucleation and rapid crack coalescence, ultimately resulting in a lower peak compressive strength (UCS) and more brittle post-peak failure.

Many studies typically focus on a fixed C/T ratio or a single slurry concentration and often use tailings with a single particle size, without thoroughly exploring the impact of varying conditions on mechanical behavior.

Table 5 below summarizes the key innovations in the current research compared to the reported literature.

The current research distinguishes itself through its comprehensive approach, considering multiple interacting factors—such as particle size distribution, cement-to-tailings ratio, slurry concentration, and curing time—providing a more nuanced understanding of CTB mechanical behavior and failure mechanisms compared to the more isolated focus seen in previous studies.

Finally, the microstructural evolution and failure mode transition observed in this study can be conceptualized as a progressive symmetry-breaking process. Initially, the backfill is nearly isotropic and homogeneous. However, as microcracks nucleate, pores become anisotropic and stress concentrations form, causing the system to transition from stable deformation to localized brittle or ductile failure. Future research should focus on quantifying these transitions, such as by measuring packing fraction, pore connectivity, and ITZ thickness as functions of mix design and curing age and linking these metrics to constitutive models for more accurate performance predictions under real-world conditions.

5. Conclusions

This study presents a multi-scale investigation of cemented tailings backfill (CTB) prepared with classified and unclassified tailings, integrating mechanical testing, failure mode analysis, and microstructural characterization. From a symmetry-breaking perspective, the deformation and failure of CTB are interpreted as a progressive transition from early-stage microstructural and stress field symmetry to macroscopic asymmetry and localization, offering a new theoretical framework for linking microstructure evolution with mechanical behavior.

Unclassified tailings exhibit a distinct late-age strength advantage, achieving a maximum 28-day UCS of 5.38 MPa at C/T = 1:4 and 70% slurry concentration, with a 244.9% strength increase compared with early ages. In contrast, classified tailings show a smaller 58.5% gain but demonstrate greater early-age stability, attributed to their narrower particle size distribution and reduced water demand. The coupling between a high cement-to-tailings ratio and high slurry concentration produces a nonlinear strengthening effect in unclassified systems (UCS > 5.0 MPa), resulting from enhanced gel formation, reduced porosity, and improved interfacial bonding.

Overall, the particle size of tailings governs the stress–strain characteristics and failure modes of CTB. Lower C/T and concentration promote splitting-type failures due to weak bonding, whereas higher C/T and concentration yield denser, shear-dominated structures with superior integrity. These findings not only elucidate the multi-scale mechanisms governing CTB performance but also provide quantitative and theoretical guidance for optimizing binder dosage, slurry concentration, and tailings classification to achieve both early support capacity and long-term durability in backfill engineering.

Author Contributions

Conceptualization, W.L. and H.W.; methodology, W.L.; validation, J.X., L.Y. and Y.K.; formal analysis, W.L.; investigation, H.W.; writing—original draft preparation, W.L.; writing—review and editing, L.Y.; funding acquisition, H.W. and Z.W.; visualization, B.Z.; supervision, J.X.; data curation, Z.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Xinjiang Autonomous Region Major Science and Technology Project (2024A03001-2) and Shandong Provincial Natural Science Foundation, Youth Program (ZR2025MS946).

Informed Consent Statement

Informed consent was obtained from all subjects involved in this study.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

During the preparation of this manuscript, the authors used ChatGPT (OpenAI, GPT-5) for the purpose of language polishing. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors Wenhai Liang, Jinsheng Xin, Liu Yang, Yunpeng Kou, Zaihai Wu, and Baoshan Zhan were employed by the company Shandong Gold Group Co., Ltd. The remaining authors declare that this research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SEM | Scanning Electron Microscopy |

| CTB | Cemented Tailings Backfill |

| UCS | Uniaxial Compressive Strength |

| CPB | Cemented Paste Backfill |

| XRF | X-ray Fluorescence |

References

- Liu, S.; Wang, F.; Li, G.; Liu, G.; Wang, J.; Qi, Z. Optimization of mixture ratio and microstructure influence mechanism of composite filling slurry based on response surface method. Acta Mater. Compos. Sin. 2021, 38, 2724–2736. [Google Scholar]

