Abstract

Aeration used in wastewater treatment is energy-intensive, subsequently increasing the cost of treatment. Aeration is used to supply oxygen that is required for bacterial metabolism that degrades organic compounds in wastewater. In this review, we will focus on the effect of aeration rates on the performance of biofilm-based technologies for wastewater treatment and the evaluation of the oxygen transfer rate (OTR) of these technologies. The performance of biofilm reactors in terms of removal efficiency increases with air flow rate, as increased flow helps to increase the contact area between wastewater and the biofilm on the carrier. The same is true for the OTR due to the greater availability of oxygen at higher airflow rates. Excessive aeration can negatively affect wastewater treatment through biofilm shearing and detachment from the carrier. Through a critical review of these technologies, the optimal air flow rate and aeration methods can be determined in biofilm reactors to improve the quality of the treated water, increase the efficiency of the aeration system, and attain energy savings.

1. Introduction

The rapid growth of industries and populations has resulted in more untreated wastewater being discharged into rivers and lakes, polluting these water bodies with harmful chemicals and pathogens. Wastewater can be divided into three main types: domestic, industrial, and municipal. Domestic wastewater, which comprises a significant portion of wastewater, comes from household sources such as toilets, showers, laundry, kitchens, and wash basins []. For example, in a Malaysian village, greywater originating mainly from bath (25%), showers (17%), basins (9%), bathroom cleaning (15%), laundry (17%), kitchen dishwashing (5%), and kitchen cooking (12%) was found to have a high biochemical oxygen demand (BOD; up to 333.8 mg/L) and chemical oxygen demand (COD; up to 760 mg/L), with a pH as low as 5.68, often exceeding environmental discharge standards []. Wastewater from industries such as mining, paper, steel, chemical, and petroleum refining is defined as industrial wastewater and often contains a wide range of carcinogens and other harmful pollutants []. Municipal wastewater is usually called sewage, containing a mixture of wastewater types such as domestic, industrial, and hospital wastewater, along with stormwater [].

According to Widyarani et al. [], most domestic wastewater comes from homes (75%) and is a major source of pollution. It contains nutrients (nitrogen and phosphorus), organic matter, inorganic salts, heavy metals, bacteria, and viruses []. For instance, greywater, a significant component of domestic sewage, can have a chemical oxygen demand (COD) ranging from 880 to 2070 mg/L, a biological oxygen demand (BOD) of 820–1180 mg/L, a suspended solids (SS) content of between 1370 and 3540 mg/L, and a pH varying from 5.5 to 8.8 [,]. It may also be contaminated with pathogens such as Enterococcus sp., Salmonella, and enteropathogenic E. coli (EPEC) []. Sewage treatment plants are often built near urban environments. This is also where wastewater is treated to meet the discharge limit regulations set by authorities [] in order to conserve resources and protect communities from harmful substances []. If sewage is not treated, it can be harmful because it contains many potentially hazardous substances, including emerging contaminants (ECs) (i.e., pharmaceuticals, pesticides, chemical intermediates, microplastics, and antibiotics) [,], heavy metals [], and pathogens [].

Wastewater treatment plants (WWTPs) often use aerobic processes, e.g., employing activated sludge, oxidation ditches, rotating biological contactors, and trickling filters, to degrade organic components. However, employing biological processes such as the activated sludge process, aeration, or extended aeration as the main treatment causes notable increases in operational costs mainly due to the consumption of oxygen (O2). This is because the organic content in WWTP influent often has a low C/N ratio and requires denitrification by microorganisms []. Adopted microorganisms are usually exploited in biological treatment, and over 95% of the bacterial species found in wastewater treatment reactors [] are affected by the O2 concentration. Since O2 consumption is directly related to operational cost, researchers often make an attempt to enhance biological treatment system performance through varying the oxygen concentration by adjusting the aeration rate. For example, Deng et al. [] used the intermittent aeration technique to accelerate the granulation of aerobic granular sludge (AGS). As a result, they found that AGS formed in a sequencing batch reactor (SBR) with an anoxic phase created larger granules with superior nitrogen removal capacity and reduced energy consumption by nearly 40% due to the shortened aeration period. Benatti et al. [] also supported the idea of using aeration in an activated sludge reactor to influence granular sludge formation, granule size, density, and stability during wastewater treatment. Thus, effective wastewater treatment is crucial in order to ameliorate water resource pollution and preserve the environment more sustainably and at a lower operational cost.

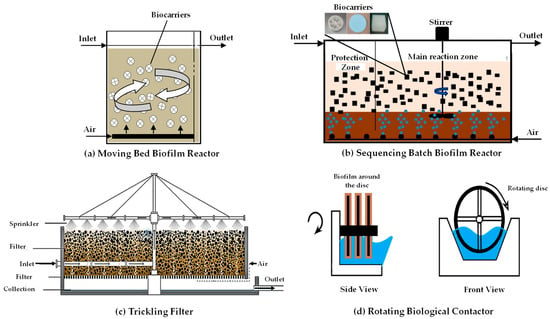

Biofilm reactors are considered innovative technologies in wastewater treatment, with some examples being moving bed biofilm reactors (MBBRs), sequencing biofilm batch reactors (SBBRs), trickling filters (TFs), and rotating biological contactors (RBCs) (Figure 1). An SBBR is an upgraded version of a conventional SBR wherein suspended and attached growth are induced in a single batch reactor in order to speed up the aeration stage in wastewater treatment []. Studies have shown that an upgraded SBR with biofilm carriers can reduce excess sludge production by about 23% and improve sludge-settling properties by lowering the sludge volume index (SVI) by approximately 33% compared to conventional SBR systems [].

Figure 1.

Typical biofilm reactors used in wastewater treatment: (a) MBBR [], (b) SBBR [], (c) TF [], and (d) RBC []. Images were reproduced with permission from Elsevier.

In a TF, wastewater is uniformly sprayed over the packing filler to create a liquid phase before it is periodically recirculated over the column; it has recently become popular for the treatment of odorous pollutants []. However, TF systems, like other aerated biofilm reactors, tend to produce a moderate amount of excess sludge due to sustained aerobic microbial activity, necessitating regular sludge management. For instance, levels of settleable solids in TF effluents have been reported to range from 0.2 to 1.5 mg/L, influenced by factors such as media type and biofilm detachment dynamics [].

In a RBC, a sequence of rotating disks is used for microbial attachment and biofilm formation, wherein the rotary motion aids the engagement of microorganisms with wastewater organic materials on the disk surface []. However, Rahmadi et al. [] also emphasized that the performance of an RBC is often limited by the available surface area for microorganism growth when handling larger wastewater volumes and high concentrations of pollutants. A study by Waqas and Bilad [] indicated that RBC systems produce approximately 10–20% less sludge compared to conventional activated sludge processes. This reduction was attributed to longer solid retention times and the attached-growth nature of RBCs, which minimize biomass washout.

In an MBBR, both suspended and attached growth systems are present, with carriers used to aid biofilm development [] and complete mixing via aeration. The unique biofilm structure and effective performance of the biofilm in an MBBR improve the simultaneous removal of organic matter and nitrogen in wastewater []. Some of the other advantages of MBBRs include their low requirements for backwash, ability to provide a larger surface area for microorganism growth, resistance to clogging, tolerance of sudden changes in the loading rate, flexibility in process design, and fully mixed hydraulic regime that is highly efficient in wastewater treatment [,]. However, it has often been observed that this system also requires high energy consumption for aeration. To address sludge management challenges, Khudhair et al. [] demonstrated that increasing the solid retention time (SRT) from 5 to 15 days significantly reduced excess sludge production from 750 to 150 g/day, providing an effective approach to minimizing sludge generation in MBBRs.

Above all, aerobic systems require oxygen to facilitate effective treatment, either with the aid of an aeration system or with mechanical support. Zhu et al. [] studied a hybrid mixotrophic sequencing batch biofilm reactor (SBBR) that combined pyrite-based autotrophic denitrification and heterotrophy for real domestic wastewater treatment. At an aeration frequency of 16 operation cycles (fIA = 16), the reactor achieved outstanding removal efficiencies of 83.74% for ammonium-nitrogen (NH4+-N), 54.41% for total nitrogen (TN), and 90.45% for orthophosphate (PO43−-P). Although the high aeration frequency improved ammonium and phosphate removal, it also led to elevated levels of dissolved oxygen (DO), which suppressed heterotrophic and autotrophic denitrification processes. The excess DO disrupted the transition to the anoxic conditions required for denitrification, hence reducing the role of autotrophic pathways in TN removal. These findings emphasize the importance of accurate optimization of aeration not only for maximizing pollutant removal but also for managing oxygen demand and ensuring there is balanced microbial activity in biofilm systems.

