Abstract

To enhance our understanding of the thermal characteristics of lithium-ion batteries and gain valuable insights into the thermal impacts of battery thermal management systems (BTMSs), it is crucial to develop precise thermal models for lithium-ion batteries that enable numerical simulations. The primary objective of creating a battery thermal model is to define equations related to heat generation, energy conservation, and boundary conditions. However, a standalone thermal model often lacks the necessary accuracy to effectively anticipate thermal behavior. Consequently, the thermal model is commonly integrated with an electrochemical model or an equivalent circuit model. This article provides a comprehensive review of the thermal behavior and modeling of lithium-ion batteries. It highlights the critical role of temperature in affecting battery performance, safety, and lifespan. The study explores the challenges posed by temperature variations, both too low and too high, and their impact on the battery’s electrical and thermal balance. Various thermal analysis approaches, including experimental measurements and simulation-based modeling, are described to comprehend the thermal characteristics of lithium-ion batteries under different operating conditions. The accurate modeling of batteries involves explaining the electrochemical model and the thermal model as well as methods for coupling electrochemical, electrical, and thermal aspects, along with an equivalent circuit model. Additionally, this review comprehensively outlines the advancements made in understanding the thermal behavior of lithium-ion batteries. In summary, there is a strong desire for a battery model that is efficient, highly accurate, and accompanied by an effective thermal management system. Furthermore, it is crucial to prioritize the enhancement of current thermal models to improve the overall performance and safety of lithium-ion batteries.

1. Introduction

Maintaining optimal operating temperatures for lithium-ion batteries (LIBs) is crucial to maximize their performance and ensure safe operation. Precisely monitoring temperature distribution within tightly sealed batteries during usage poses significant challenges [1]. To address safety concerns associated with lithium-ion batteries, extensive research has focused on thermal modeling at different levels, including cell, module, and pack levels. A notable study by Hoelle et al. [2] investigated and compared three empirical modeling approaches for predicting heat release during thermal runaway (TR) in a battery cell. The researchers employed a 3D-CFD framework to model a prismatic lithium-ion battery and compared the simulation results with autoclave calorimetry experiments. Additionally, the study examined the influence of critical parameters such as mass loss during TR, specific heat capacity, and thermal conductivity of the jelly roll. All three modeling approaches demonstrated high accuracy in reproducing experimental results, with varying levels of computational effort required. The study emphasized the importance of considering mass loss during TR, specific heat capacity, and thermal conductivity of the jelly roll to achieve precise simulation results. By highlighting the advantages and disadvantages of each modeling approach and identifying key modeling parameters, the research aimed to enhance TR and TR propagation simulation. These findings can be valuable for researchers and engineers in selecting appropriate models to design safer battery packs [2].

To meet the growing demand for safety and precise control in electric vehicles, there is an urgent need for a physics-based electrochemical model of lithium-ion batteries that can provide simple calculations and high accuracy across a wide temperature range, particularly for battery management systems (BMS). However, existing electrochemical models often prove too complex for practical use and lack the ability to accurately capture the battery cell’s thermal characteristics. To address these limitations, Zhu, Guorong et al. [3] introduced a fractional-order model of lithium-ion batteries that considers both electrolyte polarization and thermal effects (FOMeT). The enhanced fractional-order model (FOM) incorporates electrolyte polarization, and a particle thermal model is introduced to describe heat generation and absorption within the cell. By combining the FOM considering electrolyte polarization with the particle thermal model, the researchers developed FOMeT, effectively coupling the cell temperature with lithium-ion dynamics. The study demonstrated that the proposed FOMeT model achieves high accuracy in predicting voltage and temperature across a wide range of temperatures (273.15 K to 318.15 K) and current loads (0.5 C to 2 C). This significant advancement in modeling contributes to improved battery management systems by providing a simplified yet accurate representation of lithium-ion battery behavior [3]. Electric vehicles face significant challenges in colder regions with low temperatures. To tackle this issue, Luo, Mingyun et al. [4] introduced a battery self-preheating system. Existing self-heating systems have limitations such as slow heating rates, complex control systems, single thermal management functions, and compromised safety. However, this study presented a conductive phase-change material (cPCM)-based self-preheating system that overcomes these drawbacks.

The self-preheating system presented in the study harnesses both the internal resistance of cells and the external resistance of the conductive phase-change material (cPCM) simultaneously. This innovative system achieves an impressive heating rate of 17.14 °C per minute and ensures excellent temperature uniformity, with a temperature difference of only 3.58 °C. The preheating process is safe within a battery capacity range of 20% to 100%, and when the battery pack is exposed to −20 °C, the effective electric energy increases significantly by 550% after preheating. Additionally, the researchers developed an energy conversion model that establishes a relationship between battery energy improvement and energy consumption during preheating. This model optimizes the preheating strategy, leading to maximum discharge energy. The study’s findings demonstrate that the proposed self-preheating strategy effectively addresses low-temperature battery issues and maximizes the battery’s effective electric energy. This advancement holds great promise for enhancing electric car performance in cold climates [4]. Accurate physical simulation of lithium-ion batteries plays a crucial role in gaining deeper insights into their operating mechanisms and potential state of health. However, calibrating reliable battery models proves complex due to the multitude of involved physical parameters. To address these challenges, Rabissi, C. et al. [5] conducted an extensive sensitivity analysis on the simulation of discharge, relaxation, and impedance spectroscopy tests. The focus of the analysis was on the response of the Doyle–Fuller–Newman model, which includes a thermal model to account for heat-transfer effects. The researchers investigated variations in 28 model parameters across approximately 160 combinations of temperature, battery state of charge, and C-rate. As a result of the sensitivity analysis, up to 14 parameters were identified as insensitive and could be reasonably excluded from model calibration. However, certain parameters exhibited diverse responses that could be maximized under specific conditions. To overcome these challenges and achieve accurate calibration, the researchers proposed an innovative method that combines two temperature levels and utilizes all three testing techniques (discharge, relaxation, and impedance spectroscopy). The combination of these techniques proved highly complementary and enabled fast and reliable calibration of the model. To demonstrate the efficacy of their proposed method, the researchers applied it to a commercial battery sample. The method facilitated a repeatable and physically sound calibration of the model parameters, as successfully demonstrated across a range of full discharges at 12 combinations of temperatures and C-rates. In comparison to a standard discharge-based calibration process, the proposed protocol showcased its strengths. Overall, this study underscored the significance of accurately calibrating lithium-ion battery models and proposed an innovative method that effectively addresses the challenges associated with model parameter calibration [5].

