Development of Innovative Composite Nanofiber: Enhancing Polyamide-6 with ε-Poly-L-Lysine for Medical and Protective Textiles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Electrospinning Solution

2.3. Electrospinning

2.4. Morphological Analysis

2.5. Fourier Transform Infrared (FTIR) Spectroscopy

2.6. Water Contact Angle

2.7. Water Absorption Test

2.8. Thermal Analysis

2.9. Mechanical Analysis

2.10. Antimicrobial Analysis

2.11. Long Term Stability of Antimicrobial Property

2.12. Statistical Analysis

3. Results

3.1. Electrospinning of PA/PL Nanofiber Membranes

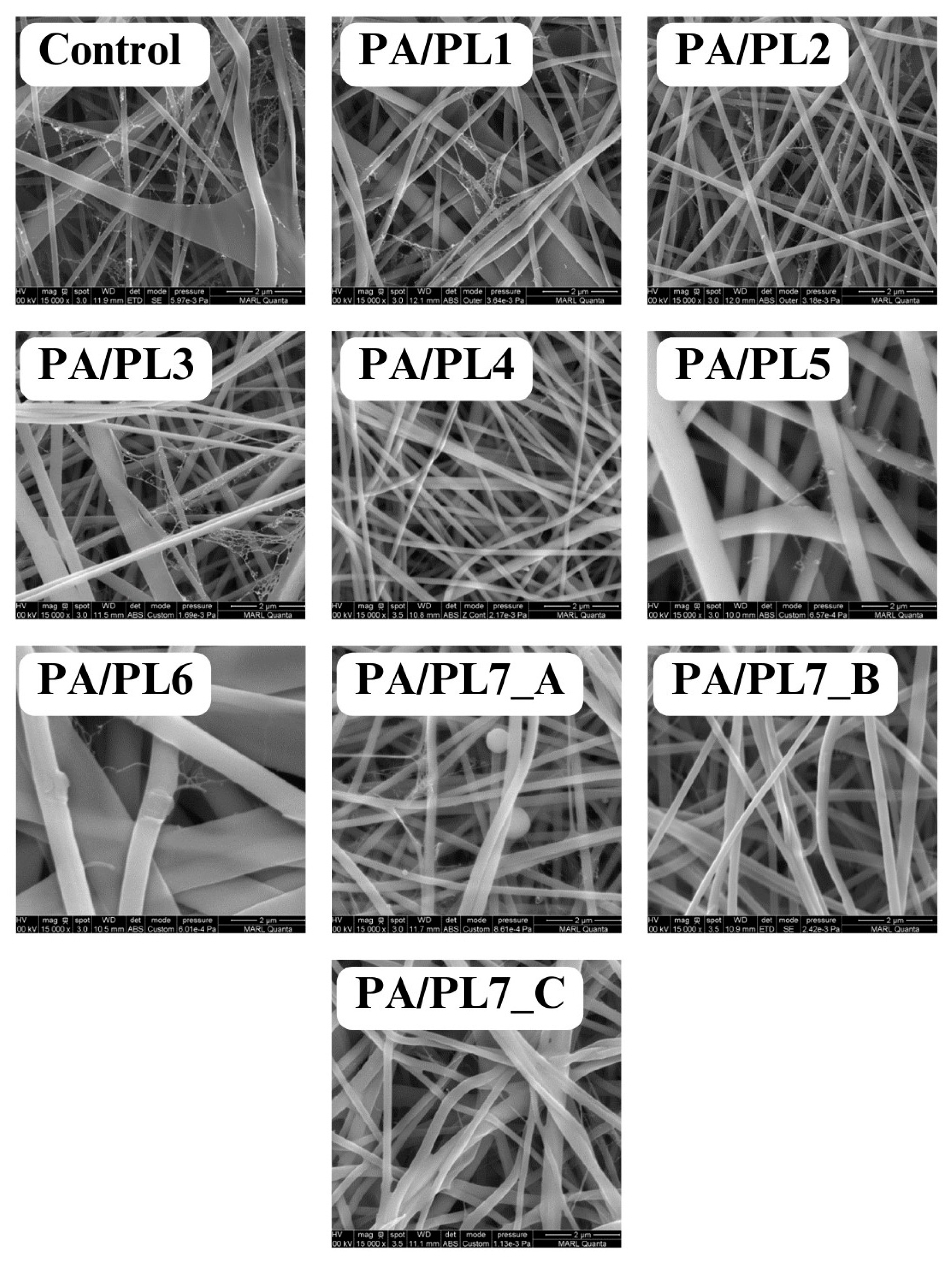

3.2. Morphological Analysis

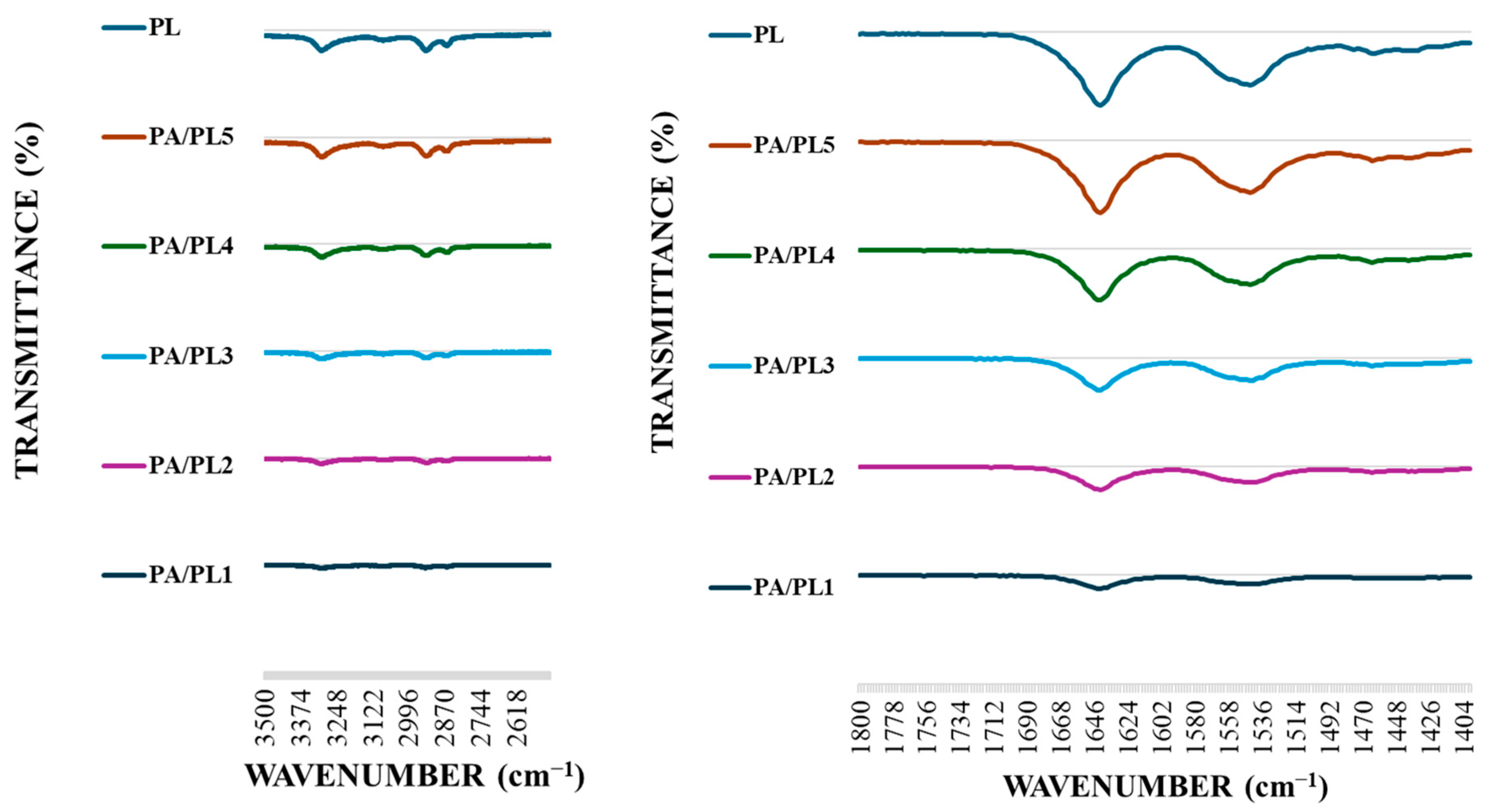

3.3. Fourier Transform Infrared (FTIR) Spectroscopy

3.4. Analysis of Hydrophilic Behavior

