Hydraulic Resistance and Protein Fouling Resistance of a Zirconia Membrane with a Tethered PVP Layer

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

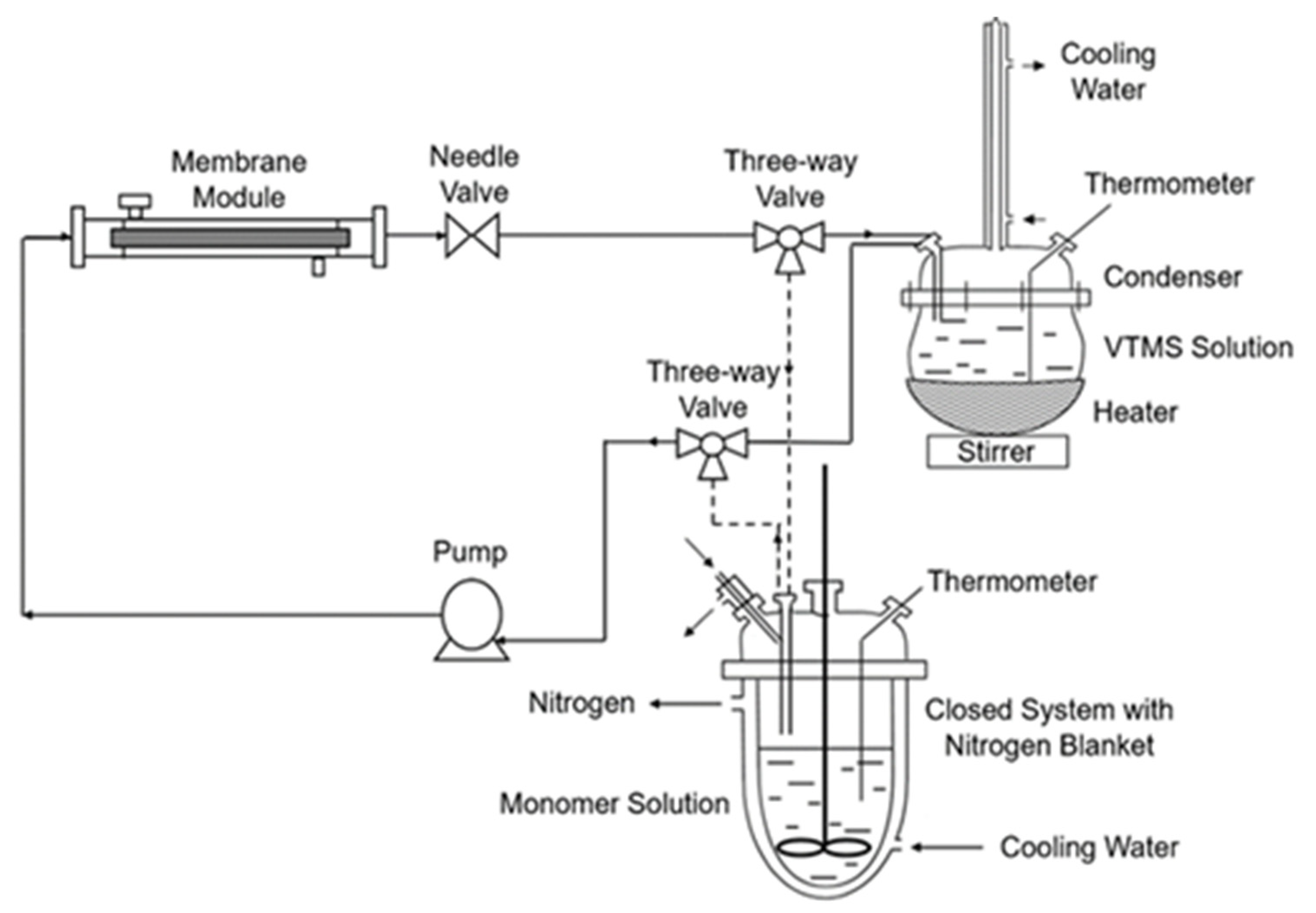

2.2. Surface Modification

2.3. Membrane Hydraulic Resistance and Fouling Test

3. Results and Discussion

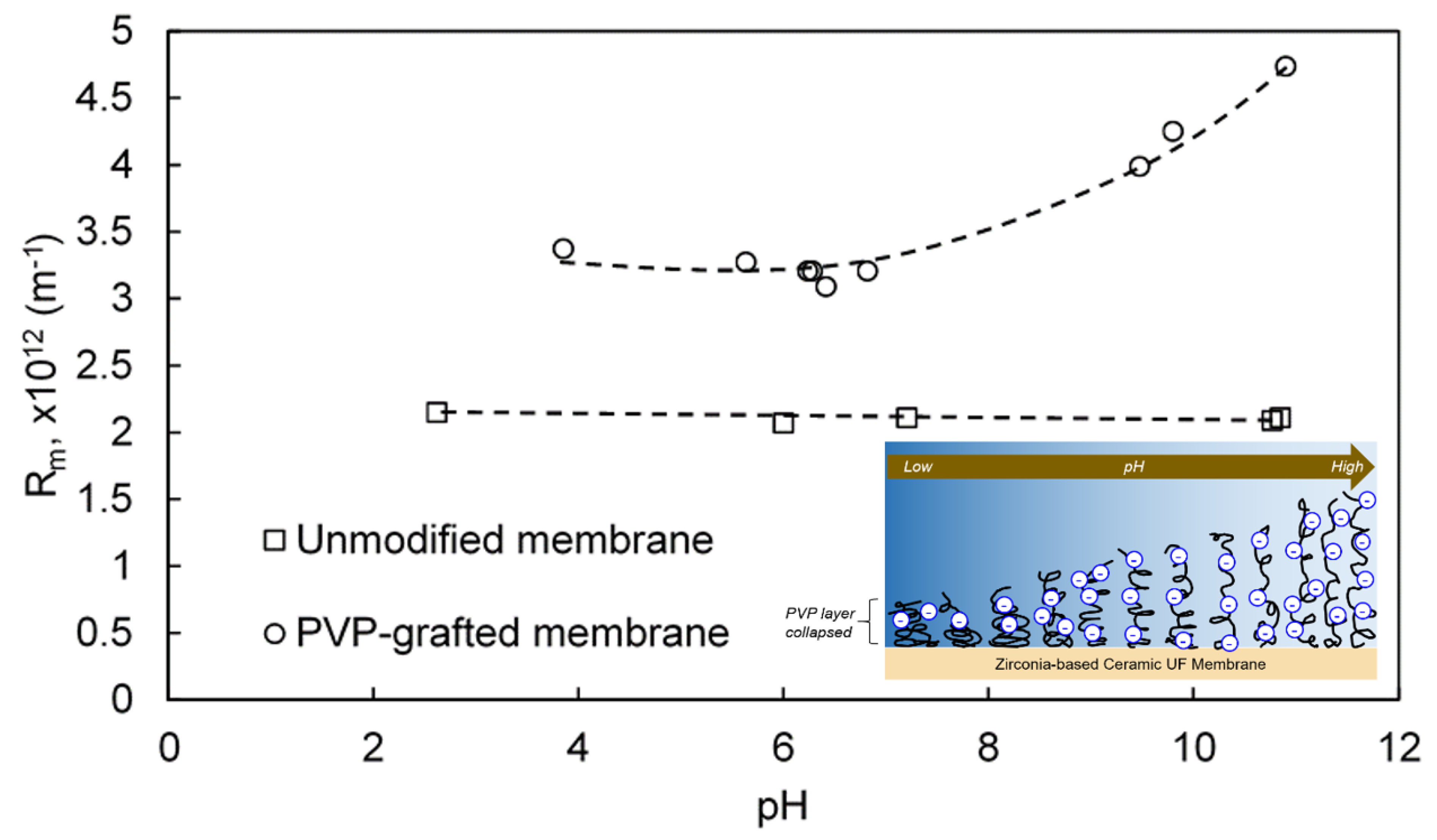

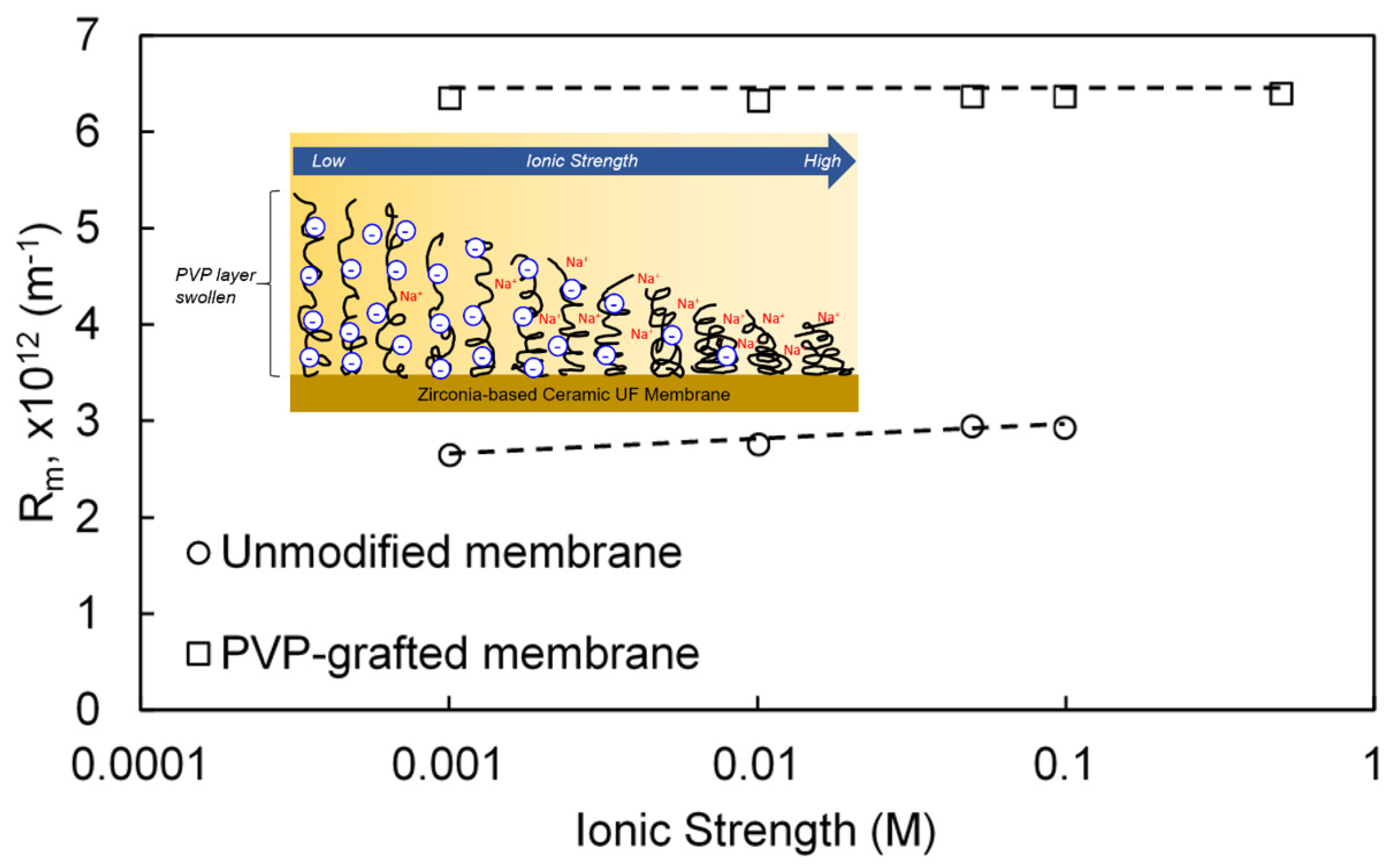

3.1. Hydraulic Resistance of Native and Modified Zirconia Membranes