Despite the growing popularity of lithium-ion batteries (LIBs) in new energy vehicles, understanding the heat-generation patterns during their operation remains a challenging endeavor. Wu et al. [6] addressed this issue by introducing an electrochemical-thermal model (ETM) that assesses the heat-generation characteristics of cylindrical LIBs, considering discharge rates and the ratio of negative to positive electrode capacity (N/P ratio). To comprehensively research the thermal behavior of LIBs, the proposed ETM was validated using experimental data collected at ambient temperatures of 25 °C and 35 °C. The study further investigated the distribution profiles of heat-generation characteristics under various conditions using numerical simulations. Additionally, the research thoroughly analyzed the effects of different discharge rates and N/P ratios on battery heat generation. The results revealed that heat generation in the negative electrode plays a crucial role, and the impact of the reversible term on the total heat generation of the LIB cell cannot be ignored, especially at low discharge rates. Furthermore, the study observed that selecting an appropriate N/P ratio can enhance the total heat generation of LIBs, which proves beneficial for optimizing performance during the early stages of battery design and thermal management. Overall, this research significantly contributes to a better understanding of the heat-generation characteristics of LIBs during their operation. The proposed ETM provides valuable insights into the distribution profiles of heat generation under different conditions and emphasizes the influence of discharge rates and N/P ratios on battery heat generation. Such knowledge can be instrumental in optimizing LIB performance and developing effective thermal management strategies during battery design [6]. Accurate temperature prediction is crucial for improving battery performance and preventing thermal runaway in lithium-ion batteries. However, precise temperature estimation is challenging due to the complex nonlinear characteristics of heat generation and dissipation as well as the influence of external factors. In recent years, artificial neural networks (ANNs) have gained popularity in various aspects of lithium-ion battery research, including battery modeling, state-of-charge (SOC) estimation, residual life prediction, and battery temperature prediction. Nevertheless, there is limited research on temperature prediction for lithium-ion batteries with foam metal thermal management systems, and no consensus exists on the most suitable neural network architecture for this purpose. To fill this research gap, Wang et al. [7] utilized an artificial neural network approach to predict temperature changes in lithium-ion batteries within a metal foam thermal management system. They employed three types of neural networks, namely backpropagation neural network (BP-NN), radial basis functions neural network (RBF-NN), and Elman neural network (Elman-NN), to establish temperature prediction models. The study compared the performance of these different neural network models in temperature prediction and conducted performance tests under both sample and new conditions to validate the accuracy and effectiveness of the neural network thermal model. The results indicated that the Elman neural network model demonstrated better adaptability and generalization ability compared to the other neural network models. Moreover, the training time of the Elman neural network model was shorter, making it more suitable for temperature prediction in lithium-ion batteries with metal foam and forced air cooling systems. In summary, this research highlighted the application of artificial neural networks for temperature prediction in lithium-ion batteries with a metal foam thermal management system. The findings suggest that the Elman neural network model outperforms others in terms of adaptability, generalization, and training time, making it an effective choice for temperature prediction in such battery systems [7].

Cui et al. [8] introduced an innovative online method for estimating temperature distribution in lithium-ion batteries (LIBs), considering non-uniform heat-generation and boundary cooling effects. The researchers developed a thermal model for the tab area using the lumped parameter method, considering heat-generation and -transfer mechanisms. This tab thermal model served as the initial boundary condition for the core area of the battery. A difference equation was formulated using the heat balance method to describe temperature distribution within the core area. The researchers derived boundary conditions and a convection coefficient model for further calculations. They designed a disturbance observer to enhance temperature estimation accuracy. The proposed method outperformed traditional approaches, with an estimation error below 1.5 °C, offering valuable insights for battery modeling, parameter estimation, and thermal management in LIB systems [8]. Zhai et al. [9] conducted a series of experiments to investigate temperature distribution in a lithium-ion battery (LIB) using open-circuit voltage (OCV) tests, discharge rate tests, hybrid pulse power characteristic (HPPC) tests, and discharge temperature rise tests. They developed a thermal model (TM) incorporating a user-defined function (UDF) to account for variable heat-generation rate. The TM accurately predicted temperature rise at different discharge rates and offered valuable insights for LIB thermal management, aiding in the design of efficient cooling systems and optimizing battery performance [9]. Khaboshan et al. [10] researched the design of a high-performance battery thermal management system (BTMS) for lithium-ion batteries (LIBs) in electric vehicle (EV) applications. They employed a combination of phase-change material (PCM), metal foam, and fins in different configurations. The study investigated the effects of various fin shapes and identified the optimal BTMS configuration that achieved the lowest battery surface temperature and provided insights into the roles of different components in heat management. The research highlighted challenges in selecting an ideal fin shape for diverse environmental conditions [10]. Overall, these studies contributed significantly to the understanding and improvement of temperature distribution and thermal management in lithium-ion batteries, which are crucial for enhancing battery performance and safety in various applications.

Temperature plays a crucial role in influencing the performance and limitations of lithium-ion batteries (LIBs). Ma et al. [11] conducted a study to investigate the consequences of temperature on LIBs in both low and high temperature ranges. They discussed various techniques for monitoring internal battery temperature, highlighting the significance of temperature in LIB performance and the need for efficient temperature management. Feng and colleagues [12] presented a comprehensive review of approaches to address thermal runaway issues in LIBs. They introduced a time-sequence map to understand the progression of physical and chemical processes leading to thermal runaway and undesirable fires. This map aided in identifying transformation flows and developing effective strategies to prevent thermal runaway, enhancing the safety of LIBs for future applications. Zhang and colleagues [13] extensively investigated the thermal effects experienced by LIBs, including thermal runaway and battery performance in cold temperatures. They analyzed various heat-generation methods and assessed battery thermal management (BTM) strategies. The paper emphasized the importance of achieving uniform temperature distribution within battery packs to improve safety and extend battery lifespan, particularly for electric vehicles. Liao and colleagues [14] conducted a comprehensive review of monitoring and detection methods to improve the safety and robustness of LIB systems. They compared different approaches to identify the most effective methods for enhancing safety and reliability, focusing on identifying and tracking thermal runaway events. Patel and colleagues [15] provided a comprehensive review of battery thermal management systems, categorizing them as active and passive systems. They emphasized passive BTMS, particularly those utilizing phase-change material (PCM) and heat pipe technologies. The paper also explored hybrid BTMS, combining both active and passive techniques, and demonstrated their superior thermal management performance compared to individual approaches. In conclusion, these studies contributed valuable insights into understanding and addressing temperature-related challenges in LIBs. They emphasized the importance of precise temperature measurement, effective thermal management, and safety-enhancing strategies to optimize LIB performance and reliability across various applications.

Khaboshan et al. [10] outlined the development of a Battery Thermal Management System (BTMS) utilizing phase change materials (PCMs), metal foam, and fins to regulate battery surface temperatures during discharge. Four distinct BTMS configurations are formulated, with experimentation on various fin shapes (rectangular, triangular, trapezoidal, I-shape, and wavy fins). The application of a precise two-equation thermal model enhances the simulation of heat transfer between PCM and metal foam. The most effective BTMS integrates PCM, metal foam, and fins, resulting in a 3 Kelvin reduction in battery surface temperature and a maximum delay of around 470 seconds for PCM melting. The influence of diverse fin shapes on temperature is minimal, indicating the absence of a single optimal shape for all scenarios.

Li and colleagues [16] presented an overview of various EIS-based methods for predicting LIB temperature. These methods utilize impedance, phase shift, and intercept frequency to achieve high prediction accuracy, real-time performance, simplicity, and practicality. The study discussed the principles, advantages, disadvantages, and future directions of each method. Y. Kobayashi and colleagues [17] utilized an isothermal calorimeter to investigate the thermal behavior of a lithium-ion cell during charging and discharging processes. They prepared separate cells to distinguish between the thermal properties of the cathode and anode (graphite) materials. The study revealed unique thermal characteristics attributed to the distinct electrode materials and identified the gradual reduction in effective active material within the graphite electrode as the primary cause of capacity degradation after repeated cycles. Overall, these studies contribute valuable insights into the significance of temperature in LIB performance, the potential of EIS-based methods for temperature prediction, and the thermal behavior of different electrode materials. Understanding these aspects is essential for optimizing LIB performance and ensuring their reliable and efficient operation in various applications.

A. Pesaran and colleagues [18] developed a specialized calorimeter explicitly designed for accurately measuring heat generation in large battery modules. The calorimeter can accommodate battery modules with dimensions of up to 21 cm × 39 cm in cross-section and 20 cm in height, operating over a wide temperature range from −30 °C to +60 °C. It demonstrates high precision, capable of detecting small heat effects as low as 10 joules with an accuracy of 5%. The paper provided a detailed description of the calorimeter’s design and functionality, along with calibration test results and test results obtained from a module replicating a lead–acid battery used in hybrid electric vehicles (HEVs). This research is crucial for understanding and managing thermal effects in large battery modules, especially in the context of hybrid electric vehicles [18]. Kong and colleagues [19] conducted a comprehensive review focused on advanced warning systems to prevent thermal runaway incidents in lithium-ion batteries (LIBs). They analyzed monitoring parameters used to detect thermal runaway and compared the sensitivity and robustness of multiple warning methods relying on these characteristic parameters. The study explored practical applications of early warning systems in various devices, such as portable devices, electric vehicles, and energy storage systems. Additionally, the researchers proposed potential future warning methods involving the integration of existing approaches with operational data from battery systems. This research contributes to the development of effective warning systems to enhance the safety and reliability of LIBs in diverse applications [19].

