Abstract

The surface subsidence duration and the maximum subsidence velocity are critical indicators to evaluate the stability and severity of surface damage. Precisely predicting them is important for guiding engineering design and protecting ground infrastructure. Traditional manual measurement methods are time-consuming and laborious, and the existing empirical formulas have low accuracy and poor applicability. Therefore, a new prediction method was established in this paper. Measured data from 30 mining areas were used for verification. The results show that the predicted surface subsidence duration is basically consistent with the measured value. The standard deviation of the two is 61 d, and the relative standard deviation is 6.6%. The predicted surface maximum subsidence velocity is basically consistent with the measured value. The standard deviation of the two is 10.0 mm/d, and the relative standard deviation is 1.6%. The surface subsidence duration and the maximum subsidence velocity are positively correlated with the coal seam thickness, negatively and positively correlated with the mining speed, and positively and negatively correlated with the mining depth. The mining speed and mining depth have the same sensitivity to the two indicators, and the coal seam thickness is more sensitive to the surface subsidence duration. Furthermore, construction within the subsidence basin may further contribute to surface subsidence. Therefore, land reuse measures should be implemented following the predicted surface subsidence duration in this paper. This study addresses the knowledge gap in this field by deriving theoretical formulas for surface subsidence duration and maximum subsidence velocity. In the absence of sufficient measured data, engineers can calculate predicted values in combination with geological mining conditions and develop appropriate mining plans based on the extent of surface subsidence.

1. Introduction

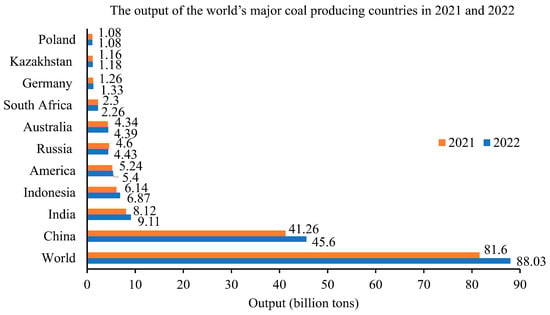

Coal is “black gold” and plays an essential role in global economic development. Petroleum, coal, and natural gas were for the top three primary energy consumption types globally in 2022. Among them, petroleum accounted for 31.6%, coal accounted for 26.7%, and natural gas accounted for 23.5%. At present, global coal production has exceeded 8 billion tons and will remain at this level for the next few years. Figure 1 shows the output of the world’s major coal-producing countries in 2021 and 2022 (World Energy Statistics Yearbook). From the perspective of coal output in various countries, most countries in the world are growing [1,2,3]. The mining of underground coal seams results in the redistribution of stress in the rock mass surrounding the goaf, which leads to the deformation and failure of rock strata. When the mining area reaches a certain extent, the mining influence is transmitted to the surface, resulting in vertical displacement, which is referred to as surface subsidence [4,5]. According to the subsidence degree, surface subsidence can be divided into three categories: slight subsidence, moderate subsidence, and severe subsidence. Slight subsidence usually does not exceed a few centimeters, which has a minimal impact on the environment. Moderate subsidence ranges from a few centimeters to tens of centimeters, while severe subsidence typically exceeds tens of centimeters. Both can adversely impact the ecological environment and compromise building safety [5]. The surface is usually covered by a specific thickness of soil. When surface subsidence occurs, the soil layer will be subjected to additional pressure, causing the rearrangement and compaction of soil particles, thus enhancing soil compaction. This compaction will affect the air permeability and water retention capacity of the soil, impacting groundwater supply and soil moisture distribution, thereby influencing the surrounding vegetation. In addition, when surface subsidence is severe, the soil layer may collapse or crack, which can compromise the physical structure of the soil and negatively impact its productivity. Therefore, mining subsidence alters the structural and physical properties of the soil [6,7]. Under global ecological civilization construction, the efficient utilization of land in mining subsidence areas has become one of the current research hotspots [6,7,8]. The rapid development of the city has led to the fact that some ground infrastructures should be built in the damaged land. The key is to master the stability and intensity of surface damage. Studying the surface subsidence duration provides a crucial foundation for land reuse and building stability assessment in subsidence areas. Studying the surface maximum subsidence velocity provides a crucial foundation for the optimal design of working faces and the assessment of mining damage. Accurately determining these two indicators is vital for protecting buildings, implementing ecological protection measures, and determining appropriate land reuse timing. Therefore, it is important to establish prediction models that can be applied to different geological and mining conditions [9,10].

Figure 1.

The output of the world’s major coal-producing countries in 2021 and 2022.

The surface subsidence caused is a complex multi-dimensional problem. During coal mining, the surface subsidence generally goes through three stages: the initial, active, and decline stage. The sum of the three stages is called the surface subsidence duration [11,12]. At present, the mining resources are gradually exhausted, and the premise of land reuse in subsidence areas is whether the surface state is stable. The surface subsidence duration is used as an indicator to evaluate the surface damage degree, and the accurate prediction of it becomes particularly important [13,14]. In Europe, scholars have employed InSAR technology to monitor surface residual subsidence. Due to the influence of vector coherence, it is not feasible to monitor the surface subsidence duration throughout the entire mining stage [15,16,17]. To solve this limitation, Tajduś and Sroka proposed a method to predict residual subsidence and duration using height measurement data from the German Survey Bureau over several years. This method combines the Gauss–Markov algorithm with the Knothe time function and has been successfully applied in various mining areas across Germany [18,19]. The prediction of surface subsidence in Poland has been studied for hundreds of years. The most groundbreaking research outcomes are the Knothe influence function and the random medium theory. These two methods are widely employed in the mining industry across various countries and have become the foundation for numerous studies [20,21,22]. Building on this foundation, Polish scholars continue to advance research on surface subsidence prediction from three perspectives: numerical simulation, field measurement, and theoretical modelling. For instance, Białek et al. utilized numerical simulation to calculate surface subsidence during the partial exploitation of the Marcel mine. This was corroborated by geodetic results, confirming that establishing an unextracted coal solid belt would significantly reduce surface subsidence. Additionally, Białek et al. investigated the impact of caulking goafs on surface subsidence and established the relationship between caulking height and the mining coefficient [20,21]. Using the Siltech mine as a case study, Polanin derived the optimal coal pillar width necessary to maintain roadway stability based on numerical simulation results and the Knothe–Budryk theory [22]. In China, from the 1950s to the 1960s, mobile observation stations began to be established on a large scale in mining areas. By collecting many measured data, some empirical formulas for the surface subsidence duration were established and successfully applied [23,24,25]. An et al. comprehensively considered the relationship between geological mining conditions and the surface subsidence duration. They established a new prediction model, and the prediction accuracy was improved by 44% [11]. Li et al. believed that the previous empirical formula was no longer applicable to the prediction of the surface subsidence duration under insufficient mining [26]. Therefore, a prediction model considering the mining degree was established, which showed that the mining degree was proportional to the surface subsidence duration.

With the large-scale mining of mine resources, relying solely on static prediction results can no longer evaluate the surface damage degree. It is necessary to provide data support based on indicators such as the maximum subsidence velocity. Mastering the variation characteristics and laws of the surface maximum subsidence velocity can determine the surface damage degree at any time and provide an essential basis for determining the working face size [26,27,28]. Based on many measured data, the Coal Research Institute proposed an empirical formula for the surface maximum subsidence velocity by considering the maximum subsidence, mining depth, working face advance speed, and overburden lithology and verified it in some mining areas [23]. Zhang et al. and Li et al. derived the calculation expressions of the surface maximum subsidence velocity based on Knothe and logistic time functions, respectively, and compared their accuracy [29,30]. Combined with the skewed distribution characteristics of the subsidence velocity curve, Chen et al. constructed the skewed prediction model and analyzed its accuracy. The results showed that the fitting degree of the predicted and measured values was above 0.95, and the relative standard deviation was less than 9% [27].

In summary, rich results have been obtained in the prediction of the surface subsidence duration and the maximum subsidence velocity. However, there are still some shortcomings: (1) The theoretical basis of the existing prediction model is weak. (2) Some parameters in the empirical formula depend on human experience values. The prediction accuracy is low, and it is difficult to promote the application. (3) The prediction model considers fewer influencing factors, is more suitable for some specific areas, and has poor applicability. In view of this, a method for predicting the surface subsidence duration and the maximum subsidence velocity is established for the first time. Combined with the measured data of 30 mining areas, it is found that the two models have a high prediction accuracy, strong applicability, and a wide application range, which provides theoretical support for mining damage and protection in mining areas. The main innovations of this paper are as follows:

(1) Two prediction models of surface subsidence duration and maximum subsidence velocity are derived by combining the Weibull time function for the first time. The model parameters do not need to be obtained through regression inversion or practical experience based on extensive monitoring data; rather, they are determined based on geological and mining conditions, resulting in wider applicability and greater potential for dissemination.

