Abstract

The increasing penetration of distributed generation sources in low-voltage distribution grids, electric vehicles, and new appliances from the consumer side can generate short repetitive overloads on the low-voltage cable network. This work investigates the change in the dielectric properties of low-voltage cable insulation caused by short-term overloads, examining how the cable structure affects the dielectric characteristics of the cable specimens in the case of cyclic short-term thermal aging. PVC-insulated low-voltage cable samples were exposed to an accelerated aging test in a temperature-controlled oven after changing their structures by removing different layers. Three aging cycles, each of six hours, were applied to the samples. After each cycle, the tan and capacitance were measured by an Omicron DIRANA Dielectric Response Analyzer in the laboratory at room temperature 24 °C. Furthermore, the polarization and depolarization currents were also studied. The results show that changing the cable structure impacts the dielectric parameters; in particular, the effect of the belting layer is significant. From the point of view of aging, the PVC belting layer protects the diffusion of the plasticizers of the inner structure. The findings of the study show that an asymmetric aging phenomenon can be observed in different polymeric components of the cables, even though the cables were aged in an air-circulated oven ensuring a homogeneous temperature distribution in the samples.

1. Introduction

The low-voltage (LV) distribution system contains several elements such as transformers, switches, circuit breakers, relays, etc. These elements are essential for a safe and uninterrupted supply for the users. It is also important to remember that cables are one of the most important and main parts of the network. The existing networks, which were built decades ago, face new challenges with the increasing penetration of distributed generation (DG), electric vehicles, new appliances from the consumer side, and reverse power flow due to renewables [1]. According to Eurostat, the EU’s share of renewable energy has doubled since 2004 [2]. These new challenges may cause unbalanced and cyclic load distribution on the cable network. The accelerated aging tests used for the lifetime estimation of insulating materials are usually executed at constant elevated temperatures for relatively long periods; nevertheless, in real cable lines, the thermal cycling caused by cyclic loads causes additional stress initiating additional degradation mechanisms for the insulation, which is not simulated in the normal thermal aging test [3]. Short-term overloads and short-circuit operations raise the temperature above the maximum operating limit [4], damaging the cable insulation and shortening the lifespan [5]. The thermal cycles also affect the dielectric parameter of cable insulation, and an increase in the tan was observed in a wider frequency range [6].

The most commonly used insulating material for LV distribution cables is PVC [7]. Aside from its distribution network application, PVC is also used as an insulating material for nuclear power plant cables; however, installing PVC-insulated cables in a new reactor is not allowed [8]. Nevertheless, due to the second license renewal of NPPs, the condition monitoring of LV cables is paramount. High temperatures on plasticized PVC typically cause two main degradation processes. One of these is dehydrochlorination, while the second process is a mass loss of the plasticizer [9]. However, the diffusional desorption of the plasticizers is the dominant process at lower temperatures [10,11]. Plasticizers are used to change a polymer’s glass transition temperature (Tg) [12]. The glass transition temperature is the temperature at which an amorphous polymer changes from a hard/glassy state to a soft/leathery state. Plasticizer diffusion and evaporation have been identified as causes of insulation degradation during thermal aging by several studies [13,14,15,16]. According to Nedjar et al., the early stages of aging cause insulation degradation due to plasticizer loss. Over a longer time, the degradation is attributed to stabilizer consumption followed by material coloration and hydrochloric acid emission. A change in the color, shrinking, and mass loss is observed as degradation [14]. Wie et al. described that plasticizers could leave the polymer through migration, evaporation, or extraction, which causes changes in the mechanical properties by reducing the flexibility, extensibility, and toughness [15]. Konecna et al. investigated the temperature dependence of the dielectric parameters under thermal aging by measuring the tan and capacitance. It has been proven that these parameters are affected [17]. Nedjar et al. published that the evaporation of plasticizers resulted in increases in the tan [16]. Later, Csanyi et al. published several studies showing that the PVC cable insulation hardens when exposed to cyclic thermal stress and showed a correlation between the dielectric parameters and the hardness of the material [13,18,19].

In investigating cable aging, single-core simple cables are usually used to eliminate the effect of the complex structure of multicore cables and the interaction among the polymeric components [20,21,22]. However, a typical LV cable contains layers such as conductors, core insulations, protective tape screens, a jacket, etc. The degradation of these layers may be different due to the nonuniform temperature distribution in the cable and the interdiffusion of the plasticizer between the layers [22,23]. Honing et al. found that an increased number of insulation layers could add several degrees to the cable temperature [24].

In this study, the effect of the structure is investigated to reveal whether the behavior due to repetitive aging is a characteristic of the polymer itself or whether it results from the structure as well. Hence, four cable samples, each 50 cm in length, were prepared for this purpose. One sample was kept intact, and different layers were removed from the other samples to investigate the impact of the cable structure on the dielectric parameters during aging. Then, short-term artificial cyclic aging was applied to simulate the short-term temperature changes due to the load variation. Although, an unbalanced load on the cable causes an asymmetric heat distribution, the samples were aged in an intensively air-circulated aging chamber to ensure a homogeneous temperature distribution in the samples. By executing the aging in this way, the asymmetric aging of the cable components was not affected by their different temperatures but by their different positions inside the cable cross section, causing, e.g., differences in contact with the atmosphere or the interdiffusion of additives among them. Previous studies have successfully adopted dielectric spectroscopy measurements on LV cables [21,25,26,27,28]. Therefore, the dielectric parameters, tan , the capacitance, and the polarization and depolarization currents were measured after each aging cycle. The hardness was also measured but was executed on the belting layer only because the cable’s structure does not enable measuring it on the core insulations.

Section 2 introduces the applied methodology, while Section 3 details the sample preparation and equipment used. Section 4.1 describes the results and discusses them. Finally, in the last section, the main findings are summarized.

2. Methodology

For the characterization of the change in the properties of the cable polymeric components, the dielectric response and the hardness were measured.

2.1. Dielectric Response Measurements

The Dielectric Response Measurement (DRM) is widely accepted and used as a useful condition monitoring (CM) technique [29]. These techniques measure the current flowing through the tested insulation. If the exciting voltage is DC, the current is measured and recorded in the time domain. When applying AC voltage, the magnitude and the phase of the current are measured. In the case of dielectric spectroscopy, these parameters are investigated in a wide frequency range, i.e., the frequency domain measurement.

In general, the tan and capacitance are measured in the frequency domain, and the polarization–depolarization currents are measured in the time domain [30]. These measurements are capable of monitoring the degradation of the LV cables [25,26].

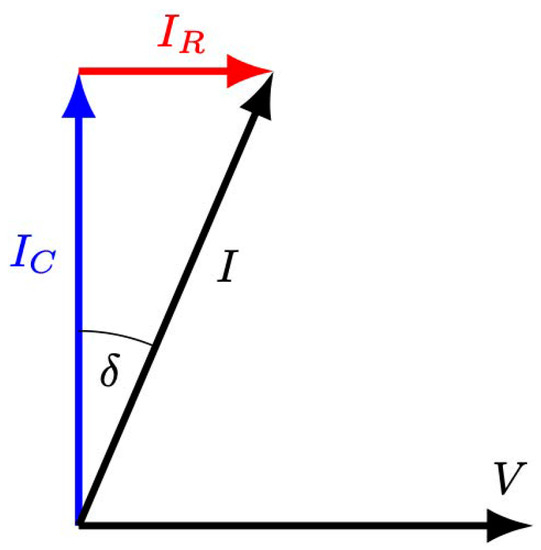

The tan , or loss factor, is a ratio of the resistive and capacitive current flowing through a dielectric excited with alternating voltage (Figure 1):

Figure 1.

Currents and voltage of the tan measurement.

The value of the tan characterizes the dielectric loss of insulation and is widely used in the condition monitoring of electrical equipment [31].

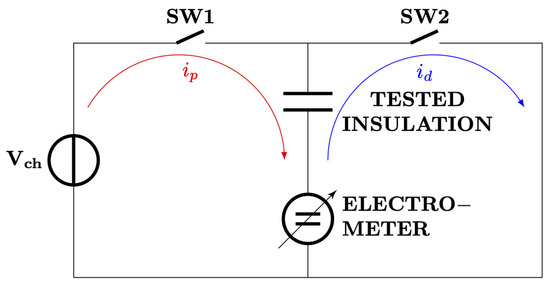

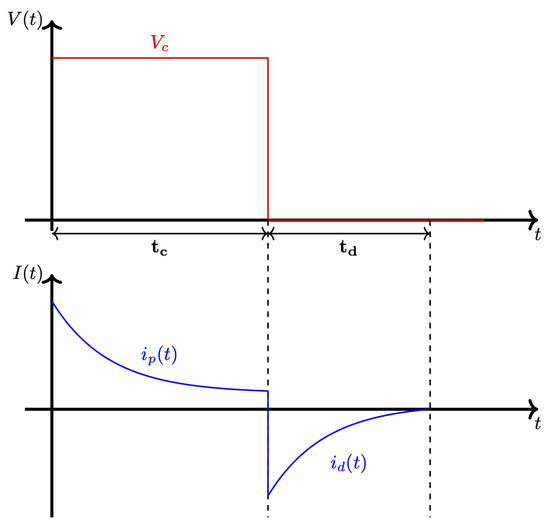

The PDC measurement is based on two processes, charging and discharging the dielectric. The cable sample is charged with a voltage source for a defined period of time. Once the charging period is over, the cable sample is discharged again for a predefined discharging time. The PDC is measured, from which the conduction current is calculated. The polarization current is strongly dependent on the insulation conductivity. The circuit diagram of a PDC can be seen in Figure 2, while the timing diagram is shown in Figure 3.