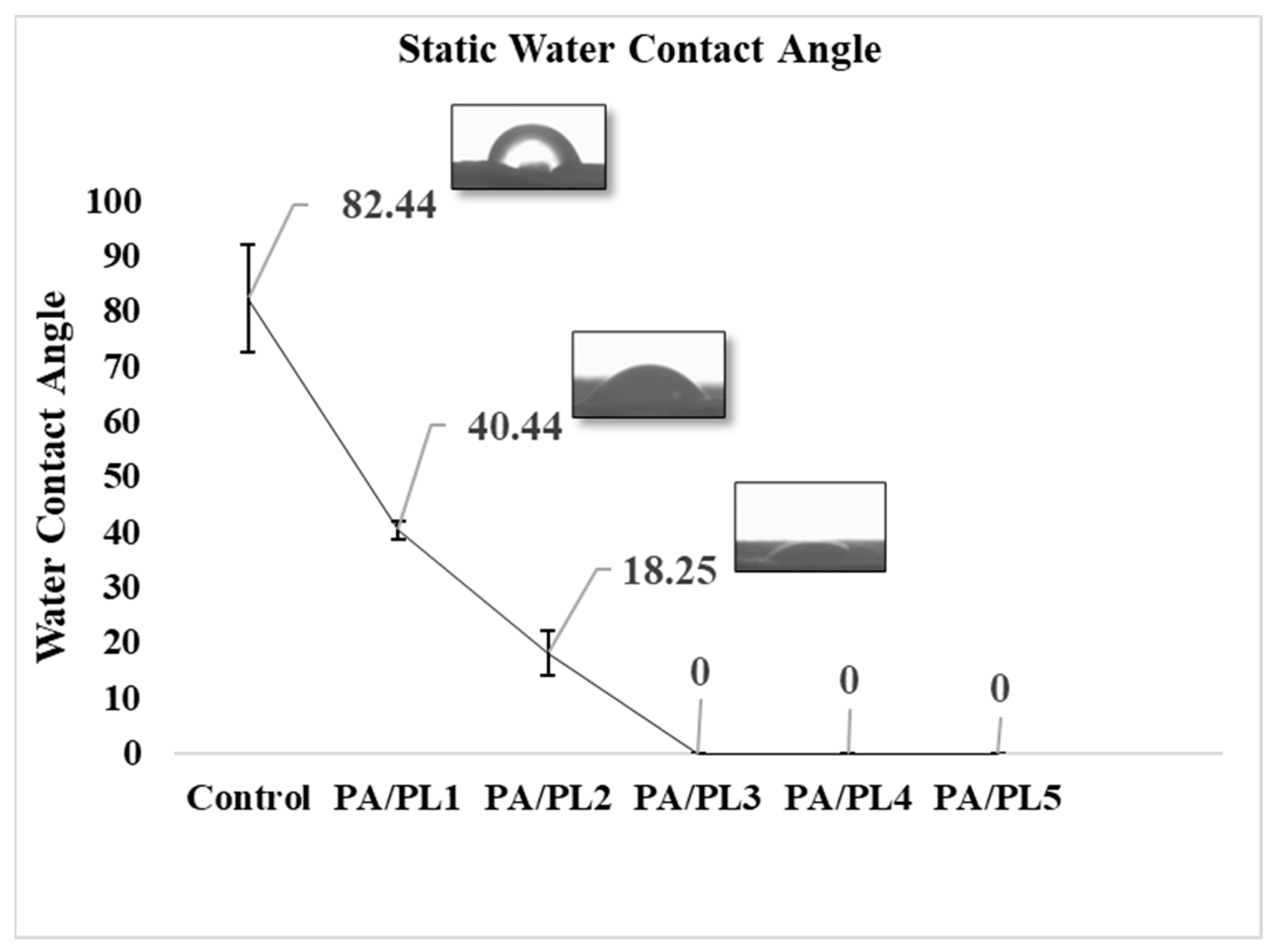

3.4.1. Water Contact Angle

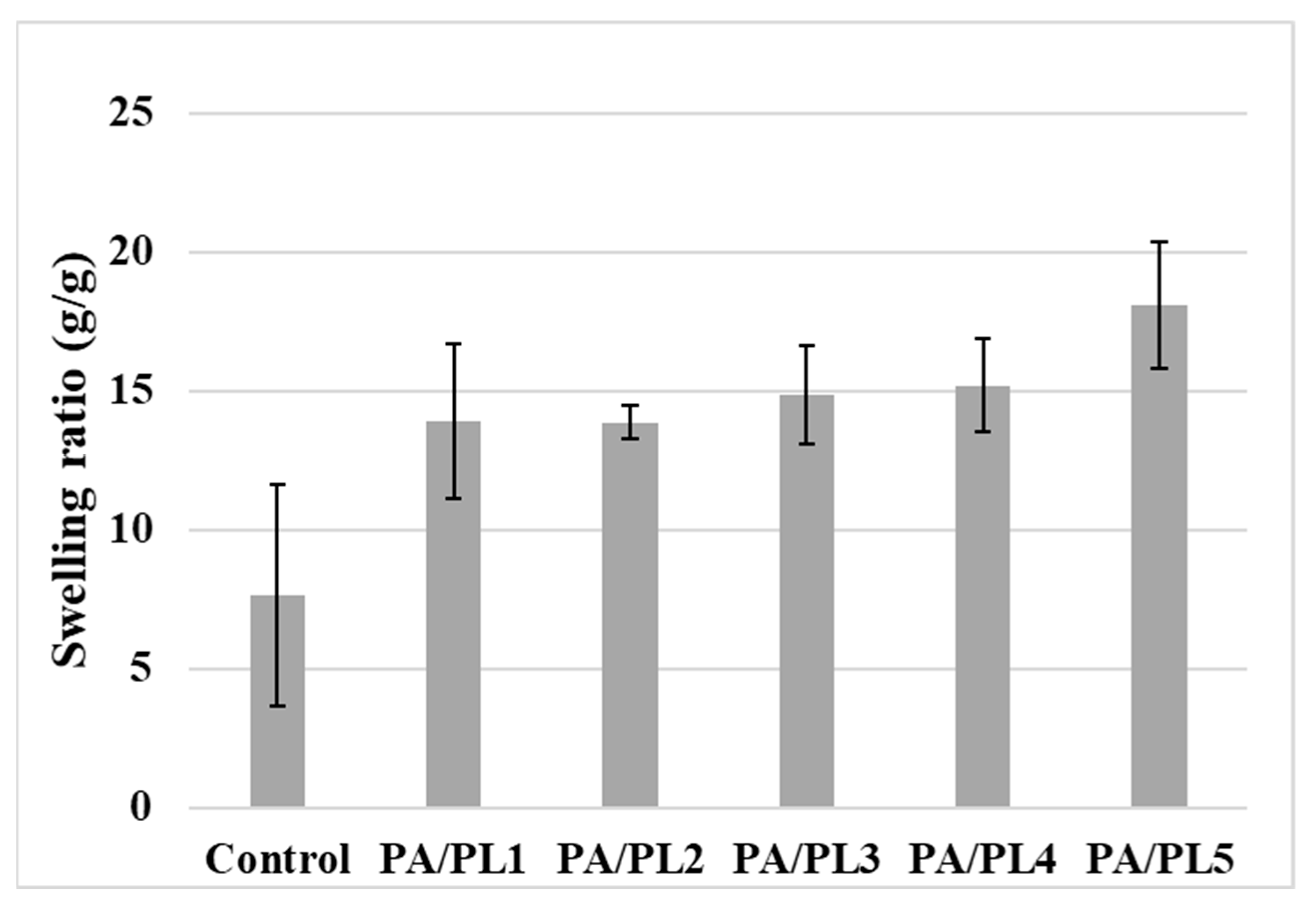

3.4.2. Water Absorption Test

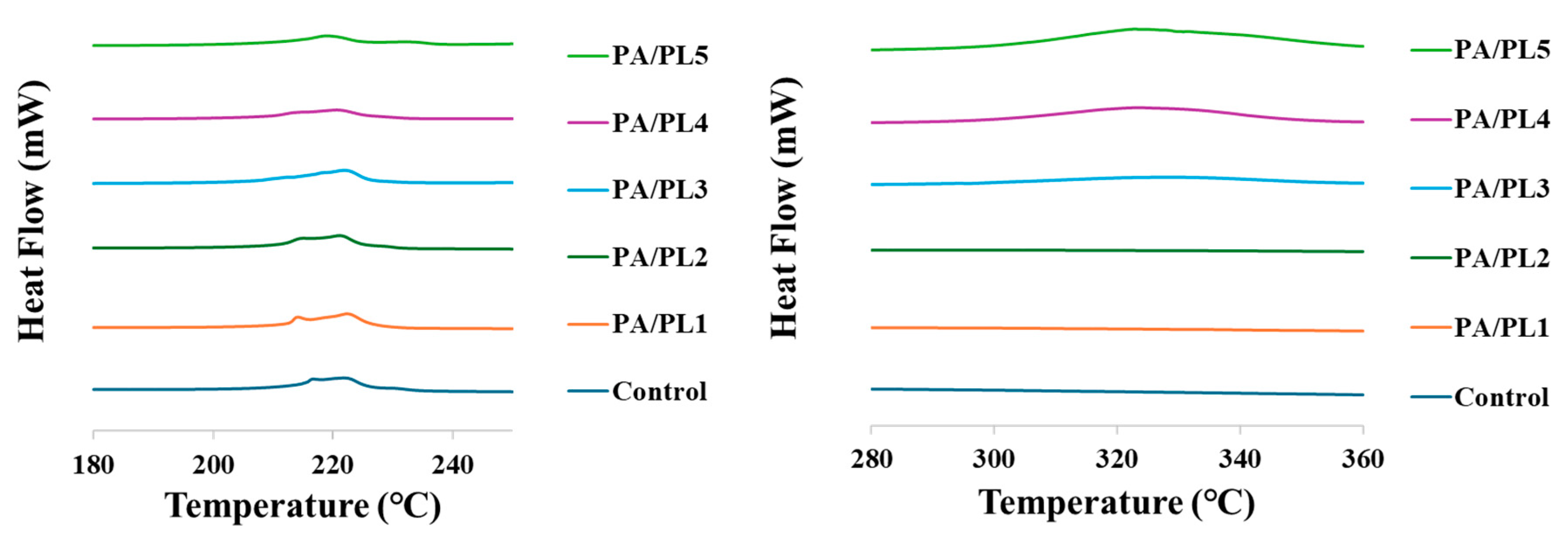

3.5. Thermal Analysis

3.6. Mechanical Analysis