(2) The specific influence mechanisms of geological mining conditions on surface subsidence duration and maximum subsidence velocity are revealed for the first time, and the sensitivity of each factor to the two indicators is assessed.

2. Materials and Methods

2.1. Datasets

In previous studies, researchers have employed various time functions to develop multiple prediction models [31,32,33,34,35]. Based on measured or experimental data, the corresponding model parameters are determined by using the curve fitting method, and the theoretical curve is obtained and compared with the measured curve or experimental curve. Although this method demonstrates high accuracy, it fails to establish the reliability of the prediction model, and it is insufficiently convincing to derive the prediction curve solely by fitting the measured data to determine the model parameters [29,34]. Therefore, to improve the applicability of the prediction model, the model parameters should be determined according to the geological mining conditions. Subsequently, these parameters should be substituted into the prediction model to calculate the predicted values. The information related to a total of 30 working faces was collected, including mining depth, coal seam thickness, mining speed, surface maximum subsidence, surface subsidence duration, and maximum subsidence velocity [23,29]. Half of each was used to verify the two prediction models (Table 1 and Table 2).

Table 1.

Relevant information from 15 mining areas utilized to verify prediction model 1 (surface subsidence duration).

Table 2.

Relevant information from 15 mining areas utilized to verify prediction model 2 (surface maximum subsidence velocity).

2.2. Weibull Time Function Model

Surface subsidence is a vertical subsidence problem. The subsidence of any point increases with time in an inverse “S” shape [36,37]. Many scholars have introduced time functions to analyze the subsidence process of actual surface points over time. If W0 is the maximum subsidence of any points, and is the time function, the subsidence of a certain time is . Therefore, determines the subsidence curve trend, and it is important to select a reasonable time function.

The common time functions are Weibull, logistic, Knothe, and normal distribution time functions [36]. An ideal time function should have the following characteristics: (1) strong applicability—it can be applied to predict surface subsidence under different geological and mining conditions; (2) strong fitting—it can accurately describe the subsidence process of any surface point; and (3) low complexity—to avoid the overfitting phenomenon, the model parameters are reduced. Many measured data show that the Weibull time function can reflect the variation trend of any point in subsidence, subsidence velocity, and subsidence acceleration. Its expression is:

where W0 is the maximum subsidence, mm; t is the subsidence time, d; and c and k are the coefficients related to geological mining conditions.

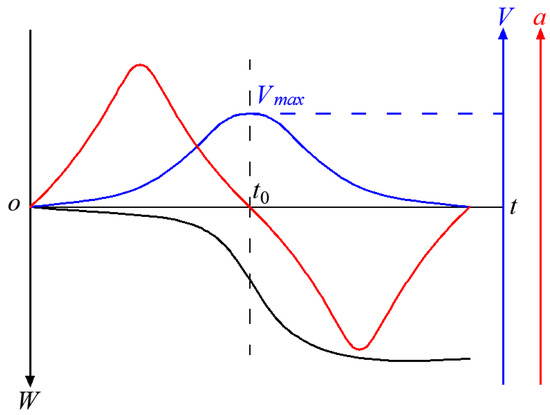

The curve corresponding to Formula (1) itself and its first-order derivation (subsidence velocity V) and second-order derivation (subsidence acceleration a) is shown in Figure 2. When a is 0, V is the maximum value, and W reaches the inflection point. When t = 0, W, V and a subsidence acceleration are all 0. When t = ∞, the subsidence is W0, and V and a are all 0. The variation process of W, V, and a satisfy the law of 0 → W0, 0 → Vmax → 0, 0 → amax → 0 → amin → 0, respectively. The variation curves of the three align with the actual subsidence process of any surface point, it shows that the completeness of the Weibull time function is good. Completeness means that the elements with property p are in the set; that is, given a set S and an operation rule, if the elements in the set are closed under the operation rule, then the set S is complete under the operation rule. The subsidence characteristics satisfy one algorithm, respectively, and can be expressed by the Weibull time function itself, first-order derivation, and second-order derivation. Therefore, it can be said that the Weibull function is complete.

Figure 2.

Variation law of surface subsidence.

To show the applicability of the Weibull time function, the measured data of No.22 surface observation point of a mine and No.C39 surface observation point of a mine were used as the research objects to verify it [38,39]. Table 3 is the specific working face information.

Table 3.

The specific working face information.

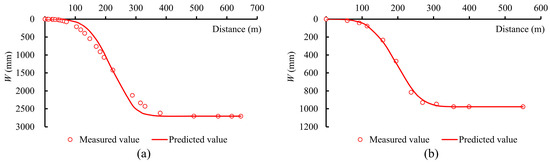

According to the least square method, the model parameters corresponding to the two observation points are determined, respectively. No.22 surface observation point: c = 1.2801 × 10−10, k = 4.1589. No.39 surface observation point: c = 4.3811 × 10−10, k = 4.0171. The standard deviation and relative standard deviation of the No.22 surface observation point are 134 mm and 4.9%, respectively. The standard deviation and relative standard deviation of No.39 surface observation point are 61 mm and 6.2%, respectively. Figure 3 is the measured subsidence and model fitting results. It can be seen that the Weibull function model can better reflect the subsidence–time change process of the observation points.

Figure 3.

Comparison of measured subsidence and fitting results at No.22 and No.39 observation points: (a) No.22; (b) No.39.

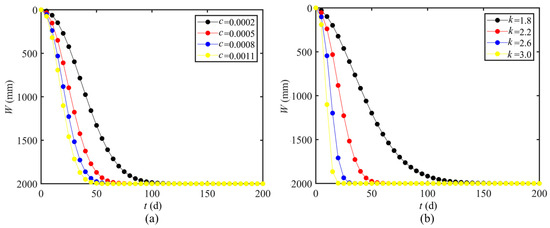

In order to study c and k on the curve shape, let W0 = 2000 mm, c = 0.0002~0.0011, and k = 1.8~3.0; draw the subsidence curve represented by the Weibull time function under different parameter values (Figure 4). It can be seen that when the parameter k is constant, the larger the parameter c is, the time corresponding to the maximum subsidence velocity moves backward, and the starting time of subsidence and the stable time of subsidence are shortened; when the parameter c is constant, the larger the parameter k is, the steeper the curve is (the larger the slope is); that is, the maximum subsidence velocity increases and the surface subsidence duration is shortened. In summary, parameter c mainly affects the starting time of subsidence and the stable time of subsidence, and both are negatively correlated. The parameter k mainly affects the maximum subsidence velocity and duration, which are positively correlated and negatively correlated, respectively, reflecting the subsidence velocity and severity of the monitoring points. An et al. found that the greater the mining depth, the softer the overburden lithology, the greater the mining thickness, and the longer the surface subsidence duration [11]. Based on the data of 11 monitoring points in Changcun mining area, Liu et al. considered that the main influencing factors of the maximum surface subsidence velocity were the mining method, the roof management method, and the thickness and properties of the bedrock and the loose layer [38]. According to Figure 4, the parameter c is related to the mining depth, mining thickness, and overlying strata properties. The parameter k is related to the roof management method, the mining method, and the bedrock and loose layer thickness and properties. The influence c and k on the shape of the subsidence curve is synergistic. Therefore, it is essential to reasonably determine c and k to improve the prediction accuracy.

Figure 4.

The influence of c and k on the subsidence curve: (a) the influence of parameters c (k = 2.2); (b) the influence of parameters k (c = 0.0008).

2.3. Establishment of Prediction Model

2.3.1. Prediction Model of the Surface Subsidence Duration

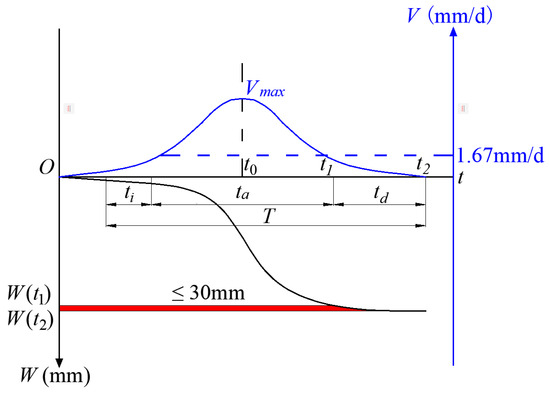

Surface damage has the characteristics of continuity, regularity, and complexity. In the field of mining subsidence science, the surface subsidence velocity (V) reflects the intensity of surface subsidence (W). Based on the influence of surface subsidence velocity on buildings, many scientists divide the entire subsidence process into three stages: the initial stage (ti), the active stage (ta), and the decline stage (td), as shown in Figure 5 [5,40,41,42,43]. The surface point at which the subsidence reaches 10 mm marks the commencement of the subsidence process. The initial stage of subsidence extends from the beginning of W = 10 mm to V = 1.67 mm/d (50 mm/month). The V of the surface point is greater than or equal to 1.67 mm/d (50 mm/month), it is the active stage of subsidence. When V of the surface point is less than 1.67 mm/d (50 mm/month) and the cumulative subsidence in 6 months does not exceed 30 mm, it is the decline stage of subsidence. Although numerous factors influence surface subsidence, they primarily affect the duration of each subsidence stage. The critical values defined for each subsidence stage remain constant, reflecting a consensus among scientists [5,40,41,42,43]. The sum of the time experienced by these three stages is the surface subsidence duration (T), expressed as Formula (2). The surface subsidence duration is an important index to judge the stability of surface stable. The accurate prediction of this is essential for the stability evaluation of ground infrastructures [40].

