Metamaterial with Tunable Positive and Negative Hygrothermal Expansion Inspired by a Four-Fold Symmetrical Islamic Motif

Abstract

1. Introduction

2. Analysis

3. Results and Discussion

4. Conclusions and Recommendation

Funding

Data Availability Statement

Conflicts of Interest

Notations

| Coefficients of moisture expansion for layers 1 and 2 of the bimaterial spiral spring. | |

| Coefficients of thermal expansion for layers 1 and 2 of the bimaterial spiral spring. | |

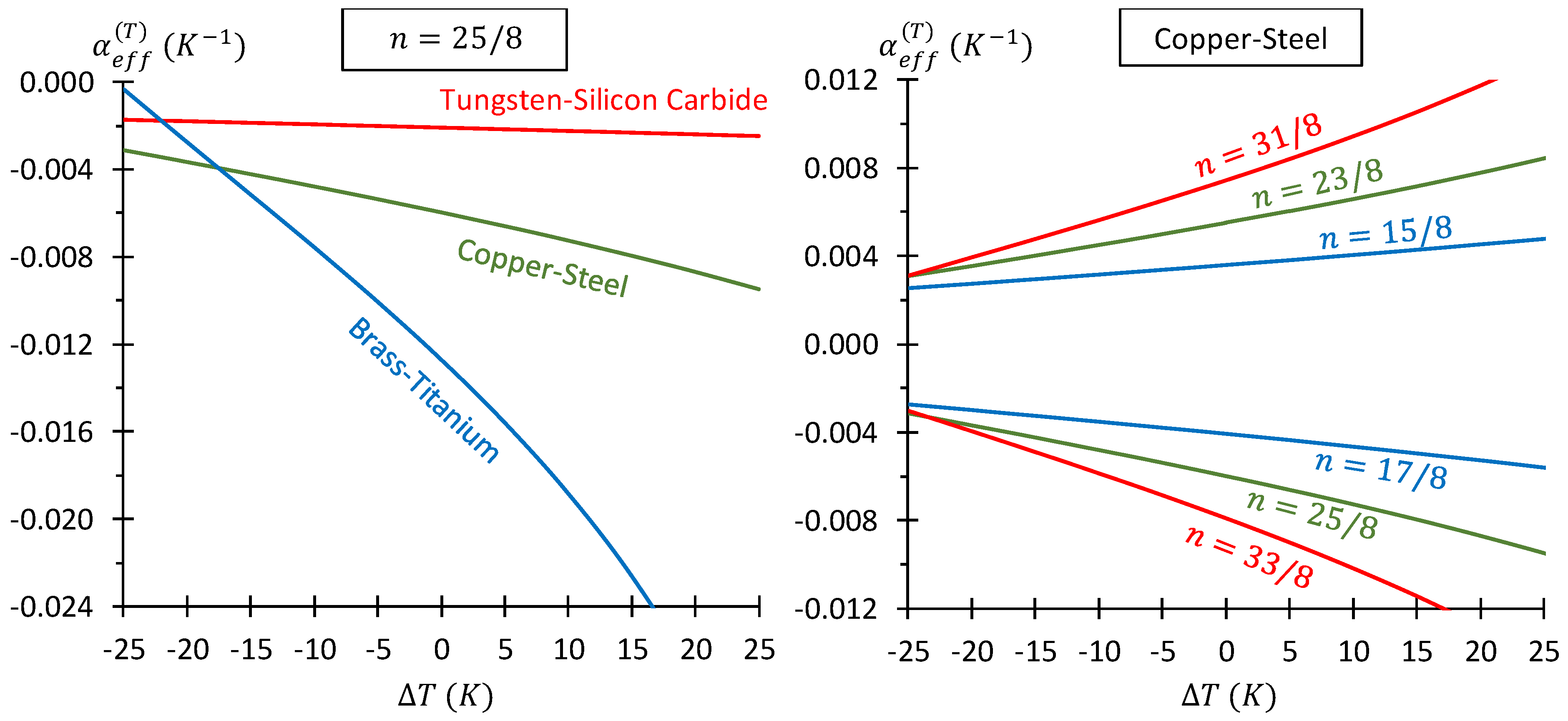

| Effective coefficients of moisture and thermal expansions of metamaterial. | |

| Moisture concentration. | |

| Moisture concentrations in layers 1 and 2 of the bimaterial spiral spring. | |

| Strain | |

| Moisture and thermal strains in directions. | |

| Young’s moduli in layers 1 and 2 of the bimaterial spiral spring. | |

| Thickness of bimaterial spiral spring. | |

| Thicknesses of layers 1 and 2 of the bimaterial spiral spring. | |

| Second moment area for layers 1 and 2 of the bimaterial spiral spring. | |

