Abstract

With the increasing application of box culvert-type two-way channel pumping systems in low-head pumping stations along rivers in China, a comprehensive investigation of their hydraulic performance is of significant importance. In this study, a physical model test was conducted on a box culvert-type two-way channel pumping station located along the Yangtze River. The energy performance, cavitation characteristics, runaway characteristics, and pressure pulsation behavior of the pumping system were systematically examined. The experimental results indicate that the pumping system achieves optimal energy performance when the blade installation angle is −2°, under which the maximum system efficiency reaches 68.0% while satisfying the operational requirements across different head conditions. For a given blade angle, the critical cavitation margin of the pumping system initially decreases and subsequently increases as the head decreases. At the same head, the critical cavitation margin increases with increasing blade installation angle. Furthermore, the unit runaway speed of the pumping system increases as the blade angle decreases. The blade installation angle significantly influences the amplitude of pressure pulsations at the impeller, whereas its effect on the dominant frequency is relatively minor. The overall pressure pulsation amplitudes measured at the impeller are less than 0.20 m. These findings provide valuable experimental insights for the hydraulic optimization design and operational regulation of similar pumping stations, contributing to improved operational efficiency and reliability while reducing operating costs.

1. Introduction

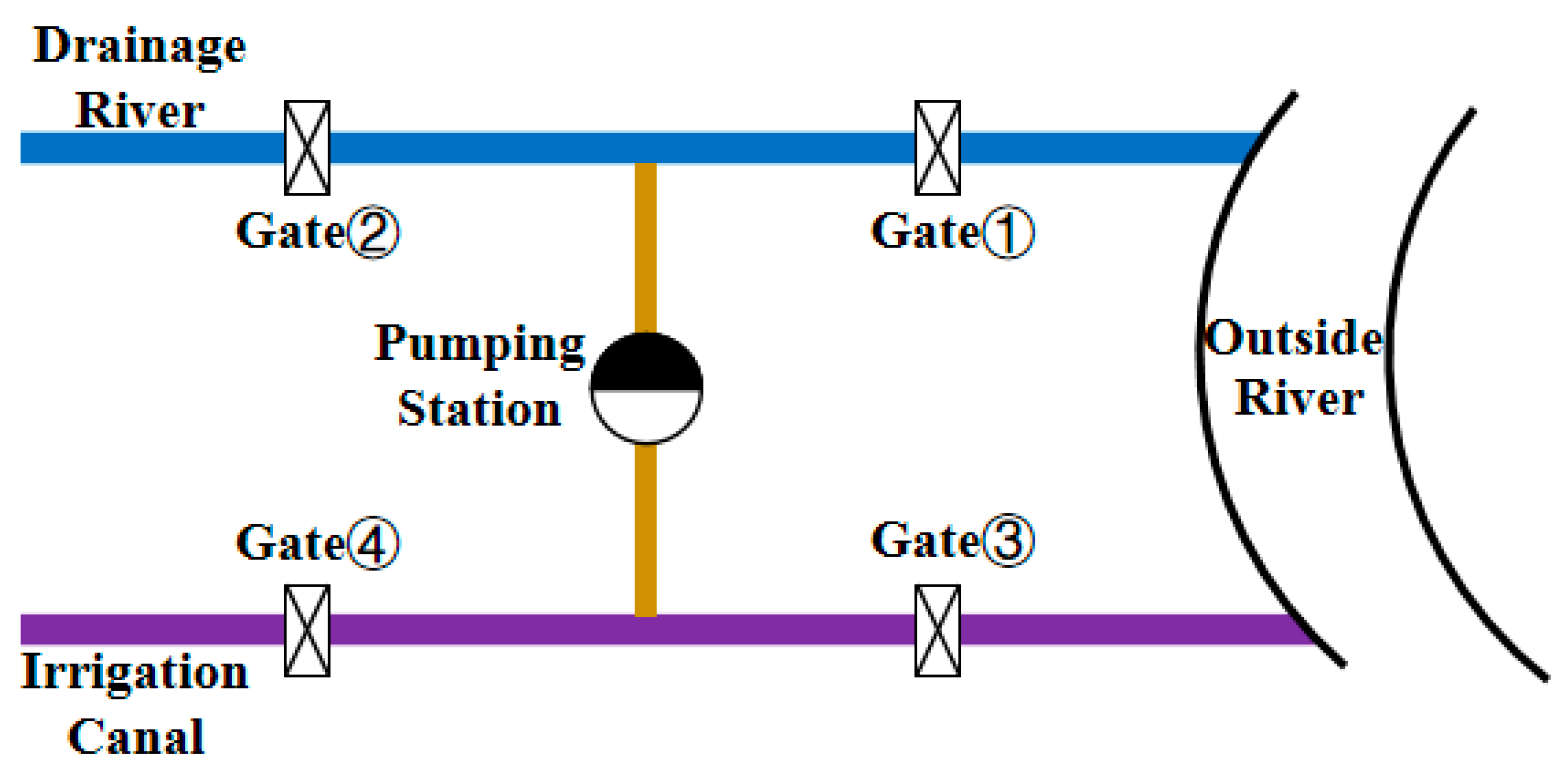

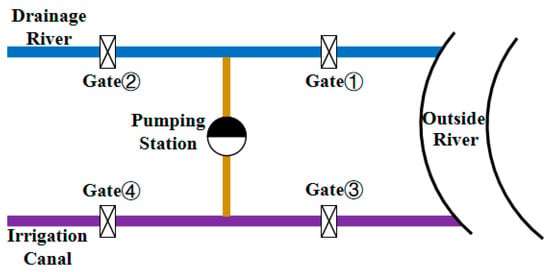

Pumping stations, serving as critical nodal projects in the development of the water network, play a vital role in flood control, disaster mitigation, and the allocation of water resources [1]. Low-head pumping stations are predominant in flat regions such as the middle and lower reaches of the Yangtze River and the Pearl River Delta in China [2]. Furthermore, they represent a significant component of the eastern route of the South-to-North Water Diversion Project. Based on their functions, low-head pumping stations can be categorized into irrigation pumping stations, drainage pumping stations, and combined irrigation-drainage pumping stations. These stations contribute significantly to agricultural irrigation and drainage, urban flood control and disaster reduction, and inter-basin water transfer [3]. In earlier designs, low-head pumping stations were primarily developed with a single function—specifically for either irrigation or drainage—based on regional or municipal planning considerations. However, with the ongoing advancements in water conservancy projects and the accelerating process of urban–rural integration in China, these single-function low-head pumping stations have proven inadequate to address the dual demands of both irrigation and drainage. This inadequacy is particularly apparent in plain regions adjacent to rivers, where complex geographical features and uneven spatiotemporal distribution of water resources frequently result in resource wastage and diminished operational efficiency within traditional single-purpose stations. As a result, combined irrigation–drainage pumping stations have emerged. They offer significant advantages in enhancing operational efficiency, reducing both capital and operational costs, improving disaster prevention and mitigation capabilities, as well as adapting to complex topographical and hydrological conditions [4]. To achieve both irrigation and drainage functions simultaneously, sluice gates are often installed alongside pumping stations within low-head pumping hub projects. This configuration facilitates irrigation through pumping while enabling drainage via the opening of the gates. A typical configuration, illustrated in Figure 1, is the “one station with four gates” model. This system consists of a single pumping station and four sluice gates. Through coordinated operation of these four gates alongside the pumping station, four operational modes can be achieved: gravity diversion, gravity drainage, pumping diversion, and pumping drainage.

Figure 1.

The “one station with four gates” combined irrigation and drainage pumping station.