Figure 5.

The surface subsidence duration.

According to Figure 5 and the definition of the subsidence decline stage, the time corresponding to the end of the subsidence decline stage is the surface subsidence duration, expressed by t2. Substituting it into Formula (1), the surface subsidence at this time is:

The time corresponding to the first six months of surface stability is recorded as t1, and it is substituted into Formula (1) to obtain the surface subsidence at this time:

t2 and t1 satisfy Formula (5):

According to the definition of the surface subsidence duration, the surface subsidence corresponding to time t2 and time t1 should satisfy Formula (6).

Simplify Formula (6) to obtain:

Formula (7) is the prediction model of the surface subsidence duration combined with the Weibull time function. The model has two parameters and is based on theoretical derivation, which is convenient for field application.

2.3.2. Prediction Model of the Surface Maximum Subsidence Velocity

Formulas (8) and (9) are the expressions V(t) and a(t) obtained based on the Weibull time function, respectively.

Let Formula (9) be equal to 0. When the subsidence acceleration a(t) is 0, the three times are obtained:

Formula (10) shows that the subsidence curve is “S” shape, and there is an inflection point. By the function extremum principle, when , V reaches Vmax:

Formula (11) is the prediction model of the surface maximum subsidence velocity. It contains two model parameters, c and k. The reasonable value of c and k is the key to accurately predicting the surface maximum subsidence velocity.

2.3.3. Determination of Model Parameters

The following is a discussion of the model parameters in Formulas (7) and (11). W0 is the surface maximum subsidence, mainly determined by the measured or empirical formula. This is a very common and practical formula, derived from the probability integral theory; the expression is:

where q is the subsidence coefficient (which can be determined by referring to the existing subsidence coefficient); M is the coal seam thickness, m; α is the dip angle of the coal seam, °.

When , , the corresponding time , substituting into Formula (1) to obtain [44,45]:

Simplify Formula (13) to obtain:

According to the probability integral theory, when the working face advances 1.2–1.4 H0 (average mining depth), [43,44,45]. Then, the maximum surface subsidence will increase slightly until it reaches W0. Assuming that the mining speed of is v, and the critical size is Lf, the critical time for the surface subsidence to reach full mining is . c is obtained by combining Formula (15):

Simplify Formula (15) to obtain:

Studies have shown that when the working face advances 1.2~1.4 H0, the surface reaches full mining [45], and its expression is:

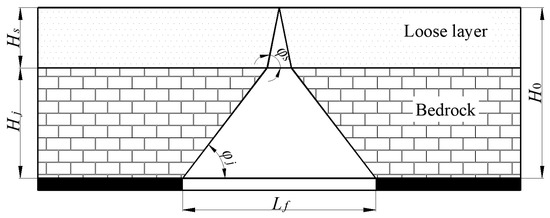

Surface damage is the coupling result of rock breaking and topsoil deformation; the critical size can also be calculated by the full mining angle of the two (Figure 6) [45,46,47]. Lf is:

where Hs is the loose layer thickness, m; hj is the bedrock thickness, m; is the full mining angle of the loose layer, generally 82~86°; is the fully mining angle of the bedrock, generally 53~61° [36,37].

Figure 6.

Calculation model of critical size of working face mining.

Formulas (17) and (18) can be used to calculate the critical size. If the geological mining conditions are clear, the critical size of the working face mining is calculated by Formula (18). Otherwise, it is calculated by Formula (17).

By substituting Formula (14) and Formula (16) into Formula (7) and Formula (11), respectively, the expressions of the surface subsidence duration and the maximum subsidence velocity can be obtained, respectively. The two prediction models established can consider the comprehensive influence of mining parameters, and their applicability is more extensive.

3. Results and Analysis

3.1. Analysis of the Prediction Results of the Surface Subsidence Duration

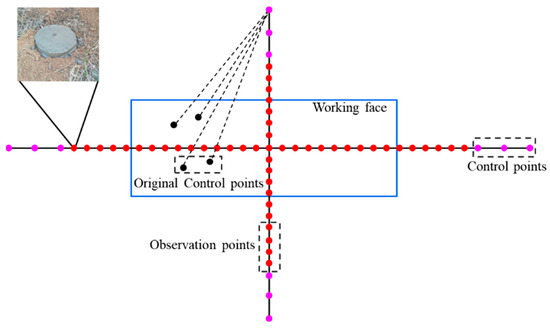

Before mining the working face, technicians usually arrange two mutually perpendicular observation lines in the main section and inclination of the surface. Each observation line consists of multiple observation points, with the length of the lines, the density, and the number of points being related to the geological and mining conditions of each area. The observation process is generally divided into connection measurement, comprehensive measurement, and daily observation. Connection measurement is employed to ascertain the relative positional relationship between the observation station and the working face. Typically, the horizontal position and elevation of the control points are determined using existing control points within the mining area. Comprehensive measurement establishes the initial coordinates and elevation of the observation points, usually conducted twice before mining, with a time interval of no more than five days. Daily observation assesses the subsidence of observation points at varying distances from the advancing working face, with the number of observations adjustable according to operational accuracy. Given that the dataset collected in this paper originates from different mining areas across various literature, a detailed understanding of the layout of each observation station is not feasible. Therefore, we provide a schematic diagram of a surface movement observation station (Figure 7).

Figure 7.

Surface movement observation station.

In the section “Establishment of prediction model”, the detailed definitions and determination methods for surface subsidence duration and maximum subsidence velocity are given. During actual observation, technicians arrange multiple observation points on the surface and use total stations or GPS-RTK systems to obtain the elevation and coordinates of the observation points at specified intervals. The differences in elevation represent the subsidence of the observation points during this period. By plotting the surface subsidence curve over different periods, it becomes evident that subsidence changes dynamically. When the cumulative subsidence of any surface point in 6 months does not exceed 30 mm, the corresponding time is defined as the surface subsidence duration. The surface subsidence velocity is defined as the ratio of the difference between two adjacent subsidence values at an observation point to the time interval, with the maximum value representing the maximum subsidence velocity. The measured values in Table 4 and Table 5 can be obtained through the above methods.

Table 4.

The predicted values of surface subsidence duration for the 15 mining areas obtained using prediction model 1.

The parameters in Table 1 are substituted into Formulas (16) and (17) to obtain the parameter c of the calculation model of the surface subsidence duration corresponding to different mining areas. Combined with Formulas (7) and (14), Table 4 is the predicted values of the surface subsidence duration in 15 mining areas. According to the table, since the parameter c is related to the critical size, the mining speed, the mining depth, and other conditions, the parameter c range is distributed as 2.299 × 10−9~9.588 × 10−7, and the dimension of c is generally 1 × 10−10~1 × 10−6.

