Development of Polymer–Gel Fibrous Composites for Well Water Shutoff in Fractured–Porous Carbonate Formations

Abstract

1. Introduction

2. Materials and Methods

2.1. Gel and Additives

2.2. Oscillatory Rheology Studies

2.3. Low-Pressure Filter Press Testing

2.4. Particle and Fiber Size Determination

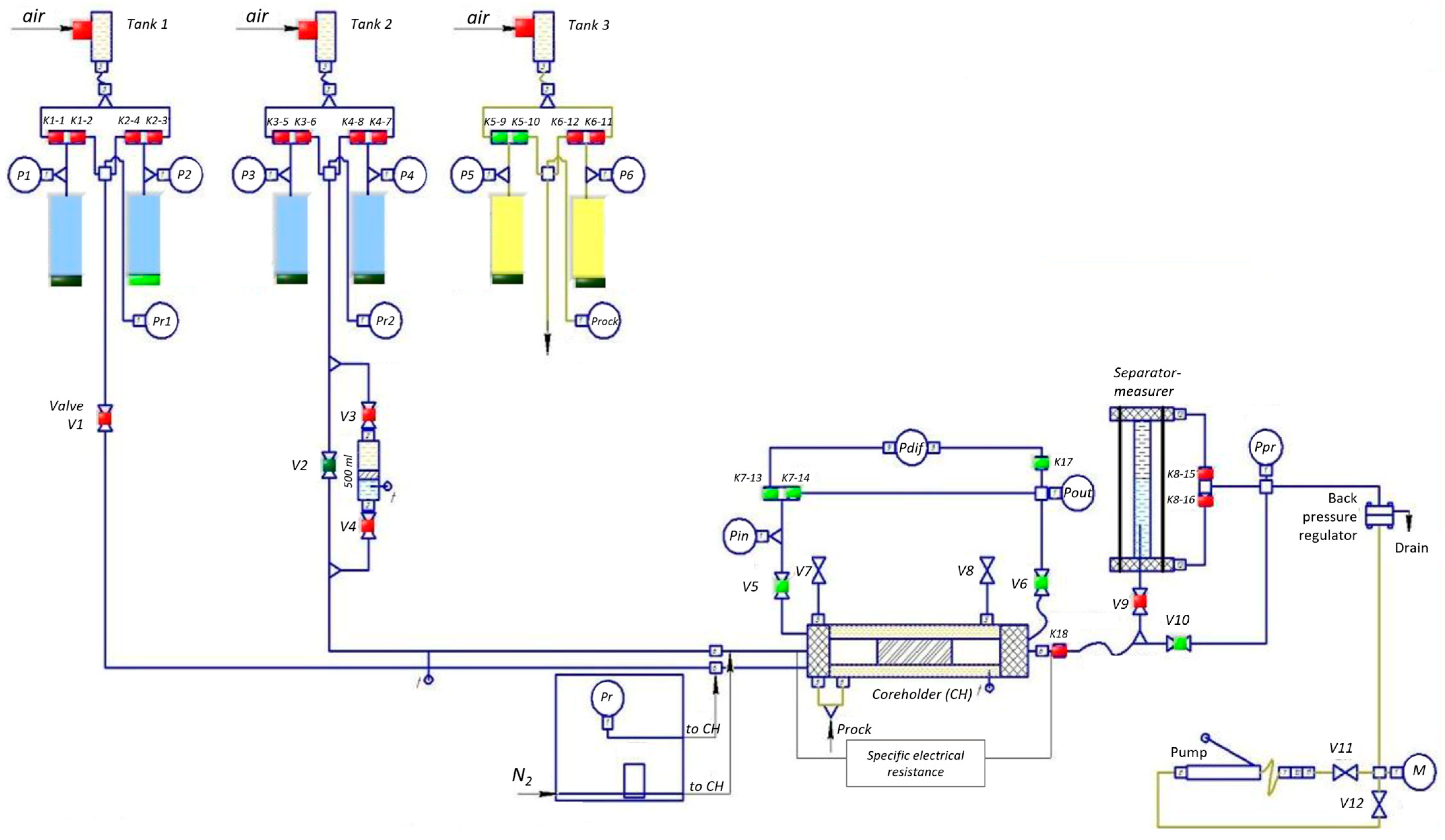

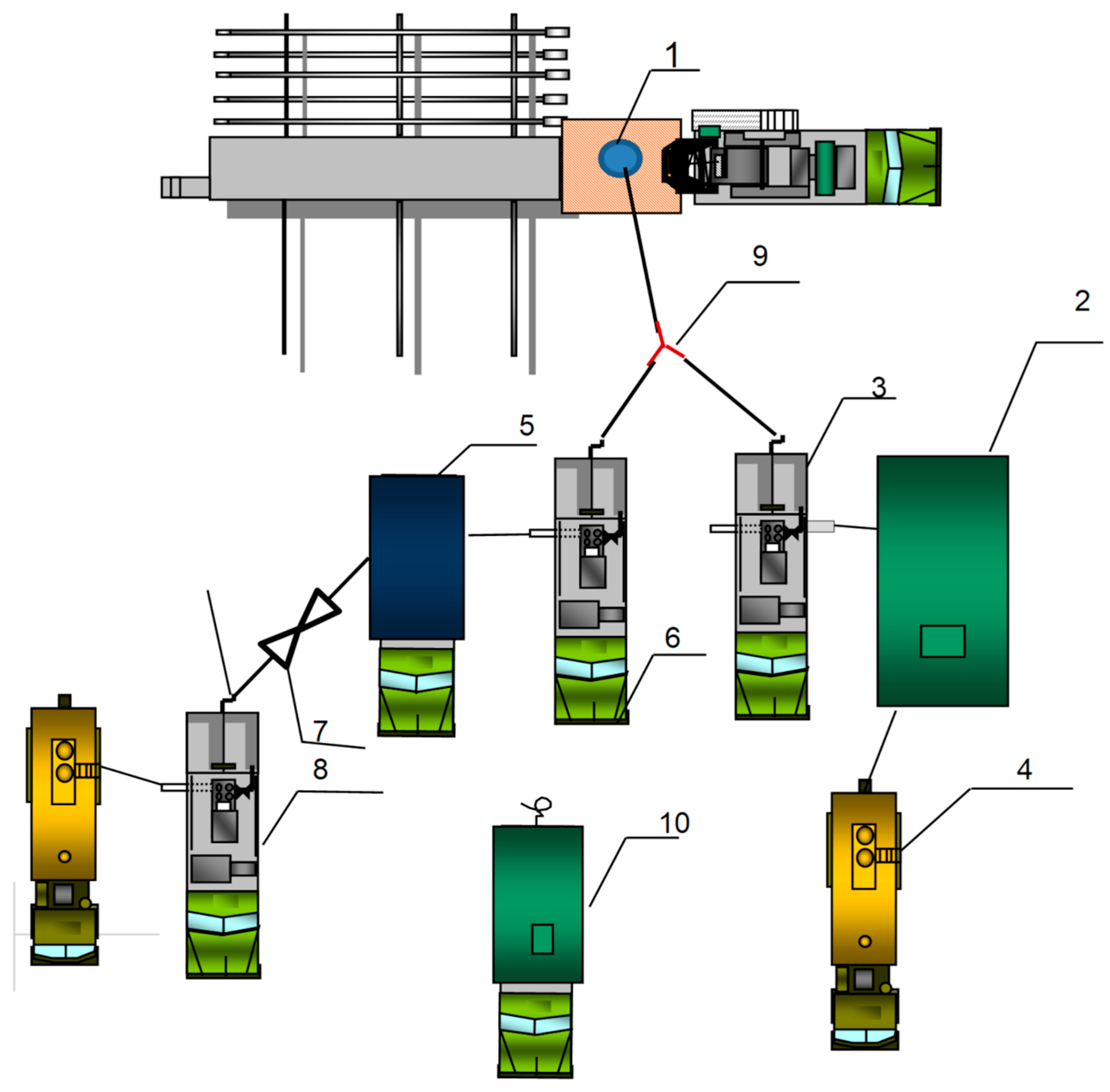

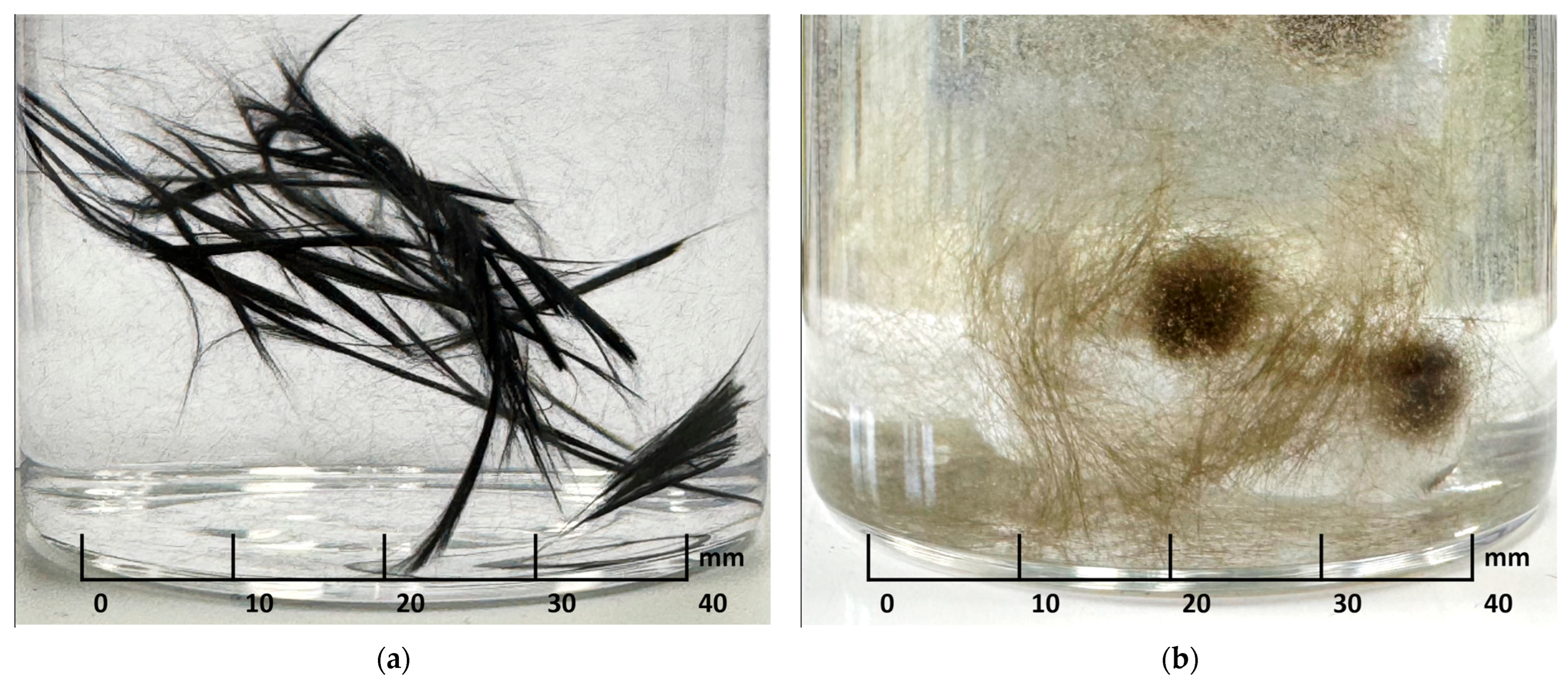

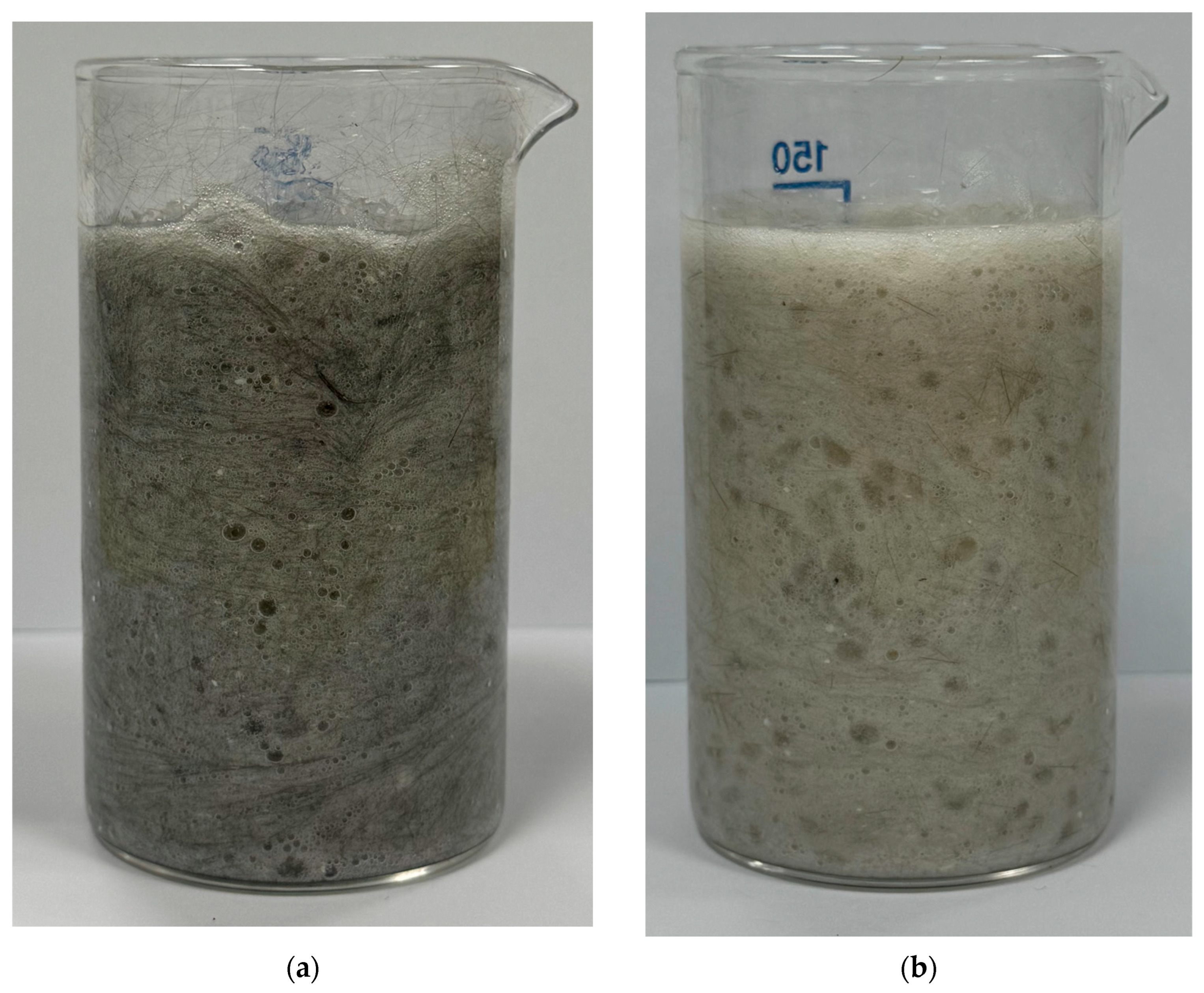

2.5. Filtration Studies

- -

- Core holder with an electric heater;

- -

- The main hydraulic system, which performs the functions of formation fluid supply and determination of their volumes (the main system includes two sub-systems corresponding to two fluid phases);

- -

- An auxiliary hydraulic system designed to create rock (crimp) pressure;

- -

- A system for creating back pressure during filtration;

- -

- The sensors of the control and measurement system;

- -

- The distribution gas combs of the pneumatic valve control system connected to the air line at 5.5–6.5 atm.

