Study on a Pseudo-Elastic Model for High-Damping Rubber

Abstract

1. Introduction

2. Test Methods

2.1. Test Set-Up

2.2. Test Procedure and Test Cases

3. Development of the Pseudo-Elastic Model

3.1. Classification of Effective Behavior

- Level A classifies effective behavior as either loading or unloading, by comparing the shear strain at the previous moment with the shear strain at the current moment ;

- Level B further categorizes the effective behavior as either first-time or repeated loading/unloading at the current strain amplitude, by examining the relationship between the current strain energy or the initial strain energy of the current unloading behavior and the historical maximum strain energy , in preparation for analyzing the Mullins effect;

- Level C further divides the effective behavior into large strain and small strain, based on whether the shear-strain amplitude exceeds 100%, in preparation for analyzing stiffness hardening.

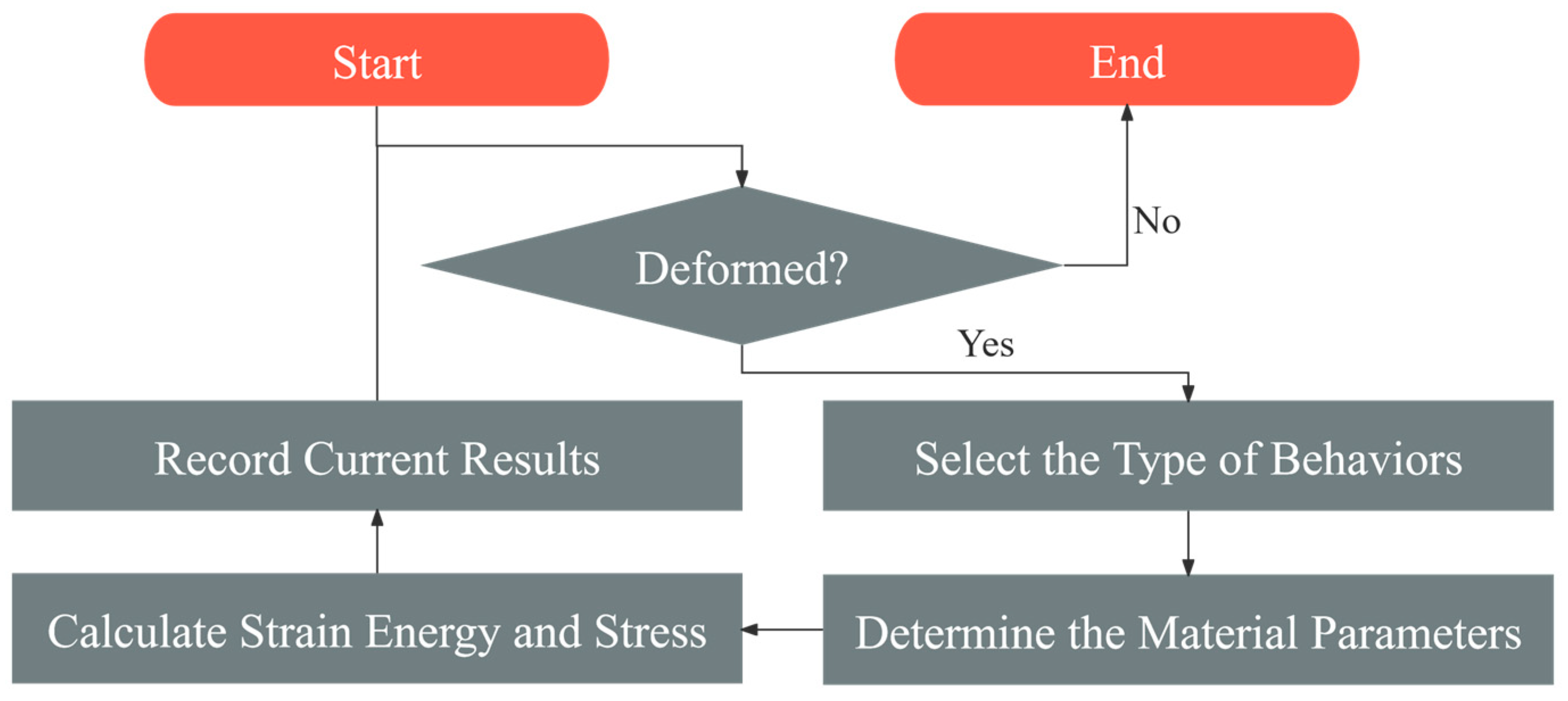

3.2. Model Development Process

- Mathematical models for loading and unloading behaviors are developed based on pseudo-elasticity theory, with cumulative damage considered only during the unloading phase, to explain energy changes.

