Abstract

The increasing global commitment to carbon neutrality has propelled a heightened focus on sustainable construction materials, with wood emerging as pivotal due to its environmental benefits. This review explores the development and application of eco-friendly polymer nanocomposite coatings to enhance wood’s fire resistance, addressing a critical limitation in its widespread adoption. These nanocomposites demonstrate improved thermal stability and char formation properties by integrating nanoparticles, such as nano-clays, graphene oxide, and metal oxides, into biopolymer matrices. This significantly mitigates the flammability of wood substrates, creating a robust barrier against heat and oxygen. The review provides a comprehensive examination of these advanced coatings’ synthesis, characterization, and performance. By emphasizing recent innovations and outlining future research directions, this review underscores the potential of eco-friendly polymer nanocomposite coatings as next-generation fire retardants. This advancement supports the expanded utilization of wood in sustainable construction practices and aligns with global initiatives toward achieving carbon neutrality.

1. Introduction

The international community, including key organizations such as the United Nations Framework Convention on Climate Change (UNFCCC), has increasingly prioritized policies aimed at reducing carbon emissions to combat the climate crisis [1]. In this context, the issue of fire safety, particularly in structures made of wood, takes on a new urgency. One significant milestone in the global effort to combat climate change is the widespread declaration of carbon neutrality, or net-zero emissions, by around 130 countries, including the EU, the United States, and Japan, with some nations already enacting legislation to achieve this goal by 2050 [2,3]. Central to these initiatives is the promotion of green building materials, particularly wood, which is recognized for its renewability and environmental benefits [4,5]. However, the inherent combustibility of wood poses significant challenges in ensuring the safety and resilience of structures against fire hazards [6]. Traditional fire retardants, often based on halogenated compounds, have been effective in enhancing fire resistance but pose significant environmental and health risks [7]. These conventional fire retardants release toxic gases and persistent organic pollutants during combustion, leading to severe environmental and human health issues [8]. Consequently, there is a pressing need to develop safer, more sustainable alternatives that can provide effective fire protection without compromising environmental integrity [9].

Considering the pressing need for safer fire retardants, the focus has shifted to eco-friendly alternatives. The application methods for these retardants on wood-based materials include impregnation [10] and surface coatings [11]. Impregnation, although effective in penetrating deep into the wood, is often expensive and leads to substantial chemical and solvent wastage, raising environmental and economic concerns. In contrast, coatings offer a more efficient and less wasteful alternative, especially when using adhesive polymers to ensure durability and effectiveness. These eco-friendly coatings not only enhance fire resistance but also contribute to a more sustainable and environmentally conscious approach to fire safety.

Recently, eco-friendly polymer nanocomposite coatings have garnered significant attention from researchers [12]. Bio-composites made from renewable polymers, such as poly (lactic acid) [13], furfuryl alcohol [14], gluten [15], soy flour [15], and starch [16], combined with naturally available fibers, have been attracting significant interest due to their environmentally friendly characteristics [12]. These coatings incorporate nanoparticles, such as graphene [17], layered double hydroxides (LDH) [18], natural clay minerals [19], MXene [20], nano-metal oxides [21], polyphosphazene [22], cellulose nanofibrils (CNF) [23], biochar [24], and responsive color-changing materials. Notably, graphene oxide (GO), a two-dimensional carbon-based nanomaterial [25], and chitin composites have garnered significant attention in recent decades [26]. Natural clay minerals, including montmorillonite, kaolin, and bentonite, are frequently utilized in the composites industry due to their widespread availability, recyclability, and non-toxic nature [27]. The resulting nanocomposites provide enhanced fire resistance and align with green chemistry principles due to their low toxicity and biodegradability. Therefore, a review focusing on the development of novel eco-friendly polymer nanocomposite coatings for fire retardancy could provide valuable insights for researchers.

This review provides an overview of the current state of eco-friendly polymer nanocomposite coatings for fire retardancy. It examines fire-retardant treatment methods, including impregnation and coatings, and explores various nanofillers, such as layered silicates, carbon-based nanomaterials, and bio-based nanoparticles. The review covers these nanocomposites’ synthesis, fabrication, and characterization and the mechanisms underlying their fire-retardant properties. Environmental and health considerations, recent advances, case studies, and prospects are also discussed. This comprehensive analysis offers valuable insights for researchers and industry professionals in developing safer and more sustainable fire-retardant systems.

2. Fire-Retardant Chemicals

Fire-retardant chemicals are substances used to reduce the flammability of materials and delay their combustion. Traditional fire retardants include halogenated compounds, ammonium polyphosphate, borates, and intumescent systems [28]. Halogenated compounds, such as brominated and chlorinated flame retardants, are highly effective but pose significant environmental and health risks due to releasing toxic gases during combustion [8,29]. Ammonium polyphosphate and borates work by promoting char formation and suppressing flame propagation, making them safer alternatives [30]. Intumescent systems form a protective char layer during heat exposure, providing an insulating barrier that slows down combustion [31]. Despite their effectiveness, many conventional fire retardants face scrutiny for their potential toxicity and environmental persistence, leading to a growing interest in developing eco-friendly alternatives [32]. A list of fire-retardant chemicals with their chemical formulas and melting points (MP) or boiling points (BP) are shown in Table 1.

Table 1.

List of fire-retardant chemicals, along with their chemical formulas and melting or boiling points (MP/BP), sourced from the internet (Wikipedia).

2.1. Treatment Methods

Fire retardants can be applied to materials using several methods, such as impregnation and coating, each with its distinct advantages and drawbacks.

2.1.1. Impregnation

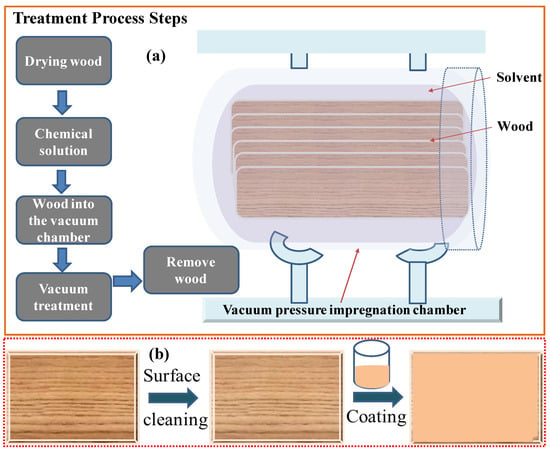

The impregnation process for fire retardants involves several meticulous steps to ensure deep penetration and effectiveness in enhancing the fire resistance of wood. First, the wood is prepared by drying it to a specific moisture content, as the moisture level affects the uptake of the fire-retardant solution. Second, fire-retardant chemicals are dissolved in suitable solvents to create a homogeneous solution. Common fire retardants include ammonium polyphosphate, borates, and other inorganic salts, with the choice of solvent depending on these chemicals’ solubility and ability to penetrate the wood structure effectively. Water is the most common solvent, but organic solvents can also be used for specific formulations. Third, the wood is placed in a vacuum chamber, and a vacuum is applied to remove air from the wood’s pores, facilitating deeper penetration of the fire-retardant solution. Fourth, after the vacuum treatment, the fire-retardant solution is introduced into the chamber, and the pressure is increased to force the solution into the wood’s cellular structure. This pressure treatment ensures the chemicals reach deep into the wood, providing comprehensive fire protection. Fifth, the impregnated wood is removed from the chamber and dried to remove excess solvent and stabilize the wood, which can be performed using kilns or air drying, depending on the desired final moisture content and the type of wood. A schematic of the vacuum pressure impregnation chamber is shown in Figure 1a.

Figure 1.

Schematic of (a) the vacuum pressure impregnation process and (b) surface coating.

The impregnation process for fire retardants is a highly effective method to enhance the fire resistance of wood by introducing protective chemicals deep into its structure [59]. This method involves sophisticated equipment and precise control over various factors, including solvent selection, chemical solubility, and wood pore structure. Impregnation with fire-retardant chemicals can lead to color changes in the wood due to the interaction between the chemicals and the natural components of the wood, such as tannins and lignin [60,61]. Depending on the fire-retardant formulation, the treated timber may darken or take on a different hue. While this color change can sometimes be mitigated through post-treatment processes or additives that stabilize the wood’s appearance, it is often an unavoidable aspect of chemical impregnation. Throughout this process, considerations such as the solubility of chemicals, dispersion within the wood’s cell wall, and the wood’s pore structure are paramount, influencing the efficacy and uniformity of the treatment. Impregnation, although effective in penetrating deep into the wood, is often expensive and leads to substantial chemical and solvent wastage, raising environmental and economic concerns [62].

2.1.2. Coatings

Coating methods offer an alternative approach to applying fire retardants to materials, including wood, offering distinct advantages over impregnation [63]. Below, we delve into the details of coating methods for fire retardants, exploring the procedures, types of coatings, application techniques, and considerations involved. Prior to coating, meticulous surface preparation is imperative. This involves cleaning and smoothing the material’s surface to ensure optimal adhesion and uniform coverage of the fire-retardant coating (as shown in Figure 1b). The formulation process entails blending fire-retardant chemicals with appropriate binders and additives to create a homogeneous mixture. Standard binders encompass adhesive polymers, such as acrylics, epoxies, and polyurethanes. A list of polymers with their chemical formulas and melting or boiling points is noted in Table 2.

Table 2.