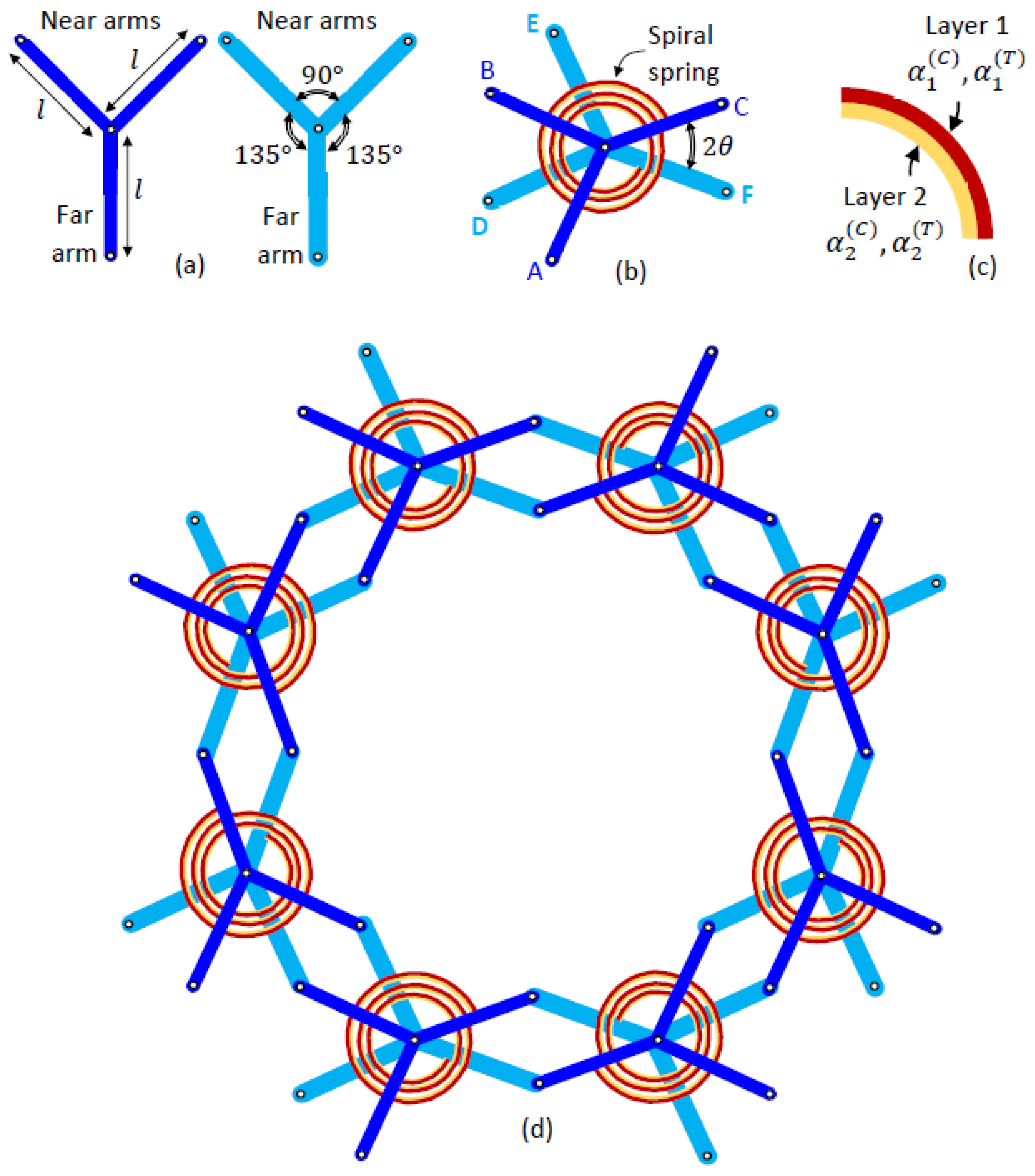

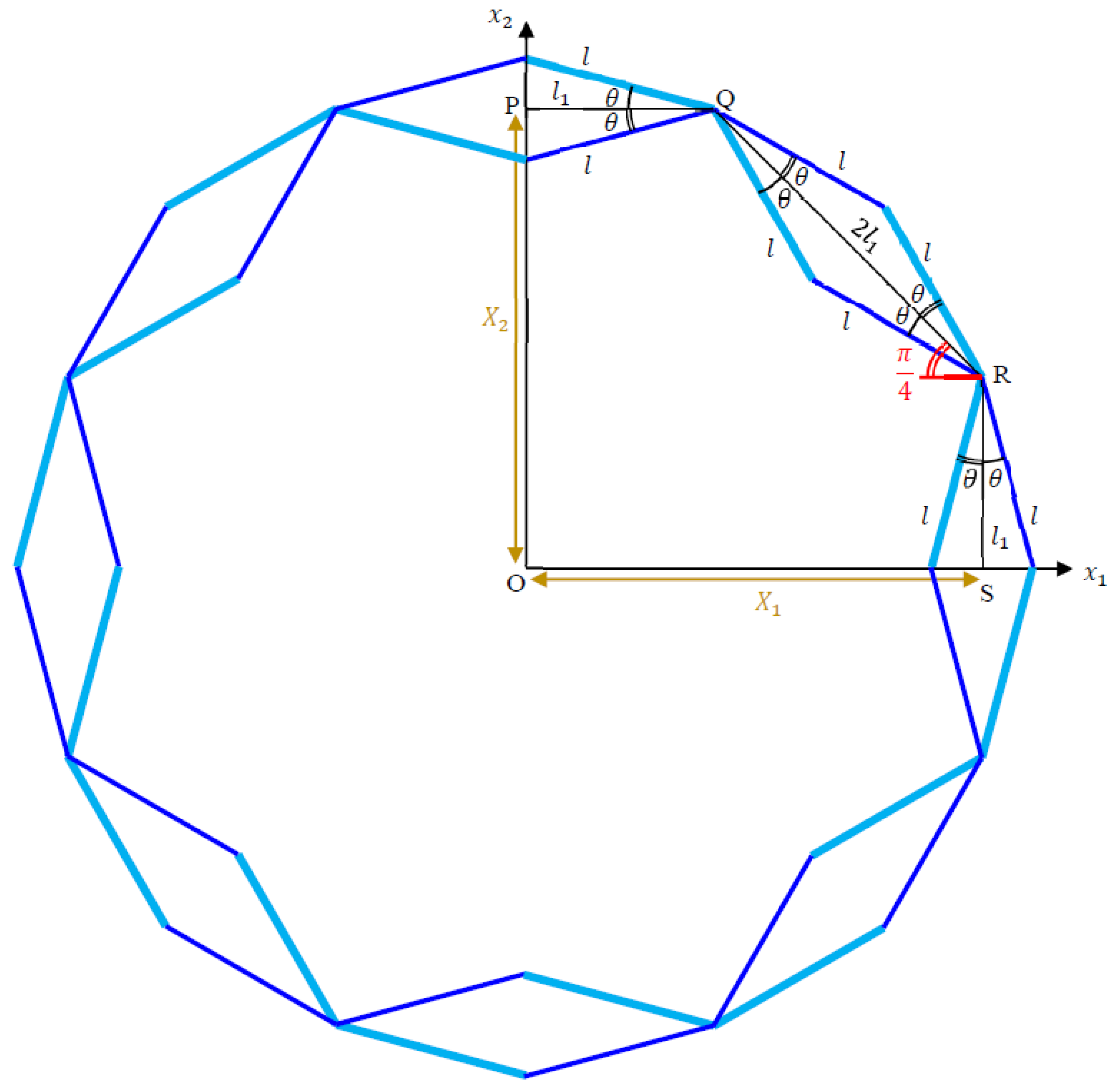

| Arm length of Y-element. | |

| Half-distance between centers of two adjacent pairs of Y-elements. | |

| Dry mass. | |

| Moisture mass. | |

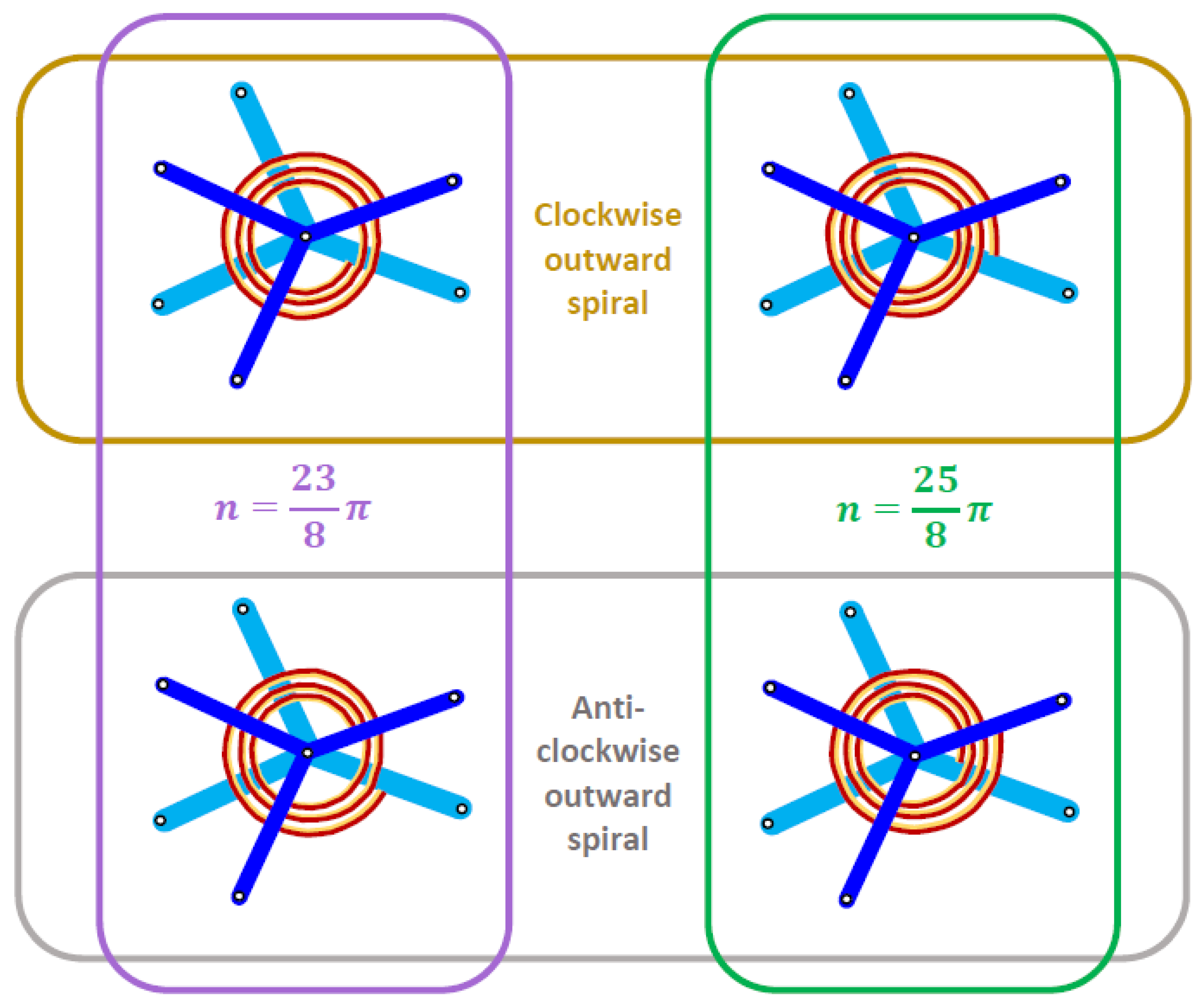

| Number of coils for the bimaterial spiral spring. | |

| Positive integer. | |

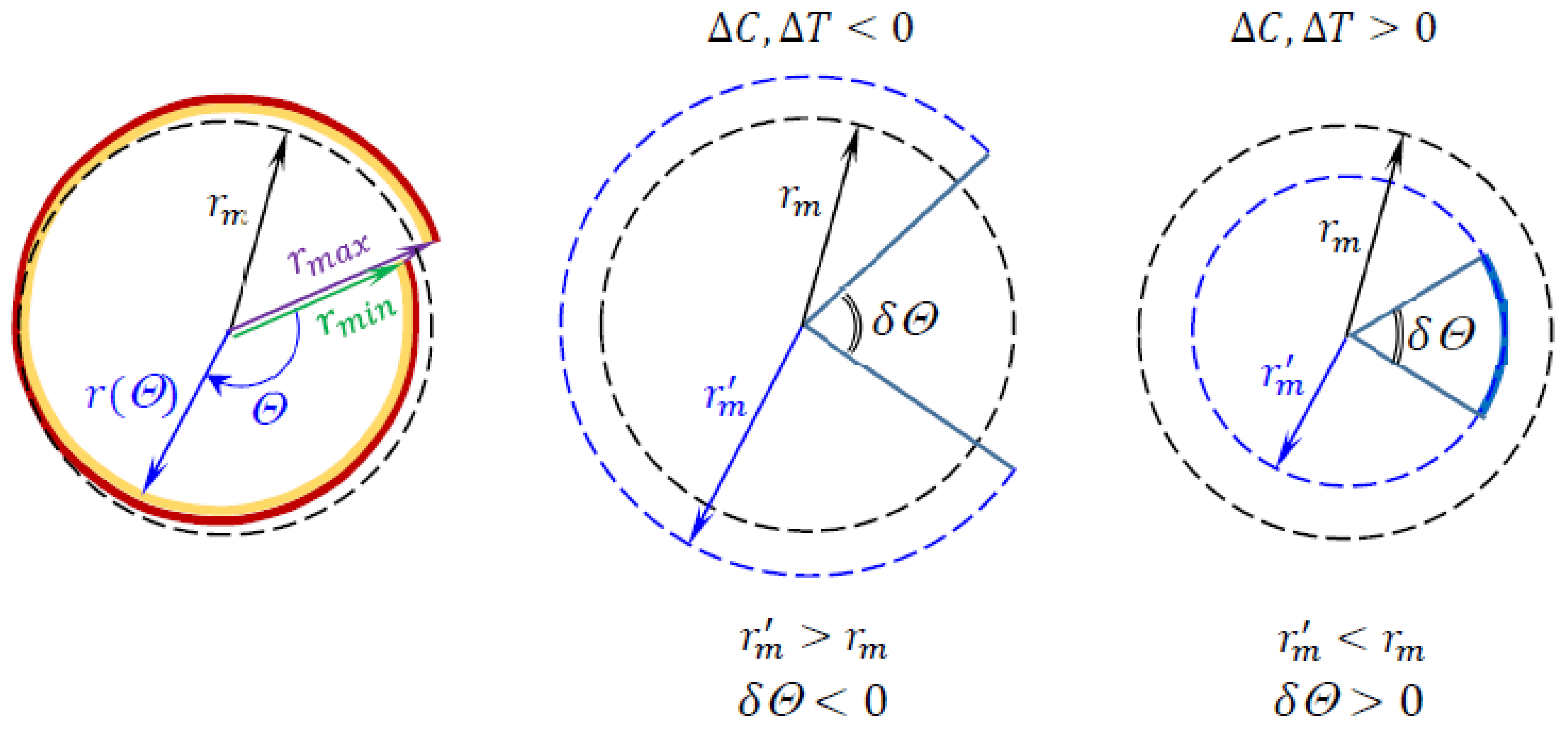

| Mean radius of curvature of bimaterial spiral spring. | |

| Updated radius of curvature of bimaterial spiral spring. | |

| Maximum radius of curvature of bimaterial spiral spring. | |

| Minimum radius of curvature of bimaterial spiral spring. | |

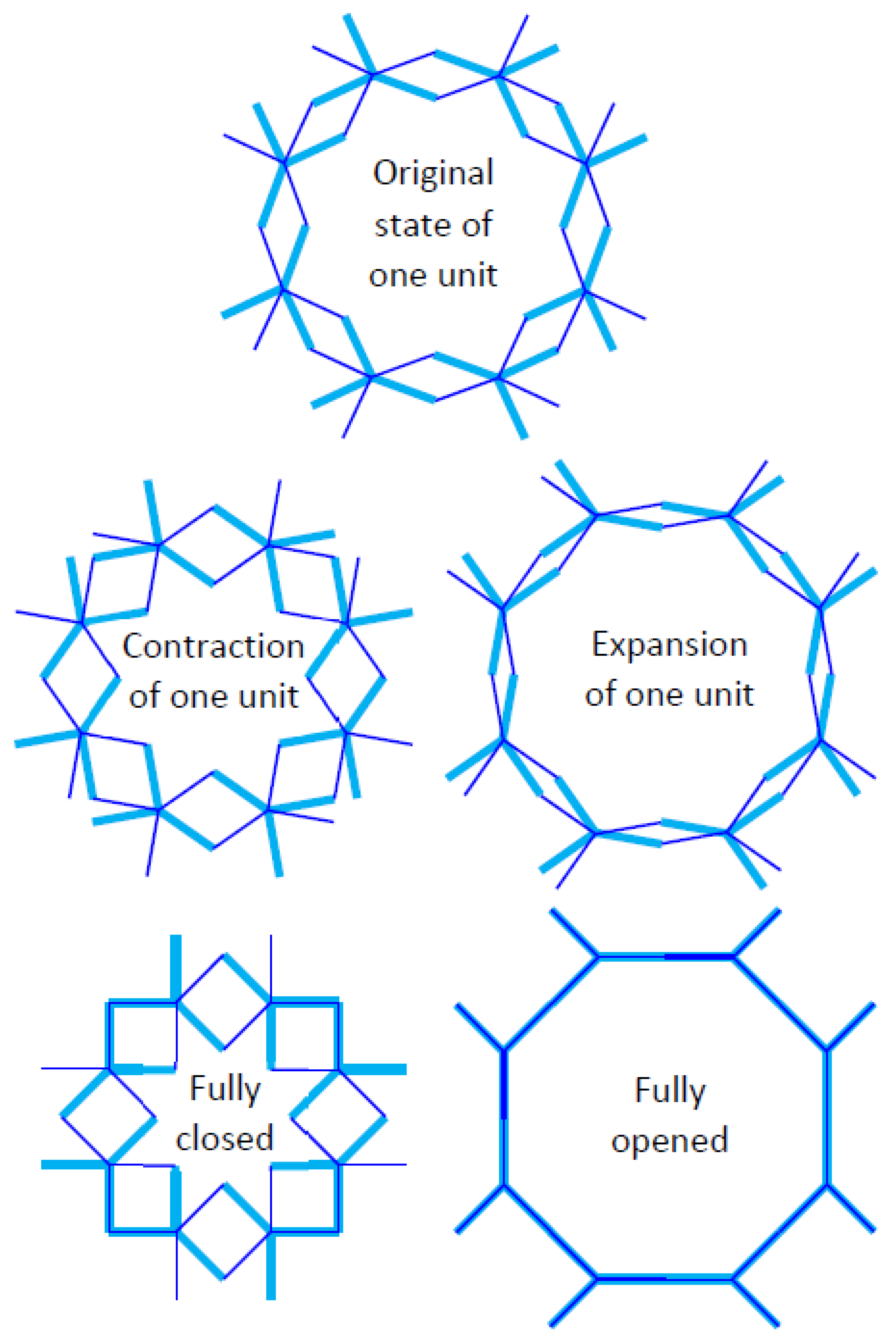

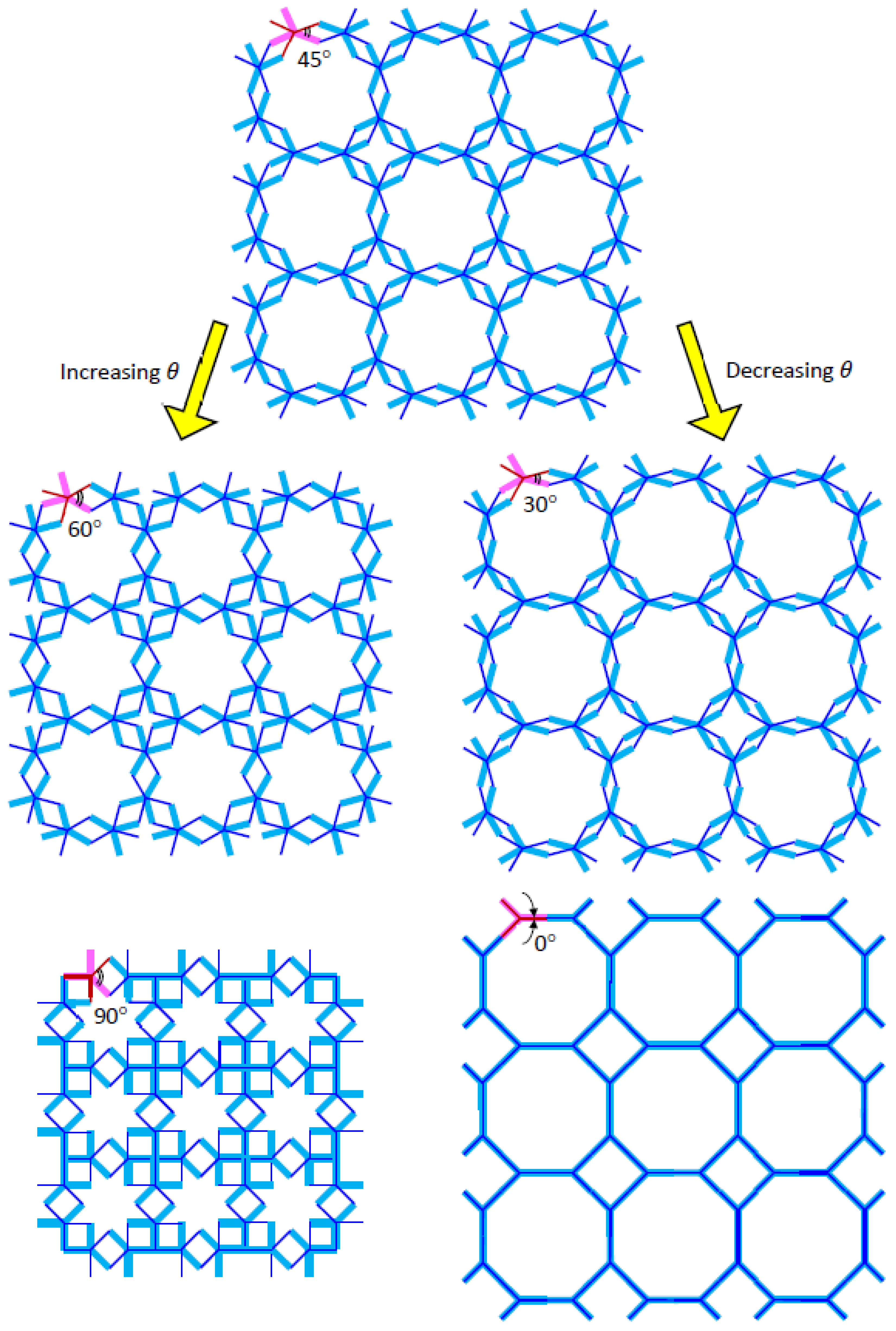

| Half-angular offset for a paired Y-elements. | |

| Angle formed between inner and outer ends of the spiral spring. | |

| Environmental temperature | |

| Half-dimensions of a unit cell measured along the and axes. |

Abbreviations

| CME | Coefficient of moisture expansion |