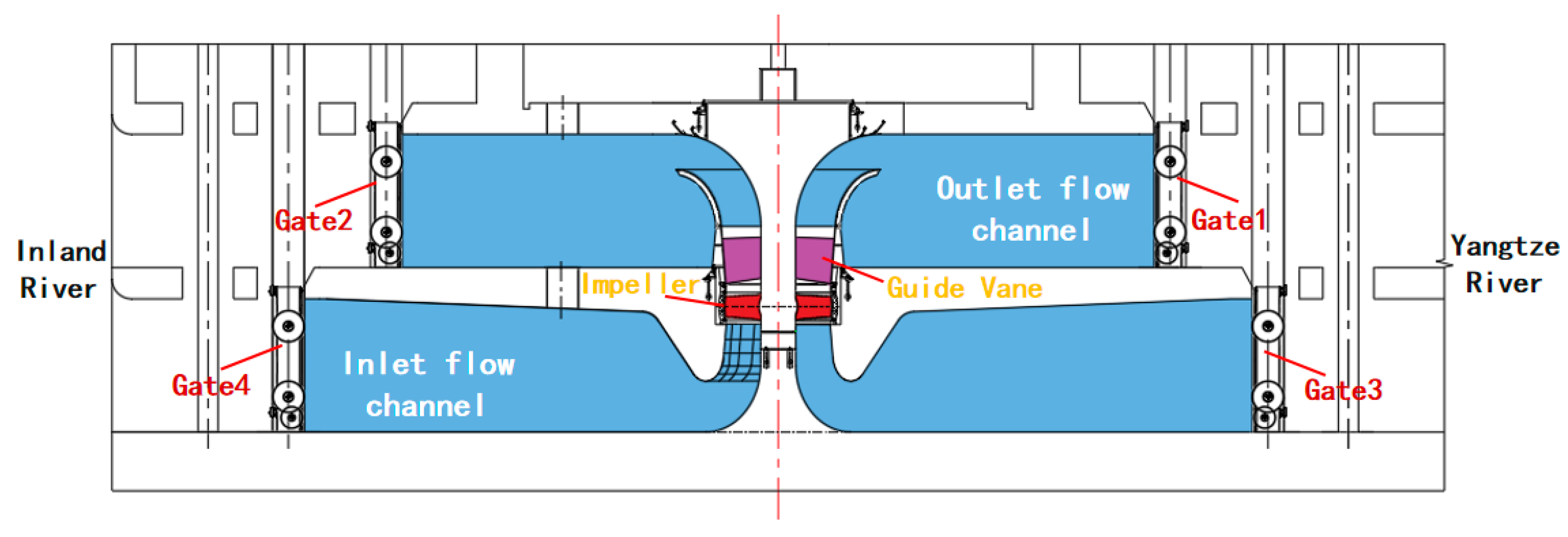

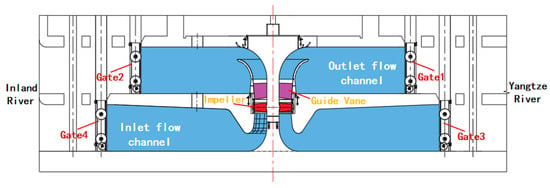

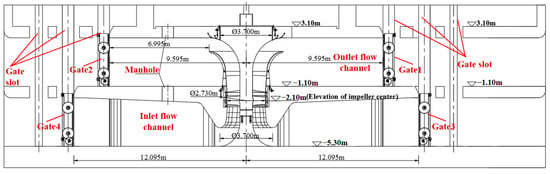

While the “one station with four gates” model can achieve four operational modes—gravity diversion, gravity drainage, pumping diversion, and pumping drainage—it requires a significant footprint, encompasses numerous auxiliary structures, and incurs high construction and operational costs [5]. To mitigate these limitations while simultaneously fulfilling the dual requirements for irrigation and drainage, researchers have conducted extensive investigations into two-way pumping systems integrated with one-way channels [6,7,8] and one-way pumping systems integrated with two-way channels [9,10,11]. Among these, one-way pumping systems integrated with two-way channels are increasingly prevalent in horizontal pumping applications, such as tubular pumps. This design facilitates two-way functionality by reversing the operation of the two-way pump, thereby enabling both irrigation and drainage capabilities. On the other hand, one-way pumping systems integrated with two-way channels primarily adopt the box culvert-type two-way channel, which merges the characteristics of a bell-shaped channel with an open sump. This particular design is widely employed in combined irrigation and drainage pumping stations situated in polder regions along riverbanks and lakes throughout China [12]. As shown in Figure 2, this configuration comprises upper and lower flow layers. The upper layer functions as the outlet channel, whereas the lower layer serves as the intake channel. Gates are strategically installed on both sides of each layer. Through the coordinated operation of four gates across these layers, coupled with the one-way pump, four operational modes can be achieved: gravity diversion, gravity drainage, pumping diversion, and pumping drainage [13].

Figure 2.

Sectional view of the box culvert-type two-way channel pumping station.

China is among the earliest countries in the world to adopt the two-way channel pumping system. This type of pumping system is widely implemented in the riverine plain regions of China [14]. Taking the Jiangsu riverine area as a case study, it is observed that due to the minimal difference between inland and external river water levels, coupled with frequent alternations between drought and flood conditions, low-head pumping stations in these regions must effectively serve both irrigation and drainage functions. The box culvert-type two-way channel pumping system has proven to be one of the most suitable configurations for these applications.

As early as the 1960s, Academician Zhou Junliang [15] first proposed the “X”-shaped two-way channel pumping station in China. This innovative design allows for four operational functions—gravity diversion, gravity drainage, pumping diversion, and pumping drainage—while significantly minimizing land use requirements, engineering workload, and investment costs. The inaugural application of Zhou Junliang’s “X”-shaped two-way channel pumping station was seen in the renovation of the Wudingmen pumping station in Nanjing. This project circumvented extensive residential demolitions and resulted in savings exceeding 10 million yuan [16]. In 1994, the Jianbi pumping station, which utilized this innovative “X”-shaped two-way channel structure, was awarded the National Silver Medal for Outstanding Engineering Design. In recent years, several newly constructed or renovated pumping stations located within riverine plain areas—including Xingou River pumping station, Zongyang Station, Wangyu River pumping station, Xueliujing pumping station, and Jiuqu River pumping station—have also adopted this effective box culvert-type two-way channel pumping system.

With the advancement of water infrastructure construction in China, box culvert-type two-way channel pumping stations have played a crucial role in optimizing water resource allocation in plain regions, enhancing regional flood control and drainage capabilities, and improving the aquatic ecological environment. Due to the unique structural characteristics of the two-way channel, large-scale backflow and vortex zones frequently develop at the blind ends during normal operation, significantly compromising the safe and efficient performance of the pumps.

In recent years, experts and scholars have conducted extensive research on the two-way channel pump. Related studies primarily employ two approaches: numerical simulation and experimental investigation. In terms of numerical simulation, Wang et al. [17] used the SST-CC turbulence model and the ZGB cavitation model based on the method of RANS to simulate the clearance cavitation of the two-way pump. Kan et al. [18] employed the entropy production method for both visualization and quantitative analysis of high-energy-loss regions within critical components, aiming to investigate the variations in energy loss during the transition process of a two-way axial-flow pump. Wang et al. [19] examined the East Route of the South-to-North Water Diversion Project in China as a prospective case to conduct a comprehensive technical assessment of scale effects related to energy conversion in ultra-low-head pumped hydroelectric storage (PHES) units. Subsequently, they performed a generalized economic analysis that took into account both benefits and stability. Regarding experimental research, Zhao et al. [20] develops a high-precision multi-channel synchronous pressure measurement system for simultaneous acquisition of pressure fluctuation signals across the vaneless space and draft tube. Liu et al. [21] employed high-precision pressure testing techniques to investigate the pressure fluctuations in both the vaneless space and draft tube within the S-shaped region. This study combined time and frequency domain analyses with chaos theory through a series of experimental tests. Furthermore, some researchers have adopted a combined approach of experiment and numerical simulation. For example, Jiao et al. [22] used the entropy production method with computational fluid dynamics and the high-frequency pressure fluctuation test to analyze the pump device’s internal energy loss and pressure fluctuation. Zhang et al. [23] developed a specialized experimental test bench for evaluating coastal axial flow pumping systems. Through unsteady numerical simulations, the energy loss characteristics and propagation behavior of CAPS under both PC and TC conditions were investigated. The simulation results were subsequently compared with the experimental findings to validate the accuracy of the model. Xue [24] used a numerical and experimental study to investigate the structural vibrations of the water pump turbine, a part of the world’s first hydro-solar combined power generation system.

In terms of research content, current studies on two-way channel pumps primarily focus on hydraulic optimization design and hydraulic stability analysis. For instance, Tao et al. [25] conducted a numerical simulation study on the influence of the outlet diffusion section’s diameter on the hydraulic performance of the two-way channel pumping system, based on an elliptical profile design of the flow channel outlet. Their study revealed the impact mechanism of the overall diameter of the diffusion section on pump performance. Li [26] performed flow pattern analysis and hydraulic optimization of the inlet and outlet channels of the X-type two-way channel pumping system, and discussed the application of optimized hydraulic design in real-world pumping station projects. Wang et al. [27] carried out model testing and numerical simulations on the hydraulic characteristics of the vertical axial-flow pumping system at Weicun Hub pumping station, identifying that hydraulic losses in the two-way outlet flow channel are the primary factor affecting pump efficiency. Jiao et al. [28] aimed to address the pressure pulsation caused by pump cavitation during bidirectional operation of low head pumped storage systems. They used a combination of experimental measurements and CFD simulations to systematically reveal the evolution of cavitation and pressure fluctuation characteristics. Duan et al. [29] studied the impact of unsteady flow-induced hydraulic excitation on the stable operation of pumping stations, clarifying the characteristics of hydraulic excitation and identifying the main sources of excitation forces. Xiao et al. [30] classified common failure types in two-way channels into hydraulic, mechanical, and electrical faults, provided detailed analyses of the causes of typical failures, and proposed targeted improvement measures to ensure the safe and stable operation of two-way channel pumping stations. Zhao et al. [31] examined the energy conversion mechanism in the pump section of a vertical mixed-flow pump under pumps as turbines conditions. They identified circumferential forces that are strongly correlated with the fluid-driven forces acting on the impeller by decomposing the fluid forces acting on the impeller using an impeller force field model. Wang et al. [32] employed the Liutex method to analyze the vortices in the outlet passage of a pump device at various moments during a cycle. Their findings revealed that the vortices can be categorized into three distinct types: lumpy vortices, strip vortices, and sheet vortices, depending on the specific moment observed. Zhao et al. [33] systematically investigated the evolution of three-dimensional corner vortices in the runner and their cross-scale effects on hydraulic efficiency and pressure fluctuations through combined experimental and numerical approaches.

In conclusion, existing research on box culvert-type two-way channel pumping stations has yielded substantial results, which partially fulfill engineering application requirements. However, for the construction of a specific pumping station, it remains essential to conduct relevant performance tests on the pump device model in accordance with the Water Conservancy Industry Standard SL 140-2006 [34], Acceptance Test Procedures for Pump Models and Device Models, to ensure efficient and stable operation during actual service. Therefore, to guarantee the reliable performance of the newly built pumping station in China, this study carries out a physical model test on the box culvert-type two-way channel system, obtaining key performance characteristics, including energy characteristics, cavitation phenomena, runaway behavior, and pressure pulsation characteristics. These findings provide a scientific basis for the hydraulic optimization design and operational management of similar pumping stations. Following this introduction, Section 2 describes the project profile and key parameters. Section 3 details the experimental setup, model specifications, test procedures, and measurement uncertainty analysis. Section 4 presents and discusses the results from energy performance, cavitation, runaway, and pressure pulsation tests. Finally, Section 5 summarizes the main conclusions drawn from the study.

