Abstract

A cost-effective harvesting method and equipment for small-scale farms is essential to ensure the viability and sustainability of their operations. This study aims to retrofit and test a pull-type combine harvester for effective and efficient operations in small grains. A 1960s-era functional combine harvester was retrofitted with a stripper header rotor in place of the sickle bar cutting system to increase the harvesting capacity. Preliminary field testing found that the original header auger and feeder house could not handle the changed crop composition at an increased capacity and did not properly convey the grain from the auger to the feeder house and onto the threshing system. Therefore, redesign modifications were conducted for the auger and feeder house to help increase the efficiency and capacity required to use the stripper header. Various design concepts were proposed, analyzed, and prototyped in this study. The machine performance of the material-conveying efficiency of the wheat-material-other-than-grain mixture was evaluated at various material throughput rates. The results showed that the auger shim and feeder house paddle redesign increased the efficiency from 80.68% to 98.56%, as compared to the original machine configuration. The cost-effective and high-performance pull-type combine harvester proposed in this study has a high potential in solving the bottleneck problem of local production of small grains by small-scale farming operations.

1. Introduction

The ownership and operating costs of agricultural equipment have been steadily increasing in the past decades. Part of this is attributed to the increase in machine size, but it is also largely due to an increased capacity and added technology. Generally, with modern agricultural equipment, the purchasing of a machine that is more efficient or has more technology integrated, usually comes at the cost of an increased size and price. This has led to the rise in popularity of retrofitting comparatively older equipment to gain the benefits of top-of-the-line machines at a much lower price point [1]. This trend is especially noticeable in small farms, organic farming, and urban agriculture sectors [2]. For example, a common modification is the addition of guidance systems to tractors and combines, which add the ability to accurately map fields and allow for the creation of planting and fertilizer prescriptions [3]. Additionally, these systems can be used to track yields for making field management decisions [4]. Other examples of modifications include adding modern fertilizer application equipment and technologies to planters [5], installing grain-saver kits to combines [6], implementing row-following technology to headers [7], etc.

The basic concepts and techniques employed in harvesting equipment have not changed much in the last half-century. Specifically, with the advent of combine harvesters, the same basic concepts can be found in machines from the 1970s and even earlier. One notable comparatively recent major innovation is the axial rotor combine [8,9]. Other innovations have been related to the headers used by combines to remove the crop from the field [10]. Arguably the most predominant of these is the invention of stripper headers originally developed at Silsoe Research Institute in the UK [11] and commercially manufactured by Shelbourne Reynolds Engineering, Ltd. [12]. A stripper header strips grain from the crop, leaving the stems and majority of material-other-than-grain (MOG) on the field, to reduce the material being ingested into the threshing and separating sections of the combine harvesters [13]. As a result, a greater threshing and cleaning capacity per unit width of the crop harvested was obtained [14]. Despite having a relatively higher header grain loss than other combine header types, the stripper header has many advantages, such as high throughput (up to 17 kg/s), high collecting speed (as fast as 2.2 m/s or 5 mph), reduced fuel consumption, and less demand for maintenance [15,16]. This technology has radically changed the way small grains are harvested.

Small grains such as oats, wheat, and barley have only recently entered the portfolios of small-scale agriculture operations. This is due in part to the fact that grains have a lower value per acre as compared to the fruits and vegetables commonly found at farmer’s markets and via community-supported agriculture (viz. direct marketed). However, small producers have found ways to add value. One way has been to produce more diverse species of grain, including spelt, teff, millet, quinoa, and flax [17]. Another opportunity has been to plant ancient varieties that have unique flavors, malting, or bread-making properties. For example, some ancient varieties of wheat are gluten-free, creating a possible niche market for producers [18]. Moreover, small-scale producers have touted their abilities to grow the crops locally, organically, or with fewer inputs [19].

Producing grains on a small scale requires the same field operations as large-scale production. The farmer must prepare the soil, fertilize, seed, harvest (cut, thresh, and separate), clean, and finally, store or bag the grain. There is a variety of small-scale equipment available at most stages of the process as there is a primary demand for this equipment in seed production and research. However, one stage where a cost-effective solution is not available is the harvest phase. This leaves the producer with the option of hiring a custom harvester, purchasing a small self-propelled combine, or restoring a turn-of-the-20th-century, tractor-towed (pull-type) combine. Retrofitting is typically the most cost-effective and long-term solution among these options [20,21].

Retrofitting and improvement of agricultural equipment must be rigorously tested to evaluate their cost–benefits and ensure some degree of consistency in varying conditions [1,22]. Evaluations can be performed through laboratory testing and/or field testing. Field testing measures the overall performance and validates the major function of the equipment in real-world conditions [23]. Additionally, durability and serviceability may be evaluated as well [24]. Laboratory testing mainly focuses on the theoretical performance and functionality evaluation of the components and subsystems of agriculture equipment. Conditions and operating parameters are controlled in ways not feasible in most real-world scenarios [25,26]. In some cases, field testing is not necessary if all parameters can be sufficiently evaluated in a laboratory or controlled setting.

The overarching goal of this study was to retrofit a pull-type combine harvester for effective and efficient operations in small grains. The specific objectives were to: (1) retrofit a pull-type combine harvester with a stripper header rotor, (2) redesign key components including the auger and feeder house to complement the retrofitting, and (3) test the machine performance in terms of the conveying efficiency of the wheat-MOG mixture at various material throughput rates/travel speeds.