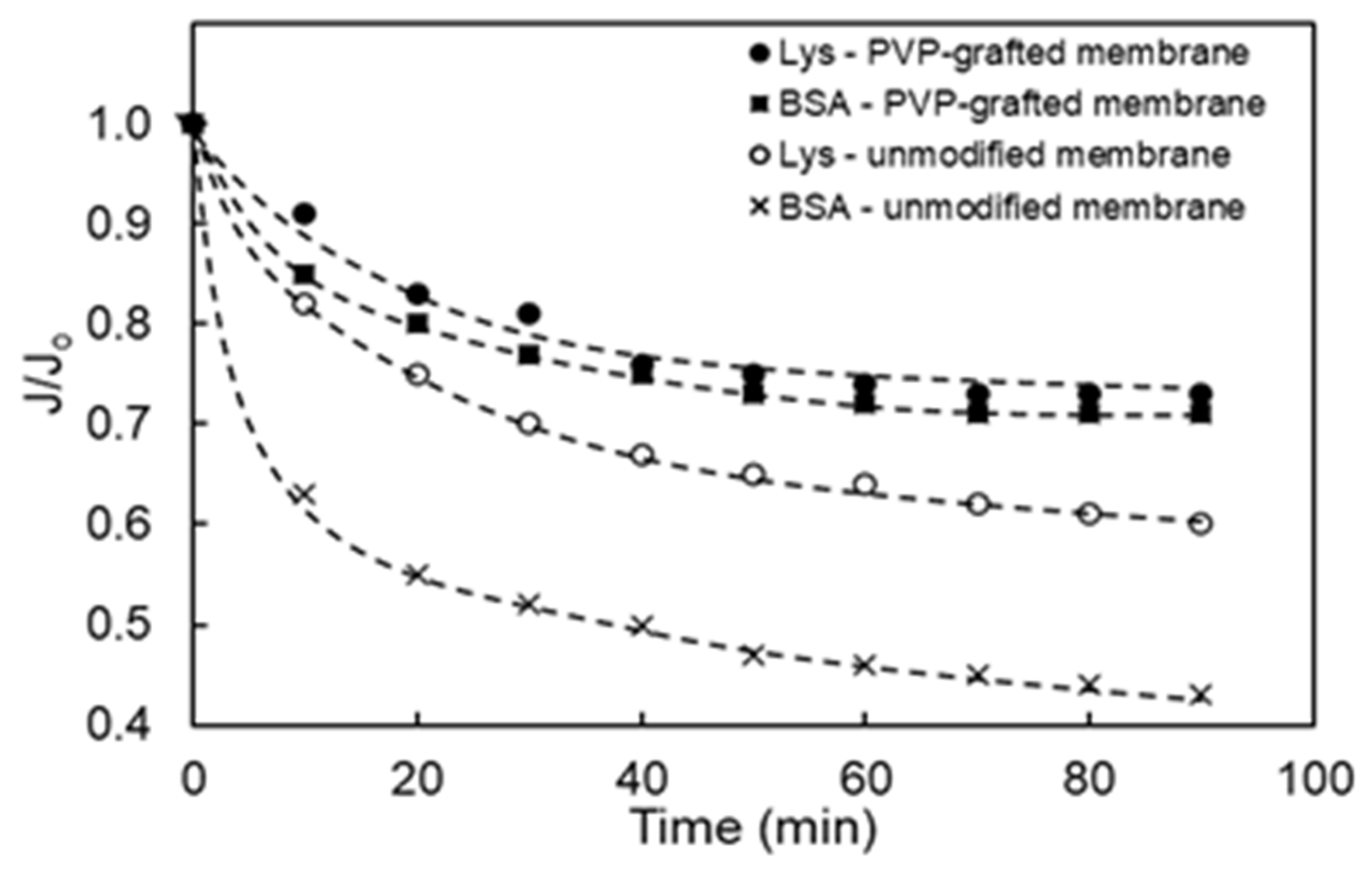

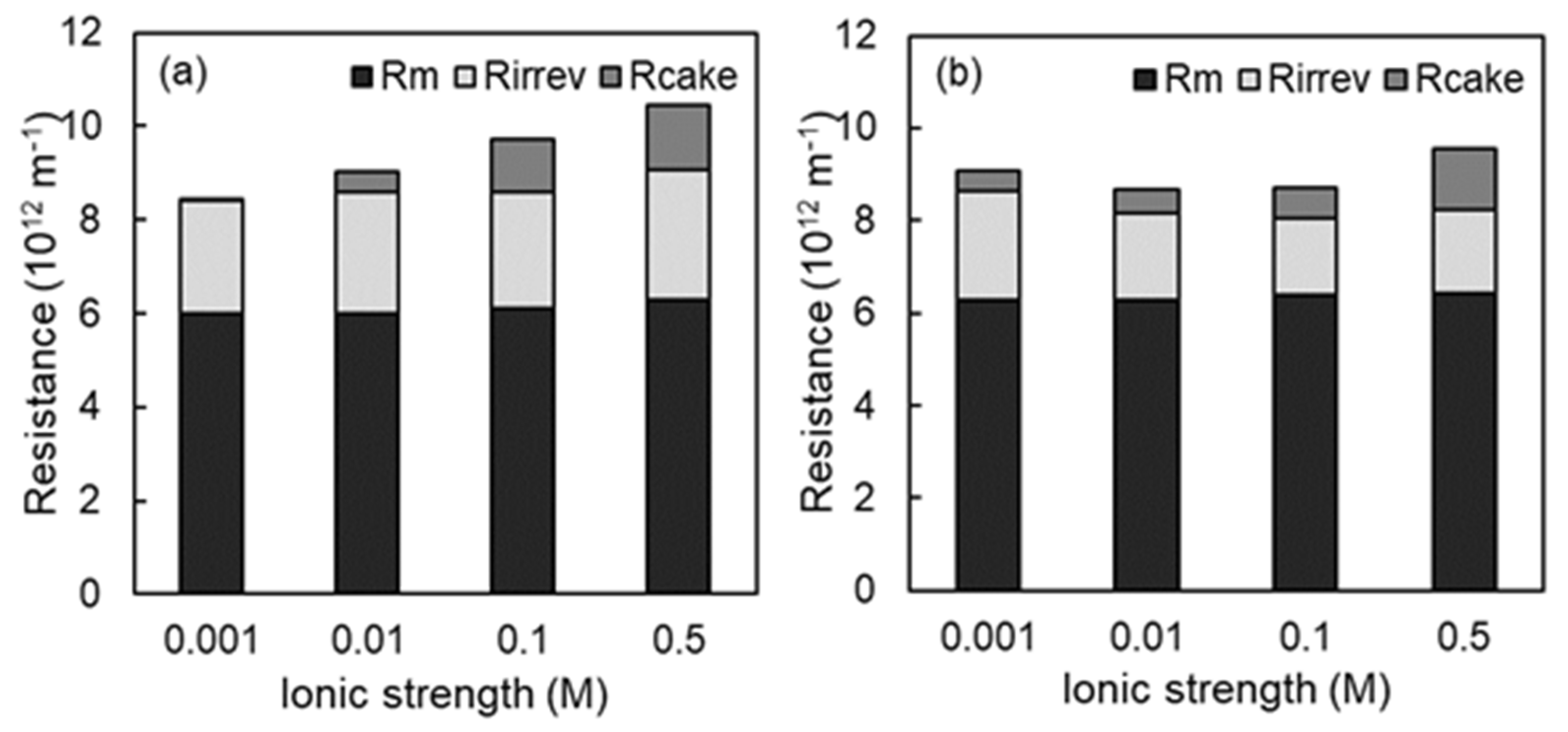

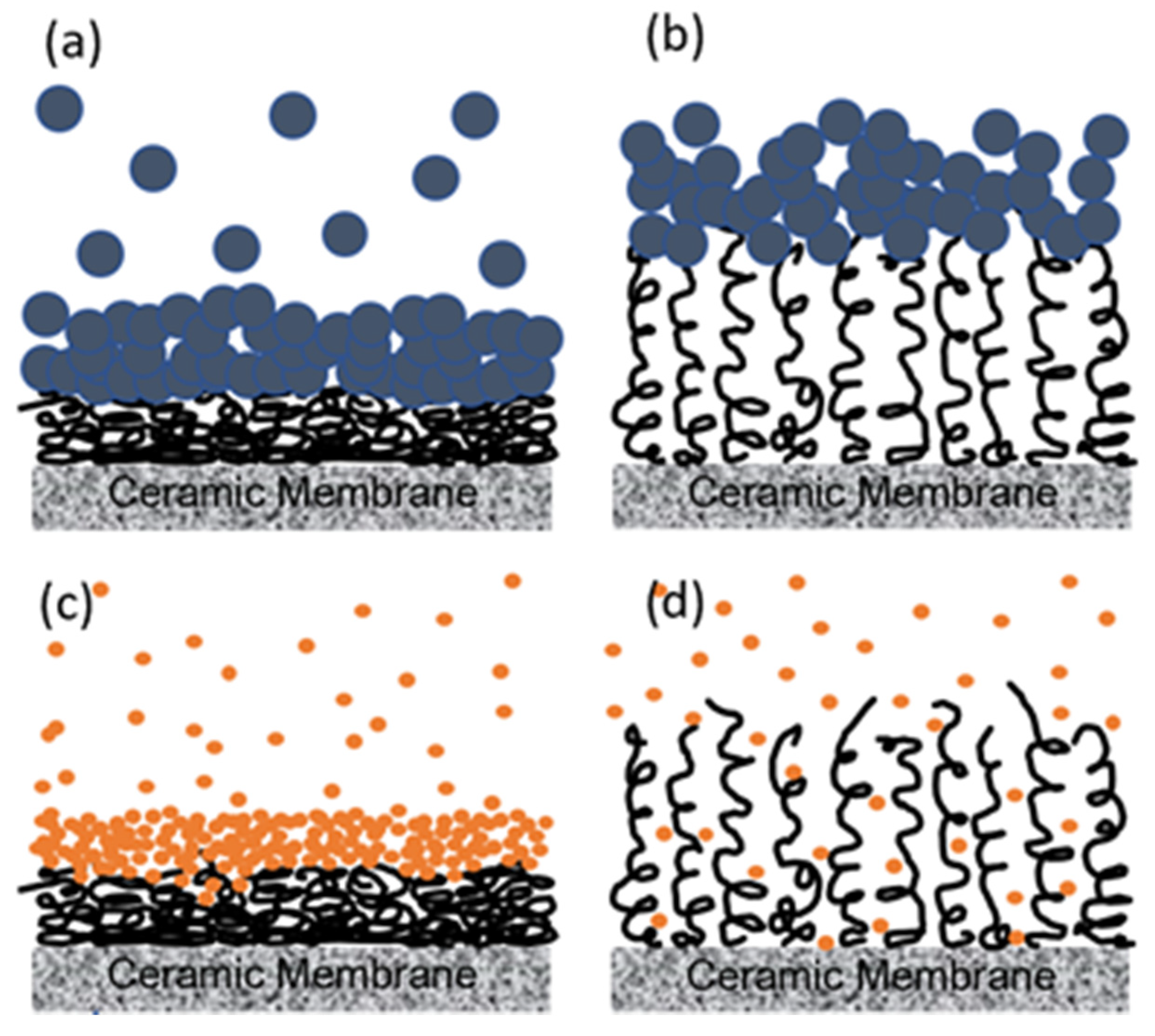

3.2. Effect of Ionic Strength on PVP-ZrO2 Membrane Protein Fouling

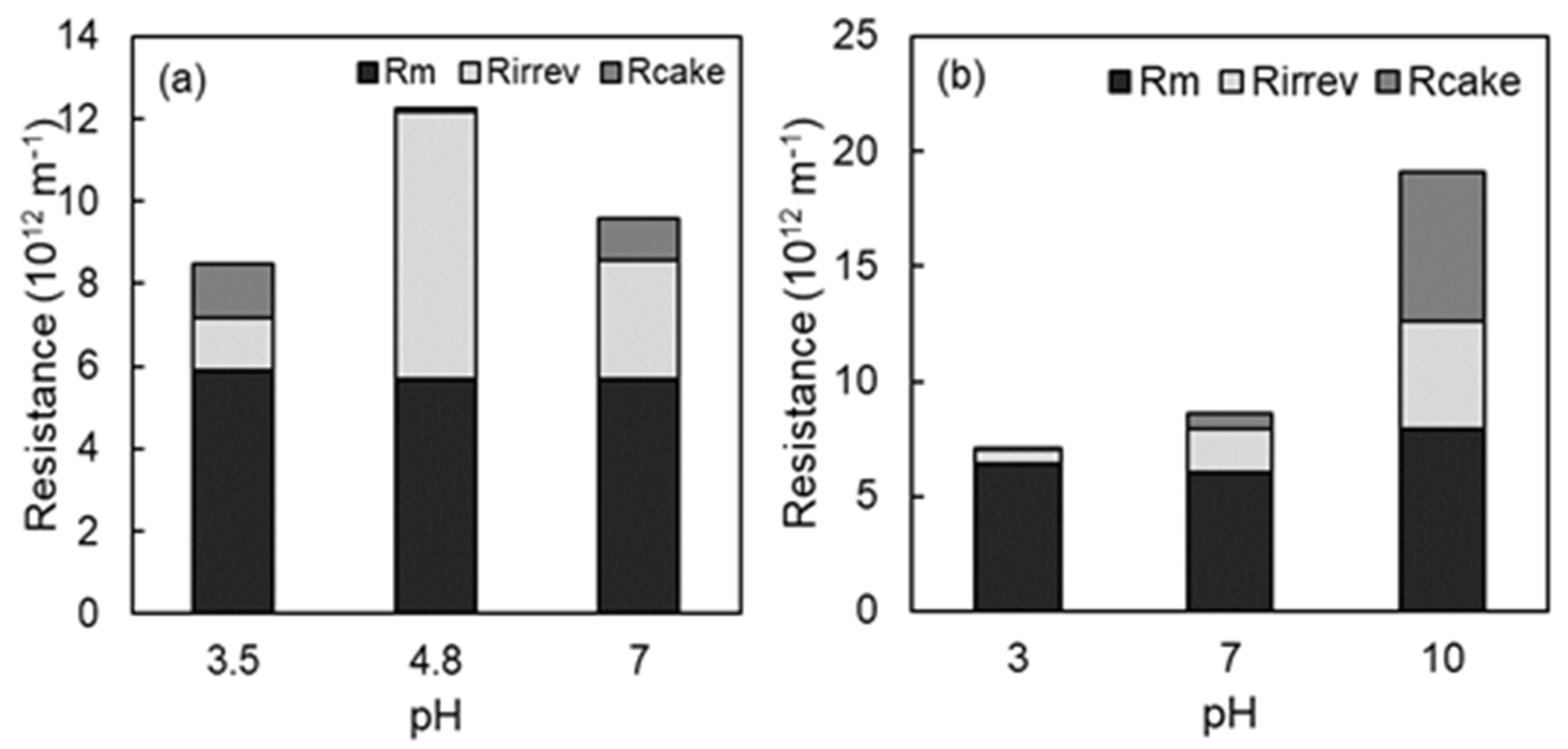

3.3. Impact of pH on PVP-ZrO2 Membrane Protein Fouling

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| ΔP (kPa) | Re | Rm, ×1012 m−1 |

|---|---|---|

| 30 | 1187 | 2.79 |

| 30 | 1818 | 2.66 |

