Multi-Objective Optimization of Biodegradable and Recyclable Composite PLA/PHA Parts

Abstract

1. Introduction

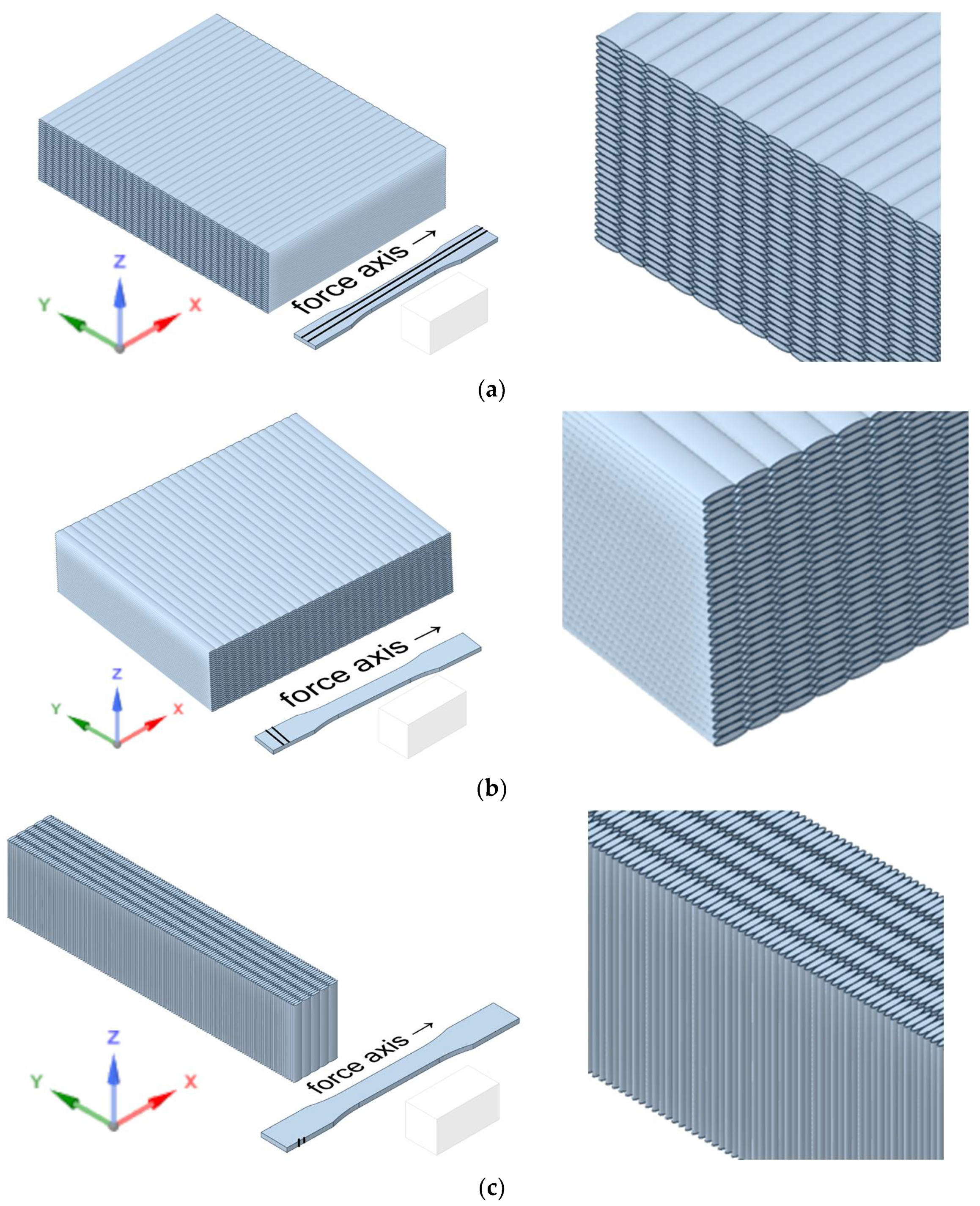

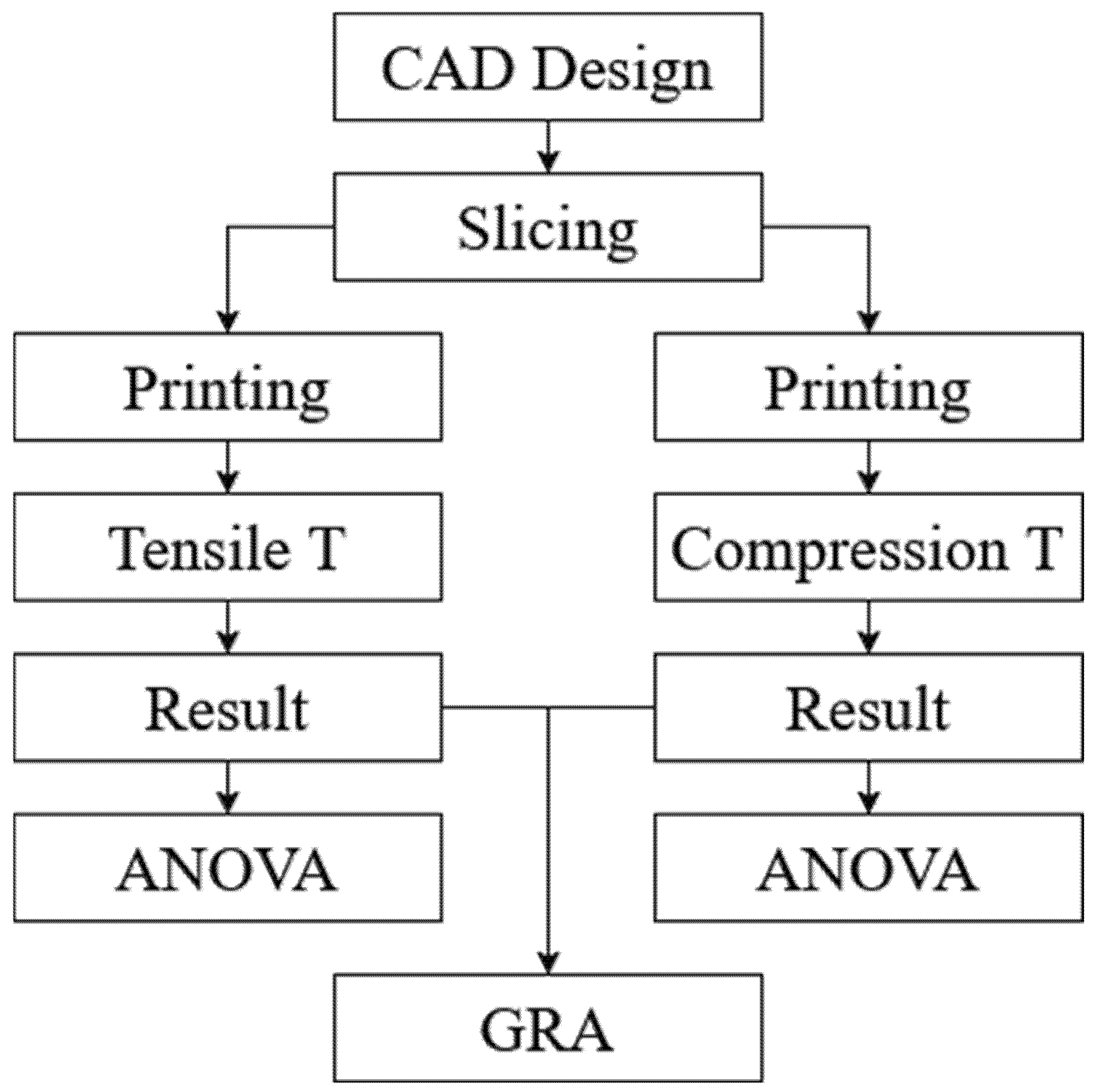

2. Materials and Methods

3. Results and Discussion

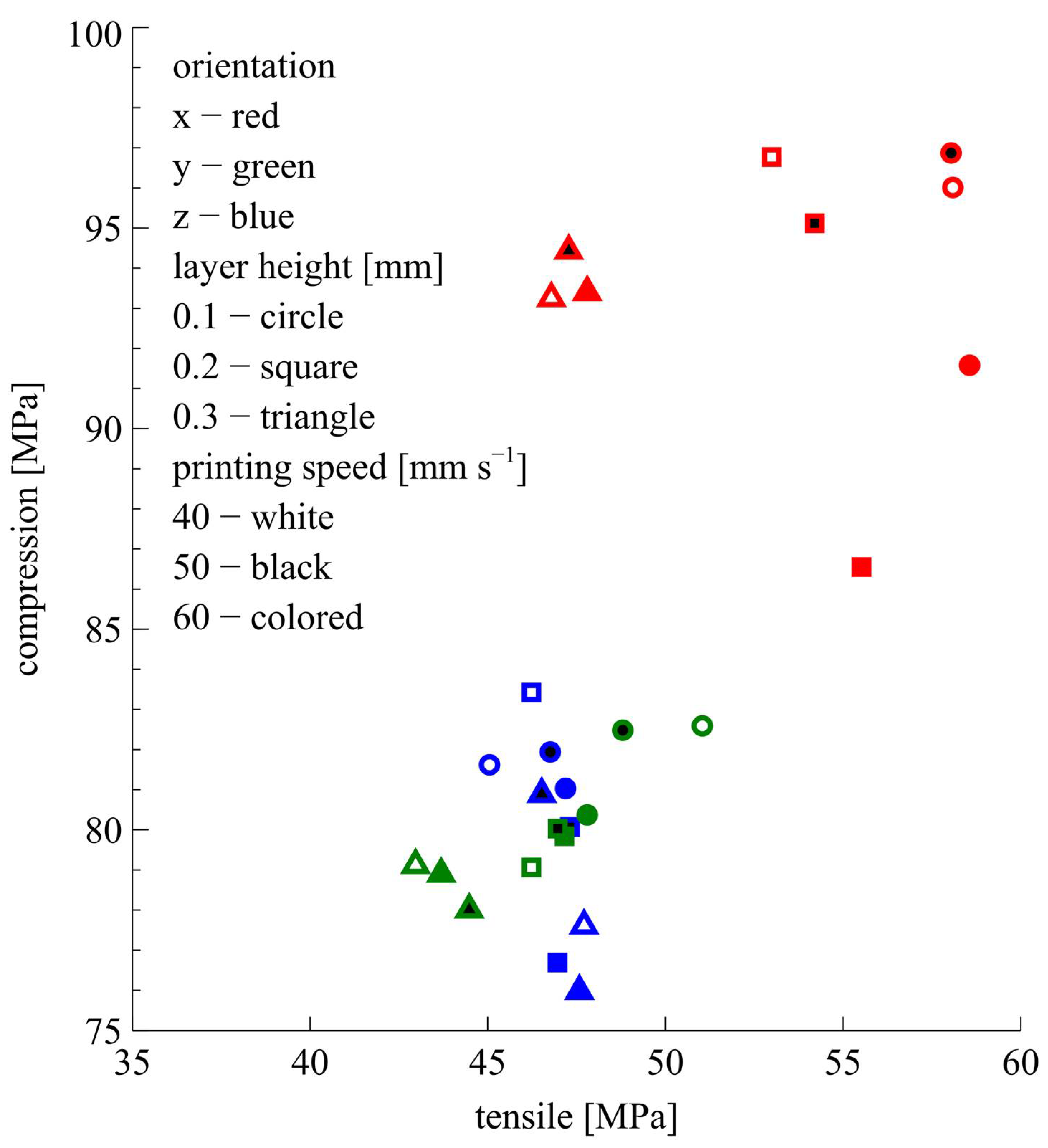

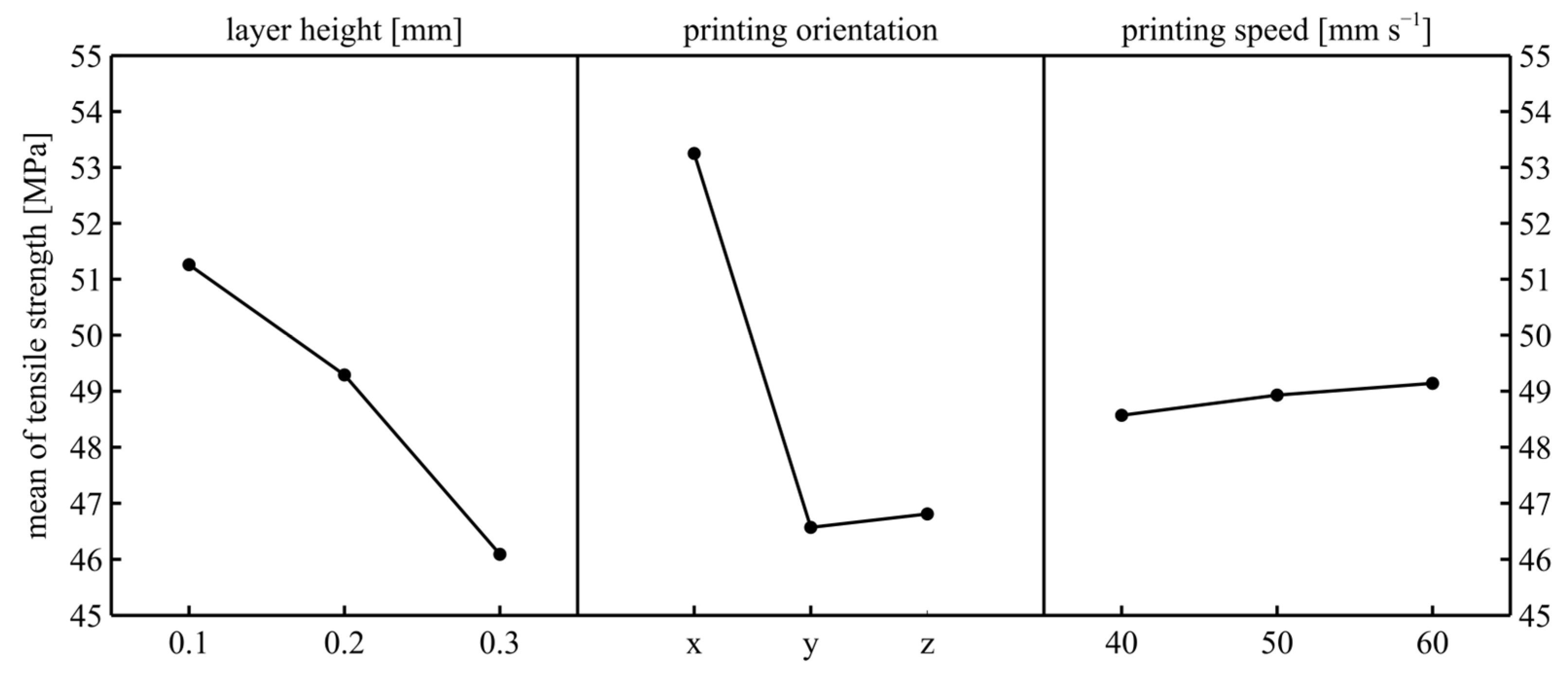

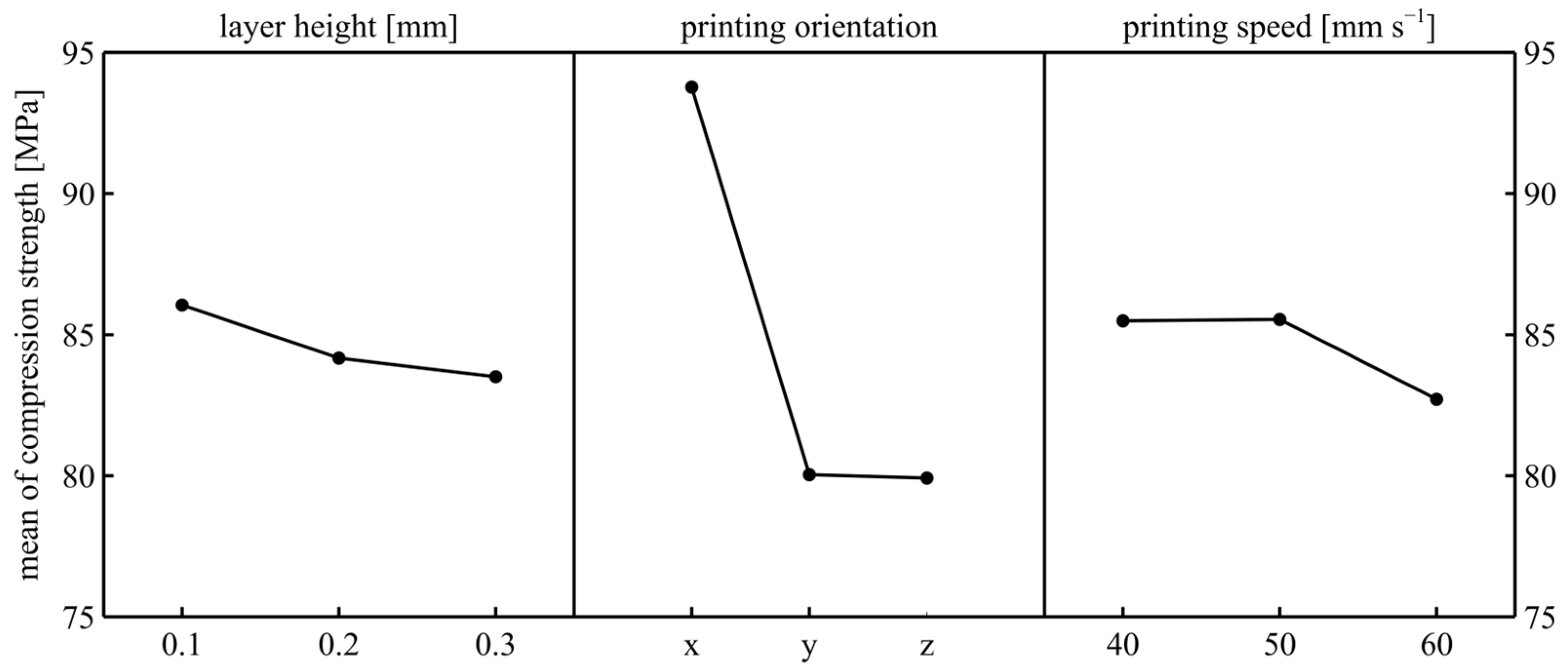

3.1. Test Results

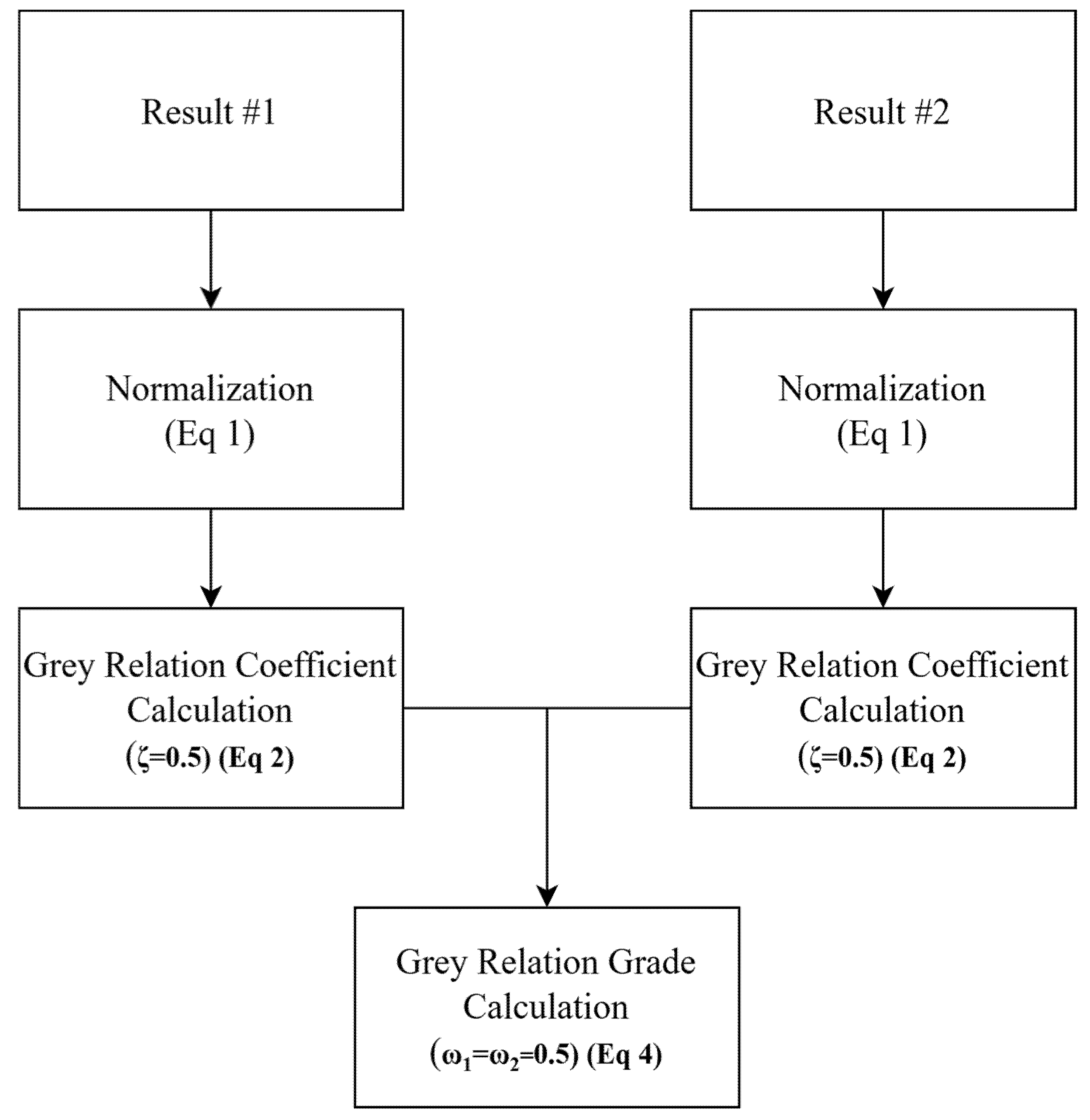

3.2. Grey Relational Analysis Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PLA | Polylactic acid |

| aPHA | Polylactic acid/amorphous |

| PHA | Polyhydroxyalkanoate |

| CAD | Computer aided design |