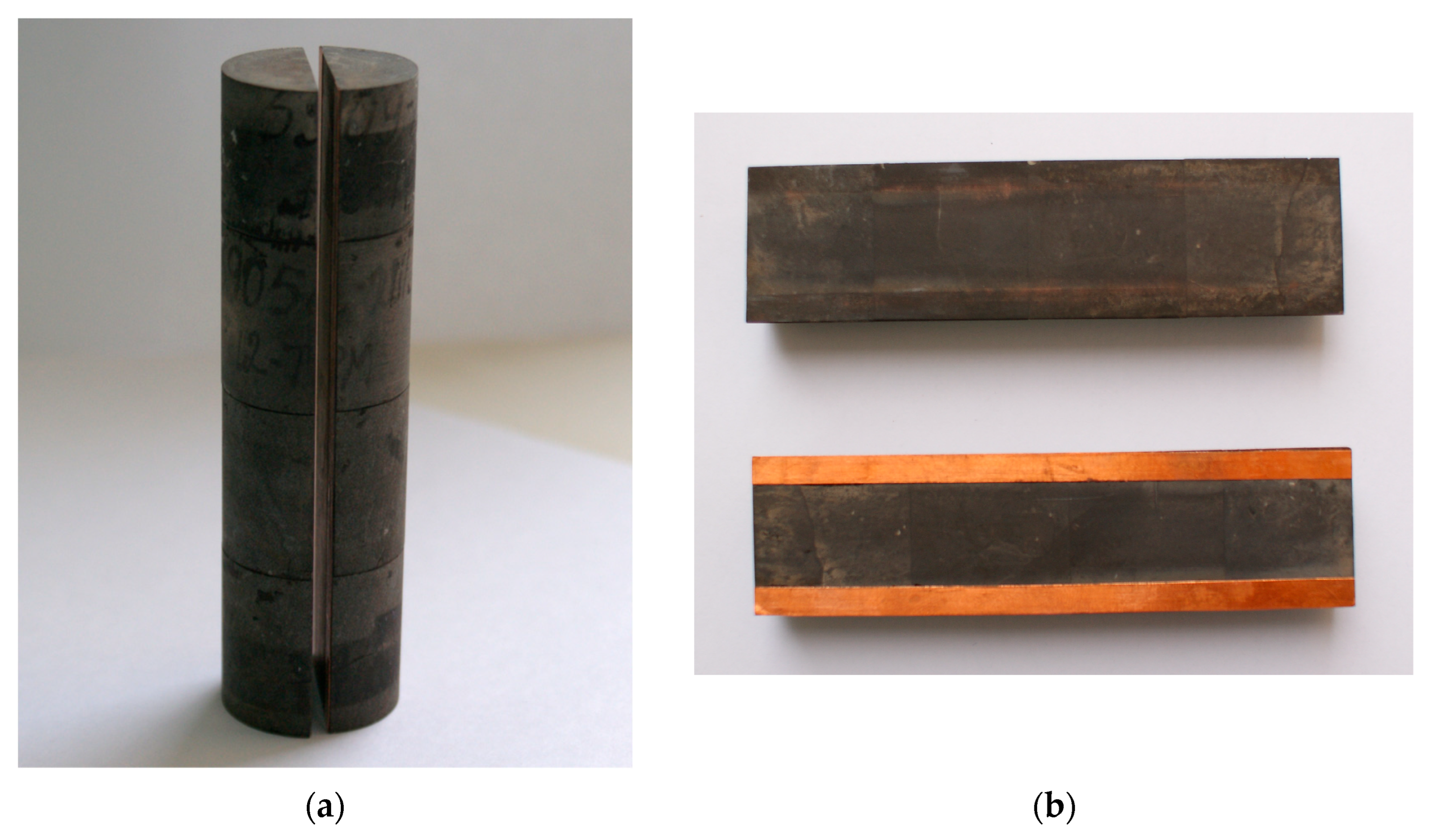

2.6. Field Test

3. Results and Discussion

3.1. Rheological Studies

3.2. Filtration Studies

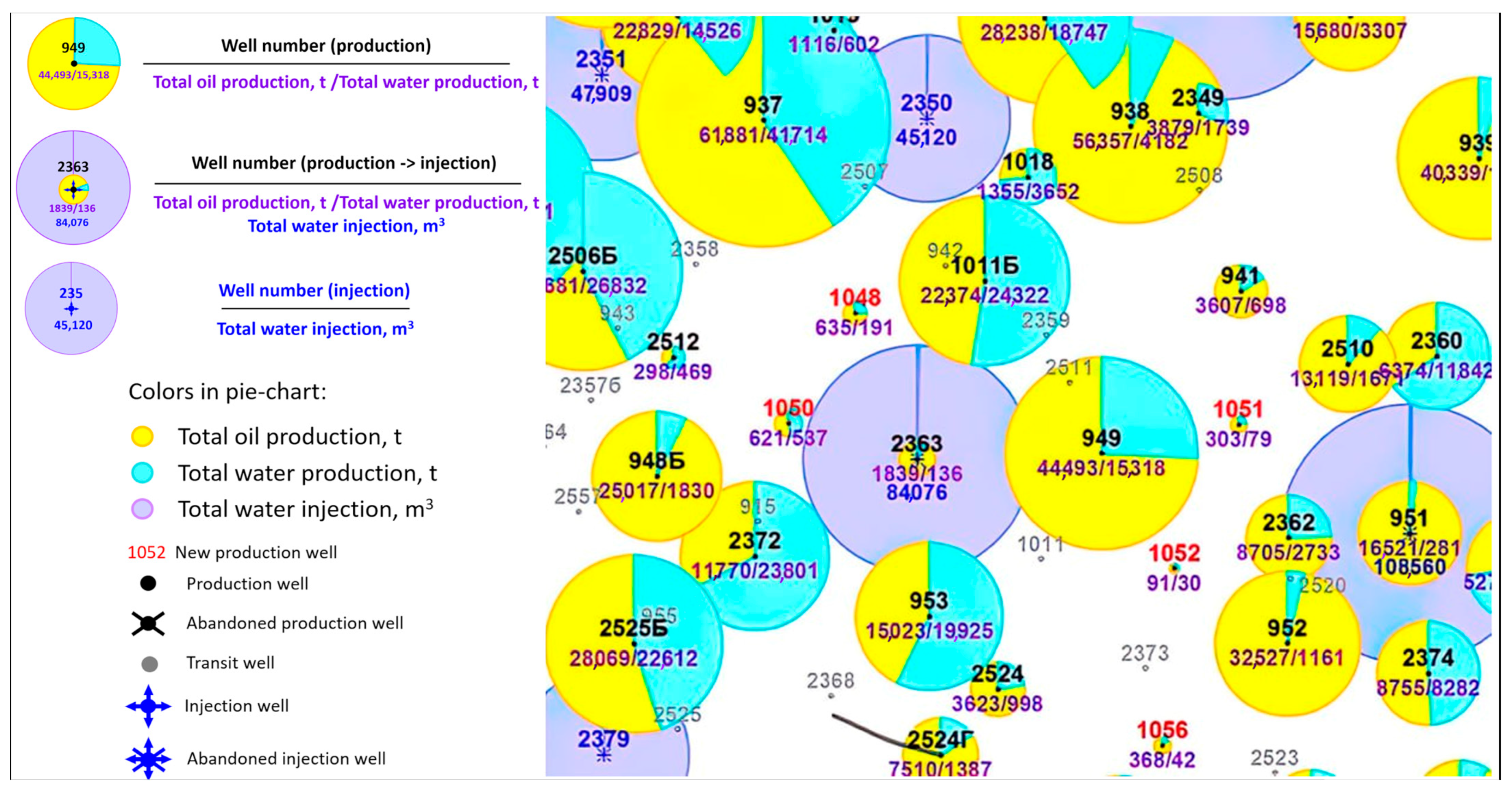

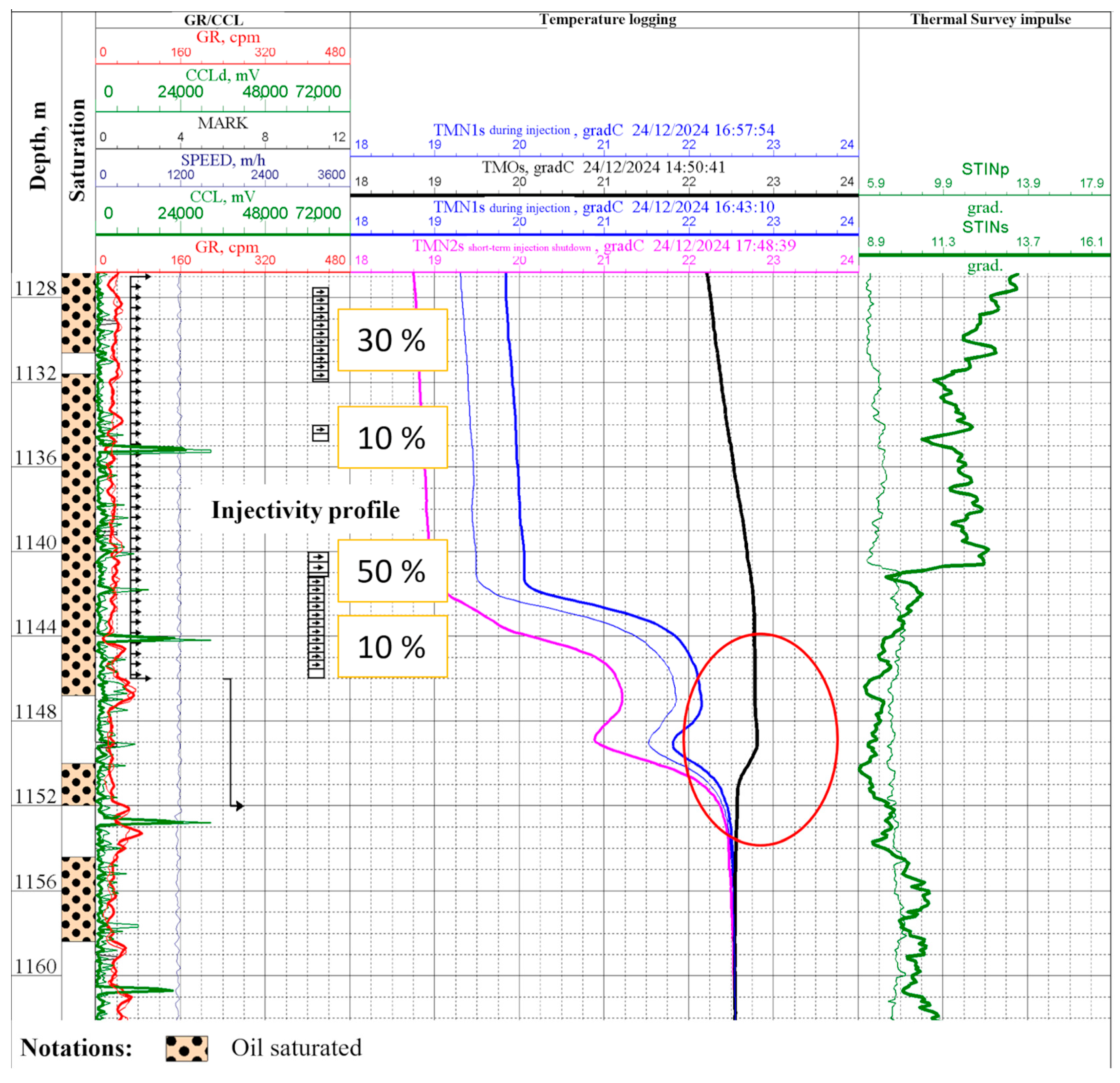

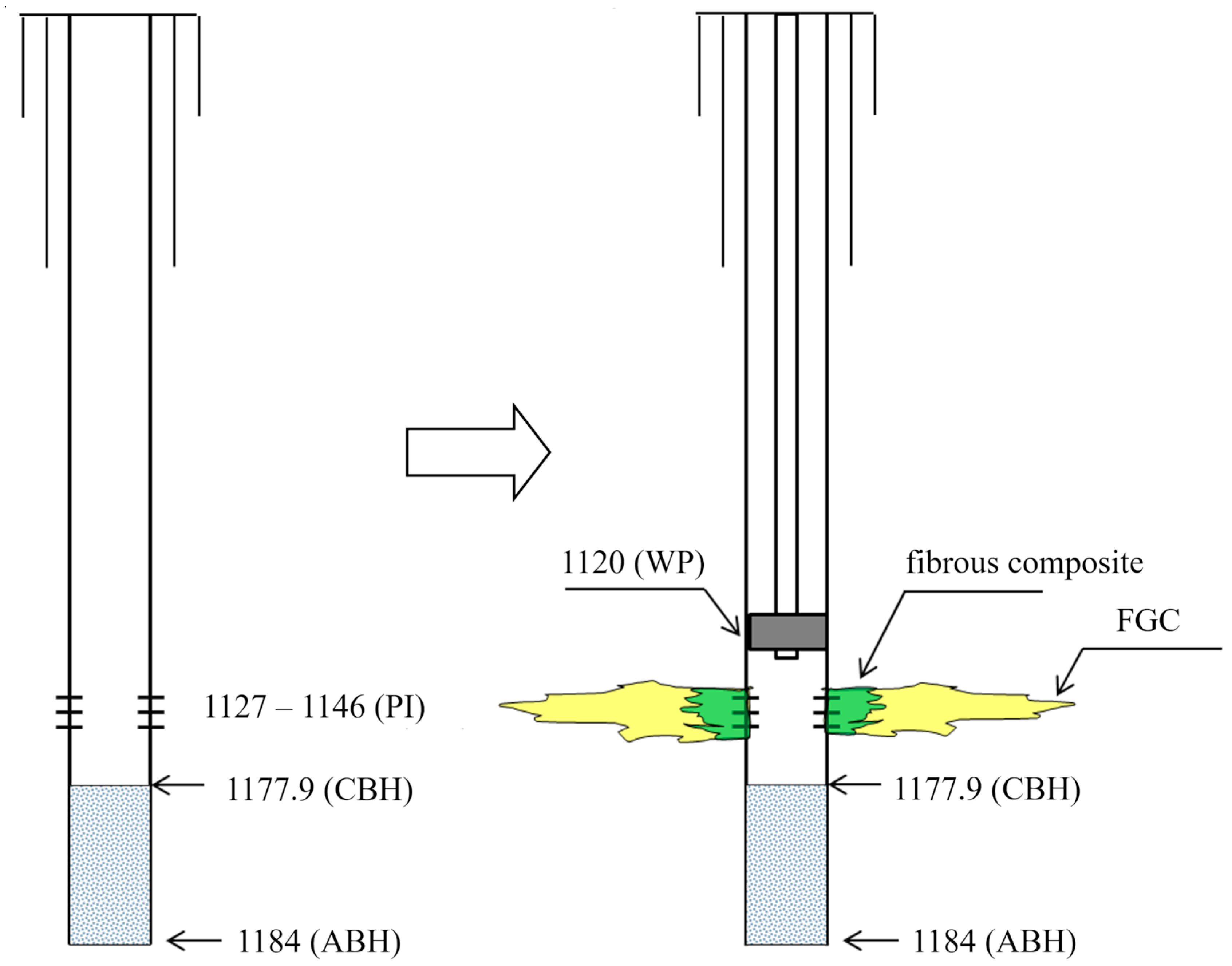

3.3. Field Test

3.4. Environmental Impact, Sustainability, and Risk Assessment of Additives

4. Conclusions

- Single-fiber systems: composition with 0.15–0.2% PPF/PANF, showing G′ ≈ 28 Pa;

- Multi-fiber systems: best result (G′ = 46.5 Pa) with 1.5% chrysotile + 0.1% PANF + 0.1% CF;

- Fiber-reinforced gel-dispersed composites: optimal results (G′ ≈ 30 Pa) with 0.2% PPF/PANF + 1.5% chrysotile + 1% dispersed filler (shungite/zinc oxide).

- At a 0.1 cm3/min flow rate: RRF values of 24.72, 167.3, and 82.3 for fracture widths of 50, 100, and 650 μm, respectively;

- At a 0.5 cm3/min flow rate: RRF values of 7.23, 162.4, and 9.76 for the same fracture widths.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PANF | polyacrylonitrile fiber |

| PPF | polypropylene fiber |

| BF | basalt fiber |

| CF | carbon fiber |

| PAM | polyacrylamide |

| MFMC | mass fraction of the main component |

| BM | base matrix |

| SEM | scanning electron microscope |

| LVR | linear viscoelastic region |

| RRF | residual resistance factor |

| BCC | behind-casing channeling |

| PL | production logging |

| WIO | workover and isolation operation |

| PPE | personal protective equipment |

References

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Agzamov, F.A.; Tikhonov, N.A.; Karimov, I.N. Effect of fiber reinforcement on the properties of plugging materials. Territ. Neft. 2013, 4, 25–28. [Google Scholar]

- Ovchinnikov, V.P.; Rogkov, S.Y.; Rozhkova, O.V.; Ovchinnikov, P.V. Technologies of the cutting cement with fiber added. Drill. Oil 2021, 3, 46–49. [Google Scholar]