L. Guldbæk Karlsen and colleagues [20] conducted a literature study that focused on isothermal reaction calorimeters, exploring different types of equipment available. The review provides detailed descriptions and classifications of these instruments based on their measurement principles and design. Additionally, the study presented a case study of a new data treatment system implemented in a commercial bench-scale isothermal calorimeter, demonstrating how advanced data analysis techniques can enhance the accuracy and reliability of parameter determination in calorimetry experiments. This research contributed to a better understanding of available calorimeter equipment and showcased the potential for improved data analysis methods to advance the field of calorimetry.

The purpose of creating models to explore the thermal performance of batteries is to enhance our understanding of how batteries respond to and manage heat. These models aim to analyze, predict, and improve the thermal properties of batteries, which is a critical factor in enhancing their efficiency, operational quality, and safety. Through precise simulations and examinations of thermal elements, scientists and engineers can identify potential issues, develop more effective thermal control mechanisms, and ultimately improve the overall performance and reliability of battery systems. In our research, we extensively investigate various methodologies for battery modeling, with a particular focus on understanding the interactions and distinctions between thermo-electrochemical and thermal-electrical aspects. Our main objective is to conduct a comprehensive analysis of thermal behavior, temperature, and heat generation to develop accurate battery thermal models. Furthermore, we delve into a thorough investigation of existing strategies used in battery modeling to identify the challenges and discrepancies that researchers face. Our paper aims to provide an overview of modeling approaches that prioritize safety considerations, with a specific focus on the thermal aspects of battery behavior. Through this research, we hope to contribute to the development of safer and more reliable battery systems. By gaining a deeper understanding of thermal behavior, we can optimize battery performance, enhance safety protocols, and pave the way for more efficient and sustainable energy storage solutions.

2. Experimental Method for Thermal Analysis of Lithium-Ion Batteries

The experimental method for thermal analysis of lithium-ion batteries is essential for understanding their thermal behavior and optimizing their performance and safety. Table 1 provides a comprehensive compilation of detailed information on various experimental techniques used for this purpose. These experiments have contributed to advancing thermal analysis and modeling for lithium-ion batteries. Thermal analysis of lithium-ion batteries can be broadly classified into two main approaches: experimental and numerical methods. Both approaches involve studying the thermal behavior under normal operating conditions as well as abusive conditions. Factors such as heat generation, heat transport, storage mechanisms, and heat dissipation are considered in these analyses. Some investigations have utilized precise experimental setups, such as battery calorimeters, to accurately determine heat loss. These findings offer valuable inputs for thermal management systems and can be integrated with computational fluid dynamics simulations to enhance the thermal management of lithium-ion batteries. A key objective in the thermal design of lithium-ion batteries is to effectively mitigate heat generation and reduce the maximum temperature of battery cells under different conditions. Achieving these objectives simplifies the complexity of the thermal management system for lithium-ion batteries, leading to improved safety and performance. During the charging and discharging processes of lithium-ion battery cells, heat loss can be classified into two main sources: irreversible and reversible. The irreversibility of a lithium-ion battery cell, indicated by its overpotential, plays a significant role in determining heat losses. Additionally, the reversible entropic heat or entropy variation is another critical factor contributing to heat loss. Heat loss during both charging and discharging cycles can be further divided into two segments. Firstly, when a charge or discharge current is applied to the battery, the heat loss is referred to as heat loss during charging or discharging. Subsequently, when the current reaches zero, and the resting period begins, heat loss during rest occurs. This heat loss starts immediately after charge or discharge cycles when there is no current flowing and continues until the battery reaches its operating temperature. This phenomenon is crucial to consider in battery thermal management and plays a role in determining the overall efficiency and performance of lithium-ion batteries during operation.

The experiments were conducted using an isothermal battery calorimeter (IBC), which is designed to maintain a constant temperature and can operate within a temperature range of −30 °C to 60 °C. The IBC consists of various components, including a tank, cooling plate, heating element, and an isothermal bath. Fluid flow is controlled using four solenoid valves, one manual valve, and a motorized ball valve. The calorimeter is capable of measuring the heat generated by different types of batteries, with power levels ranging from 100 mW to 50 W. For the experiments, the IBC was connected to the Maccor automated test system using four cables. The IBC has maximum current, power, and voltage ratings of 250 A, 50 W, and 50 V, respectively. To measure the surface temperature of the battery and track its distribution over time, contact thermocouples were used. The IBC was able to measure these parameters simultaneously. However, it is important to note that the IBC has limited cooling and heating rates due to its high thermal inertia. At the middle of the temperature range, a maximum rate of five K/h could be achieved, while rates of around one to two K/h were possible near the temperature extremes. The stability of the isothermal bath and the accuracy of enthalpy measurements for the IBC are reported to be 0.01 °C and 2%, respectively. The heat flux area was determined using a linear baseline method, as the IBC operates under isothermal conditions. Linear measurements were found to be suitable for all experiments, and baseline stability and noise levels were recorded at 30 and 5 mW, respectively.

In the research conducted by [21,22], a novel method that combines thermal and electrochemical modeling was introduced to predict the simultaneous thermal and electrochemical behaviors of lithium-ion batteries. The approach involved linking the thermal and electrochemical models to achieve accurate predictions. Using first principles and the volume-averaging procedure, the researchers established a generic thermal energy equation model for different lithium-ion battery configurations.

Table 1.

Experimental method for thermal analysis of lithium-ion batteries.

Table 1.

Experimental method for thermal analysis of lithium-ion batteries.

| Battery | Description | Reference |

|---|---|---|

| Lithium-ion batteries | Investigation of lithium-ion battery’s self-discharge | Aurbach D et al. [23] |

| Lithium-ion batteries | Investigation of lithium-ion battery’s self-discharge for one month at 25 °C | Johnson BA et al. [24] |

| LiFePO4 | Investigation of the positive electrode material of LiFePO4 in thermal stability issue | Joachin H et al. [25] |

| Lithium-ion batteries | This paper presents a general path to thermal runaway in lithium-ion batteries. | Amiruddin S et al. [26] |

| Lithium-ion batteries | Experimental study of thermal runaway inside a 1.35 Ah cylindrical Sony battery with a LiCoO2 positive electrode | Al Hallaj S et al. [27] |

| Lithium-ion batteries | Experimental investigation of thermal runaway | Roth EP et al. [28] |

| lead-acid battery packs | Study of the effect of the charge algorithm, ambient temperature, and module connection methods for parallel strings on the performance and cycle life of these laboratory packs | Dickinson BE et al. [29] |

| Lithium-ion batteries | Investigation of specific properties of lithium-ion batteries essential for automotive applications, especially cell balancing | Kuhn BT et al. [30] |

| Lithium-ion batteries | A review of the primary charge equalization schemes for lithium-ion batteries | Moore SW et al. [31] |

| Lithium-ion batteries | Experimental balancing method for lithium-ion batteries | Kasnatscheew J et al. [32] |

| Lithium-ion batteries | Measuring the heat effects of electrochemical processes to find areas where such measurements might prove helpful, such as determining reaction heat | Sherfey JM et al. [33] |

| Lithium-ion batteries | Experimental determination of the effective heat capacity of the cell and calorimeter constant | Al Hallaj S et al. [34] |