| ANOVA | Analysis of variance |

| GRA | Grey relational analysis |

| GRC | Grey relational coefficient |

| ASTM | American society for testing and materials |

| H | High |

| L | Low |

| DF | Degree of freedom |

| ADJ SS | Adjusted sums of squares |

| ADJ MS | Adjusted mean squares |

References

- Turan, M.K.; Sabirli, M.Ü.; Bakirci, A.; Kartal, E.; Karpat, F. A Comprehensive Study on the Effects of Printing Parameters on the Mechanical Properties of PLA. Rapid Prototyp. J. 2025, 31, 174–183. [Google Scholar] [CrossRef]

- Notta-Cuvier, D.; Odent, J.; Delille, R.; Murariu, M.; Lauro, F.; Raquez, J.M.; Bennani, B.; Dubois, P. Tailoring Polylactide (PLA) Properties for Automotive Applications: Effect of Addition of Designed Additives on Main Mechanical Properties. Polym. Test. 2014, 36, 1–9. [Google Scholar] [CrossRef]

- Giammaria, V.; Capretti, M.; Del Bianco, G.; Boria, S.; Santulli, C. Application of Poly(Lactic Acid) Composites in the Automotive Sector: A Critical Review. Polymers 2024, 16, 3059. [Google Scholar] [CrossRef]

- Rațiu, S.A.; Zgaverdea, A.C. The Potential of Using Bio Plastic Materials in Automotive Applications. Mater. Plast. 2019, 56, 901–909. [Google Scholar] [CrossRef]

- De Luca, S.; Milanese, D.; Gallichi-Nottiani, D.; Cavazza, A.; Sciancalepore, C. Poly(Lactic Acid) and Its Blends for Packaging Application: A Review. Clean Technol. 2023, 5, 1304–1343. [Google Scholar] [CrossRef]

- Stublić, K.; Ranilović, J.; Ocelić Bulatović, V.; Kučić Grgić, D. Advancing Sustainability: Utilizing Bacterial Polyhydroxyalkanoate for Food Packaging. Processes 2024, 12, 1886. [Google Scholar] [CrossRef]

- Cecen, B. FDM-Based 3D Printing of PLA/PHA Composite Polymers. Chem. Pap. 2023, 77, 4379–4386. [Google Scholar] [CrossRef]

- Ahmed, S.S.; Abdul-Hamead, A.A.; Flaieh, E.H.; Abdulhameed, S.A. Effect of Seed Husk Waste Powder on the PLA Medical Thread Properties Fabricated via 3D Printer. Curved Layer. Struct. 2024, 11, 20220222. [Google Scholar] [CrossRef]