| CTE | Coefficient of thermal expansion |

| NC | Negative compressibility |

| NME | Negative moisture expansion |

| NTE | Negative thermal expansion |

References

- Lakes, R. Advances in negative Poisson’s ratio materials. Adv. Mater. 1993, 5, 293–296. [Google Scholar] [CrossRef]

- Alderson, A. A triumph of lateral thought. Chem. Ind. 1999, 10, 384–391. [Google Scholar]

- Yang, W.; Li, Z.M.; Shi, W.; Xie, B.H.; Yang, M.B. Review on auxetic materials. J. Mater. Sci. 2004, 39, 3269–3279. [Google Scholar] [CrossRef]

- Alderson, A.; Alderson, K.L. Auxetic materials. IMechE J. Aerosp. Eng. 2007, 221, 565–575. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H. A review on auxetic structures and polymeric materials. Sci. Res. Essays 2010, 5, 1052–1063. [Google Scholar]

- Greaves, G.N.; Greer, A.L.; Lakes, R.S.; Rouxel, T. Poisson’s ratio and modern materials. Nat. Mater. 2011, 10, 823–837. [Google Scholar] [CrossRef]

- Prawoto, Y. Seeing auxetic materials from the mechanics point of view: A structural review on the negative Poisson’s ratio. Comput. Mater. Sci. 2012, 58, 140–153. [Google Scholar] [CrossRef]

- Critchley, R.; Corni, I.; Wharton, J.A.; Walsh, F.C.; Wood, R.J.K.; Stokes, K.R. A review of the manufacture, mechanical properties and potential applications of auxetic foams. Phys. Status Solidi B 2013, 250, 1963–1982. [Google Scholar] [CrossRef]

- Saxena, K.K.; Das, R.; Calius, E.P. Three decades of auxetics research − materials with negative Poisson’s ratio: A review. Adv. Eng. Mater. 2016, 18, 1847–1870. [Google Scholar] [CrossRef]

- Novak, N.; Vesenjak, M.; Ren, Z. Auxetic cellular materials—A review. Stroj. Vestn. J. Mech. Eng. 2016, 62, 485–493. [Google Scholar] [CrossRef]

- Jiang, J.W.; Kim, S.Y.; Park, H.S. Auxetic nanomaterials: Recent progress and future development. Appl. Phys. Rev. 2016, 3, 041101. [Google Scholar] [CrossRef]

- Park, H.S.; Kim, S.Y. A perspective on auxetic nanomaterials. Nano Converg. 2017, 4, 10. [Google Scholar] [CrossRef]

- Lakes, R.S. Negative-Poisson’s-ratio materials: Auxetic solids. Annu. Rev. Mater. Res. 2017, 47, 63–81. [Google Scholar] [CrossRef]

- Lim, T.C. Analogies across auxetic models based on deformation mechanism. Phys. Status Solidi RRL 2017, 2016, 1600440. [Google Scholar] [CrossRef]

- Kolken, H.M.A.; Zadpoor, A.A. Auxetic mechanical metamaterials. RSC Adv. 2017, 7, 5111–5129. [Google Scholar] [CrossRef]

- Duncan, O.; Shepherd, T.; Moroney, C.; Foster, L.; Venkatraman, P.D.; Winwood, K.; Allen, T.; Alderson, A. Review of auxetic materials for sports applications: Expanding options in comfort and protection. Appl. Sci. 2018, 8, 941. [Google Scholar] [CrossRef]

- Ren, X.; Das, R.; Tran, P.; Ngo, T.D.; Xie, Y.M. Auxetic metamaterials and structures: A review. Smart Mater. Struct. 2018, 27, 023001. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, G.; You, Z. Large deformation and energy absorption of additively manufactured auxetic materials and structures: A review. Compos. B Eng. 2020, 201, 108340. [Google Scholar] [CrossRef]