2. Project Profile

This study takes a two-way pumping station in Jiangsu Province as its prototype. The station operates under two conditions: drainage and diversion, with drainage being the primary function and diversion supplementary. Both operational directions achieve a flow rate of 60 m3/s. For drainage, the net head ranges from 0 to 3.37 m, with a design net head of 2.66 m. For diversion, the net head ranges from 0 to 3.33 m, with a design net head of 2.37 m. The key head parameters of the pumping station are summarized in Table 1.

Table 1.

The key head parameters of the pumping station.

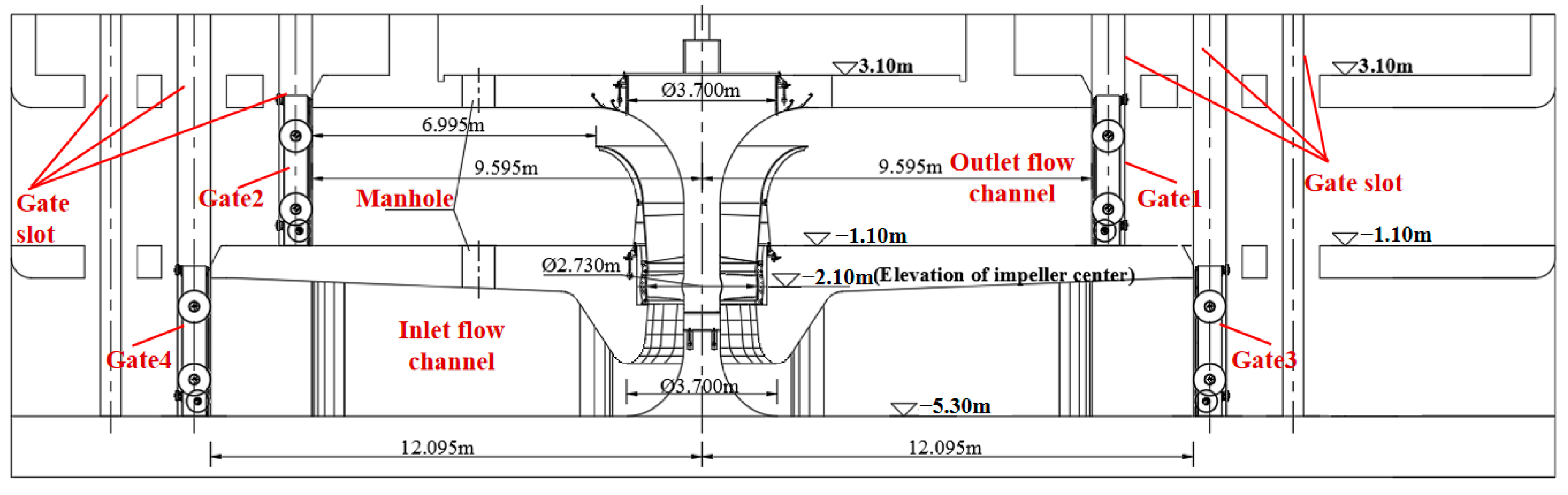

The pumping station is equipped with three sets of fully adjustable vertical axial-flow pumps. Each pump has a design flow rate of 20 m3/s and features an impeller diameter (D0) of 2730 mm, with three blades per impeller. The blade angles can be adjusted within a range of −8° to +2°, a setting determined by the manufacturer to cover the required head-flow operational envelope while maintaining mechanical safety. The rated rotational speed of the impeller is set at 136.4 r/min. Each pump is coupled to a vertical synchronous motor rated at 1120 kW, which operates at a voltage of 10 kV through direct drive. The station employs an X-type two-way channel, with impeller installation elevation set at −2.10 m. On both the inner section (facing the station) and outer section (facing river side), each is equipped with two quick-operating gates as well as one safety grille. A longitudinal sectional view of the pumping station is illustrated in Figure 3.

Figure 3.

Longitudinal sectional view of the pumping station.

3. Model Test

3.1. Test Facility

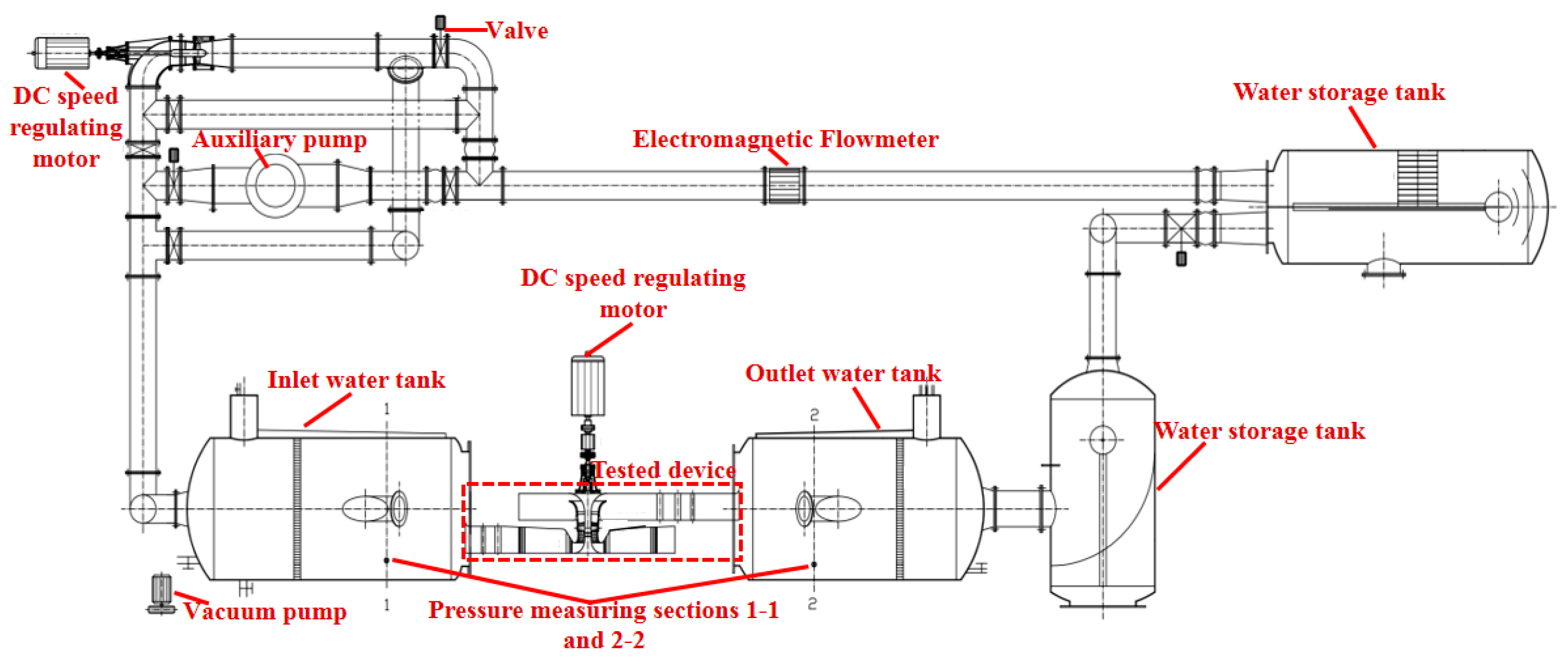

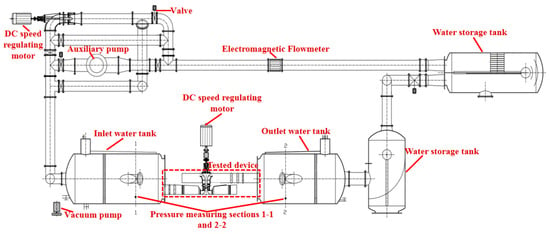

The testing of the model pump device for the pumping station is conducted using a high-precision test rig located at the Fluid Power Engineering Laboratory, part of the Jiangsu Province Key Laboratory of Water Resources and Power Engineering at Yangzhou University. As shown in Figure 4, this test rig operates as a closed-loop system that includes a hydraulic circulation system, power system, control system, and measurement system.

Figure 4.

Model pump device for the pumping station.