- Promnil, S.; Ruksakulpiwat, C.; Numpaisal, P.; Ruksakulpiwat, Y. Electrospun Poly(Lactic Acid) and Silk Fibroin Based Nanofibrous Scaffold for Meniscus Tissue Engineering. Polymers 2022, 14, 2435. [Google Scholar] [CrossRef]

- Yang, Z.; Yin, G.; Sun, S.; Xu, P. Medical Applications and Prospects of Polylactic Acid Materials. iScience 2024, 27, 111512. [Google Scholar] [CrossRef]

- Efstathiadis, A.; Symeonidou, I.; Tsongas, K.; Tzimtzimis, E.K.; Tzetzis, D. Parametric Design and Mechanical Characterization of 3D-Printed PLA Composite Biomimetic Voronoi Lattices Inspired by the Stereom of Sea Urchins. J. Compos. Sci. 2023, 7, 3. [Google Scholar] [CrossRef]

- Kafshgar, A.R.; Rostami, S.; Aliha, M.R.M.; Berto, F. Optimization of Properties for 3D Printed PLA Material Using Taguchi, ANOVA and Multi-Objective Methodologies. Procedia Struct. Integr. 2021, 34, 71–77. [Google Scholar] [CrossRef]

- Günay, M.; Gündüz, S.; Yilmaz, H.; Yaşar, N.; Kaçar, R. PLA Esaslı Numunelerde Çekme Dayanımı İçin 3D Baskı İşlem Parametrelerinin Optimizasyonu. Politek. Derg. 2020, 23, 73–79. [Google Scholar] [CrossRef]

- Andronov, V.; Beránek, L.; Krůta, V.; Hlavůňková, L.; Jeníková, Z. Overview and Comparison of PLA Filaments Commercially Available in Europe for FFF Technology. Polymers 2023, 15, 3065. [Google Scholar] [CrossRef]

- Bakirci, A.; Turan, M.K.; Karpat, F. Comprehensive Analysis of Heat Treatment Effects on PLA-Wood Biocomposites. Rapid Prototyp. J. 2025. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, D.; Wan, G.; Li, B.; Zhao, G. Glass Fiber Reinforced PLA Composite with Enhanced Mechanical Properties, Thermal Behavior, and Foaming Ability. Polymer 2019, 181, 121803. [Google Scholar] [CrossRef]

- Calles, A.F.; Carou, D.; Ferreira, R.T.L. Experimental Investigation on the Effect of Carbon Fiber Reinforcements in the Mechanical Resistance of 3D Printed Specimens. Appl. Compos. Mater. 2022, 29, 937–952. [Google Scholar] [CrossRef]

- Tunçel, O.; Tüfekci, K.; Kahya, Ç. Multi-Objective Optimization of 3D Printing Process Parameters Using Gray-Based Taguchi for Composite PLA Parts. Polym. Compos. 2024, 45, 12870–12884. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Microstructure and Mechanical Performance of 3D Printed Wood-PLA/PHA Using Fused Deposition Modelling: Effect of Printing Temperature. Polymers 2019, 11, 1778. [Google Scholar] [CrossRef]

- Montalvão, G.R.; Moshrefi-Torbati, M.; Hamilton, A.; Machado, R.; João, A. Behaviour of 3D Printed PLA and PLA-PHA in Marine Environments. In IOP Conference Series: Earth and Environmental Science, Proceedings of the 2019 5th International Conference on Advances in Environment Research, Singapore, 13–15 August 2019; IOP Publishing: Bristol, UK, 2020; Volume 424, pp. 1–9. [Google Scholar] [CrossRef]

- Zgodavová, K.; Lengyelová, K.; Bober, P.; Eguren, J.A.; Moreno, A. 3D Printing Optimization for Environmental Sustainability: Experimenting with Materials of Protective Face Shield Frames. Materials 2021, 14, 6595. [Google Scholar] [CrossRef]

- Zaharia, S.M.; Enescu, L.A.; Pop, M.A. Mechanical Performances of Lightweight Sandwich Structures Produced by Material Extrusion-Based Additive Manufacturing. Polymers 2020, 12, 1740. [Google Scholar] [CrossRef] [PubMed]

- Pop, M.A.; Croitoru, C.; Bedo, T.; Geamăn, V.; Radomir, I.; Zaharia, S.M.; Chicoş, L.A. Influence of Internal Innovative Architecture on the Mechanical Properties of 3D Polymer Printed Parts. Polymers 2020, 12, 1129. [Google Scholar] [CrossRef] [PubMed]

- Chatrath, S.; Alotaibi, M.; Barry, C.F. Performance of Recycled Polylactic Acid/Amorphous Polyhydroxyalkanoate Blends. Polymers 2024, 16, 1230. [Google Scholar] [CrossRef] [PubMed]

- Mondragón-Herrera, L.I.; Vargas-Coronado, R.F.; Carrillo-Escalante, H.; Cauich-Rodríguez, J.V.; Hernández-Sánchez, F.; Velasco-Santos, C.; Avilés, F. Mechanical, Thermal, and Physicochemical Properties of Filaments of Poly(Lactic Acid), Polyhydroxyalkanoates and Their Blend for Additive Manufacturing. Polymers 2024, 16, 1062. [Google Scholar] [CrossRef]

- Abu Aldam, S.; Dey, M.; Javaid, S.; Ji, Y.; Gupta, S. On the Synthesis and Characterization of Polylactic Acid, Polyhydroxyalkanoate, Cellulose Acetate, and Their Engineered Blends by Solvent Casting. J. Mater. Eng. Perform. 2020, 29, 5542–5556. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Thermal Cycling, Microstructure and Tensile Performance of PLA-PHA Polymer Printed Using Fused Deposition Modelling Technique. Rapid Prototyp. J. 2020, 26, 122–133. [Google Scholar] [CrossRef]

- Oviedo, A.M.; Puente, A.H.; Bernal, C.; Pérez, E. Mechanical Evaluation of Polymeric Filaments and Their Corresponding 3D Printed Samples. Polym. Test. 2020, 88, 106561. [Google Scholar] [CrossRef]

- Ali, S.; Mehra, V.; Eltaggaz, A.; Deiab, I.; Pervaiz, S. Optimization and Prediction of Additively Manufactured PLA-PHA Biodegradable Polymer Blend Using TOPSIS and GA-ANN. Manuf. Lett. 2024, 41, 795–802. [Google Scholar] [CrossRef]