2. Materials and Methods

2.1. Description of the Combine

The combine chosen for this project was an Oliver model number 18 combine. This combine was a 1960s-era pull-type, with right-hand cut and a standard threshing system well-suited for small grains. This combine platform was popular in the 1960s and there were many different versions made by several manufacturers. The wide availability of the combine in farm equipment auctions in the Midwest region not only made it easier to secure one but would also increase the potential for the retrofitting method and results being adopted by others.

2.1.1. Structure of the Combine

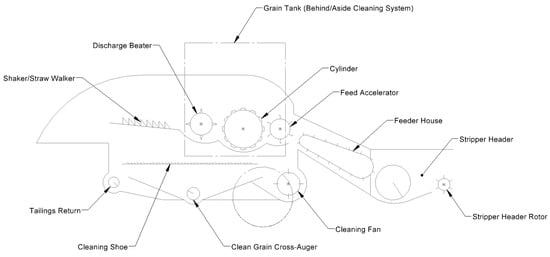

Common header configurations of combines use a sickle bar-type mechanism to cut the crop from the field. This mechanism uses an oscillating row of sharp, triangular blades (sickle sections) that slide past fixed guard fingers to produce a shearing action that cuts the crop from the field. This system closely resembles that of a pair of scissors. Similarly, the sickle sections can break or become dull and will need to be replaced to prevent plugging. Once cut, a reel guides the crop to an auger or a draper belt system which transfers the crop to the feeder house. Draper header systems provide more consistent product feeding and reduce damage to fragile crops. Due to these benefits, draper headers are the header of choice on newer combines. Once delivered to the feeder house, the crop is then transferred up into the combine via the feeder house chain and paddles. Just after the feeder house, the crop is run through a feed accelerator which breaks up any clumps or slugs and accelerates the crop into the threshing system. The threshing system uses a combination of impact and rubbing actions to separate the grain from MOG. The MOG is then transferred and ejected out the rear of the machine and either chopped and spread onto the field or windrowed and baled for animal bedding. The grain falls through the concaves and into the cleaning shoe, which separates the finer chaff from the grain as well as any other small foreign material. A fan is used to remove the lighter chaff in conjunction with a combination of sieves to finish cleaning the grain. Once cleaned, the grain is transferred to the clean grain tank. Any grain that passes through the sieves falls into the tailings return elevator that returns the unseparated crop to the threshing system.

The Oliver 18 combine contains all the aforementioned subsystems in one form or another. Key component locations can be found in Figure 1. For more detailed information on the dimensions and specifications, readers should refer to the operator’s manual and related literature.

Figure 1.

Schematic diagram of the Oliver 18 combine harvester with principal components.

2.1.2. Conditions of the Combine

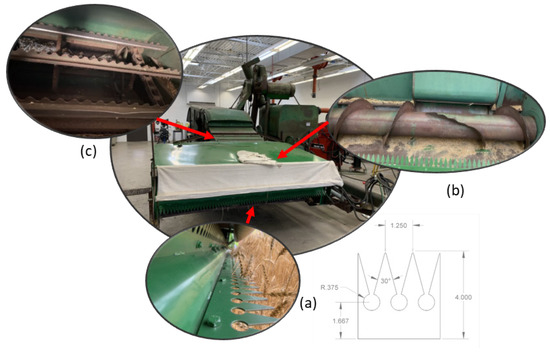

The combine harvester used in this study was in functional order. However, the combine was not perfect in terms of performance and appearance. This, however, had no effect on the functionality of the subsystems of interest, including the header and feeder house (Figure 2). In general, the combine showed its age in the oxidation of various body panels and mechanical components. Necessary repairs were completed to ensure the reliable and repeatable function of the combine during testing procedures.

Figure 2.

Combine subsystems of interest in this study, including: (a) stripper header rotor, (b) auger, and (c) feeder house.

The key driving factor, in the following redesigns, was the replacement of the sickle bar cutting system (including the cutter bar and reel) with a stripper header rotor (Figure 2a). The rotor had a center roll diameter of 14 inches and an overall width of 6 ft. Six rows of stripping fingers were evenly distributed along the center roll. The stripping fingers had a height of 4 inches and a stripping keyhole diameter of 0.75 inches. Other dimensions of the fingers are shown in Figure 2a. The stripper header rotor was attached to both the frame of the header and the reel support arms. The stripper header drum was driven by a hydraulic motor. The rotating rotor mounted in the front of the header combs through the crop, feeding the heads back into the keyhole area of the stripping finger, where the grain is stripped from the head and thrown back into the header. Majority of straw remains standing whilst the combine processes predominantly grain. The introduction of the stripper header to this combine was intended to greatly increase the throughput capacity of the machine and speed up harvest operations, as compared to the original base unit. The necessary concave coverings were constructed of canvas attached to a steel frame. The stripper header height adjustment utilized the original header height adjustment system.