List of polymers used for making fire-retardant composite polymers, along with their melting or boiling points (MP/BP), sourced from the internet (Wikipedia).

Different coating processes include spraying, brushing, rolling, dipping, and electrostatic coating. After application, the coated material can cure or dry, depending on the type of coating used [87]. Depending on the coating formulation, curing may involve air-drying, heat-curing in ovens, or exposure to ultraviolet (UV) light. Coatings offer a cost-effective, flexible, and environmentally friendly alternative to impregnation, though they may require more frequent maintenance and provide primarily surface-level protection.

3. Synthesis and Characterization of Fire-Retardant Polymers

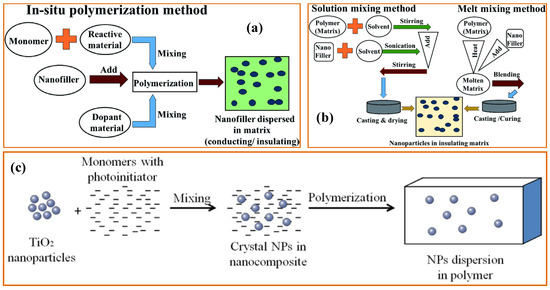

Historical records show the use of various materials to develop flame-retardant properties. Over time, alum, ferrous sulfate, stannic oxide, borax, and ammonium phosphates were used to absorb heat and prevent fire spread. The infusion of financial resources and advancements in polymeric materials has led to the introduction of hybrid materials for fire safety. Generally, solution-mixing, in situ, and ex situ methods are employed to create flame-retardant polymer nanocomposites by optimizing the composition and conditions. In the in situ method, nanomaterials are dispersed in a liquid monomer, with surfactants controlling filler agglomeration and geometry during polymerization. This method enhances porosity, making the composite lighter.

The solution-mixing method involves dissolving one or more components in a solvent to create a solution, which is then mixed thoroughly to ensure uniform distribution of the components. After mixing, the solvent may be evaporated or removed to yield the final product. The ex situ methods often involve preparing or modifying materials outside their intended operational environment. For example, nanoparticles can be synthesized separately and incorporated into a composite material. A schematic of each process is shown in Figure 2.

Figure 2.

A schematic illustration of the preparation of fire-retardant polymer nanocomposites using (a) the in situ method and (b) the solution-mixing method [88]. Copyright 2019, reproduced with permission from the authors, RSC. (c) Ex situ method [89]. Copyright 2014, reproduced with permission from the authors, MDPI, Basel.

Generally, the characterization of prepared materials involves thermal analysis (DSC, DTA, TGA, TMA, and DMA) [90], microscopy (TEM, SEM, and AFM) [91], spectroscopy (UV-Visible, FTIR, NMR, and Raman) [92], tribological properties [93], and X-ray diffraction techniques, which are employed for chemical characterization of polymer nanocomposites [94]. Mechanical properties for structural stability are assessed using universal testing machines, dynamic mechanical analyzers, and impact and surface analyzers [95]. Weathering effects and electrical properties are measured with resistivity meters and dielectric strength analyzers [96]. Chakraborty et al. provided detailed insights into microscopy and analytical techniques for cellulose morphological, structural, chemical, and thermal characterization [97].

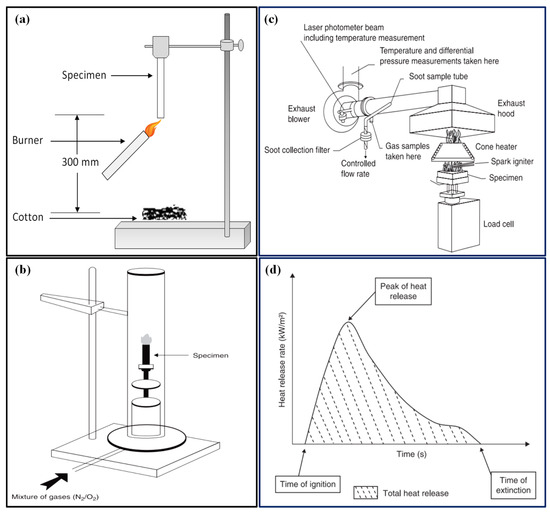

Flame retardancy assessment for fire-retardant polymer nanocomposites uses cone calorimetry and UL-94 tests [98,99]. UL-94, a standard preliminary test (as shown in Figure 3a), categorizes polymers based on vertical and horizontal burn testing and thin films, grading them into V0, V1, and V2 based on the burning time, rate, and dripping behavior (details are shown in Table 3) [100]. Limiting of oxygen index (LOI) testing (ISO 4589-2 [101]) measures the minimum oxygen concentration needed to sustain combustion in a closed atmosphere, with better flame-retardant materials requiring higher oxygen concentrations (as shown in Figure 3b).

Figure 3.

Schematic diagram of (a) the UL-94 vertical burning test [98]. Copyright 2020, reproduced with permission from the authors, MDPI, Basel. (b) The cone calorimeter, (c) the limiting oxygen index test, and (d) a typical cone calorimeter curve [100]. Copyright 2011, reproduced with permission from Woodhead Publishing Limited.

Table 3.

Classification of UL-94 V testing.

Cone calorimetry is a highly effective test for evaluating the fire behavior of medium-sized polymer samples. This method measures the decrease in oxygen concentration in the combustion gases of a sample exposed to a specific heat flux, generally between 10 and 100 kW/m2. In the United States, it is standardized under ASTM E 1354 [102] and covered by the international standard ISO 5660 [103]. In this test, a sample measuring 100 × 100 × 4 mm3 is placed on a load cell to monitor mass loss throughout the experiment. The sample is irradiated uniformly from above by a conical radiant electric heater, and combustion is initiated using an electric spark (Figure 3c). The resulting combustion gases pass through the heating cone and are captured by an exhaust system equipped with a centrifugal fan and hood. This system measures gas flow, oxygen, CO, CO2 concentrations, and smoke density.

The data from gas flow and oxygen concentration are used to calculate the heat release rate (HRR), expressed in kW/m2, indicating the amount of heat released per unit time and surface area. The progression of HRR over time, especially its peak value (pHRR or HRRmax), is critical for assessing fire properties. The total heat release (THR), expressed in kJ/m2, is obtained by integrating the HRR over time. Additionally, this test provides information on the time to ignition (TTI), duration of combustion or extinction (TOF), mass loss during combustion, quantities of CO and CO2 produced, and total smoke released (TSR), as depicted in Figure 3d [100].

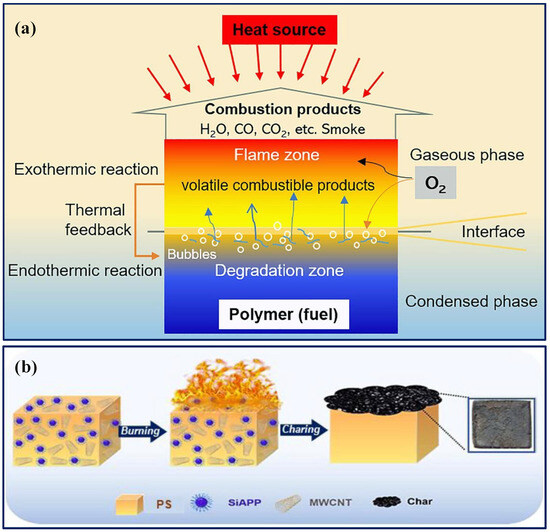

4. Mechanism of Flame Retardancy

The flame retardancy mechanisms of fire-retardant polymer nanocomposites involve gas phase inhibition, char formation or heat sink effect, and cooling through the generation of insulating layers. Gas phase inhibition occurs when flame retardants added to gases produced during polymer heating trap free radicals, halting the combustion process, typically seen with halogenated flame retardants (Figure 4a) [104]. Char formation involves flame-retardant chemicals reacting with the material’s surface to create a carbonaceous layer, insulating the polymer, and reducing pyrolysis and gas release during burning, often used with non-halogen systems utilizing phosphorous and nitrogen chemistries [105]. The formation of carbonaceous char reduces the release of volatile by-products. The mechanism depicting the reactivity of phosphorus-based flame retardants in the gas phase is shown in this paper [26]. The cooling mechanism involves endothermic reactions releasing water molecules, which cool the polymer and dilute combustion, with hydrated metal salts, such as aluminum trihydroxide, utilized for this purpose. Additionally, synergistic approaches combining different flame retardants, such as antimony oxide, with halogen-containing ones, enhance flame retardancy by inhibiting vapor phase combustibility and generating heat sink behavior in polymer composites (Figure 4b) [105].

Figure 4.

(a) The typical combustion process of polymers [104]. Copyright 2020, reproduced with permission from Published by Elsevier Ltd. (b) A schematic illustration of the flame-retardant nature [106]. Copyright 2023, reproduced with permission from Wiley-VCH GmbH.

5. Research on Flame-Retardant Chemicals

Research on flame-retardant treatment and combustion characteristics of wood has been evolving over the years, with studies from different years providing valuable insights into the effectiveness of various flame-retardant formulations and treatment methods. For instance, Park et al. [107] conducted a thermal analysis to examine the combustion characteristics of fire-retardant-treated wood. Their findings indicated that flame-retardant treatment significantly influences wood’s thermal decomposition and combustion properties. Zhang Zhi-jun et al. [108] conducted a fire retardation performance test on a wood flour/polystyrene composite (WF-PS) treated with ammonium polyphosphate (APP) and tested using a cone calorimeter. The study found that the heat release rate was 35 kW/m2, significantly reducing the total heat release. Additionally, the treatment with APP extended the ignition time of the composite, indicating improved fire-retardant properties.