- Sabalina, A.; Platnieks, O.; Gaidukova, G.; Aunins, A.; Eiduks, T.V.; Gaidukovs, S. Thermomechanical and Mechanical Analysis of Polylactic Acid/Polyhydroxyalkanoate/Poly(Butylene Succinate-Co-Adipate) Binary and Ternary Blends. RSC Adv. 2025, 15, 501–512. [Google Scholar] [CrossRef]

- Park, G.; Jang, H.; Choi, T.; Park, S.-I. Degradation Behavior of Poly(Lactic Acid) and Poly(Hydroxyalkanoate) Blends in Simulated Marine Environments. Macromol. Res. 2025. [Google Scholar] [CrossRef]

- Loureiro, N.; Esteves, J.; Viana, J.; Ghosh, S. Mechanical Characterization of Polyhydroxyalkanoate and Poly(Lactic Acid) Blends. J. Thermoplast. Compos. Mater. 2015, 28, 195–213. [Google Scholar] [CrossRef]

- Ranakoti, L.; Gangil, B.; Mishra, S.K.; Singh, T.; Sharma, S.; Ilyas, R.A.; El-Khatib, S. Critical Review on Polylactic Acid: Properties, Structure, Processing, Biocomposites, and Nanocomposites. Materials 2022, 15, 4312. [Google Scholar] [CrossRef] [PubMed]

- MatWeb. NaturePlast PHI 002 PHA Injection. Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=ac3411fe439446c793676abaebeb356c (accessed on 23 July 2025).