| Lithium-ion batteries | Experimental determination of the effective heat capacity of the cell and calorimeter constant | Hong JS et al. [35] |

| LFP cell and ternary (Li(Ni1/3Co1/3Mn1/3)O2, NCM)Lithium-ion cell |

| Lei Sheng et al. [36] |

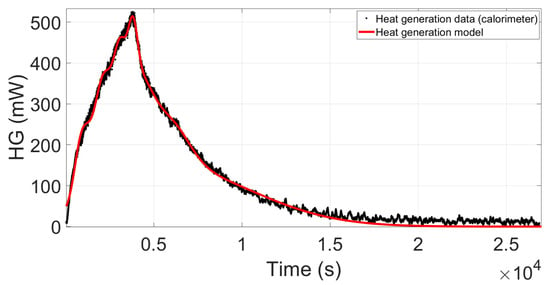

Figure 1 depicts the heat-generation model for lithium-ion batteries. The thermal modeling of a lithium-ion battery was successfully performed, revealing that the area near the negative tab of the battery cell experienced the highest temperature during the discharging process. Moreover, an uneven temperature distribution was observed, indicating potential areas for concern. At higher current rates, it took longer for the battery to reach thermal equilibrium, highlighting the importance of considering different operating conditions in thermal analysis. The research also indicated that the electrical conductivity of the active material in the negative electrode was notably higher than that of the positive electrode, leading to differences in current flow near the tabs of both electrodes. The non-homogeneity of the battery surface was identified as a significant concern, which calls for modifications to address this undesirable thermal behavior. The study suggests potential improvements, such as modifying physical and material properties and enhancing the thermal management system, to achieve better thermal performance and overall safety of lithium-ion batteries. This research represents a significant advancement in understanding and predicting the thermal behavior of lithium-ion batteries, contributing to the development of more efficient and reliable battery systems. The integration of thermal and electrochemical modeling provides valuable insights for optimizing battery design and thermal management, ultimately improving the performance and safety of lithium-ion batteries in various applications.

Figure 1.

Lithium-ion battery heat-generation (HG) model [21].

In their research, Aurbach et al. [23] focused on enhancing Li-ion batteries through diverse research and development (R&D) approaches. The study specifically emphasized novel methods to assess the aging processes of Li-ion battery electrodes and to create innovative electrode materials. The researchers successfully utilized standard LiPF6 solutions with organosilicon additives at elevated temperatures, even in 5 V systems, showcasing the potential for improved battery performance under such conditions. They also explored the measurement of self-discharge current in lithiated graphite electrodes during cycling to gain insights into the intricate aging mechanisms that impact battery performance over time. Additionally, the article presented various techniques for synthesizing nanomaterials, including carbonaceous materials, tin-based compounds, and transition metal oxides. These methods included soft reactions in the liquid phase and high-temperature reactions under autogenic pressure, microwave radiation, and sonochemistry. By leveraging these techniques, the researchers aimed to enhance the performance and stability of electrode materials, thus contributing to the advancement of Li-ion batteries. On the other hand, Johnson et al. [24] conducted a study to evaluate the physical design, performance, and characteristics of lithium-ion batteries available from different companies in the market. The research involved analyzing cells from various manufacturers, including Sony, Matsushita, A&T, Moli, and Sanyo, totaling 85 cells. Throughout their analysis, the researchers found that the cells generally met the manufacturers’ specifications. The study explored design differences through various methods, including gas chromatography–mass spectrometry (GC-MS) analysis of electrolytes, differential scanning calorimetry (DSC) analysis of separators, activation of positive temperature coefficient (PTC), and a comparison of basic physical parameters. The findings revealed important distinctions among the different cells from various manufacturers. For instance, A&T and Matsushita cells exhibited strong performance at high discharge rates, while Sony cells demonstrated excellent cycle-lifetime performance, and self-discharge effects were minimal. Overall, these research efforts contributed valuable insights into advancing Li-ion battery technology. Aurbach et al.’s work highlighted the importance of understanding electrode aging and developing innovative materials, while Johnson et al.’s study provided a comprehensive assessment of commercially available lithium-ion batteries, shedding light on performance variations among different manufacturers’ cells. Such knowledge is essential for driving advancements in battery technology and improving battery performance and reliability in various applications.

In their research, Joachin et al. [25] focused on the carbon-coated LiFePO4 material used as a cathode in Li-ion batteries, with particular attention to its electrochemical and thermal performance. The study revealed that the carbon-coated LiFePO4 electrode exhibited a reversible capacity of over 90% of its theoretical capacity when subjected to cycling between 2.5 and 4.0 V. This indicates that the material has good cycling stability and retains its capacity even at high power levels. The carbon coating was found to enhance electronic conductivity, contributing to the improved cycling performance of the electrode. The researchers also employed electrochemical impedance spectroscopy to determine the diffusion coefficient of the material, providing valuable insights into its transport properties. Regarding thermal properties, the study investigated heat generation during charge and discharge using an isothermal microcalorimeter. Comparisons with other commonly used lithium metal oxide cathodes with layered structures were made, showing that LiFePO4 is safer in terms of thermal behavior. Thermal studies conducted using a differential scanning calorimeter and an accelerating rate calorimeter validated this safety aspect, highlighting the advantages of using LiFePO4 as a cathode material for lithium-ion batteries. On the other hand, Al Hallaj et al. [27] developed a one-dimensional thermal mathematical model with lumped parameters to simulate temperature profiles in lithium-ion cells, specifically using Sony US18650 cells. The model demonstrated good agreement with temperature measurements for various discharge rates, with only slight deviations observed at one discharge rate. The researchers extended the model’s application to simulate temperature profiles in larger cylindrical lithium-ion cells (10 and 100 Ah). They found that cooling rate significantly influenced cell temperature, with notable temperature gradients observed at higher cooling rates (Biot number below 0.1). This indicates the importance of effective cooling strategies in large battery systems. Furthermore, the study tested commercial lithium-ion cells with different open-circuit potentials to determine onset-of-thermal-runaway (OTR) temperatures. They observed OTR temperatures of 104 °C, 109 °C, and 144 °C for cells with open circuit voltages of 4.06, 3.0, and 2.8 V, respectively. Additionally, internal short circuits occurred near the separator material’s melting point for all tested open-circuit voltages, emphasizing the significance of separator material selection for thermal safety. Both research efforts contribute valuable insights into the electrochemical and thermal performance of lithium-ion batteries and highlight the importance of electrode material choice and thermal management for enhancing battery safety and reliability.

Roth et al. [28] conducted a study using differential scanning calorimetry (DSC) to investigate thermal interactions between different binder materials and representative anode carbons in lithium-ion cells. The research explored various binder materials, including vinylidene fluoride (VDF) homo- or copolymers and fluorinated and non-fluorinated binders. They found that the exothermic reactions in the anode were influenced by the state of charge and the presence of an electrolyte. The magnitude of these reactions increased with higher carbon surface area but showed similar reaction enthalpies for all binder materials and levels used in the study. This research provided valuable insights into the thermal behavior of different binder materials in lithium-ion cells and contributed to the understanding of binder material selection for improved battery performance. Kuhn BT et al. [30] conducted a study focusing on the essential properties of lithium-ion batteries, with particular relevance to automotive applications. The research involved long-term laboratory tests to thoroughly analyze and characterize these batteries. The primary areas of investigation included state-of-charge measurement and characterization, input-output charge efficiency, and the role of charge equalization. The study found that open-circuit voltage serves as a reliable indicator for state-of-charge measurement. Additionally, Li-ion technology was identified to have high input–output energy storage efficiency, making it particularly advantageous for hybrid vehicles. The importance of charge equalization in Li-ion applications was emphasized, with the need for active equalization to ensure safe operation and maximize battery lifespan. The study also highlighted the variability in commercial charge equalization devices among manufacturers. Overall, this research provided valuable insights into the performance characteristics of lithium-ion batteries in automotive applications and underscored the significance of charge equalization for battery safety and longevity. Moore SW et al. [31] focused on battery balancing in lithium-based batteries compared to traditional lead–acid batteries. Unlike lead–acid battery packs that can be balanced through controlled overcharging, lithium-based batteries require alternative methods, as they cannot be balanced through overcharging. The paper explored various cell-balancing methodologies specifically designed for lithium-based batteries. Active cell balancing methods involve transferring charge from high cells to low cells to achieve a more balanced charge distribution. In contrast, dissipative techniques identify high cells and dissipate excess energy through a resistive element until their charges align with the low cells. The paper thoroughly discussed the underlying theories behind these charge-balancing techniques and provided a comprehensive analysis of their advantages and disadvantages. The primary objective of the research was to offer valuable insights into cell balancing for lithium-based batteries and present different available approaches to optimize battery performance. This information is essential for ensuring the efficient and safe operation of lithium-ion batteries in various applications.