The efficiency of biofilm reactors depends on several parameters or factors, including the hydraulic retention time (HRT), the surface area loading rate (SALR), DO, the size and shape of the carrier, the microbial community used, and the carrier-filling percentage in the reactor. Unfortunately, there is a lack of studies that focus on the aeration of biofilm reactors. Aeration is the most important parameter in treatment because it provides O2 to bacteria for their growth, consequently allowing biodegradation to occur.

DO concentrations can be increased by increasing the air flow rate. Once the treatment of wastewater is completed, the amount of DO increases and becomes saturated because the consumption of oxygen by microorganism biofilms decreases. This leads to redundant energy consumption caused by excessive aeration []. A higher DO content can also decrease the efficiency of denitrification in a treatment []. The efficiency of aeration depends on oxygen transfer efficiency (OTE), which also affects the cost of a wastewater treatment operation []. In wastewater treatment, aeration is a costly part of the process because of its high energy consumption, often accounting for 50–90% of the total electricity used, depending on the scale and the type of technology []. Thus, the airflow rate in biofilm reactors must be optimized to ensure the efficient treatment of wastewater.

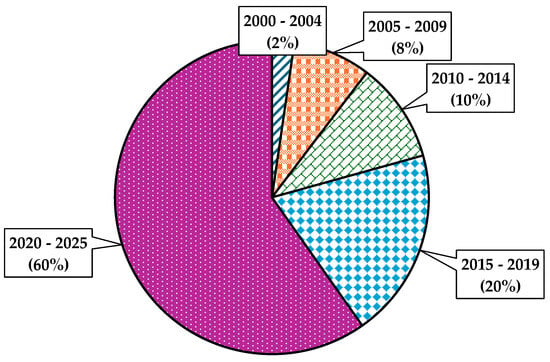

In this review paper, we aim to ascertain how airflows affect biofilm reactors’ efficacy in treating wastewater, specifically with regard to the stability of the biofilm and its ability to remove pollutants. We also attempt to assess the oxygen transfer rate in wastewater treatment, considering oxygen transfer efficiency and effects on biofilm processes. Several search engines were used to find research articles for this study by using related keywords, including “airflow”, “biofilm reactor”, “oxygen transfer rate”, “oxygen mass transfer”, and “wastewater treatment”. The search engines employed included Elsevier, ResearchGate, SpringerLink, and Google Scholar. The date range of the research articles was limited to the period from 2000 to 2025 (Figure 2).

Figure 2.

Distribution of reviewed studies over the years 2000–2025.

2. Effect of Aeration on the Performance of Biofilm-Technology-Based Wastewater Treatment

Aeration is one of the most important elements in biological wastewater treatment, wherein it enhances microbial growth and shortens the time needed for aerobic digestion. It uses a lot of energy, which can account for up to 45–75% of the cost of a plant []. Table 1 shows a summary of studies related to the effect of aeration on the performance of biofilm reactors in wastewater treatment. To the best of our knowledge, there is no advanced study that focuses on aeration in biofilm reactors. The following sections provide further discussion on the effect of aeration on dissolved oxygen, pollutant removal, and biofilm thickness as well as microbial compositions during wastewater treatment.

Table 1.

Summary of studies related to the effect of aeration on the performance of biofilm reactors.

2.1. Dissolved Oxygen

According to Rahimi et al. [], a low DO concentration led to an increase in the ratio of sloughing upon biofilm formation while a reactor was run at a low airflow rate, such as <85 L/h. This decreased the thickness of the biofilm layer and the effectiveness of its removal. Turbulence increased and more media collisions occurred at higher airflow rates, such as >295 L/h. In addition to separating the suspended biofilm flocs into smaller pieces, this turbulence separated biofilm layers from the medium. Other studies have also reported that high airflow rates can lead to the depletion and thinning of biofilm biomass [,]. In Rahimi et al.’s [] study, the lowest nitrogen concentration was not attained at the greatest airflow rate but rather at an MBBR airflow rate of 151 L/h and a specific aeration demand per membrane area (SADm) of 1.2 m3/m2 h−1.

Khoshfetrat al. [] investigated how air flow rate and organic loading rate (OLR) affected reactor performance in an aerated submerged fixed-film bioreactor (ASFF). The system consisted of a plexiglass cylindrical column with a circular diffuser placed at the bottom to create medium-sized air bubbles. The authors highlighted how airflow rate affected DO concentration. The DO content decreased less at an airflow rate of 8 L/min than it did at 4 L/min, especially at the maximum organic loading rate of 2.5 kg COD/m3 d. At lower airflow rates, the significant drop in DO concentration probably occurred because there was not enough oxygen available to meet the high demand of the OLR.

According to Li et al. [], removal efficiency with respect to slaughterhouse effluent was higher with higher airflow rates when using a sequencing batch reactor (SBR). Air was sporadically pumped into the reactor four times in 50 min intervals via an air pump that was attached to a porous stone diffuser at the reactor’s base. With an airflow rate of 0.2 L/min, the reactor remained anaerobic, with DO concentrations being close to 0 mg/L throughout the entire reaction phase, which prevented oxygen-dependent processes such as nitrification and aerobic carbon oxidation. When the airflow was increased to 0.4 L/min, the DO during the first three aeration periods was stable at approximately 1.76 mg/L (20% saturation) and gradually rose to 3.52 mg/L (40% saturation) during the final aeration period. Under these conditions, COD and TP removal were 90%, but TN removal was limited to 34%. Further increases in airflow to 0.8 and 1.2 L/min led to improved oxygenation. At 0.8 L/min, the average DO concentrations during the four aeration periods were 0.7, 1.3, 2.6, and 6.0 mg/L, respectively. At 1.2 L/min, the DO concentration rose quickly to 25% saturation (about 2.2 mg/L) within 20 min of the first aeration period and remained above 30% saturation (≥2.64 mg/L) throughout. These enhanced DO levels supported full nitrification and phosphorus uptake, resulting in removal efficiencies of 97% for COD, 95% for TN, and 97% for TP.

Fanta et al. [] investigated simultaneous nitrification–denitrification and phosphorus removal (SNDPR) in pilot-scale sequencing-batch moving-bed biofilm reactors (SB-MBBRs). In addition to air flowrate, they also investigated the effect of external volatile fatty acid (VFA) dosing and temperature on SNDPR with respect to raw municipal wastewater. They found that SNDPR was optimum at 20 °C and 2.5 L air/min (DO: 4.6 mg/L) with acetic acid supplied at 150 mg SCOD/L. Also, when the airflow rate was decreased from 2.5 L/min (DO: 4.6 mg/L) to 1.0 L/min (DO: 0.5 mg/L), significant decreases in phosphorus (23.8%) and nitrogen (27.5%) removal were recorded. This suggests that low DO availability decreases nitrification and limits phosphorus uptake due to the reduced availability of NO2−-N and NO3−-N, resulting in lower nitrogen removal efficiency. Conversely, higher airflow rates improve DO levels, leading to better nitrification and phosphorus removal.

An upgraded artificial floating-type biological treatment system (FTBS) was employed in a study by Wang et al. []. The system comprised a floating bed (FB), artificial biofilm carriers (polyurethane sponges), macrophytes (Canna indica Linn.), and an aerator. A micro-aeration system was included in the microbial carrier (MC) system to improve eutrophic water treatment, and the floating bed was composed of polyvinyl chloride perforated plates spaced 0.20 meters apart. To enhance the redox conditions and remove the biofilm from the carrier surface, the aerator was fixed to the bottom of the frame. The experimental setups with aeration and biofilm carriers led to greater COD removal, increasing it by up to 69.6%. Theoretically, this improvement was caused by the aeration provided, which raised the levels of DO [,]. Sustaining sufficient DO is essential for treating wastewater since research indicates that a concentration of at least 2 mg/L is necessary for the removal of organic matter and to avoid oxygen depletion [].

Singh et al. [] used integrated fixed-film activated sludge (IFAS) to monitor the impacts of several aeration techniques at a high airflow rate, 110 m3/h, which can sustain bulk DO levels between 4.5 and 5.0 mg/L. The IFAS included submerged membrane diffusers that were connected to an external blower. The study was conducted in two phases with four stages: an intermittent aeration phase (IA1: 150/30 min, IA2: 120/60 min, and IA3: 90/60 min) and a continuous aeration phase. The percentages of COD removed during the intermittent aeration phases were marginally lower: 92.7% in IA1, 89.9% in IA2, and 86.9% in IA3. The effectiveness of COD removal during intermittent aeration decreased by 2–3% as the off-aeration time increased, presumably as a result of lower DO levels. Singh et al. [] emphasized that with a removal efficiency of 67.37%, continuous aeration was the most effective method for lowering TN, whereas intermittent aeration demonstrated the importance of oxygen in lowering TN levels, with slightly lower removal rates. This is probably because facultative bacteria prefer oxygen as an electron acceptor because it provides higher energy yields or because aerobic denitrification occurs.