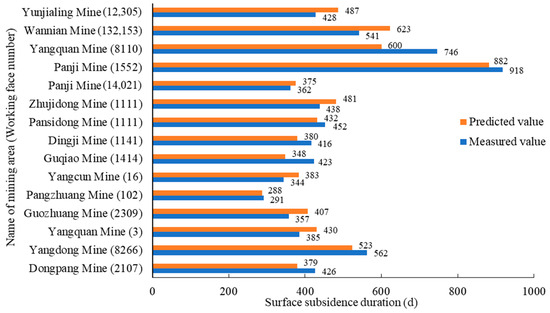

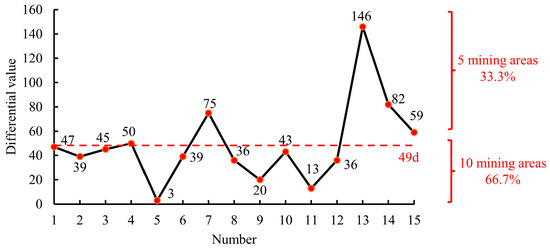

Figure 8 shows the predicted and measured values of the surface subsidence duration in 15 mining areas. The predicted value is basically consistent with the measured value, and the prediction accuracy is high. Combined with Table 1 and Table 4, the mining depth varies from 99 m to 920 m, the mining speed of the working face varies from 1.30 m/d to 6.20 m/d, the coal seam thickness varies from 1.3 m to 7.1 m, and the surface maximum subsidence varies from 750 mm to 4620 mm, thereby encompassing different geological mining conditions. The prediction results of the surface subsidence duration are similar to the measured results. The minimum difference between the two is 3 d, the maximum difference is 146 d, and the average difference is 49 d. Although the predicted value of the 8110 working face in Yangquan mine is quite different from the measured value (146 d), the relative error of the sample is only 19.6%, and the prediction accuracy of a single sample cannot reflect the overall accuracy. The prediction results of the proposed model align closely with the measured results, demonstrating suitability for predicting surface subsidence duration across various geological mining conditions and exhibiting strong applicability.

Figure 8.

Comparison of the predicted and measured values of the surface subsidence duration.

The relative standard deviation f and the standard deviation m are used as the criteria for the prediction accuracy:

where di is the difference value of the surface subsidence duration in the mining area; n is the number of errors; and tmax is the measured maximum value of the surface subsidence duration in 15 mining areas.

It can be seen from Table 4 that the standard deviation of the surface subsidence duration model proposed in this paper is 61 d, with a relative standard deviation of 6.6%. The prediction accuracy satisfies the requirements of field engineering applications. Therefore, the theoretical prediction will also produce certain errors. Figure 9 shows the difference value distribution of the surface subsidence duration in 15 mining areas. The difference value of 5 mining areas is above the average value, accounting for 33.3%, and the difference value of 10 mining areas is below the average value, accounting for 66.7%. On the one hand, there are some errors in the field monitoring instruments and means. On the other hand, when predicting the surface subsidence duration, the critical size coefficient is 1.4, and different mining areas are also different. However, the average difference is only 49 d, and the relative standard deviation is only 6.6%, which is enough to prove that the established model has high accuracy. It shows that the prediction model of the surface subsidence duration established has high accuracy, further confirming its accuracy and reliability.

Figure 9.

The difference value of the surface subsidence duration.

3.2. Analysis of the Prediction Results of the Surface Maximum Subsidence Velocity

The parameters in Table 2 are substituted into Formulas (16) and (18) to obtain the parameter c of the calculation model of the surface maximum subsidence velocity corresponding to different mining areas (where the full mining angle of the loose layer and the full mining angle of the bedrock are taken as the average value, respectively, that is, , ). Combined with Formulas (11) and (14), the predicted values of the surface maximum subsidence velocity of 15 mining areas are obtained (Table 5). According to the table, the parameter c range is distributed as 1.551 × 10−7~3.630 × 10−3, and the dimension of c is generally 1 × 10−8~1 × 10−2.

Table 5.

The predicted values of surface maximum subsidence velocity for the 15 mining areas obtained using prediction mode 2.

Table 5.

The predicted values of surface maximum subsidence velocity for the 15 mining areas obtained using prediction mode 2.

| Number | Name of Mining Area (Working Face Number) | c | Vmax (mm·d−1) | Relative Error (%) | |

|---|---|---|---|---|---|

| Measured Value | Predicted Value | ||||

| 1 | Mazhuang Mine (102) | 6.203 × 10−7 | 32 | 24.7 | 22.8 |

| 2 | Wuyang Mine (7305) | 1.186 × 10−6 | 61 | 51.5 | 15.6 |

| 3 | Erkuang Mine (1404) | 1.551 × 10−7 | 11 | 10.7 | 2.7 |

| 4 | Gengcun Mine (11,061) | 3.012 × 10−7 | 11.2 | 13.9 | 24.1 |

| 5 | Fengfeng Mine (0252) | 1.066 × 10−6 | 54.2 | 45.5 | 16.1 |

| 6 | Wangzhuang Mine (6206) | 3.177 × 10−6 | 144.3 | 127.1 | 11.9 |

| 7 | Sima Mine (1101) | 1.344 × 10−5 | 241 | 231.4 | 4.0 |

| 8 | Changcun Mine (S6-7) | 1.807 × 10−6 | 76.8 | 83.2 | 8.3 |

| 9 | Dongpo Mine (914) | 1.020 × 10−6 | 181.7 | 204.4 | 12.5 |

| 10 | Xiadian Mine (3111) | 5.539 × 10−7 | 74 | 74 | 0.0 |

| 11 | Xinyuan Mine (1101) | 5.555 × 10−6 | 205 | 200.8 | 2.0 |

| 12 | Tianzhu Mine (3229) | 2.824 × 10−7 | 21.5 | 18.9 | 12.1 |

| 13 | Xiaobaodang Mine (112,201) | 9.358 × 10−5 | 267.8 | 263.3 | 1.7 |

| 14 | Daliuta Mine (22,201) | 3.630 × 10−3 | 643.3 | 632.4 | 1.7 |

| 15 | Wuyang Mine (7806) | 2.979 × 10−7 | 64.3 | 56.1 | 12.8 |

| Standard deviation (mm·d−1) | 10.0 | ||||

| Relative standard deviation (%) | 1.6% | ||||

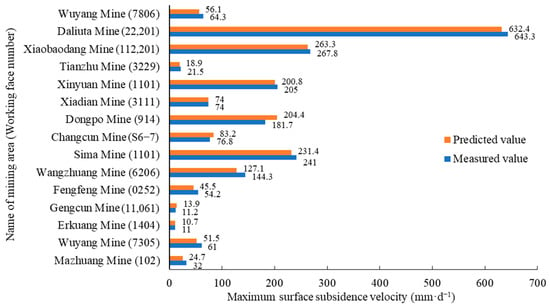

Figure 10 shows the predicted and measured values of the maximum subsidence velocity in 15 mining areas. The predicted value is basically consistent with the measured value, and the prediction accuracy is high. Combined with Table 2 and Table 5, the loose layer thickness ranges from 7 m to 285 m, the bedrock thickness ranges from 61 m to 401 m, the mining speed of the working face ranges from 0.83 m/d to 12.00 m/d, the coal seam thickness ranges from 1.4 m to 14.4 m, and the surface maximum subsidence ranges from 1036 mm to 11,127 mm, thereby encompassing different geological mining conditions. The predicted results of the surface maximum subsidence speed are similar to the measured results. The minimum difference between the two is 0 mm/d, the maximum difference is 22.7 mm/d, and the average difference is 7.7 mm/d. The prediction results of the proposed model align closely with the measured results, demonstrating suitability for predicting surface maximum subsidence velocity across various geological mining conditions and exhibiting strong applicability.

Figure 10.

Comparison of the predicted and measured values of the surface maximum subsidence velocity.

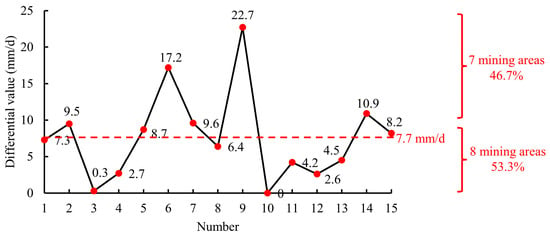

It can be seen from Table 5 that the standard deviation of the surface maximum subsidence velocity model proposed in this paper is 10.0 mm/d, with a relative standard deviation is 1.6%. The prediction accuracy satisfies the requirements of field engineering applications. Figure 11 shows the difference distribution of the surface maximum subsidence velocity in 15 mining areas. The difference value of seven mining areas is above the average value, accounting for 46.7%, and the difference value of eight mining areas is below the average value, accounting for 53.3%. Because the critical size of the working face is determined by the average value of the full mining angle of the loose layer and the full mining angle of the bedrock, and the value of different mining areas is slightly different, the theoretical prediction value is not completely consistent with the measured value. However, the average difference is only 7.7 mm/d, and the relative standard deviation is only 1.6%. It shows that the prediction model of the surface maximum subsidence velocity established in this paper has high accuracy and can provide theoretical support for protecting ground infrastructures.

Figure 11.

The difference value of the surface maximum subsidence velocity.

3.3. Related Influencing Factors Analysis

3.3.1. Influence of the Coal Seam Thickness

According to the analysis in Section 2.3, the surface subsidence duration and the maximum subsidence velocity are affected by the subsidence coefficient, mining speed, coal seam thickness, and mining depth. Therefore, it is of great significance to analyze the correlation between various factors and two indicators for evaluating the stability of ground infrastructures. However, geological mining conditions in mining areas worldwide differ, making it challenging to analyze the relationship between a single factor and the two indicators using measured data. Therefore, we assume several common mining parameters for analysis.