- Compression–shear cyclic loading tests are conducted under various conditions to acquire data and clean it.

- The mathematical models are integrated with parameter-determination test data to establish material parameter values for each test case and identify the variation patterns of these parameters with changing working conditions, namely, the functions of the parameters.

- The model’s effectiveness is validated by comparing its results with those from validation tests. If the model’s calculations align well with the validation tests, the pseudo-elastic model is finalized.

3.3. Loading-Behavior Model

3.4. Unloading-Behavior Model

4. Results

4.1. Multifactor Functions of Parameters

4.1.1. Functions of Loading Parameters

4.1.2. Functions of Unloading Parameters

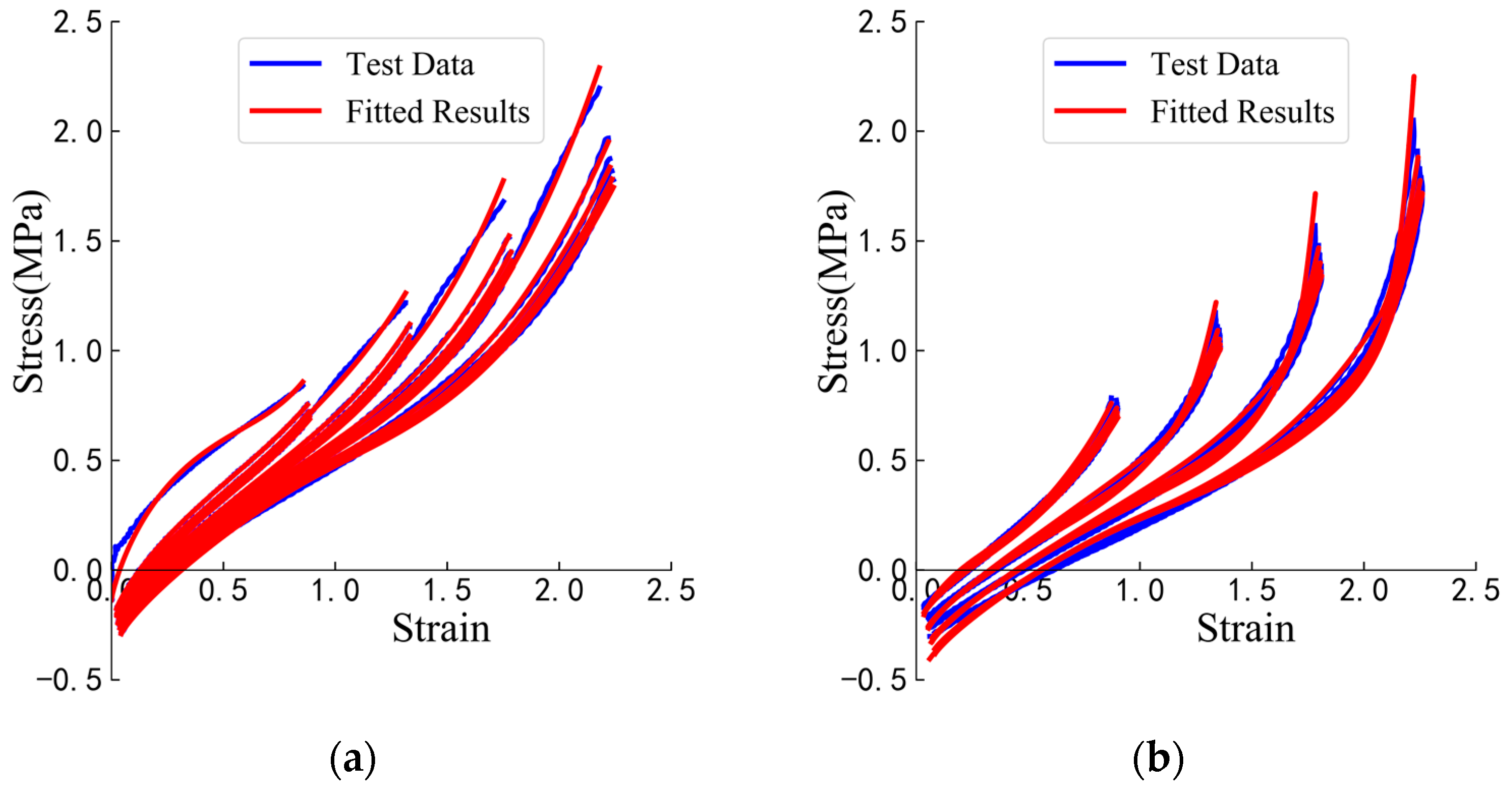

4.2. Validation of the Pseudo-Elastic Model

5. Conclusions

- Classifying effective behaviors is highly effective for phenomenological-based HDR model research methods. The patterns of parameters corresponding to different types of effective behaviors show significant differences, and it may not even be appropriate to explain them using the same equation.

- Further integration with test data allows for a more specific explanation of the Mullins effect, stiffness-hardening effect, and the impacts of temperature and shear-strain amplitude through the material parameter functions.

- The Mullins effect and stiffness-hardening effect are inevitable material behaviors in HDR applications, with temperature, shear-strain amplitude, and compressive stress being the most common influencing factors. Failure to consider these issues simultaneously may lead to significant calculation errors.

- The pseudo-elastic model for HDR proposed in this study can effectively predict the behavior of HDR under compression–shear conditions. The R-squared values obtained from the validation test data compared to the calculated results of the model are greater than 0.98.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Nguyen, V.-Q.; Nizamani, Z.A.; Park, D.; Kwon, O.-S. Numerical Simulation of Damage Evolution of Daikai Station during the 1995 Kobe Earthquake. Eng. Struct. 2020, 206, 110180. [Google Scholar] [CrossRef]