Kasnatscheew et al. [32] conducted a study on balancing active materials in lithium-ion batteries to enhance safety and cycle life. The researchers aimed to find the optimal trade-off between maximizing specific energy and minimizing the risk of lithium plating. To achieve this, they adjusted the state of charge (SOC) through active mass ratios and charge cutoff voltage. By using specific charge capacity, they were able to indirectly predict electrode potentials, enabling better investigation and control. The study revealed that specific capacity losses were primarily influenced by the negative electrode’s BET surface area, providing valuable insights for optimizing performance and safety in lithium-ion batteries. This research contributes to understanding the relationship between specific energy and lithium plating risk, which is crucial for developing safer and more efficient lithium-ion battery systems. Lei Sheng et al. [36] conducted a study to characterize the thermal parameters of lithium-ion batteries with the goal of accurately predicting the temperature distribution in battery cell modules. They proposed a novel method based on quasi-steady-state heat-transfer analysis, allowing for the simultaneous determination of the batteries’ thermal conductivity and specific heat. In the experimental test, prismatic lithium iron phosphate cells and pouch cells with different electrode materials were utilized. The researchers applied a constant heat flux to the cell surface and estimated the heat loss by analyzing the temperature drop curve. This approach facilitated achieving quasi-steady-state heat transfer, enabling the determination of cell thermal parameters. The study findings indicated that the thermal parameters of the cells increased linearly with the operating temperature. Additionally, the operating temperature had a more substantial impact on the cell’s specific heat compared to its thermal conductivity. On the other hand, the state of charge had a minimal effect on these two parameters. Overall, the developed method presents an effective and practical approach to simultaneously determine the thermal conductivity and specific heat of lithium-ion battery cells. This research provided valuable insights into the thermal behavior of lithium-ion batteries, which is critical for designing efficient thermal management strategies and ensuring battery safety and performance.

Ping et al. [37] addressed the flammability concerns associated with organic phase change materials (PCMs) commonly used for thermal management in lithium-ion batteries. To mitigate these concerns, the study introduces an encapsulated inorganic PCM (EIPCM) synthesized through nano-encapsulation. The core material, Na2HPO4·12H2O, is encapsulated within a matrix of silica. The EIPCM exhibits a melting temperature of 51 °C and a latent heat of 111.69 kJ/kg. Experimental tests conducted on battery modules reveal that the implementation of EIPCM results in a substantial 23.7% reduction in peak battery temperature (from 86.6 °C to 66.1 °C) at a discharge rate of 3C, while simultaneously maintaining a minimal temperature difference. Furthermore, EIPCM demonstrates the ability to delay thermal runaway by 495 seconds and significantly lower the peak surface temperature by 194 °C. This characteristic offers nonflammable suppression of thermal runaway and an enhanced level of battery safety. The study concludes by suggesting promising practical applications of EIPCM in the realms of batteries and energy storage.

Liang et al. [38] aimed to enhance the performance of lithium-ion batteries in electric vehicles (EVs) during cold conditions by introducing an innovative battery thermal management system (BTMS) utilizing a unique bent flat micro heat pipe array (FMHPA). The bent FMHPAs serve as efficient thermal bridges, facilitating independent preheating and cooling operations while optimizing spatial efficiency. Experimental results highlight the impressive thermal conductivity of the Z-shaped bending FMHPA, measured at 15,741 Wm-1K−1, resulting in a temperature rise rate of approximately 1 ℃/min across a temperature range of −20 °C to 0 °C. The temperature differences within both cell and module levels remain within 5 °C. Additionally, the introduction of a 20 mm insulation shell enhances the temperature rise rate and difference at the module level, yet has minimal impact on the active cooling performance at higher ambient temperatures.

The disadvantages of utilizing the experimental approach in the realm of thermal analysis for lithium-ion batteries encompass the following aspects:

- High Cost and Resource Intensity: The execution of experimental thermal analysis necessitates specialized equipment, materials, and proficient personnel, which can incur substantial expenses for establishment and maintenance. This entails procuring thermal imaging cameras, calorimeters, and other measurement instruments as well as conducting trials within controlled environments;

- Time-Consuming Nature: The undertaking of experimental thermal analysis can consume significant time, particularly when investigating diverse battery configurations, materials, and operational circumstances. The preparatory stages, actual experimentation, and subsequent analysis may lead to delays in acquiring findings and insights;

- Limited Adaptability: Experimental setups are frequently tailored to specific conditions, posing challenges in exploring a broad spectrum of scenarios and parameters. Such constraints can impede the exploration of intricate interactions influencing thermal behavior in real-world applications;

- Intrusive Character: Numerous experimental techniques involve modifying the battery’s surroundings or structure, potentially affecting its performance. For instance, embedding sensors or thermocouples within the battery could disrupt its thermal attributes and influence the outcomes;

- Environmental and Safety Considerations: Certain experimental methodologies, like abuse testing or simulations of thermal runaway, carry inherent safety hazards and environmental implications. These assessments might involve deliberately inducing battery malfunctions, which could lead to perilous situations or contribute to waste generation;

- Real-Time Monitoring Challenges: Continual real-time monitoring of thermal performance during battery operation proves arduous with experimental methods. This constraint hampers researchers from capturing dynamic and momentary effects transpiring during swift alterations in operating conditions;

- Scale and Reproducibility Complexities: Upscaling experiments to mirror real-world circumstances can be intricate and might not entirely emulate the actual conduct of lithium-ion batteries within larger systems. Replicating experimental outcomes across diverse laboratories can also be demanding due to variations in equipment and protocols;

- Data Complexity: Experimental thermal analysis generates copious volumes of data that necessitate meticulous analysis and interpretation. Extracting meaningful insights from intricate experimental data can be labor-intensive and may mandate sophisticated data analysis techniques;

- Limited Holistic Insights: Experimental methodologies may not furnish an all-encompassing comprehension of the fundamental physical and chemical mechanisms accountable for thermal behavior. Frequently, they supply surface-level observations without disclosing the molecular-level interactions;

- Equipment Inherent Constraints: The precision and resolution of experimental apparatus can introduce uncertainties and limitations into the amassed data, affecting the precision of thermal analysis outcomes.

To summarize, while experimental approaches hold value in studying thermal attributes of lithium-ion batteries, they entail drawbacks encompassing cost, time, adaptability, intrusiveness, safety, reproducibility, and data interpretation. Integrating experimental findings with computational modeling and simulation can help surmount some of these limitations and offer a more comprehensive insight into thermal characteristics within lithium-ion batteries.