Figure 2.

Circuit diagram of PDC.

Figure 3.

Timing diagram of PDC.

The polarization current () is measured when the tested insulation is connected to the voltage source (), the SW1 is in the ON position, and the SW2 is in the OFF position (Figure 2). The depolarization current () measurement can be measured on the short-circuited test object by switching the SW1 to the OFF position and the SW2 to the ON position. The charging time is denoted by , while the discharging time is denoted by .

2.2. Hardness Testing

The change in the mechanical properties of the cable’s plastic components was measured by the Shore D hardness. The hardness measures the penetration depth of the indenting foot in the material by applying a constant. The Shore D hardness is used to measure the hardness of plastics and is also applied for condition monitoring in cable diagnostics. In the case of the Shore D scale, if the indenting foot has no indention to the material, the hardness value is 100, while if the indention has a maximum (2.54 mm), the value is 0. The applied force is 4450.0 mN.

3. Experiment

3.1. Cable Sample

SZAMKAM kV 16 mm × 4 PVC insulated, manufactured by Prysmian MKM Kft, Hungary, cable samples were submitted to an accelerated aging test. The cable samples were produced according to the requirements of IEC 60502-1 [32]. The cable structure can be seen in Figure 4. According to the technical data, the maximum conductor operating temperature of the cable is 70 °C.

Figure 4.

SZAMKAM cable structure.

- 1.

- 4 x Solid Aluminium Conductor.

- 2.

- PVC core insulation.

- 3.

- PVC tape.

- 4.

- Aluminium tape screen.

- 5.

- PVC jacket.

As previously mentioned, this research aims to determine the effect of the cable construction on the dielectric characteristics that are impacted by thermal aging. Therefore, the layers of the cable were removed. It is worth emphasizing that the dielectric parameters were measured before changing the structure and thermal aging to ensure the sample homogeneity. Figure 5 shows the samples before and after changing the structure.

Figure 5.

Cable samples before (A) and after (B) the structure changes.

Table 1 depicts the leftover layers for each sample after changing the structure. Sample 1 was kept intact. The outer PVC jacket was removed from Sample 2. By comparing the measurements on this sample with those on the intact sample, it is possible to test whether the layers under the jacket (aluminum tape screen and PVC tape) adequately insulate the core insulations from the air. In the case of Sample 3, in addition to the PVC jacket, the aluminum screening tape was also removed. Only the PVC belt isolated the core insulations from the atmosphere of the aging chamber, while in Sample 4, the core insulations were not covered by anything. Hence, if the atmosphere affects the aging of the core insulations, it will be seen in the measurement results.

Table 1.

Remaining cable layers per sample; ✓: layer is present, ✕: layer is removed.

3.2. Thermal Aging

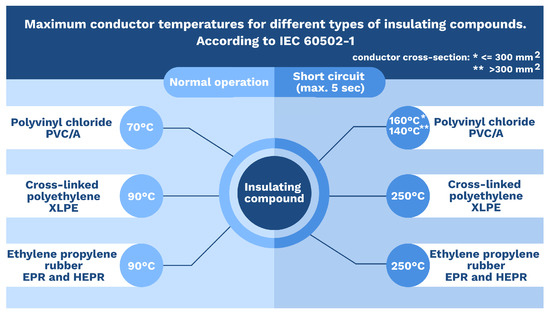

The cables are subjected to various stresses during operation. However, the dominant stress may be responsible for the majority of the degradation. A previous study showed that thermal stress can dominate, resulting in insulation degradation [33]. As mentioned in Section 1, the cable temperature may rise for a short time due to an overload, a short-circuit operation, and daily periodic generations. Especially in summer, the generation rate of photovoltaics is high at noon. Therefore, short-term cyclic thermal aging was used in this study. The cable samples were placed inside a temperature-controlled oven for three rounds (each of 6 h). According to IEC 60502-1, thermal aging should be carried out at at least 10 °C more than the maximum conductor temperature, which is 70 °C during normal operation and 160 °C during a short-circuit operation [32]. The respective information can be seen in Figure 6.

Figure 6.

Maximum conductor temperature according to IEC 60502-1.

The standard prescribes the maximum conductor temperature since, in real conditions, the heat is generated as Joule-loss in conductors by the loading current. Since the generated heat is conducted through the cable components to the soil, the temperature will not be the same in the different parts of the cables. In contrast, in a well-ventilated aging chamber, the temperature of the cable components can be considered the same, enabling investigation of the different aging behavior of cable components. The temperature for thermal aging was set to 110 °C. This temperature was chosen for easier comparison with previous studies, and it was intended to use a temperature higher than specified in the standard [13,18,19,25,34,35]. Eighteen hours of aging were achieved. Using the Arrhenius equation, this aging time would be equal to 330 h of service time at 70 °C.

3.3. Dielectric Response Measurement

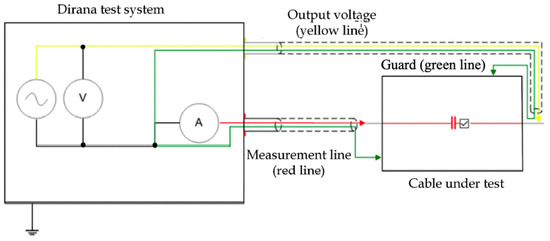

The dielectric parameters in the time and frequency domains were measured by a DIRANA Dielectric Response Analyzer, manufactured by Omicron Electronics Gmbh, Klaus, Austria. This equipment combines frequency-domain spectroscopy (FDS) and polarization–depolarization current (PDC) techniques to measure the dielectric response. The FDS method is applied at higher frequencies above 0.1 Hz. The time-domain PDC data are captured to measure the dielectric response in the lower frequency band. The collected PDC data are then transformed to the frequency domain using Fourier transformation [31,36,37,38]. The measurement setup can be seen in Figure 7. The general dielectric measurement configuration was chosen from the DIRANA library. The frequency range was given so that the interfacial polarization could be investigated [39]. The cable samples were placed inside a Faraday cage to avoid external electromagnetic disturbances. The measurement setup is depicted in Figure 8. In this investigation, the brown-colored insulation was measured against the others. Hence, one of the test leads was connected to the brown core. The other cores were connected to the aluminum armor, and the other test lead was connected to them.

Figure 7.

Measurement configuration from the DIRANA library.

Figure 8.

Measurement setup.

The measurement parameters were set as:

- Configuration: general dielectric.

- Test voltage: 100 V.

- Frequency range: 300 μHz–5 kHz.

- Charging time: 3333 s.

- Discharging time: 1000 s.

3.4. Shore D Hardness Measurement

The hardness was measured only on the cable’s belt layer, since the diameter of the cores was too small, and the thickness of the insulation was lower than the maximum penetration depth of the Shore D hardness technique. The ASTMD2240-05 [40] standard prescribes a 6 mm minimal material thickness for the Shore D hardness measurement. The PVC belt thickness was 0.2 mm, and a double layer was used for cable belting. Since the double-layer PVC belt thickness was only 0.4 mm, the PVC belt was folded three times resulting in a 3.2 mm thickness for the measurements. More folding of the samples was not possible because each folding halved the sample area, and on a smaller surface area, the test could not be repeated as many times to give a sufficiently small uncertainty in the measurement. Thus, the Shore D hardness did not provide standardized results, but it can be applied to compare the hardness of the samples with reasonable accuracy. The applied equipment was a Bareiss HPE II Shore D durometer (Bareiss Prüfgerätebau GmbH, Oberdischingen, Germany). The hardness was measured 12 times on each sample at randomly selected points. The average and standard deviation of the results were calculated from 10 measurement values dropping the highest and the lowest values.