In a study utilizing a biofiltration unit consisting of the aquatic plants Eichhornia crassipes and Salvinia natans, the effect of aeration was evaluated at an airflow rate of 0.5 L/min []. The authors used a multi-pore aeration system with a PVC pipe 50 cm long and 8 cm in diameter installed at the bottom. The ability to lower BOD5 was 3.2 times higher in the aerated unit than in the non-aerated unit. The increased elimination of organic materials was due to higher levels of DO, which accelerated the oxidation reaction. Inorganic matter was removed in oxygenated circumstances, which facilitated nitrification and phosphate degradation. This demonstrates how aeration directly affects the efficiency of pollutant removal in wastewater. Furthermore, the aquatic plant root systems served as a medium, providing oxygenated conditions in the rhizosphere, promoting microbial development and aiding in the breakdown of organic materials by microbes attached to the roots.

2.2. Pollutant Removal

Zhu et al. [] showed that nutrient removal in wastewater is greatly impacted by optimizing aeration in sequencing batch biofilm reactors (SBBRs) using pyrite-based autotrophic denitrification (PAD). Their reactor had two zones: a bottom anaerobic zone filled with natural pyrite and an upper aerobic zone filled with a polyurethane sponge. An air flow meter was used to regulate the aeration rate, which was set to 1.0 L/min, utilizing two nano-microporous aeration discs that were positioned at the bottom of the aerobic zone. With a timer controlling the alternating aeration/non-aeration times, the reactors was run in sequential batch mode. The operation of the SBBR resulted in intermittent aeration at four, eight, or sixteen times per cycle. The SBBR was able to remove 83.7% of NH4+-N, 54.4% of the TN, and 90.5% of PO43−-P by varying the aeration frequency. Higher aeration frequencies, on the other hand, improved the removal of NH4+-N and PO43−-P but inhibited the PAD process and heterotrophic denitrification, indicating the necessity for careful aeration balancing in order to maximize treatment efficacy.

Other studies have also suggested that increasing the level of aeration allows the process of nutrient removal to occur more rapidly and improves the performance of wastewater treatment plants []. The findings of Nadayil et al. [] showed that utilizing aeration tanks with fine-bubble diffusers greatly increases pollutant removal. Fine-bubble diffusers are able to transmit oxygen more efficiently than coarse-bubble diffusers. Throughout the course of a 72 h treatment period, the reductions in turbidity, COD, and BOD at the maximum airflow rate of 4 L/min were 95.9%, 95.7%, and 37.7%, respectively. This demonstrates the superior performance of circular tanks and fine bubble diffusers in aeration systems, providing greater treatment efficiency.

Abu Hasan et al. [] used a biological aerated filter (BAF) to treat highly polluted drinking water using aerobic and anoxic state strategies. Using an air compressor, aeration was provided at various flow rates during the study periods. As aeration increased, the recorded COD reduction increased from 96.1% to 97.9%. It was also shown that different airflow rates did not have a significant effect on COD reduction.

Wei et al. [] employed a laboratory-scale MBBR system to treat synthetic wastewater, reaching a COD reduction rate of up to 70% and an NH4+-N removal of 95%. Aeration was provided via an aerator installed at the bottom in the center of each reactor, ensuring adequate oxygen supply for biofilms attached to suspended polyethylene carriers. The airflow rate remained constant at 60 L/h.

Forouzesh et al. [] investigated the effects of aeration and the C:N ratio in the treatment of synthetic wastewater using a partially aerated submerged fixed-film bioreactor (UP/ASFF). A fine-bubble diffuser positioned halfway through the bioreactor was used to introduce airflow, resulting in the creation of both anoxic and aerobic zones with a volume ratio of 2.5 each. The COD reduction reached 100% at higher airflow rates because there was enough oxygen available to meet the microbiological demand. Additionally, the study demonstrated that by lowering the nitrogen loading rate, heterotrophic and autotrophic microbes were prevented from competing with one another for DO and biofilm space, which allowed heterotrophic microorganisms to take the lead and improve COD reduction even more.

Ren et al. [] studied the impact of aeration on pollutant removal using an up-flow biological aerated filter (UBAF). To guarantee that water and air were spread uniformly, it was designed with a support zone filled with cobbles (diameter: 10–30 mm) and ceramic materials (effective diameter: 3–5 mm). Analysis revealed that there was no discernible difference in the percentage of COD reduction across the different airflow rates studied. This study also reported the effects of different airflow rates on the flow field within a BAF reactor’s filter media area and studied the correlation of the flow field with the DO, microbial community composition, and the levels of pollutant removal. Regarding COD reduction, no significant fluctuations in removal efficiency were observed, possibly due to the varying levels of carbon consumption during the nitrification process. Phosphorus removal, on the other hand, increased when the airflow rate was increased, perhaps due to an increase in the breakdown of biomass from the ceramic surface being released along with the effluent. However, Ren et al. [] stated that the mechanism of nitrogen and phosphorus removal at different air flow rates remains unclear.

Mehrabi et al. [] investigated a membrane-aerated biofilm reactor (MABR) intermittently delivering process air with an aeration sequence of 3 min on and 7 min off and then 5 min on and 12 min off. The researchers emphasized the necessity of delivering process air, which diffuses into the biofilm and acts as an electron acceptor throughout the ammonia and carbon oxidation processes.

2.3. Biofilm Thickness and Microbial Compositions

A hybrid MBBR-MBR system was used to examine the impact of airflow rate on the efficacy of synthetic wastewater treatment []. A mesh plexiglass sheet separated the MBBR compartment from a hollow fiber membrane module (polyvinylidene fluoride, with a pore size of 0.1 µm) in the membrane compartment of the system. In the MBBR, biomass flourished on polypropylene carriers that moved about freely inside the reactor as a result of aeration. The authors stated that the consistent quality of the permeate over the course of the experiment suggested that, in the presence of adequate DO, varying airflow speeds had no effect on the removal efficiency of organic matter. Aeration, however, had an impact on the stability of the media and the thickness of the biofilm in the biofilm-based reaction. Air intensity was shown to affect the removal of biological nutrients, and a parabolic correlation was found between the amount of biofilm on the media and the aeration rate.

In a study by Ren et al. [], experiments were conducted in a laboratory-scale aerobic fluidized bed biofilm reactor (AFBBR) consisting of an aeration system (an air disperser, an air chamber, and an aeration orifice plate) and a DO-monitoring system. Three distinct airflow rates (0.064, 0.096, and 0.128 L/min) were evaluated in this investigation. There were no notable variations in the COD removal rates at these airflow rates; however, variations in airflow affected the oxygen transfer rates and the compositions of microbial communities.

3. Oxygen Transfer Rate in Biological Wastewater Treatment

The transfer of oxygen from gas to liquid is important in biological wastewater treatment processes that depend on the availability of sufficient quantities of oxygen []. At steady DO concentrations, the oxygen transfer rate (OTR) is equal to the oxygen uptake rate (OUR); i.e., OTR = OUR. The concentration of DO in an aerobic process depends on the OTR from the gas phase to the liquid phase, i.e., the rate at which oxygen is transported into a bacterial cell to be of use []. The OTR and OUR are also correlated with the oxygen transfer coefficient (kLa), where kLa can be used to assess the quality of oxygen transfer in a biological wastewater treatment process. Theoretically, oxygenation performance, the OUR, and kLa values will all increase with an increasing airflow rate []. However, to the best of our knowledge (informed by a literature search), there do not seem to be many studies that discuss the effect of the airflow rate on the oxygen transfer rate in biofilm reactors.

In one of the studies in which an MBBR was used, the kLa value increased when the aeration intensity increased []. When the air intensity was increased during the mass transfer of gas–liquid oxygen to the surface of the biofilm, the driving force increased through a reduction in the liquid concentration at any point in time as well a possible increase in mass transfer between gases and liquids. Although increasing the airflow rate helped increase the value of kLa, there was still a limit. This was because when a high air flow rate is used, the resulting bubbles have a tendency to coalesce and become strong. This can cause the flow to become increasingly turbulent and put it in contact with the reactor at high velocities, thus increasing power consumption and its associated expenditure. Turbulent flow in a biofilm reactor can create difficulties in the adhesion of biofilms to the carrier. Considering the value of kLa, Jing et al. [] concluded that an air flow rate of 0.3 m3 h−1 with a carrier filling percentage of 30–50% had a good oxygen transfer effect and high oxygen transfer efficiency (OTE).

