Abstract

In the present work, four (4) samples of sylvite (KCl) from different deposits in Canada, Belarus and Germany were analyzed in order to determine the differences between them in terms of chemical composition, morphology and impurities present. Different non-instrumental and instrumental techniques were used. A scanning electron microscope analysis showed that the particles are completely amorphous. Bueno mineral has particles with the largest area (with 91.4% particles larger than 0.50 mm), and the BPC mineral samples have those with the smallest area (with 49.9% particles smaller than 0.50 mm). The Bueno mineral has the highest angle of repose. Bueno mineral has the highest surface area and pore volume when compared to the other KCl minerals. On the other hand, the BPC KCl mineral presented a lower surface area and pore volume. The problem mineral has the highest percentage composition of K. Blanco mineral did not present Al, and the element Mo was not detected in the Blanco and Bueno mineral. The IR bands of O-H, C-N, N-H and C=O bonds were observed. These results are useful for the fertilizer industry. These differences can produce adverse effects in a subsequent application in fertilizer production processes. Such differences can be attributed to the origin of this mineral, the way it is obtained and exploited, or to the transport and storage process through the use of anticompacting additives due to the high hygroscopicity of the mineral.

Keywords:

chemical composition; KCl; sylvite; mineral; fertilizers; angle of repose; SEM analysis; TGA; FTIR 1. Introduction

The mineral sylvite (KCl), commonly called potassium chloride, has had great importance for many years, due to its commercial value and different forms of application. Research has established that in Colombia and other countries worldwide, this mineral is mostly used as a raw material for the production of fertilizers, because it possesses potassium (K), a monovalent cation used as a plant nutrient to help overcome plant deficiencies in non-competent soils [1,2,3].

Potassium acts as a growth regulator and controls the development of certain physiological disorders that affect the internal and external appearance of fruits [4]. Potassium is the second most important nutrient after nitrogen. It plays an important role in protein and starch synthesis, increases disease resistance and low temperature, sugar and starch formation, facilitates the movement of nutrients through plants, and also promotes a healthy root system [5,6].

In recent years, the increase in human population has been evolving, and thus, greater food and energy demands are needed to satisfy the quality of life [7]. Food and crop production will increase in the same way as the resources of our planet are preserved [8].

Climate changes have a significant role in crop production due to periods of drought, high temperatures and heavy rains [9]. Each of these factors usually has a negative effect, carrying with them a risk to our food security [10]. Therefore, an industrial sector based on agriculture must generate strategies to improve crop yields by relying on increasingly efficient systems based on the use of fertilizers and resources under biotic and abiotic stress conditions [11].

One of the most used tools in the agricultural industry is the use of potassium-based fertilizers, since this is an indispensable element that participates in physiological, biochemical and other vital processes of plants [12]. As established by Kant and Kafkafi in 2002 [13], a low contribution of this element leads to unbalanced fertilization affecting the reproductive organs, generating problems of growth, quality, quantity of production and efficiency to stress resistance in crops.

The use of fertilizers has been established as one of the strategies implemented and extended by private sectors and governments, with the objective of reaching a production magnitude that benefits a country’s economy and supplies the needs of the population to supply food. It is established that currently approximately 50% of the world’s population depends on fertilizers [14,15]. Therefore, new sources and production alternatives from solid potassium minerals (polyhalite, carnalite, sylvite, kainite) are considered to maintain the production of fertilizers [16,17,18].

In addition to its important role in the fertilizer industry, potassium has uses in health and food processing. This is because potassium is an essential mineral in the human body, being present inside the cells in abundant quantity and participating actively in numerous vital functions: it regulates the passage of water in and out of the body together with sodium. It is also involved in the stability of cell membranes and in muscular, cardiovascular and nervous functions. The amount of potassium ingested by humans and animals must be controlled at the time of ingestion, as potassium is not accumulated by the body and is supplied by food; likewise, it is often used as a substitute for salt in diets for people with NaCl restriction [19].

Sylvite, also known as potassium salt (KCl), is used as a raw material for fertilizer production, and additives are added by large export companies during storage to prevent easy compaction. Potash is a commercial term used in agriculture to cover a variety of minerals and refined products containing varying proportions of sylvite and carnallite. In relation to their chemical composition in mineral form, they are known to be made up of components, such as potassium oxide K2O and Halite-NaCl, among others [20].

J. A. Stewart in 1985 found that of the most common potassium-containing minerals such as sylvite, carnallite, kainite, langbeinite, leonite, schoenite and polyhalite, sylvite is the most sought-after mineral for its high potassium content (524.4 g Kg−1). He also found that of the K extracted, 93% is used as fertilizer; the remaining 7% is used in the manufacture of a variety of chemical intermediates and products. In the United States, about 95% of the K used on cropland is applied as chloride, and the remainder of 5% is applied as sulfates and nitrates [21].