| 30 | 3724 | 2.72 |

| 100 | 743 | 3.09 |

| 100 | 1822 | 3.15 |

| 100 | 2804 | 3.20 |

| 100 | 3724 | 3.17 |

| Foulant | pH | Ionic Strength (M) | Unmodified Membrane Rirrev (×1012 m−1) | PVP-ZrO2 Membrane Rirrev (×1012 m−1) |

|---|---|---|---|---|

| Lys | 3 | 0.1 | 2.3 | 0.6 |

| 7 | 0.1 | 3.7 | 1.9 | |

| 10 | 0.1 | 4.1 | 4.7 | |

| 7 | 0.001 | 2.8 | 2.3 | |

| 7 | 0.01 | 3.0 | 1.9 | |

| 7 | 0.5 | 3.5 | 1.8 | |

| BSA | 3.5 | 0.1 | 1.7 | 1.3 |

| 4.8 | 0.1 | 7.3 | 6.5 | |

| 7 | 0.1 | 5.3 | 2.7 | |

| 7 | 0.001 | 4.7 | 2.4 | |

| 7 | 0.01 | 5.1 | 2.6 | |

| 7 | 0.5 | 5.3 | 2.8 |

References

- Samaei, S.M.; Gato-Trinidad, S.; Altaee, A. The application of pressure-driven ceramic membrane technology for the treatment of industrial wastewaters—A review. Sep. Purif. Technol. 2018, 200, 198–220. [Google Scholar] [CrossRef]

- Amin, S.K.; Abdallah, H.A.M.; Roushdy, M.H.; El-Sherbiny, S.A. An overview of production and development of ceramic membranes. Int. J. Appl. Eng. Res. 2016, 11, 7708–7721. [Google Scholar]

- He, Z.; Lyu, Z.; Gu, Q.; Zhang, L.; Wang, J. Ceramic-based membranes for water and wastewater treatment. Colloids Surf. A Physicochem. Eng. Asp. 2019, 578, 123513. [Google Scholar] [CrossRef]

- Membrane Separation Materials Market Research Report—Global Forecast Till 2023; Market Research Future (MRFR): Maharashtra, India, 2019.