Strubbe et al. [] defined OTE as the fraction of the supplied oxygen that actually entered the water and characterized OTE as noted in Equation (1) below.

where kL aO2 (h−1) represents the gas–liquid mass transfer coefficient in clean water, which is decreased by a fouling factor F(-) to incorporate diffuser fouling and the alpha factor α (-) to introduce the dependency of operational and environmental conditions of the process; (C*O2 − CO2) is the difference between the DO concentration in water upon saturation (C*O2, g O2 m−3) and the dissolved oxygen concentration in water (CO2, g O2 m−3); V is water volume (m3); and WO2 is the mass flow of oxygen fed by the blower to the aeration tank (g O2 h−1). It is true that OTE is closely related to the OTR. However, high OTR values do not represent high OTE, as a system might transfer some oxygen quickly, but this oxygen may not be effectively utilized during wastewater treatment.

OTE = {αF kL aO2 (C*O2 − CO2)V}/WO2

The authors concluded that OTE tends to decrease with an increasing airflow rate. This statement is also supported by several other studies [,,]. Iranpour & Stenstrom [] also suggested that a higher airflow rate does not necessarily result in high OTR values. At adequate aeration levels, if the flow is further increased, the OTR is likely to decrease because the resultant decrease in OTE may exceed rather than offset the effect of additional oxygen availability with higher airflow rates. Other studies conducted on MABRs also support this statement []. Syron and Casey [] found that OTE significantly decreased at higher airflow rates, attributed to shorter gas residence times. The OTE varied between 50% and 80% at 55 mL/min, but at 400 mL/min, it fell to 5–20%, negating the advantages of increased oxygen levels and lowering the total oxygen transfer rate. In addition to preventing diminishing returns, maintaining ideal airflow rates guarantees effective oxygen transfer. Although the maximum airflow rate tested was 400 mL/min, Syron & Casey [] found that the highest OTR was obtained at an airflow rate of 200 mL/min. This result emphasizes the fact that greater OTR values are not usually the result of increased airflow. The highest OTR readings were obtained at a flow rate of 100 mL/min in situations where only oxygen was supplied. This demonstrates that only in the presence of pure oxygen are OTR values precisely proportionate to airflow rates.

In another study conducted using the off-gas method, under process conditions where an MBBR was equipped with a biofilm carrier, there was no significant change in the value of the standard oxygen transfer efficiency (αSOTE) when various airflow rates were used, but there was a slight improvement compared with wastewater treated in a non-biofilm reactor []. According to Wei et al. [], microbial respiration and airflow rates affect OTE values, wherein microbial respiration can increase the OTR. Most previous studies show that the presence of carriers with biofilms has a large effect on the kLa value as well as on the OTR value [,]. The studies by Syron & Casey [] also showed a linear relationship between OTR and OTE when using a MABR.

The OTR needs to be higher than the OUR to ensure the growth and retention of microorganisms []. To increase the OTR during wastewater treatment, the flow rate of the supplied air also needs to be increased so that kLa also increases, consequently increasing operating costs. Hence, one study has suggested intermittent aeration at an OTR of 5–6 mg O2/L h can save up to 35% in energy costs []. The recorded OTE value was also still high, proving that intermittent aeration has the potential to ensure an optimum OTR value, saving energy used for aeration. The authors also highlighted that when the carrier filling percentage was 40% and air was supplied at 0.21 m3 h−1, kLa reached its highest value of 1.38 h−1 due to the high OTE in the reactor.

Ren et al. [] conducted a study to observe the OTR at different airflow rates in a laboratory-scale AFBBR. As shown throughout their results, when the airflow rate increased, the values of kLa and the OUR also increased. This was due to the increased fluidization efficiency of the suspended carrier caused by the increase in the air flow rate. These conditions also increase microbial activity and the OTR. The authors of this study also stated that the distribution of OTE is related to the size of kLa and the mass flow rate of oxygen (ṁO2), with an increase in the airflow rate increasing kLa but decreasing the value of ṁO2.

Cheng et al. [] conducted a study on the effect of bubble plumes on the OTR in an MBBR operated at various airflow rates. The value of kLa increased as the airflow rate increased, but the relationship between the two factors was nonlinear. They noted that the velocity of the gas phase in the flow region increases with an increasing OTR, causing the number of bubbles in the liquid flow region and the contact area between the liquid and gas phases to increase. Thus, when the air flow rate increases, the velocity increases until it reaches a certain level. When this limit is reached, the distribution of the motion and residence time of the bubble plume becomes more dispersed, and the velocity no longer increases but becomes asymmetrical, so kLa does not increase linearly with the airflow rate or with the OTE. Hence, the airflow rate influences the distribution of movement and velocity in the bubble plume, which causes nonlinear changes in the kLa and OTE.

Collivignarelli et al. [] conducted a study using an MBBR in order to observe oxygen mass transfer at three different specific airflow rates: 60, 100, and 150 Nm3/h. High specific airflow rates created large bubbles with a small relative surface area and a high ascending velocity. In a clean-water test, SOTE decreased when the air flow rate was increased from 60 to 100 Nm3/h, but SOTE increased slightly when air was supplied at 150 Nm3/h. In wastewater tests, the SOTE value was seen to increase from 4.1 kg O2/h to 4.5 kg O2/h when the air flow rate was increased from 100 Nm3/h to 150 Nm3/h, while the value of SOTE decreased from 13.8% to 10.1%. According to Collivignarelli et al. [], OTR efficiency increases at higher biomass concentrations as the fluid density of the system increases. Therefore, the upward vertical flow of air bubbles decreases, causing the resistance time between the bubbles in the liquid to increase, which could therefore allow the removal of more pollutants. The presence of aerobic bacteria would also aid in the transfer of oxygen between the air bubbles and the liquid.

Dias et al. [] conducted experiments using a moving attached-growth system to evaluate the effect of carriers on oxygen transport at airflow rates of 2.2 m3/m2 h, 9.0 m3/m2 h, and 16.2 m3/m2 h. The experiments were conducted using a clean-water test without media followed by a clean-water test with 60% media presence. It was found that without the presence of media, the kLa value increased as the airflow rate was raised. When media were introduced into the system, the kLa value varied but still followed a similar trend, increasing with the airflow rate.

Sander et al. [] used an MBBR-IFAS to evaluate the energy, cost, and design aspects of coarse-bubble aeration and fine-bubble aeration systems through volumetric filling rate differences. The airflow rate was expressed as the superficial gas velocity. Air was supplied between 10 and 14 m/h for coarse-bubble aerators and 7 and 9 m/h for fine-bubble aerators. In these studies, the OTE observed when fine-bubble aerators were used was always greater than that observed when using coarse-bubble aerators. During the clean-water test, the OTE values for both types of aerators were directly proportional to the volumetric filling fraction of the carrier. Under process conditions, the OTE for the coarse-bubble aerator was also directly proportional to the volumetric filling fraction of the carrier; however, the OTE value did not show a fixed trend, and the value was found to vary for each volumetric filling rate of the carrier.

Sander et al. [] found that fine-bubble aerators had no significant effect on superficial gas velocity (SGV), different volumetric filling fractions, or specific standard oxygen transfer efficiency (SSOTE) values. Overall, the SSOTE values for fine-bubble aerators were higher than those observed when using coarse-bubble aerators at different SGV values due to incomplete mixing of the carrier that could be seen on the water surface. Without the carrier, the SSOTE was directly proportional to the airflow rate for the coarse-bubble aerator but not for the fine-bubble aerator. Although the efficiency of coarse-bubble aerators improved with the presence of carriers, fine-bubble aerators consistently achieved higher SSOTE values, indicating better overall oxygen transfer performance.

Leung et al. [] used a BAF equipped with angled clay media to assess oxygen transfer characteristics based on various gas and liquid flow rates. The airflow rates in this study were expressed as SGV, and the rates were 8, 16, 24, 32, and 40 Nm/h. The value of kLa was found to increase as the SGV increased.

The predicted value of kLa can be calculated using the following equation:

where

a = empirical coefficient;

b = empirical coefficient;

c = empirical coefficient;

kLaT = oxygen transfer coefficient based on void or liquid volume at temperature T (h−1);

UG = superficial gas velocity at normal conditions of 1 atm and 20 °C (Nm3/m2 of surface area/h);

UL = superficial liquid velocity (m3/m2 of surface area/h);

Csat = saturated DO concentration at gas–liquid interface (mg/L);

α = (kLawastewater)/(kLacleanwater);

ꞵ = (Csat,wastewater)/(Csat,cleanwater);

T = temperature (°C);

θ = dimensionless constant for temperature correction.