- Wang, Z.; Luan, C.; Liao, G.; Liu, J.; Yao, X.; Fu, J. Progress in auxetic mechanical metamaterials: Structures, characteristics, manufacturing methods, and applications. Adv. Eng. Mater. 2020, 22, 2000312. [Google Scholar] [CrossRef]

- Chu, C.N.; Saka, N.; Suh, N.P. Negative thermal expansion ceramics: A review. Mater. Sci. Eng. 1987, 95, 303–308. [Google Scholar] [CrossRef]

- Sleight, A.W. Thermal contraction. Endeavour 1995, 19, 64–68. [Google Scholar] [CrossRef]

- Sleight, A.W. Isotropic negative thermal expansion. Annu. Rev. Mater. Sci. 1998, 28, 29–43. [Google Scholar] [CrossRef]

- Barrera, G.D.; Bruno, J.A.O.; Barron, T.H.K.; Allan, N.L. Negative thermal expansion. J. Phys. Condens. Matter 2005, 17, R217–R252. [Google Scholar] [CrossRef]

- Grima, J.N.; Zammit, V.; Gatt, R. Negative thermal expansion. Xjenza 2006, 11, 17–29. [Google Scholar]

- Miller, W.; Smith, C.W.; Mackenzie, D.S.; Evans, K.E. Negative thermal expansion: A review. J. Mater. Sci. 2009, 44, 5441–5451. [Google Scholar] [CrossRef]

- Lind, C. Two decades of negative thermal expansion research: Where do we stand? Materials 2012, 5, 1125–1154. [Google Scholar] [CrossRef]

- Takenaka, K. Negative thermal expansion materials: Technological key for control of thermal expansion. Sci. Technol. Adv. Mater. 2012, 13, 013001. [Google Scholar] [CrossRef]

- Takenaka, K. Progress of research in negative thermal expansion materials: Paradigm shift in the control of thermal expansion. Front. Chem. 2018, 6, 267. [Google Scholar] [CrossRef]

- Chen, J.; Hu, L.; Deng, J.; Xing, X. Negative thermal expansion in functional materials: Controllable thermal expansion by chemical modifications. Chem. Soc. Rev. 2015, 44, 3522–3567. [Google Scholar] [CrossRef]

- Dove, M.T.; Fang, H. Negative thermal expansion and associated anomalous physical properties: Review of the lattice dynamics theoretical foundation. Rep. Prog. Phys. 2016, 79, 066503. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, Q.; Che, J.; Deng, J.; Lin, K.; Xing, X.R. Negative thermal expansion in molecular materials. Chem. Commun. 2018, 54, 5164–5176. [Google Scholar] [CrossRef]

- Mittal, R.; Gupta, M.K.; Chaplot, S.L. Phonons and anomalous thermal expansion behavior in crystalline solids. Prog. Mater. Sci. 2018, 92, 360–445. [Google Scholar] [CrossRef]

- Attfield, J.P. Mechanism and materials for NTE. Front. Chem. 2018, 6, 371. [Google Scholar] [CrossRef]

- Baughman, R.H.; Stafstrom, S.; Cui, C.; Dantas, S.O. Materials with negative compressibilities in one or more dimensions. Science 1998, 279, 1522–1524. [Google Scholar] [CrossRef]

- Gatt, R.; Grima, J.N. Negative compressibility. Phys. Status Solidi RRL 2008, 2, 236–238. [Google Scholar] [CrossRef]

- Nicolaou, Z.G.; Motter, A.E. Mechanical metamaterials with negative compressibility transitions. Nat. Mater. 2012, 11, 608–613. [Google Scholar] [CrossRef]

- Imre, A.R. Metamaterials with negative compressibility—A novel concept with a long history. Mater. Sci. Pol. 2014, 32, 126–129. [Google Scholar] [CrossRef]

- Cairns, A.B.; Goodwin, A.L. Negative linear compressibility. Phys. Chem. Chem. Phys. 2015, 17, 20449–20465. [Google Scholar] [CrossRef]

- Miller, W.; Evans, K.E.; Marmier, A. Negative linear compressibility in common materials. Appl. Phys. Lett. 2015, 106, 231903. [Google Scholar] [CrossRef]

- Lim, T.C. 2D structures exhibiting negative area compressibility. Phys. Status Solidi B 2017, 254, 1600682. [Google Scholar] [CrossRef]

- Barrett, D.G.; Bushnell, G.G.; Messersmith, P.B. Mechanically robust, negative-swelling, mussel-inspired tissue adhesives. Adv. Healthc. Mater. 2013, 2, 745–755. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Gu, T.; Shan, S.; Kang, S.H.; Weaver, J.C.; Bertoldi, K. Harnessing buckling to design architected materials that exhibit effective negative swelling. Adv. Mater. 2016, 28, 6619–6624. [Google Scholar] [CrossRef] [PubMed]

- Curatolo, M. Effective negative swelling of hydrogel-solid composites. Extrem. Mech. Lett. 2018, 25, 46–52. [Google Scholar] [CrossRef]

- Zhang, H.; Gou, X.; Wu, J.; Fang, D.; Zhang, Y. Soft mechanical metamaterials with unusual swelling behavior and tunable stress-strain curves. Sci. Adv. 2018, 4, eaar8535. [Google Scholar] [CrossRef] [PubMed]

- Lakes, R.; Wojciechowski, K.W. Negative compressibility, negative Poisson’s ratio, and stability. Phys. Status Solidi B 2008, 245, 545–551. [Google Scholar] [CrossRef]

- Lim, T.C. Auxetic and negative thermal expansion structure based on interconnected array of rings and sliding rods. Phys. Statius Solidi B 2017, 254, 1600775. [Google Scholar] [CrossRef]

- Surjadi, J.U.; Gao, L.; Du, H.; Li, X.; Xiong, X.; Fang, N.X.; Lu, Y. Mechanical metamaterials and their engineering applications. Adv. Eng. Mater. 2019, 21, 1800864. [Google Scholar] [CrossRef]

- Lim, T.C. Composite metamaterial with sign-switchable coefficients of hygroscopic, thermal and pressure expansions. Adv. Compos. Hybrid Mater. 2019, 2, 657–669. [Google Scholar] [CrossRef]