4. Results and Discussion

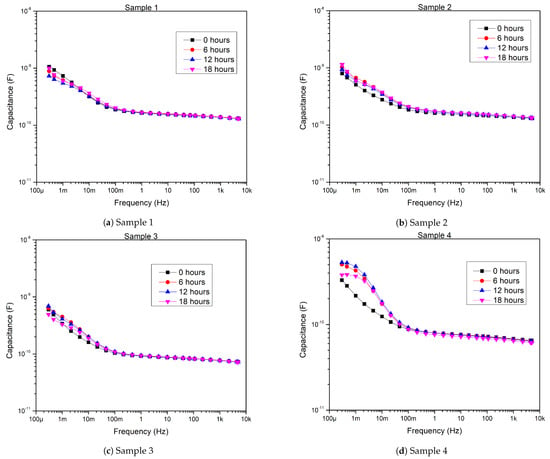

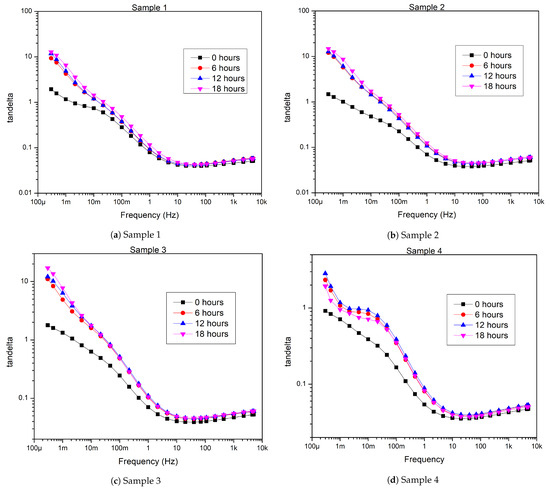

The dielectric parameters were measured after each round of aging. The tan and capacitance values were registered and presented in a log–log chart.

4.1. Effect on Tan and Capacitance

All measurement results are presented in Appendix A. In this section, only the results included in the detailed analysis are shown.

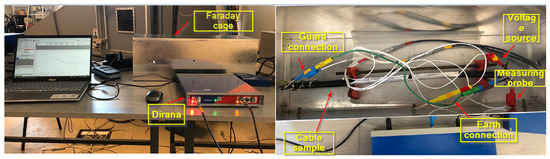

4.1.1. Before Aging

The homogeneity of the cable samples was checked by measuring them while unaged and intact. Figure 9 shows that there was no significant difference between the samples. Therefore, it can be considered that the samples were homogeneous. Hence, the different aging behavior of the samples was caused by only the various structures of the samples. The typical trend of the tan with frequency is that it decreases until it reaches the minimum point, from where it increases to 5 kHz.

Figure 9.

The results of the tan measurements on the intact samples before aging.

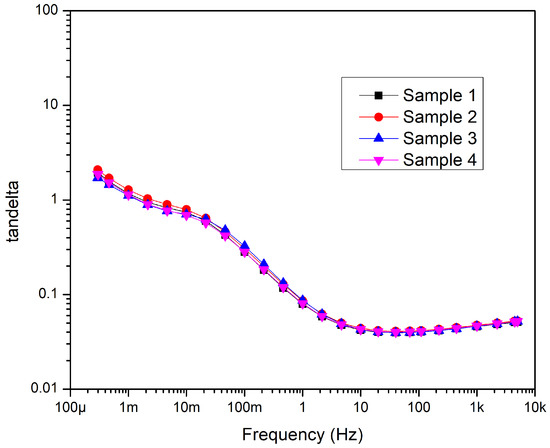

Table 1 shows that Sample 1 was the only sample kept intact during the measurement. However, the structure of Samples 2, 3, and 4 were changed before the thermal aging. The tan was measured after the structural change. The results are plotted in Figure 10. As shown before, the curves followed a similar trend over the frequency range, but removing the layers affected the tan . The cross comparison shows that the tan of Sample 4 decreased significantly compared to Sample 1, the intact cable, while Samples 2 and 3 did not show a drastic change. This is probably due to the distribution of the electric field changes inside the cable, as removing the layers decreases the compressing force on the cable structure, causing a minimal change in the cable geometry. Otherwise, recent studies have revealed the compressing force can cause a significant increase in the dissipation factor at the low-frequency range [41,42].

Figure 10.

The effect of the structure changes on the tan before aging.

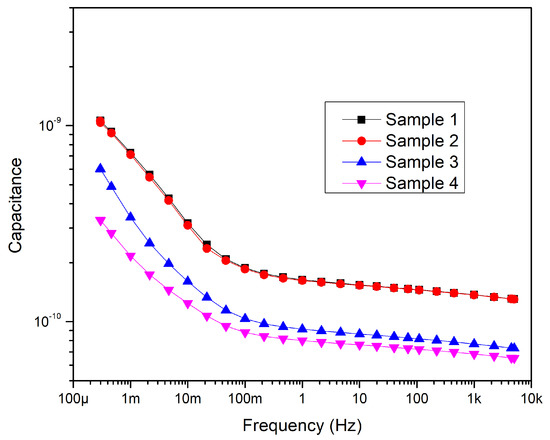

Figure 11 shows how the capacitance changed by removing the layers. It is observed that removing the jacket did not show a considerable difference compared to the intact sample. However, the graph shows that the capacitance of Samples 3 and 4 dropped. The reason is that removing the aluminum tape screen reduces the electrode surface, which results in decreased capacitance values. Interestingly, the capacitance change between Samples 3 and 4 was relatively large despite only the thin PVC belt being removed from the cores. Thus, this layer significantly affects the field strength distribution within the cable.

Figure 11.

The effect of the change in structure on the capacitance [F] before aging.

4.1.2. After Aging

The tan values measured after aging were compared with the results of the measurements before aging, and a cross comparison was also executed between samples after aging.

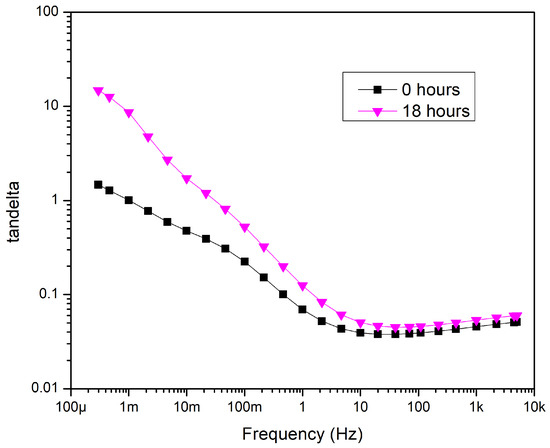

Sample 1.

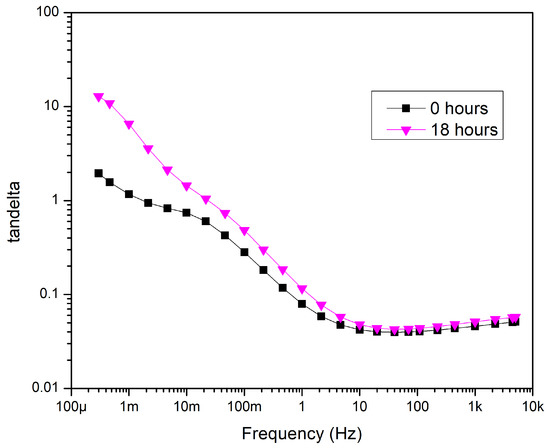

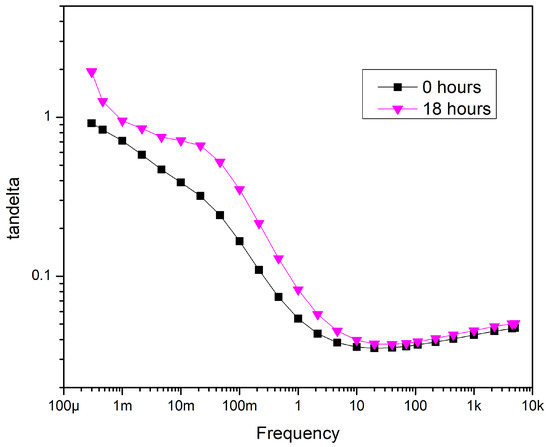

As mentioned above, Sample 1 was the intact cable. Therefore, we expected to observe the general aging behavior from Sample 1. In addition, Sample 1 can be used as a reference for the other three samples. The results of 18 h of aging on the tan can be seen in Figure 12. It can be seen that the tan increased, especially at low frequencies from 300 μHz to 10 Hz, and the difference decreased with the increase in frequency. The increasing intensity of the interfacial polarization can explain this behavior due to the higher conductivity after aging.

Figure 12.

The change in the tan with aging, Sample 1.