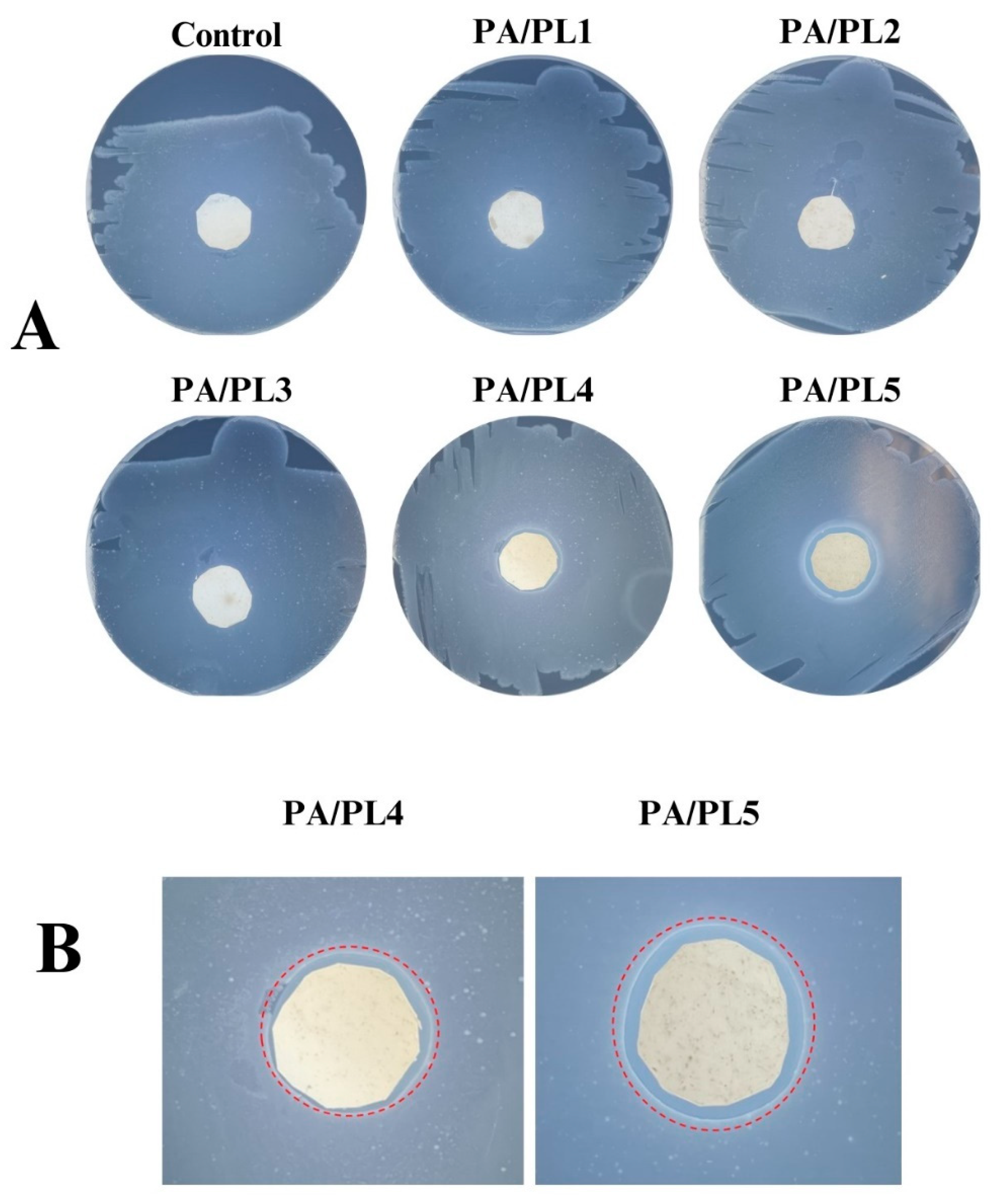

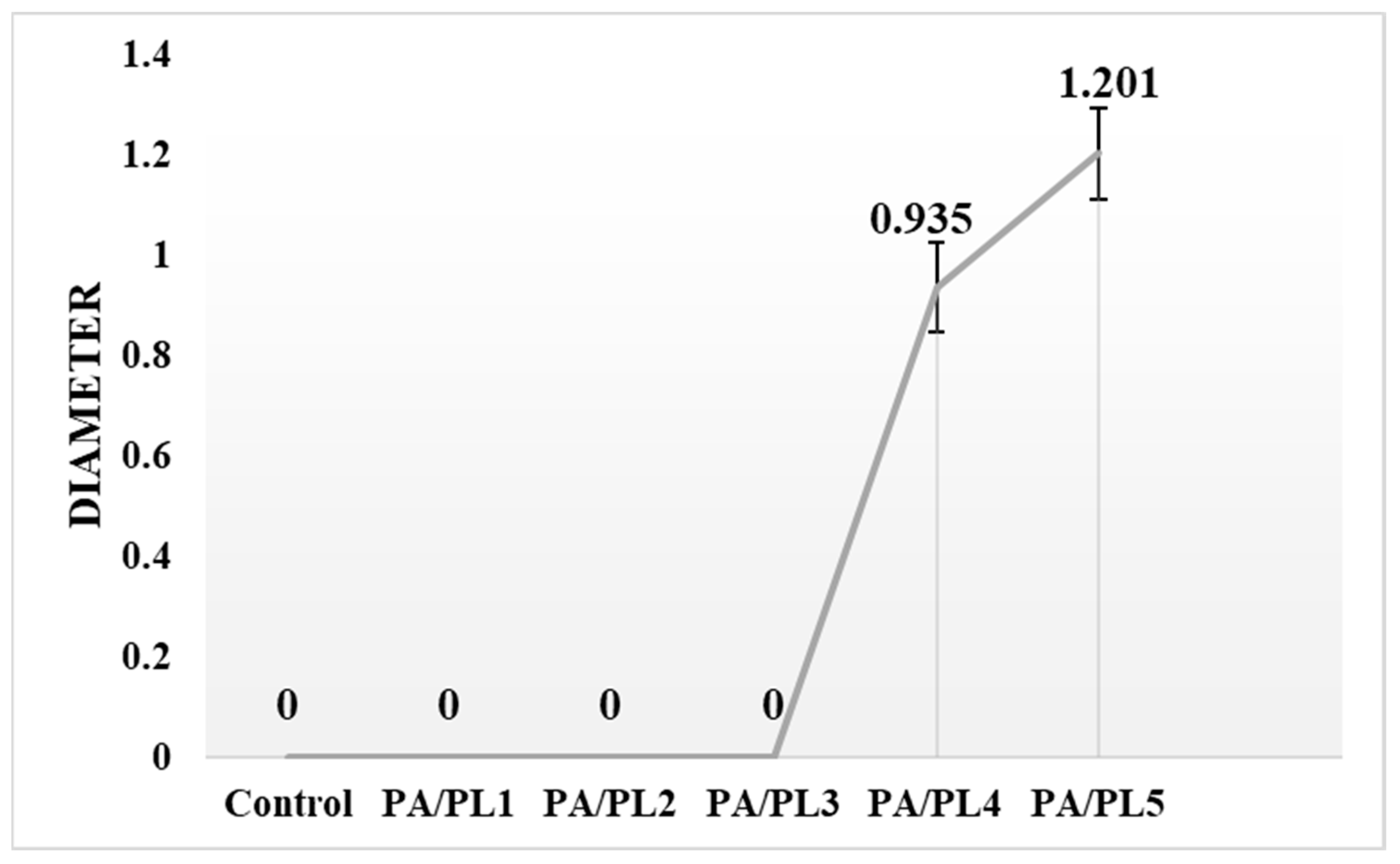

3.7. Antimicrobial Analysis

3.8. Long-Term Stability of Antimicrobial Property

4. Conclusions and Future Scope

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X. Fundamentals of Fiber Science; DEStech Publications, Inc.: Lancaster, PA, USA, 2014. [Google Scholar]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and electrospun nanofibers: Methods, materials, and applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef] [PubMed]