- Wang, P.; Zhao, J.; Chugh, Y.P.; Wang, Z. A novel longwall mining layout approach for extraction of deep coal deposits. Minerals 2017, 7, 60. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Liu, J.; Li, X.; Zhou, Z. The role of gangue on the mitigation of mining-induced hazards and environmental pollution: An experimental investigation. Sci. Total Environ. 2019, 664, 436–448. [Google Scholar] [CrossRef]

- He, Z.; Zhao, K.; Yan, Y.; Ning, F.; Zhou, Y.; Song, Y. Mechanical response and acoustic emission characteristics of cement paste backfill and rock combination. Construct. Build. Mater. 2021, 288, 123119. [Google Scholar] [CrossRef]

- Kermani, M.; Hassani, F.; Aflaki, E.; Benzaazoua, M.; Nokken, M. Evaluation of the effect of sodium silicate addition to mine backfill, Gelfill—Part 2: Effects of mixing time and curing temperature. J. Rock Mech. Geotech. Eng. 2015, 7, 668–673. [Google Scholar] [CrossRef]

- Tenchov, B.; Yanev, T. Weibull distribution of particle sizes obtained by uniform random fragmentation. J. Colloid Interface Sci. 1986, 111, 1–7. [Google Scholar] [CrossRef]

- Shi, C.; Yu, H.; Qian, G.; Li, X.; Zhu, X.; Yao, D.; Zhang, C. Research on the characteristics of asphalt mixture gradation curve based on Weibull distribution. Constr. Build. Mater. 2023, 366, 130151. [Google Scholar] [CrossRef]

- Song, X.; Hao, Y.; Huang, J.; Wang, S.; Liu, W. Study on mechanical properties and destabilization mechanism of unclassified tailings consolidation body under the action of dry-wet cycle. Construct. Build. Mater. 2023, 365, 130022. [Google Scholar] [CrossRef]

- Adiguzel, D.; Tuylu, S.; Eker, H. Utilization of tailings in concrete products: A review. Constr. Build. Mater. 2022, 360, 129574. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Ouellet, S. Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill. Miner. Eng. 2005, 18, 41–44. [Google Scholar] [CrossRef]

- Ke, X.; Hou, H.; Zhou, M.; Wang, Y.; Zhou, X. Effect of particle gradation on properties of fresh and hardened cemented paste backfill. Constr. Build. Mater. 2015, 96, 378–382. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, Z.; Yang, L.; Jiang, H.; Zhao, Y. Effect of tailings fineness on flow, strength, ultrasonic and microstructure characteristics of cemented paste backfill. Constr. Build. Mater. 2020, 263, 120645. [Google Scholar] [CrossRef]

- Cao, S.; Xue, G.L.; Yilmaz, E.; Yin, Z.Y.; Yang, F.D. Utilizing concrete pillars as an environmental mining practice in underground mines. J. Clean. Prod. 2021, 278, 123433. [Google Scholar] [CrossRef]

- Li, Y.; Guo, S.; Yang, R.; Xie, L.; Lu, S. Effects of gangue particle-size gradation on damage and failure behavior of cemented backfill under uniaxial compression. Int. J. Miner. Metall. Mater. 2025, 32, 1483–1495. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.W.; Taheri, A.; Deng, J.R.; Ke, B. Effects of superplasticizer on the hydration, consistency, and strength development of cemented paste backfill. Minerals 2018, 8, 381. [Google Scholar] [CrossRef]