- Li, Z.; Guo, T.; Chen, Y.; Fang, C.; Chang, Y.; Nie, J.X. Influence of basalt fiber and polypropylene fiber on the mechanical and durability properties of cement-based composite materials. J. Build. Eng. 2024, 90, 109335. [Google Scholar] [CrossRef]

- Yao, X.; Kinloch, I.A.; Bissett, M.A. Fabrication and Mechanical Performance of Graphene Nanoplatelet/Glass Fiber Reinforced Polymer Hybrid Composites. Front. Mater. 2021, 8, 773343. [Google Scholar] [CrossRef]

- Amani, M.; Rauf, A.A. An Update on the Use of Fiberglass Casing and Tubing in Oil and Gas Wells. Int. J. Pet. Petrochem. Eng. 2017, 3, 43–53. [Google Scholar] [CrossRef]

- Presnyakov, A.Y.; Strizhnev, V.A.; Umetbaev, V.G.; Tyapov, O.A.; Sakhan, A.V. New technologies of repair-isolation squeeze in complicated conditions. Oilfield Eng. 2012, 7, 47–51. [Google Scholar]

- Leighton, J.; Saltel, J.L.; Morrison, J.; Riley, W.; Pilla, J. Water Shutoff Using an Inflatable Composite Sleeve Polymerized In-Situ: A Case History on Forties Delta. SPE Prod. Facil. 2001, 16, 97–105. [Google Scholar] [CrossRef]

- Kadyrov, R.R.; Andreev, V.A.; Khasanova, D.K.; Vashetina, E.Y. The Method of Isolating Water Inflow Zones in a Well. Russian Patent RU 2504640, 20 January 2014. [Google Scholar]

- Yang, Y.; He, X.; Sun, D.; Zhang, H.; Zhang, Y.; She, J. Pseudointerpenetrating network nanocomposite hydrogel for temporary plugging in fractured reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2023, 656, 130369. [Google Scholar] [CrossRef]

- Uguna, G.; Rachid, R.; Milne, A.; Ali, S. Controlling Losses When Recompleting Low-Pressure Reservoirs. In Proceedings of the SPE European Formation Damage Conference and Exhibition, Budapest, Hungary, 3–5 June 2015. [Google Scholar] [CrossRef]

- Musabirov, M.K.; Kuryashov, D.A.; Garifov, K.M.; Dmitrieva, A.Y.; Abusalimov, E.M. Developing structure-forming colloidal systems for matrix acidizing of porous-fractured carbonate reservoirs. Oil Ind. 2019, 6, 71–73. [Google Scholar] [CrossRef]