Leung et al. [] concluded that the correlation of the equation was in the range of ± 20% of the values observed in most of the data. This means that the equation or relationship is valid for this study, where the temperature was in the range of 10–24 °C, UG was between 8 and 40 Nm/h, and UL was between 4 and 16 m/h. These ranges reflect the experimental conditions tested using a bench-scale BAF filled with angular clay media. The close agreement between the predicted and observed kLa values confirms the model’s reliability and its applicability to systems operating under similar flow and temperature conditions.

In a pilot study of an artificial floating-type biological treatment system (FTBS), Wang et al. [] found that the tank (tank A) that was not aerated had the lowest OUR. The DO concentration was higher than 0.5 mg/L even in the absence of aeration, creating anoxic conditions. Plant roots offered a substantial surface area for the growth of microorganisms and biofilms; however, a synthetic medium showed a greater OUR. Table 2 shows a summary of the studies on the relationship between kLa, OTR, OUR, OTE, and airflow rate.

Table 2.

Summary of studies on the relationship between kLa, OTR, OUR, OTE, and airflow rate.

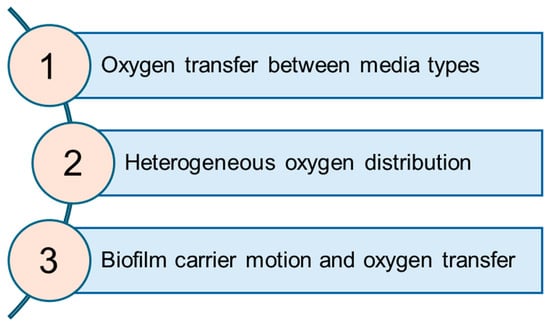

4. Future Challenges and Prospects Regarding Aeration Optimization

Aeration is a major factor in enabling efficient biological reactions in wastewater treatment systems, specifically biofilm-based reactors. However, as these systems become more complex and sophisticated, several new concerns must be considered to enable better oxygenation and reactor function. As wastewater treatment demands grow globally, aerated systems are increasingly scrutinized for their high energy consumption and large physical footprints, both of which pose significant sustainability challenges in the 21st century [,]. Figure 3 illustrates major problems and prospects for the future optimization of aeration, with a focus on the most crucial aspects of oxygen transfer between media types, the dispersion of oxygen in heterogeneous form, and the influence of biofilm carrier motion on oxygen dynamics. Explaining and overcoming these kinds of challenges are imperative to further optimize the design and operation of next-generation treatment technologies.

Figure 3.

Future challenges and prospects regarding aeration optimization.

4.1. Oxygen Transfer Between Media Types

A major problem in biofilm reactors is determining how to optimize oxygen transmission, especially between plant root zones and biofilm carriers. Bacteria on biofilm carriers and plant roots have different oxygen demands, which can lead to an uneven distribution of oxygen if aeration is not properly controlled. Within these reactors, oxygen diffuses from gas bubbles into the liquid phase, where it is assimilated by microbes. Partitioning of oxygen zones is necessary to prevent oxygen shortages in specific locations. This guarantees that every zone receives the oxygen it requires, avoiding inefficiencies in microbial activity and decreases in the rate at which pollutants degrade.

By preventing the formation of low-oxygen zones and increasing treatment capacity, compartmentalization adjusts aeration to the various sections of a reactor. Improved diffuser patterns, such as lateral and checkered designs, improve the efficiency of oxygen transport and the distribution of bubble sizes. There have been notable differences in bubble breakdown, coalescence, and overall mixing quality amongst studies in which computational fluid dynamics (CFD) models were used to mimic different diffuser patterns, including lateral, grid, line, stripe, and checkered designs. Specifically, the checkered design performed better in terms of air distribution and bubble size, resulting in more effective oxygen transfer. Further developments that combine biological kinetics and CFD models may improve these results even further by enabling real-time modifications and more effective pollutant breakdown, which would enhance biofilm reactor performance and treatment procedures as a whole [].

4.2. Heterogeneous Oxygen Distribution

A persistent key challenge in regard to biofilm reactors is achieving uniform oxygen delivery. Bacteria on multiple media such as plant roots and biofilm carriers require oxygen, which must be provided via aeration. In systems that are not built to efficiently handle the competition for DO, this requirement might result in an uneven distribution of oxygen. The development of adaptive aeration systems that can maintain system-wide oxygen balance while maximizing energy efficiency and lowering carbon emissions should be the main goal of future research. Advanced machine learning models used in conjunction with real-time DO monitoring may improve the control of oxygen supply across various media for more effective treatment. According to Ao et al. [], newer models such as extreme gradient boosting and bidirectional long short-term memory employ real-time data to dynamically optimize aeration, potentially reducing energy consumption by as much as 23%.

Furthermore, current aeration systems often account for up to 70% of the total energy usage in wastewater treatment plants, making aeration one of the most energy-intensive processes in this sector []. The large physical footprint required for an extensive aeration infrastructure, especially in densely populated urban areas, presents additional barriers to implementation and scalability. These concerns are driving the development of compact, modular biofilm reactor designs with integrated aeration zones, which are designed to reduce both energy and land requirements while maintaining high treatment performance [].

In wastewater treatment plants, investigating pure oxygen aeration may improve treatment efficacy and energy efficiency. Pure oxygen, corresponding to an oxygen concentration of over 90%, removes pollutants more effectively and can lower operating expenses, which make up between 30 and 60% of the entire cost of wastewater treatment []. Industrial and high-strength wastewaters are better served by pure-oxygen systems; however, low-strength wastewaters can be handled by conventional air-based systems. Nonetheless, further study is needed to determine the economic viability of pure-oxygen systems.

4.3. Biofilm Carrier Motion and Oxygen Transfer

In biofilm reactors, oxygen transmission may be hampered by the mobility of biofilm carriers, resulting in low-oxygen zones that impair microbial activity. Careful control of mass transfer across phases is necessary in these reactors to ensure adequate oxygen availability following gas–liquid–solid interactions. Creating intelligent biofilm carriers with built-in sensors to control oxygen delivery dynamically is one possible avenue of future research. Recent developments have accelerated reactor start-up times and enhanced bacterial enrichment through the use of hydrophobic biofilm carriers and quorum sensing []. The incorporation of sensors has the potential to enhance the efficiency of microbial control and treatment performance by further optimizing these carriers.

It is also possible to improve oxygen diffusion throughout a system by altering carriers to promote the generation of improved flow patterns. It has been found that hollow-structured recirculating flow biofilm carriers improve hydraulic properties, promoting pollutant removal and speeding up biofilm formation []. Reactor performance can be enhanced by minimizing low-oxygen zones and ensuring a consistent oxygen supply through the synchronization of mechanical mixing and aeration operations. A hybrid aeration system that included surface aerators, fine blowers, and bottom aerators improved oxygen transfer and guaranteed uniform dispersion at the Skoghall paper mill. This system reduced energy use by 60% while also enhancing pollutant reduction []. In this study, the optimization of aeration decreased costs and had a positive environmental impact in addition to improving reactor performance.

5. Conclusions

Biofilm-based technology for wastewater treatment requires aeration, whose high energy consumption contributes to the high cost of the corresponding treatment. The performance of biofilm reactors is expected to increase as the airflow rate increases, while the OTR will increase with an increase in the airflow rate up to an optimum value. The OTR is influenced by several other factors such as the type of aerator, the presence of biofilm carriers, the surface area of the carriers, and temperature. In the future, the optimal airflow rate and aeration strategies for a biofilm reactor can be determined so that the quality of the treated water can be increased, the efficiency in the aeration system can be increased and energy savings can be achieved. Biofilm reactors using dual-media biofilm carriers may be used as suitable replacements for existing conventional biofilm treatments to produce high-quality treated wastewater for water reuse and recycling at a low operational cost.

Author Contributions

Conceptualization, H.A.H. and N.A.A.; methodology, H.A.H. and N.A.A.; validation, H.A.H. formal analysis, H.A.H. and N.A.A.; investigation, H.A.H. and N.A.A.; resources, H.A.H.; data curation, H.A.H.; writing—original draft preparation, N.A.A.; writing—review and editing, H.A.H. and M.H.M.; supervision, H.A.H.; project administration, H.A.H.; funding acquisition, H.A.H. All authors have read and agreed to the published version of the manuscript.

Funding

TRGS/1/2022/UKM/02/3.