- Wu, W.; Hu, W.; Qian, G.; Liao, H.; Xu, X.; Berto, F. Mechanical design and multifunctional applications of chiral mechanical metamaterials: A review. Mater. Des. 2019, 180, 107950. [Google Scholar] [CrossRef]

- Lim, T.C. Negative environmental expansion for interconnected array of rings and sliding rods. Phys. Status Solidi B 2019, 256, 1800032. [Google Scholar] [CrossRef]

- Grima-Cornish, J.N.; Grima, J.N.; Attard, D. A novel mechanical metamaterial exhibiting auxetic behavior and negative compressibility. Materials 2020, 13, 79. [Google Scholar] [CrossRef]

- Lim, T.C. Negative hygrothermal expansion of reinforced double arrowhead microstructure. Phys. Status Solidi B 2020, 257, 1800055. [Google Scholar] [CrossRef]

- Peng, X.L.; Bargmann, S. Tunable auxeticity and isotropic negative thermal expansion in three-dimensional lattice structures of cubic symmetry. Extrem. Mech. Lett. 2021, 44, 101201. [Google Scholar] [CrossRef]

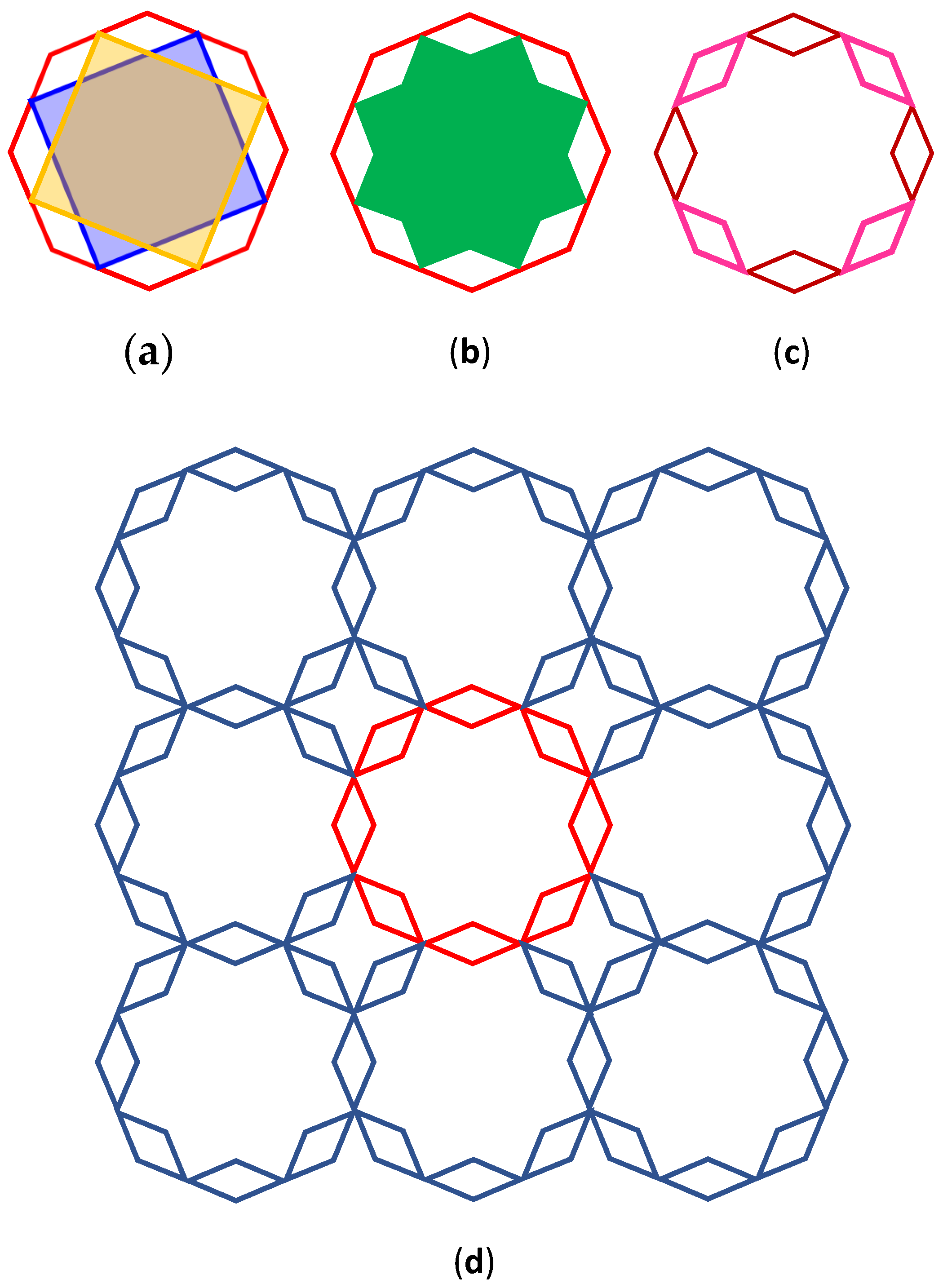

- Rafsanjani, A.; Pasini, D. Multistable compliant auxetic metamaterials inspired by geometric patterns in Islamic arts. Bull. Am. Phys. Soc. 2016, 61, K40.00008. [Google Scholar]

- Rafsanjani, A.; Pasini, D. Bistable auxetic mechanical metamaterials inspired by ancient geometric motifs. Extrem. Mech. Lett. 2016, 9, 291–296. [Google Scholar] [CrossRef]

- Lim, T.C. Composite metamaterial square grids with sign-flipping expansion coefficients leading to a type of Islamic design. SN Appl. Sci. 2020, 2, 918. [Google Scholar] [CrossRef]

- Lim, T.C. Metacomposite structure with sign-changing coefficients of hygrothermal expansions inspired by Islamic motif. Compos. Struct. 2020, 251, 112660. [Google Scholar] [CrossRef]

- Lim, T.C. A perfect 2D auxetic sliding mechanism based on an Islamic geometric pattern. Eng. Res. Express 2021, 3, 015025. [Google Scholar] [CrossRef]

- Lim, T.C. Metamaterial honeycomb with sign-toggling expansion coefficients that manifests an Islamic mosaic pattern at the Alhambra Palace. Adv. Compos. Hybrid Mater. 2021, 4, 966–978. [Google Scholar] [CrossRef]

- Lim, T.C. Metamaterial with sign-toggling thermal expansivity inspired by Islamic motifs in Spain. J. Sci. Adv. Mater. Devices 2022, 7, 100401. [Google Scholar] [CrossRef]