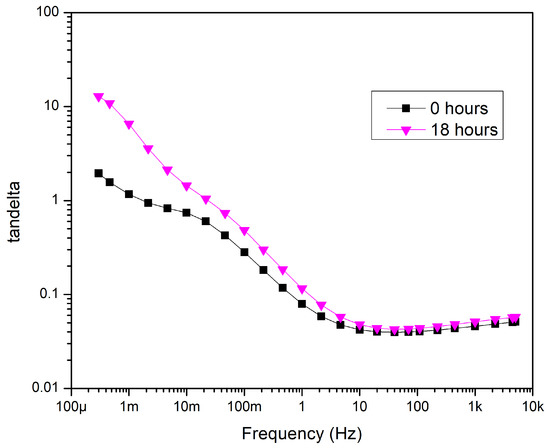

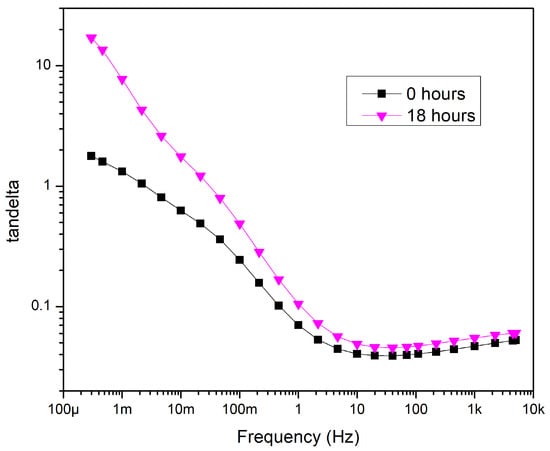

Sample 2.

The comparison before and after aging (Figure 13) showed a tendency similar to Sample 1. The tan increased after eighteen hours of thermal aging. It is also noted that the difference between the tan values in the 10 mHz...100 mHz range was higher than that of Sample 1. This difference is due to the different values of the loss factor before aging (Figure 10).

Figure 13.

After aging, Sample 2.

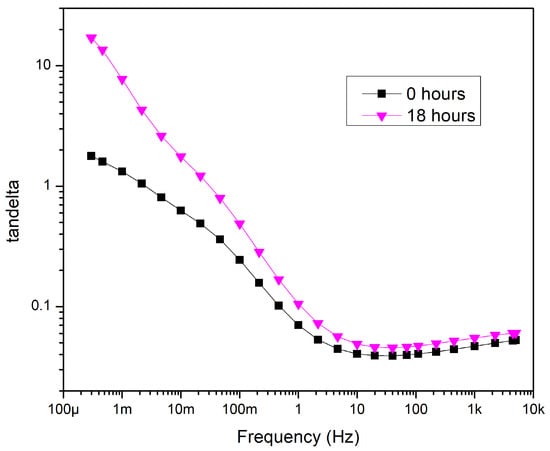

Sample 3.

Sample 3 showed a similar result to sample 2. The tan increased at the end of eighteen hours of aging (Figure 14). The results of the measurements suggest removing the aluminum tape screen did not significantly affect the tan .

Figure 14.

After aging, Sample 3.

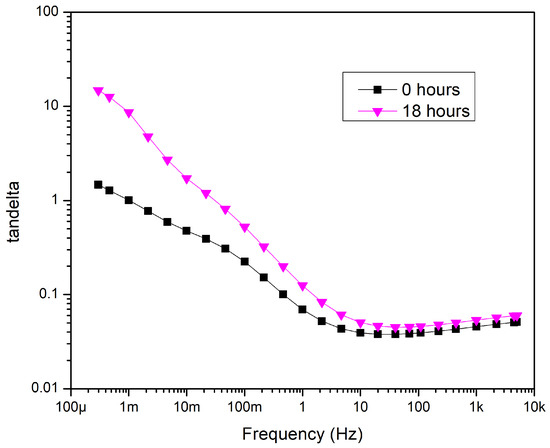

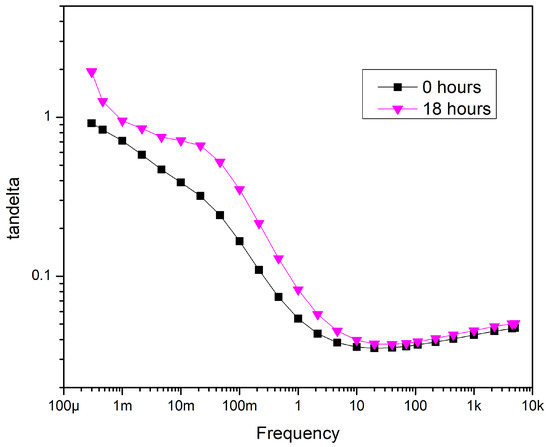

Sample 4.

Sample 4 is the sample that had only the conductors and the core insulations. The result can be seen in Figure 15. This sample’s tan values also showed an increasing trend compared to before aging; even the shape of the curve was also changed. Nevertheless, while the loss factor decreased steadily over the 300 μHz…1 Hz range in the previous cases, there were two knee points around 1 mHz and 100 mHz of the tan curve of this sample. It can be stated that removing the PVC belt has the most significant effect on the electrical parameters changing due to aging.

Figure 15.

After aging, Sample 4.

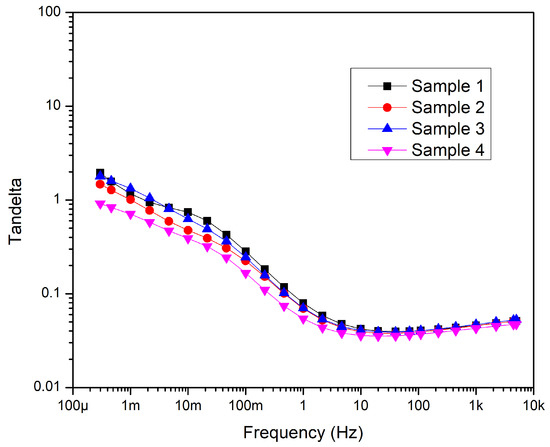

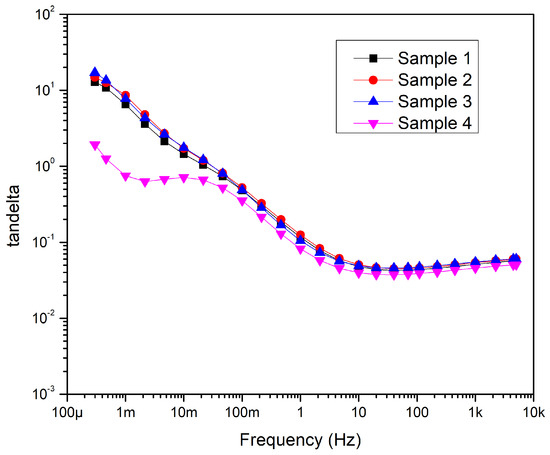

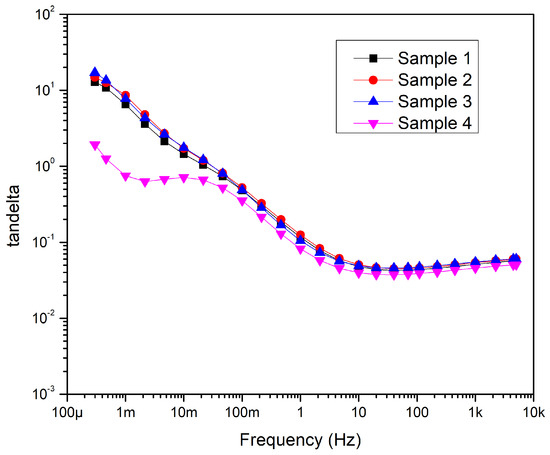

Cross comparison.

As shown in the previous section, all four samples showed a similar increasing trend when compared individually with their results. However, the cross comparison gives interesting results. The tan of Sample 4 was noticeably lower than the other samples (Figure 16).

Figure 16.

Cross comparison between the samples after aging.

The reason for the difference is that in the case of Samples 1–3, the core insulations did not come into contact with air during thermal aging. Moreover, the result suggests that the PVC belt layer itself was enough to prevent the core insulations from coming into contact with the atmosphere of the aging chamber.

In a normal air atmosphere, there are three degradation mechanisms of plasticized PVC: dehydrochlorination, oxidation, and the migration of the plasticizer [43]. All of these processes affect the dielectric property of the material. Dehydrochlorination mainly results in a double-bond formation in the chain molecule [44]. The double bonds act as shallow electron traps or hopping places for electrons, increasing the conductivity of the material [45,46,47]. The presence of oxygen affects the thermal degradation of the PVC. Compared to an inert atmosphere, the dehydrochlorination rate is higher in normal air [48]. At higher temperatures, chain scission and cross-linking reactions are also observed [49]. Since the low-frequency tan increased in all cases, an increase in the conductivity can be assumed, indicating the thermal degradation of the PVC core insulation. Because of the 110 °C aging temperature, the dominant degradation process was the plasticizer loss, controlled by the environmental conditions in this temperature range [43]. Previous studies have shown that thermal aging affects the plasticizer component content inside the PVC, leading to the tan alteration [13]. The tan of the dielectrics in the low-frequency range is mostly the result of the conductivity, and the plasticized PVC conductivity is proportional to the plasticizer content. The different behavior of Sample 4 from the other samples can be explained by the fact that the core insulations of Sample 4 were in contact with the air. Therefore, the plasticizer could easily evaporate from them, unlike the other samples, which were covered with other structural elements of the cables, such as the PVC belt layer, the aluminum tape, and the jacket. The conductivity decrease due to the plasticizer loss can partly compensate for the conductivity increase caused by the dehydrochlorination. The Sample 3 insulations were covered only with the PVC belt layer. The Sample 3 aging behavior was similar to Samples 1 and 2; hence, the PVC belt layer alone could prevent the plasticizer evaporation. However, this requires further investigation.