R. L. Mikkelsen et al. reported that over 95% of global potash fertilizer production originates with KCl obtained from sylvinite, carnallitite, or hartsalz. In 2015, approximately 74% of the KCl produced was used directly for plant nutrition. Of the remaining 26%, about 2% was reacted with nitric acid or nitrate salts to produce nitrate of potash, 5% was reacted with sulfuric acid to produce sulfate of potash, and 19% was incorporated into various N and P sources to produce N-P-K or P-K complex/compound fertilizers [6].

S. K. Jena indicates that of all the techniques such as bioleaching, chemical leaching, roast leaching, and flotation of different potash minerals, the roast-leach technique is the best method to recover potash values from mineral sources due to its high efficiency and simple operating procedure. It is important for many countries which have no soluble potash sources, but natural potash minerals such as feldspar, mica, nepheline syenite, glauconitic sand stone and sericite are highly available. Hence, it is a futuristic work to utilize these available natural sources for the recovery of potash values for fertilizer making [18].

J. Sanz et al. say that sylvite is mainly used in the production of agricultural fertilizers to improve plant growth and the quality of fruits, vegetables, trees, cereals, flowers, and so on, since potassium is one of the three most important macronutrients for vegetables. There is currently increased demand for potassium for agricultural fertilizers for crops of sunflowers, soybeans, corn, sugar cane, and so on, due to the expanding production of biofuels and the cultivation of cereals as a fundamental aspect of subsistence in emerging countries [3].

The importance of the mineral KCl as a source of potassium has motivated the agricultural industry to become interested in knowing and analyzing the chemical composition, morphology and structure of the mineral and their relationship according to its origin, in order to optimize the processes and quality of products obtained from sylvite. In the different processes of extraction or exploitation of sylvite, a product with different physicochemical characteristics can be obtained, which directly affects the yield and quality of the product. So, it is convenient to know its properties such as: elemental composition, shape, color, and its interaction in the environment and components present in the structure of the material by way of impurities caused by the origin and extraction method [22].

Given the above, complete characterization of these minerals is important when they are used in the elaboration of fertilizers. For example, the angle of repose and sieving are important because they provide information on the degree of intermobility or fluidity of the particles that make up the minerals, useful information when it is desired to store large quantities of particulate material. Additionally, time in solubility can be dependent on particle size [23,24,25,26]. The Surface area BET method is important for the determination of the porosity of a solid surface. In minerals, it is important to know the porosity, since this parameter influences the processes of storage, mixing of the mineral with other materials and solubility. Differences in water solubility become important when solid K sources are dissolved for use in foliar sprays or fluid fertilizers. When solid K fertilizers are used for these purposes, both the solubility and the time required for dissolution need to be considered when making a suitable liquid fertilizer. There are additional restrictions to consider when selecting a K source for organic crop production [6,27].

In addition to the macronutrients (N, P, K, H, Mg, Ca, and S), micronutrients (B, Ni, Cl, Mn, Fe, Zn, Cu, and Mo) are required for optimal plant growth. Micronutrients are required by plants in small amounts but are no less essential than macronutrients. The micronutrients play a significant role in a variety of cellular and metabolic processes such as gene regulation, hormone perception, energy metabolism and signal transductions, etc. Thus, deficiencies and toxicities of micronutrients adversely affect plant health, causing reductions in growth rate (and yield), overt symptoms of physiological stress and, in extreme cases, death. Consequently, techniques such as energy dispersive X-ray spectroscopy (EDS) and Fourier-transform infrared spectroscopy (FTIR) are useful to evaluate the presence and nature of these macronutrients and micronutrients [28,29,30,31].

In the present work, four (4) samples of the mineral sylvite (KCl) from different deposits in Canada, Belarus and Germany were analyzed in order to determine the differences between them in terms of chemical composition, morphology and impurities present, which can produce adverse effects in a later application in fertilizer production processes. Such differences can be attributed to the origin of this mineral, the way it is obtained and exploited or to the transport and storage process through the use of anticompacting additives given the high hygroscopicity of the mineral. Instrumental analyses such as molecular infrared spectroscopy (FTIR), thermogravimetric analysis, morphological analysis using SEM, energy-dispersive X-ray spectroscopy, surface area analysis and non-instrumental analyses such as angle of repose were carried out.