Acknowledgments

The authors would like to acknowledge the Ministry of Higher Education, Malaysia, for funding this research program through the Transdisciplinary Research Grant Scheme (TRGS) with the grant title Resilience and Security of Water through Sustainable Localised Domestic Wastewater Reclamation for Landscaping and Toilet Use under grant no. TRGS/1/2022/UKM/02/3, Project No. 1: Immobilized Microalgae-Photocatalytic Membrane Technology for the Elimination of Emerging Contaminants and Viruses for High Quality Reclaimed Domestic Wastewater (Grant no.: TRGS/1/2022/UKM/02/3/1).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, C.; Feng, B.; Wang, P.; Guo, W.; Li, X.; Gao, H. Revealing factors influencing spatial variation in the quantity and quality of rural domestic sewage discharge across China. Process Saf. Environ. Prot. 2022, 162, 200–210. [Google Scholar] [CrossRef]

- Mohamed, R.M.S.R.; Al-Gheethi, A.; Khalifa, N.A.; Fitriani, N.; Adeleke, A.; Ebenehi, I.Y.; Siti Asmah Bakar, S.A. Greywater treatment using pottery waste ceramic filter. J. Kej. 2021, 33, 891–901. [Google Scholar] [CrossRef]

- Dicataldo, G.; Desmond, P.; Al-Maas, M.; Adham, S. Feasibility and application of membrane aerated biofilm reactors for industrial wastewater treatment. Water Res. 2025, 280, 123523. [Google Scholar] [CrossRef] [PubMed]

- Kagami, K.; Kitajima, M.; Watanave, H.; Hamada, T.; Kobayashi, Y.; Kubo, H.; Oono, S.; Takai, H.; Ota, S.; Nagakura, T.; et al. Association between confirmed COVID-19 cases at hospitals and SARS-CoV-2 levels in municipal wastewater during the pandemic and endemic phases. Environ. Int. 2025, 197, 109342. [Google Scholar] [CrossRef]

- Widyarani; Wulan, D.R.; Hamidah, U.; Komarulzaman, A.; Rosmalina, R.T.; Sintawardani, N. Domestic wastewater in Indonesia: Generation, characteristics and treatment. Environ. Sci. Pollut. Res. 2022, 29, 32397–32414. [Google Scholar] [CrossRef]

- Ang, S.Y.; Goh, H.W.; Bashirah Mohd Fazli, B.M.; Haris, H.; Nor Ariza Azizan, N.A.; Zakaria, N.A.; Johar, Z. Heavy metals removal from domestic sewage in batch mesocosm constructed wetlands using tropical wetland plants. Water 2023, 15, 797. [Google Scholar] [CrossRef]

- Compaoré, C.O.T.; Ouili, A.S.; Zongo, S.G.; Dabré, D.; Maiga, Y.; Mogmenga, I.; Palé, D.; Tindouré, R.G.N.; Nikiema, M.; Ouattara, C.A.T.; et al. Assessing greywater characteristics in the sahel region and perception of the local population on its reuse in agriculture. Heliyon 2024, 10, e33473. [Google Scholar] [CrossRef]

- Shaikh, I.N.; Ahammed, M.M. Effect of washing method and detergent type on laundry greywater characteristics. J. Water Process Eng. 2024, 66, 106103. [Google Scholar] [CrossRef]

- Roy, I.R.W.; Raj, A.S.; Viaroli, S. Microplastic removal, identification and characterization in Chennai sewage treatment plants. J. Environ. Manag. 2025, 380, 125120. [Google Scholar] [CrossRef]

- Rafaai, N.H.; Lee, K.E.; Nazir, N.Z.M.; Rahim, A.R.A.; Goh, T.L.; Mokhtar, M.; Abdullah, W.A.R.W.; Husain, H.; Mamat, R.B.R. Mapping sewage treatment plants for wastewater reclamation and reuse in industrial parks of Peninsular Malaysia: A path towards water security. Water Resour. Ind. 2025, 33, 100284. [Google Scholar] [CrossRef]

- Zhu, X.; Liu, S.; Gao, X.; Gu, Y.; Yu, Y.; Li, M.; Chen, X.; Fan, M.; Jia, Y.; Tian, L.; et al. Typical emerging contaminants in sewage treatment plant effluent, and related watersheds in the Pearl River Basin: Ecological risks and source identification. J. Hazard. Mater. 2024, 476, 135046. [Google Scholar] [CrossRef]

- de Freitas, R.M.P.; Souza, M.B.; Sotero, D.F.; Lopes, A.T.C.; Santos, M.A.; Oliveira, J.M.; Costa, D.C.; Filho, N.R.A.; Vieira, T.B.; Silva, D.M. Ecotoxicological consequences of urbanization: A multi-biomarker approach to assessing sewage treatment plant effects on free-living birds. Environ. Res. 2024, 258, 119424. [Google Scholar] [CrossRef]

- Liu, C.; Liu, F.; Andersen, M.N.; Wang, G.; Wu, K.; Zhao, Q.; Ye, Z. Domestic wastewater infiltration process in desert sandy soil and its irrigation prospect analysis. Ecotoxicol. Environ. Saf. 2021, 208, 111419. [Google Scholar] [CrossRef]

- Buslima, F.A.; Abu Hasan, H.; Sheikh Abdullah, S.R.; Othman, A.R. Water recovery from domestic wastewater using integrated biofilm-phytoremediation technology: A review. J. Water Process Eng. 2024, 65, 105875. [Google Scholar] [CrossRef]

- Li, J.; Xiao, Z.; Gu, J.; Yang, Z.; Dong, W.; Liu, Y.; Xu, Z.; Zhu, W. Brewery wastewater as an alternative external carbon source for full-scale municipal wastewater treatment plants: A performance, cost, and environmental assessment. J. Water Process Eng. 2025, 72, 107483. [Google Scholar] [CrossRef]

- Ali, A.A.A.; Naddeo, V.; Hasan, S.W.; Yousef, A.F. Correlation between bacterial community structure and performance efficiency of a full-scale wastewater treatment plant. J. Water Process Eng. 2020, 37, 101472. [Google Scholar] [CrossRef]

- Deng, S.; Liu, L.; Li, X.Y.; Xue, W.; Liang, L.; Yu, Z.; Lin, L. Rapid granulation of aerobic sludge for tretment of brewery wastewater: Aeration strategy and nitrogen removal mechanism. J. Environ. Chem. Eng. 2025, 13, 115108. [Google Scholar] [CrossRef]

- Benatti, J.C.B.; de Andrade, A.E.F.; Nour, E.A.A.; Cruz, L.M.O. Aeration-driven microbial aggregation in aerobic granular sludge systems for low-strength wastewater treatment. Desalin. Water Treat. 2025, 322, 101050. [Google Scholar] [CrossRef]

- Sadaf, S.; Singh, A.K.; Iqbal, J.; Kumar, R.N.; Sulejmanović, J.; Habila, M.A.; Américo-Pinheiro, J.H.; Sher, F. Advancements of sequencing batch biofilm reactor for slaughterhouse wastewater assisted with response surface methodology. Chemosphere 2022, 307, 135952. [Google Scholar] [CrossRef]

- Abdelaziz, H.A.; Fouad, M.; Mossad, M. Upgrading sequencing batch reactor using attached biofilm. Water Environ. Res. 2021, 93, 1700–1713. [Google Scholar] [CrossRef]

- Abu Bakar, S.N.H.; Abu Hasan, H.; Sheikh Abdullah, S.R.; Mohammad, A.W.; Muhamad, M.H. Interactions between operating parameters of moving bed biofilm reactors in treating palm oil mill effluent. Process Saf. Environ. Prot. 2022, 158, 567–575. [Google Scholar] [CrossRef]

- Dan, N.H.; Luu, T.L. High organic removal of landfill leachate using a continuous flow sequencing batch biofilm reactor (CF-SBBR) with different biocarriers. Sci. Total Environ. 2021, 787, 147680. [Google Scholar] [CrossRef] [PubMed]

- Rezai, B.; Allahkarami, E. Wastewater treatment processes—Techniques, technologies, challenges faced, and alternative solutions. In Soft Computing Techniques in Solid Waste and Wastewater Management; Karri, R.R., Ravindran, G., Dehghani, M.H., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; Chapter 2; pp. 35–53. [Google Scholar]

- Murshid, S.; Antonysamy, A.J.; Dhakshinamoorthy, G.P.; Jayaseelan, A.; Pugazhendhi, A. A review on biofilm-based reactors for wastewater treatment: Recent advancements in biofilm carriers, kinetics, reactors, economics, and future perspectives. Sci. Total Environ. 2023, 892, 164796. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Wang, Y.; Zhang, Y.; Yang, Y.; Cui, R.; Ren, L.; Zhang, M.; Wang, Y. Highly efficient degradation of ethanol, acetaldehyde, and ethyl acetate removal by bio-trickling filter reactors with various fillers. Process Saf. Environ. Prot. 2024, 191, 1407–1418. [Google Scholar] [CrossRef]

- Martins, V.F.; da Silva, G.J.; Borges, A.C. Effects of packing media and the insertion of vegetation on the performance of biological trickling filters. Water 2021, 13, 1735. [Google Scholar] [CrossRef]