Jinxue Jiang et al. [109] found that flame-retardant-treated wood exhibited the highest limiting oxygen index (LOI) values, indicating synergistic interactions between phosphorus and nitrogen (P–N). As the degree of degradation increased, the activation energies of the treated wood decreased by 19.6–50.4% compared to untreated wood. This led to higher char formation and reduced production of combustible products during degradation. These findings highlight the effectiveness of the P–N flame-retardant treatment in enhancing the fire resistance of wood by promoting char formation and inhibiting combustion. Lin Zhou et al. [110] investigated the effects of ammonium polyphosphate (APP) and 3-(methylacryloxyl) propyltrimethoxy silane-modified APP (M-APP) on wood flour/polypropylene composites (WF/PP). M-APP significantly improved the mechanical properties of WF/PP composites and acted as an effective flame retardant, surpassing the performance of APP according to cone calorimetry results. Moreover, M-APP enhanced char formation, as evidenced by SEM analysis, indicating its potential in enhancing the fire resistance of WF/PP composites through improved char formation capabilities. Using cone calorimetry and thermogravimetric analysis (TGA), the study found significant reductions in the peak heat release rate (HRR) by 21% and total heat release (THR) by 44.2%.

Dong Won Son et al. [111] treated Japanese red pine, hemlock, and radiate pine with inorganic chemicals, such as 50% sodium silicate, 3% boric acid, 3% ammonium phosphate, and 3% ammonium borate, using a vacuum/pressure (vacuum 78 kPa, 30 min, pressure 18 kg/cm2, time 2 h) impregnated method. The study reported that the ignition time of the treated wood was effectively delayed by these treatments, particularly with sodium silicate, ammonium phosphate, and ammonium borate, demonstrating an improvement in fire resistance. Seo et al. [112] analyzed the combustion and thermal properties of wood used indoors, such as the heat release rate, total heat release, and gas generation, using TGA and a cone calorimeter (KS F ISO 5660-1 [103]). They found that wood’s material properties significantly impacted its combustion behavior, and the formation of a carbonization layer notably varied by tree species, showing a high correlation between total heat release and weight loss. The study emphasized that ignition time and total heat release are crucial data for imparting fire resistance performance to wood.

Chai, et al. [113] evaluated the fire retardation effect on Cryptomeria fortunei wood treated with a boric acid-urea-formaldehyde (MUF) resin mixed with borax. The treatment increased the oxygen index and time to ignition (TTI). Park et al. [114] compared the flame-retardant performance and combustion characteristics of cypress wood and particle board. Cypress wood injected with flame-retardant resin via vacuum pressurization outperformed specimens treated with surface flame-retardant paint. In their study, this group demonstrated that water-soluble phosphate flame retardants, when mixed with poly ammonium phosphate, guanylurea phosphate, phosphoric acid, and resin, effectively impregnated perforated Hinkoi plywood used as a sound absorber. They found that the frequency of perforations influenced the impregnation process, with narrower hole spacing leading to increased impregnation. This resulted in a 15% improvement in flame-retardant performance compared to untreated samples [115].

Sathasivam Pratheep Kumar et al. [116] applied a composite coating of sodium silicate and clay minerals to wood as an innovative inorganic flame retardant. Cone calorimeter tests revealed that the composite-coated wood significantly reduced the heat release rate, delayed total heat release and ignition, and exhibited superior flame retardation compared to other tested coatings due to the dense surface layer. The addition of vermiculite to sodium silicate enhanced ignition resistance and resulted in lower HRR values than the wood coated solely with sodium silicate. Ribeiro et al. [117] developed an unsaturated polyester-based composite with enhanced fire retardancy using nano/micro-oxide particles and common flame retardants. Results showed that hybrid-flame-retardant systems improved fire properties but sometimes decreased mechanical properties due to poor matrix-filler adhesion.

Rocha et al. [118] engineered a high-density polyethylene composite reinforced with lignocellulosic fibers as a potential substitute for natural pine wood. The HDPE/sponge gourd fiber composite demonstrated the best impact resistance, and with the addition of magnesium hydroxide, it showed improved flammability and thermal stability. Sheng Li et al. [119] developed a biomass-based flame-retardant additive derived from renewable chitosan, melamine formaldehyde resin-coated ammonium polyphosphate, and organic montmorillonite, incorporated into waterborne epoxy resin (WBEP) for wood coatings. The resulting coated wood composites achieved a UL-94 V-0 rating, a limiting oxygen index of 31.8%, and maintained excellent flame-retardant performance even after water resistance tests. The biomass-based additive enhanced the carbonization capability, with residual char reaching 23.9 wt.% at 800 °C. Cone calorimeter tests showed reduced heat and smoke release, forming an effective char layer that protected the wood substrate. The WBEP coating demonstrated superior water resistance and flame-retardant efficiency, making it suitable for flame-retardant wood composites.

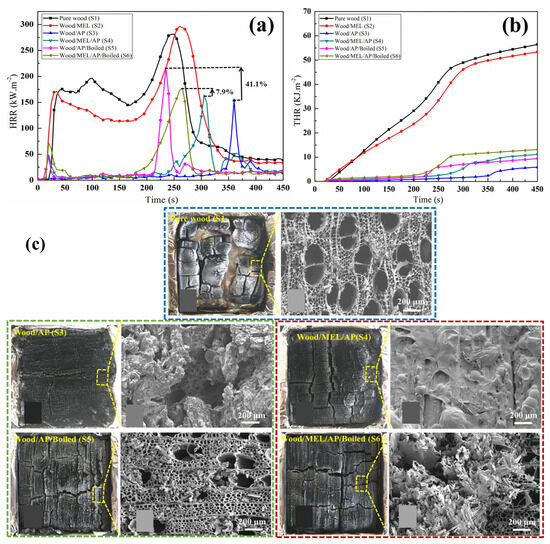

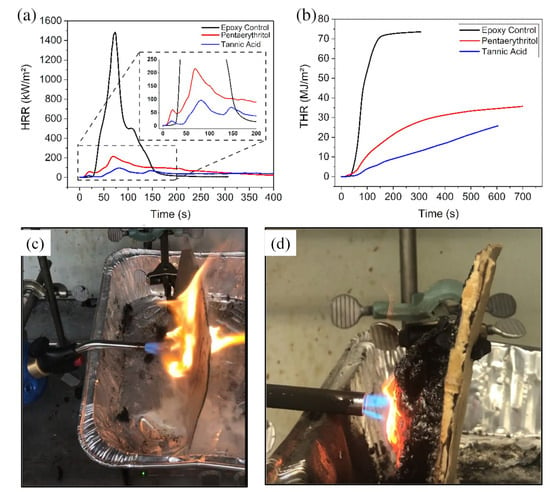

Lu et al. [61] impregnated melamine (MEL) with organic phosphoric acid (AP) into the porous structure of wood. The limiting oxygen index (LOI) and cone calorimetry tests showed that MEL/AP presence significantly improved fire resistance. The LOI value increased from 21.0% to 68.5%, and the peak heat release rate and total heat release amount decreased by 41.7% and 80.2%, respectively, compared to the control sample (as shown in Figure 5). This indicates that MEL/AP in a porous wood structure improves flame retardancy. Price et al. [120] developed tannic acid (TA)-based composites for fire safety, comparing them to pentaerythritol (PER) composites. TA composites significantly extended the time to failure from seconds or minutes to over 15 min, with a maximum of 27 min. They exhibited better fire performance, with lower peak heat release values (211 vs. 108 kW/m2), lower total heat release values (37.2 vs. 24.4 MJ/m2; as shown in Figure 6), and slower fire growth rates (2.43 vs. 1.27 kW/m2s−1).

Figure 5.

(a) Heat release rate (HRR) and (b) total heat release (THR) curves for both pure and modified wood. (c) Digital photographs and SEM images of pure wood and modified wood after cone calorimeter testing (CCT) [61]. Copyright 2020, reproduced with permission from Elsevier Ltd.

Figure 6.

Cone calorimetry data illustrating (a) heat release rate (HRR) versus time and (b) total heat release (THR) versus time for cardboard coatings exposed to a propane blow torch. The uncoated cardboard was compromised after 7 s (c) and the 1 mm coated cardboard burned for 27 min (d). The coated sample exhibited a final expansion 25 times its original thickness [120]. Copyright 2020, reproduced with permission from the authors. SPE Polymers published by Wiley Periodicals LLC on behalf of the Society of Plastics Engineers.

X-ray photoelectron spectroscopy showed that TA char was more carbonaceous (54.71 at.% C vs. 39.63 at.% C in PER char). These findings demonstrate that TA composites provide superior fire protection, offering significant advancements for fire safety applications [120].

Özkan et al. [121] treated with fire retardants, including di-ammonium phosphate (DAP), borax, boric acid, and glucose, in aqueous solutions of 10%, 20%, and 30%. Post-heat treatment at 120 °C, 150 °C, and 180 °C improved water resistance, dimensional stability, mechanical strength, and thermal properties. The DAP/glucose complex enhanced phosphorus fixation, reducing leaching and providing long-term fire protection. These findings suggest potential for using treated wood in structural applications, offering enhanced durability and fire safety.