3. Numerical Method for Thermal Analysis of Lithium-Ion Batteries

Numerical methods for thermal analysis of lithium-ion batteries are crucial for predicting battery behavior and assessing its performance under various conditions. These models encompass nominal electrothermal modeling, considering aging and mechanical stress, as well as thermal runaway modeling. Numerical simulations play a significant role in understanding the intricate relationship between electrochemical reactions and transport processes, which directly affect the battery’s temperature. Temperature has a significant impact on battery performance, lifespan, and safety. Hence, thermal management techniques are essential to address thermal challenges in lithium-ion batteries. These challenges include battery capacity and power degradation, the risk of thermal runaway, cell imbalances within battery packs, and the influence of low temperatures on battery performance. Understanding how temperature affects these phenomena is crucial for developing effective thermal management strategies. Heat generation in batteries is a critical aspect that needs to be understood for effective thermal management. Various studies have critically assessed research in this field, identifying knowledge gaps and prerequisites for thermal management systems in lithium-ion batteries, particularly in hybrid electric vehicles (HEVs) and electric vehicles (EVs). The comparison of estimated battery surface temperatures from numerical models with experimental data is essential for model validation. To achieve optimal performance in thermal management, different studies have investigated temperature distribution in various thermal management systems, such as air and liquid cooling. Efficient heat-transfer capabilities are crucial for lithium-ion battery thermal management systems.

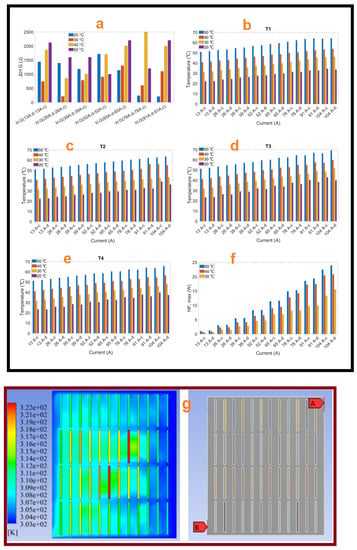

Figure 2 presents a systematic approach for designing a thermal modeling system for lithium-ion batteries. The use of numerical methods for thermal analysis offers valuable insights into the thermal behavior of lithium-ion batteries, contributing to the development of safer, more efficient, and reliable battery systems for various applications. A three-dimensional model was developed in ANSYS, based on the battery cell’s construction and geometry and enabling detailed analysis of the battery’s structure. The figure illustrates the components of the positive and negative current tabs responsible for facilitating current flow through the battery cell. The model consists of five distinct parts, each playing a specific role in the analysis. Geometrical meshing of the lithium titanate oxide battery cell’s structure is shown in another figure, providing a detailed representation of the cell’s internal configuration. To accurately represent the battery’s behavior, a 2-RC-quivalent circuit model was used. The parameters of this model were determined through different loading profiles involving various charge and discharge cycles at different C-rates. The model was solved within ANSYS using the multi-scale multi-dimensional (MSMD) battery module, which integrates key design parameters of the battery cell, such as physical attributes, materials, and dimensions, into the realm of computational fluid dynamics and heat transfer. Importantly, the battery model can simulate both a single battery cell and an entire battery pack, enabling investigation into their electrochemical and thermal behaviors. During the solution phase of the model, unsteady-state problems and interdependent thermal effects over time were addressed through numerical techniques, considering the dynamic heat generation within the battery cell. The quantity of heat generated within the lithium-ion battery cell, which is influenced by temperature and current rate, was quantified using IBC measurements and used as input for the thermal model. By employing this systematic approach and integrating numerical simulations with experimental data, a more comprehensive understanding of the thermal behavior of lithium-ion batteries can be achieved, leading to improved battery design, performance, and safety.

Figure 2.

(a) Difference between charge and discharge heat losses [21], (b–e) the battery surface temperature at different working temperatures and position [22], (f) maximum of heat flux at different current rates and temperatures [39], and (g) temperature profile inside the battery pack during air cooling [40], A: input, B = output.

Table 2 provides a comprehensive overview of numerical methods used for thermal analysis of lithium-ion batteries. These methods are valuable for accurately predicting temperature distribution and addressing temperature inhomogeneities within the battery cell. The findings from these simulations can aid in the design of efficient thermal management systems to optimize battery performance and ensure safety. One notable study by Verbrugge et al. [41] focused on analyzing the current and temperature distributions in large-scale battery modules using three-dimensional simulations. The research emphasizes the nonlinear relationship between power output and system temperature, with temperature significantly influencing electrochemical reaction rates and ionic conductivity. The study also provided a practical approach to estimate physicochemical parameters crucial for their model, addressing potential data limitations and enhancing simulation accuracy. Overall, the numerical methods presented in Table 2 offer valuable insights into the thermal behavior of lithium-ion batteries, paving the way for more effective thermal management strategies and improved battery performance and safety.

Table 2.

Numerical method for thermal analysis of lithium-ion batteries.

The studies conducted by Chen et al. [42] and Kim et al. [43] provided valuable insights into the thermal behavior and safety considerations of lithium-ion batteries. Chen et al. [42] employed a mathematical model to conduct thermal analysis during charge/discharge cycles and thermal runaway events. The research focused on understanding the thermal behavior of room temperature batteries and the potential for significant temperature increases that could lead to thermal runaway. The study investigated the impact of various battery design parameters and operating conditions on temperature rise and profiles during normal battery operation. Additionally, the likelihood of thermal runaway occurring under abusive or extreme conditions was evaluated. The findings contribute to enhancing our understanding of thermal management and safety in lithium-ion batteries, enabling the development of effective strategies to improve battery safety. Kim et al. [43] conducted a study specifically focused on the thermal abuse behavior of large-format Li-ion batteries designed for automotive applications. The research used a three-dimensional modeling approach to simulate oven tests and analyze local hot spots and their propagation within the cell. The results showed that the three-dimensional model predicted thermal runaway occurrence at different times compared to the lumped one-dimensional model. The study emphasized the importance of considering three-dimensional effects and cell size when assessing the risk of thermal runaway. Understanding these thermal behaviors is crucial for designing safe and reliable large-format Li-ion batteries for automotive applications. In conclusion, the findings from these studies contributed significantly to the field of lithium-ion battery thermal analysis, helping to enhance safety considerations and develop effective thermal management strategies for practical applications.

The studies conducted by Gu et al. [44], Liu et al. [45], and Cao et al. [46] focused on different aspects of battery modeling and optimization for improved performance and economic charging. Gu et al. [44] proposed a thermal-electrochemical-coupled modeling approach to predict the electrochemical and thermal behaviors of batteries. By considering heat-generation and temperature-dependent properties, their model allows for the analysis of average cell temperature and temperature distribution. The coupling of the thermal energy equation with a multiphase micro-macroscopic electrochemical model enables simultaneous analysis of both aspects. The study demonstrated the importance of thermal-electrochemical coupling, emphasizing its significance in optimizing battery design and performance under various charging conditions. Liu et al. [45] addressed technical challenges in battery economic charging for energy management by proposing a constrained multi-objective optimization framework. Their approach incorporated a coupled electrothermal-aging model for a lithium-ion battery, considering electrical, thermal, and aging characteristics. The framework included an economic indicator that considers charging costs related to battery aging and energy loss. The conflicting objectives of charging time and battery average temperature were also considered, along with hard constraints related to state of charge (SOC), charging current, terminal voltage, and temperature. The proposed approach provided a systematic and efficient way to optimize battery economic charging, taking into account economic and user-oriented objectives while respecting battery operation constraints. Cao et al. [46] addressed the challenge of accurately estimating battery degradation costs in the energy arbitrage market using a model-free deep reinforcement learning (DRL) approach. Their method combined a DRL technique with an accurate battery degradation model to optimize battery energy arbitrage. By formulating the control problem as a Markov decision process (MDP), sequential decisions in battery charging/discharging strategies were made. The proposed approach used a noisy network-based DRL technique to learn an optimized control policy, and a hybrid model with CNN and LSTM was employed to predict electricity prices for the next day. The study demonstrated the effectiveness and advantages of the proposed framework in optimizing battery energy arbitrage in the presence of uncertain electricity prices. Overall, these studies contributed valuable insights into battery modeling and optimization, addressing key challenges and providing solutions for improved battery performance and cost-effective charging strategies.