- Rahmadi, R.; Nugrohoputri, A.S.; Adam, M.S.; Astuti, A.D.; Cho, J.; Kurniawan, A. Biokinetic modeling approach to investigate the impact of rotational speed variations in modified rotating biological contactors for palm oil mill effluent treatment. Bioresour. Technol. Rep. 2024, 28, 101992. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R. A review on rotating biological contactors. Indones. J. Sci. Technol. 2019, 4, 241–256. [Google Scholar] [CrossRef]

- Aslam, Z.; Alam, P.; Rather, N.A. Startup kinetics of aerobic Moving Bed Biofilm Reactors for phenolic wastewater treatment by mesophilic bacteria. J. Water Process Eng. 2025, 72, 107401. [Google Scholar] [CrossRef]

- Buhari, J.; Abu Hasan, H.; Setyo Budi Kurniawan, S.B.; Sheikh Abdullah, S.R.; Othman, A.R. Future and challenges of co-biofilm treatment on ammonia and Bisphenol A removal from wastewater. J. Water Process Eng. 2023, 54, 103969. [Google Scholar] [CrossRef]

- Kawan, J.A.; Abu Hasan, H.; Suja, F.; Jaafar, O.; Abd-Rahman, R. A review on sewage treatment and polishing using moving bed bioreactor (MBBR). J. Eng. Sci. Technol. 2016, 11, 1098–1120. [Google Scholar]

- Farhami, N.; Derrakhshandeh, M.; Hakki, H.K. Exploring COD and BOD removal from industrial wastewater using a Moving Bed Biofilm Reactor (MBBR). Desalin. Water Treat. 2025, 332, 101177. [Google Scholar] [CrossRef]

- Khudhair, D.N.; Hosseinzadeh, M.; Zwain, H.M.; Siadatmousavi, S.M.; Majdi, A.; Mojiri, A. Upgrading the MBBR process to reduce excess sludge production in activated sludge system treating sewage. Water 2023, 15, 408. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, J.; Yuan, S.; Sang, W.; Ban, Y.; Zhang, S. Impact of aeration frequency on performance of mixotrophic sequencing batch biofilm reactor (SBBR) treating real domestic wastewater: Removal efficiency, pathways, and mechanisms. J. Clean. Prod. 2023, 385, 135747. [Google Scholar] [CrossRef]

- Abu Hasan, H.; Sheikh Abdullah, S.R.; Kamarudin, S.K.; Tan Kofli, N. On-off control of aeration time in the simultaneous removal of ammonia and manganese using a biological aerated filter system. Process Saf. Environ. Prot. 2013, 91, 415–422. [Google Scholar] [CrossRef]

- Du, X.; Wang, J.; Jegatheesan, V.; Shi, G. Dissolved oxygen control in activated sludge process using a neural network-based adaptive PID algorithm. Appl. Sci. 2018, 8, 261. [Google Scholar] [CrossRef]

- Wei, Y.; Yin, X.; Qi, L.; Wang, H.; Gong, Y.; Luo, Y. Effects of carrier-attached biofilm on oxygen transfer efficiency in a moving bed biofilm reactor. Front. Environ. Sci. Eng. 2016, 10, 569–577. [Google Scholar] [CrossRef]

- Drewnowski, J.; Remiszewska-Skwarek, A.; Duda, S.; Łagód, G. Aeration process in bioreactors as the main energy consumer in a wastewater treatment plant. Review of solutions and methods of process optimization. Processes 2019, 7, 311. [Google Scholar] [CrossRef]

- Rosso, D.; Larson, L.E.; Stenstrom, M.K. Aeration of large-scale municipal wastewater treatment plants: State of the art. Water Sci. Technol. 2008, 57, 973–978. [Google Scholar] [CrossRef]

- Li, J.; Healy, M.G.; Zhan, X.; Norton, D.; Rodgers, M. Effect of aeration rate on nutrient removal from slaughterhouse wastewater in intermittently aerated sequencing batch reactors. Water Air Soil Pollut. 2008, 192, 251–261. [Google Scholar] [CrossRef]

- Khoshfetrat, A.B.; Nikakhtari, H.; Sadeghifar, M.; Khatibi, M.S. Influence of organic loading and aeration rates on performance of a lab-scale upflow aerated submerged fixed-film bioreactor. Process Saf. Environ. Prot. 2011, 89, 193–197. [Google Scholar] [CrossRef]

- Rahimi, Y.; Torabian, A.; Mehrdadi, N.; Habibi-Rezaie, M.; Pezeshk, H.; Nabi-Bidhendi, G.R. Optimizing aeration rates for minimizing membrane fouling and its effect on sludge characteristics in a moving bed membrane bioreactor. J. Hazard. Mater. 2011, 186, 1097–1102. [Google Scholar] [CrossRef] [PubMed]

- Abu Hasan, H.; Sheikh Abdullah, S.R.; Kamarudin, S.K.; Tan Kofli, N.; Anuar, N. Simultaneous NH4⁺-N and Mn2⁺ removal from drinking water using a biological aerated filter system: Effects of different aeration rates. Sep. Purif. Technol. 2013, 118, 547–556. [Google Scholar] [CrossRef]

- Forouzesh, M.; Khoshfetrat, A.B.; Kordkandi, S.A. Partially aerated submerged fixed-film bioreactor for simultaneous removal of carbon and nutrients from high-strength nitrogen wastewaters: Effect of aeration rate and C:N:P ratio. Water Sci. Technol. 2017, 76, 877–884. [Google Scholar] [CrossRef]

- Ren, J.; Cheng, W.; Wan, T.; Wang, M.; Jiao, M. Effect of aeration rates on hydraulic characteristics and pollutant removal in an up-flow biological aerated filter. Environ. Sci. Water Res. Technol. 2018, 4, 2041–2050. [Google Scholar] [CrossRef]

- Ren, J.; Cheng, W.; Wan, T.; Wang, M.; Zhang, C. Effect of aeration rates and filter media heights on the performance of pollutant removal in an up-flow biological aerated filter. Water 2018, 10, 1244. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, X.; Cai, Y.; Yang, Z. An enhanced system with macrophytes and polyurethane sponge as an eco-technology for restoring eutrophic water: A pilot test. Water 2019, 11, 1828. [Google Scholar] [CrossRef]

- Singh, N.K.; Yadav, M.; Singh, R.P.; Kazmi, A.A. Efficacy analysis of a field scale IFAS reactor under different aeration strategies applied at high aeration rates: A statistical comparative analysis for practical feasibility. J. Water Process Eng. 2019, 27, 185–192. [Google Scholar] [CrossRef]

- Mehrabi, S.; Houweling, D.; Dagnew, M. Establishing mainstream nitrite shunt process in membrane aerated biofilm reactors: Impact of organic carbon and biofilm scouring intensity. J. Water Process Eng. 2020, 37, 101460. [Google Scholar] [CrossRef]

- Ren, J.; Cheng, W.; Jiao, M.; Wan, T.; Wang, M.; Li, D. Characteristics of oxygen mass transfer and its impact on pollutant removal performance and microbial community structure in an aerobic fluidized bed biofilm reactor for treatment of municipal wastewater. Bioresour. Technol. 2021, 323, 124552. [Google Scholar] [CrossRef]

- Fanta, A.B.; Nair, A.M.; Sægrov, S.; Østerhus, S.W. Phosphorus removal from industrial discharge impacted municipal wastewater using sequencing batch moving bed biofilm reactor. J. Water Process Eng. 2021, 41, 102034. [Google Scholar] [CrossRef]

- Cai, Q.; Lai, C.; Yang, P. Biomass yield characteristics and removal kinetic model construction with mass transfer optimization of a moving bed and constructed wetland (MBCW) integrated bioreactor. Biochem. Eng. J. 2023, 200, 109085. [Google Scholar] [CrossRef]

- Wei, C.-H.; Zhai, X.-Y.; Jiang, Y.-D.; Rong, H.-W.; Zhao, L.-G.; Liang, P.; Huang, X.; Ngo, H.H. Simultaneous carbon, nitrogen, and phosphorus removal in sequencing batch membrane aerated biofilm reactor with biofilm thickness control via air scouring aided by computational fluid dynamics. Bioresour. Technol. 2024, 409, 131267. [Google Scholar] [CrossRef] [PubMed]

- Fanta, A.B.; Sægrov, S.; Azrague, K.; Østerhus, S.W. Experimental investigation of simultaneous nitrification-denitrification and phosphorus removal in pilot-scale sequencing batch moving bed biofilm reactors (SB-MBBRs). Water Resour. Ind. 2024, 31, 100258. [Google Scholar] [CrossRef]