- Fall, M.; Célestin, J.C.; Pokharel, M.; Touré, M. A contribution to understanding the effects of temperature on the mechanical properties of cemented mine backfill. Eng. Geol. 2010, 14, 397–413. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, D.; Lu, H.; Liu, L.; Zheng, S. Improvement of tailings gradation on workability and strength of cemented tailings backfill. Constr. Build. Mater. 2023, 387, 131633. [Google Scholar] [CrossRef]

- Libos, I.L.S.; Cui, L. Effects of curing time, cement content, and saturation state on mode-I fracture toughness of cemented paste backfill. Eng. Fract. Mech. 2020, 235, 107174. [Google Scholar] [CrossRef]

- Cihangir, F.; Ercikdi, B.; Kesimal, A.; Turan, A.; Deveci, H. Utilisation of alkali-activated blast furnace slag in paste backfill of high-sulphide mill tailings: Effect of binder type and dosage. Miner. Eng. 2012, 30, 33–43. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B.; Alp, I.; Deveci, H. Effect of properties of tailings and binder on the short-and long-term strength and stability of cemented paste backfill. Mater. Lett. 2005, 59, 3703–3709. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, L.; Ren, F.; Qiu, J.; Ding, H. Rheological and mechanical properties of cemented foam backfill: Effect of mineral admixture type and dosage. Cem. Concr. Compos. 2020, 112, 103689. [Google Scholar] [CrossRef]

- Li, J.; Yilmaz, E.; Cao, S. Influence of Solid Content, Cement/Tailings Ratio, and Curing Time on Rheology and Strength of Cemented Tailings Backfill. Minerals 2020, 10, 922. [Google Scholar] [CrossRef]

- Wang, H.; Qiao, L. Coupled Effect of Cement-to-Tailings Ratio and Solid Content on the Early Age Strength of Cemented Coarse Tailings Backfill. Geotech. Geol. Eng. 2019, 37, 2425–2435. [Google Scholar] [CrossRef]

- Cai, F.; Sun, W.; Wen, Y.; Zhang, P.; Ding, F.; Zhu, A.; Huang, Y.; Wang, S. Strength and energy dissipation of whole tailings cemented backfill body. J. Mt. Sci. 2025, 22, 2676–2688. [Google Scholar] [CrossRef]

- Zhu, K.; Wang, H.; Zhao, X.; Luo, G.; Dai, K.; Hu, Q.; Liu, Y.; Liu, B.; Miao, Y.; Liu, J.; et al. Effects of Superfine Cement on Fluidity, Strength, and Pore Structure of Superfine Tailings Cemented Paste Backfill. Minerals 2024, 15, 24. [Google Scholar] [CrossRef]

- Ru, W.-K.; Li, D.-Y.; Han, Z.-Y.; Luo, P.-K.; Gong, H. Failure mechanism and damage constitutive model of cemented tailings backfill with different cement-tailings ratios under uniaxial compression. J. Cent. South Univ. 2025, 32, 2979–2997. [Google Scholar] [CrossRef]

- Song, X.; Hao, Y. Mechanical response of stress damaged cemented tailings backfill based on pore structure and acoustic emission characteristics. Constr. Build. Mater. 2023, 404, 133278. [Google Scholar] [CrossRef]

- Tian, S.; He, Y.; Bai, R.; Chen, J.; Wang, G. Experimental study on consolidation and strength properties of tailings with different particle size distribution characteristics. Nat. Hazards 2022, 114, 3683–3699. [Google Scholar] [CrossRef]

- Yang, L.; Kou, Y.; Li, G.; Chen, M.; Zhu, G.; Song, Z.; Wang, P. Investigation of macro-micro mechanical behaviors and failure mechanisms in cemented tailings backfill with varying proportions of fine. Constr. Build. Mater. 2024, 438, 16. [Google Scholar] [CrossRef]

- Tana, A.E.B.; Yin, S.; Wang, L. Investigation on Mechanical Characteristics and Microstructure of Cemented Whole Tailings Backfill. Minerals 2021, 11, 592. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).