- Yue, X.; Koh, Y.K.K.; Ng, H.Y. Effects of dissolved organic matters (DOMs) on membrane fouling in anaerobic ceramic membrane bioreactors (AnCMBRs) treating domestic wastewater. Water Res. 2015, 86, 96–107. [Google Scholar] [CrossRef]

- Tang, S.; Zhang, Z.; Liu, J.; Zhang, X. Double-win effects of in-situ ozonation on improved filterability of mixed liquor and ceramic UF membrane fouling mitigation in wastewater treatment? J. Membr. Sci. 2017, 533, 112–120. [Google Scholar] [CrossRef]

- Tang, S.; Zhang, Z.; Zhang, X. Coupling in-situ ozonation with ferric chloride addition for ceramic ultrafiltration membrane fouling mitigation in wastewater treatment: Quantitative fouling analysis. J. Membr. Sci. 2018, 555, 307–317. [Google Scholar] [CrossRef]

- Laîné, J.-M.; Campos, C.; Baudin, I.; Janex, M.-L. Understanding membrane fouling: A review of over a decade of research. Water Supply 2003, 3, 155–164. [Google Scholar] [CrossRef]

- Biron, D.D.S.; Dos Santos, V.; Zeni, M. Ceramic Membranes Applied in Separation Processes; Metzler, J.B., Ed.; Springer: New York, NY, USA, 2018. [Google Scholar]

- Guo, W.; Ngo, H.-H.; Li, J. A mini-review on membrane fouling. Bioresour. Technol. 2012, 122, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Liang, H.; Ma, J.; Han, M.; Chen, Z.-L.; Han, Z.-S.; Li, G.-B. Membrane fouling control in ultrafiltration technology for drinking water production: A review. Desalination 2011, 272, 1–8. [Google Scholar] [CrossRef]

- Ambrosi, A.; Cardozo, N.S.M.; Tessaro, I.C. Membrane Separation Processes for the Beer Industry: A Review and State of the Art. Food Bioprocess. Technol. 2014, 7, 921–936. [Google Scholar] [CrossRef]

- Kumar, P.; Sharma, N.; Ranjan, R.; Kumar, S.; Bhat, Z.F.; Jeong, D.K. Perspective of Membrane Technology in Dairy Industry: A Review. Asian-Australas. J. Anim. Sci. 2013, 26, 1347–1358. [Google Scholar] [CrossRef]

- El Rayess, Y.; Albasi, C.; Bacchin, P.; Taillandier, P.; Mietton-Peuchot, M.; Devatine, A. Analysis of membrane fouling during cross-flow microfiltration of wine. Innov. Food Sci. Emerg. Technol. 2012, 16, 398–408. [Google Scholar] [CrossRef]

- Zhou, S.; Xue, A.; Zhao, Y.; Li, M.; Wang, H.; Xing, W. Grafting polyacrylic acid brushes onto zirconia membranes: Fouling reduction and easy-cleaning properties. Sep. Purif. Technol. 2013, 114, 53–63. [Google Scholar] [CrossRef]

- Faibish, R.S.; Cohen, Y. Fouling-resistant ceramic-supported polymer membranes for ultrafiltration of oil-in-water microemulsions. J. Membr. Sci. 2001, 185, 129–143. [Google Scholar] [CrossRef]

- Malik, A.A.; Kour, H.; Bhat, A.; Kaul, R.K.; Khan, S.; Khan, S.U. Commercial utilization of membranes in food industry. Int. J. Food Nutr. Saf. 2013, 3, 147–170. [Google Scholar]

- Zhou, S.; Xue, A.; Zhang, Y.; Li, M.; Wang, J.; Zhao, Y.; Xing, W. Fabrication of temperature-responsive ZrO2 tubular membranes, grafted with poly (N-isopropylacrylamide) brush chains, for protein removal and easy cleaning. J. Membr. Sci. 2014, 450, 351–361. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, S.; Li, M.; Xue, A.; Zhang, Y.; Wang, J.; Xing, W. Humic acid removal and easy-cleanability using temperature-responsive ZrO2 tubular membranes grafted with poly(N-isopropylacrylamide) brush chains. Water Res. 2013, 47, 2375–2386. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, I.; Pangule, R.C.; Kane, R.S. Antifouling Coatings: Recent Developments in the Design of Surfaces That Prevent Fouling by Proteins, Bacteria, and Marine Organisms. Adv. Mater. 2010, 23, 690–718. [Google Scholar] [CrossRef]

- Mustafa, G.; Wyns, K.; Vandezande, P.; Buekenhoudt, A.; Meynen, V. Novel grafting method efficiently decreases irreversible fouling of ceramic nanofiltration membranes. J. Membr. Sci. 2014, 470, 369–377. [Google Scholar] [CrossRef]

- Iv, J.J.K.; Imbrogno, J.; Belfort, G. Polymer Brushes for Membrane Separations: A Review. ACS Appl. Mater. Interfaces 2016, 8, 28383–28399. [Google Scholar] [CrossRef]

- Ismail, N.; Salleh, W.; Ismail, A.; Hasbullah, H.; Yusof, N.; Aziz, F.; Jaafar, J. Hydrophilic polymer-based membrane for oily wastewater treatment: A review. Sep. Purif. Technol. 2020, 233, 116007. [Google Scholar] [CrossRef]

- Kim, S.; Cohen, Y. Surface Modified Reverse Osmosis Membranes. In Advances in Water Desalination Technologies; Cohen, Y., Ed.; World Scientific: Hackensack, NJ, USA, 2021. [Google Scholar]

- Wandera, D.; Wickramasinghe, S.R.; Husson, S.M. Stimuli-responsive membranes. J. Membr. Sci. 2010, 357, 6–35. [Google Scholar] [CrossRef]

- Darvishmanesh, S.; Qian, X.; Wickramasinghe, S.R. Responsive membranes for advanced separations. Curr. Opin. Chem. Eng. 2015, 8, 98–104. [Google Scholar] [CrossRef]