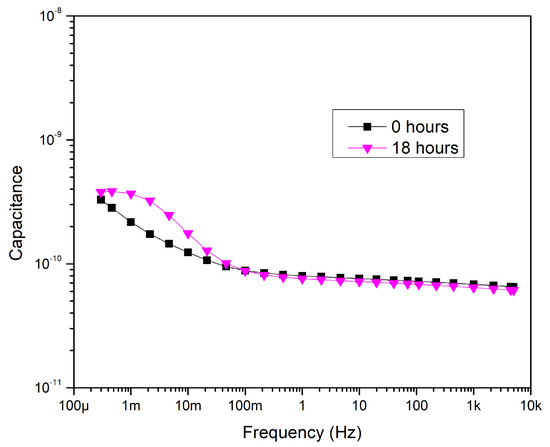

A local peak in a tan curve is related to a dominant polarization process on a given frequency, resulting in a significant change in the capacitance–frequency curve [31,38]. Since the tan of Sample 4 had a local peak between 10 and 100 mHz (Figure 16), it is worth looking at its capacitance curve (Figure 17). Between 1 mHz and 30 mHz, the capacitance dropped below 100 nF from 300 nF. The reason for this capacitance decrease could be due to the appearance of a dominant interfacial polarization in this frequency range [26].

Figure 17.

Capacitance of Sample 4 after aging.

The other samples’ capacitances showed a small increase below Hz with aging (see Appendix A), due to the increase in the conductivity of the material with aging.

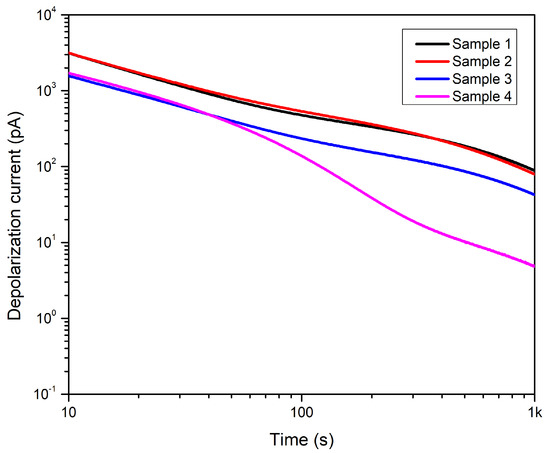

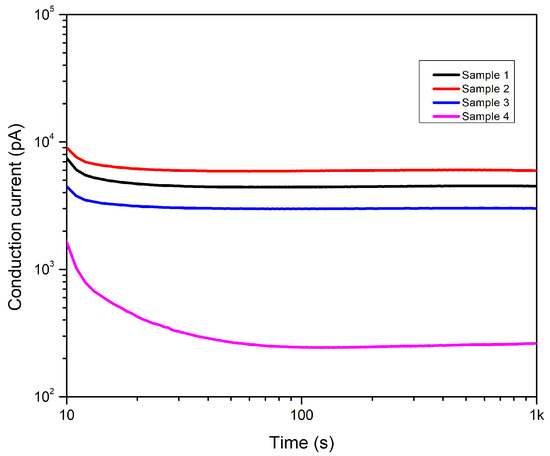

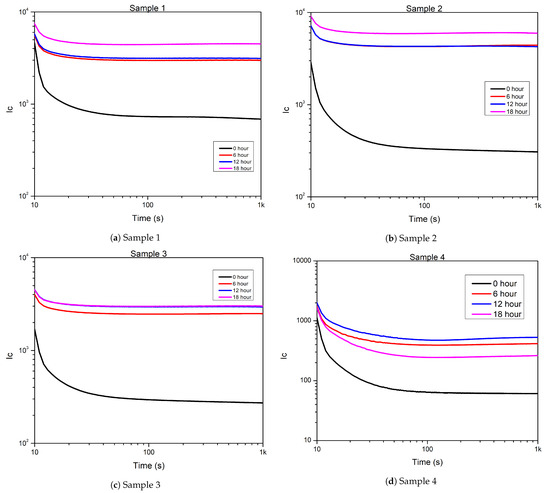

4.2. Impact on the Polarization, Depolarization, and Conduction Currents

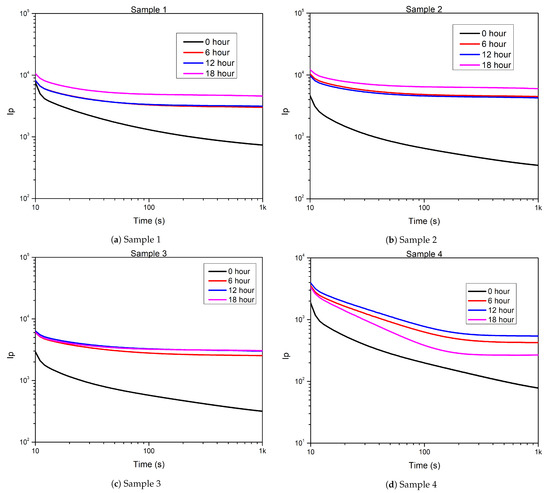

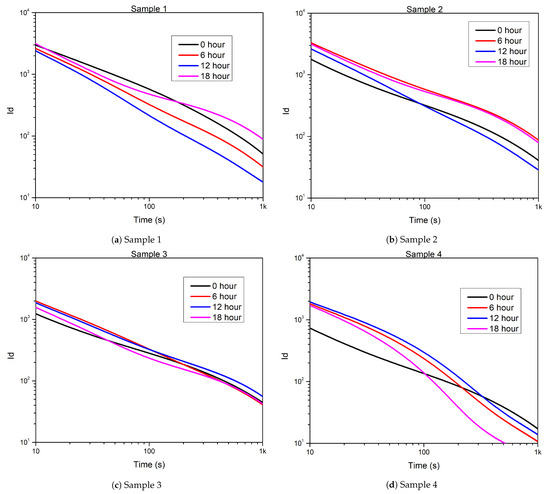

As mentioned in Section 3.3, the measuring equipment registered the PDC curves; hence, the results of the time-domain measurements were also involved in the aging investigation. All the measurement results of the PDC measurement are presented in Appendix B.

From the results of the PDC measurement using Equation (4), the change in the conductive current due to aging can also be compared. The calculated conductive currents for all samples after each aging cycle are in Appendix C. Although Equation (4) would allow the specific conductivity to be determined, given the complexity of the cable structure, it would be difficult to calculate accurately. Hence, the conductive current change with aging was analyzed.

4.2.1. Before Aging

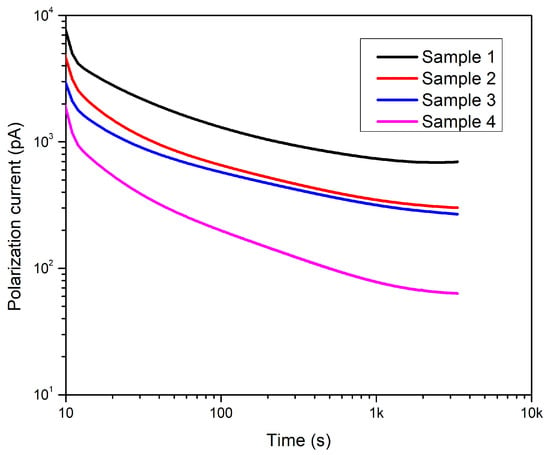

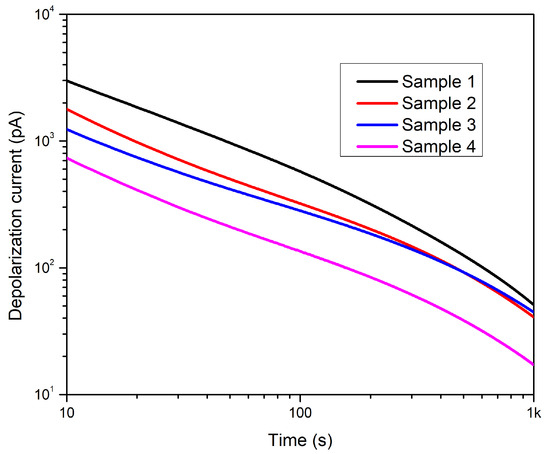

The polarization and depolarization currents were measured after changing the structure of the cable samples. Figure 18 and Figure 19 show the polarization and depolarization currents before aging, respectively.