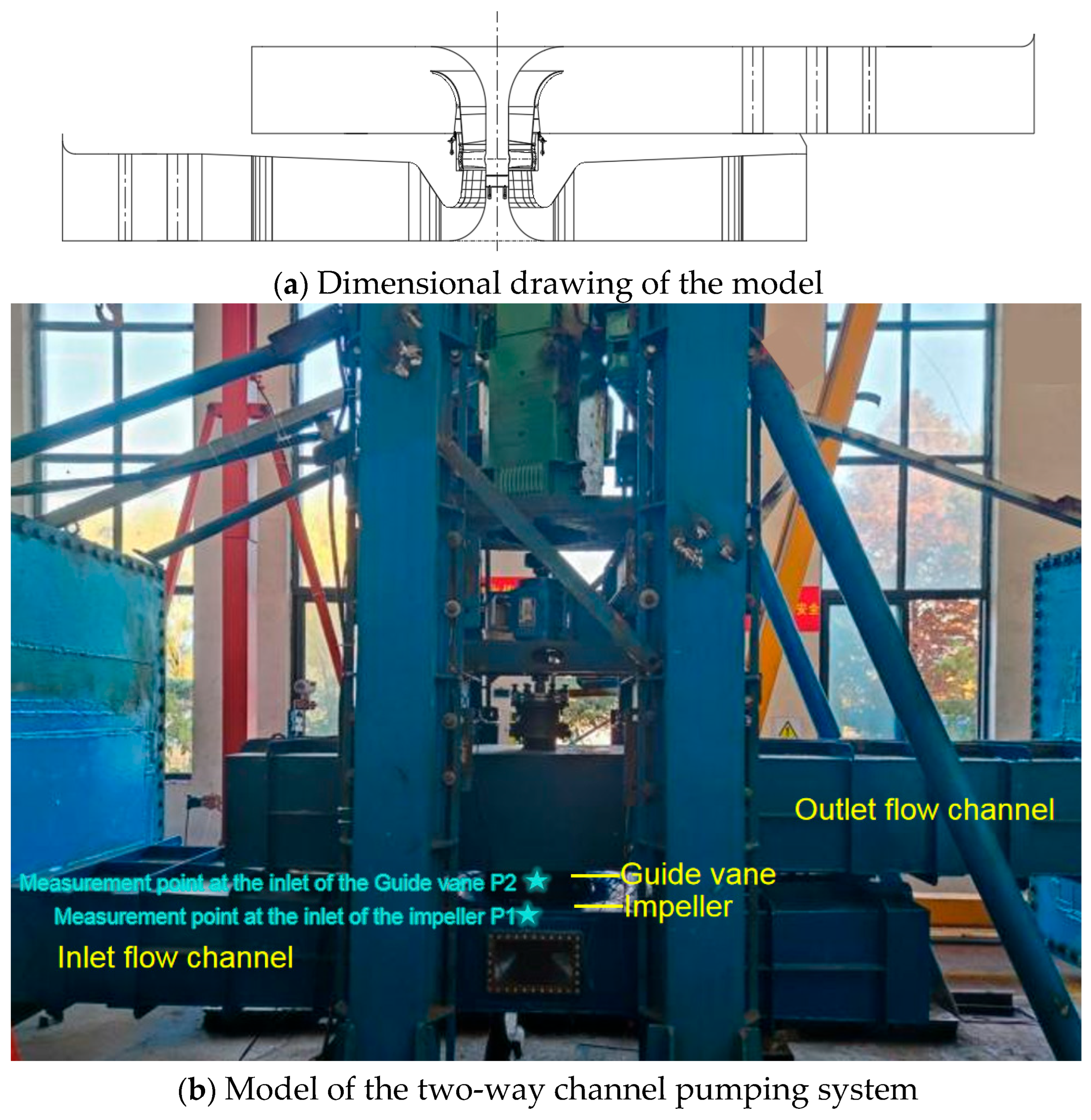

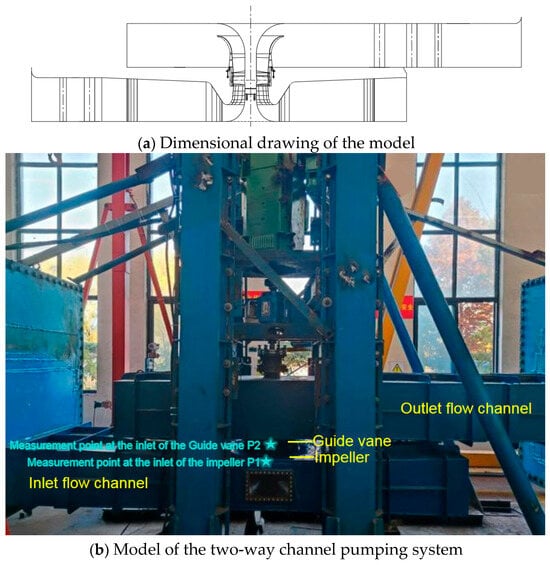

Figure 4 illustrates the tested device, which represents a model of the two-way channel pumping system utilized at the pumping station. This model consists of an “X”-type double-layer box culvert inlet/outlet flow passage, an impeller, a guide vane, and gate slots. It maintains geometric similarity with its prototype. The dimensional drawing of the model is illustrated in Figure 5a, while its physical photograph is displayed in Figure 5b. The inlet channel of the model unit is constructed by welding steel plates that are 5 mm thick, ensuring that machining accuracy and dimensions conform to the permissible deviations outlined in the Code for model pump and its installation acceptance tests (SL140-2006). To guarantee satisfaction of hydraulic loss similarity between the model and prototype, polyurethane paint has been applied to the inner surfaces of both inlet and outlet flow passages.

Figure 5.

Dimensions and physical image of the pumping system model.

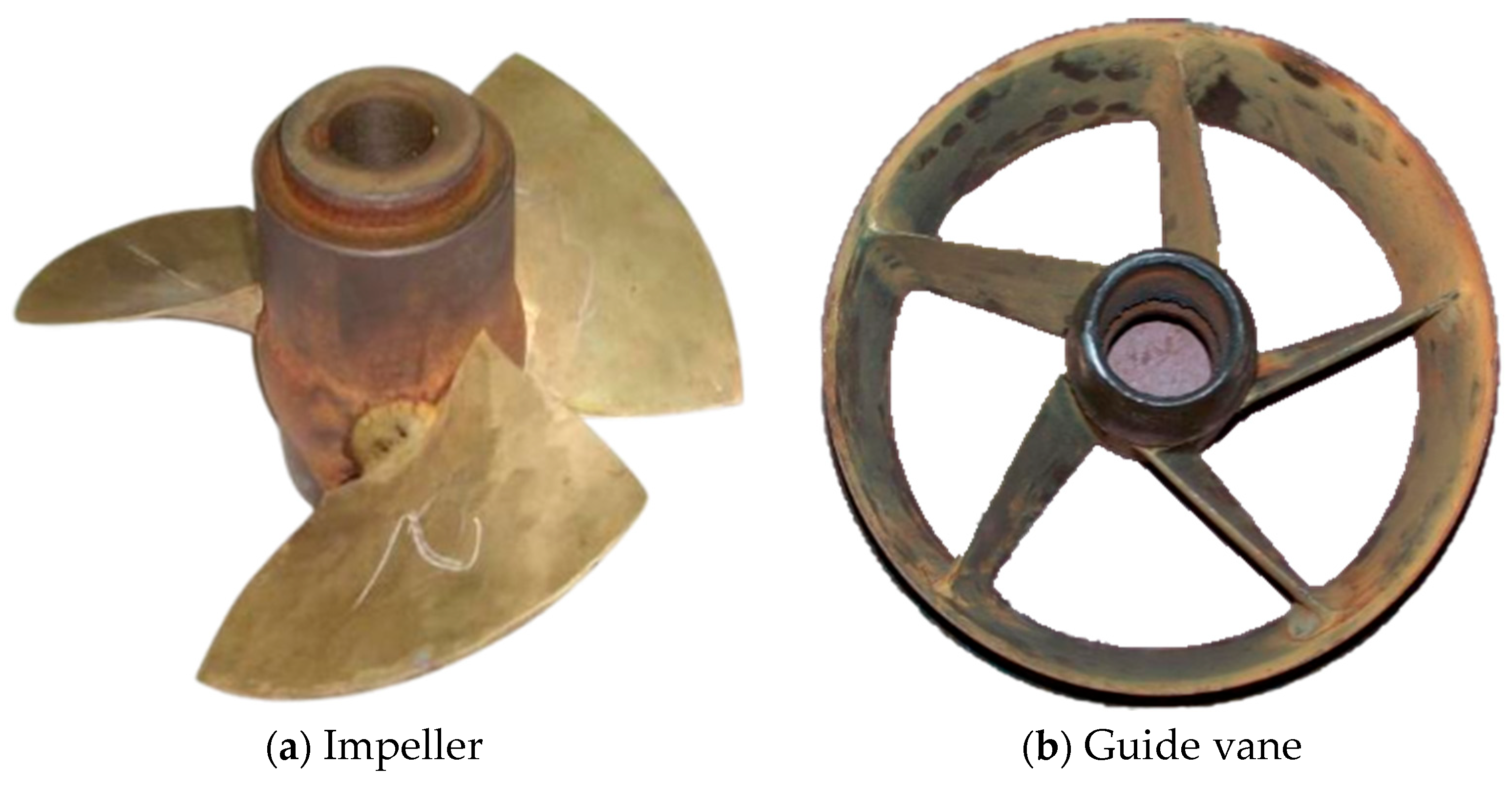

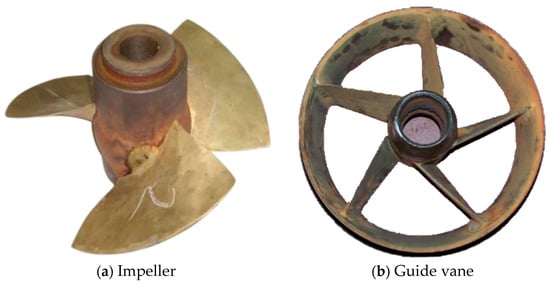

The model pump serves as the fundamental component of the pumping system model. This system utilizes the TJ04-ZL-07 hydraulic model (China), which has been subjected to comparative testing alongside the South-to-North Water Diversion Project at the same facility. The model pump features a three-blade impeller and a five-blade guide vane assembly. The impeller, with a diameter (D) of 300 mm, is constructed from bronze material using computer numerical control (CNC) machining, as depicted in Figure 6. To enable adjustments to the blade angles, the impeller casing adopts a horizontally split design. The dimensional tolerances of the impeller and guide vanes meet the requirements of relevant specifications.

Figure 6.

Physical image of the model pump.

3.2. Experimental Procedures and Measurement Methodologies

To fulfill the practical engineering application requirements for the pumping system model, an experimental program was crafted in accordance with the Code for model pump and its installation acceptance tests (SL140-2006). The testing regimen includes four primary components: energy characteristics, cavitation phenomena, runaway behavior, and pressure pulsation characteristics. These tests were conducted across six different blade angles, ranging from −8° to +2°. During the energy characteristic tests, cavitation was meticulously avoided. The rotational speed was established through nD similarity conversion and set at 1241.2 rpm. The energy characteristic assessments encompassed operating conditions corresponding to maximum, design, average, and minimum head levels; during these evaluations, the model impeller’s blade angle was adjusted to 2°. For the cavitation phenomena test, a constant flow rate was maintained while systematically reducing the net positive suction head (NPSH) of the system. The critical cavitation parameter (NPSHc) is defined as the NPSH value at which there is a 1% decrease in efficiency [35,36]. In evaluating runaway characteristics, an auxiliary pump generated reverse hydraulic head to drive the impeller into free rotation—simulating load rejection conditions typical of pump-as-turbine scenarios—while simultaneously recording both rotational speed and flow rate. The pressure pulsation test incorporated high-frequency pressure sensors installed at both the inlet and outlet of the impeller, as well as at the guide vane outlet, to accurately capture instantaneous pressure fluctuations.