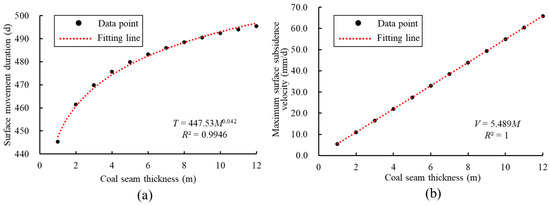

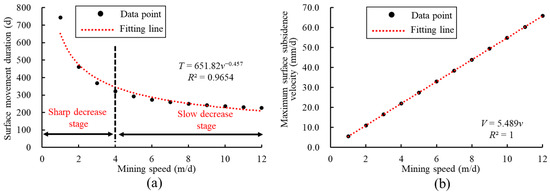

According to Formula (12), the subsidence coefficient and the coal seam thickness affect the surface maximum subsidence simultaneously, affecting the surface subsidence duration and the maximum subsidence speed. In essence, the influence relationship is consistent. Therefore, this paper only discusses the influence of the change in coal seam thickness on the surface subsidence duration and the maximum subsidence speed. Assuming a mining speed of 2 m/d, a mining depth of 400 m, and a subsidence coefficient of 0.8, the surface subsidence duration and maximum subsidence velocity are calculated for coal seam thicknesses of 1 m, 2 m, 3 m, …, up to 12 m, respectively (Figure 12).

Figure 12.

The influence of coal seam thickness on the surface subsidence duration and the maximum subsidence velocity: (a) surface subsidence duration; (b) maximum subsidence velocity.

When the coal seam thickness increases, the surface subsidence duration increases nonlinearly (power function), and the surface maximum subsidence velocity increases linearly. The greater the coal seam thickness, the more severe the surface subsidence and deformation, the greater the subsidence speed when it reaches the surface, and the longer the time for the surface subsidence to reach stability.

When the coal seam thickness increases from 1 m to 12 m, the surface subsidence duration increases from 445 d to 495 d, an increase of 11.2% (50 d), indicating that the change in coal seam thickness has little effect on the surface subsidence duration. When the coal seam thickness increases from 1 m to 12 m, the surface maximum subsidence velocity increases from 5.5 mm/d to 65.9 mm/d, an increase of 60.4 mm/d, which is significant. It shows that the surface maximum subsidence velocity is more sensitive.

3.3.2. Influence of the Mining Speed

Assuming a mining depth of 400 m, a coal seam thickness of 2 m, and a subsidence coefficient of 0.8, the surface subsidence duration and maximum subsidence velocity are calculated for mining speeds of 1 m/d, 2 m/d, 3 m/d, …, up to 12 m/d, respectively (Figure 13).

Figure 13.

The influence of mining speed on the surface subsidence duration and the maximum subsidence velocity: (a) surface subsidence duration; (b) maximum subsidence velocity.

When the mining speed increases, the surface subsidence duration decreases nonlinearly and gradually tends to be stable (power function), and the surface maximum subsidence velocity increases linearly. The greater the mining speed, the shorter the time of the end of mining, that is, the shorter the time of the surface beginning to sink to the final stability. The larger the mining speed, the more severe the movement and deformation of the overlying strata, and the greater the subsidence velocity when it reaches the surface.

When the mining speed increases from 1 m/d to 12 m/d, the surface subsidence duration experiences two stages of change, namely, a sharp decrease stage (from 743 d to 321 d, a decrease of 422 d, a significant decrease) and a slow decrease stage (from 321 d to 227 d, a decrease of 94 d, a slow decrease). It shows that the change in mining speed has a great influence on the surface subsidence duration. The surface subsidence duration can be shortened by accelerating the mining speed (when the mining speed is greater than 4 m/d, the control effect is not obvious); when the mining speed increases from 1 m/d to 12 m/d, the maximum subsidence speed of the surface increases from 5.5 mm/d to 65.9 mm/d, an increase of 60.4 mm/d. Under the same increase in mining speed, the sensitivity of the two indicators is the same.

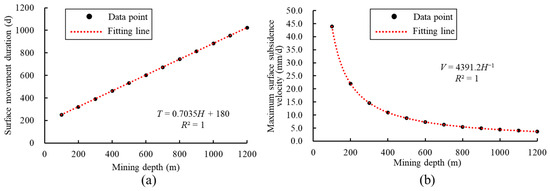

3.3.3. Influence of the Mining Depth

Assuming a mining speed of 2 m, a coal seam thickness of 2 m, and a subsidence coefficient of 0.8, the surface subsidence duration and maximum subsidence velocity are calculated for mining depths of 100 m, 200 m, 300 m, …, up to 1200 m, respectively (Figure 14). When the mining depth increases, the surface subsidence duration increases linearly, and the surface maximum subsidence velocity decreases nonlinearly and gradually tends to be stable (power function). The deeper the mining depth, the more time it takes for the mining-induced influence to reach the surface, and the longer the surface begins subsidence to the final stability. At the same time, the mining depth effect slows down the mining-induced influence. When it reaches the surface, the subsidence speed decreases, and the surface subsidence is slower and more uniform.

Figure 14.

The influence of mining depth on the surface subsidence duration and the maximum subsidence velocity: (a) surface subsidence duration; (b) maximum subsidence velocity.

When the mining depth increases from 100 m to 1200 m, the surface subsidence duration increases from 250 d to 1024 d, an increase of 774 d, a significant increase, indicating that the mining depth has a greater impact on the surface subsidence duration; when the mining depth increases from 100 m to 1200 m, the surface maximum subsidence velocity has experienced two stages of change, namely, a sharp decrease stage (from 43.9 mm/d to 11.0 mm/d, a decrease of 32.9 mm/d, a significant decrease) and a slow decrease stage (from 11.0 mm/d to 3.7 mm/d, a decrease of 7.3 mm/d, a slow decrease). It shows that the mining depth greatly influences the surface maximum subsidence velocity and reasonably explains the phenomenon that the ground infrastructures in eastern China (deep mining depth) are not easily damaged. Under the same increase in mining depth, the sensitivity of the two indicators is the same.

4. Discussion

4.1. Comparison of the Surface Subsidence Duration Prediction Under Different Methods

With the continuous expansion of the goaf area, the mining-induced influence is gradually strengthened, and the subsidence values at each surface position are obviously changed. The buildings located in the surface subsidence basin are prone to damage. Therefore, when formulating mining plans and selecting measures to protect ground infrastructures, it is necessary to consider whether the surface state has stabilized. The surface subsidence has an obvious lag effect. That is, after the end of mining, the surface subsidence will continue for some time.

At present, the surface subsidence duration is mainly predicted by empirical formulas. For example, Zhang derived an empirical formula considering the lithology coefficient from the factors affecting the surface subsidence duration (empirical Formula (1)), such as Formula (21) [24].

where p is the lithology coefficient, which is determined according to Table 6.

Table 6.

Lithological coefficient under different mining depth.

The empirical formula for the surface subsidence duration with a mining depth of less than 400 m and greater than 400 m (empirical Formula (2)) was given in the “three-under mining guide”, as shown in Formula (22) [23].

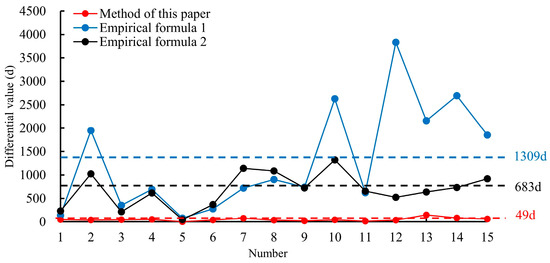

However, the above empirical formulas are less targeted, and the calculation results are too large. To further verify the superiority of this proposed method in predicting the surface subsidence duration, the experimental results of three methods (the prediction model and two empirical formulas) are compared within the dataset (see Table 7 and Table 8). Table 7 and Table 8 illustrate that the measured values of surface subsidence duration in 15 mining areas differ significantly from the predicted values obtained through the two empirical formulas. For empirical Formula (1), the minimum difference is 78 d, the maximum difference is 3831 d, the standard deviation is 1767 d, and the relative standard deviation is 192.5%. For empirical Formula (2), the minimum difference is 44 d, the maximum difference is 1322 d, the standard deviation is 798 d, and the relative standard deviation is 87.0%. The accuracy of empirical Formula (2) is higher than that of empirical Formula (1), but the relative standard deviations of the two methods are more than 50%. The prediction accuracy is lower than the proposed.

Table 7.