Preliminary field tests were conducted with the new header system. It was observed that the transfer of auger in the header, while perfectly functional in the original configuration, was inadequate in transferring the stripped crop material being taken into the header (Figure 2b). With the sickle bar cutting system, both grain and straw are taken into the combine and processed accordingly, but with the stripper header, very little straw was being taken into the header. With the addition of the stripper header, the material profile moving through the machine changed. There was a drastic reduction in the amount of MOG being harvested with the grain and as a result, the efficiency and capacity of the auger were reduced. One contributing factor that led to this loss in capacity was that the small-grain kernels, in this study’s case: wheat, were simply passing between the auger and the auger housing, or “auger pan”. This gap was approximately 12.7 mm (0.5 inches). This had an impact on the overall mass conveying efficiency of the header system. A similar problem was observed with the feeder house system (Figure 2c), where the gap between the feeder house paddles and its housing floor was too wide to effectively convey small-grain kernels up into the combine chamber.

2.1.3. Design Constraints and Requirements

The goal of the redesign was to improve the harvesting capacity of the machine and bring it into the modern era. It should be noted that while the improvements made and tested here can be applied to other makes of machines, the implementation of these designs may vary from machine to machine. An evaluation should be performed if such a project is to be undertaken to evaluate the resulting crop flow and identify potential problem areas in which one of the following strategies may be implemented.

The following design experiments were solely geared toward improving the flow of material in the header and feeder house subsystems. The results gained in testing and numerically represented in this paper are representative of the crop-conveying ability improvements that were observed in testing. Additional comments referring to the feasibility of implementation and cost analyses are subjective and should be treated as supplemental information to the primary goal of improving the harvesting capacity.

2.2. The Auger Redesign

The first area of focus was the auger located in the header of the machine. An auger is used to gather and convey the straw and grain to the feeder house. The auger was initially designed and optimized to convey the grain-MOG mixture of the sickle bar cutting system, and as such relied on the straw stalks to help ‘carry’ the small-grain kernels through the machine to the threshing cylinder. This was not adequate for the performance improvement goals of this project and left valuable crops sitting in the machine to be wasted.

2.2.1. Design Principles

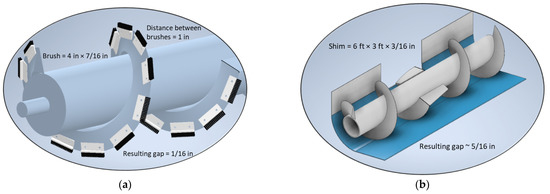

Brainstorming for solutions to this issue yielded two possible solutions. The first was the brush design. Strip brushes with direct-mount backing, also called stapled-set strip brushes, have integrated plastic holders, and can be directly mounted to conveyors, which are typically found in warehouses, package handling areas, manufacturing and assembly facilities, and distribution centers. This solution suggested that the addition of brushes would fill the excessive gap between the auger and auger pan and provide a soft interface between the steel flighting of the auger and the grain as it is conveyed to the feeder house. As shown in Figure 3a, brushes would need to be sectioned to conform to the circumference of the auger and the auger pan. The bristle brushes were made to be bolted-on to assist in testing as the brush sections would need to be removed and installed several times. One benefit to this design is that the brush sections can contour to an uneven surface and easily travel over bolt heads, seams, and other surface imperfections. This sectioned method would allow for easy installation and maintenance.

Figure 3.

CAD models of auger redesigns: (a) brush concept and (b) shim concept.

The second solution employed a plastic shim that would be fitted between the auger and the auger pan to reduce the gap. Plastic shims are commonly used as agricultural equipment liners that help to stop and/or slow the amount of wear on the equipment’s original metal sheeting areas. As shown in Figure 3b, the shim would be attached to the auger pan via low-profile hardware as well as a hold-down bracket that maintains pressure on the shim to conform to the curvature of the pan. This is necessary as the material selected for the shim was stiff and resistant to bending or forming operations. This solution modified the clearances within the auger system to allow the auger to work at a higher degree of conveying efficiency.

2.2.2. Design Details

The materials chosen for the two design solutions were selected based on availability and expediency. The brushes used were composed of nylon bristles and a PVC backing material at a length of 1.83 m (6 ft) (Grainger, Lake Forest, IL, USA). The brushes were cut to 101.6 mm (4 inches) wide per piece as this was determined to be adequate for maximizing the effective area the brush filled. Considering the materials and resources available to the project, the PVC-backed nylon brush was selected for its ability to be sectioned, while still being pliable enough to be fastened to the helical auger flighting. Additionally, the PVC backing was structurally sound to handle the oscillatory nature of the forces applied to it in the application. Nylon bristles of a diameter of 0.508 mm (0.02 inch) provide good resistance to wear and abrasion and are effective when used in wet or intermittently hot environments as well. The height of the brush was selected to yield a final theoretical gap of 1.58 mm (1/16 inch) between the tip of the bristles and the auger pan, which was deemed sufficient considering the size of the wheat kernels. The distance between adjacent brushes was arbitrarily determined at 25.4 mm (1 inch) along the auger flighting direction. The actual gap between two brushes on the bottom of the auger along the width of the header would be 12.7 mm (0.5 inches) considering the auger flighting angle of 60°. The addition of the brushes reduced the gap width and height by 80% and 87.5%, respectively, which yielded an effective gap area reduction of 70%.