2. Materials and Methods

Four (4) samples of the mineral sylvite (KCl) from different deposits in Canada (Saskatchewan, Coordinates: 54°00′00″N 106°00′02″ W), Belarus (Salihorsk, Coordinates: 52°48′N 27°32′ E) and Germany (Philippsthal (Werra), Coordinates: 50°51′N 10°00′ E) were analyzed. These samples were donated by fertilizer company in Cartagena–Colombia, and labelled as Blanco (Germany), Problema (Belarus), BPC (Canada) and Bueno (Canada). Figure 1 shows a photographic image of these samples.

Figure 1.

Photographic images of sylvite mineral samples from different deposits.

2.1. Morphological Analysis

The characterization of the sylvite minerals was carried out at Sena-Centro Nacional Colombo Alemán, Barranquilla. The analysis to determine the morphology of the crystalline particles was carried out with a scanning electron microscope (SEM) coupled to EDS, for which a mapping was performed. The instrument used was a Hitachi SU3500. The samples were placed on a steel plate, with the objective of making the sample conductive and thus being able to observe the image. The images were obtained with a voltage of 10 kV, and different magnifications were used [32,33].

2.2. Sieving

Sieves of numbers 2.000, 1.000, 0.500, 0.355, 0.212 and 0.150 with AISI 316 mesh, 304 mesh frame were used. For each experiment, about 30 g of sample were taken. It was carried out using ASTM C136 as reference (without drying the sample to constant mass) [34].

2.3. Angle of Repose

Angle-of-repose tests were performed on the four mineral samples. Each test was performed with approximately 122 g of sample and with the funnel at three different heights. The angle of repose was determined by means of a constructed stack, letting the material flow through a funnel maintained at a constant height. The angle of repose was calculated at three different funnel heights of 10, 20 and 30 cm. The standard method ASTM C1444-00 was used as a reference [23].

2.4. Thermogravimetric Analysis (TGA)

The thermogravimetric analysis was carried out in a temperature range of 26 °C to 42 °C, which allowed us to analyze the percentage of weight loss of the material from the water dew temperature to the estimated maximum temperature corresponding to the common environmental changes in the city of Cartagena. The results allow us to know the behavior of surface water or unbound water when the materials are in this temperature range. About 50 mg of sample was used in the analysis. Thermogravimetric analysis (TGA) was performed on an SDT Q600 V20.9 Build 20 thermal analyzer with a heating rate of 1 °C min−1 over a temperature range of 26–42 °C under flowing Ar.

2.5. Surface Area and Porosity Analysis

For this analysis, about 0.1000 g of samples were used. The measurements were made using N2 gas. The degassing rate was 31 °C/30 min. The bath temperature analysis was around −195.837 °C. A period of 10 s was used for the equilibrium interval, and 50.5275 cm3 was cold headspace. ASAP 2020 Micrometrics Instrument, Series: A213749 was used.

2.6. Energy-Dispersive X-ray Spectroscopy (EDS)

For energy dispersive spectroscopy (EDS), the samples were analyzed by performing an X-ray mapping in which the individual elemental distribution of the selected sample area is represented. The instrument used was a Hitachi SU3500 with EDS detector.

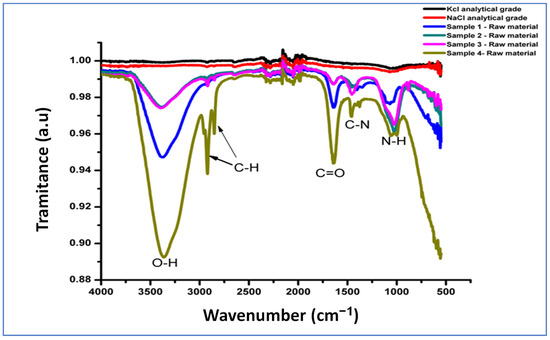

2.7. Fourier-Transform Infrared Spectroscopy Analysis (FTIR)

The Fourier-Transform Transmission Infrared Spectroscopy (FTIR) technique was used for the analysis of the identification of functional groups of the mineral Sylvite. A Shimadzu 8400s spectrophotometer was used for the analysis of each sample, using the KBr pellet preparation method. The spectral range of 400 cm−1–4000 cm−1 and spectral resolution of 4 cm−1 were used. The samples were dried in a conventional oven, at 120 °C, then in a vacuum oven for 2 h, at 120 °C. Infrared vibrational analysis of mineral samples without drying treatment were also performed. Analytical-grade KCl and NaCl spectra were taken and compared as reference spectra.

3. Results

3.1. Morphological Analysis

A scanning electron microscope (SEM) was used for morphological analysis. SEM analysis is a very useful technique for the morphological and textural study of crystalline materials, in which the electron beam passes through the column and reaches the sample. A scanning generator is responsible for producing the movement of the beam, so that it sweeps the sample point by point. From the interaction between the incident electrons with the atoms that make up the sample, signals are generated, which can be captured with specific detectors for each of them. The detector captures a signal and converts it into an electronic signal that is projected on a screen (CRT). The scanning of the beam is synchronized with the scanning of the CRT and produces a one-to-one ratio between points on the sample and points on the CRT [35].