- Polozov, M.B.; Al-Rumaima, D. Self-disseminating discoverer for acid processing. Manag. Technos. 2018, 1, 94–100. [Google Scholar]

- Pu, L.; Xu, A.; Xu, M.; Song, J.; He, M. Effect of Fiber on Rheological Properties and Flow Behavior of Polymer Completion Fluids. ACS Omega 2021, 6, 17136–17148. [Google Scholar] [CrossRef] [PubMed]

- Zemtsov, Y.V.; Mazaev, V.V. The Current State of Physico-Chemical Methods of Production Enhancement: Literary-Patent Review; Publisher Solutions: Ekaterinburg, Russia, 2021; 240p, ISBN 978-5-0053-8847-6. [Google Scholar]

- Chen, L.; Qian, Z.; Li, L.; Fu, M.; Zhao, H.; Fu, L.; Li, G. Synergism of polyvinyl alcohol fiber to hydrogel for profile modification. Colloids Surf. A Physicochem. Eng. Asp. 2019, 578, 123609. [Google Scholar] [CrossRef]

- Zhu, D.; Wang, Z.; Liu, Y.; Zhang, H.; Qin, J.; Zhao, Q.; Wang, G.; Shi, C.; Su, Z. Carbon Nanofiber-Enhanced HPAM/PEI Gels for Conformance Control in Petroleum Reservoirs with High Temperatures. Energy Fuels 2022, 36, 12606–12616. [Google Scholar] [CrossRef]

- Zhao, Z.; Ma, J.; Guo, J.; Yang, O.; Omeiza, A.A. Experimental investigation of rheological properties of fiber-laden crosslinked fracturing fluids. J. Nat. Gas Sci. Eng. 2016, 32, 28–34. [Google Scholar] [CrossRef]

- Guo, J.; Ma, J.; Zhao, Z.; Gao, Y. Effect of Fiber on the rheological property of fracturing fluid. J. Nat. Gas Sci. Eng. 2015, 23, 356–362. [Google Scholar] [CrossRef]

- Briggs, T.; Obinichi, N. Engineered natural fibre composites for oil and gas application: A review. Eng. Environ. Sci. Mater. Sci. 2017, 6, 113–137. [Google Scholar]

- Solovyev, R.V.; Sarvarov, A.N. Gel-forming systems for water shutoff in low-pressure and lost-circulation wells at JSC “Belkamneft”. Eng. Pract. 2011, 7, 67–69. [Google Scholar]

- Vinokurov, V.; Novikov, A.; Rodnova, V.; Anikushin, B.; Kotelev, M.; Ivanov, E.; Lvov, Y. Cellulose Nanofibrils and Tubular Halloysite as Enhanced Strength Gelation Agents. Polymers 2019, 11, 919. [Google Scholar] [CrossRef]

- Chen, H.; Wei, P.; Qi, Y.; Xie, Y.; Huang, X. Water-Induced Cellulose Nanofibers/Poly(vinyl alcohol) Hydrogels Regulated by Hydrogen Bonding for In Situ Water Shutoff. ACS Appl. Mater. Interfaces 2023, 15, 39883–39895. [Google Scholar] [CrossRef]

- Veliyev, E.; Shovgenov, A. Novel Water Shut-Off Method Based on Temporary Plugging Agent and Gel Composition. SOCAR Proc. 2023, 1, 96–101. [Google Scholar] [CrossRef]

- Liu, Z.; Wei, P.; Qi, Y.; Huang, X.; Xie, Y. High stretchable and self-healing nanocellulose-poly(acrylic acid) composite hydrogels for sustainable CO2 shutoff. Carbohydr. Polym. 2023, 311, 120759. [Google Scholar] [CrossRef]

- Marsov, A.A.; Gubaidullin, F.A. Filtration testing of ACM powder composition for water shutoff in production wells and water-flooded zone isolation in injection wells. Bull. Technol. Univ. 2016, 19, 38–41. [Google Scholar]

- Cao, D.; Al-Mohsin, A.M.; Han, M.; Alharbi, B.G. Mixed Preformed Particle Gel System for Water Shutoff in Fractured Carbonate Reservoir. Aramco J. Technol. 2023, 3, 1–8. [Google Scholar]

- Ghosh, B.; Bemani, A.; Wahaibi, Y.; Hadrami, H.; Boukadi, F. Development of a novel chemical water shut-off method for fractured reservoirs: Laboratory development and verification through core flow experiments. J. Pet. Sci. Eng. 2012, 96–97, 176–184. [Google Scholar] [CrossRef]

- El-Karsani, K.S.; Al-Muntasheri, G.A.; Hussein, I.A. Polymer Systems for Water Shutoff and Profile Modification: A Review Over the Last Decade. SPE J. 2014, 19, 135–149. [Google Scholar] [CrossRef]

- Bai, Y.; Wei, F.; Xiong, C.; Li, J.; Jiang, R.; Xu, H.; Shu, Y. Effect of Fracture and Matrix on Propagation Behavior and Water Shut-off Performance of a Polymer Gel. Energy Fuels 2015, 29, 5534–5543. [Google Scholar] [CrossRef]

- Strizhnev, V.A.; Arslanov, I.R.; Gorbunova, A.A.; Gabdrafikov, R.V.; Telin, A.G. Pilot Industrial Works on Elimination of Absorption Using NGT-Chem-3 Reagent. Neft. Gas. Novatsii 2021, 11, 16–20. [Google Scholar]

- Baykova, E.N.; Muslimov, R.K. Experience in the Application of Water Shut-off and Remedial Cementing Technologies in Fractured Carbonate Reservoirs. Georesursy 2016, 18, 175–185. [Google Scholar] [CrossRef]

- Bagrintseva, K.I. Conditions of Formation and Properties of Carbonate Oil and Gas Reservoirs; Russian State University for the Humanities: Moscow, Russia, 1999; p. 285. [Google Scholar]

- Martiushev, D.A.; Lekomtsev, A.V.; Kotousov, A.G. Determining openness and compressibility of natural fractures of carbonate reserves in the Logovskoye deposit. Bull. PNRPU Geol. Oil Gas Eng. Min. 2015, 16, 61–69. [Google Scholar] [CrossRef]

- Kutukova, N.M.; Birun, E.M.; Malakhov, R.A.; Afanasyev, I.S.; Postnikova, O.V.; Rakhmatullina, A.K. Conceptual Model of the Riphean Reservoir Structure of the Yurubcheno-Tokhomskoye Field. Oil Ind. 2012, 11, 4–7. [Google Scholar]

- Shaydullin, R.G.; Gus’kov, D.V. Fracture formation model in carbonate array 302, reservoir 303 Romashkinskoye oilfield. Georesursy 2006, 21, 14–17. [Google Scholar]

- Belonovskaya, L.G.; Bulach, M.H.; Gmid, L.P. The role of fracture in the formation of capacitive-filtration space of complex reservoirs. Pet. Geol. Theor. Appl. Stud. 2007, 2, 1–19. [Google Scholar]