The shim was composed of a single sheet of high molecular weight polyethylene (HMWPE) plastic cut to 1.829 m × 0.914 m (6 ft × 3 ft) to fit in the extent of the auger pan. The HMWPE was selected for its common use in other agricultural liner applications. Commonly used in feeding areas within various agricultural applications, HMWPE is preferred for its ability to resist abrasion and impact. Additionally, in liner applications, it is usually simple and cost-effective to replace. In the case of the combine, it offers good wear resistance and is flexible enough to conform to the curvature of the auger pan. Considering the original gap of 12.7 mm (0.5 inches), a thickness of 4.76 mm (3/16 inch) for the HMWPE was selected to balance the desire for high performance and ease of installation. The addition of the plastic shim achieved a 37.5% reduction in the effective gap area between the auger and the auger pan.

2.2.3. Prototyping

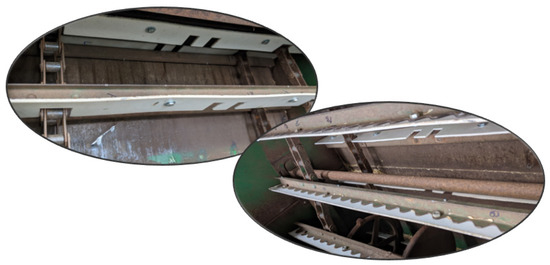

Prototypes of each concept were made and prepared for testing. Holes were marked and drilled into the flighting of the infeed auger for mounting the brush sections (Figure 4a). Brush strips were ordered and cut into 101.6 mm (4 inches) sections. These sections were fastened to the auger flighting with two ¼-20 × 1-inch bolts. Great care was taken to not crack the backing of the brushes when tightening. Once installed for the first time, the brush sections were numbered to ensure ease of assembly and disassembly during testing.

Figure 4.

Auger redesign implementation: (a) brush concept and (b) shim concept.

For the liner concept, a sheet of HMWPE plastic was ordered and cut to fit under the infeed auger of the combine. Three holes were drilled just in front of the feeder house to hold down the plastic in front of it and prevent the crop from falling in between the liner and the original auger pan (Figure 4b). A few sheet metal brackets were fabricated to secure the plastic at other locations in the feeder house. One method used to assist in the installation of this liner was to let the liner sit confined in a cylindrical shape. This material has some memory to it and maintains a shape for a few hours after being formed as such. The installation of the shim was greatly aided by preforming the sheet and using plastic guides to guide the sheet over any bolt heads protruding from the original auger pan.

Each concept was fitted and checked for any unintended interferences and adjusted accordingly. Fully assembled prototypes can be seen in Figure 4a,b.

2.3. The Feeder House Redesign

The second area of focus was the feeder house. This subsystem transfers the crop from the header to the threshing system. This is accomplished via the use of bars connected to the roller chain to push and pull the crop up into the combine. The feeder house on the combine had clearance issues very similar to that of the auger in the header. This section explores the methodology used to improve the mass conveying efficiency of the feeder house.

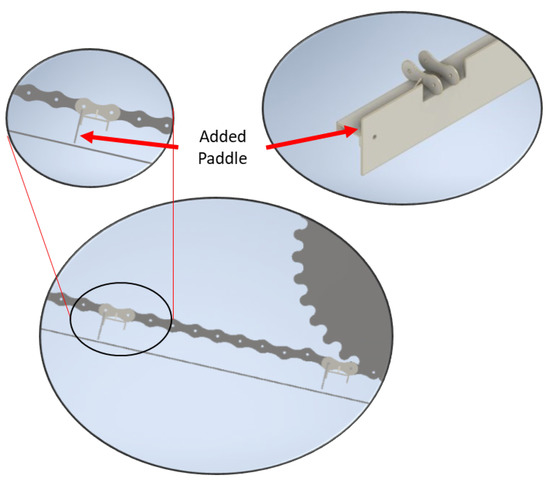

2.3.1. Design Principles

The main design objective was to decrease the clearance between the feeder house floor and the gathering chain bars to better suit the new crop material being transferred. Additionally, it was surmised that increasing the effective surface area of the paddles would lead to an overall increase in capacity. To accomplish both improvements, a supplementary paddle was designed to be attached to the bar sticking out in both directions (Figure 5). The added height toward the housing would reduce the undesired gap. Meanwhile, the added height in the other direction would increase the surface area for carrying capacity.

Figure 5.

CAD model of the feeder house paddle concept.

2.3.2. Design Details

The HMWPE plastic was used to make these paddles. The stiffness of the plastic allows it to maintain the desired shape as well as ensure almost continuous contact with the floor. Additionally, using the same material would potentially save the overall cost of the retrofitting project. The paddle increased the surface area of the paddle from 162 cm2 (25.125 in2) to 540.3 cm2 (83.75 in2), with a more than 3-fold improvement. The gap between the bars and the feeder house floor was reduced from 12.7 mm (0.5 inches) to 0. This was possible with the use of a plastic paddle that could ride on the floor of the feeder house and not succumb to excessive wear. The slack of the chain also helped to achieve a design clearance of 0 mm.

2.3.3. Prototyping

The prototype was constructed using pre-cut paddles with a custom geometry that allowed for clearance to critical components. To create these paddles, careful measurements were taken of the feeder house, including width, height, clearance from the paddle to the floor, clearance to drive and idler sprockets and other chain guides, etc. Installation of the paddles was performed using 4 HHCS ¼-20 × 1-inch bolts. The paddles were fastened to the leading edge of the channel section bars (Figure 6).