- Khan, W.S.; Asmatulu, R.; Ceylan, M.; Jabbarnia, A. Recent progress on conventional and non-conventional electrospinning processes. Fibers Polym. 2013, 14, 1235–1247. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, J.; Cheng, H.; Li, G.; Cho, H.; Jiang, M.; Gao, Q.; Zhang, X. Developments of advanced electrospinning techniques: A critical review. Adv. Mater. Technol. 2021, 6, 2100410. [Google Scholar] [CrossRef]

- Gupta, D. Functional clothing-Definition and classification. Indian J. Fiber Text. Res. 2011, 36, 321–326. [Google Scholar]

- Zhang, Y.; Xia, X.; Ma, K.; Xia, G.; Wu, M.; Cheung, Y.H.; Yu, H.; Zou, B.; Zhang, X.; Farha, O.K.; et al. Functional Textiles with Smart Properties: Their Fabrications and Sustainable Applications. Adv. Funct. Mater. 2023, 33, 2301607. [Google Scholar] [CrossRef]

- Riga, E.K.; Vöhringer, M.; Widyaya, V.T.; Lienkamp, K. Polymer-based surfaces designed to reduce biofilm formation: From antimicrobial polymers to strategies for long-term applications. Macromol. Rapid Commun. 2017, 38, 1700216. [Google Scholar] [CrossRef] [PubMed]

- Qiu, H.; Si, Z.; Luo, Y.; Feng, P.; Wu, X.; Hou, W.; Zhu, Y.; Chan-Park, M.B.; Xu, L.; Huang, D. The mechanisms and the applications of antibacterial polymers in surface modification on medical devices. Front. Bioeng. Biotechnol. 2020, 8, 910. [Google Scholar] [CrossRef] [PubMed]

- Stokes, K.; Peltrini, R.; Bracale, U.; Trombetta, M.; Pecchia, L.; Basoli, F. Enhanced medical and community face masks with antimicrobial properties: A systematic review. J. Clin. Med. 2021, 10, 4066. [Google Scholar] [CrossRef] [PubMed]

- Bhandari, V.; Jose, S.; Badanayak, P.; Sankaran, A.; Anandan, V. Antimicrobial finishing of metals, metal oxides, and metal composites on textiles: A systematic review. Ind. Eng. Chem. Res. 2022, 61, 86–101. [Google Scholar] [CrossRef]

- Karypidis, M.; Karanikas, E.; Papadaki, A.; Andriotis, E.G. A Mini-Review of Synthetic Organic and Nanoparticle Antimicrobial Agents for Coatings in Textile Applications. Coatings 2023, 13, 693. [Google Scholar] [CrossRef]

- Tao, Y.; Chen, X.; Jia, F.; Wang, S.; Xiao, C.; Cui, F.; Li, Y.; Bian, Z.; Chen, X.; Wang, X. New chemosynthetic route to linear ε-poly-lysine. Chem. Sci. 2015, 6, 6385–6391. [Google Scholar] [CrossRef] [PubMed]

- Patil, N.A.; Kandasubramanian, B. Functionalized polylysine biomaterials for advanced medical applications: A review. Eur. Polym. J. 2021, 146, 110248. [Google Scholar] [CrossRef]

- Shoji, S.; Hiroyoshi, M.; Toshiro, I.; Heiichi, S. Antimicrobial action of ε-poly-l-lysine. Jpn. J. Antibiot. 1984, 37, 1449–1455. [Google Scholar] [CrossRef]

- Li, M.; Tao, Y. Poly (ε-lysine) and its derivatives via ring-opening polymerization of biorenewable cyclic lysine. Polym. Chem. 2021, 12, 1415–1424. [Google Scholar] [CrossRef]

- Lin, L.; Xue, L.; Duraiarasan, S.; Haiying, C. Preparation of ε-polylysine/chitosan nanofibers for food packaging against Salmonella on chicken. Food Packag. Shelf Life 2018, 17, 134–141. [Google Scholar] [CrossRef]