The predicted and measured values of the surface subsidence duration in 15 mining areas under different methods.

Table 8.

The accuracy of the surface subsidence duration under different methods.

Figure 15 is the difference value distribution of the surface subsidence duration in 15 mining areas under different methods. It can be seen that the average difference between the two empirical formulas is more than 500 d. When the mining depth is large, the prediction accuracy is low, and the applicability is poor. The average difference obtained by the prediction model is only 49 d, and it is suitable for predicting the surface subsidence duration with strong applicability.

Figure 15.

The difference value of the surface subsidence duration under different methods.

4.2. Comparison of the Surface Maximum Subsidence Velocity Prediction Under Different Methods

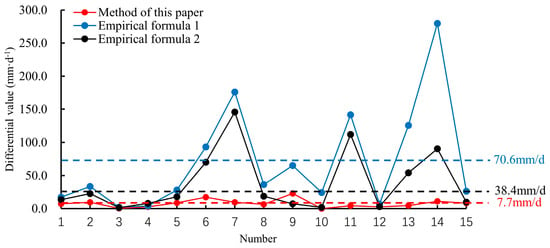

Generally, the greater the surface subsidence velocity, the more severe the surface damage degree, and the greater the impact on the ground infrastructures. The surface maximum subsidence velocity is a key parameter to reflect the surface damage degree. It is of great significance to predict the surface maximum subsidence velocity in time to protect of ground infrastructures.

In “Deformation Monitoring and Mining Subsidence”, a method for calculating the surface maximum subsidence velocity under different lithologic conditions (empirical Formula (1)) was given, which reasonably explained the phenomenon that the surface maximum subsidence velocity under the soft rock strata is slight, as shown in Formula (23) [48].

The formula for calculating the maximum subsidence velocity (empirical Formula (2)) was determined by fitting and verified by several mining areas, as shown in Formula (24) [23].

where K is the subsidence velocity coefficient, generally 0~3.

However, the above methods mostly estimate the surface maximum subsidence velocity through the measured data, which are difficult to popularize and need better applicability. To further verify the superiority of this method in predicting the surface maximum subsidence velocity, the experimental results of three methods (the prediction model and two empirical formulas) are compared within the dataset (see Table 9 and Table 10). Table 9 and Table 10 illustrate that the measured values of surface maximum subsidence velocity in 15 mining areas differ significantly from the predicted values obtained through the two empirical formulas. For empirical Formula (1), the minimum difference is 2.1 mm/d, the maximum difference is 279.5 mm/d, the standard deviation is 107.8 mm/d, and the relative standard deviation is 16.8%. For empirical Formula (2), the minimum difference is 1.4 mm/d, the maximum difference is 145.6 mm/d, the standard deviation is 60.5 mm/d, and the relative standard deviation is 9.4%. The accuracy of empirical Formula (2) is higher than that of empirical Formula (1), but the standard deviation of the two methods is more than 50 mm/d. The prediction accuracy is lower than the method proposed in this paper.

Table 9.

The predicted and measured values of the surface maximum subsidence velocity in 15 mining areas under different methods.

Table 10.

The accuracy of the surface maximum subsidence velocity under different methods.

Figure 16 is the difference value distribution of the surface maximum subsidence velocity in 15 mining areas under different methods. The average difference between the two empirical Formulas is more than 30 mm/d, which is quite different from the measured value. When fitting empirical Formula (1), the measured data are mostly from eastern China, which is not applicable to the western mining area with a large mining depth. The subsidence velocity coefficient in empirical Formula (2) uses mostly empirical values, and the artificial interference is strong, which has a great influence on the prediction results. The average difference obtained by the prediction model is only 7.7 mm/d, which has higher accuracy and stronger applicability.

Figure 16.

The difference value of the surface maximum subsidence velocity under different methods.

In Section 4.1 and Section 4.2, the accuracy of the prediction models proposed in this paper was compared with existing empirical formulas, demonstrating their capability to accurately predict the surface subsidence duration and maximum subsidence velocity. In practical engineering applications, numerous monitoring points are typically established above the surface, with total stations or RTK systems employed to obtain subsidence values at regular intervals. Calculating the corresponding surface subsidence duration and maximum subsidence velocity using theoretical formulas is both time-consuming and laborious. The two prediction models presented in this paper can directly calculate surface subsidence duration and maximum subsidence velocity based on geological mining conditions, eliminating the need to establish on-site monitoring points and perform measurements. Once the surface subsidence duration is calculated, the time at which the surface subsidence reaches a stable state can be determined. Subsequent to this point, the surface will experience only minor subsidence, which will not pose a threat to public safety. At this juncture, the subsidence area can be rehabilitated, and strategies for land reuse may be formulated. Following the calculation of the maximum subsidence velocity, the severity of surface subsidence can be assessed in advance. When the maximum subsidence velocity is high, the subsidence is severe and can significantly impact infrastructures. In extreme cases, this may result in cracking and the potential collapse of buildings. Based on the prediction results, the mining plan for the working face can be adjusted proactively to mitigate surface subsidence by reducing either the mining thickness or the width of the working face.

In addition, the primary focus of this research is to accurately predict the surface subsidence duration and the maximum subsidence velocity, rather than evaluating the impact of coal mining on ground infrastructures. Engineering and infrastructure information are not important to this paper. Table 1 and Table 2 present the working-face-related information necessary for predicting these two indicators and assessing prediction accuracy, including mining depth, mining thickness, mining speed, surface subsidence duration, and maximum subsidence velocity. Furthermore, in the future, we will gather engineering and infrastructure information from various mining areas to study the impact of coal mining on them.

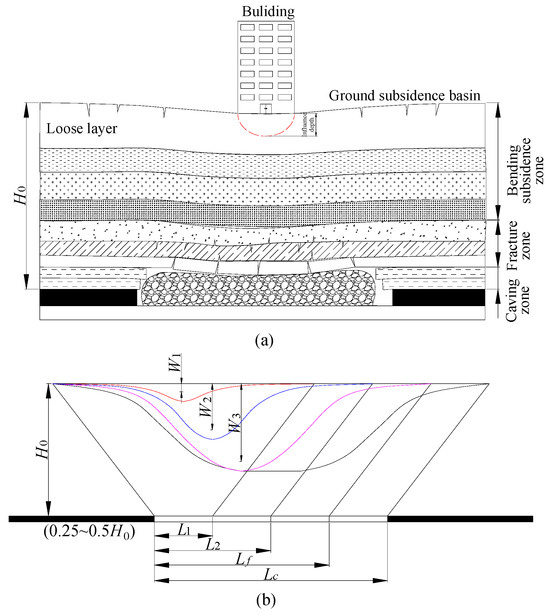

4.3. The Movement and Deformation Process of the Overlying Strata and Surface

When the working face is mined, the rock strata around the goaf lose support and move, bend, and destroy into the goaf. The surface subsidence occurs from the original elevation, which will form a subsidence basin [49]. During coal mining, the movement and failure of the overlying strata have zoning. When, near the surface, the damage degree gradually weakens, the damage range gradually increases. In general, the overlying strata will form “three zones”, that is, the bending subsidence, the caving zone, and the fracture zone (Figure 17a). When the mining thickness is relatively small, they only form “two zones”. Among them, the caving zone refers to the rock strata that collapses to the goaf in an irregular shape, and there are many voids. It is a channel for water and sediment to break into the underground. The height is generally 3~4 times the coal seam thickness. There are cracks and bed separation cracks obliquely crossing the rock strata in the fracture zone. The bed separation crack is the channel of water conduction, resulting in the surface subsidence being less than the coal seam thickness. The height is generally 9~28 times the coal thickness. The curved subsidence zone moves as a whole [39]. The surface above the bending subsidence zone will form a subsidence basin, and the tensile cracks often appear at the basin edge, extending downward in a “V” shape.

Figure 17.

The development process of surface subsidence basin: (a) “three zones” distribution; (b) development process.

The surface subsidence basin is the result of mining influence on the surface. When the working face advances to L1 (starting distance), the mining-induced influence spreads to the surface, resulting in sinking, which is about 0.2~0.5 times the mining depth, as shown in Figure 17b. When the working face advances to L2, the range and subsidence of the surface subsidence basin gradually increase, called the non-full mining stage. When the advancing distance is Lf, the surface subsidence reaches the maximum value, which is called the full mining stage. Subsequently, the surface maximum subsidence no longer increases, and the bottom of the subsidence basin appears flat, which is called the super-full mining stage. In summary, surface subsidence is a dynamic evolution process covering “coal seam mining–overlying strata movement–surface subsidence” from bottom to top.