Figure 6.

Feeder house paddle concept implementation showing the custom-made paddles being fastened to the leading edge of the channel section bars of the feeder house.

2.4. Testing and Analysis

A laboratory test was conducted for each of the two redesigns. The two tests shared the same experimental set-up and similar procedures with different experimental designs, as will be described in this section.

2.4.1. Testing Set-Up and Procedures

Several sheet steel slides were made to aid in product feeding and recovery during testing (Figure 7). The inlet was a single piece of sheet steel with the same width as the stripper header guiding the material onto the auger area. To make room for the slides on the collection end, a floating floor was removed at the feeder house transition before the product accelerator. Sheet steel pieces were used to block the passage between the feeder house and the cylinder and re-direct the material to the collection area. A cardboard catch tray was also assembled and placed at the bottom of the collection area to catch all the material that would have made it to the threshing system.

Figure 7.

Combine in testing configuration with the grain-material-other-than-grain mixture.

Preliminary field sampling and measurements suggested that the wheat grain-MOG mixture found in the stripper header area is composed of 85% grain and 15% MOG on a mass basis. This finding was consistent with previous studies [27,28]. Therefore, winter wheat and straw samples collected from a farm in River Falls, WI, USA, in July 2021, were prepared at a 15–85 ratio to simulate field conditions. A picture of the grain-MOG mixture is shown in Figure 7.

After all safety shielding and testing devices were in place, the combine was operated at a PTO speed of 1800 rpm based on the Operating Instructions of the machine. A given amount of the mixture was weighed as the input weight (WI). The mixture was evenly distributed into the inlet slide and a timer started right as the wheat mixture entered the combine header. The rate of feeding was determined to ensure the inlet device would be clear of the wheat mixture after 20 s. The combine was shut off after another 10 s to allow all possible wheat mixture to travel up the feeder house and into the collection bin. The weight of the collected mixture was measured as the output weight (WO). The mixture was recycled, and the combine header and feeder house areas were thoroughly cleaned out to prepare for the next test run. The material-conveying efficiency (η) was calculated based on the equation below. No visible damaged grains were observed in the experiment. Therefore, the difference between 100% and the measured η would be the grain loss rate in percentage.

where η is the material-conveying efficiency in %, WI is the initial weight of the feeding material in pounds, and WO is the final weight of the collected material in the output, in pounds.

2.4.2. Experimental Design

As for the auger redesign, three header configurations were tested, including the brush concept, the shim concept, and the original factory set-up as the control. Three different mass flow rates were selected to see if the field speed influenced the performance of the three header configurations. The difference in mass flow rate was designed to reflect the difference in field travel speed. A recommended travel speed range of 2 to 4 mph for grain combine harvesters was obtained from ASABE D497.7 [29]. The mass flow rate in pounds per second was calculated based on the speeds and average wheat yield of 69 bu/ac in 2020 in Wisconsin [30]. Finally, the initial weight of the mixture was determined by multiplying the mass flow rates by the feeding time (20 s). The initial weights were 45.37, 68.05, and 90.73 lb for the low (2 mph or 0.89 m/s), medium (3 mph or 1.34 m/s), and high (4 mph or 1.79 m/s) field speeds, respectively. A completely randomized factorial design was used for the experiment of auger redesign. Treatments were the nine combinations of the three header configurations (brush, shim, and original) and three mass flow rates (low, medium, and high). Each treatment was replicated three times. Therefore, a total of 27 experimental runs were conducted in the auger experiment.

Analysis of the auger experiment results suggested that the flow rate had no significant effect on the performance of the header and the shim concept had the superior performance among the header configurations. Therefore, the shim concept was used as the auger configuration and the factor of mass flow rate was excluded in the feeder house design evaluation experiment. The medium mass flow rate was used. A completely randomized design was used for the experiment of the feeder house redesign. Treatments were two feeder house configurations: the redesigned plastic paddle addition and the original configuration as the control. Each treatment was replicated three times, yielding a total of six experimental runs.

2.4.3. Data Analysis

Analysis of variance (ANOVA) was performed using statistical software (SAS for Windows v 9.4). The means between treatments were compared with Duncan’s multiple range tests at the significance level of 0.05. The main effects of machine configuration and flow rate were presented when the interaction effects were not significant; otherwise, the simple effects of flow rate for the three machine configurations were examined and presented.

3. Results and Discussions

3.1. Auger Redesign Results

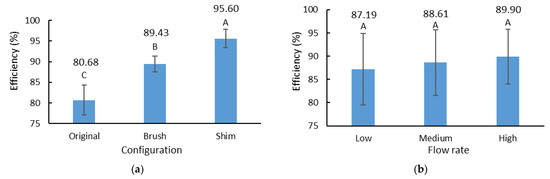

Both the brush and shim concepts significantly improved the material-conveying efficiency of the auger, as compared to the original configuration, regardless of the material flow rate (Figure 8a). The shim concept had the highest material-conveying efficiency of 95.6%, which was significantly higher than that of the brush concept. The shim concept increased the conveying efficiency of the auger by 15% from its original value of 80.68%. In other words, a 15% reduction in grain header loss was achieved by adding the shim to the auger. Similarly, the addition of brushes delivered an approximately 9% reduction in grain loss.

Figure 8.