- Aldilla Fajri, J.; Fujisawa, T.; Trianda, Y.; Ishiguro, Y.; Cui, G.; Li, F.; Yamada, T. Effect of aeration rates on removals of organic carbon and nitrogen in small onsite wastewater treatment system (Johkasou). MATEC Web Conf. 2018, 147, 04008. [Google Scholar] [CrossRef]

- Dezotti, M.; Lippel, G.; Bassin, J.P. Advanced Biological Processes for Wastewater Treatment: Emerging, Consolidated Technologies and Introduction to Molecular Techniques; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Kumari, M.; Tripathi, B.D. Effect of aeration and mixed culture of Eichhornia crassipes and Salvinia natans on removal of wastewater pollutants. Ecol. Eng. 2014, 62, 48–53. [Google Scholar] [CrossRef]

- Hait, S.; Mazumd, D. High-rate wastewater treatment by a shaft-type activated sludge reactor. World Acad. Sci. Eng. Technol. 2011, 73, 22–27. [Google Scholar] [CrossRef]

- Nadayil, J.; Mohan, D.; Dileep, K.; Rose, M.; Rose, R.; Parambi, P. A study on effect of aeration on domestic wastewater. Int. J. Interdiscip. Res. Innov. 2015, 3, 10–15. [Google Scholar]

- Barge, P.; Malviya, R.K.; Parmar, N. A review on oxygen transfer rate, efficiency, capacity and their kinetic on aeration system in activated sludge process of sewage treatment plant. Int. J. Sci. Res. Publ. 2014, 4, 2250–3153. [Google Scholar]

- Garcia-Ochoa, F.; Gomez, E. Bioreactor scale-up and oxygen transfer rate in microbial processes: An overview. Biotechnol. Adv. 2009, 27, 153–176. [Google Scholar] [CrossRef]

- Jing, J.Y.; Feng, J.; Li, W.Y. Carrier effects on oxygen mass transfer behavior in a moving-bed biofilm reactor. Asia-Pac. J. Chem. Eng. 2009, 4, 618–623. [Google Scholar] [CrossRef]

- Strubbe, L.; van Dijk, E.J.H.; Deenekamp, P.J.M.; van Loosdrecht, M.C.M.; Volcke, E.I.P. Oxygen transfer efficiency in an aerobic granular sludge reactor: Dynamics and influencing factors of alpha. Chem. Eng. J. 2023, 452, 139548. [Google Scholar] [CrossRef]

- Gillot, S.; Capela-Marsal, S.; Roustan, M.; Héduit, A. Predicting oxygen transfer of fine bubble diffused aeration systems—Model issued from dimensional analysis. Water Res. 2005, 39, 1379–1387. [Google Scholar] [CrossRef] [PubMed]

- Gillot, S.; Héduit, A. Effect of air flow rate on oxygen transfer in an oxidation ditch equipped with fine bubble diffusers and slow speed mixers. Water Res. 2000, 34, 1756–1762. [Google Scholar] [CrossRef]

- Iranpour, R.; Stenstrom, M.K. Relationship Between Oxygen Transfer Rate and Airflow for Fine-Pore Aeration Under Process Conditions. Water Environ. Res. 2001, 73, 266–275. [Google Scholar] [CrossRef]

- Syron, E.; Casey, E. Performance of a pilot scale membrane aerated biofilm reactor for the treatment of landfill leachate. Procedia Eng. 2012, 44, 2082–2084. [Google Scholar] [CrossRef]

- Barwal, A.; Chaudhary, R. Impact of carrier filling ratio on oxygen uptake & transfer rate, volumetric oxygen transfer coefficient and energy saving potential in a lab-scale MBBR. J. Water Process Eng. 2015, 8, 202–208. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, H.; Wang, M.; Wang, M. The effect of bubble plume on oxygen transfer for moving bed biofilm reactor. J. Hydrodyn. 2014, 26, 664–667. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Abbà, A.; Bertanza, G. Oxygen transfer improvement in MBBR process. Environ. Sci. Pollut. Res. 2019, 26, 10727–10737. [Google Scholar] [CrossRef]

- Dias, J.; Bellingham, M.; Hassan, J.; Barrett, M.; Stephenson, T.; Soares, A. Impact of carrier media on oxygen transfer and wastewater hydrodynamics on a moving attached growth system. Chem. Eng. J. 2018, 351, 399–408. [Google Scholar] [CrossRef]

- Sander, S.; Behnisch, J.; Wagner, M. Energy, cost and design aspects of coarse- and fine-bubble aeration systems in the MBBR IFAS process. Water Sci. Technol. 2017, 75, 890–897. [Google Scholar] [CrossRef]

- Leung, S.M.; Little, J.C.; Holst, T.; Love, N.G. Air/water oxygen transfer in a biological aerated filter. J. Environ. Eng. 2006, 132, 181–189. [Google Scholar] [CrossRef]

- Veleva, I.; Van Weert, W.; Van Belzen, N.; Cornelissen, E.; Verliefde, A.; Vanoppen, M. Petrochemical condensate treatment by membrane aerated biofilm reactors: A pilot study. Chem. Eng. J. 2022, 428, 131013. [Google Scholar] [CrossRef]

- Elad, T.; Hallya, M.P.; Domingo-Félez, C.; Knoop, O.; Drewes, J.E.; Valverde-Pérez, B.; Smets, B.F. Exploring the effects of intermittent aeration on the performance of nitrifying membrane-aerated biofilm reactors. Sci. Total Environ. 2023, 891, 164329. [Google Scholar] [CrossRef]

- Campo, G.; Cerutti, A.; Zanetti, M.; Ruffino, B. Membrane aerated biological reactors (MABRs) to enhance the biological treatment process at a WWTP. J. Environ. Manag. 2024, 371, 122921. [Google Scholar] [CrossRef]

- Gu, Y.; Li, Y.; Yuan, F.; Yang, Q. Optimization and control strategies of aeration in WWTPs: A review. J. Clean. Prod. 2023, 418, 138008. [Google Scholar] [CrossRef]

- Kadam, R.; Khanthong, K.; Park, B.; Jun, H.; Park, J. Realizable wastewater treatment process for carbon neutrality and energy sustainability: A review. J. Environ. Manag. 2023, 328, 116927. [Google Scholar] [CrossRef]

- SeyedSharifi, M.; Taheriyoun, M.; Qandari, H. Analyzing the effects of different patterns of diffuser layouts on air distribution and mixing quality in an aeration tank using CFD. Process Saf. Environ. Prot. 2024, 181, 182–194. [Google Scholar] [CrossRef]

- Ao, Z.; Li, H.; Chen, J.; Yuan, J.; Xia, Z.; Zhang, J.; Chen, H.; Wang, H.; Liu, G.; Qi, L. A new approach to optimizing aeration using XGB-Bi-LSTM via the online monitoring of oxygen transfer efficiency and oxygen uptake rate. Environ. Res. 2023, 238, 117142. [Google Scholar] [CrossRef]

- Campo, G.; Miggiano, A.; Panepinto, D.; Zanetti, M. Enhancing the energy efficiency of wastewater treatment plants through the optimization of the aeration systems. Energies 2023, 16, 2819. [Google Scholar] [CrossRef]

- Rathnaweera, S.S.; Rusten, B.; Manamperuma, L.D.; Wang, S.; Helland, B. Innovative, compact and energy-efficient biofilm process for nutrient removal from wastewater. Water Sci. Technol. 2020, 81, 1941–1950. [Google Scholar] [CrossRef]

- Abdelfattah, A.; Ramadan, H.; Elsamahy, T.; Eltawab, R.; Mostafa, S.; Zhou, X.; Cheng, L. Multifaced features and sustainability of using pure oxygen in biological wastewater treatment: A review. J. Water Process Eng. 2023, 53, 103883. [Google Scholar] [CrossRef]

- Zhang, B.; Xu, R.; Liang, Y.; Wei, G.; Wei, C.; Chen, H.; Wu, H. Carrier with cyclodextrin and quorum sensing synergy: An efficient method for selective enrichment of anammox bacteria. Chem. Eng. J. 2024, 481, 148461. [Google Scholar] [CrossRef]

- Li, X.; Li, G.; Yu, Y.; Jia, H.; Ma, X.; Yang, H.; Opoku, P.A. Hydraulic characterization and start-up of a novel circulating flow bio-carriers. Sci. Rep. 2024, 14, 6384. [Google Scholar] [CrossRef] [PubMed]

- Zetterlund, S.; Schwartz, O.; Sandberg, M.; Venkatesh, G. Computational modelling to advise and inform optimization for aeration and nutrient-dosing in wastewater treatment: Case study from pulp and paper mill in south-central Sweden. J. Water Process Eng. 2023, 56, 104508. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).