- Zhang, X.; Tian, J.; Gao, S.; Shi, W.; Zhang, Z.; Cui, F.; Zhang, S.; Guo, S.; Yang, X.; Xie, H.; et al. Surface functionalization of TFC FO membranes with zwitterionic polymers: Improvement of antifouling and salt-responsive cleaning properties. J. Membr. Sci. 2017, 544, 368–377. [Google Scholar] [CrossRef]

- Rovira-Bru, M.; Giralt, F.; Cohen, Y. Protein Adsorption onto Zirconia Modified with Terminally Grafted Polyvinylpyrrolidone. J. Colloid Interface Sci. 2001, 235, 70–79. [Google Scholar] [CrossRef]

- Faibish, R.S.; Cohen, Y. Fouling and rejection behavior of ceramic and polymer-modified ceramic membranes for ultrafiltration of oil-in-water emulsions and microemulsions. Colloids Surfaces A Physicochem. Eng. Asp. 2001, 191, 27–40. [Google Scholar] [CrossRef]

- Chang, X.; Wang, Z.; Quan, S.; Xu, Y.; Jiang, Z.; Shao, L. Exploring the synergetic effects of graphene oxide (GO) and polyvinylpyrrodione (PVP) on poly(vinylylidenefluoride) (PVDF) ultrafiltration membrane performance. Appl. Surf. Sci. 2014, 316, 537–548. [Google Scholar] [CrossRef]

- Chaimberg, M.; Parnas, R.; Cohen, Y. Graft polymerization of polyvinylpyrrolidone onto silica. J. Appl. Polym. Sci. 1989, 37, 2921–2931. [Google Scholar] [CrossRef]

- Pachova, V.; Ferrando, M.; Guell, C.; Lóapez, F. Protein Adsorption onto Metal Oxide Materials in White Wine Model Systems. J. Food Sci. 2002, 67, 2118–2121. [Google Scholar] [CrossRef]

- Jaspe, J.; Hagen, S.J. Do Protein Molecules Unfold in a Simple Shear Flow? Biophys. J. 2006, 91, 3415–3424. [Google Scholar] [CrossRef] [PubMed]

- El Rayess, Y.; Mietton-Peuchot, M. Membrane Technologies in Wine Industry: An Overview. Crit. Rev. Food Sci. Nutr. 2015, 56, 2005–2020. [Google Scholar] [CrossRef]

- Daufin, G.; Escudier, J.-P.; Carrère, H.; Bérot, S.; Fillaudeau, L.; Decloux, M. Recent and Emerging Applications of Membrane Processes in the Food and Dairy Industry. Food Bioprod. Process. 2001, 79, 89–102. [Google Scholar] [CrossRef]

- Braeken, L.; Van Der Bruggen, B.; Vandecasteele, C. Regeneration of brewery waste water using nanofiltration. Water Res. 2004, 38, 3075–3082. [Google Scholar] [CrossRef]

- Dufrechou, M.; Poncet-Legrand, C.; Sauvage, F.-X.; Vernhet, A. Stability of White Wine Proteins: Combined Effect of pH, Ionic Strength, and Temperature on Their Aggregation. J. Agric. Food Chem. 2012, 60, 1308–1319. [Google Scholar] [CrossRef] [PubMed]

- Jimenez-Lopez, A.; Leconte, N.; Garnier-Lambrouin, F.; Bouchoux, A.; Rousseau, F.; Gésan-Guiziou, G. Ionic strength dependence of skimmed milk microfiltration: Relations between filtration performance, deposit layer characteristics and colloidal properties of casein micelles. J. Membr. Sci. 2011, 369, 404–413. [Google Scholar] [CrossRef]

- Nokdbo, R. The concentration of ionized magnesium and calcium in milk. J. Biol. Chem. 1939, 128, 745–757. [Google Scholar]

- Lin, H.; Gao, W.; Meng, F.; Liao, B.-Q.; Leung, K.-T.; Zhao, L.; Chen, J.; Hong, H. Membrane Bioreactors for Industrial Wastewater Treatment: A Critical Review. Crit. Rev. Environ. Sci. Technol. 2012, 42, 677–740. [Google Scholar] [CrossRef]

- Chew, C.M.; Aroua, M.; Hussain, M. A practical hybrid modelling approach for the prediction of potential fouling parameters in ultrafiltration membrane water treatment plant. J. Ind. Eng. Chem. 2017, 45, 145–155. [Google Scholar] [CrossRef]

- Chakrabarty, B.; Ghoshal, A.; Purkait, M. SEM analysis and gas permeability test to characterize polysulfone membrane prepared with polyethylene glycol as additive. J. Colloid Interface Sci. 2008, 320, 245–253. [Google Scholar] [CrossRef] [PubMed]

- Tian, J.-Y.; Ernst, M.; Cui, F.; Jekel, M. Effect of particle size and concentration on the synergistic UF membrane fouling by particles and NOM fractions. J. Membr. Sci. 2013, 446, 1–9. [Google Scholar] [CrossRef]

- Li, D.; Yao, J.; Liu, B.; Sun, H.; Van Agtmaal, S.; Feng, C. Preparation and characterization of surface grafting polymer of ZrO2 membrane and ZrO2 powder. Appl. Surf. Sci. 2019, 471, 394–402. [Google Scholar] [CrossRef]

- Xu, F.; Wei, M.; Zhang, X.; Song, Y.; Zhou, W.; Wang, Y. How Pore Hydrophilicity Influences Water Permeability? Research 2019, 2019, 2581241. [Google Scholar] [CrossRef] [PubMed]

- Faibish, R.S.; Yoshida, W.; Cohen, Y. Contact Angle Study on Polymer-Grafted Silicon Wafers. J. Colloid Interface Sci. 2002, 256, 341–350. [Google Scholar] [CrossRef]

- Artigas, J. Development of a multiparametric analyser based on ISFET sensors applied to process control in the wine industry. Sens. Actuators B Chem. 2003, 89, 199–204. [Google Scholar] [CrossRef]