When the working face advances to the critical mining distance, the surface reaches the full mining stage, and the surface subsidence reaches its maximum value. At this juncture, construction within the subsidence basin will impose additional vertical stress on the surface. The greater the load applied to a building per unit area, the greater the additional vertical stress that is generated. Under the action of additional vertical stress, the load on the building propagates downwards to a specific depth, called the influence depth (Figure 17a). According to the Boussinesq formula, the influence depth is correlated with the load size and soil properties.

where hz is the influence depth, m; P is the load, kN; k is the coefficient, generally 0~1; n is the coefficient, generally 5~10; and is the bulk density, kN/m3.

When the influence depth fails to reach the height of the facture zone (hl), surface subsidence may increase slightly, that is, , but will only occur in localized areas. When the influence depth intersects with the height of the fracture zone, that is, , surface subsidence increases significantly and occurs throughout the entire basin, particularly in areas of soft soil. Furthermore, construction within subsidence basin may create underground cavities, alter the groundwater level, and consequently, affect the additional stress in the soil, thereby further contributing to surface subsidence. It is evident that after reaching the maximum subsidence value, construction within the subsidence basin will continue to induce surface subsidence, and the magnitude of this subsidence is associated with factors such as construction type, soil properties, and construction methods. This further indicates that different engineering projects exert varying degrees of impact on surface subsidence, attributable to their construction types and methods. As the working face continues to advance, the surface will reach the super-full mining stage, and the extent of the subsidence basin will further increase. At this juncture, construction cannot be undertaken within the subsidence basin. After the subsidence reaches a stable state, specifically following the predicted surface subsidence duration in this paper, subsidence may slightly increase, allowing for the implementation of land reuse measures. Given that this topic is not the primary focus of this paper, it is only introduced here in brief.

5. Conclusions and Outlook

The surface subsidence duration and the maximum subsidence velocity are critical indicators to evaluate the stability and severity of the surface damage. In this paper, the prediction models of two indicators are established. The main conclusions are as follows:

(1) To address the limitations of existing research, the Weibull time function is incorporated into the definitions of the two indicators (surface subsidence duration and maximum subsidence velocity), and their functional expressions are subsequently derived. The model parameters do not need to be obtained through regression inversion or practical experience based on extensive monitoring data; rather, they are determined based on geological and mining conditions, resulting in wider applicability and greater potential for dissemination. The standard deviation of the surface subsidence duration prediction model is 61 d, and the relative standard deviation is 6.6%. The standard deviation of the surface maximum subsidence velocity prediction model is 10.0 mm/d, and the relative standard deviation is 1.6%. Compared with the existing methods, the accuracy is greatly improved.

(2) When the Weibull time function is employed to describe surface subsidence, the influence of the model parameters c and k on the curve shape is synergistic. The former primarily affects the surface subsidence duration, while the latter principally influences the maximum subsidence velocity. Based on the derived functional expressions between these two indicators, the relationships among coal seam thickness, mining speed, and mining depth with respect to these indicators are analyzed by assuming different values for the mining parameters. It is found that the surface subsidence duration and the maximum subsidence velocity are positively correlated with coal seam thickness, negatively and positively correlated with mining speed, positively and negatively correlated with mining depth. Notably, mining speed and mining depth exhibit the same sensitivity towards the two indicators; whereas, coal seam thickness shows greater sensitivity to the surface subsidence duration.

(3) When calculating the surface subsidence duration, the point at which subsidence reaches a stable state can be identified. Subsequent to this point, the surface will experience only minor subsidence, which does not pose a threat to public safety. Following the calculation of maximum subsidence velocity, the severity of surface subsidence can be assessed in advance. Based on the prediction results, the mining plan for the working face can be adjusted proactively to mitigate surface subsidence by reducing either the mining thickness or the width of the working face. Furthermore, construction within the subsidence basin may create underground cavities, alter groundwater levels, and consequently, affect the additional stress in the soil, thereby further contributing to surface subsidence. Therefore, land reuse measures should be implemented following the predicted surface subsidence duration in this paper.

The prediction method proposed in this paper has high precision and can be combined with many time functions. The premise is that the time function has the characteristics of strong adaptability, strong fitting, and low complexity. In addition, it is worth noting that the amount of data is small in this paper. In the future, we will further compare the prediction accuracy under different time functions and collect measured data from around the world to verify the feasibility of the prediction method. Meanwhile, when a substantial number of measured data samples are available from various mining areas, deep learning or machine learning can be employed to facilitate the automation and visualization of surface subsidence prediction. This will be the focus of future research.

Author Contributions

Writing—review editing: Y.Z. (Yanjun Zhang); methodology, Y.Z. (Yanjun Zhang); funding acquisition, F.W., Y.Z. (Yanjun Zhang) and Y.Z. (Yuanhao Zhu); resources, F.W.; data curation, Y.Y.; supervision, Y.Z. (Yuanhao Zhu); software, L.D.; investigation, J.K. All authors have read and agreed to the published version of the manuscript.

Funding

The work is supported by the Open Fund of State Key Laboratory of Water Resource Protection and Utilization in Coal Mining (grant no. GJNY-20-113-20) and the Fundamental Research Funds for China University of Mining and Technology (Beijing): Doctoral Top-Notch Innovative Talents Cultivation Fund (grant nos. BBJ2023018 and BBJ2023023).

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

References

- Deng, K.Z.; Zheng, M.N.; Zhang, H.Z.; Fan, H.D.; Tan, Z.X. Research status and prospect of secondary subsidence in closed mine. Coal Sci. Technol. 2022, 50, 10–20. [Google Scholar]

- Guzy, A.; Witkowski, W.T. Land subsidence estimation for aquifer drainage induced by underground mining. Energies 2021, 14, 4658. [Google Scholar] [CrossRef]

- Krawczyk, A.; Grzybek, R. An evaluation of processing InSAR Sentinel-1A/B data for correlation of mining subsidence with mining induced tremors in the Upper Silesian Coal Basin (Poland). E3S Web Conf. 2018, 26, 00003. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Lian, X.G.; Yan, Y.G.; Zhu, Y.H.; Dai, H.Y. Study on the development law of mining-induced ground cracks under gully terrain. Remote Sens. 2022, 14, 5985. [Google Scholar] [CrossRef]

- Peng, S.S. Surface Subsidence Engineering; The Society for Mining, Metallurgy, and Exploration, Inc.: New York, NY, USA, 1992. [Google Scholar]

- Rurek, M.; Gonia, A.; Hojan, M. Environmental and socio-economic effects of underground brown coal mining in PiłaMłyn (Poland). Land 2022, 11, 219. [Google Scholar] [CrossRef]

- Fu, Y.; Wu, Y.; Yin, X. A study on the movement and deformation law of overlying strata and the self-healing characteristics of ground fissures in non-pillar mining in the aeolian sand area. Sustainability 2023, 15, 15136. [Google Scholar] [CrossRef]

- Williams, S.; Bock, Y.; Pang, P. Integrated satellite interferometry, tropospheric noise, GPS estimates and implications for interferometric synthetic aperture radar products. Geophysics 1998, 103, 27051–27067. [Google Scholar] [CrossRef]

- Malinowska, A.; Hejmanowski, R. Building damage risk assessment on mining terrains in Poland with GIS application. Int. J. Rock. Mech. Min. Sci. 2010, 47, 238–245. [Google Scholar] [CrossRef]

- Sun, C.; Xu, N.Z.; Liu, Y.X.; Liu, G.; Gao, C. Prediction of dynamic subsidence of ground point under loose stratum based on two-factor time function. Rock. Soil. Mech. 2017, 38, 821–826. [Google Scholar]

- An, S.L.; Li, Y.H.; Wang, X.P.; Zhou, D.W.; An, Y.F.; Bi, B. Study on prediction method of surface movement duration in thick alluvial mining area. Coal Sci. Technol. 2022, 50, 24–31. [Google Scholar]

- Troncone, A.; Pugliese, L.; Conte, E. Analysis of an excavation-induced landslide in stiff clay using the material point method. Eng. Geol. 2022, 296, 106479. [Google Scholar] [CrossRef]

- Ghabraie, B.; Ren, G.; Barbato, J.; Smith, J.V. A predictive methodology for multi-seam mining induced subsidence. Int. J. Rock. Mech. Min. Sci. 2017, 93, 280–294. [Google Scholar] [CrossRef]

- Loupasakis, C.; Angelitsa, V.; Rozos, D.; Spanou, N. Mining geohazards-land subsidence caused by the dewatering of opencast coal mines, the case study of the Amyntaio coal mine, Florida, Greece. Nat. Hazards 2014, 70, 675–691. [Google Scholar] [CrossRef]

- Vervoort, A. The time duration of the effects of total extraction mining methods on surface movement. Energies 2020, 13, 4107. [Google Scholar] [CrossRef]