3.3. Test Uncertainty Analysis

To ensure the reliability of the model test results, an uncertainty analysis was performed on the pumping system model test. This analysis primarily consists of two components: the uncertainty analysis of the test bench system and the random test uncertainty analysis.

3.3.1. Test Bench System Uncertainty Analysis

The uncertainty of the test bench system is calculated as the square root of the sum of the squares of the uncertainties from each individual subsystem, that is

Due to the large cross-section of the inlet water tank and the pressure water tank, the flow rate is low, and the dynamic head can be neglected.

- where EQ represents the systematic uncertainty in flow measurement, and the calibration result is 0.16%; EH represents the systematic uncertainty in head measurement, which has been calibrated to 0.1%; EM represents the systematic uncertainty in torque measurement, which has been calibrated to 0.12%; En denotes the systematic uncertainty in rotational speed measurement, which is ±0.06% under conditions of a 2 s sampling interval and a rotational speed of at least 1000 r/min.

3.3.2. Random Test Uncertainty Analysis

The repeatability of the energy performance test is assessed based on the dispersion characteristics of the efficiency measurements from the pump device model tests. The random uncertainty is calculated using the following formula:

where denotes the standard deviation of the mean efficiency; N is the number of measurements (N = 20); is the i-th efficiency measurement; is the average efficiency, and t0.95(N−1) is confidence coefficient corresponding to a 95% confidence level and (N−1) degrees of freedom. For N = 20, t0.95(N−1) = 1.7291.

When the blade installation angle of the water pump was set to −2° and the flow rate was maintained at 241.55 L/s, 20 sets of data were obtained through repeated testing. The calculation results based on the experimental data are presented as follows:

In this study, the measurement values were determined as the arithmetic mean of 20 repeated measurements. Accordingly, the random uncertainty of the energy performance test for the pump device is expressed as follows:

3.3.3. Comprehensive Uncertainty Analysis of the Pumping Unit Model Efficiency Test

In this experiment, the comprehensive uncertainty of the pump device’s test efficiency is calculated as the square root of the sum of the squares of the systematic and random uncertainties.

In conclusion, the comprehensive uncertainty of the test efficiency for the pump device is ±0.355%, which meets the requirements of national standard GB 3216-2016 [37] (equivalent to ISO 9906:2012 [38]) Level 1 (δη ≤ ±2.9%), GB/T l8l49-2000 [39] (equivalent to ISO 5198: 1999 [40]) (δη ≤ ±2.25%), and the industry standard SL 140-2006 of the Ministry of Water Resources (δη ≤ ±0.40%). These results demonstrate a high level of measurement accuracy.

4. Results and Discussion

4.1. Energy Performance Test

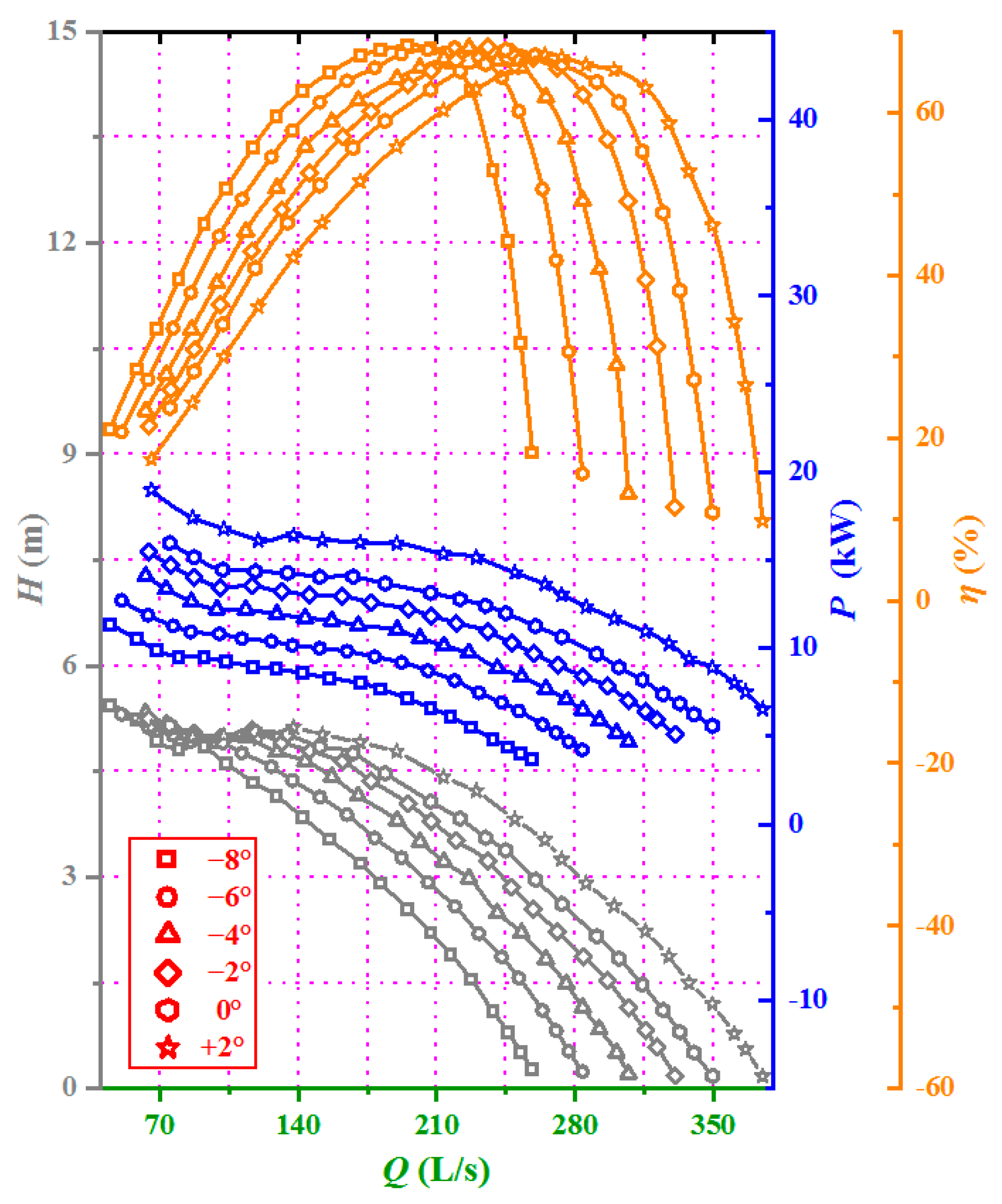

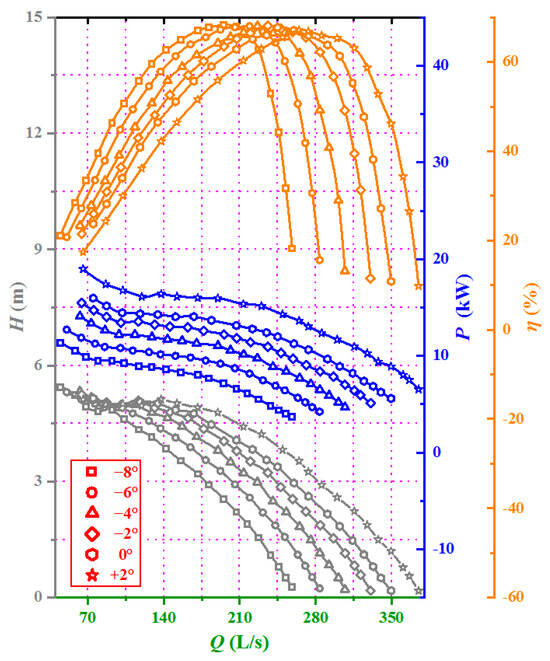

Figure 7 presents the performance curves of the pumping system at different blade angles. The energy performance tests were conducted on the model pump unit at six blade angles: −8°, −6°, −4°, −2°, 0°, and +2°. This range was selected as it represents the entire designed operational envelope for the prototype pump, as specified by the manufacturer to cover the required spectrum of net heads (0–3.37 m for drainage and 0–3.33 m for diversion) while maintaining structural safety and hydraulic stability. During these tests, the head, power, and efficiency of the pumping system were measured under various flow conditions. At the design head condition, the efficiencies corresponding to the six blade angles from −8° to +2° were 67.5%, 67.7%, 67.6%, 68.0%, 67.4%, and 66.5%, respectively. From the overall trend of the flow–efficiency curves, it can be observed that as the blade angle increases from negative to positive values, the high-efficiency region shifts toward higher flow rates, while the peak efficiency remains relatively stable. The highest efficiency of the pump unit, 68.0%, was achieved at a blade angle of −2°. Regarding the flow–head curves, the results indicate that with the increase in blade angle from negative to positive values, the entire head curve shifts toward higher flow rates. Except within the low-flow saddle zone, the head generally increases under the same flow condition as the blade angle becomes more positive. The flow–power curves show that under identical flow conditions, the power consumption gradually rises as the blade angle changes from negative to positive values. It is noteworthy that, by comparing the flow–head curves, a distinct saddle zone is evident at the positive extremity of the tested range (+2°), where the head exhibits significant fluctuations. In contrast, at negative blade angles, the head variations within the saddle zone are comparatively smaller, indicating more stable operational performance. These results validate the engineered angle range: operation beyond the negative limit would shift the best efficiency point away from the design flow, while exceeding the positive limit would intensify hydraulic instability, thereby justifying the selected range for safe and efficient pumping station operation.