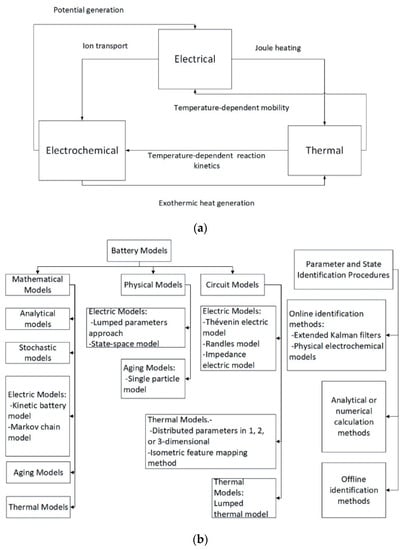

4. Thermal Modelling of Lithium-Ion Batteries

The thermal modeling of lithium-ion batteries involves considering various parameters and factors that influence their temperature behavior and performance. Some of the key parameters that are typically included in thermal models are heat capacity, density, along-plane and through-plane thermal conductivity, electric conductivity, and equivalent circuit model parameters. These parameters collectively determine how heat is generated, distributed, and dissipated within the battery during charging and discharging processes. Heat generation is a significant factor in thermal modeling, as it acts as a volumetric heat source within the battery. This heat generation can vary based on the operating conditions and the rate of charge or discharge. Temperature gradients also play a crucial role in influencing the rate of electrochemical reactions within the battery. Higher temperature gradients can lead to increased reaction rates, affecting the overall battery performance. Different regions within a lithium-ion battery may experience varying temperature gradients and current rates, especially in high-demand applications like electric vehicles that require high discharge rates. The interplay between thermal, electrochemical, and electrical processes within the battery is depicted in Figure 3a, illustrating the coupled nature of these phenomena and how they influence each other. To develop accurate lithium-ion battery models, parameter identification is crucial. Various methods, as shown in Figure 3b, are employed to determine and validate the model parameters. These methods help in understanding battery performance, optimizing battery design for specific applications, and developing efficient lithium-ion battery systems for energy applications. Overall, thermal modeling of lithium-ion batteries is a complex and critical aspect of battery research and development, enabling the study of their dynamic behavior and ensuring their suitability for various applications.

Figure 3.

(a) Scheme for coupled thermal, electrochemical, and electrical processes interacting in a lithium-ion battery [47]; (b) parameter identification methods and models of lithium-ion batteries [48].

The intricate connections and interactions among thermal, electrochemical, and electrical mechanisms within a battery play a pivotal role in comprehending its overall effectiveness, safety, and efficiency. Batteries, being intricate electrochemical contrivances, transform chemical energy into electrical energy. The following parts describe the interconnections of these mechanisms:

- Electrochemical Mechanisms: These operations encompass the movement of ions between the battery’s positive and negative electrodes during charging and discharging cycles. Discharge triggers chemical reactions at both electrodes, liberating energy in the form of electrons. Charging reverses these reactions, storing energy within the battery. These electrochemical mechanisms ascertain the battery’s capacity, voltage, and overall energy storage potential;

- Electrical Mechanisms: Electrical mechanisms pertain to the electron movement through the external circuit during discharge and charging. As the battery discharges, electrons flow from the negative electrode (anode) through the external circuit to the positive electrode (cathode), energizing the connected device. During charging, electron flow is reversed, moving from cathode to anode. This electron flow engenders an electric current, forming the foundation for the battery’s power delivery capability;

- Thermal Mechanisms: Thermal mechanisms emanate from the electrochemical and electrical processes, giving rise to heat generation and dissipation within the battery. During charge and discharge cycles, resistive losses within battery components and internal resistance induce heat production. Efficient heat management impacts the battery’s efficacy. Excessive heat can precipitate thermal runaway, compromising performance and safety.

The interplay among these mechanisms yields several implications:

- Efficiency: Optimal electrochemical reactions lead to efficient charge and discharge cycles, curtailing energy losses as heat. Inefficiencies in electrochemical processes can curtail battery performance;

- Heat Regulation: Thermal processes are pivotal for safe battery operation. Effective heat management is imperative to avert overheating and thermal runaway, which could trigger battery damage, fires, or explosions;

- Capacity and Cycle Life: Interplay between electrochemical and electrical mechanisms influences battery capacity (charge retention) and cycle life (number of charge-discharge cycles before capacity decline). Effective electrochemical reactions and judicious electrical utilization bolster prolonged cycle life;

- Voltage and Power Output: Electrochemical mechanisms determine battery voltage, influencing power output and compatibility with connected devices. The speed of electrochemical reactions can influence the battery’s capacity to provide high power on demand.

In summation, the intricate interplay of thermal, electrochemical, and electrical processes within batteries is multifaceted and interconnected. Comprehending and optimizing these mechanisms is indispensable for designing batteries that exhibit heightened performance, safety, efficiency, and durability.

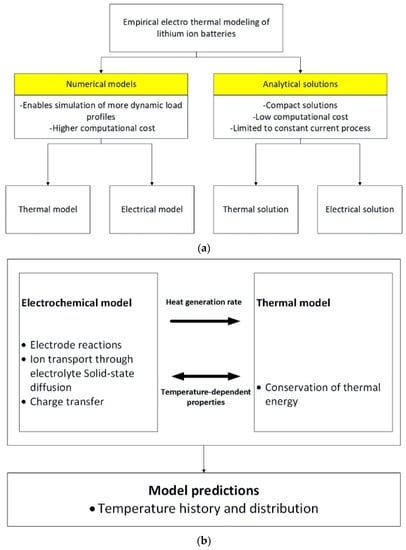

Empirical electrothermal modeling of lithium-ion batteries has made significant progress and is categorized into different approaches, as shown in Figure 4a. Developing accurate thermal models for lithium-ion batteries is crucial for their successful integration into various applications and understanding their behavior under real-world operating conditions. By integrating heat-generation and electrical models, dynamic thermal models can be created, enabling the analysis of data obtained from battery experiments. Figure 4b illustrates the classification of thermal and electrochemical modeling approaches for lithium-ion batteries. Creating thermal models that accurately represent the behavior of lithium-ion batteries is essential for research and development purposes as well as for activities related to system integration, thermal management, and designing battery packs. The development of models for both thermal and electrochemical behavior contributes to a deeper understanding of how lithium-ion batteries behave thermally under different operating conditions. One critical concern in the thermal modeling of lithium-ion batteries is the non-uniform temperature distributions within battery cells. To address this issue, various methods can be employed to achieve and demonstrate 3D thermal analysis, considering the spatial variations of temperature within the battery cell. Overall, the progress made in empirical electrothermal modeling and the classification of modeling approaches for lithium-ion batteries have enhanced our capability to study and optimize their thermal behavior in real-world applications. These advancements contribute to improving battery performance, safety, and efficiency in various practical settings, enabling researchers and engineers to design better thermal management systems and enhance the overall performance of lithium-ion batteries for diverse applications.

Figure 4.

(a) Empirical electrothermal modeling of lithium-ion batteries [49]; (b) thermal-electrochemical modeling method [44].