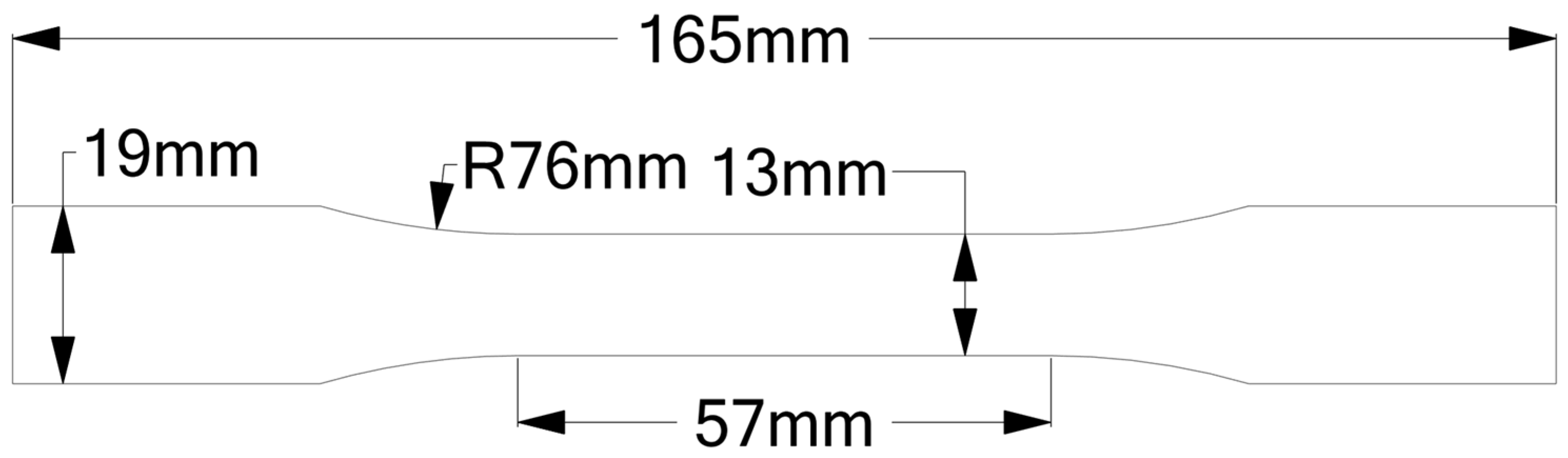

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

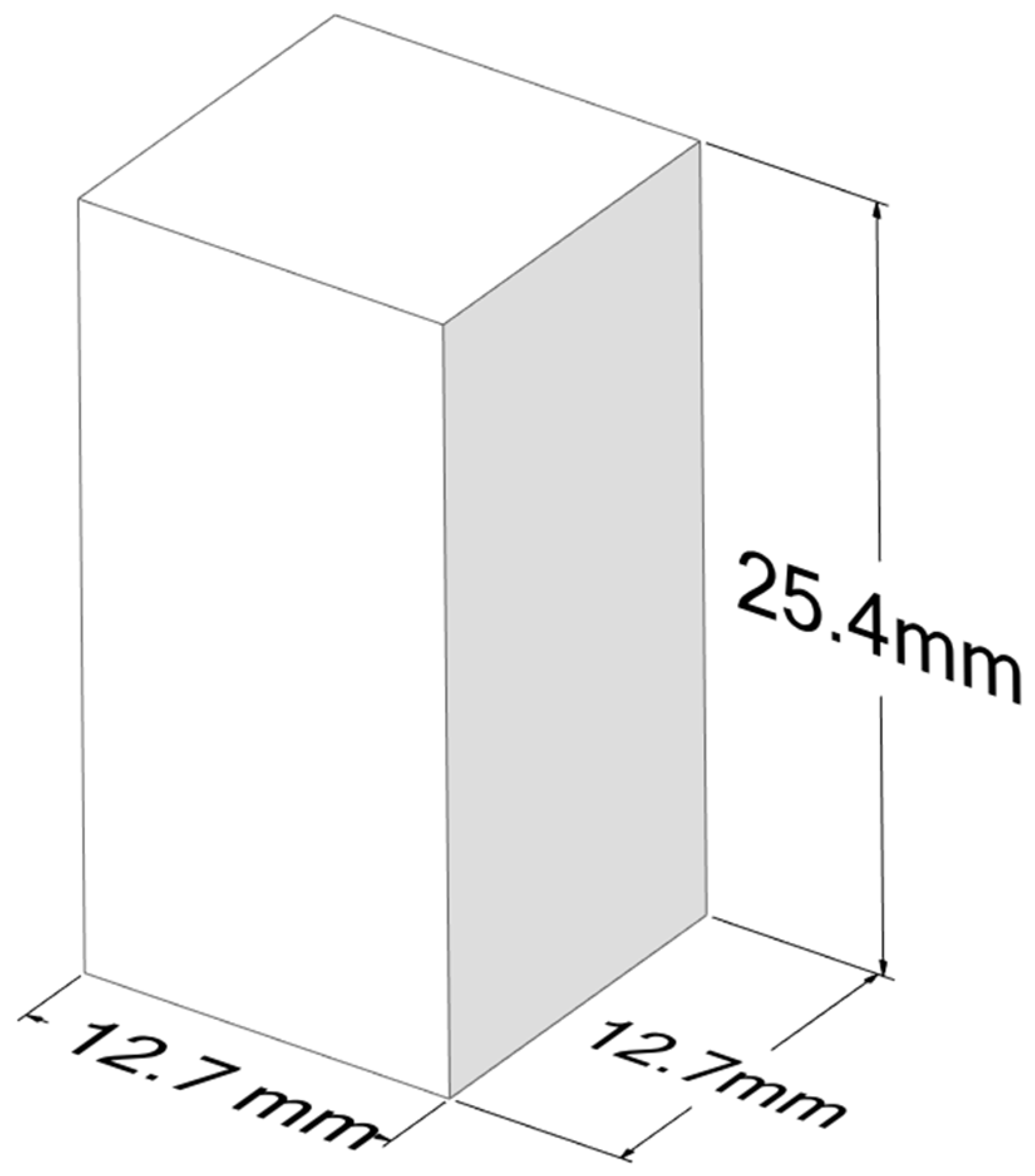

- ASTM D695-23; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM: West Conshohocken, PA, USA, 2023.

- Raj, S.S.; Michailovich, K.A.; Subramanian, K.; Sathiamoorthyi, S.; Kandasamy, K.T. Philosophy of Selecting ASTM Standards for Mechanical Characterization of Polymers and Polymer Composites. Mater. Plast. 2021, 58, 247–256. [Google Scholar] [CrossRef]

- Ziółkowski, D.; Maćkowiak, P.; Marzec, M. The Influence of Layer Height and Nozzle Diameter on the Strength of Elements Manufactured Using FDM Technology. J. Phys. Conf. Ser. 2024, 2927, 012015. [Google Scholar] [CrossRef]

- Veeman, D.; Dutta, H.; Vellaisamy, M. Additive Manufacturing of Component Based on Polyethylene Terephthalate Glycol: Multi-Response Optimization Using Grey Relational Analysis. Eng. Res. Express 2025, 7, 025402. [Google Scholar] [CrossRef]

- Yuce, C. Multi-Objective Optimisation for Indentation Rate, Nugget Diameter and Tensile Load in Resistance Spot Welding Using Taguchi-Based Grey Relational Analysis. Int. J. Mater. Prod. Technol. 2021, 63, 321–338. [Google Scholar] [CrossRef]

- Liu, S. Series on Grey System Grey Systems Analysis: Methods, Models and Applications, 2nd ed.; Springer: Singapore, 2025; ISBN 9789819787265. [Google Scholar]

- Saravanamuthukumar, P.; Kaaviya, J.; Palaniyappan, S.; Sivakumar, N.K.; Bodaghi, M.; Rahaman, M.; Pandiaraj, S. Compressive Strength Performance of 3D Printed PLA/Almond Shell Particles Reinforced PLA Multi-Material Composite. J. Elastomers Plast. 2024, 56, 786–806. [Google Scholar] [CrossRef]

| Material | Density (g/cm3) | Melt Flow Index (g/10 min) |

|---|---|---|

| PLA | 1–1.5 | 4–22 |

| PHA | 1.25 | 15–30 |

| Printing Parameters | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Printing Orientation | X | Y | Z |

| Printing Speed | 40 mm/s | 50 mm/s | 60 mm/s |

| Layer Height | 0.1 mm | 0.2 mm | 0.3 mm |

| Experimental No | Layer Height [mm] | Printing Orientation | Printing Speed [mm/s] | Tensile Strength [MPa] | Tensile Strength Upper Value [MPa] | Tensile Strength Lower Value [MPa] | Compression Strength [MPa] | Compression Strength Upper Value [MPa] | Compression Strength Lower Value [MPa] |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.1 | X-axis | 40 | 58.09 | 58.51 | 57.30 | 96.01 | 97.70 | 94.46 |