- Araújo, J.C.D.; Márquez, R.G. The Sumatra-Andaman Tsunami in Banda Aceh: A Linear Model for Representation. REMAT Rev. Electron. Math. 2023, 9, e3007. [Google Scholar] [CrossRef]

- Xu, J.-G.; Wu, G.; Feng, D.-C. Near Fault Ground Motion Effects on Seismic Resilience of Frame Structures Damaged in Wenchuan Earthquake. Struct. Infrastruct. Eng. 2020, 16, 1347–1363. [Google Scholar] [CrossRef]

- Ohsumi, T.; Dohi, Y.; Hazarika, H. Damage Related to the 2011 Tohoku Earthquake in and around Kamaishi City—Beyond the Tsunami Disaster. J. Disaster Res. 2019, 14, 1185–1200. [Google Scholar] [CrossRef]

- Hu, M.; Han, Q.; Wen, J.; Bai, Y. Seismic Failure of Multi-Span Simply Supported RC Slab-on-Grider Bridge in 2008 Wenchuan Earthquake: Case Study. Eng. Fail. Anal. 2019, 95, 140–153. [Google Scholar] [CrossRef]

- Zeng, X.; Deng, K.; Wang, Y.; Yan, G.; Zhao, C. Field Investigation and Numerical Analysis of Damage to a High-Pier Long-Span Continuous Rigid Frame Bridge in the 2008 Wenchuan Earthquake. J. Earthq. Eng. 2022, 26, 5204–5220. [Google Scholar] [CrossRef]

- Dargush, G.F.; Sant, R.S. Evolutionary Aseismic Design and Retrofit of Structures with Passive Energy Dissipation. Earthq. Eng. Struct. Dyn. 2005, 34, 1601–1626. [Google Scholar] [CrossRef]

- Alifani, N.; Nirbito, W. Analysis of Vibration Response from High Damping Rubber Bearing and Lead Rubber Bearing for Using in High Rise Building Foundations Subjected to Earthquake. IOP Conf. Ser. Mater. Sci. Eng. 2020, 855, 012004. [Google Scholar] [CrossRef]

- Fakrunnisa, I.A.; Hayu, G.A. Analisis Kinerja High Damping Rubber Bearing Dan Lead Rubber Bearing Pada Bangunan Beton Bertulang. J. Rekayasa Sipil Lingkung. 2022, 5, 48–57. [Google Scholar] [CrossRef]

- Jie, S.; Akira, I.; Ji, D.; Yuki, H.; Takehiko, H. Heating and Thermal Conductivity Effect Inside High Damping Rubber Bearing at Low Temperature. In Proceedings of the IABSE Symposium: Construction’s Role for a World in Emergency, Manchester, UK, 10–12 April 2024; pp. 904–912. [Google Scholar]