- Vervoort, A. Surface movement above an underground coal longwall mine after closure. Nat. Hazards Earth Syst. Sci. 2016, 16, 2107–2121. [Google Scholar] [CrossRef]

- Modeste, G.; Doubre, C.; Masson, F. Time evolution of mining-related residual subsidence monitored over a 24-year period using InSAR in southern Alsace, France. Int. J. Appl. Earth Obs. Geoinf. 2021, 102, 10239. [Google Scholar] [CrossRef]

- Tajduś, K.; Sroka, A.; Misa, R.; Hager, S.; Rusek, J.; Dudek, M.; Wollnik, F. Analysis of mining-induced delayed surface subsidence. Minerals 2021, 11, 1187. [Google Scholar] [CrossRef]

- Dudek, M.; Sroka, A.; Tajduś, K.; Misa, R.; Mrocheń, D. Assessment and duration of the surface subsidence after the end of mining operations. Energies 2022, 15, 8711. [Google Scholar] [CrossRef]

- Białek, J.; Wesołowski, M.; Mielimąka, R.; Sikora, P. Deformations of mining terrain caused by the partial exploitation in the aspect of measurements and numerical modeling. Sustainability 2020, 12, 5072. [Google Scholar] [CrossRef]

- Kowalski, A.; Białek, J.; Rutkowski, T. Caulking of goafs formed by cave-in mining and its impact on surface subsidence in hard coal mines. Arch. Min. Sci. 2021, 66, 85–100. [Google Scholar]

- Polanin, P.; Kowalski, A.; Walentek, A. Numerical simulation of subsidence caused by roadway system. Arch. Min. Sci. 2019, 64, 385–397. [Google Scholar]

- State Administration of Work Safety; National Coal Ming Safety Administration; National Energy Administration; National Railway Administration. Regulations of Coal Mining Under Buildings, Water Bodies, Railway and Safety Pillar Design; Coal Industry Press: Beijing, China, 2017. [Google Scholar]

- Zhang, G.W.; Wei, Y.J.; Zhu, Q. Study on the calculation method of surface movement time. In Proceedings of the National “Three Unders” Coal Mining Academic Conference: Professional Committee of Mine Surveying of China Coal Society (China Coal Society), Chengdu, China, 1 October 2012; pp. 92–96. [Google Scholar]

- Zheng, Z.G.; Teng, Y.H. Ground surface rock strata movement parameters of thick loose strata with fully mechanized top coal caving. Coal Min. Technol. 2016, 21, 22–25. [Google Scholar]

- Li, C.Y.; Gao, Y.G.; Cui, X.M.; Yuan, D.B.; He, R. Spatiotemporal evolution of surface subsidence induced by fully mechanized thick coal underground mining in Yunjialing colliery. J. Min. Saf. Eng. 2019, 36, 37–43, 50. [Google Scholar]

- Chen, J.J.; Liu, S.W.; Yan, W.T. Construction of skew prediction model for surface subsidence velocity in horizontal coal seam mining. J. Henan Polytech. Univ. 2023, 42, 71–75. [Google Scholar]

- Gonzalez-Nicieza, C.; Alvarez-Fernandez, M.I.; Menendez-Diaz, A.; Alvarez-Vigil, A.E. The influence of time on subsidence in the Central Asturian Coalfield. Bull. Eng. Geol. Environ. 2007, 66, 319–329. [Google Scholar] [CrossRef]

- Zhang, L.L.; Cheng, Y.; Yao, Z.S.; Wang, X.J. Prediction of maximum surface subsidence velocity based on improved Knothe time model. Rock. Soil. Mech. 2023, 44, 1111–1119. [Google Scholar]

- Li, Q.S.; Guo, J.T.; Dai, H.Y. Surface dynamic subsidence prediction method based on mining sufficiency degree. J. China Coal Soc. 2020, 45, 160–167. [Google Scholar]

- Knothe, S. Effect of time on formation of basin subsidence. Arch. Min. Steel Ind. 1953, 1, 1–7. [Google Scholar]

- Li, C.Y.; Gao, Y.G.; Cui, X.M. Progressive subsidence prediction of ground surface based on the normal distribution time function. Rock. Soil. Mech. 2016, 37, 108–116. [Google Scholar]

- Saeidi, A.; Deck, O.; Heib, A.M.; Rouleau, A. Adjusting the influence function method for subsidence prediction. Key Eng. Mater. 2013, 553, 59–66. [Google Scholar] [CrossRef]

- Taherynia, M.; Aghda, S.; Ghazifard, A.; Moradi, E. Prediction of subsidence over oil and gas fields with use of influence functions (case study: South pars gas field, Iran). Iran. J. Sci. Technol. Trans. A Sci. 2017, 41, 375–381. [Google Scholar] [CrossRef]

- Roser, J.; Potocnik, D.; Vulic, M. Analysis of Dynamic Surface Subsidence at the Underground Coal Mining Site in Velenje. Minerals 2018, 8, 74. [Google Scholar] [CrossRef]

- Bo, H.; Lu, G.; Li, H.; Guo, G.; Li, Y. Development of a dynamic prediction model for underground coal mining-induced ground subsidence based on the Hook function. Remote Sens. 2024, 16, 377. [Google Scholar] [CrossRef]

- Nie, L.; Wang, H.; Xu, Y. Application of the arctangent function model in the prediction of ground mining subsidence deformation: A case study from Fushun City, Liaoning Province, China. Bull. Eng. Geol. Environ. 2017, 76, 1383–1398. [Google Scholar] [CrossRef]

- Liu, D.H.; Deng, N.G.; Yao, T.; Shang, H. Study on parameters of Weibull time function model based on sited measured mining subsidence data. Coal Sci. Technol. 2021, 49, 152–158. [Google Scholar]

- Zhang, Y.J.; Yan, Y.G.; Long, S.F.; Zhu, Y.H.; Dai, H.Y.; Kong, J.Y. Dynamic prediction model of mining subsidence combined with improved Weibull time function. Rock. Soil. Mech. 2024, 45, 1824–1834. [Google Scholar]

- Cui, X.; Zhao, Y.; Wang, G.; Zhang, B.; Li, C. Calculation of residual surface subsidence above abandoned longwall coal mining. Sustainability 2020, 12, 1528. [Google Scholar] [CrossRef]

- Cui, X.; Miao, X.; Wang, J.; Yang, S.; Liu, H.; Song, Y.; Liu, H.; Hu, X. Improved prediction of differential subsidence caused by underground mining. Int. J. Rock. Mech. Min. Sci. 2000, 37, 615–627. [Google Scholar] [CrossRef]

- Cui, X.M.; Wang, J.C.; Liu, Y.S. Prediction of progressive surface subsidence above longwall coal mining using a time function. Int. J. Rock. Mech. Min. Sci. 2001, 38, 1057–1063. [Google Scholar] [CrossRef]

- He, G.Q.; Yang, L.; Ling, G.D.; Jia, F.C.; Hong, D. Mining Subsidence Science; China University of Mining and Technology Press: Xuzhou, China, 1989. [Google Scholar]

- Cheng, H.; Zhang, L.L.; Guo, L.H.; Wang, X.J.; Peng, S.L. A new dynamic prediction model for underground mining subsidence based on inverse function of unstable creep. Adv. Civil. Eng. 2021, 2021, 1–9. [Google Scholar] [CrossRef]

- Zhang, L.; Cheng, H.; Yao, Z.; Wang, X. Application of the improved Knothe time function model in the prediction of ground mining subsidence: A case study from Heze city, Shandong province, China. Appl. Sci. 2020, 10, 3147. [Google Scholar] [CrossRef]

- Wang, B.; Xu, J.; Xuan, D. Time function model of dynamic surface subsidence assessment of grout-injected overburden of a coal mine. Int. J. Rock. Mech. Min. Sci. 2018, 104, 1–8. [Google Scholar] [CrossRef]

- Nie, L.; Wang, H.F.; Xu, Y.; Li, Z.C. A new prediction model for mining subsidence deformation, the arc tangent function model. Nat. Hazards 2015, 75, 2185–2198. [Google Scholar] [CrossRef]

- Deng, K.Z.; Tan, Z.X.; Jiang, Y.; Dai, H.Y.; Xu, L.J. Deformation Monitoring and Mining Subsidence; China University of Mining and Technology Press: Xuzhou, China, 2014. [Google Scholar]

- Zhu, Y.H.; Yan, Y.G.; Zhang, Y.J.; Zhang, W.Q.; Kong, J.Y.; Dai, A.J. Study on the evolution law of overlying strata structure in stope based on “space–air–ground” integrated monitoring network and discrete element. Drones 2023, 7, 309. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).