Figure 7.

The performance curves of the pumping system at different blade angles.

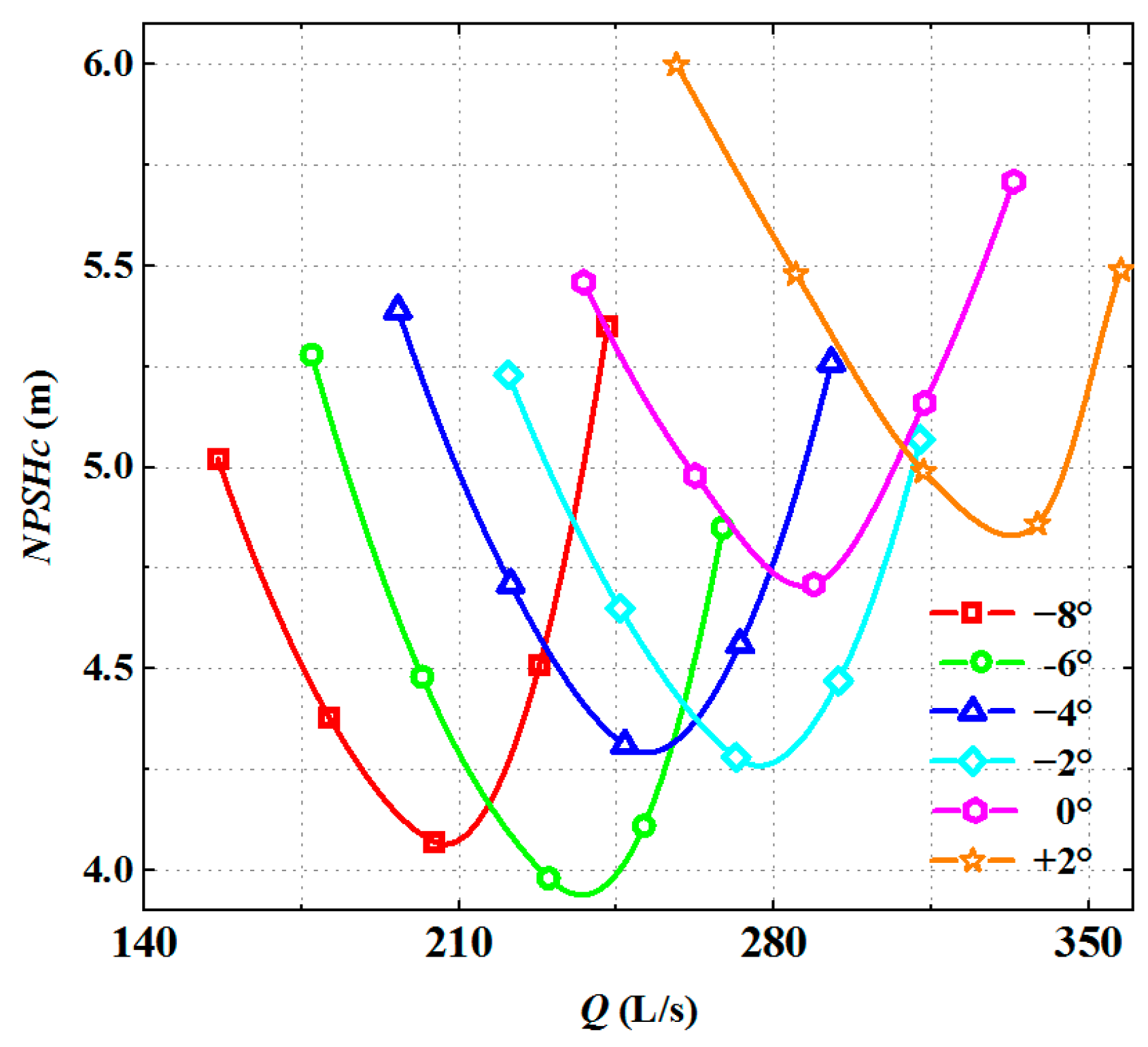

4.2. Cavitation Performance Test

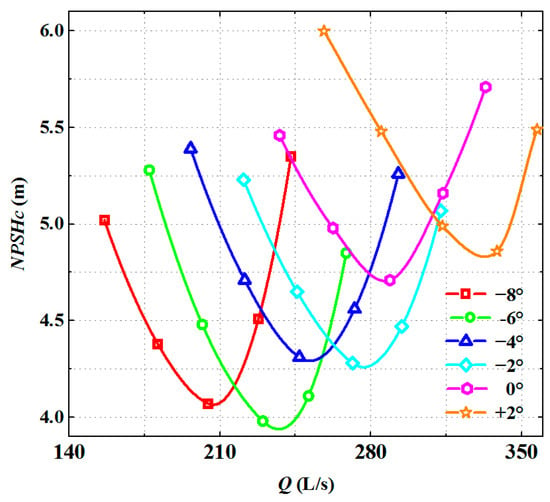

Cavitation performance tests were conducted at six blade angles under five distinct characteristic head conditions, yielding the cavitation performance curves of the pumping system model as shown in Figure 8. It should be noted that the corresponding heads for the five characteristic conditions remained relatively consistent across different blade angles, albeit with minor variations. As illustrated in the figure, the critical net positive suction head (NPSHc) of the pump unit initially decreases and then increases with rising head. Under the same blade angle, the cavitation performance of the model pump unit is optimal at the design head condition, where the corresponding critical NPSH is also the lowest. Across different blade angles, the critical NPSH corresponding to the same characteristic head generally exhibits a negative correlation with the blade angle. That is, as the blade angle increases from negative to positive values, the critical NPSH of the pump unit gradually increases, indicating a deterioration in cavitation performance.

Figure 8.

Cavitation performance curves of the pumping system model.

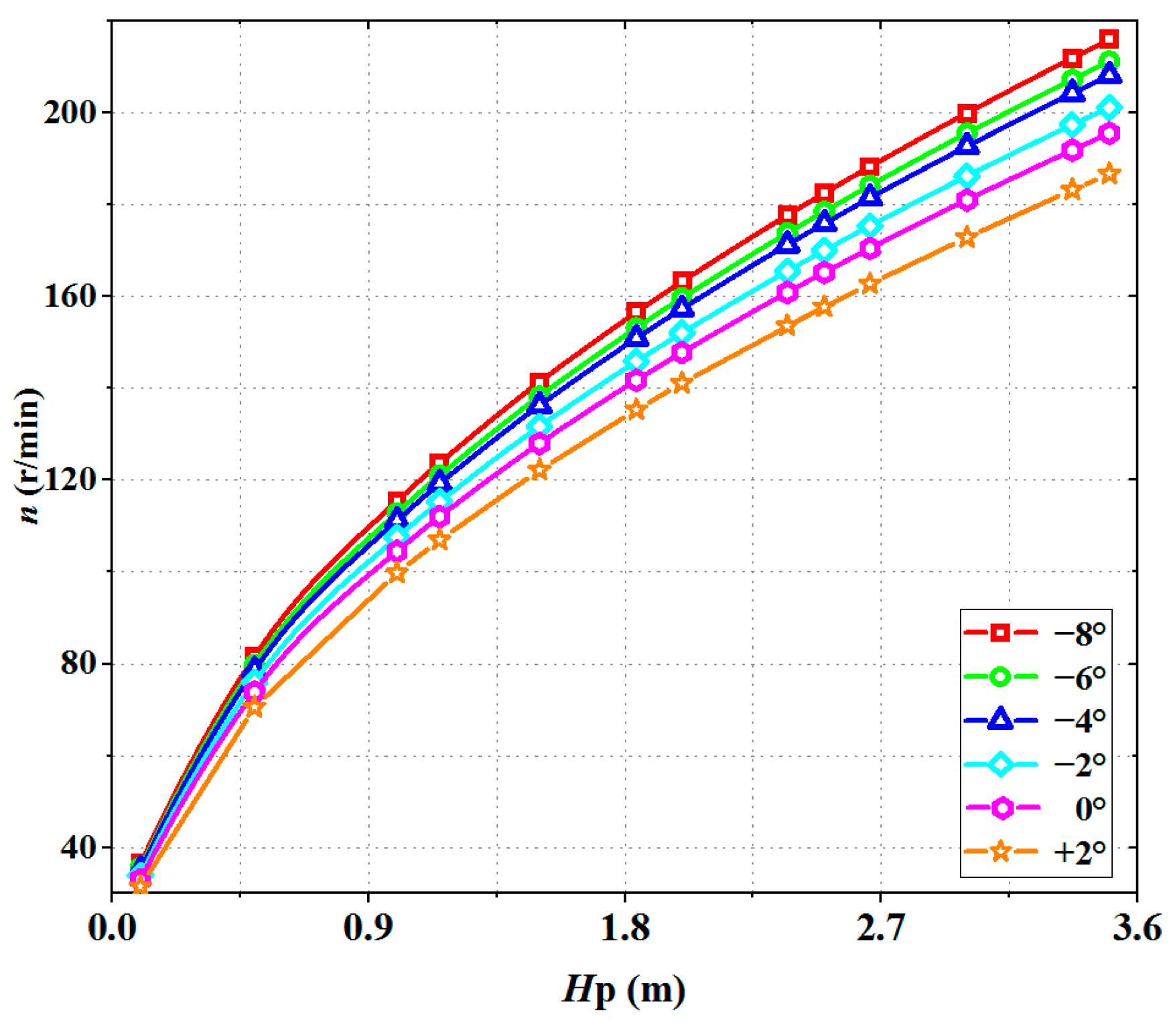

4.3. Runaway Performance Test

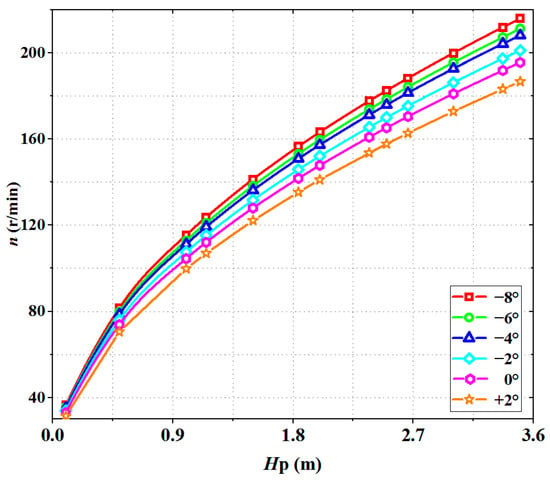

Runaway characteristic tests were conducted under six blade angle conditions, and the resulting runaway performance curves are presented in Figure 9. As shown in the figure, the runaway speed increases with the rise in reaction head under each blade setting angle. At the same reaction head, the runaway speed decreases as the blade setting angle increases. The prototype pump attains its maximum runaway speed at a blade setting angle of −8°.