- Chen, B.; Dai, J.; Song, T.; Guan, Q. Research and Development of High-Performance High-Damping Rubber Materials for High-Damping Rubber Isolation Bearings: A Review. Polymers 2022, 14, 2427. [Google Scholar] [CrossRef]

- Shen, J.; Akira, I.; Dang, J.; Hamada, Y.; Himeno, T. A Multi-layer Thermo-mechanical Coupling Hysteretic Model for High Damping Rubber Bearings at Low Temperature. Earthq. Eng. Struct. Dyn. 2024, 53, 1028–1047. [Google Scholar] [CrossRef]

- Saito, T.; Miyamori, Y.; Nakamura, Y.; Takenouchi, K.; Yamazaki, N. The Pseudo-Dynamic Simulation of o Seismic Isolation Bridge About the Temperature Dependence of High Damping Rubber Bearings. J. Jpn. Soc. Civ. Eng. Ser. A1 2022, 78, I_468–I_477. [Google Scholar] [CrossRef] [PubMed]

- Markou, A.A.; Oliveto, N.D.; Athanasiou, A. Modeling of High Damping Rubber Bearings. In Dynamic Response of Infrastructure to Environmentally Induced Loads; Sextos, A.G., Manolis, G.D., Eds.; Lecture Notes in Civil Engineering; Springer International Publishing: Cham, Switzerland, 2017; Volume 2, pp. 115–138. ISBN 978-3-319-56134-9. [Google Scholar]

- Saito, T.; Nakamura, Y.; Takenouchi, K.; Yamazaki, N.; Miyamori, Y.; Yamazaki, T. Experiments about the Temperature Dependency of High Damping Rubber Bearings due to the Differences of Shear Strain and Vertical Compressive Stress. J. Jpn. Soc. Civ. Eng. Ser. A1 2020, 76, I_507–I_515. [Google Scholar] [CrossRef] [PubMed]

- Tamai, K.; Fujita, K.; Murakami, S.; Taniguchi, R. Hysteretic Rules of High-Damping Rubber Considering Hardening Effect in Large Strain Range. AIJ J. Technol. Des. 2020, 26, 496–501. [Google Scholar] [CrossRef]

- Markou, A.A.; Manolis, G.D. Mechanical Models for Shear Behavior in High Damping Rubber Bearings. Soil Dyn. Earthq. Eng. 2016, 90, 221–226. [Google Scholar] [CrossRef]

- Diani, J.; Fayolle, B.; Gilormini, P. A Review on the Mullins Effect. Eur. Polym. J. 2009, 45, 601–612. [Google Scholar] [CrossRef]

- Holt, W.L. Behavior of Rubber under Repeated Stresses. Rubber Chem. Technol. 1932, 5, 79–89. [Google Scholar] [CrossRef]

- Dorfmann, A.; Ogden, R.W. A Constitutive Model for the Mullins Effect with Permanent Set in Particle-Reinforced Rubber. Int. J. Solids Struct. 2004, 41, 1855–1878. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, W.; Wu, T.; Zhang, X.; Zhang, H.; Zhao, L.; Zhang, C.; Jiang, H.; Chen, M. Investigation on Mullins Effect of Rubber Materials by Spherical Indentation Method. Forces Mech. 2021, 4, 100037. [Google Scholar] [CrossRef]

- Jankowski, R. Nonlinear Rate Dependent Model of High Damping Rubber Bearing. Bull. Earthq. Eng. 2003, 1, 397–403. [Google Scholar] [CrossRef]

- Pan, T.-C.; Yang, G. Nonlinear Analysis of Base-Isolated MDOF Structures. In Proceedings of the 11th World Conference on Earthquake Engineering, Acapulco, Mexico, 23–28 June 1996; Volume 1534, pp. 1–8. [Google Scholar]

- Li, F.; Peng, T. Developing a New Constitutive Model of High Damping Rubber by Combining GRU and Attention Mechanism. Polymers 2024, 16, 567. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Y.; Zhong, D.; Rudykh, S.; Zhou, H.; Qu, S.; Yang, W. A Review of Physically Based and Thermodynamically Based Constitutive Models for Soft Materials. J. Appl. Mech. 2020, 87, 110801. [Google Scholar] [CrossRef]