To obtain corresponding details on morphology and porosity, in order to correlate this information with the compaction phenomena presented by the raw material, SEM analysis was carried out.

By means of SEM analysis, images corresponding to different magnifications were obtained. Magnifications of ×30, ×50, ×200 were carried out, respectively. The details about the observed images can be found at the bottom of each one.

Figure 2 shows that the particles are completely amorphous, with different shades of gray in different areas of each particle. It determines the existence of roughness in the material (darker areas are the roughest). Such porosity observed in the material indicates the existence of physisorption and moisture chemisorption, which can occur during storage, and its quantification is a function of the pore size distribution; the deterioration shown is a consequence of the forces acting on the particles as a result of the stacking of the stored material.

Figure 2.

SEM images of sylvite samples from different deposits. Images were taken at ×50 and ×200 at 10.0 kV. Samples analyzed were (A1): Blanco, (B1): Problema, (C1): BPC and (D1): Bueno, at ×50. Images (A2), (B2), (C2) and (D2) correspond to the area marked with red dotted lines in the images of (A1), (B1), (C1) and (D1), respectively, at ×200.

3.2. Particle Area

From the data obtained in the SEM analysis, the average particle size was calculated using software (from the instrument, Hitachi SU3500, Hitachi High-Tech Corporation, Tokyo, Japan) at magnification of ×50. Figure 3 shows the histograms of particle numbers as a function of area for the different samples analyzed. Table 1 shows the values corresponding to minimum, mean and maximum particle area. It can be observed that the sample corresponding to Bueno has particles with the largest area, and the BPC samples have those with the smallest area.

Figure 3.

Histogram of particle number as a function of area in mm2.

Table 1.

Average particle size from SEM images at ×50 for KCl mineral sample.

3.3. Sieving

In order to obtain information corresponding to the particle size distribution of KCl minerals from different deposits, different sieves were made, as mentioned above. Table 2 shows the percentage of particle size distribution retained in each sieve used. The results show that the Bueno mineral sample had the highest particle size distribution with 91.4% particles larger than 0.50 mm. The BPC mineral sample presented the largest particle size distribution with 49.9% particles smaller than 0.50 mm. It is worth mentioning that these results are in agreement with those obtained by SEM analysis of the same samples discussed in the previous section.

Table 2.

Percentage of particles retained on each mesh.

3.4. Angle of Repose

Angle of repose is the maximum angle at which a granular material monticule remains stable without sliding failure. This is a property of granular material that is determined by friction, cohesion, particle shape, grain size (the larger the grain size, the greater the angle of repose), and moisture. When granular material is slowly poured onto a horizontal surface, it flows forming a mound in which the free surface intermittently fails until the process stops and a stable slope is formed. Thus, the angle of repose corresponds to the angle formed between the inclined surface of the mound and the base and is obtained by direct measurement or by measuring the diameter and height of the granular material mound [24].

The angle of repose for each of the samples were calculated from the following equation.

where is the Diameter, is the Height and 1.2 is the funnel outlet diameter in cm.

Table 3 shows the angles of repose for the four mineral samples at three different funnel heights and the percent free moisture of each sample calculated from the TGA.

Table 3.

Angle of repose (θ) and free moisture (%) of KCl mineral sample analyzed.

In Table 3, the angle of repose showed various values by different factors such as volume, grain size, moisture and shape of minerals.

When analyzing each of the angle of repose values obtained from minerals from different deposits, with the free moisture content (see Table 3), it is corroborated that the percentage of moisture has a large influence on the angle of repose. The higher the moisture content, the more the granular material tends to increase its angle of repose [36].

Of the four minerals analyzed, the mineral from the Canada deposit (Bueno KCL) has the highest angle of repose (Table 3), this can be attributed to the fact that this mineral has the highest percentage of free moisture, the highest distribution of large particle size and heterogeneity in particle shape according to SEM images and sieve analysis.

The mineral from the Germany deposit (Blanco KCl) showed the lowest angle of repose when compared to the other KCl samples. This can be attributed to the fact that this mineral presents higher sphericity and lower particle roughness as observed in the SEM images.

The BPC KCl sample and Problema KCl show very similar angles of repose (<Bueno KCl and >Blanco KCl), probably due to their similar free moisture and similar granule shape according to SEM images.