Figure 9.

Runaway performance curves of the pumping system model.

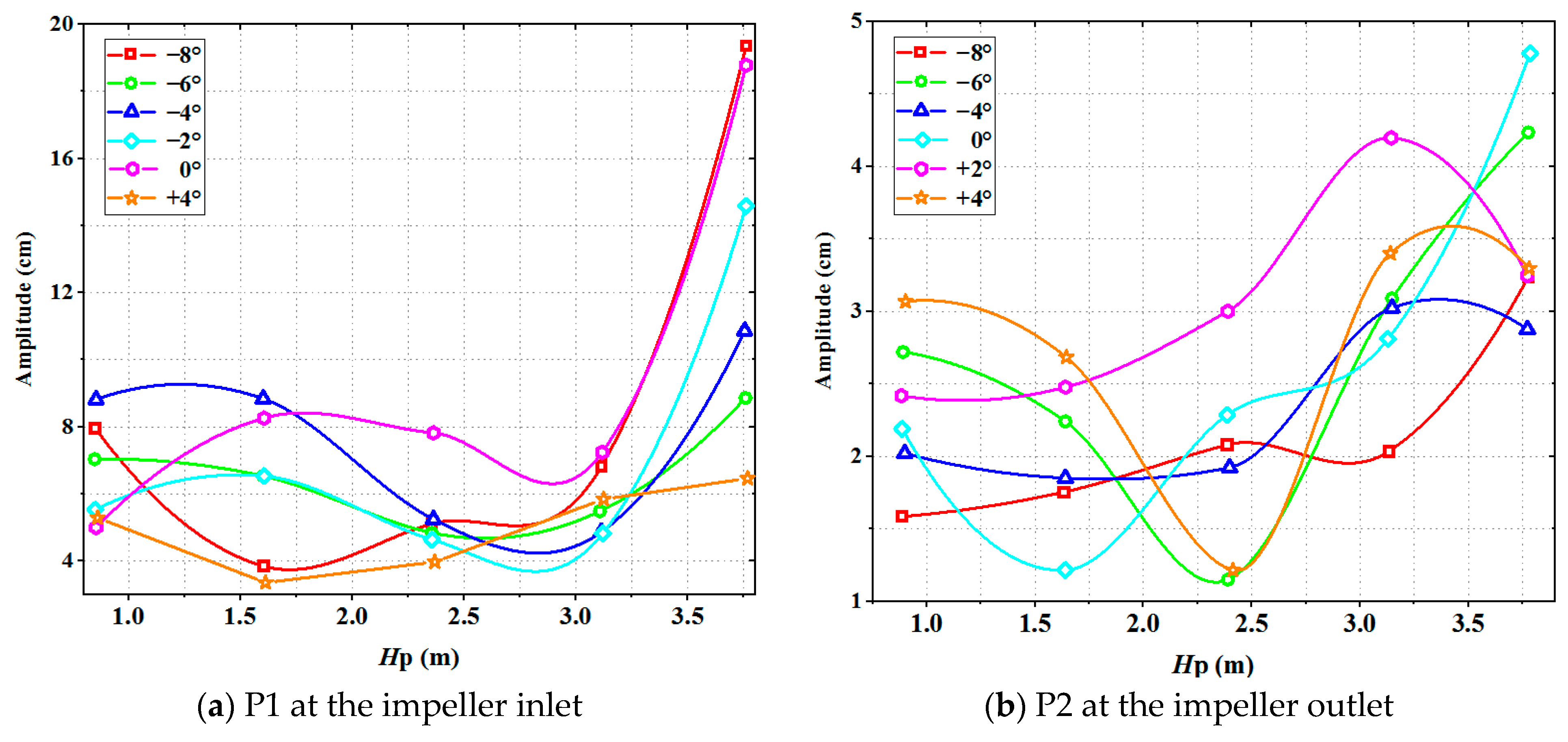

4.4. Pressure Pulsation Performance Test

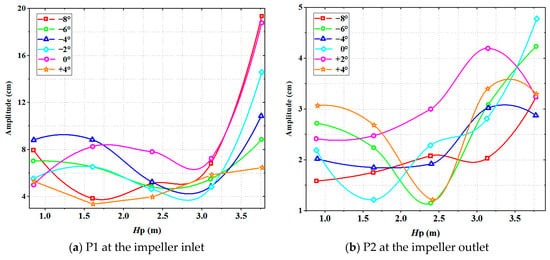

Pressure pulsation characteristic tests were conducted at six blade setting angles under five characteristic head conditions, and the resulting relationship curves between pressure pulsation amplitude and head for the model pump unit are shown in Figure 10. The tests focused on two measurement points: the pump impeller inlet (P1) and the pump impeller outlet (guide vane inlet, P2). The pressure pulsation data were processed using a bilateral amplitude statistical method with a 97% confidence level, and the pressure values were converted into equivalent water column height. The variation in pressure pulsation amplitude with head under different operating conditions at the five blade angles is illustrated in Figure 10. As shown in the figure, the pulsation amplitudes vary to some extent across different blade angles and operating conditions. However, the amplitude values at both the impeller inlet and the impeller outlet measurement points remain below 0.20 m. Overall, the pressure pulsation of the model pump unit exhibits stable behavior.

Figure 10.

Pressure fluctuation amplitude curves at Monitoring Points.

5. Conclusions

This paper analyzes the hydraulic performance of the pumping system under different blade angles and different working conditions through the experimental study of the model of the box culvert-type two-way channel pumping system along the Yangtze River:

- (1)

- Under different blade angles, the efficiency, head and power of the pumping system show obvious differences. Under the design head condition, the pump efficiency is the highest at −2° blade angle, which is 68.0%. As the blade angle changes from negative to positive, the high efficiency zone shifts to the direction of large flow, but the maximum efficiency point changes little. The head and power increase with the increase in blade angle, but when the blade angle is positive, the saddle area of the pumping system is more obvious, and the head variation is larger.

- (2)

- The critical cavitation margin of the pumping system decreases first and then increases with the increase in head. Under the same blade angle, the cavitation performance under the design head condition is the best, and the critical cavitation margin is the smallest. Under different blade angles, the critical cavitation margin is negatively correlated with the blade angle; that is, the larger the blade angle, the worse the cavitation performance.

- (3)

- The results show that the runaway speed increases with the increase in reaction head at each blade angle, and decreases with the increase in blade angle at the same reaction head. When the blade placement angle is −8°, the runaway speed of the prototype pump is the maximum.

- (4)

- Under the conditions of different blade angles and characteristic heads, the pressure pulsation of the pump device is relatively stable as a whole, and the pulsation amplitudes of the impeller inlet and outlet are less than 0.20 m, indicating that the pressure fluctuation of the pump device is small and the hydraulic stability is good during operation.

In conclusion, the blade angle has a significant impact on the hydraulic performance of the box culvert two-way channel pump device. The operating efficiency, cavitation performance and stability of the pump device can be optimized by reasonably selecting the blade angle. The experimental results and operational insights presented in this study, derived from a standardized model test, bridge the gap between generalized research and specific engineering applications. They provide a validated reference for the hydraulic optimization design and operation of similar pumping stations, contributing to improved operational efficiency, reliability, and cost-effectiveness.