Figure 18.

Polarization current.

Figure 19.

Depolarization current.

The conductive current was calculated from the polarization and depolarization currents. Figure 20 shows how the conductive current was affected after the cable structure changed.

Figure 20.

Conduction current.

It can be seen clearly that Sample 1, which was the intact one, had the highest conductive current. The conduction current decreased with removing components, i.e., the jacket, aluminum tape, and PVC belt, of the cable. The current curves obtained were consistent with the previous findings that the difference between Samples 1 and 2 can be explained by the compression exerted by the jacket because the jacket removal decreases the contact area between the cable components, increasing the contact resistance between them [50]. The increased contact resistance lowered the conductive current, but the effect on the capacitance was negligible because the electrode arrangement was the same for both samples (see Figure 10). Surprisingly, a relatively small change was observed between Samples 2 and 3. This small change in the conductive current means that without the compression force of the jacket, the smaller part of the conductive current flowed between the aluminum tape and the cores. The determinant part of the current flowed between the core conductors. By comparing the conductive currents of Sample 3 and 4, the difference showed the PVC belt layer’s significant role in the field distribution as previously assumed in Section 4.1.1 based on the results of the tan and capacitance measurements of the structurally changed samples before aging.

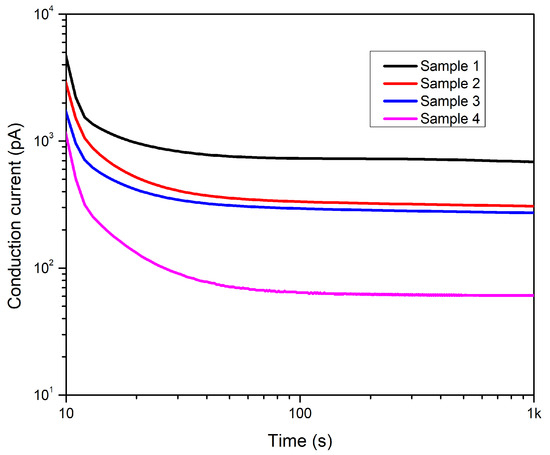

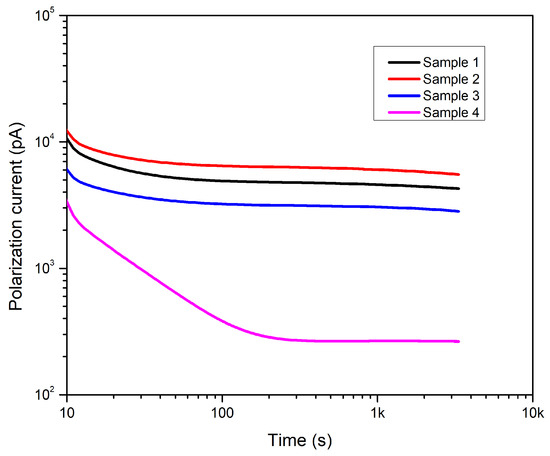

4.2.2. After Aging

The polarization and depolarization currents were measured after each aging cycle, and the conduction currents were derived from them. Previous studies have shown that thermal aging affects the polarization level of the dielectric. The polarization current is increased by thermal aging. With the increase in the conductivity, the conductive current increases too. To summarize, only the results of 18 h of aging are presented here. Figure 21, Figure 22 and Figure 23 depict the polarization, depolarization, and conduction currents for all four samples. It is understood that removing the cable layers affects the polarization, depolarization, and conduction currents. Therefore, the polarization process was affected by the structure change. The most significant difference can be seen in Sample 4 compared to the intact sample, namely, Sample 1. In the case of Samples 1, 2, and 3, the conductors were covered with a PVC belt. However, Table 1 indicates that in Sample 4 this PVC belt was removed. Removing the PVC belting could cause the easier movement of the plasticizer and evaporation from the core insulation. The lower the concentration of the plasticizer molecules, the lower the conductivity. Therefore, the conduction current decreased.

Figure 21.

Polarization current of all samples after aging.

Figure 22.

Depolarization current of all samples after aging.

Figure 23.

Conduction current of all samples after aging.

Since the specific conductivity cannot be calculated, each sample’s before and after aging conductive currents must be compared to assess the conductivity change due to aging. Therefore, the rates of the conductive currents at 1000 s after and before aging were calculated. The results and the before and after aging conductive currents values at 1000 s are shown in Table 2.

Table 2.

Conduction current in pA at 1000 s of samples before and after aging.

The results show that the highest increase (by 19.37 times) in the conductive current can be observed in Sample 2, where the PVC jacket was removed, and both the aluminum tape and the PVC belting layers covered the cores. A 11.05 times increment in the conductive current was observed in Sample 3. In this sample, only the PVC belting layer covered the cores. In the intact sample, i.e., Sample 1, the conductive current increased by 6.55 times after aging, while in the case of Sample 4, with no covered conductors, the conduction current increased by 4.31 times.

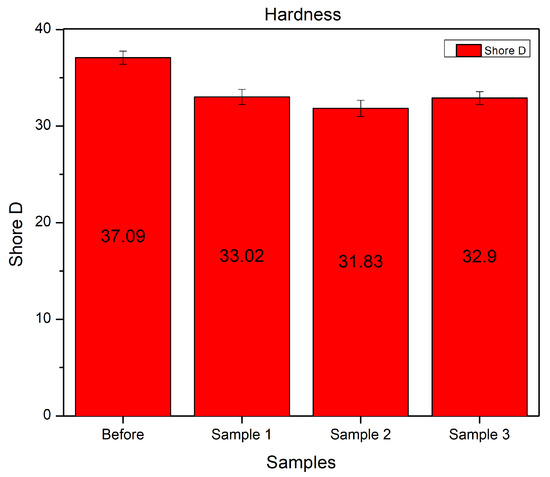

4.3. Shore D Hardness

The results of the Shore D hardness measurements of the PVC belting layers are depicted in Figure 24. The sample before aging exhibited the highest hardness. In Sample 1, the hardness decreased after aging, and Sample 2 had the lowest Shore D hardness. Surprisingly, the hardness of Sample 3 was higher than that of Sample 2.

Figure 24.

Results of the Shore D hardness measurements of the belting layers.

It is well known that long-term thermal aging increases the hardness of the PVC due to the evaporation of the plasticizer; however, earlier cyclical aging studies have shown softening of the PVC cable insulation at the beginning of the aging process before the hardness starts to increase [13]. In this experiment, the aging times were the same for all samples, but the belt layers of the different samples were exposed to the atmosphere of the aging chamber to different extents. In Sample 1, the belting layer was covered by the jacket and aluminum tape. Only the aluminum tape covered the belting layer in Sample 2, while Sample 3’s belting layer could freely come into contact with air. Since the presence of oxygen increases the degradation of the PVC, it probably caused the different hardnesses of the samples after aging [48,49]. However, the softening of the PVC at the beginning of the thermal aging can also be caused by the annealing effect [51,52]. At the beginning of the aging process, the annealing and the plasticizer loss rise in parallel. At the same time, dehydrochlorination only takes effect in the later aging phase at the low temperature used for aging in this experiment. Therefore, the combination of the effects of annealing and the plasticizer loss determined the hardness of the PVC belting layer in the cable insulation system. Since the structure of the cable samples intensively affected the evaporation of the plasticizer, the structural changes affected the hardness of the PVC belt layer through this process. Nevertheless, the plasticizer evaporated most easily from the belting layer of Sample 3. Based on the earliest studies, at the beginning of aging, the effect of the annealing on the hardness of the PVC was stronger than the impact of the plasticizer loss. Later, the effect of plasticizer loss became more dominant; so, the material started to harden.

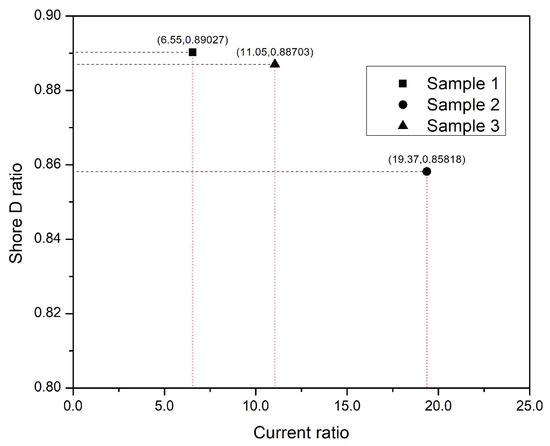

Similar to the conductive current, the ratio of the before and after aging Shore D values can also be calculated, and the results are shown in Table 3.

Table 3.

Ratio of the Shore D hardness of the PVC belting layer of the samples before and after aging.