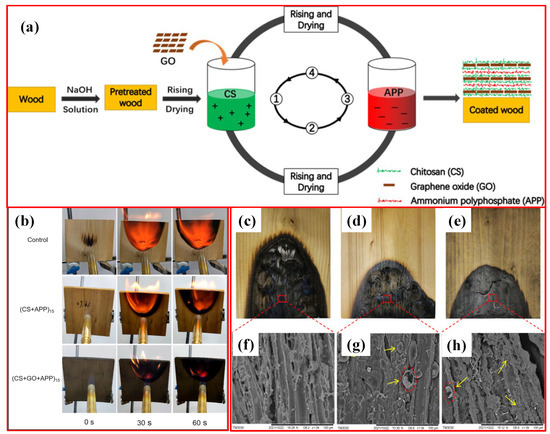

Yutao Yan et al. [122] developed a durable flame-retardant coating on wood using a layer-by-layer self-assembly method with chitosan (CS), graphene oxide (GO), and ammonium polyphosphate (APP; as shown in Figure 7). The coating enhanced thermal stability by lowering decomposition temperatures and increasing char residue due to the effective heat barrier properties of GO. Fire resistance significantly improved, with the LOI increasing from 22 to 42 and the heat release rate decreasing from 105.50 kW/m2 to 57.51 kW/m2 after 15 layers of CS-GO-APP were applied. The coating showed excellent durability in immersion and abrasion tests, forming a protective char layer that inhibited flame spread on wood surfaces.

Figure 7.

(a) Schematic illustration of the layer-by-layer (LBL) self-assembly CS-GO-APP coating on wood. (b) Fire behavior comparison of coated and uncoated wood samples at various burning times. Digital photographs and SEM images after combustion test: (c,f) uncoated wood, (d,g) (CS-APP)15-coated wood, and (e,h) (CS-GO-APP)15-coated wood [122]. Copyright 2022, reproduced with permission from the authors. Published by the American Chemical Society.

Recently, Rantuch et al. [24] treated spruce wood with a furfuryl alcohol solution enriched with biochar via vacuum infiltration. The research aimed to assess the suitability of this treatment and evaluate its impact on thermal degradation properties. Thermal gravimetric analysis revealed that the biochar-furfurylated wood bio-composite (BFW) exhibited enhanced thermal stability compared to untreated wood (W) and furfurylated wood (FW). BFW also demonstrated improved fire characteristics, including decreased effective heat of combustion and carbon monoxide yield, highlighting its potential for enhancing wood’s fire resistance properties [24]. Besides, mineral fillers, such as aluminum and magnesium hydroxide, and natural mixtures, such as huntite and hydro-magnesite, are increasingly used as eco-friendly fire retardants. They act through endothermic decomposition, increasing the heat capacity of polymer residues, and enhancing the gas phase heat capacity with water or carbon dioxide. Despite the complexities in application across polymers, these fillers reduce flammability by up to 70%, as evidenced by LOI, UL-94, and cone calorimeter tests. Quantifying their effects reveals their nuanced impacts, crucial for sustainable fire safety solutions [123].

Liu et al. [124] explored the use of industrial lignin modified with phosphorus, nitrogen, and copper as a bio-based flame-retardant additive for wood-plastic composites (WPCs). The modified lignin (F-lignin) significantly enhanced the thermal stability and flame retardancy of WPCs compared to unmodified lignin (O-lignin). It reduced the heat release rate, total heat release, and smoke production during combustion, while promoting the formation of a dense, protective char layer. This innovative approach demonstrates the potential of utilizing industrial lignin in green flame-retardant strategies for sustainable WPC applications.

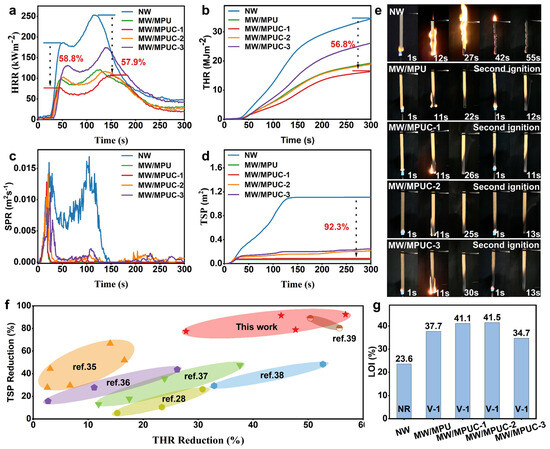

Moreover, Yang et al. [125] developed high-performance bio-composite materials from recyclable forestry waste, using lignin and cellulose as a natural adhesive matrix. Pretreatment with hydrogen peroxide, sodium hydroxide, and sodium silicate enhanced the material properties significantly, increasing tensile and bending strengths by over 90%. The bio-composite exhibited hydrophobicity with a water contact angle of 99.96° and maintained thermal stability up to 1300 °C without disintegration. These attributes make it highly suitable for eco-friendly construction applications, offering sustainable alternatives to petroleum-based materials. Yu et al. [126] introduced an eco-friendly method for creating flame-retardant wood composites using carboxymethylated alkali lignin, phytic acid, and melamine-urea-glyoxal resin. The resulting modified wood (MW/MPUC) showed significant improvements in flame retardancy, with a 56.8% reduction in total heat release, a 92.3% decrease in total smoke production, and an increase in the limiting oxygen index from 23.6% to 41.5% (as shown in Figure 8). Additionally, all modified wood samples passed the UL-94 V-1 flammability test and exhibited enhanced mechanical properties and dimensional stability.

Figure 8.

(a) The HRR curves, (b) the THR curves, (c) the SPR curves, and (d) the TSP curves of the specimens. (e) Digital photographs of specimens during UL-94 testing. (f) Summary of flame-retardant efficiency of PA and lignin, and (g) LOI and UL-94 testing results of the specimens [126]. Copyright 2024, reproduced with permission from Elsevier B.V. All rights are reserved.

From the above literature study, a summary table focusing on eco-friendly flame retardants is shown in Table 4.

Table 4.

Summary of some eco-friendly flame retardants from the above literature review.

5.1. Discussions

The trend in fire-retardant research has been shifting significantly toward eco-friendly polymer nanocomposite coatings, reflecting an increasing emphasis on sustainability and environmental safety. Early studies focused primarily on inorganic chemicals and conventional flame retardants, such as ammonium polyphosphate (APP), boric acid, and sodium silicate [108,109,110,111]. However, the growing awareness of the environmental impact and the potential health risks associated with these traditional retardants have driven researchers to explore green alternatives [7]. Recent advancements have seen the development of bio-based and eco-friendly flame retardants, utilizing natural materials such as chitosan, lignin, and cellulose, often enhanced with nanotechnology [122,123]. For instance, the use of carboxymethylated alkali lignin, phytic acid, and melamine-urea-glyoxal resin to create flame-retardant wood composites exemplifies this shift, achieving significant improvements in fire resistance and reduced smoke production while maintaining mechanical properties and dimensional stability [125]. Nanocomposite coatings incorporating materials such as graphene oxide, clay minerals, and biochar are becoming prominent, leveraging their superior thermal stability and char-forming capabilities to enhance fire retardancy [126]. These innovations not only meet the stringent fire safety standards but also align with the principles of green chemistry, paving the way for sustainable applications in construction and material science. This eco-conscious direction marks a significant evolution in the field, aiming to mitigate the environmental impact while ensuring effective fire protection.

5.2. Limitation, Challengs, and Opportunities

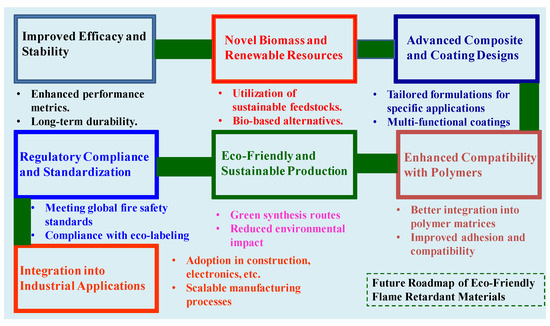

The shift toward eco-friendly polymer nanocomposite coatings for flame retardancy presents challenges and opportunities in the field. Challenges include higher production costs and the need to scale manufacturing processes to meet industrial demands. There are also concerns about potential compromises in mechanical properties and the long-term durability of these coatings under various environmental conditions. Standardizing testing protocols and gaining acceptance from industries and consumers are additional hurdles. However, these challenges are accompanied by significant opportunities. Advances in nanotechnology offer the potential to develop highly effective flame retardants with minimal environmental impact. Integrating renewable resources, such as chitosan, lignin, and cellulose, supports sustainability goals and enhances the value of agricultural by-products. Innovation in multifunctional coatings that offer additional benefits beyond fire resistance is another promising avenue. Moreover, increasing regulatory pressures and consumer demand for greener products create a favorable market environment for developing and adopting eco-friendly flame-retardant technologies. A probable future roadmap for eco-friendly flame-retardant materials is illustrated in Figure 9.

Figure 9.

A probable future roadmap for the development and application of eco-friendly flame-retardant materials.