Author Contributions

Methodology, P.X., and L.L.; validation, P.X., L.L. and W.J.; formal analysis, P.X., L.L. and W.J.; data curation, L.L. and W.J.; writing—original draft preparation, P.X. and L.L.; writing—review and editing, P.X., L.L. and W.J.; funding acquisition, W.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Open Research Fund Program of State Key Laboratory of Water Disaster Prevention (2025492611), the Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions [PAPD], the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant No: 23KJB570003), and the Open Research Subject of Key Laboratory of Fluid and Power Machinery (Xihua University), Ministry of Education (Grant No: LTDL-2024011).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Pu Xu and Lingyu Li were employed by the company Shanghai Shangzi Engineering Design Co., Ltd. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Ding, P. Practice and Implications of Promoting National Water Network Major Projects with the New Era Water Management Philosophy. Water Resour. Dev. Res. 2024, 24, 15–18. [Google Scholar]

- Dai, Q.; Sheng, W.; Zhong, Z.; Xu, F.; Yao, W.; Wan, J. Key Technologies for Transformation and Renovation of low-Lift Pumping Stations. Jiangsu Water Resour. 2023, 5, 13–16. [Google Scholar]

- Li, G. Further Comprehensively Deepen Water Conservancy Reform to Promote High-Quality Development of Water Conservancy and Safeguard National Water Security: A Speech at the 2025 National Water Conservancy Work Conference. Water Resour. Dev. Res. 2025, 25, 1–12. [Google Scholar]

- Xu, J.; Xiao, R. Research on Energy-Saving Operation Technology for Large and Medium-Sized Irrigation and Drainage Pumping Stations; China Water & Power Press: Beijing, China, 2017. [Google Scholar]

- Yao, J.; Jiang, J. Application of New Structural Types in Small-Scale Combined Drainage and Irrigation pumping stations. Jiangsu Water Resour. 2014, 13+16. [Google Scholar]

- Sun, Z.; Zhu, Y.; Chen, J.; Wang, M.; Tang, F.; Lv, N.; Chen, S. Multi-objective Optimization of S-shaped Hydrofoil and Bidirectional Axial-flow Pumps Based on NSGA-II. Trans. Chin. Soc. Agric. Eng. 2024, 40, 39–48. [Google Scholar]

- Ma, P.; Wang, J. Influence of Geometric Parameters of Straight Guide Vanes on the Flow Field and Hydraulic Performance of Bidirectional Pumps. J. Hydraul. Eng. 2017, 48, 1126–1133. [Google Scholar]

- Ma, P.; Wang, J.; Wang, J.; Liu, W.; Cai, K. Flow Characteristics Analysis in Saddle Zone for High Specific Speed Bidirectional Pump. Fluid Mach. 2014, 42, 11–15+86. [Google Scholar]

- Li, L.; Chen, Y.; Tang, F.; Guo, C. Speed Regulation Performance and Test of Large Bidirectional Pump Device for Xinchuansha Pump and Sluice. Water Resour. Power 2024, 42, 167–170. [Google Scholar]

- Zhang, R.; Zhu, F.; Xia, Z.; Shao, Y.; Liu, X.; Zhou, W.; Li, C. Similarity Laws of Pressure Fluctuations for Vertical Dual-directional Pumping System. South-to-North Water Divers. Water Sci. Technol. (Chin. Engl.) 2024, 22, 1173–1180. [Google Scholar]

- Lin, P.; Bai, Z.; Tang, F.; Zhang, Y.; Zheng, B.; Wang, Y. The Influence of Guide Vanes on Force Imposed to Bidirectional Shaft Tubular Pump. J. Irrig. Drain. Eng. 2023, 42, 82–89. [Google Scholar]

- Chen, Y.; Li, L.; Jiao, W.; You, J. Performance Analysis of Vertical Flow Pump Device in X-channel Bidirectional Pump Station. South-to-North Water Divers. Water Sci. Technol. (Chin. Engl.) 2025, 23, 1–12. [Google Scholar]

- Zhou, J.; Liu, C.; Yuan, J.; Yan, B.; Tang, F.; Lu, L.; Feng, X.; Zhang, P.; Zhang, R. Model Test on the Two-way Suction Box of Large Pumping Station. J. Yangzhou Univ. (Nat. Sci. Ed.) 1999, 4, 79–82. [Google Scholar]

- Liu, C.; Zhou, J.; Tang, F.; Yuan, J.; Cheng, L. Study on a Low-lift and Two-way Pumping System. Trans. Chin. Soc. Agric. Mach. 2001, 1, 49–51. [Google Scholar]

- Zhou, J. Selection of Bidirectional Flow Passage pumping station Devices. Jiangsu Water Conserv. Technol. 1994, 4, 34–44+63. [Google Scholar]

- Dai, L. Analysis of the Characteristics of Bidirectional Flow Passage pumping stations. Jiangsu Water Resour. 1999, 7, 33–34. [Google Scholar]

- Wang, L.; Tang, F.; Liu, H.; Zhang, X.; Zhang, X.; Sun, Z.; Wang, F. Investigation of cavitation and flow characteristics of tip clearance of bidirectional axial flow pump with different clearances. Ocean Eng. 2023, 288, 115960. [Google Scholar] [CrossRef]

- Kan, K.; Zhao, F.; Xu, H.; Feng, J.; Chen, H.; Liu, W. Energy performance evaluation of an axial-flow pump as turbine under conventional and reverse operating modes based on an energy loss intensity model. Phys. Fluids 2023, 35, 015125. [Google Scholar] [CrossRef]

- Wang, H.; Wang, F.; Wang, C.; Wang, B.; Li, C.; Li, D. A prospective assessment of scale effects of energy conversion in ultra-low-head pumped hydro energy storage units. Energy Convers. Manag. 2024, 315, 118798. [Google Scholar] [CrossRef]

- Zhao, N.; Feng, J.; Zhu, G.; Li, Y.; Zhang, Y.; Luo, X. Spatiotemporal correlation evolution of pressure fluctuations in the hump region of a pump-turbine. J. Energy Storage 2026, 141, 119350. [Google Scholar] [CrossRef]

- Liu, B.; Feng, J.; Zhu, G.; Ge, Z.; Gao, L.; Luo, X. Chaotic characteristics of pressure fluctuations and operation state recognition in S-shaped region of a pump turbine. Mech. Syst. Signal Process. 2025, 239, 113294. [Google Scholar] [CrossRef]

- Jiao, W.; Chen, H.; Cheng, L.; Zhang, B.; Gu, Y. Energy loss and pressure fluctuation characteristics of coastal two-way channel pumping stations under the ultra-low head condition. Energy 2023, 278, 127953. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, F.; Jiang, Y. Experimental and numerical study of reverse power generation in coastal axial flow pumping system using coastal water. Ocean Eng. 2023, 271, 113805. [Google Scholar] [CrossRef]

- Xue, Y.; Jiao, Y.; Cheng, C.; Wang, S.; Yang, B.; Li, H.; Li, W. Numerical and experimental study of structural vibrations in pump turbines. Energy Rep. 2025, 14, 1987–1992. [Google Scholar] [CrossRef]

- Tao, X.; Liu, H.; Chen, Y.; Zhang, J.; Li, Y.; Li, Y. Influence of Outlet Diffusion Segment Diameter on the Hydraulic Performance of Bidirectional Flow Passage Pump Devices. Yangtze River 2025, 56, 162–168+185. [Google Scholar] [CrossRef]

- Li, F. Study on Flow Pattern and Hydraulic Optimization of X-Type Two way Pump System. Master’s thesis, Yangzhou University, Yangzhou, China, 2023. [Google Scholar]

- Wang, Q.; Yuan, Y.; Lv, Y.; Chen, Y.; Li, Y.; Yang, F. Model Test and Flow Field Analysis of a Bidirectional Vertical Pump Device for the Expansion and Reconstruction Project of Weicun Hub. China Rural. Water Hydropower 2022, 12, 168–172. [Google Scholar]

- Jiao, W.; Jia, X.; Cheng, L.; Xu, J.; Liang, A.; Fan, H.; Lu, J. Numerical simulation and experimental study on cavitation and pressure fluctuation characteristics of low head pumped storage system under pump operating conditions. Energy 2025, 328, 136515. [Google Scholar] [CrossRef]

- Duan, X. Research on the Hydraulic Excitation Characteristicsof the Axial-flow Pump Unit with Two-Way Channel. Ph.D. Thesis, Yangzhou University, Yangzhou, China, 2021. [Google Scholar]

- Xiao, Z.; Yan, H.; Jiang, H.; Cheng, L.; Liu, Z. Typical Fault Case Analysis of Two-way Passage Pumping Station. Jiangsu Water Resour. 2021, 12, 11–14. [Google Scholar]

- Zhao, H.; Cheng, L.; Jiao, W.; Xu, W.; Lei, S.; Shen, J. Study on the dynamic energy conversion mechanisms of a vertical mixed-flow pump under pump-as-turbine conditions. Energy Convers. Manag. 2025, 332, 119765. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, L. Research on the flow characteristics and energy variation characteristics of the outlet passage of a two-way flow pump device based on Liutex and energy balance equation method. Energy 2025, 318, 134805. [Google Scholar] [CrossRef]

- Zhao, H.; Zhu, B.; Wang, C.; Han, Y. A prospective assessment of vortex evolution mechanisms and pressure fluctuation coupling in novel low-head pumped hydro energy storage units. Energy Convers. Manag. 2025, 342, 120136. [Google Scholar] [CrossRef]

- SL 140-2006; Code for Model Pump and Its Installation Acceptance Tests. China Water & Power Press: Beijing, China, 2007.

- Fu, Q.; Zhang, F.; Zhu, R.; He, B. A systematic investigation on flow characteristics of impeller passage in a nuclear centrifugal pump under cavitation state. Ann. Nucl. Energy 2016, 97, 190–197. [Google Scholar] [CrossRef]

- Poullikkas, A. Effects of two-phase liquid-gas flow on the performance of nuclear reactor cooling pumps. Prog. Nucl. Energy 2003, 42, 3–10. [Google Scholar] [CrossRef]

- GB/T 3216-2016; Rotodynamic Pumps—Hydraulic Performance Acceptance Tests—Grades 1, 2 and 3. China Standards Press: Beijing, China, 2016.

- ISO 9906:2012; Rotodynamic Pumps—Hydraulic Performance Acceptance Tests—Grades 1, 2 and 3. National Organization for Standardization (ISO): Geneva, Switzerland, 2012.

- GB/T 18149-2000; Centrifugal, Mixed Flow and Axial Pumps—Code for Hydraulic Performance Tests—Precision Class. China Standards Press: Beijing, China, 2000.

- ISO 5198:1987; Centrifugal, Mixed Flow and Axial Pumps—Code for Hydraulic Performance Tests—Precision Grade. International Organization for Standardization (ISO): Geneva, Switzerland, 1987.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.