- Hoberman, C. Radial Expansion/Retraction Truss Structure. U.S. Patent No. 5,024,031, 11 June 2014. [Google Scholar]

- Li, Y.; Chen, Y.; Li, T.; Cao, S.; Wang, L. Hoberman-sphere-inspired lattice metamaterials with tunable negative thermal expansion. Compos. Struct. 2018, 189, 586–597. [Google Scholar] [CrossRef]

- Li, R.; Chen, H.; Choi, J.H. Auxetic two-dimensional nanostructures from DNA. Angew. Chem. 2021, 60, 7165–7173. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Chen, H.; Choi, J.H. Topological assembly of a deployable Hoberman flight ring from DNA. Small 2021, 17, 2007069. [Google Scholar] [CrossRef] [PubMed]

- Cabras, L.; Brun, M. Auxetic two-dimensional lattices with Poisson’s ratio arbitrarily close to −1. Proc. R Soc. A 2014, 470, 20140538. [Google Scholar] [CrossRef]

- Cabras, L.; Brun, M. A class of auxetic three-dimensional lattices. J. Mech. Phys. Solids 2016, 91, 56–72. [Google Scholar] [CrossRef]

- Lim, T.C. An auxetic metamaterial with tunable positive to negative hygrothermal expansion by means of counter-rotating crosses. Phys. Status Solidi B 2021, 258, 2100137. [Google Scholar] [CrossRef]

- Lim, T.C. Adjustable positive and negative hygrothermal expansion metamaterial inspired by the Maltese cross. R. Soc. Open Sci. 2021, 8, 210593. [Google Scholar] [CrossRef]

- Lim, T.C. A Partially Auxetic Metamaterial Inspired by the Maltese Cross; Cambridge University Press: Cambridge, UK, 2022. [Google Scholar]

- Cabras, L.; Brun, M.; Misseroni, D. 2019 Micro-structured medium with large isotropic negative thermal expansion. Proc. R. Soc. A 2022, 475, 20190468. [Google Scholar] [CrossRef]

- Lim, T.C. An auxetic system based on interconnected Y-elements inspired by Islamic geometric patterns. Symmetry 2021, 13, 865. [Google Scholar] [CrossRef]

- Lim, T.C. Aspect ratio and size effects of a metacomposite with interconnected Y-elements. J. Phys. Conf. Ser. 2021, 2047, 012029. [Google Scholar] [CrossRef]

- Lim, T.C. A class of shape-shifting composite metamaterial honeycomb structures with thermally-adaptive Poisson’s ratio signs. Compos. Struct. 2019, 226, 111256. [Google Scholar] [CrossRef]

- Timoshenko, S.P. Analysis of bi-metal thermostat. J. Opt. Soc. Am. 1925, 11, 233–255. [Google Scholar] [CrossRef]

- Adams, D.F.; Monib, M.M. Moisture expansion and thermal expansion coefficients of a polymer-matrix composite material. In Fibrous Composites in Structural Design; Lenoe, E.M., Oplinger, D.W., Burke, J.J., Eds.; Plenum Press: New York, NY, USA, 1980; pp. 819–830. [Google Scholar]

- Adamson, M.J. Thermal expansion and swelling of cured epoxy resin used in graphite/epoxy composite materials. J. Mater. Sci. 1980, 15, 1736–1745. [Google Scholar] [CrossRef]

- Cairns, D.S.; Adams, D.F. Moisture and thermal expansion properties of unidirectional composite materials and the epoxy matrix. In Environmental Effects on Composite Materials; Technomic Publishing Company: Lancaster, PA, USA, 1984; Volume 2, pp. 300–325. [Google Scholar]

- Weitsman, Y.J. Effects of fluids on polymeric composites—A review. In Comprehensive Composite Materials; Kelly, A., Zweben, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2000; Volume 2, pp. 369–401. [Google Scholar]

| Category | Shape of Paired Rigid or High Stiffness Elements | NPR | NTE | NME | Refs. |

|---|---|---|---|---|---|

| Hoberman mechanism | Rigid linear elements | Yes | No | No | [61] |

| Hoberman mechanism | Rigid linear elements with high CTE radial beams | NA | Yes | NA | [62] |

| Hoberman mechanism | High stiffness of approximately linear elements in some DNA | Yes | No | No | [63,64] |

| Equal armed crosses | Rigid equal armed cross elements | Yes | No | No | [65,66] |

| Equal armed crosses | Rigid equal armed cross elements with high CTE connecting beams | NA | Yes | Yes | [67] |

| Maltese crosses | Rigid equal armed cross elements with bimetallic spiral springs, hinge rods and connecting rods | NA | Yes | Yes | [68] |

| Maltese crosses | Rigid equal armed cross elements with spiral springs, hinge rods and connecting rods | Yes | No | No | [69] |

| Y-elements | Rigid Y-elements of equal angular spacing and high CTE connectors | NA | Yes | NA | [70] |

| Y-elements | Rigid Y-elements of unequal angular spacing with spiral springs | Yes | No | No | [71,72] |

| Y-elements | Rigid Y-elements of unequal angular spacing with bimetallic spiral springs | Yes | Yes | Yes | This paper |

| Bimaterial Spiral Spring System | CTE of Bimaterial Layers | Young’s Modulus of Bimaterial Layers |

|---|---|---|

| (1) Tungsten (2) Silicon Carbide | ||

| (1) Carbon (2) Steel | ||

| (1) Brass (2) Titanium |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, T.-C. Metamaterial with Tunable Positive and Negative Hygrothermal Expansion Inspired by a Four-Fold Symmetrical Islamic Motif. Symmetry 2023, 15, 462. https://doi.org/10.3390/sym15020462

Lim T-C. Metamaterial with Tunable Positive and Negative Hygrothermal Expansion Inspired by a Four-Fold Symmetrical Islamic Motif. Symmetry. 2023; 15(2):462. https://doi.org/10.3390/sym15020462

Chicago/Turabian StyleLim, Teik-Cheng. 2023. "Metamaterial with Tunable Positive and Negative Hygrothermal Expansion Inspired by a Four-Fold Symmetrical Islamic Motif" Symmetry 15, no. 2: 462. https://doi.org/10.3390/sym15020462

APA StyleLim, T.-C. (2023). Metamaterial with Tunable Positive and Negative Hygrothermal Expansion Inspired by a Four-Fold Symmetrical Islamic Motif. Symmetry, 15(2), 462. https://doi.org/10.3390/sym15020462