3.5. Analysis of Surface Area and Porosity

Total Pore Volume refers to all the space inside the analyzed mineral particle, which serves to retain adsorbate molecules; this is expressed in mL/g (cm3/g). Considering the analysis conditions, it can be observed that the degassing process was carried out at 30 °C, which is the average temperature of the city of Cartagena. This condition guarantees that the samples subjected to the analysis have in their matrix the equilibrium humidity that they have during their storage in warehouses, which is important to analyze the amount of water adsorbed in ambient temperature conditions, relating the pore volume with the bound water or free water that the materials can adsorb.

The smaller the particle size, the higher the non-evaporable water content. Smaller molecules can fill the small pores and larger molecules can only go so far in the cavities. Small molecules will be retained mainly in the micropores of the mineral and larger molecules in larger pores such as mesopores or micropores. The surface chemistry plays an important role as heteroatoms and oxygenated functional groups on the surface can act as active sites [37].

Table 4 shows different parameters calculated from surface and porosity analysis. These results show that the mineral sample Bueno KCl has the highest surface area and pore volume when compared to the other KCl minerals. On the other hand, the BPC KCl mineral presented lower surface area and pore volume. These results are in agreement with those obtained by SEM and TGA, confirming that the mineral with the highest water adsorption capacity is Bueno KCl.

Table 4.

Analysis of surface area and porosity of KCl mineral samples.

It is worth mentioning that the adsorptive properties of the mineral are determined not only by its porous structure but also by its chemical composition. In the KCl mineral, with a highly oriented structure, adsorption takes place mainly by Van Der Waals forces. In the samples analyzed, the morphology and presence of chemical compounds means that unsaturated valences and unpaired electrons will influence the adsorption behavior, especially for polar or polarizable molecules. Thus, samples are invariably associated with appreciable amounts of heteroatoms such as oxygen, and other inorganic compounds. It is important to note that surface-oxygenated groups exert the greatest influence on the surface characteristics and adsorption behavior of minerals. Surface-oxygenated groups are not formed exclusively by reaction with oxygen. They can also result from reaction with many other gases (ozone, carbon dioxide, nitrous oxide, etc.) or with oxidizing solutions.

The analyzed minerals have disordered structures and a more exposed area than the pure KCl mineral, so they will have a high tendency for oxygen chemisorption. In addition, the basal planes in amorphous solids could contain various defects, dislocations and discontinuities, which are sites for oxygen chemisorption, which is enhanced by porosity [38].

3.6. Energy-Dispersive X-ray Spectroscopy (EDS) Analysis

Energy-dispersive X-ray spectroscopy (EDS), sometimes called energy dispersive X-ray analysis, is an analytical technique used for the elemental analysis or chemical characterization of a sample. It relies on an interaction between some source of X-ray excitation and a sample. Its characterization capabilities are due in large part to the fundamental principle that each element has a unique atomic structure allowing a unique set of peaks on its electromagnetic emission spectrum. EDS allows the elemental composition of the specimen to be measured [39].

It is pertinent to mention that the elemental distribution in a particle is not homogeneous, which means that the individual elemental distribution can be higher or lower in a specific zone of the particle. An illustration of the proportions of the chemical elements for each sample can be seen in Figure 4. These images show that the major elements are Cl and K. Other elements in smaller proportions were also detected.

Figure 4.

Distribution of elemental chemical composition of KCl minerals from different deposits using EDS-SEM.

Table 5 shows the percentage composition of the elements found when the EDS analysis was performed. The elements found were Be, O, Na, Mg, Si, Cl, K, Al, Mo and Fe. The mineral sample of Blanco KCl was the only one with the element Be. The mineral sample with the lowest element amount of O, Na, Mg and Si was Blanco KCl. Bueno KCl had the highest amount for O, Na and Mg. As expected, the elements in higher proportion are Cl and K. These elements (Cl, K) are in a percentage of about 40% by weight. This means that the concentration of KCl in these minerals is higher than 80% by weight. On the other hand, Blanco KCl did not present Al, and the element Mo was not detected in Blanco and Bueno KCl.

Table 5.

Percentage composition of chemical elements in KCl minerals (Wt%).