- He, H.; Zhang, Q.; Zhang, Y.; Chen, J.; Zhang, L.; Li, F. A Comparative Study of 85 Hyperelastic Constitutive Models for Both Unfilled Rubber and Highly Filled Rubber Nanocomposite Material. Nano Mater. Sci. 2022, 4, 64–82. [Google Scholar] [CrossRef]

- Gallardo, J.A.; de la Llera, J.C.; Restrepo, J.I.; Chen, M.C. A Numerical Model for Non-Linear Shear Behavior of High Damping Rubber Bearings. Eng. Struct. 2023, 289, 116234. [Google Scholar] [CrossRef]

- Ogden, R.W. Large Deformation Isotropic Elasticity—On the Correlation of Theory and Experiment for Incompressible Rubberlike Solids. Proc. R. Soc. Lond. A 1972, 326, 565–584. [Google Scholar] [CrossRef]

- Ogden, R.W.; Roxburgh, D.G. A Pseudo–Elastic Model for the Mullins Effect in Filled Rubber. Proc. R. Soc. Lond. A 1999, 455, 2861–2877. [Google Scholar] [CrossRef]

- GB 20688.2-2006; Rubber Bearings Part 2: Elastomeric Seismic-Protection Isolators for Bridges. Standards Press of China: Beijing, China, 2006.

- GB 20688.1-2007; Rubber Bearings Part 1: Seismic-Protection Isolators Test Methods. Standards Press of China: Beijing, China, 2007.

- Reimann, C.; Filzmoser, P.; Garrett, R.G.; Dutter, R. Regression Analysis (RA). In Statistical Data Analysis Explained: Applied Environmental Statistics with R; Wiley: Hoboken, NJ, USA, 2008; pp. 249–268. ISBN 978-0-470-98581-6. [Google Scholar]

- Freund, R.J.; Wilson, W.J.; Sa, P. Multiple Linear Regression. In Regression Analysis: Statistical Modeling of a Response Variable; Chongqing University Press: Chongqing, China, 2012; Volume 3, pp. 62–90. ISBN 978-7-5624-6976-6. [Google Scholar]

- Freund, R.J.; Wilson, W.J.; Sa, P. Curve Fitting. In Regression Analysis: Statistical Modeling of a Response Variable; Chongqing University Press: Chongqing, China, 2012; Volume 7, pp. 231–254. ISBN 978-7-5624-6976-6. [Google Scholar]

| Influencing Factor | Values | |||

|---|---|---|---|---|

| Temperature | 253.15 K | 273.15 K | 293.15 K | 313.15 K |

| Compressive Stress | 6 MPa | 8 MPa | 10 MPa | |

| Shear-Strain Amplitude | 100% | 150% | 200% | 250% |

| Influencing Factor | Values | |||

|---|---|---|---|---|

| Temperature | 278.15 K | 288.15 K | ||

| Compressive Stress | 6.5 MPa | 9.5 MPa | ||

| Shear-Strain Amplitude | 90% | 130% | 170% | 210% |

| HDR Behaviors * | Parameters | Functions |

|---|---|---|

| Type 1: | ||

| Type 2: | ||

| Type 3: | ||

| Type 4: | ||

| HDR Behaviors * | Parameters | Functions |

|---|---|---|

| Type 5: | ||

| Type 6: | ||

| Type 7: | ||

| Type 8: | ||

| Strain Amplitude | 90% | 130% | 170% | 210% |

|---|---|---|---|---|

| First loading cycle | 0.96 | 0.99 | 0.97 | 0.99 |

| Fifth loading cycle | 0.98 | 0.98 | 0.99 | 0.99 |

| All loading cycles | 0.98 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Z.; Peng, T. Study on a Pseudo-Elastic Model for High-Damping Rubber. Polymers 2024, 16, 3042. https://doi.org/10.3390/polym16213042

Guo Z, Peng T. Study on a Pseudo-Elastic Model for High-Damping Rubber. Polymers. 2024; 16(21):3042. https://doi.org/10.3390/polym16213042

Chicago/Turabian StyleGuo, Zhihao, and Tianbo Peng. 2024. "Study on a Pseudo-Elastic Model for High-Damping Rubber" Polymers 16, no. 21: 3042. https://doi.org/10.3390/polym16213042

APA StyleGuo, Z., & Peng, T. (2024). Study on a Pseudo-Elastic Model for High-Damping Rubber. Polymers, 16(21), 3042. https://doi.org/10.3390/polym16213042