The Shore D hardnesses’ ratios show a similar change to the conductive current ratios. The greatest change in the Shore D hardness can be observed in the case of Sample 2, while the lowest was in Sample 1. The change ratio of Sample 3 was between them.

The variables were plotted in a scatter plot to observe the relationship between the before and after aging ratios of the conductive current and the Shore D hardness (Figure 25).

Figure 25.

Comparison of the Shore D hardness and the conduction current after and before aging ratios.

The figure shows a clear relationship between the change in the conductive current and the Shore D hardness; however, the number of points was insufficient for correlation analysis. For this purpose, the experiments should be repeated with more aging rounds to reveal the link between the results of dielectric measurements and the mechanical properties of the belting layer. However, this kind of examination requires a large number of samples since the cable samples would have to be dismantled to test the hardness of the belting layers. Nevertheless, previous studies have shown clear evidence between the Shore D hardness and the dielectric properties of PVC cable insulation.

5. Conclusions

Short-term overloads and short-circuit operations raise the temperature above the maximum operating limit, damaging the cable insulation and shortening the lifespan. In the case of these short-term temperature rises, the temperature distribution in the cable is not even. Therefore, the cable components are not degraded evenly and similarly. The effect of the component degradation on the dielectric spectrum was investigated; for this purpose, four samples were prepared. One was intact. Only the jacket was removed from the second one. In addition to the jacket, the aluminum tape layer was removed from the third one. In addition, the PVC belting layer was removed from the fourth sample. The dielectric parameters were measured by the FDS and PDC techniques, and the Shore D hardness was also tested on the PVC belting layer. Before aging, the measurements revealed that the compression pressure of the PVC jacket on the inner cable structure significantly affected the low-frequency tan values. After removing the jacket, the tan delta decreased. This fact was also reflected in the PDC measurement results after calculating the conductive current. Due to the lower compression force, the decrease in the contact surfaces between the polymeric components can explain this. Another important finding of the comparison of the dielectric parameters after the structure change is that the capacitance measurements showed that the PVC belting layer was the most dominant component in the dielectric behavior of this kind of cable. After removing this thin layer, the capacitance values were changed significantly. The after-aging measurements proved the dominant effect of the PVC belting layer. Moreover, this layer provided enough protection from the environmental air, since after removing this layer, the plasticizer evaporation occurred more easily. The results of the Shore D hardness measurement also proved this, as well as the conductive current correlation with the Shore D hardness change in the belting layer. The study results revealed that the PVC belting layer is an important component of PVC-insulated power cables if they are exposed to repetitive thermal aging caused by cyclic overloads. Although the change in the material properties usually shows a clear trend for longer aging times, at the beginning of cyclic aging, no clear direction was observed in the variation of the dielectric and mechanical parameters, as several parallel processes affected the change in the dielectric and mechanical properties. Moreover, the different polymeric components of the cable are not in the same contact with the ambient atmosphere, further complicating the progression of every single process in time.

Author Contributions

Conceptualization, S.B. and Z.Á.T.; methodology, S.B.; formal analysis, S.B. and Z.Á.T.; investigation, S.B.; resources, S.B.; writing—original draft preparation, S.B. and Z.Á.T.; writing—review and editing, Z.Á.T.; visualization, S.B. and Z.Á.T.; supervision, Z.Á.T.; funding acquisition, Z.Á.T. All authors have read and agreed to the published version of the manuscript.

Funding

Project no. 123672 was implemented with support provided by the National Research, Development, and Innovation Fund of Hungary, financed under the KNN_16 funding scheme.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Results of the FDS Measurement

Appendix A.1. Capacitance of Samples

Figure A1.

Capacitances of the samples after each aging round.

Appendix A.2. Tan δ of Samples

Figure A2.

Tan values of the samples after each aging round.

Appendix B. Results of the PDC Measurement

Appendix B.1. Polarization Current of Samples

Figure A3.

Polarization currents of the samples after each aging round [pA].

Appendix B.2. Depolarization Current of Samples

Figure A4.

Depolarization currents of the samples after each aging round [pA].

Appendix C. Calculated Conductive Current of Samples

Figure A5.

Calculated conductive currents of the samples after each aging round [pA].

References

- Kruizinga, B.; Wouters, P.; Steennis, E. Fault development on water ingress in damaged underground Low Voltage cables with plastic insulation. In Proceedings of the 2015 IEEE Electrical Insulation Conference (EIC), Seattle, WA, USA, 7–10 June 2015; pp. 309–312. [Google Scholar] [CrossRef]

- Eurostat. Renewable Energy Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Renewable_energy_statistics#Share_of_renewable_energy_more_than_doubled_between_2004_and_2021 (accessed on 14 April 2023).

- Densley, J. Ageing mechanisms and diagnostics for power cables—An overview. IEEE Electr. Insul. Mag. 2001, 17, 14–22. [Google Scholar] [CrossRef]

- Phayomhom, A.; Kveeyarn, K. Heat cycles test set for power cable. In Proceedings of the 2013 10th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology, Krabi, Thailand, 15–17 May 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Mazzanti, G. The Effects of Seasonal Factors on Life and Reliability of High Voltage AC Cables Subjected to Load Cycles. IEEE Trans. Power Deliv. 2020, 35, 2080–2088. [Google Scholar] [CrossRef]

- Lingvay, I.; Stancu, C.; Budrugeac, P.; Cucos, A.; Lingvay, C. Studies concerning the fast ageing by thermal cycling of power cables. In Proceedings of the 2011 7th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 12–14 May 2011; pp. 1–4. [Google Scholar]

- Muniz, P.R.; Teixeira, J.L.; Santos, N.Q.; Magioni, P.L.Q.; Cani, S.P.N.; Fardin, J.F. Prospects of life estimation of low voltage electrical cables insulated by PVC by emissivity measurement. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3951–3958. [Google Scholar] [CrossRef]

- Bowler, N.; Liu, S. Aging mechanisms and monitoring of cable polymers. Int. J. Progn. Health Manag. 2015, 6. [Google Scholar] [CrossRef]

- Jakubowicz, I.; Yarahmadi, N.; Gevert, T. Effects of accelerated and natural ageing on plasticized polyvinyl chloride (PVC). Polym. Degrad. Stab. 1999, 66, 415–421. [Google Scholar] [CrossRef]

- Wilson, A.S. Plasticisers: Selection, Applications and Implications; iSmithers Rapra Publishing: Shawbury, UK, 1996; Volume 88. [Google Scholar]

- Gumargalieva, K.; Ivanov, V.; Zaikov, G.; Moiseev, J.V.; Pokholok, T. Problems of ageing and stabilization of poly (vinyl chloride). Polym. Degrad. Stab. 1996, 52, 73–79. [Google Scholar] [CrossRef]

- Cheremisinoff, N.P. P. In Condensed Encyclopedia of Polymer Engineering Terms; Cheremisinoff, N.P., Ed.; Butterworth-Heinemann: Boston, MA, USA, 2001; pp. 200–255. [Google Scholar] [CrossRef]

- Csányi, G.M.; Bal, S.; Tamus, Z.A. Dielectric Measurement Based Deducted Quantities to Track Repetitive, Short-Term Thermal Aging of Polyvinyl Chloride (PVC) Cable Insulation. Polymers 2020, 12, 2809. [Google Scholar] [CrossRef]

- Nedjar, M.; Beroual, A.; Bournane, M. Thermal aging of polyvinyl chloride. In Proceedings of the CEIDP’05. 2005 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Piscataway, NJ, USA, 16–19 October 2005; pp. 261–264. [Google Scholar] [CrossRef]

- Wei, X.F.; Linde, E.; Hedenqvist, M.S. Plasticiser loss from plastic or rubber products through diffusion and evaporation. NPJ Mater. Degrad. 2019, 3, 18. [Google Scholar] [CrossRef]

- Nedjar, M.; Béroual, A.; Boubakeur, A. Influence of thermal aging on the electrical properties of poly (vinyl chloride). J. Appl. Polym. Sci. 2006, 102, 4728–4733. [Google Scholar] [CrossRef]

- Konečná, Z. Temperature dependence of electrical parameters of coaxial cables. In Proceedings of the 2016 Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic, 6–8 September 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Csányi, G.M.; Tamus, Z.Á.; Varga, Á. Impact of distributed generation on the thermal ageing of low voltage distribution cables. In Proceedings of the Doctoral Conference on Computing, Electrical and Industrial Systems, Caparica, Portugal, 3–5 May 2017; pp. 251–258. [Google Scholar]

- Csányi, G.M.; Tamus, Z.Á.; Kordás, P. Effect of Enhancing Distribution Grid Resilience on Low Voltage Cable Ageing. In Proceedings of the Doctoral Conference on Computing, Electrical and Industrial Systems, Costa de Caparica, Portugal, 2–4 May 2018; pp. 300–307. [Google Scholar]