6. Conclusions

The evolution toward eco-friendly polymer nanocomposite coatings represents a pivotal advancement in fire-retardant technology for building materials. These coatings offer substantial opportunities, while facing challenges such as production costs, scalability, and ensuring mechanical integrity. Advances in nanotechnology enable the development of highly efficient flame retardants using renewable resources, aligning with sustainability objectives and regulatory requirements. Innovations in multifunctional coatings enhance fire resistance and provide added benefits, such as antimicrobial properties and thermal insulation. With growing market demand and regulatory support for greener solutions, the future holds promising prospects for integrating eco-friendly polymer nanocomposite coatings into mainstream building materials, ensuring safer environments while minimizing the environmental impact.

Author Contributions

H.K., conceptualization, writing—original draft preparation, writing—review and editing; C.-W.K., project administration, funding acquisition, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

The Basic Science Research Program supported this research through the National Research Foundation of Korea (NRF), funded by the Ministry of Education (NRF-2019R1I1A3A02059471).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bakhtiari, F. International cooperative initiatives and the United Nations Framework Convention on Climate Change. Clim. Policy 2018, 18, 655–663. [Google Scholar] [CrossRef]

- Rogelj, J.; Geden, O.; Cowie, A.; Reisinger, A. Net-zero emissions targets are vague: Three ways to fix. Nature 2021, 591, 365–368. [Google Scholar] [CrossRef]

- Costa, C.; Wollenberg, E.; Benitez, M.; Newman, R.; Gardner, N.; Bellone, F. Roadmap for achieving net-zero emissions in global food systems by 2050. Sci. Rep. 2022, 12, 15064. [Google Scholar] [CrossRef]

- Nässén, J.; Hedenus, F.; Karlsson, S.; Holmberg, J. Concrete vs. wood in buildings—An energy system approach. Build. Environ. 2012, 51, 361–369. [Google Scholar] [CrossRef]

- Webster, M.D.; Arehart, J.; Ruthwik, C.; Aloisio, J.; Karineh, G.; Gryniuk, M.; Hogroian, J.; Jezeritz, C.; Johnson, L.; Kestner, D. Achieving Net Zero Embodied Carbon in Structural Materials by 2050; American Society of Civil Engineers: Reston, VA, USA, 2020. [Google Scholar]

- Zang, X.; Liu, W.; Wu, D.; Pan, X.; Zhang, W.; Bian, H.; Shen, R. Contemporary Fire Safety Engineering in Timber Structures: Challenges and Solutions. Fire 2024, 7, 2. [Google Scholar] [CrossRef]

- Hull, T.R.; Law, R.J.; Bergman, Å. Chapter 4—Environmental drivers for replacement of halogenated flame retardants. In Polymer Green Flame Retardants; Papaspyrides, C.D., Kiliaris, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 119–179. ISBN 978-0-444-53808-6. [Google Scholar]

- Shaw, S. Halogenated Flame Retardants: Do the Fire Safety Benefits Justify the Risks? Rev. Environ. Health 2010, 25, 261–306. [Google Scholar] [CrossRef]

- Sabet, M. Advancements in halogen-free polymers: Exploring flame retardancy, mechanical properties, sustainability, and applications. Polym. Technol. Mater. 2024, 63, 1794–1818. [Google Scholar] [CrossRef]

- Popescu, C.-M.; Pfriem, A. Treatments and modification to improve the reaction to fire of wood and wood based products—An overview. Fire Mater. 2020, 44, 100–111. [Google Scholar] [CrossRef]

- Sandberg, D. Additives in Wood products—today and future development. In Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts; Kutnar, A., Muthu, S.S., Eds.; Springer: Singapore, 2016; pp. 105–172. ISBN 978-981-10-0655-5. [Google Scholar]

- Hazarika, A.; Baishya, P.; Maji, T.K. Bio-based Wood Polymer Nanocomposites: A sustainable high-performance material for future. In Eco-Friendly Polymer Nanocomposites: Processing and Properties; Thakur, V.K., Thakur, M.K., Eds.; Springer: New Delhi, India, 2015; pp. 233–257. ISBN 978-81-322-2470-9. [Google Scholar]

- Ling, M.; Yin, N.; Chen, Y.; Zhou, Z.; Chen, H.; Dai, C.; Huang, J.; Zhang, W. Construction of polylactic acid-based flame retardant composites by zinc oxide and bamboo carbon. Carbon Lett. 2024, 34, 665–675. [Google Scholar] [CrossRef]

- Liu, M.; Wang, J.; Yan, Q.; Lyu, J.; Lei, Y.; Lyu, S.; Yan, L. Green bio-derived epoxidized linseed-oil plasticizer improves the toughness, strength, and dimensional stability of furfuryl alcohol-modified wood. Ind. Crops Prod. 2024, 217, 118886. [Google Scholar] [CrossRef]

- Du, X.; Li, Z.; Zhang, J.; Li, X.; Du, G.; Deng, S. Development of environmentally friendly glyoxal-based adhesives with outstanding water repellency utilizing wheat gluten protein. Int. J. Biol. Macromol. 2024, 273, 133081. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Rao, Y.; Liu, P.; Wu, L.; Zhang, G.; Zhang, J.; Xie, F. High-amylose starch-based gel as green adhesive for plywood: Adhesive property, water-resistance, and flame-retardancy. Carbohydr. Polym. 2024, 339, 122247. [Google Scholar] [CrossRef] [PubMed]

- Nine, M.J.; Tran, D.N.H.; Tung, T.T.; Kabiri, S.; Losic, D. Graphene-Borate as an Efficient Fire Retardant for Cellulosic Materials with Multiple and Synergetic Modes of Action. ACS Appl. Mater. Interfaces 2017, 9, 10160–10168. [Google Scholar] [CrossRef]

- Hu, X.; Sun, Z. Nano CaAlCO3-layered double hydroxide-doped intumescent fire-retardant coating for mitigating wood fire hazards. J. Build. Eng. 2021, 44, 102987. [Google Scholar] [CrossRef]

- Guo, G.; Park, C.B.; Lee, Y.H.; Kim, Y.S.; Sain, M. Flame retarding effects of nanoclay on wood–fiber composites. Polym. Eng. Sci. 2007, 47, 330–336. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Y.; Li, M.-C.; Zhang, S.; Zhou, W.; Mei, C.; Pan, M. Bioinspired, stable adhesive Ti3C2Tx MXene-based coatings towards fire warning, smoke suppression and VOCs removal smart wood. Chem. Eng. J. 2023, 452, 139360. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Walkiewicz, J.; Dziurka, D.; Mirski, R. Nanomaterials to improve fire properties in wood and wood-based composite panels. In Emerging Nanomaterials: Opportunities and Challenges in Forestry Sectors; Taghiyari, H.R., Morrell, J.J., Husen, A., Eds.; Springer: Cham, Germany, 2023; pp. 65–96. ISBN 978-3-031-17378-3. [Google Scholar]

- Qiu, S.; Wang, X.; Yu, B.; Feng, X.; Mu, X.; Yuen, R.K.K.; Hu, Y. Flame-retardant-wrapped polyphosphazene nanotubes: A novel strategy for enhancing the flame retardancy and smoke toxicity suppression of epoxy resins. J. Hazard. Mater. 2017, 325, 327–339. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Li, S.-N.; Wu, Q.; Li, Q.; Huang, J.; Li, W.; Zhang, W.; Wang, S. Phosphorus containing group and lignin toward intrinsically flame retardant cellulose nanofibril-based film with enhanced mechanical properties. Compos. Part B Eng. 2021, 212, 108699. [Google Scholar] [CrossRef]

- Rantuch, P.; Kvorková, V.; Wachter, I.; Martinka, J.; Štefko, T. Is biochar a suitable fire retardant for furfurylated wood? Compos. Part C Open Access 2024, 14, 100454. [Google Scholar] [CrossRef]

- Kolya, H.; Mondal, S.; Kang, C.-W.; Nah, C. 18—The use of polymer-graphene composites in catalysis. In Woodhead Publishing Series in Composites Science and Engineering; Rahaman, M., Nayak, L., Hussein, I.A., Das, N.C.B.T.-P.N.C.G., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 537–556. ISBN 978-0-12-821639-2. [Google Scholar]

- Taib, M.N.A.M.; Antov, P.; Savov, V.; Fatriasari, W.; Madyaratri, E.W.; Wirawan, R.; Osvaldová, L.M.; Hua, L.S.; Ghani, M.A.A.; Al Edrus, S.S.A.O.; et al. Current progress of biopolymer-based flame retardant. Polym. Degrad. Stab. 2022, 205, 110153. [Google Scholar] [CrossRef]

- Padil, V.V.T.; Akshay Kumar, K.P.; Murugesan, S.; Torres-Mendieta, R.; Wacławek, S.; Cheong, J.Y.; Černík, M.; Varma, R.S. Sustainable and safer nanoclay composites for multifaceted applications. Green Chem. 2022, 24, 3081–3114. [Google Scholar] [CrossRef]

- Green, J. An overview of the fire retardant chemicals industry, Past—Present—Future. Fire Mater. 1995, 19, 197–204. [Google Scholar] [CrossRef]

- Zhang, M.; Buekens, A.; Li, X. Brominated flame retardants and the formation of dioxins and furans in fires and combustion. J. Hazard. Mater. 2016, 304, 26–39. [Google Scholar] [CrossRef] [PubMed]

- Beyer, G. Chapter 1—Introduction to flame retardant systems. In Flame Retardant Nanocomposites; Thomas, S., Vahabi, H., Somasekharan, L., Eds.; Woodhead Publishing: Sawston, UK, 2024; pp. 1–22. ISBN 978-0-443-15421-8. [Google Scholar]