3.7. Fourier-Transform Infrared Spectroscopy Analysis (FTIR)

Infrared analysis of the mineral samples with and without a drying process were performed. The IR spectra of analytical grade reference KCl and NaCl were acquired. As expected, the IR spectra of the reference salts did not show IR bands in the 400 cm−1–4000 cm−1 region, except for the atmospheric CO2 bands present around 2200 cm−1 [31,40,41]. When the IR spectra of the mineral samples (with and without drying) were analyzed, The IR bands of O-H, C-N, N-H and C=O bonds were observed, as shown in Figure 5 and Figure 6 [31,42,43]. These minerals (Blanco, BPC, Problema and Bueno) not having a purification process, it is expected that other compounds of inorganic nature such as oxides are present, as shown in the EDS analysis discussed above. These unpurified minerals also have compounds of organic nature such as carboxylic acids, amines and amides, as shown by the IR bands in Figure 5 and Figure 6 [42,43]. This organic matter is responsible for the red coloration present in three of the mineral samples. During the drying process, it is expected that compounds such as water and low-molecular-weight organic physiadsorbates were removed and substantially decreased. IR bands were generally similar before and after the drying process. However, the Bueno KCL (sample 4) showed the greatest change in the intensity of its bands, as can be observed for the IR band for -OH around 3300 cm−1. This behavior of KCl is supported by the surface and TGA analyses because it is the mineral with the largest surface area and pore volume, so its capacity for physisorption of water and volatile organic compounds (rich in hydroxyl groups) is higher; consequently, the IR bands (3300 cm−1) will decrease. The drying treatment allowed us to observe the N-H vibration (3600 cm−1) confirming that these minerals show the presence of possible amines and amides [43].

Figure 5.

IR spectra of mineral samples without drying treatment. Sample 1: Blanco; Sample 2: BPC; Sample 3: Problema and Sample 4: Bueno.

Figure 6.

IR spectra of mineral samples with drying treatment. Sample 1: Blanco; Sample 2: BPC; Sample 3: Problema and Sample 4: Bueno.

4. Conclusions

Chemical composition, morphology and impurities present in four sylvite (KCl) minerals used in fertilizer production were analyzed. Non-instrumental techniques such as sieving and angle of repose, and instrumental techniques such as thermogravimetric analysis (TGA), surface area and porosity, scanning electron microscopy analysis, energy-dispersive X-ray spectroscopy (EDS) and Fourier-transform infrared spectroscopy analysis (FTIR) were used. From the morphological and porosity analyses, it was observed that the KCl particles are completely amorphous. It could be observed that the sample corresponding to Bueno has particles with larger size, surface area and pore volume when compared to the other KCl minerals. The BPC samples have the smallest particle size and porosity. Of the four minerals analyzed, the mineral from the Canada deposit (Bueno mineral) has the highest angle of repose. The mineral from the Germany deposit (Blanco mineral) showed the lowest angle of repose. The concentration of KCl in these minerals is higher than 80% by weight. In the samples, elements Fe and O were detected, which are expected to contribute to the red coloration in many of the minerals analyzed. The IR bands of O-H, C-N, N-H and C=O bonds were observed, giving the presence of organic compounds. In general, the results show useful information in terms of size distribution, porosity, surface area and chemical composition. These results are important for decision making at the moment of transport and storage of the KCl mineral, as well as to know the contribution in micronutrients that these minerals can provide during the manufacture of the fertilizer.

Author Contributions

Conceptualization, J.R.C.-S. and A.T.-D.; methodology, J.R.C.-S. and F.C.-C.; validation, F.C.-C.; investigation, F.C.-C. and A.T.-D.; data curation, J.R.C.-S. and F.C.-C.; writing—original draft preparation, J.R.C.-S., F.C.-C. and A.T.-D.; writing—review and editing, J.R.C.-S. and F.C.-C.; visualization, J.R.C.-S.; supervision, F.C.-C. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by The University of Sinú.

Data Availability Statement

Not applicable.

Acknowledgments

We acknowledge the University of Cartagena and Sena-Barranquilla for providing their laboratories to analyze the samples for this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- International Plant Nutrition Institute. Cloruro de Potasio. Available online: http://www.ipni.net/publication/nss-es.nsf/0/A48F7C5B42D2D6BF85257BBA0059A849/$FILE/NSS-ES-03.pdf (accessed on 7 October 2022).

- Sanz, J.; Tomasa, O.; Jimenez-Franco, A.; Sidki-Rius, N. Potassium (K) [Z = 19]. Elem. Miner. Resour. 2022, 1, 167–169. [Google Scholar] [CrossRef]

- Sanz, J.; Tomasa, O.; Jimenez-Franco, A.; Sidki-Rius, N. Sylvite. Elem. Miner. Resour. 2022, 387–389. [Google Scholar] [CrossRef]

- Hernández Díaz, M.I.; Chailloux Laffita, M.; Moreno Placeres, V.; Ojeda Veloz, A.; Salgado Pulido, J.M.; Bruzón Guerrero, O. Relaciones Nitrógeno-Potasio En Fertirriego Para El Cultivo Protegido Del Tomate En Suelo Ferralítico Rojo. Pesqui. Agropecuária Bras. 2009, 44, 429–436. [Google Scholar] [CrossRef][Green Version]