- Suraci, S.V.; Fabiani, D.; Xu, A.; Roland, S.; Colin, X. Ageing Assessment of XLPE LV Cables for Nuclear Applications Through Physico-Chemical and Electrical Measurements. IEEE Access 2020, 8, 27086–27096. [Google Scholar] [CrossRef]

- Afia, R.S.A.; Mustafa, E.; Tamus, Z.A. Aging Mechanisms and Non-Destructive Aging Indicators of XLPE/CSPE Unshielded LV Nuclear Power Cables Subjected to Simultaneous Radiation-Mechanical Aging. Polymers 2021, 13, 3033. [Google Scholar] [CrossRef] [PubMed]

- Quennehen, P.; Royaud, I.; Seytre, G.; Gain, O.; Rain, P.; Espilit, T.; François, S. Determination of the aging mechanism of single core cables with PVC insulation. Polym. Degrad. Stab. 2015, 119, 96–104. [Google Scholar] [CrossRef]

- Quennehen, P.; Seytre, G.; Royaud, I.; Gain, O.; Rain, P.; Espilit, T. Dielectric and Physicochemical Behavior of Aged PVC Insulated Cables. In Proceedings of the 2012 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Montreal, QC, Canada, 14–17 October 2012. [Google Scholar] [CrossRef]

- Höning, N.; De Jong, E.; Bloemhof, G.; Poutre, H.L. Thermal behaviour of low voltage cables in smart grid—Related environments. In Proceedings of the IEEE PES Innovative Smart Grid Technologies, Europe, Istanbul, Turkey, 12–15 October 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Bal, S.; Tamus, Z.A. Investigation of Effects of Thermal Ageing on Dielectric Properties of Low Voltage Cable Samples by using Dielectric Response Analyzer. In Proceedings of the 2022 International Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic, 6–8 September 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Afia, R.S.; Mustafa, E.; Ádám Tamus, Z. Dielectric Spectroscopy of Low Voltage Nuclear Power Cables Under Simultaneous Thermal and Mechanical Stresses. Energy Rep. 2020, 6, 662–667. [Google Scholar] [CrossRef]

- Afia, R.S.; Mustafa, E.; Ádám Tamus, Z. Condition Monitoring of Photovoltaic Cables Based Cross-Linked Polyolefin Insulation Under Combined Accelerated Aging Stresses: Electrical and Mechanical Assessment. Energy Rep. 2022, 8, 1038–1049. [Google Scholar] [CrossRef]

- Afia, R.S.A.; Mustafa, E.; Tamus, Z.A. Condition Assessment of XLPO Insulated Photovoltaic Cables Based on Polarisation/Depolarisation Current. In Proceedings of the 2020 International Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic, 1–4 September 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Zaengl, W. Dielectric spectroscopy in time and frequency domain for HV power equipment. I. Theoretical considerations. IEEE Electr. Insul. Mag. 2003, 19, 5–19. [Google Scholar] [CrossRef]

- Morsalin, S.; Phung, T.B.; Danikas, M.; Mawad, D. Diagnostic challenges in dielectric loss assessment and interpretation: A review. IET Sci. Meas. Technol. 2019, 13, 767–782. [Google Scholar] [CrossRef]

- Fofana, I.; Hadjadj, Y. Electrical-Based Diagnostic Techniques for Assessing Insulation Condition in Aged Transformers. Energies 2016, 9, 679. [Google Scholar] [CrossRef]

- IEC 60502-1; Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1.2 kV) up to 30 kV (Um = 36 kV)—Part 1: Cables for rated voltages of 1 kV (Um = 1.2 kV) and 3 kV (Um = 3.6 kV). International Electrotechnical Commission: Geneva, Switzerland, 2004.

- Mustafa, E.; Afia, R.S.; Tamus, Z.Á. Dielectric loss and extended voltage response measurements for low-voltage power cables used in nuclear power plant: Potential methods for aging detection due to thermal stress. Electr. Eng. 2021, 103, 899–908. [Google Scholar] [CrossRef]

- Bal, S.; Tamus, Z.A. Investigation of Effects of Short-term Thermal Stress on PVC Insulated Low Voltage Distribution Cables. Period. Polytech. Electr. Eng. Comput. Sci. 2021, 65, 167–173. [Google Scholar] [CrossRef]

- Tamus, Z.A. Practical consideration of mechanical measurements in cable diagnostics. In Proceedings of the 2011 Electrical Insulation Conference (EIC), Annapolis, MD, USA, 5–8 June 2011; pp. 359–363. [Google Scholar] [CrossRef]

- Fothergill, J.C.; Dodd, S.J.; Dissado, L.A.; Liu, T.; Nilsson, U.H. The measurement of very low conductivity and dielectric loss in XLPE cables: A possible method to detect degradation due to thermal aging. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1544–1553. [Google Scholar] [CrossRef]

- Koch, M.; Raetzke, S.; Krueger, M. Moisture diagnostics of power transformers by a fast and reliable dielectric response method. In Proceedings of the 2010 IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 6–9 June 2010; pp. 1–5. [Google Scholar] [CrossRef]

- Afia, R.S.A.; Mustafa, E.; Tamus, Z.Á. Comparison of Mechanical and Low-Frequency Dielectric Properties of Thermally and Thermo-Mechanically Aged Low Voltage CSPE/XLPE Nuclear Power Plant Cables. Electronics 2021, 10, 2728. [Google Scholar] [CrossRef]

- Mustafa, E.; Afia, R.S.A.; Tamus, Z.A. Investigation of Electrical and Mechanical Properties of Low Voltage Power Cables under Thermal Stress. In Proceedings of the 2020 International Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic, 1–4 September 2020; pp. 1–4. [Google Scholar] [CrossRef]

- ASTM D2240-05; Standard Test Method for Rubber Property—Durometer Hardness. American Society for Testing and Materials: Philadelphia, PA, USA, 2000.

- Raza, M.H.; Butt, S.U.; Khattak, A.; Alahmadi, A.A. Investigation of Ramped Compression Effect on the Dielectric Properties of Silicone Rubber Composites for the Coating of High-Voltage Insulation. Materials 2022, 15, 2343. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, M.B.; Khattak, A.; Ali, A.; Raza, M.H.; Ullah, N.; Alahmadi, A.A.; Khan, A. Influence of Ramped Compression on the Dielectric Behavior of the High-Voltage Epoxy Composites. Polymers 2021, 13, 3150. [Google Scholar] [CrossRef]

- Linde, E.; Gedde, U. Plasticizer migration from PVC cable insulation—The challenges of extrapolation methods. Polym. Degrad. Stab. 2014, 101, 24–31. [Google Scholar] [CrossRef]

- Starnes, W.H. Structural and mechanistic aspects of the thermal degradation of poly(vinyl chloride). Prog. Polym. Sci. 2002, 27, 2133–2170. [Google Scholar] [CrossRef]

- Zhu, M.X.; Li, J.C.; Song, H.G.; Chen, J.M.; Zhang, H.Y. Determination of trap energy in polyethylene with different aging status by molecular dynamics and density function theory. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1823–1830. [Google Scholar] [CrossRef]

- Huzayyin, A.; Boggs, S.; Ramprasad, R. Density functional analysis of chemical impurities in dielectric polyethylene. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 926–930. [Google Scholar] [CrossRef]

- Kryshtob, V.I.; Rasmagin, S.I.; Vlasova, T.V. On Improving the Running Ability of Cables with Polymer Insulation. Russ. Electr. Eng. 2018, 89, 385–387. [Google Scholar] [CrossRef]

- Beneš, M.; Milanov, N.; Matuschek, G.; Kettrup, A.; Plaček, V.; Balek, V. Thermal degradation of PVC cable insulation studied by simultaneous TG-FTIR and TG-EGA methods. J. Therm. Anal. Calorim. 2004, 78, 621–630. [Google Scholar] [CrossRef]

- Wypych, G. 4-PRINCIPLES OF THERMAL DEGRADATION. In PVC Degradation and Stabilization (Third Edition), 3rd ed.; Wypych, G., Ed.; ChemTec Publishing: Boston, MA, USA, 2015; pp. 79–165. [Google Scholar] [CrossRef]

- Bazilchuk, M.; Sumigawa, T.; Kitamura, T.; Zhang, Z.; Kristiansen, H.; He, J. Contact area measurement of micron-sized metal-coated polymer particles under compression. Int. J. Mech. Sci. 2020, 165, 105214. [Google Scholar] [CrossRef]

- Ito, M.; Nagai, K. Analysis of degradation mechanism of plasticized PVC under artificial aging conditions. Polym. Degrad. Stab. 2007, 92, 260–270. [Google Scholar] [CrossRef]

- Audouin, L.; Dalle, B.; Metzger, G.; Verdu, J. Thermal aging of plasticized PVC. II. Effect of plasticizer loss on electrical and mechanical properties. J. Appl. Polym. Sci. 1992, 45, 2097–2103. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).