Material-conveying efficiency of different auger configurations (a) at different mass flow rates (b). Means followed by different letters are significantly different according to Duncan’s multiple range test at the significance level of 0.05, and error bars are standard deviations.

Higher mass flow rates tended to yield a higher material-conveying efficiency; however, the effect of the flow rate on the efficiency was insignificant (Figure 8b). The slightly higher efficiencies were probably attributed to more continuous and consistent material flows at higher mass flow rates [31,32]. Large standard deviations were found for different flow rates and the trend seemed to be random. It was then concluded that the machine configuration was the dominant factor in determining the performance of the auger and the mass flow rate could be set at a value within the tested range.

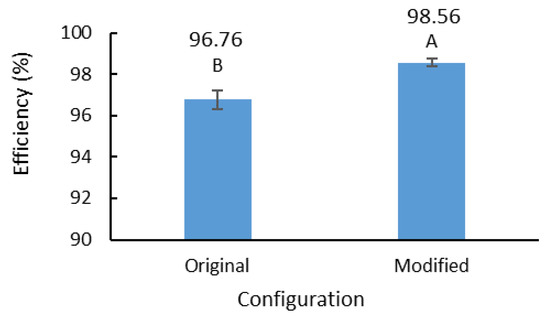

3.2. Feeder House Redesign Results

Considering the shim auger configuration, the modified feeder house with added paddles had a material-conveying efficiency of 98.56%, which was significantly higher than that of the original feeder house configuration (Figure 9). The modified feeder house was able to reduce the total grain loss to 1.5% for the header and feeder house subsystems.

Figure 9.

Material-conveying efficiency of different feeder house configurations. Means followed by different letters are significantly different according to Duncan’s multiple range test at the significance level of 0.05, and error bars are standard deviations.

3.3. Discussions

The retrofitting created an economically friendly, small-grain combine harvester that would help in the harvesting of small-scale farms, while reducing soil compaction, limiting input costs, increasing efficiency, and adapting older equipment to the new and improved ways of farming. With the two proposed redesigns appropriately implemented, the overall material-conveying efficiency of the combine was increased from 80.68% to 98.56%. The cost of materials, including major parts and miscellaneous hardware, was $150 USD. The manufacturing and assembling of the auger shim and feeder house paddles would take approximately 3 h, which would cost around $45 USD at an average labor rate of $15 per hour. Therefore, the total cost of material and manufacturing of the auger shim and feeder house paddles was around $200 USD and should only take an hour or two for a mechanically inclined farmer or practitioner to install them properly if they choose to do it themselves. Considering an average price of wheat of $6 USD/bu and the average wheat yield of 69 bu/ac, the 17.88% improvement in crop-conveying efficiency (crop savings) would yield a return of $74 USD/ac. It was therefore estimated that the cost of the retrofitting could be fully offset if the combine harvester was only used on 3 acres of land. The more acreage the machine is being used on, the higher the levels of return on investment that can be realized. The composition of the plastic shim and paddle ensured that the improvement would be relatively durable and increased the longevity of the Oliver 18 combine by protecting the original sheet metal, shielding from wear. The fasteners used can be found in any local hardware store and the fabricated holders are relatively easy to make with common tools available in a garage or shop. Furthermore, the stripping header reduces the need for a sickle-cutting mechanism and associated gearboxes, thereby reducing the complexity, weight, and cost of the combine, improving the cost-efficiency benefit and adaptation potential of the design. Moreover, the harvesting technique with a stripper header has potential soil and water conservation benefits with high-standing crop straws and stalks [33,34,35].

Jiang et al. [36] proposed a pneumatic conveyor system for providing air suction to reduce the grain header loss of the stripper harvester. The auger shim and feeder house paddle solution proposed in this study would be advantageous by being simple, cost-effective, and low maintenance. Kalsirisilp and Singh [15] modified a Thai-made rice combine harvester by replacing the cutter bar system with a custom-made stripper header. The authors reported that rubber paddles were attached to the auger edge and feeder conveyor chain to effectively convey stripped material without specifically testing the performance improvement of the modifications. However, their field experiment showed a header loss ranging from 1.63% to 5.3%, which is higher than the total loss of 1.5% obtained in this study. Kalsirisilp and Singh [15] recommended that a different feeder house conveyor should be used to increase its conveying capacity with stripped material. The header losses of a combine harvester in field conditions are grain kernels lying on the ground after the header unit passes over, primarily due to improper design and operational parameters of the header. In our indoor study, the header loss was assumed to be the percentage of the material that failed to be conveyed into the threshing system. One should note that the header shatter loss was not included in the experiment.

Even though the shim and paddle concepts were the most promising candidates in terms of improving the material-conveying efficiency, their wear resistance and long-term durability should be further evaluated considering the extremely abrasive nature of crop kernels in harvesting. Further field experiments would be required to evaluate the design improvements in a variety of crop and weather conditions by measuring field and material capacities, grain losses, damage, and contamination, as well as the overall productivity of the combine harvester. Additionally, the integration of the proposed combine harvester header to the existing threshing and separation systems of the combine needs to be assessed since previous studies found that the type of grain separator significantly affected the separation efficiency of handling grain mixture from the stripper header [28].