- Choudhary, S.; Singh, A.; Rani, M. Role of Potassium in Plants. Mag. Agric. 2022, 1, 76–79. [Google Scholar]

- Mikkelsen, R.L.; Roberts, T.L. Inputs: Potassium Sources for Agricultural Systems. In Improving Potassium Recommendations for Agricultural Crops; Springer: Cham, Switzerland, 2020; pp. 47–73. [Google Scholar] [CrossRef]

- Livi Bacci, M. Historia Mínima de La Población Mundial; Crítica: Barcelona, Spain, 2009. [Google Scholar]

- Lobo, M. Importancia de Los Recursos Genéticos de La Agrobiodiversidad En El Desarrollo de Sistemas de Producción Sostenibles. Cienc. Tecnol. Agropecu. 2009, 9, 19–30. [Google Scholar] [CrossRef]

- Oswaldo Benavides, H.; Mayorga Márquez, R.; Hurtado Moreno, G. Análisis de Índices de Extremos Climáticos Para Colombia Usando El RCLIMDEX; IDEAM–METEO/007-2007; Instituto de Hidrología, Meteorología y Estudios Ambientales: Bogotá, Colombia, 2007. [Google Scholar]

- Zamorio, M.J.; Peña, E.; López, C.; Silva, T. Efectos de La Sequía Y Del Cambio Climático En Los Recursos Hídricos Y En La Seguridad Alimentaria de Cinco Comunidades Del Municipio de Ciudad Darío, Matagalpa. Cuad. Investig. 2017, 1, 9–38. [Google Scholar]

- Soliveres, S. Efectos Del Estrés Abiótico Y Factores Bióticos En Las Interacciones Planta-Planta: Implicaciones Para El Funcionamiento Y La Restauración de Los Ecosistemas Semiáridos. Ecosistemas 2011, 20, 121–128. [Google Scholar]

- Martínez Castizo, D. La silvinita. Available online: https://diario16.com/la-silvinita/ (accessed on 7 October 2022).

- Kant, S.; Kafkafi, U. Absorción de Potasio Por Los Cultivos En Distintos Estadios Fisiológicos. (En Línea). In Proceedings of the Internacional Potash Institute Annual Conference, Hebrew University, Rehovot, Israel, 5 July 2000; Potasio en Plantas y Animales. pp. 263–302. [Google Scholar]

- Singh, T.A.; Thomas, G.W.; Moschler, W.W.; Martens, D.C. Phosphorus Uptake by Corn (Zea mays L.) under No-Tillage and Conventional Practices. Agron. J. 1966, 58, 147–148. [Google Scholar] [CrossRef]

- Ladha, J.K.; Pathak, H.; Krupnik, T.J.; Six, J.; van Kessel, C. Efficiency of Fertilizer Nitrogen in Cereal Production: Retrospects and Prospects. Adv. Agron. 2005, 87, 85–156. [Google Scholar] [CrossRef]

- Li, R.; Liu, C.; Jiao, P.; Liu, W.; Wang, S. The Present Situation, Existing Problems, and Countermeasures for Exploitation and Utilization of Low-Grade Potash Minerals in Qarhan Salt Lake, Qinghai Province, China. Carbonates Evaporites 2020, 35, 34. [Google Scholar] [CrossRef]

- Soumare, A.; Sarr, D.; Diédhiou, A.G. Potassium Sources, Microorganisms, and Plant Nutrition—Challenges and Future Research Directions: A Review. Pedosphere, 2022; In Press. [Google Scholar] [CrossRef]

- Jena, S.K. A Review on Potash Recovery from Different Rock and Mineral Sources. Min. Metall. Explor. 2021, 38, 47–68. [Google Scholar] [CrossRef]

- Gonzales, O. ¿Para qué Sirve el Potasio?, Propiedades y Beneficios. 2018. Available online: https://laguiadelasvitaminas.com/para-que-sirve-el-potasio/ (accessed on 7 October 2022).

- Warren, J.K. Geological controls on the quality of potash. In Proceedings of the 8th World Salt Symposium, The Hague, The Netherlands, 7—11 May 2000; Elsevier: Amsterdam, The Netherlands, 2000; pp. 173–180. [Google Scholar]

- Stewart, J.A. Potassium Sources, Use, and Potential. Potassium Agric. 2015, 1, 83–98. [Google Scholar] [CrossRef]

- Kraus, H.; Hunt, F.; Ramsdell, S.; Navarro, A. Mineralogía: Una Introducción al Estudio de Minerales y Cristales, 5th ed.; Ediciones del Castillo: Madrid, España, 1965. [Google Scholar]

- ASTM C1444-00; Standard Test Method for Measuring the Angle of Repose of Free-Flowing Mold Powders. American Society for Testing and Materials: West Conshohocken, PA, USA, 2000.