| 2 | 0.1 | X-axis | 50 | 58.04 | 60.91 | 55.78 | 96.87 | 97.45 | 96.39 |

| 3 | 0.1 | X-axis | 60 | 58.56 | 61.49 | 57.07 | 91.58 | 95.61 | 88.58 |

| 4 | 0.1 | Y-axis | 40 | 51.04 | 51.81 | 50.28 | 82.59 | 85.35 | 78.13 |

| 5 | 0.1 | Y-axis | 50 | 48.80 | 49.32 | 47.79 | 82.48 | 83.95 | 80.56 |

| 6 | 0.1 | Y-axis | 60 | 47.80 | 50.04 | 45.01 | 80.37 | 81.06 | 79.60 |

| 7 | 0.1 | Z-axis | 40 | 45.05 | 45.87 | 44.24 | 81.62 | 84.75 | 77.75 |

| 8 | 0.1 | Z-axis | 50 | 46.76 | 47.60 | 37.86 | 81.94 | 84.36 | 80.67 |

| 9 | 0.1 | Z-axis | 60 | 47.19 | 49.77 | 41.94 | 81.03 | 84.29 | 75.78 |

| 10 | 0.2 | X-axis | 40 | 52.99 | 55.80 | 51.02 | 96.77 | 99.42 | 93.24 |

| 11 | 0.2 | X-axis | 50 | 54.20 | 54.88 | 52.89 | 95.12 | 98.83 | 91.72 |

| 12 | 0.2 | X-axis | 60 | 55.52 | 56.23 | 54.53 | 86.55 | 97.32 | 70.27 |

| 13 | 0.2 | Y-axis | 40 | 46.23 | 46.58 | 45.72 | 79.06 | 84.74 | 75.42 |

| 14 | 0.2 | Y-axis | 50 | 46.97 | 47.58 | 46.44 | 80.03 | 86.85 | 76.17 |

| 15 | 0.2 | Y-axis | 60 | 47.16 | 47.86 | 46.76 | 79.84 | 84.08 | 76.32 |

| 16 | 0.2 | Z-axis | 40 | 46.23 | 47.65 | 44.44 | 83.42 | 85.46 | 82.04 |

| 17 | 0.2 | Z-axis | 50 | 47.31 | 48.01 | 46.68 | 80.07 | 82.74 | 75.81 |

| 18 | 0.2 | Z-axis | 60 | 46.96 | 48.81 | 44.76 | 76.69 | 84.20 | 62.59 |

| 19 | 0.3 | X-axis | 40 | 46.79 | 47.97 | 44.74 | 93.25 | 94.43 | 91.23 |

| 20 | 0.3 | X-axis | 50 | 47.28 | 47.98 | 46.13 | 94.43 | 96.11 | 93.02 |

| 21 | 0.3 | X-axis | 60 | 47.80 | 49.12 | 46.64 | 93.40 | 95.78 | 89.50 |

| 22 | 0.3 | Y-axis | 40 | 42.97 | 44.16 | 41.83 | 79.12 | 83.34 | 76.94 |

| 23 | 0.3 | Y-axis | 50 | 44.48 | 44.84 | 44.02 | 78.01 | 81.68 | 75.28 |

| 24 | 0.3 | Y-axis | 60 | 43.69 | 44.76 | 42.79 | 78.90 | 82.40 | 76.99 |

| 25 | 0.3 | Z-axis | 40 | 47.71 | 48.26 | 46.84 | 77.61 | 79.84 | 75.29 |

| 26 | 0.3 | Z-axis | 50 | 46.52 | 48.25 | 44.83 | 80.89 | 84.18 | 78.26 |

| 27 | 0.3 | Z-axis | 60 | 47.58 | 48.81 | 46.70 | 75.98 | 78.19 | 73.95 |

| Source | DF | ADJ SS | ADJ MS | F-Value | p-Value * | Contribution [%] |

|---|---|---|---|---|---|---|

| Layer height | 2 | 122.479 | 61.239 | 58.46 | <0.001 | 24.29 |

| Printing orientation | 2 | 258.463 | 129.232 | 123.37 | <0.001 | 51.25 |

| Printing speed | 2 | 1.519 | 0.759 | 0.72 | 0.514 | 0.30 |

| Layer height × printing orientation | 4 | 108.288 | 27.072 | 25.84 | <0.001 | 21.47 |

| Layer height × printing speed | 4 | 2.122 | 0.531 | 0.51 | 0.733 | 0.42 |

| Printing orientation × printing speed | 4 | 3.030 | 0.757 | 0.72 | 0.600 | 0.60 |

| Error | 8 | 8.380 | 1.048 | - | - | 1.66 |

| Total | 26 | 504.281 | - | - | - | 100 |

| Source | DF | ADJ SS | ADJ MS | F-Value | p-Value * | Contribution [%] |

|---|---|---|---|---|---|---|

| Layer height | 2 | 31.38 | 15.688 | 3.88 | 0.066 | 2.42 |

| Printing orientation | 2 | 1141.76 | 570.879 | 141.28 | <0.001 | 88 |

| Printing speed | 2 | 47.37 | 23.683 | 5.86 | 0.027 | 3.65 |

| Layer height × printing orientation | 4 | 7.33 | 1.832 | 0.45 | 0.768 | 0.56 |

| Layer height × printing speed | 4 | 17.84 | 4.460 | 1.10 | 0.418 | 1.38 |

| Printing orientation × Printing speed | 4 | 19.41 | 4.853 | 1.20 | 0.381 | 1.50 |

| Error | 8 | 32.33 | 4.041 | - | - | 2.49 |

| Total | 26 | 1297.41 | - | - | - | 100 |

| Experiment Number | Tensile Coefficient | Compression Coefficient | GRA Score |

|---|---|---|---|

| 1 | 0.94 | 0.92 | 0.93 |

| 2 | 0.94 | 1.00 H | 0.97 |

| 3 | 1.00 H | 0.66 | 0.83 |

| 4 | 0.51 | 0.42 | 0.47 |

| 5 | 0.44 | 0.42 | 0.43 |

| 6 | 0.42 | 0.39 | 0.40 |

| 7 | 0.37 | 0.41 | 0.39 |

| 8 | 0.40 | 0.41 | 0.40 |

| 9 | 0.41 | 0.40 | 0.40 |

| 10 | 0.58 | 0.99 | 0.79 |

| 11 | 0.64 | 0.86 | 0.75 |

| 12 | 0.72 | 0.50 | 0.61 |

| 13 | 0.39 | 0.37 | 0.38 |

| 14 | 0.40 | 0.38 | 0.39 |

| 15 | 0.41 | 0.38 | 0.39 |

| 16 | 0.39 | 0.44 | 0.41 |

| 17 | 0.41 | 0.38 | 0.40 |

| 18 | 0.40 | 0.34 | 0.37 |

| 19 | 0.40 | 0.74 | 0.57 |

| 20 | 0.41 | 0.81 | 0.61 |

| 21 | 0.42 | 0.75 | 0.59 |

| 22 | 0.33 L | 0.37 | 0.35 |

| 23 | 0.36 | 0.36 | 0.36 |

| 24 | 0.34 | 0.37 | 0.36 |

| 25 | 0.42 | 0.35 | 0.38 |

| 26 | 0.39 | 0.40 | 0.39 |

| 27 | 0.42 | 0.33 L | 0.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kisin, B.; Turan, M.K.; Karpat, F. Multi-Objective Optimization of Biodegradable and Recyclable Composite PLA/PHA Parts. Polymers 2025, 17, 2147. https://doi.org/10.3390/polym17152147

Kisin B, Turan MK, Karpat F. Multi-Objective Optimization of Biodegradable and Recyclable Composite PLA/PHA Parts. Polymers. 2025; 17(15):2147. https://doi.org/10.3390/polym17152147

Chicago/Turabian StyleKisin, Burak, Mehmet Kivanc Turan, and Fatih Karpat. 2025. "Multi-Objective Optimization of Biodegradable and Recyclable Composite PLA/PHA Parts" Polymers 17, no. 15: 2147. https://doi.org/10.3390/polym17152147

APA StyleKisin, B., Turan, M. K., & Karpat, F. (2025). Multi-Objective Optimization of Biodegradable and Recyclable Composite PLA/PHA Parts. Polymers, 17(15), 2147. https://doi.org/10.3390/polym17152147