4. Conclusions

A pull-type combine harvester was retrofitted and tested for effective and efficient operations in small grains in this study. The conventional sickle bar cutting system of a 1960s-era Oliver 18 combine harvester was replaced by a stripper header rotor system, aiming to increase the harvesting capacity. Key components of the machine, including the auger and feeder house, were redesigned to complement the retrofitting and to realize the expected performance improvement. Specifically, two redesign concepts, including brush and shim, were proposed for the header auger, and an add-on paddle redesign was suggested for the feeder house. New parts were sourced and manufactured in-house for the redesigns. Prototypes were tested at various material throughput rates/travel speeds to evaluate the machine’s performance in terms of the conveying efficiency of the wheat-MOG mixture. The results suggested that both the brush and shim concepts significantly improved the efficiency of the auger, as compared to the original configuration. The shim concept was superior to the brush concept. The effect of the material flow rate was statistically insignificant. The auger shim and feeder house paddle redesign combination increased the efficiency from 80.68% to 98.56%, as compared to the original machine configuration. The cost-effective and high-performance pull-type combine harvester proposed in this study has a high potential for being adapted by small-scale farmers in producing small grains.

Author Contributions

Conceptualization, Z.Z. and K.L.; methodology, Z.Z.; software, Z.Z.; validation, K.L. and Z.Z.; formal analysis, Y.T.; investigation, Y.T.; resources, Y.T.; data curation, Y.T.; writing—original draft preparation, K.L.; writing—review and editing, Y.T.; visualization, K.L.; supervision, Z.Z.; project administration, Z.Z.; funding acquisition, Z.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Institute of Food and Agriculture, USDA, grant number: 2018-70001-27840.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

Acknowledgments

The authors acknowledge Alexandra Pierson and Rames Frisch at the University of Wisconsin, River Falls, for their assistance with laboratory testing. The authors thank the editor and anonymous reviewers for providing helpful suggestions for improving the quality of this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Manandhar, A.; Zhu, H.; Ozkan, E.; Shah, A. Techno-economic impacts of using a laser-guided variable-rate spraying system to retrofit conventional constant-rate sprayers. Precis. Agric. 2020, 21, 1156–1171. [Google Scholar] [CrossRef]

- Lorencowicz, E.; Uziak, J. Repair cost of tractors and agricultural machines in family farms. Agric. Agric. Sci. Procedia 2015, 7, 152–157. [Google Scholar] [CrossRef]

- Perez-Ruiz, M.; Slaughter, D.C.; Gliever, C.; Upadhyaya, S.K. Tractor-based real-time kinematic-global positioning system (RTK-GPS) guidance system for geospatial mapping of row crop transplant. Biosyst. Eng. 2012, 111, 64–71. [Google Scholar] [CrossRef]

- Annamalai, P.; Lee, W.S. Citrus yield mapping system using machine vision. In Proceedings of the ASAE Annual International Meeting, Las Vegas, NV, USA, 27–30 July 2003. [Google Scholar]

- Wang, B.; Wang, Y.; Wang, H.; Mao, H.; Zhou, L. Research on accurate perception and control system of fertilization amount for corn fertilization planter. Front. Plant Sci. 2022, 13, 1074945. [Google Scholar] [CrossRef]

- Prisyazhnaya, I.M.; Sinegovskaya, V.T.; Prisyazhnaya, S.P.; O Sinegovskii, M. Harvester and transporting device development for high-quality soybean seeds obtaining. IOP Conf. Ser. Earth Environ. Sci. 2020, 548, 062078. [Google Scholar] [CrossRef]

- Lin, S.; Jiang, Y.; Chen, X.; Biswas, A.; Li, S.; Yuan, Z.; Wang, H.; Qi, L. Automatic detection of plant rows for a transplanter in paddy field using Faster R-CNN. IEEE Access 2020, 8, 147231–147240. [Google Scholar] [CrossRef]

- Šotnar, M.; Pospíšil, J.; Mareček, J.; Dokukilová, T.; Novotný, V. Influence of the combine harvester parameter settings on harvest losses. Acta Technol. Agric. 2018, 21, 105–108. [Google Scholar] [CrossRef]

- Wang, R.; Zhao, X.; Ji, J.; Jin, X.; Li, B. Design and performance analysis of tangential-axial flow threshing device for oat harvester. Int. J. Agric. Biol. Eng. 2021, 14, 61–67. [Google Scholar] [CrossRef]

- Wang, J.; Xu, C.; Tian, L.; Wang, J.; Tang, H. Study on the throwing mechanism and loss characteristics of three-dimensional disturbance comb. Comput. Electron. Agric. 2022, 201, 107283. [Google Scholar] [CrossRef]

- Klinner, W.E.; Neale, M.A.; Arnold, R.E.; Geikie, A.A.; Hobson, R.N. A new concept in combine harvester headers. J. Agric. Eng. Res. 1987, 38, 37–45. [Google Scholar] [CrossRef]

- Wilkins, D.E.; Douglas, C.L., Jr.; Pikul, J.L., Jr. Header loss for shelbourne reynolds stripper-header harvesting wheat. Appl. Eng. Agric. 1995, 12, 159–162. [Google Scholar] [CrossRef]

- Tado, C.J.M.; Wacker, P.; Kutzbach, H.D.; Suministrado, D.C. Development of stripper harvesters: A review. J. Agric. Eng. Res. 1998, 71, 103–112. [Google Scholar] [CrossRef]