- Rodas, R.; Rousé, P. Análisis Comparativo de Métodos Para La Medición Del Ángulo de Reposo de Suelos Granulares. Rev. la Construcción 2010, 9, 98–106. [Google Scholar] [CrossRef][Green Version]

- Maldonado Uría, P.; Pino Vargas, E. Influencia Del Tipo de Material, Superficie de Contacto Y Altura de Almacenaje Sobre El Ángulo de Reposo, En Materiales Granulares. Cienc. Desarro. 2019, 18, 22–31. [Google Scholar] [CrossRef]

- De Araujo, A.C.; Valadão, G.E.S.; Da Gama, E.M.; Hernandez, C.A. Consistencia, Fluidez Y Viscosidad de Pastas Minerales de Relaves de Hierro. Inf. Tecnol. 2006, 17, 71–79. [Google Scholar] [CrossRef]

- Mikkelsen, R.L. Managing Potassium for Organic Crop Production. HortTechnology 2007, 17, 455–460. [Google Scholar] [CrossRef]

- Tripathi, D.K.; Singh, S.; Singh, S.; Mishra, S.; Chauhan, D.K.; Dubey, N.K. Micronutrients and Their Diverse Role in Agricultural Crops: Advances and Future Prospective. Acta Physiol. Plant. 2015, 37, 139. [Google Scholar] [CrossRef]

- Aftab, T.; Hakeem, K.R. Plant Micronutrients: Deficiency and Toxicity Management; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Broadley, M.; Brown, P.; Cakmak, I.; Rengel, Z.; Zhao, F. Function of Nutrients. Marschner’s Miner. Nutr. High. Plants 2012, 3, 191–248. [Google Scholar] [CrossRef]

- Chukanov, N.V.; Chervonnyi, A.D. Infrared Spectroscopy of Minerals and Related Compounds; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Jarvis, S. Electron Microprobe Analysis and Scanning Electron Microscopy in Geology; Cambridge University Press, Cop: Cambridge, UK, 2005. [Google Scholar]

- Small, J.A. The Analysis of Particles at Low Accelerating Voltages (<= 10 KV) with Energy Dispersive X-Ray Spectroscopy (EDS). J. Res. Natl. Inst. Stand. Technol. 2002, 107, 555. [Google Scholar] [CrossRef]

- ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2000.

- Ruiz, M.E. métodos de análisis térmico. In Análisis Farmacéutico; 1st, ed, Guillermina-Volonté, M., Quiroga, P., Eds.; Universidad Nacional de La Plata: Buenos Aires, Argentina, 2013; p. 159. [Google Scholar]

- Train, D. Some Aspects of The Property of Angle Of Repose Of Powders. J. Pharm. Pharmacol. 1958, 10 (Suppl. 1), 127T–135T. [Google Scholar] [CrossRef] [PubMed]

- Contreras Pérez, J.B.; Araujo, A.L.; Fernández, R.E.; Santos Ortiz, R.D.L. Variaciones En El Equilibrio de Adsorción Según El Tamaño de Partícula Adsorbente. Cienc. Soc. 1992, 17, 52–59. [Google Scholar] [CrossRef][Green Version]

- Sands, D. Introducción a la Cristalografía; Reverteé: Barcelona, Spain, 2011. [Google Scholar]

- Goldstein, J.; Newbury, D.E.; Michael, J.R.; Ritchie, N.W.M.; Henry, J.; Joy, D.C. Scanning Electron Microscopy and X-Ray Mi-croanalysis; Springer: New York, NY, USA, 2018. [Google Scholar]

- Sharpe, S.W.; Reifschneider, D.; Wittig, C.; Beaudet, R.A. Infrared Absorption Spectroscopy of the CO2–Ar complex in the 2376 Cm−1 Combination Band Region: The Intermolecular Bend. J. Chem. Phys. 1991, 94, 233–238. [Google Scholar] [CrossRef]

- Moore, G.; Chizmeshya, A.; McMillan, P.F. Calibration of a Reflectance FTIR Method for Determination of Dissolved CO2 Concentration in Rhyolitic Glasses. Geochim. Cosmochim. Acta 2000, 64, 3571–3579. [Google Scholar] [CrossRef]

- Nandiyanto, A.B.D.; Oktiani, R.; Ragadhita, R. How to Read and Interpret FTIR Spectroscope of Organic Material. Indonesian J. Sci. Technol. 2019, 4, 97. [Google Scholar] [CrossRef]

- Pavia, D.L.; Lampman, G.M.; Kriz, G.S.; Vyvyan, J.R. Introduction to Spectroscopy; Cengage Learning: Boston, MA, USA, 2014. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).