- Kaur, A.; Kapoor, K.; Mandot, A.; Godara, S.K.; Sood, A.K.; Singh, M. Fire-Retardant coatings for modern lightweight materials. In Functional Coatings: Innovations and Challenges; Davim, J.P., Arya, R.K., Verros, G.D., Eds.; Wiley: Hoboken, New Jersey, USA, 2024; pp. 202–230. ISBN 9781394207305. [Google Scholar]

- Purser, D. Toxicity of fire retardants in relation to life safety and environmental hazards. Fire Retard. Mater. 2001, 69–127. [Google Scholar]

- Zhu, K.; Yang, Y.; Lin, C.; Wang, Q.; Ye, D.; Jiang, H.; Wu, K. Effect of Compounded Aluminum Hydroxide Flame Retardants on the Flammability and Smoke Suppression Performance of Asphalt Binders. ACS Omega 2024, 9, 2803–2814. [Google Scholar] [CrossRef] [PubMed]

- Dey, R.; Bhakare, M.A.; Some, S. One-pot synthesis of aluminum phosphate-supported, chitosan-linked expandable graphite as a novel flame retardant for textile. J. Appl. Polym. Sci. 2024, 141, e55581. [Google Scholar] [CrossRef]

- Liu, K.; Li, Y.; Xu, L.; Zhu, F.; Zhang, Y.; Meng, Y.; Xia, X. Preparation of ethyl cellulose microencapsulated ammonium polyphosphate and its application in flame retardant cellulose paper. Ind. Crops Prod. 2024, 210, 118132. [Google Scholar] [CrossRef]

- Goller, S.M.; Schartel, B.; Krüger, S. Phosphorus features halogen–calcium hypophosphite replaces antimony trioxide, reduces smoke, and improves flame retardancy. Thermochim. Acta 2024, 737, 179764. [Google Scholar] [CrossRef]

- Lin, M.; Guo, X.; Xu, Y.; Zhang, X.; Hu, D. A Top-Down Approach to the Fabrication of Flame-Retardant Wood Aerogel with In Situ-Synthesized Borax and Zinc Borate. Materials 2024, 17, 2638. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, Y.; Zhao, X.; Li, N.; Guo, X.; Zhao, L.; Yin, Y. Anisotropic composite aerogel with thermal insulation and flame retardancy from cellulose nanofibers, calcium alginate and boric acid. Int. J. Biol. Macromol. 2024, 267, 131450. [Google Scholar] [CrossRef]

- Levchik, S.; Bocchini, S.; Camino, G. Halogen-containing flame retardants. In Fire Retardancy of Polymeric Materials; Wilkie, C.A., Morgan, A.B., Eds.; CRC Press: Boca Raton, FL, USA, 2024; pp. 58–80. [Google Scholar]

- Gao, L.; Zheng, G.; Zhou, Y.; Hu, L.; Feng, G.; Zhang, M. Synergistic effect of expandable graphite, diethyl ethylphosphonate and organically-modified layered double hydroxide on flame retardancy and fire behavior of polyisocyanurate-polyurethane foam nanocomposite. Polym. Degrad. Stab. 2014, 101, 92–101. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, S.J.; Che, X.X.; Shen, C.H. Synthesis and characterization of a flame retardant Dimethyl methyl Phosphonate (DMMP) and its application in FRP. Adv. Mater. Res. 2013, 804, 29–35. [Google Scholar] [CrossRef]

- Kausar, A.; Anwar, Z.; Muhammad, B. Overview of nonflammability characteristics of graphene and graphene oxide-based polymeric composite and essential flame retardancy techniques. Polym. Plast. Technol. Eng. 2017, 56, 488–505. [Google Scholar] [CrossRef]

- Wi, S.; Kim, Y.U.; Choi, J.Y.; Shin, B.; Kim, S. Active protection against fire: Enhancing the flame retardancy of sandwich panels using an expandable graphite layer formation. Int. J. Therm. Sci. 2024, 195, 108658. [Google Scholar] [CrossRef]

- Wu, K.; Zhu, K.; Kang, C.; Wu, B.; Huang, Z. An experimental investigation of flame retardant mechanism of hydrated lime in asphalt mastics. Mater. Des. 2016, 103, 223–229. [Google Scholar] [CrossRef]

- Wang, L.; Yan, W.-J.; Zhong, C.-Z.; Chen, C.-R.; Luo, Q.; Pan, Y.-T.; Tang, Z.-H.; Xu, S. Construction of TiO2-based decorated with containing nitrogen-phosphorus bimetallic layered double hydroxides for simultaneously improved flame retardancy and smoke suppression properties of EVA. Mater. Today Chem. 2024, 36, 101952. [Google Scholar] [CrossRef]

- Dun, L.; Ouyang, Z.; Sun, Q.; Yue, X.; Wu, G.; Li, B.; Kang, W.; Wang, Y. A Simple and Efficient Magnesium Hydroxide Modification Strategy for Flame-Retardancy Epoxy Resin. Polymers 2024, 16, 1471. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, J.; Zhang, J.; Guo, W. Synergistic flame retardant modification of bio-based nylon 56 by graphitic carbon nitride and melamine cyanurate. J. Vinyl Addit. Technol. 2024, 30, 456–469. [Google Scholar] [CrossRef]

- Wang, Y.; Qu, C.; Yu, K.; Si, Z.; Zhang, J. PTFE-based flame retardant coatings optimized by melamine polyphosphate/aluminum diethyl hypophosphite/anhydrous transparent powder through orthogonal experiment. Prog. Org. Coat. 2024, 191, 108423. [Google Scholar] [CrossRef]

- Huang, G.; Liang, H.; Wang, Y.; Wang, X.; Gao, J.; Fei, Z. Combination effect of melamine polyphosphate and graphene on flame retardant properties of poly (vinyl alcohol). Mater. Chem. Phys. 2012, 132, 520–528. [Google Scholar] [CrossRef]

- Bi, X.; Song, K.; Zhang, H.; Pan, Y.-T.; He, J.; Wang, D.-Y.; Yang, R. Dimensional change of red phosphorus into nanosheets by metal–organic frameworks with enhanced dispersion in flame retardant polyurea composites. Chem. Eng. J. 2024, 482, 148997. [Google Scholar] [CrossRef]

- Chen, Q.; Huo, S.; Lu, Y.; Ding, M.; Feng, J.; Huang, G.; Xu, H.; Sun, Z.; Wang, Z.; Song, P. Heterostructured Graphene@ Silica@ Iron Phenylphosphinate for Fire-Retardant, Strong, Thermally Conductive Yet Electrically Insulated Epoxy Nanocomposites. Small 2024, 20, 2310724. [Google Scholar] [CrossRef] [PubMed]

- Kanayama, K.; Nakamura, H.; Maruta, K.; Bodi, A.; Hemberger, P. Unimolecular Decomposition Mechanism of Trimethyl Phosphate. Chem. Eur. J. 2024, 30, e202401750. [Google Scholar] [CrossRef] [PubMed]

- Gumus, N.; Doganci, E.; Aytac, A. Evaluations of the effects of different flame retardants combinations on particleboards produced using urea–formaldehyde resin. Eur. J. Wood Wood Prod. 2024, 82, 747–759. [Google Scholar] [CrossRef]

- Van der Veen, I.; de Boer, J. Phosphorus flame retardants: Properties, production, environmental occurrence, toxicity and analysis. Chemosphere 2012, 88, 1119–1153. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Deng, H.; Duan, W.; Zhu, J.; Wei, Y.; Li, W. Flame retardant properties of a guanidine phosphate–zinc borate composite flame retardant on wood. ACS Omega 2021, 6, 11015–11024. [Google Scholar] [CrossRef] [PubMed]

- Öhrn, O.; Sykam, K.; Gawusu, S.; Mensah, R.A.; Försth, M.; Shanmugam, V.; Babu, N.B.K.; Sas, G.; Jiang, L.; Xu, Q. Surface coated ZnO powder as flame retardant for wood: A short communication. Sci. Total Environ. 2023, 897, 165290. [Google Scholar] [CrossRef] [PubMed]

- Rezaei Qazviniha, M.; Piri, F. Preparation, Identification, and Evaluation of the Thermal Properties of Novolac Resins Modified with TiO2, MgO, and V2O5 Oxides. Mech. Adv. Compos. Struct. 2024, 11, 1–9. [Google Scholar]

- Jin, E.; Chung, Y.-J. Evaluation of combustion characteristics for wood specimens coated with metal oxides of different oxidation states in the secondary stage of combustion (II). Wood Sci. Technol. 2024, 58, 253–271. [Google Scholar] [CrossRef]

- Wen, M.-Y.; Kang, C.-W.; Park, H.-J. Impregnation and mechanical properties of three softwoods treated with a new fire retardant chemical. J. Wood Sci. 2014, 60, 367–375. [Google Scholar] [CrossRef]

- Che, W.; Li, Z.; Huo, S.; Dinh, T.; Hong, M.; Maluk, C.; Yu, Y.; Xie, Y. Fire-retardant anti-microbial robust wood nanocomposite capable of fire-warning by graded-penetration impregnation. Compos. Part B Eng. 2024, 280, 111482. [Google Scholar] [CrossRef]

- Lu, J.; Jiang, P.; Chen, Z.; Li, L.; Huang, Y. Flame retardancy, thermal stability, and hygroscopicity of wood materials modified with melamine and amino trimethylene phosphonic acid. Constr. Build. Mater. 2021, 267, 121042. [Google Scholar] [CrossRef]