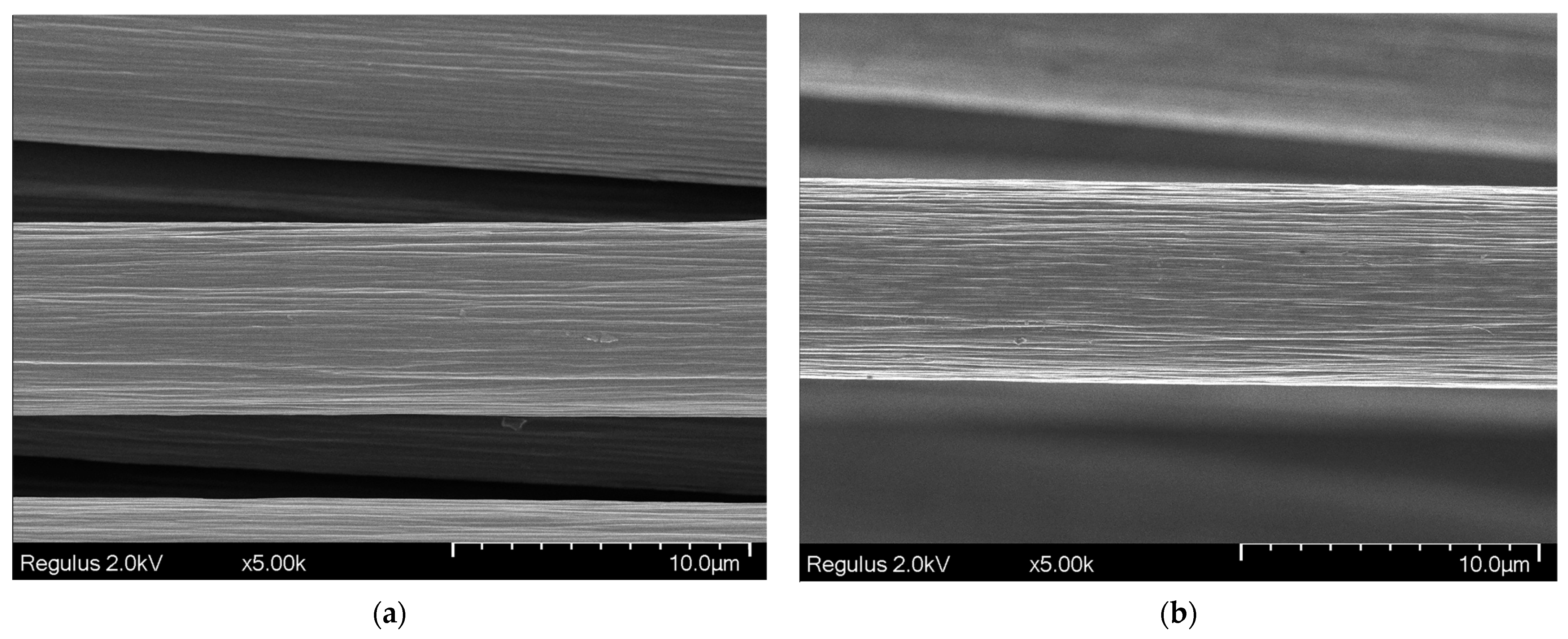

- Sharma, M.; Gao, S.; Mäder, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon fiber surfaces and composite interphases. Compos. Sci. Technol. 2014, 102, 35–50. [Google Scholar] [CrossRef]

- Zareie, C.; Bahramian, A.R.; Sefti, M.V.; Salehi, M.B. Network-Gel Strength Relationship and Performance Improvement of Polyacrylamide Hydrogel Using Nano-Silica; with Regards to Application in Oil Wells Conditions. J. Mol. Liq. 2019, 278, 512–520. [Google Scholar] [CrossRef]

- Cui, X.; Wang, C.; Huang, W.; Zhang, S.; Chen, H.; Wu, B.; Qin, D.; Zheng, X. Multiple Hydrogen Bonding-Assisted High-Strength Hydrogel of Silica/Polyacrylamide Nanocomposite Crosslinked with Polyethylenimine. ACS Omega 2023, 8, 39401–39407. [Google Scholar] [CrossRef]

- Telin, A.; Safarov, F.; Yakubov, R.; Gusarova, E.; Pavlik, A.; Lenchenkova, L.; Dokichev, V. Thermal Degradation Study of Hydrogel Nanocomposites Based on Polyacrylamide and Nanosilica Used for Conformance Control and Water Shutoff. Gels 2024, 10, 846. [Google Scholar] [CrossRef]

- Al-Muntasheri, G.A.; Nasr-El-Din, H.A.; Zitha, P.L.J. Gelation kinetics and performance evaluation of an organically crosslinked gel at high temperature and pressure. SPE J. 2008, 13, 337–345. [Google Scholar] [CrossRef]

- Mullagalin, I.Z.; Koptyaeva, E.I.; Karazeev, D.V.; Ismagilov, T.A.; Vezhnin, S.A.; Strizhnev, V.A.; Presnyakov, A.Y.; Nigmatullin, T.E.; Ganiev, I.M.; Singizova, V.K.; et al. Gel-Forming Composition, Dry Mixture, and Method for Its Preparation. Russian Patent No. 2553816, 20 June 2015. [Google Scholar]

- Lobanova, S.Y.; Elubaev, B.U.; Talamanov, N.E.; Sun, Z.; Wang, C.; Zhao, B.; Ismagilov, T.A.; Telin, A.G. Cyclic Gel-Polymer Flooding Technology—An Effective Method for Enhanced Oil Recovery in High-Viscosity Oil Fields. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 26–29 October 2020. [Google Scholar] [CrossRef]

- Telin, A.; Karazeev, D.; Vezhnin, S.; Strizhnev, V.; Levadsky, A.; Mamykin, A.; Lenchenkova, L.; Yakubov, R.; Fakhreeva, A.; Akhmetov, A.; et al. Use of Self-Generating Foam Gel Composition with Subsequent Injection of Hydrogel to Limit Gas Inflow in Horizontal Wells of Vostochno-Messoyakhskoye Field. Gels 2024, 10, 215. [Google Scholar] [CrossRef]

- Karazeev, D.V.; Strizhnev, V.A.; Vezhnin, S.A.; Gusarova, E.I.; Fakhreeva, A.V.; Telin, A.G. Gas and Water Shutoff in Wells Using Hydrogel Insulating Compositions Based on the “NGT-Chem-3” Reagent. Inzh. Neft. 2024, S5, 77–82. [Google Scholar]

- Smolikov, A.A.; Kostin, V.V. Industrial Technology for Chrysotile Monofilament Production. Bull. Belgorod State Technol. Univ. Named After V.G. Shukhov 2009, 2, 13–16. [Google Scholar]

- Tiwari, S.; Bijwe, J. Surface Treatment of Carbon Fibers—A Review. Procedia Technol. 2014, 14, 505–512. [Google Scholar] [CrossRef]

- Ansari, M.S.; Zafar, S.; Pathak, H. A Comprehensive Review of Surface Modification Techniques for Carbon Fibers for Enhanced Performance of Resulting Composites. Results Surf. Interfaces 2023, 12, 100141. [Google Scholar] [CrossRef]

- Tikhomirov, A.S.; Sorokina, N.E.; Avdeev, V.V. Surface Modification of Carbon Fibers with Nitric Acid Solutions. Inorg. Mater. 2011, 47, 609–613. [Google Scholar] [CrossRef]

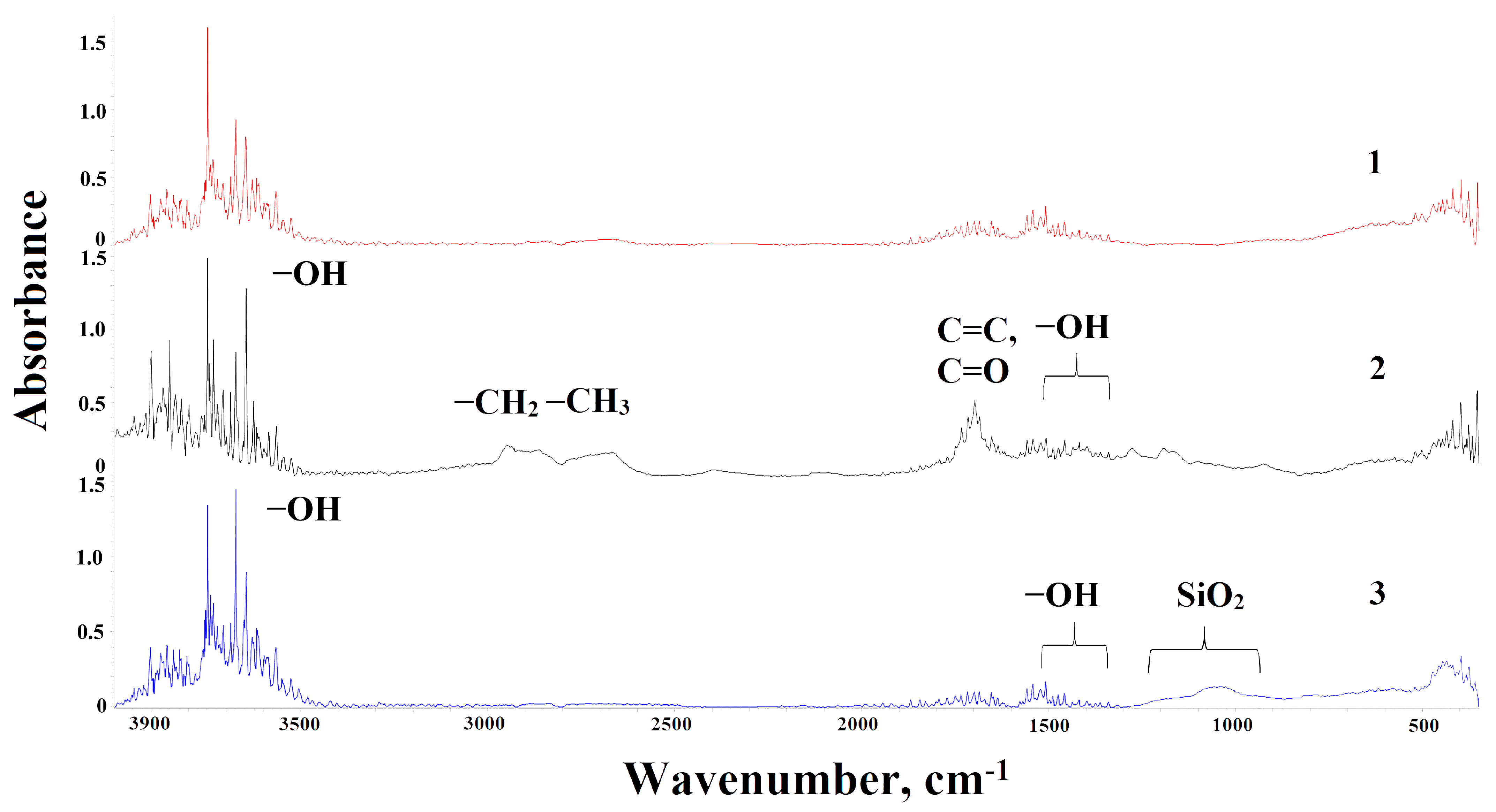

- Gallyamova, R.; Dokichev, V.A.; Musin, F. Acid Treatment of Carbon Fiber Surface. MATEC Web Conf. 2023, 376, 01002. [Google Scholar] [CrossRef]