- Tokareva, I.; Minko, S.; Fendler, A.J.H.; Hutter, E. Nanosensors Based on Responsive Polymer Brushes and Gold Nanoparticle Enhanced Transmission Surface Plasmon Resonance Spectroscopy. J. Am. Chem. Soc. 2004, 126, 15950–15951. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, W.; Xie, R.; Ju, X.-J.; Chu, L.-Y. Stimuli-responsive smart gating membranes. Chem. Soc. Rev. 2016, 45, 460–475. [Google Scholar] [CrossRef]

- Drechsler, A.; Elmahdy, M.M.; Uhlmann, P.; Stamm, M. pH and Salt Response of Mixed Brushes Made of Oppositely Charged Polyelectrolytes Studied by in Situ AFM Force Measurements and Imaging. Langmuir 2018, 34, 4739–4749. [Google Scholar] [CrossRef]

- Nazzal, F.F.; Wiesner, M.R. pH and ionic strength effects on the performance of ceramic membranes in water filtration. J. Membr. Sci. 1994, 93, 91–103. [Google Scholar] [CrossRef]

- Castro, R.P.; Monbouquette, H.G.; Cohen, Y. Shear-induced permeability changes in a polymer grafted silica membrane. J. Membr. Sci. 2000, 179, 207–220. [Google Scholar] [CrossRef]

- Miao, R.; Wang, L.; Zhu, M.; Deng, D.; Li, S.; Wang, J.; Liu, T.; Lv, Y. Effect of Hydration Forces on Protein Fouling of Ultrafiltration Membranes: The Role of Protein Charge, Hydrated Ion Species, and Membrane Hydrophilicity. Environ. Sci. Technol. 2016, 51, 167–174. [Google Scholar] [CrossRef]

- Cohen, Y.; Eisenberg, P.; Chaimberg, M. Permeability of graft-polymerized polyvinylpyrrolidone-silica resin in packed columns. J. Colloid Interface Sci. 1992, 148, 579–586. [Google Scholar] [CrossRef]

- Nguyen, T.P.B.; Lee, J.-W.; Shim, W.G.; Moon, H. Synthesis of functionalized SBA-15 with ordered large pore size and its adsorption properties of BSA. Microporous Mesoporous Mater. 2008, 110, 560–569. [Google Scholar] [CrossRef]

- Colvin, J.R. The Size and Shape of Lysozyme. Can. J. Chem. 1952, 30, 831–834. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Z.; Wang, J.; Wang, S. Positively charged aromatic polyamide reverse osmosis membrane with high anti-fouling property prepared by polyethylenimine grafting. Desalination 2015, 365, 398–406. [Google Scholar] [CrossRef]

- Nakamura, K.; Matsumoto, K. Properties of protein adsorption onto pore surface during microfiltration: Effects of solution environment and membrane hydrophobicity. J. Membr. Sci. 2006, 280, 363–374. [Google Scholar] [CrossRef]

- She, Q.; Tang, C.Y.; Wang, Y.-N.; Zhang, Z. The role of hydrodynamic conditions and solution chemistry on protein fouling during ultrafiltration. Desalination 2009, 249, 1079–1087. [Google Scholar] [CrossRef]

- Vetri, V.; Librizzi, F.; Leone, M.; Militello, V. Thermal aggregation of bovine serum albumin at different pH: Comparison with human serum albumin. Eur. Biophys. J. 2007, 36, 717–725. [Google Scholar] [CrossRef]

- Pereira, L.G.C.; Théodoly, O.; Blanch, H.W.; Radke, C.J. Dilatational Rheology of BSA Conformers at the Air/Water Interface. Langmuir 2003, 19, 2349–2356. [Google Scholar] [CrossRef]

- Lu, J.; Su, T.; Thirtle, P.; Thomas, R.; Rennie, A.; Cubitt, R. The Denaturation of Lysozyme Layers Adsorbed at the Hydrophobic Solid/Liquid Surface Studied by Neutron Reflection. J. Colloid Interface Sci. 1998, 206, 212–223. [Google Scholar] [CrossRef] [PubMed]

| Membrane | Rm (1012 m−1) | R2 (a) |

|---|---|---|

| Unmodified | 2.75 | 0.9809 |

| Vinyl-trimethoxy-silane (VTMS) Silylated | 16.07 | 0.9879 |

| VTMS/Hydrolyzed | 9.82 | 0.9990 |

| Grafted | 5.99 | 0.9908 |

| Ionic Strength (M) | BSA Rejection (%) | Lys Rejection (%) |

|---|---|---|

| 0.001 | 93.2 | 39.9 |

| 0.01 | 78.5 | 4.6 |

| 0.1 | 49.1 | 2.6 |

| 0.5 | 56.3 | 5.8 |

| pH | Protein | Rejection (%) |

|---|---|---|

| 3.5 | BSA | 84.2 |

| 4.8 | BSA | 99.7 |

| 7 | BSA | 48.4 |

| 3 | Lys | 24.4 |

| 7 | Lys | 4.3 |

| 10 | Lys | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Rovira-Bru, M.; Giralt, F.; Cohen, Y. Hydraulic Resistance and Protein Fouling Resistance of a Zirconia Membrane with a Tethered PVP Layer. Water 2021, 13, 951. https://doi.org/10.3390/w13070951

Chen Y, Rovira-Bru M, Giralt F, Cohen Y. Hydraulic Resistance and Protein Fouling Resistance of a Zirconia Membrane with a Tethered PVP Layer. Water. 2021; 13(7):951. https://doi.org/10.3390/w13070951

Chicago/Turabian StyleChen, Yian, Montserrat Rovira-Bru, Francesc Giralt, and Yoram Cohen. 2021. "Hydraulic Resistance and Protein Fouling Resistance of a Zirconia Membrane with a Tethered PVP Layer" Water 13, no. 7: 951. https://doi.org/10.3390/w13070951

APA StyleChen, Y., Rovira-Bru, M., Giralt, F., & Cohen, Y. (2021). Hydraulic Resistance and Protein Fouling Resistance of a Zirconia Membrane with a Tethered PVP Layer. Water, 13(7), 951. https://doi.org/10.3390/w13070951