- Rabajczyk, A.; Zielecka, M.; Małozięć, D. Hazards Resulting from the Burning Wood Impregnated with Selected Chemical Compounds. Appl. Sci. 2020, 10, 6093. [Google Scholar] [CrossRef]

- Mariappan, T. Fire retardant coatings. In New Technologies in Protective Coatings; Giudice, C., Canosa, G., Eds.; IntechOpen: London, UK, 2017; p. 28. [Google Scholar]

- Lu, S.; Feng, Y.; Zhang, P.; Hong, W.; Chen, Y.; Fan, H.; Yu, D.; Chen, X. Preparation of flame-retardant polyurethane and its applications in the leather industry. Polymers 2021, 13, 1730. [Google Scholar] [CrossRef] [PubMed]

- Ng, Y.H.; Dasari, A.; Tan, K.H.; Qian, L. Intumescent fire-retardant acrylic coatings: Effects of additive loading ratio and scale of testing. Prog. Org. Coat. 2021, 150, 105985. [Google Scholar] [CrossRef]

- Mathews, L.D.; Capricho, J.C.; Peerzada, M.; Salim, N.V.; Parameswaranpillai, J.; Hameed, N. Recent progress and multifunctional applications of fire-retardant epoxy resins. Mater. Today Commun. 2022, 33, 104702. [Google Scholar] [CrossRef]

- Wang, F.; Pan, S.; Zhang, P.; Fan, H.; Chen, Y.; Yan, J. Synthesis and application of phosphorus-containing flame retardant plasticizer for polyvinyl chloride. Fibers Polym. 2018, 19, 1057–1063. [Google Scholar] [CrossRef]

- Temane, L.T.; Ray, S.S.; Orasugh, J.T. Review on Processing, Flame-Retardant Properties, and Applications of Polyethylene Composites with Graphene-Based Nanomaterials. Macromol. Mater. Eng. 2024, 2400104. [Google Scholar] [CrossRef]

- Kang, F.; Han, H.; Wang, H.; He, D.; Zhou, M. Construction of a flame retardant three-dimensional network structure in sisal/polypropylene composites. Ind. Crops Prod. 2024, 209, 117973. [Google Scholar] [CrossRef]

- Kassaun, B.B.; Fatehi, P. Solvent-Free Lignin-Silsesquioxane wood coating formulation with superhydrophobic and Flame-Retardant functionalities. Chem. Eng. J. 2024, 493, 152582. [Google Scholar] [CrossRef]

- Trifeldaite-Baranauskiene, G.; Stankute, E.; Aniskevich, A.; Zeleniakiene, D.; Zukiene, K. Preparation and Characterisation of Composites from Industrial Waste: Wood Flour and Expanded Ethylene Vinyl Acetate. Mech. Compos. Mater. 2024, 60, 1–16. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, Z.; Huang, J.; Wang, Y. A flame retardant poly vinyl alcohol/graphene oxide/phytic acid composite for a quick response and ultra-long fire alarm. J. Mater. Chem. A 2024, 12, 6050–6066. [Google Scholar] [CrossRef]

- Chen, R.; Lu, S.; Li, C.; Li, M.; Lo, S. Characterization of thermal decomposition behavior of commercial flame-retardant ethylene–propylene–diene monomer (EPDM) rubber. J. Therm. Anal. Calorim. 2015, 122, 449–461. [Google Scholar] [CrossRef]

- Gadhave, R.V.I.; Dhawale, P. V State of research and trends in the development of polyvinyl acetate-based wood adhesive. Open J. Polym. Chem. 2022, 12, 13–42. [Google Scholar] [CrossRef]

- Zhang, J.; Koubaa, A.; Xing, D.; Wang, H.; Wang, F.; Wang, X.-M.; Wang, Q. Flammability, thermal stability, and mechanical properties of wood flour/polycarbonate/polyethylene bio-based composites. Ind. Crops Prod. 2021, 169, 113638. [Google Scholar] [CrossRef]

- Çelen, U.; Balçik Tamer, Y.; Berber, H. The potential use of natural expanded perlite as a flame retardant additive for acrylonitrile-butadiene-styrene based composites. J. Vinyl Addit. Technol. 2024, 30, 277–293. [Google Scholar] [CrossRef]

- Ren, G.; Fang, Y.; Yang, R.; Zhu, J.; Fu, Y.; Wang, W.; Ou, R.; Song, Y.; Wang, Q. Creation of a high strength, hydrophobic and fireproof surface on wood by polyamide acid under mild and simple conditions. Prog. Org. Coat. 2024, 189, 108313. [Google Scholar] [CrossRef]

- Jimenez, M.; Gallou, H.; Duquesne, S.; Jama, C.; Bourbigot, S.; Couillens, X.; Speroni, F. New routes to flame retard polyamide 6, 6 for electrical applications. J. Fire Sci. 2012, 30, 535–551. [Google Scholar] [CrossRef]

- De Hoyos-Martínez, P.L.; Issaoui, H.; Herrera, R.; Labidi, J.; Charrier-El Bouhtoury, F. Wood fireproofing coatings based on biobased phenolic resins. ACS Sustain. Chem. Eng. 2021, 9, 1729–1740. [Google Scholar] [CrossRef]

- Wei, A.; Ou, M.; Wang, S.; Zou, Y.; Xiang, C.; Xu, F.; Sun, L. Preparation of a Highly Flame-Retardant Urea–Formaldehyde Resin and Flame Retardance Mechanism. Polymers 2024, 16, 1761. [Google Scholar] [CrossRef]

- Wu, M.; Emmerich, L.; Kurkowiak, K.; Militz, H. Combined treatment of wood with thermosetting resins and phosphorous flame retardants. Eur. J. Wood Wood Prod. 2024, 82, 167–174. [Google Scholar] [CrossRef]

- Ma, X.; Wang, J.; Li, L.; Wang, X.; Gong, J. Co-pyrolysis model for polylactic acid (PLA)/wood composite and its application in predicting combustion behaviors. Renew. Energy 2024, 225, 120267. [Google Scholar] [CrossRef]

- Al-Mosawi, A.I.; Abdulsada, S.A.; Rijab, M.A.; Hashim, A. Flame retardancy of biopolymer polyhydroxyalkanoate composite. Int. J. 2015, 3, 883–886. [Google Scholar]

- Passauer, L.P. P–N-modified starch: A polymeric flame retardant for wood-based materials. In Bio-Based Flame-Retardant Technology for Polymeric Materials; Hu, Y., Nabipour, H., Wang, X., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 339–368. [Google Scholar]

- Breuer, R.; Zhang, Y.; Erdmann, R.; Vernaez Hernandez, O.E.; Kabasci, S.; Kostka, M.; Reinhardt, N.; Facklam, M.; Hopmann, C. Development and processing of flame retardant cellulose acetate compounds for foaming applications. J. Appl. Polym. Sci. 2020, 137, 48863. [Google Scholar] [CrossRef]

- Yang, H.; Yu, B.; Xu, X.; Bourbigot, S.; Wang, H.; Song, P. Lignin-derived bio-based flame retardants toward high-performance sustainable polymeric materials. Green Chem. 2020, 22, 2129–2161. [Google Scholar] [CrossRef]

- Wei, A.; Wang, S.; Zou, Y.; Xiang, C.; Xu, F.; Sun, L. Preparation of a Flame-Retardant Curing Agent Based on Phytic Acid–Melamine Ion Crosslinking and Its Application in Wood Coatings. Polymers 2024, 16, 1557. [Google Scholar] [CrossRef] [PubMed]

- Shukla, V. Review of electromagnetic interference shielding materials fabricated by iron ingredients. Nanoscale Adv. 2019, 1, 1640–1671. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Ghadiri, R.; Weigel, T.; Aumann, A.; Gurevich, E.L.; Esen, C.; Medenbach, O.; Cheng, W.; Chichkov, B.; Ostendorf, A. Comparison of in Situ and ex Situ Methods for Synthesis of Two-Photon Polymerization Polymer Nanocomposites. Polymers 2014, 6, 2037–2050. [Google Scholar] [CrossRef]

- Dobkowski, Z. Thermal analysis techniques for characterization of polymer materials. Polym. Degrad. Stab. 2006, 91, 488–493. [Google Scholar] [CrossRef]

- Venkateshaiah, A.; Padil, V.V.T.; Nagalakshmaiah, M.; Waclawek, S.; Černík, M.; Varma, R.S. Microscopic Techniques for the Analysis of Micro and Nanostructures of Biopolymers and Their Derivatives. Polymers 2020, 12, 512. [Google Scholar] [CrossRef]

- Praharaj, S.; Rout, D. Structural investigation of carbon nanotube-polymer composites by FTIR, UV, NMR, and Raman Spectroscopy. In Handbook of Carbon Nanotubes; Abraham, J., Thomas, S., Kalarikkal, N., Eds.; Springer: Cham, Germany, 2020; pp. 1–24. ISBN 978-3-319-70614-6. [Google Scholar]

- Danilova, S.N.; Okhlopkova, A.A.; Yarusova, S.B.; Dyakonov, A.A.; Gordienko, P.S.; Papynov, E.K.; Shichalin, O.O.; Buravlev, I.Y.; Vasilev, A.P.; Zhevtun, I.G.; et al. Study on the Impact of a Combination of Synthetic Wollastonite and 2-Mercaptobenzothiazole-Based Fillers on UHMWPE Polymeric Matrix. J. Compos. Sci. 2023, 7, 431. [Google Scholar] [CrossRef]