- Vix-Guterl, C.; Alix, I.; Ehrburger, P. Synthesis of tubular silicon carbide (SiC) from a carbon–silica material by using a reactive replica technique: Mechanism of formation of SiC. Acta Mater. 2004, 52, 1639–1651. [Google Scholar] [CrossRef]

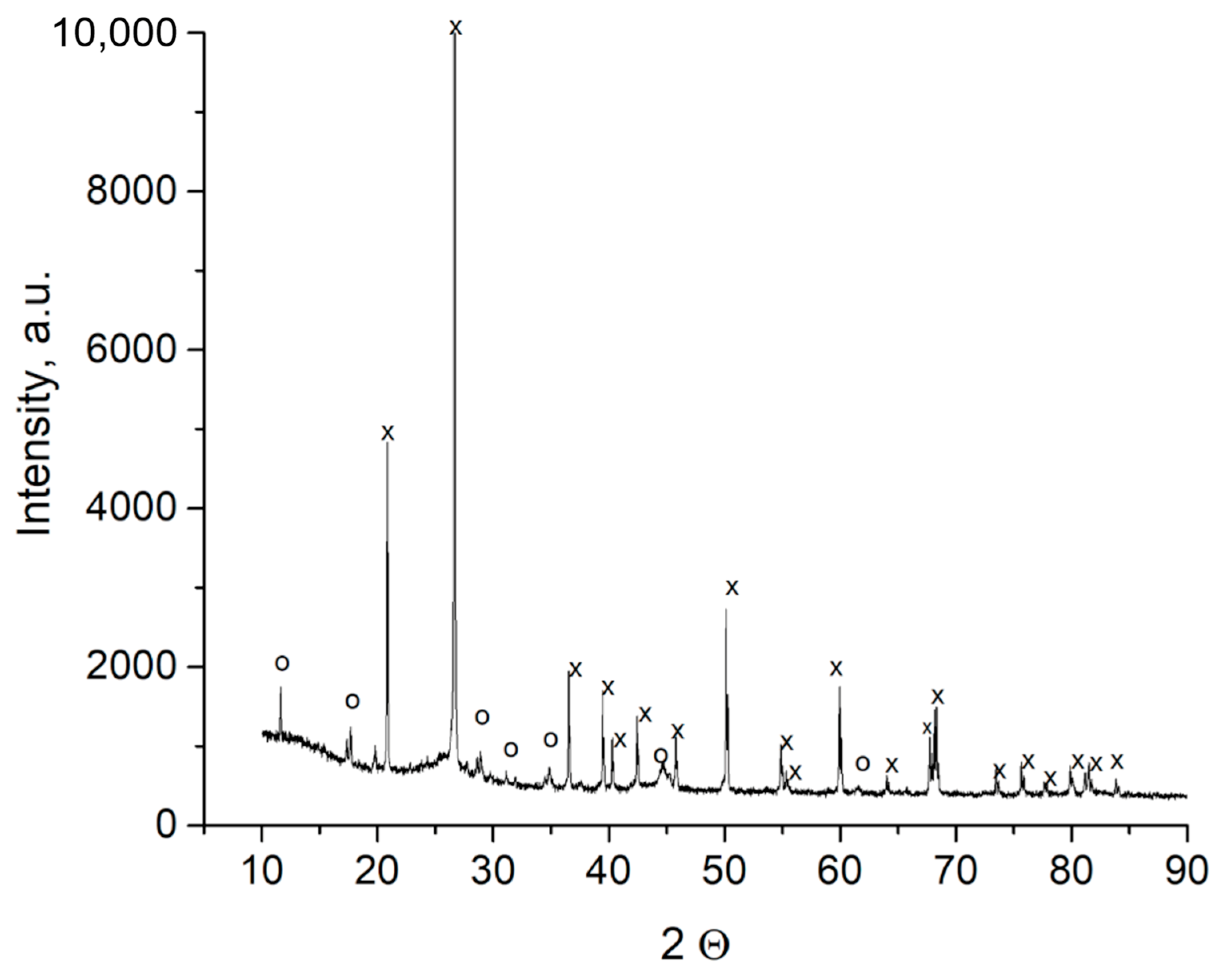

- Galyshev, S.; Postnova, E. Electrochemical Deposition of SiO2-Coatings on a Carbon Fiber. Fibers 2021, 9, 33. [Google Scholar] [CrossRef]

- Ignatov, I.; Mosin, O. Research of Influence of Shungite for Activation of Mountain Water from Different Mountain Sources. J. Health Med. Nurs. 2015, 12, 1–18. [Google Scholar]

- Volkova, E.R. Catalytic properties of shungite in reactions of urethan formation. Inorg. Mater. Appl. Res. 2021, 12, 224–229. [Google Scholar] [CrossRef]

- Kovalevskia, V.V.; Kochneva, I.V.; Rozhkova, V.S. Sorption Properties of Natural and Modified Shungite Rocks Differing in Origin. Inorg. Mater. 2023, 59, 736–741. [Google Scholar] [CrossRef]

- Polunina, I.A.; Vysotskii, V.V.; Senchikhin, I.N.; Polunin, K.E.; Goncharova, I.S.; Petukhova, G.A.; Buryak, A.K. The Effect of Modification on the Physicochemical Characteristics of Shungite. Colloid J. 2017, 79, 244–249. [Google Scholar] [CrossRef]

- Hazen, R.M.; Finger, L.W.; Hemley, R.J.; Mao, H.K. High-pressure crystal chemistry and amorphization of α-quartz. Solid State Commun. 1989, 72, 507–511. [Google Scholar] [CrossRef]

- OST 39-195-86; Oil Method of Determining the Coefficient of Displacement of Oil by Water in the Laboratory. Minnefteprom: Moscow, Russia, 1986.

- Novikova, A.; Karabchevsky, A. Green Extraction of Graphene from Natural Mineral Shungite. Nanomaterials 2022, 12, 4356. [Google Scholar] [CrossRef] [PubMed]

- Sukhinina, N.S.; Khodos, I.I.; Zverkova, I.I.; Turanov, A.N.; Karandashev, V.K.; Yemelchenko, G.A. Structural Features and Sorption Properties of Mesoporous Carbon Material Prepared from Natural Shungite. Inorg. Mater. 2022, 58, 1114–1121. [Google Scholar] [CrossRef]

- Meshalkin, V.; Akhmetov, A.; Lenchenkova, L.; Nzioka, A.; Politov, A.; Strizhnev, V.; Telin, A.; Fakhreeva, A. Application of Renewable Natural Materials for Gas and Water Shutoff Processes in Oil Wells. Energies 2022, 15, 9216. [Google Scholar] [CrossRef]

- Saduakasov, D.S.; Zholbasarova, A.T.; Bayamirova, R.U.; Toghasheva, A.R.; Tabyldanov, M.T.; Sarbopeeva, M.D.; Kasanova, A.G.; Gusakov, V.N.; Telin, A.G. Well Killing with Absorption Control. J. Min. Inst. 2025, 272, 119–135. [Google Scholar]

- Australian Government Asbestos Safety and Eradication Agency. Chrysotile Asbestos Fact Sheet. Available online: https://www.asbestossafety.gov.au/what-we-do/news-and-announcements/chrysotile-asbestos-fact-sheet (accessed on 24 May 2025).

- SanPiN 2.2.3.2887-11; Hygienic Requirements for the Production and Use of Chrysotile and Chrysotile-Containing Materials. Rospotrebnadzor: Moscow, Russia, 2019. (In Russian)

- Chrysotile Association. Safety in the Use of Chrysotile Asbestos. Available online: https://chrysotileassociation.com/data/Safety_use_Chryso-A_VF.pdf (accessed on 24 May 2025).