Table 3 provides a comprehensive overview of the current state of thermal analysis in the context of lithium-ion batteries. The literature review encompasses various studies that focused on the thermal modeling of these batteries. Three-dimensional models were developed to match the specific configurations and geometries of the batteries under investigation. Different techniques were employed to simulate and model the thermal behavior of lithium-ion batteries, and the results from these simulations were compared to laboratory measurements. The proposed models demonstrated their capability to predict the thermal behavior of lithium-ion batteries. Notably, temperature variations were observed on the surface of the batteries, especially at higher current rates, leading to significant heat loss due to increased temperature gradients. In general, the electrical conductivity of the negative electrode was found to be higher than that of the positive electrode, resulting in lower temperatures near the current collecting tab of the positive electrode compared to the negative electrode. Several studies combined numerical simulations with experimental data from the laboratory, thus laying the foundation for future thermal investigations of lithium-ion battery cells. These integrated studies contribute to the advancement of thermal-based modeling for lithium-ion batteries, providing valuable insights into the non-uniform temperature distribution within the battery cells. By modeling and simulating heat loss and the thermal behavior of lithium-ion batteries, these studies effectively describe temperature gradients at various current rates. The investigated models successfully capture and illustrate the observable heterogeneity of temperature distribution on the surface of lithium-ion batteries at different current rates. This knowledge is vital for enhancing the thermal management and overall performance of lithium-ion batteries in various applications. Improved thermal modeling and understanding of temperature distribution will lead to better battery designs, improved safety, and increased efficiency in diverse practical settings, including electric vehicles, portable devices, and energy storage systems.

Table 3.

Thermal modelling of lithium-ion batteries.

Temperature has a significant impact on the performance and operation of LIBs, and precise temperature measurement is crucial for effective battery management. Wang et al. [7] utilized artificial neural networks (ANNs) to forecast temperature fluctuations in lithium-ion batteries within a metal foam thermal management setup. The study evaluated three different ANN architectures: back propagation neural network (BP-NN), radial basis functions neural network (RBF-NN), and Elman neural networks (Elman-NN), aiming to compare their predictive capabilities. The Elman-NN model demonstrated superior adaptability, generalization, and a shorter training time, establishing it as the optimal choice for predicting temperature changes in the thermal management system, particularly when coupled with forced air cooling for lithium-ion batteries. The accuracy of the neural network thermal model was verified through separate performance tests, generating anticipated temperature data and comparison graphs for various scenarios.

The study conducted by Emre Gümüssu et al. [50] represented a significant advancement in the field of thermal analysis for lithium-ion batteries. They developed a comprehensive three-dimensional computational fluid dynamics (CFD) model to analyze the thermal behavior of lithium-ion batteries under natural convection. The model takes into account the complete flow field around the battery and conduction inside the battery, using the heat-generation model proposed by Bernardi et al. (1985). One notable feature of this model is its thermally fully predictive nature, meaning that it only requires the electrical performance parameters of the battery to calculate its temperature during discharge. This simplifies the modeling process, making it more efficient and practical for real-world applications. The researchers conducted a detailed investigation into the effects of variations in macro-scale thermo-physical properties and the entropic term of the heat-generation model. Their findings revealed that the specific heat of the battery is a critical property that significantly influences the simulation results, while the thermal conductivity has a relatively minor impact. A particularly interesting observation from their study was that the experimental data could be successfully predicted without considering the entropic term in the heat-generation calculation. This suggests that the model’s accuracy in predicting battery surface temperatures is already quite high, and further improvements may not necessarily require accounting for the entropic term. The model’s performance was validated by comparing the predicted battery surface temperatures with experimental data for various discharge rates and usage histories. The discrepancy between the predicted and experimental temperatures was found to be less than 3 °C, indicating a high level of accuracy and reliability in the model’s predictions. Overall, the developed CFD model provides valuable insights into the factors affecting battery temperature and can be utilized to aid in the design and optimization of battery cooling systems. By ensuring safe and efficient battery operation, this research significantly contributes to the advancement of thermal management in lithium-ion batteries and facilitates the development of more reliable and efficient battery systems for various applications.

The work by Mohammad Rezwan Khan et al. [51] presented a three-dimensional multi-physics-based thermal model of a battery pack, combining heat transfer (HT), and computational fluid dynamics (CFD) to analyze its cooling mechanism. The model uses experimental data to represent heat generation inside the battery cells as a lumped value. By considering time-dependent and steady-state scenarios, the model accurately captures temperature gradients across the pack’s surfaces and the temperature evolution over time. This detailed spatio-temporal thermal behavior information is crucial for understanding the thermal characteristics of battery packs, optimizing their design, and ensuring efficient cooling and safe operation. Nicolas Damay et al. [52] proposed a thermal modeling approach for a large prismatic Li-ion battery and experimentally validated its accuracy. The lumped model considers various factors such as heat capacity, internal thermal resistance, and interfacial thermal resistance between the battery cell and its cooling system. The authors combined analytical calculations based on physical and geometrical properties with experimental identification to determine model parameters. The experimental measurements and model predictions were found to be in good agreement, with an accuracy of 1 °C. This validation demonstrated the model’s capability to accurately represent the thermal behavior of the large prismatic Li-ion battery, making it valuable for assessing the thermal performance of similar battery systems, optimizing cooling strategies, and ensuring safe and efficient battery operation. Xinchen Zhao et al. [53] investigated the electrochemical performance of lithium-ion batteries at low temperatures, focusing on the effects during charging and discharging. The study highlighted the phenomenon of lithium stripping during discharging, which leads to decreased battery performance. To understand the degradation mechanisms, they developed a physics-based electrochemical-thermal model that considers lithium plating and stripping effects. The model accurately predicted battery degradation during cycling and revealed that lithium plating starts at the interface between the composite anode and separator, accelerated by lower temperatures and higher charging current rates. The model also accounted for various degradation effects, such as loss of recyclable lithium ions, anode active material, plated lithium growth, secondary solid electrolyte interphase (SEI), and electrolyte solvent consumption. The model’s capacity estimation accuracy is about 3% for capacity fade below 30%. This research provided valuable insights into mitigating degradation and enhancing battery performance and lifespan under low-temperature conditions. Overall, these studies contributed significantly to the field of thermal modeling and analysis of lithium-ion batteries, aiding in the development of more reliable, efficient, and safe battery systems for a wide range of applications.

Lin Liu et al. [54] developed a one-dimensional thermal-electrochemical model to investigate the effects of the solid electrolyte interphase (SEI) layer’s growth on the performance degradation of lithium-ion batteries. The SEI layer is known to increase internal resistance and cause capacity loss over time. The model considered diffusivity, reaction kinetics, and temperature to incorporate the growth mechanism of the SEI layer. It revealed that the growth can be either kinetics-limited or diffusion-limited, depending on the layer’s thickness. Thicker layers experienced slower growth due to increased diffusion resistance. The model also showed that the SEI layer grows faster during charging than discharging due to temperature changes during cycling. Understanding the dynamics of SEI layer growth can guide monitoring strategies and help mitigate its formation and growth, leading to improved performance and lifespan of lithium-ion batteries. Suman Basu et al. [55] proposed an efficient and compact liquid coolant-based thermal management system for an 18,650 battery pack. They developed a coupled three-dimensional electrochemical thermal model to evaluate the thermal performance of the battery pack. The model considered the electrochemical processes inside the battery cells and heat-generation and -dissipation mechanisms. By simulating different operating conditions such as coolant flow rate and discharge current, the model assessed their impact on the temperature of the battery pack. Contact resistance was identified as the most influential factor affecting the thermal performance of the battery pack, emphasizing the importance of ensuring good thermal contact between the battery cells and the cooling system. Based on the numerical solution, the researchers devised a novel temperature correlation that allows predicting the temperatures of all individual cells in the pack by measuring the temperature of just one cell. Experimental validation confirmed the validity of this correlation. The use of such temperature correlations can reduce complexity and sensor requirements in large Li-ion battery packs, especially in electric vehicles. By accurately predicting temperatures with a single measurement, the overall system becomes more cost-effective and simpler to implement. This study significantly contributed to the development of efficient and economical thermal management systems for Li-ion battery packs, enhancing their performance, safety, and overall usability in various applications, including electric vehicles.