- Abhilash, V.; Rajender, N.; Suresh, K. Chapter 14—X-ray diffraction spectroscopy of polymer nanocomposites. In Spectroscopy of Polymer Nanocomposites; Thomas, S., Rouxel, D., Ponnamma, D., Eds.; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 410–451. ISBN 978-0-323-40183-8. [Google Scholar]

- Shojaeiarani, J.; Bajwa, D.S.; Stark, N.M. Green esterification: A new approach to improve thermal and mechanical properties of poly(lactic acid) composites reinforced by cellulose nanocrystals. J. Appl. Polym. Sci. 2018, 135, 46468. [Google Scholar] [CrossRef]

- Gupta, P.; Ruzicka, E.; Benicewicz, B.C.; Sundararaman, R.; Schadler, L.S. Dielectric Properties of Polymer Nanocomposite Interphases Using Electrostatic Force Microscopy and Machine Learning. ACS Appl. Electron. Mater. 2023, 5, 794–802. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, I.; Rongpipi, S.; Govindaraju, I.; B, R.; Mal, S.S.; Gomez, E.W.; Gomez, E.D.; Kalita, R.D.; Nath, Y.; Mazumder, N. An insight into microscopy and analytical techniques for morphological, structural, chemical, and thermal characterization of cellulose. Microsc. Res. Tech. 2022, 85, 1990–2015. [Google Scholar] [CrossRef] [PubMed]

- Maqsood, M.; Seide, G. Biodegradable Flame Retardants for Biodegradable Polymer. Biomolecules 2020, 10, 1038. [Google Scholar] [CrossRef] [PubMed]

- Crossley, R.; Schubel, P.; Stevenson, A. Furan matrix and flax fibre as a sustainable renewable composite: Mechanical and fire-resistant properties in comparison to phenol, epoxy and polyester. J. Reinf. Plast. Compos. 2013, 33, 58–68. [Google Scholar] [CrossRef]

- Dewaghe, C.; Lew, C.Y.; Claes, M.; Belgium, S.A.; Dubois, P. 23—Fire-retardant applications of polymer–carbon nanotubes composites: Improved barrier effect andsynergism. In Polymer–Carbon Nanotube Composites; McNally, T., Pötschke, P., Eds.; Woodhead Publishing: Sawston, UK, 2011; pp. 718–745. ISBN 978-1-84569-761-7. [Google Scholar]

- STN EN ISO 4589-2: 2017; Plastics. Determination of Burning Behaviour by Oxygen Index. Part 2: Ambient Temperature Test. ISO: Geneva, Switzerland, 2017.

- ASTM E 1354; Standard Test Method for Heat and Visible Smoke Release Rates for Materials Using an OxygenConsumption Calorimeter. ASTM International: West Conshohocken, PA, USA,, 2004.

- ISO 5660-1; Reaction to Fire Tests—Heat Release, Smoke Production and Mass Loss Rate - Part 1: Heat Release(Cone calorimeter method). ISO: Geneva, Switzerland, 2002.

- He, W.; Song, P.; Yu, B.; Fang, Z.; Wang, H. Flame retardant polymeric nanocomposites through the combination of nanomaterials and conventional flame retardants. Prog. Mater. Sci. 2020, 114, 100687. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Gibson, A.G. Fire Properties of Polymer Composite Materials; Springer: Berlin/Heidelberg, Germany, 2007; Volume 143, ISBN 1402053568. [Google Scholar]

- Kumar, S.; Dhawan, R.; Shukla, S.K. Flame Retardant Polymer Nanocomposites: An Overview. Macromol. Symp. 2023, 407, 2200089. [Google Scholar] [CrossRef]

- Park, H.-J.; Kang, Y.-G.; Kim, H. A study on combustion characteristics of fire retardant treated wood. J. Korean Wood Sci. Technol. 2005, 33, 38–44. [Google Scholar]

- Fang, Y.Q.; Wang, Q.W.; Song, Y.M.; Zhang, Z.J. The fire retardancy of wood flour/PS composites treated with APP-starch. Polym. Mater. Sci. Eng 2008, 24, 83–86. [Google Scholar]

- Jiang, J.; Li, J.; Hu, J.; Fan, D. Effect of nitrogen phosphorus flame retardants on thermal degradation of wood. Constr. Build. Mater. 2010, 24, 2633–2637. [Google Scholar] [CrossRef]

- Zhou, L.; Guo, C.; Li, L. Influence of ammonium polyphosphate modified with 3-(methylacryloxyl) propyltrimethoxy silane on mechanical and thermal properties of wood flour–polypropylene composites. J. Appl. Polym. Sci. 2011, 122, 849–855. [Google Scholar] [CrossRef]

- Son, D.-W.; Kang, M.-R.; Kim, J.-I.; Park, S.-B. Fire performance of the wood treated with inorganic fire retardants. J. Korean Wood Sci. Technol. 2012, 40, 335–342. [Google Scholar] [CrossRef][Green Version]

- Seo, H.J.; Kang, M.R.; Son, D.W. Combustion properties of woods for indoor use (II). J. Korean Wood Sci. Technol. 2015, 43, 478–485. [Google Scholar] [CrossRef]

- Chai, Y.B.; Liu, J.L.; Zhen, X. Dimensional stability, mechanical properties and fire resistance of MUF-boron treated wood. Adv. Mater. Res. 2012, 341, 80–84. [Google Scholar] [CrossRef]

- Park, S.-H.; Baek, E.-S. A Study on the combustion characteristics of wood according to flame resistant treatment. Fire Sci. Eng. 2015, 29, 12–18. [Google Scholar] [CrossRef][Green Version]

- Jang, E.-S.; Yong, W.-J.; Jo, S.-U.; Kang, C.-W.; Park, H.-J. Evaluation of flame retardant impregnation in perforated Hinoki (Chamaecyparis obtusa) plywood: Flame retardant impregnation in perforated Hinoki plywood. Wood Fiber Sci. 2024, 56, 43–50. [Google Scholar]

- Kumar, S.P.; Takamori, S.; Araki, H.; Kuroda, S. Flame retardancy of clay–sodium silicate composite coatings on wood for construction purposes. RSC Adv. 2015, 5, 34109–34116. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Sousa, S.P.B.; Nóvoa, P.R.O. An Investigation on Fire and Flexural Mechanical Behaviors of Nano and Micro Polyester Composites Filled with SiO2 and Al2O3 Particles. Mater. Today Proc. 2015, 2, 8–19. [Google Scholar] [CrossRef]

- Rocha, J.d.S.; Escócio, V.A.; Visconte, L.L.Y.; Pacheco, É.B.A. V Thermal and flammability properties of polyethylene composites with fibers to replace natural wood. J. Reinf. Plast. Compos. 2021, 40, 726–740. [Google Scholar] [CrossRef]

- Li, S.; Wang, X.; Xu, M.; Liu, L.; Wang, W.; Gao, S.; Li, B. Effect of a biomass based waterborne fire retardant coating on the flame retardancy for wood. Polym. Adv. Technol. 2021, 32, 4805–4814. [Google Scholar] [CrossRef]

- Price, E.J.; Covello, J.; Paul, R.; Wnek, G.E. Tannic acid based super-intumescent coatings for prolonged fire protection of cardboard and wood. SPE Polym. 2021, 2, 153–168. [Google Scholar] [CrossRef]

- Özkan, O.E.; Temiz, A.; Tor, Ö.; Vurdu, H. Effect of post-heat treatment on fire retardant treated wood properties. Holzforschung 2022, 76, 645–657. [Google Scholar] [CrossRef]

- Yan, Y.; Dong, S.; Jiang, H.; Hou, B.; Wang, Z.; Jin, C. Efficient and Durable Flame-Retardant Coatings on Wood Fabricated by Chitosan, Graphene Oxide, and Ammonium Polyphosphate Ternary Complexes via a Layer-by-Layer Self-Assembly Approach. ACS Omega 2022, 7, 29369–29379. [Google Scholar] [CrossRef] [PubMed]

- Hull, T.R.; Witkowski, A.; Hollingbery, L. Fire retardant action of mineral fillers. Polym. Degrad. Stab. 2011, 96, 1462–1469. [Google Scholar] [CrossRef]

- Liu, L.; Qian, M.; Song, P.; Huang, G.; Yu, Y.; Fu, S. Fabrication of Green Lignin-based Flame Retardants for Enhancing the Thermal and Fire Retardancy Properties of Polypropylene/Wood Composites. ACS Sustain. Chem. Eng. 2016, 4, 2422–2431. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, L.; Zhang, J.; Ren, Y.; Huo, H.; Zhang, X.; Huang, K.; Rezakazemi, M.; Zhang, Z. Fabrication of environmentally, high-strength, fire-retardant biocomposites from small-diameter wood lignin in situ reinforced cellulose matrix. Adv. Compos. Hybrid Mater. 2023, 6, 140. [Google Scholar] [CrossRef]

- Yu, F.; Ba, Z.; Gao, Z.; Wang, Y.; Xie, Y.; Wang, H.; Qiu, Z.; Xiao, Z. Modification with lignin-based N-P flame retardant to improve the flame retardancy and smoke suppression of wood. Chem. Eng. J. 2024, 493, 152827. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).