- Nohynek, G.J.; Dufour, E.K. Nano-sized cosmetic formulations or solid nanoparticles in sunscreens: A risk to human health? Arch. Toxicol. 2012, 86, 1063–1075. [Google Scholar] [CrossRef]

- Skrypnik, L.; Babich, O.; Sukhikh, S.; Shishko, O.; Ivanova, S.; Mozhei, O.; Kochish, I.; Nikonov, I. A Study of the Antioxidant, Cytotoxic Activity and Adsorption Properties of Karelian Shungite by Physicochemical Methods. Antioxidants 2021, 10, 1121. [Google Scholar] [CrossRef]

| No. | Composition | G′, Pa | G″, Pa | G*, Pa | Crossover, Pa | LVR, Pa |

|---|---|---|---|---|---|---|

| 1 | BM | 23.07 | 11.72 | 25.88 | 45.27 | 31.36 |

| 2 | BM + 0.05% PPF | 24.23 | 12.28 | 27.17 | 43.99 | 30.30 |

| 3 | BM + 0.10% PPF | 26.62 | 14.19 | 30.16 | 41.34 | 26.99 |

| 4 | BM + 0.15% PPF | 27.34 | 14.81 | 31.10 | 41.03 | 25.97 |

| 5 | BM + 0.20% PPF | 27.52 | 13.88 | 30.82 | 46.45 | 32.95 |

| 6 | BM + 0.25% PPF | 28.63 | 15.23 | 32.44 | 46.16 | 32.82 |

| 7 | BM + 0.30% PPF | 28.58 | 15.35 | 32.45 | 45.72 | 31.14 |

| 8 | BM + 0.10% PANF | 23.85 | 12.54 | 26.95 | 44.82 | 32.33 |

| 9 | BM + 0.15% PANF | 26.22 | 13.10 | 29.32 | 45.73 | 31.60 |

| 10 | BM + 0.20% PANF | 27.77 | 13.26 | 30.78 | 45.04 | 30.63 |

| 11 | BM + 0.25% PANF | 26.39 | 12.84 | 29.35 | 45.91 | 32.05 |

| 12 | BM + 0.30% PANF | 26.27 | 12.97 | 29.30 | 43.03 | 29.39 |

| 13 | BM + 0.5% chrysotile | 29.38 | 16.31 | 33.61 | 42.72 | 28.11 |

| 14 | BM + 1% chrysotile | 31.08 | 18.19 | 36.02 | 40.22 | 26.97 |

| 15 | BM + 2% chrysotile | 33.65 | 19.38 | 38.84 | 41.14 | 27.50 |

| Composition | G′, Pa | G″, Pa | G*, Pa | Crossover, Pa | LVR, Pa |

|---|---|---|---|---|---|

| BM | 23.07 | 11.72 | 25.88 | 45.27 | 31.36 |

| BM + 1.5% chrysotile + 0.2% BF | 29.39 | 15.11 | 33.05 | 42.12 | 30.43 |

| BM + 1.5% chrysotile + 0.2% CF | 34.74 | 18.43 | 39.33 | 39.94 | 26.43 |

| BM + 1.5% chrysotile + 0.2% CF oxidized | 27.55 | 15.93 | 31.84 | 28.75 | 19.53 |

| BM + 1.5% chrysotile + 0.2% CF/SiO2 (sol–gel deposition) | 27.31 | 18.22 | 32.99 | 25.43 | 14.90 |

| BM + 1.5% chrysotile + 0.2% CF oxidized/SiO2 (electrochemical deposition) | 34.62 | 18.57 | 39.29 | 39.23 | 26.42 |

| BM + 1.5% chrysotile + 0.1% BF + 0.1% CF | 25.67 | 13.63 | 29.07 | 30.96 | 21.38 |

| BM + 1.5% chrysotile + 0.1% PPF + 0.1% CF | 35.68 | 22.01 | 41.93 | 37.15 | 22.01 |

| BM + 1.5% chrysotile + 0.1% PANF + 0.1% CF | 46.50 | 26.36 | 53.46 | 44.39 | 26.68 |

| Composition | G′, Pa | G″, Pa | G*, Pa | Crossover, Pa | LVR, Pa |

|---|---|---|---|---|---|

| BM | 23.07 | 11.72 | 25.88 | 45.27 | 31.36 |

| BM + 1.5% chrysotile + 1% shungite + 0.2% CF | 35.31 | 18.94 | 40.07 | 40.75 | 28.05 |

| BM + 1.5% chrysotile + 1% ZnO + 0.2% CF | 42.76 | 22.63 | 48.37 | 43.36 | 30.17 |

| BM + 1% shungite + 0.15% PANF | 31.00 | 16.82 | 35.27 | 46.28 | 31.63 |

| BM + 1% shungite + 0.15% PPF | 25.21 | 13.93 | 28.81 | 41.06 | 29.47 |

| BM + 1.5% chrysotile + 1% shungite + 0.15% PPF | 30.96 | 16.98 | 35.31 | 42.95 | 30.43 |

| BM + 1% ZnO + 0.15% PANF | 28.37 | 14.24 | 31.75 | 49.48 | 33.25 |

| BM + 1% ZnO + 0.15% PPF | 26.82 | 13.90 | 30.21 | 44.73 | 31.19 |

| BM + 1.5% chrysotile + 1% ZnO + 0.15% PANF | 31.15 | 15.86 | 34.96 | 45.25 | 31.95 |

| BM + 1.5% chrysotile + 1% ZnO + 0.15% PPF | 28.89 | 14.96 | 32.53 | 39.66 | 28.78 |

| No. | Composition | Filtration Time, min | Filtrate Volume, mL |

|---|---|---|---|

| 1 | BM | 0.25 | 150 |

| 2 | BM + 0.05% PPF | 30 | 80 |

| 3 | BM + 0.15% PPF | 30 | 30 |

| 4 | BM + 0.20% PPF | 30 | 5 |

| 5 | BM + 0.25% PPF | 30 | 5 |

| 6 | BM + 0.10% PPF + 1.50% chrysotile + 0.10% CF | 30 | 4 |

| 7 | BM + 0.10% PANF + 1.50% chrysotile + 0.10% CF | 30 | 2.5 |

| Fracture Aperture, μm | Composition | Flow Rate, m3/min | RRF |

|---|---|---|---|

| 50 | BM + 0.15% PPF | 0.1 | 24.72 |

| 0.5 | 7.23 | ||

| 100 | BM + 0.15% PPF + 1.50% chrysotile | 0.1 | 167.3 |

| 0.5 | 162.4 | ||

| 650 | BM + 0.10% PANF + 1.50% chrysotile + 0.10% CF | 0.1 | 82.3 |

| 0.5 | 9.76 |

| Fracture Aperture, μm | Composition | |

|---|---|---|

| 20–100 | 0.15–0.2% monofilament fibers (PPF/PANF) | |

| 100–300 | (a) | (a) 0.2% PPF/PANF + 1.5% chrysotile |

| (b) | (b) 0.2% PPF/PANF + 1.5% chrysotile + 1% particulate filler (shungite/zinc oxide) | |

| > 300 | 0.1% CF + 0.1% PPF/PANF + 1.5% chrysotile | |

| Well Operation Mode | Liquid Flow Rate, m3/day | Oil Flow Rate, m3/day | Water Cut,% | Bottomhole Pressure, atm |

|---|---|---|---|---|

| Before WIO | 17 | 0.2 | 99 | 8 |

| After WIO (as of 1 January 2025) (reservoir pressure maintenance system not activated) | 8 | 4.8 | 35 | 5 |

| After WIO (as of 20 January 2025) (reservoir pressure maintenance system activated) | 7.5 | 3.5 | 50 | 6 |

| After WIO (as of 1 March 2025) | 7.4 | 2.5 | 63 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Telin, A.; Yakubov, R.; Pavlik, A.; Dokichev, V.; Gallyamova, R.; Mamykin, A.; Safarov, F.; Strizhnev, V.; Vezhnin, S.; Politov, A.; et al. Development of Polymer–Gel Fibrous Composites for Well Water Shutoff in Fractured–Porous Carbonate Formations. Polymers 2025, 17, 1541. https://doi.org/10.3390/polym17111541

Telin A, Yakubov R, Pavlik A, Dokichev V, Gallyamova R, Mamykin A, Safarov F, Strizhnev V, Vezhnin S, Politov A, et al. Development of Polymer–Gel Fibrous Composites for Well Water Shutoff in Fractured–Porous Carbonate Formations. Polymers. 2025; 17(11):1541. https://doi.org/10.3390/polym17111541

Chicago/Turabian StyleTelin, Aleksey, Ravil Yakubov, Artem Pavlik, Vladimir Dokichev, Rida Gallyamova, Anton Mamykin, Farit Safarov, Vladimir Strizhnev, Sergey Vezhnin, Anatoly Politov, and et al. 2025. "Development of Polymer–Gel Fibrous Composites for Well Water Shutoff in Fractured–Porous Carbonate Formations" Polymers 17, no. 11: 1541. https://doi.org/10.3390/polym17111541

APA StyleTelin, A., Yakubov, R., Pavlik, A., Dokichev, V., Gallyamova, R., Mamykin, A., Safarov, F., Strizhnev, V., Vezhnin, S., Politov, A., & Lenchenkova, L. (2025). Development of Polymer–Gel Fibrous Composites for Well Water Shutoff in Fractured–Porous Carbonate Formations. Polymers, 17(11), 1541. https://doi.org/10.3390/polym17111541