- Strakšas, A. Development of a stripper-header for grain harvesting. Agron. Res. 2006, 4, 79–89. [Google Scholar]

- Kalsirisilp, R.; Singh, G. PM—Power and machinery: Adoption of a stripper header for a thai-made rice combine harvester. J. Agric. Eng. Res. 2001, 80, 163–172. [Google Scholar] [CrossRef]

- Chegini, G.R.; Mirnezami, S.V. Experimental comparison of combine performance with two harvesting methods: Stripper header and conventional header. Agric. Eng. Int. CIGR J. 2016, 18, 192–200. [Google Scholar]

- Sugár, E.; Fodor, N.; Sándor, R.; Bónis, P.; Vida, G.; Árendás, T. Spelt wheat: An alternative for sustainable plant production at low N-levels. Sustainability 2019, 11, 6726. [Google Scholar] [CrossRef]

- Cooper, R. Re-discovering ancient wheat varieties as functional foods. J. Tradit. Complement. Med. 2015, 5, 138–143. [Google Scholar] [CrossRef]

- Jouzi, Z.; Azadi, H.; Taheri, F.; Zarafshani, K.; Gebrehiwot, K.; Van Passel, S.; Lebailly, P. Organic farming and small-scale farmers: Main opportunities and challenges. Ecol. Econ. 2017, 132, 144–154. [Google Scholar] [CrossRef]

- Martinez-Guanter, J.; Agüera, P.; Agüera, J.; Pérez-Ruiz, M. Spray and economics assessment of a UAV-based ultra-low-volume application in olive and citrus orchards. Precis. Agric. 2019, 21, 226–243. [Google Scholar] [CrossRef]

- Celenta, G.; De Simone, M.C. Retrofitting techniques for agricultural machines. In New Technologies, Development and Application III; Karabegović, I., Ed.; Springer: Cham, Switzerland, 2020; Volume 128. [Google Scholar]

- Douthwaite, B.; Keatinge, J.D.H.; Park, J.R. Why promising technologies fail: The neglected role of user innovation during adoption. Res. Policy 2001, 30, 819–836. [Google Scholar] [CrossRef]

- Liang, Z.; Li, Y.; De Baerdemaeker, J.; Xu, L.; Saeys, W. Development and testing of a multi-duct cleaning device for tangential-longitudinal flow rice combine harvesters. Biosyst. Eng. 2019, 182, 95–106. [Google Scholar] [CrossRef]

- Kovaleva, E.V. Assessing the quality of production equipment. In Towards an Increased Security: Green Innovations, Intellectual Property Protection and Information Security; Popkova, E.G., Polukhin, A.A., Ragulina, J.V., Eds.; Springer: Cham, Switzerland, 2022; Volume 372, pp. 825–833. [Google Scholar]

- Chico-Santamarta, L.; Masebu, H.; White, D.R.; Godwin, R.J.; Crook, M. The development of an improved stripping mechanism for sorghum harvesting. In Proceedings of the ASAE Annual International Meeting, Kansas City, MO, USA, 21–24 July 2013. [Google Scholar]

- Na, M.; Qiao, J.; Li, H.; Dong, X.; Wang, J.; Sun, W. Harvesting loss on a stripping header of non-air-suction stripping combine harvester for rice. Int. Agric. Eng. J. 2019, 28, 1–15. [Google Scholar]

- Price, J.S. Evaluation of an approach to early separation of grain threshed by a stripping rotor. J. Agric. Eng. Res. 1993, 56, 65–79. [Google Scholar] [CrossRef]

- Neale, M.A.; Hobson, R.N.; Price, J.S.; Bruce, D.M. Effectiveness of three types of grain separator for crop matter harvested with a stripping header. Biosyst. Eng. 2003, 84, 177–191. [Google Scholar] [CrossRef]

- ASABE Standard D497.7; Agriculture Machinery Management Data. American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2011.

- 2022 State Agriculture Overview. Available online: https://www.nass.usda.gov/Quick_Stats/Ag_Overview/stateOver-view.php?state=WISCONSIN (accessed on 1 March 2023).

- Yuan, J.; Lan, Y. Development of an improved cereal stripping harvester. Int. Comm. Agric. Eng. 2007, 9, 1–12. [Google Scholar]

- Chegini, G.R. Determine of optimum operating conditions of combine harvester with stripper-header. World Appl. Sci. J. 2013, 23, 1399–1407. [Google Scholar]

- McMaster, G.S.; Aiken, R.M.; Nielsen, D.C. Optimizing wheat harvest cutting height for harvest efficiency and soil and water conservation. Agron. J. 2000, 92, 1104–1108. [Google Scholar] [CrossRef]

- Zobeck, T.M.; Schillinger, W.F. Soil and Water Conservation Advances in the United States—Review and Assessment; Soil Science Society of America: Madison, WI, USA, 2010. [Google Scholar]

- Schillinger, W.F.; Wuest, S.B. Wheat stubble height effects on soil water capture and retention during long fallow. Agric. Water Manag. 2021, 256, 107117. [Google Scholar] [CrossRef]

- Jiang, Y.; Du, C.; Xu, J. Study on the performance of stripping rotor with air suction. Proc. Int. Conf. Agric. Eng. 1992, 1, 176–179. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).