- Wu, C.; Sun, J.; Lu, Y.; Wu, T.; Pang, J.; Hu, Y. In situ self-assembly chitosan/ε-polylysine bionanocomposite film with enhanced antimicrobial properties for food packaging. Int. J. Biol. Macromol. 2019, 132, 385–392. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Liu, Y.; Sun, Z.; Wang, D.; Wu, H.; Du, L.; Wang, D. Preparation and antibacterial properties of ε-polylysine-containing gelatin/chitosan nanofiber films. Int. J. Biol. Macromol. 2020, 164, 3376–3387. [Google Scholar] [CrossRef] [PubMed]

- Mayandi, V.; Wen Choong, A.C.; Dhand, C.; Lim, F.P.; Aung, T.T.; Sriram, H.; Dwivedi, N.; Periayah, M.H.; Sridhar, S.; Fazil, M.H.; et al. Multifunctional antimicrobial nanofiber dressings containing ε-polylysine for the eradication of bacterial bioburden and promotion of wound healing in critically colonized wounds. ACS Appl. Mater. Interfaces 2020, 12, 15989–16005. [Google Scholar] [CrossRef] [PubMed]

- Dias, Y.J.; Robles, J.R.; Sinha-Ray, S.; Abiade, J.; Pourdeyhimi, B.; Niemczyk-Soczynska, B.; Kolbuk, D.; Sajkiewicz, P.; Yarin, A.L. Solution-blown poly (hydroxybutyrate) and ε-poly-l-lysine submicro-and microfiber-based sustainable nonwovens with antimicrobial activity for single-use applications. ACS Biomater. Sci. Eng. 2021, 7, 3980–3992. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, C.; Liu, Z.; Pan, F.; Meng, R.; Bu, X.; Xing, H.; Deng, Y.; Guo, N.; Yu, L. Antibacterial activity and mode of action of ε-polylysine against Escherichia coli O157: H7. J. Med. Microbiol. 2018, 67, 838–845. [Google Scholar] [CrossRef]

- Wahid, F.; Wang, F.P.; Xie, Y.Y.; Chu, L.Q.; Jia, S.R.; Duan, Y.X.; Zhang, L.; Zhong, C. Reusable ternary PVA films containing bacterial cellulose fibers and ε-polylysine with improved mechanical and antibacterial properties. Colloids Surf. B Biointerfaces 2019, 183, 110486. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, I.; Pangule, R.C.; Kane, R.S. Antifouling coatings: Recent developments in the design of surfaces that prevent fouling by proteins, bacteria, and marine organisms. Adv. Mater. 2011, 23, 690–718. [Google Scholar] [CrossRef] [PubMed]

- Babutan, I.; Lucaci, A.D.; Botiz, I. Antimicrobial polymeric structures assembled on surfaces. Polymers 2021, 13, 1552. [Google Scholar] [CrossRef] [PubMed]

- Matulevicius, J.; Kliucininkas, L.; Martuzevicius, D.; Krugly, E.; Tichonovas, M.; Baltrusaitis, J. Design and characterization of electrospun polyamide nanofiber media for air filtration applications. J. Nanomater. 2014, 2014, 14. [Google Scholar] [CrossRef]

- Dinç, S.D.; Göktepe, F. Production and analysis of electrospun PA 6, 6 and PVA nanofibrous surfaces for filtration. Ind. Textila 2021, 72, 552–560. [Google Scholar] [CrossRef]

- Lencova, S.; Zdenkova, K.; Jencova, V.; Demnerova, K.; Zemanova, K.; Kolackova, R.; Hozdova, K.; Stiborova, H. Benefits of polyamide nanofibrous materials: Antibacterial activity and retention ability for Staphylococcus aureus. Nanomaterials 2021, 11, 480. [Google Scholar] [CrossRef] [PubMed]

- Lencova, S.; Svarcova, V.; Stiborova, H.; Demnerova, K.; Jencova, V.; Hozdova, K.; Zdenkova, K. Bacterial biofilms on polyamide nanofibers: Factors influencing biofilm formation and evaluation. ACS Appl. Mater. Interfaces 2020, 13, 2277–2288. [Google Scholar] [CrossRef] [PubMed]

- Lencova, S.; Stiborova, H.; Munzarova, M.; Demnerova, K.; Zdenkova, K. Potential of Polyamide Nanofibers With Natamycin, Rosemary Extract, and Green Tea Extract in Active Food Packaging Development: Interactions With Food Pathogens and Assessment of Microbial Risks Elimination. Front. Microbiol. 2022, 13, 857423. [Google Scholar] [CrossRef]

- Ushimaru, K.; Hamano, Y.; Katano, H. Antimicrobial activity of ε-poly-L-lysine after forming a water-insoluble complex with an anionic surfactant. Biomacromolecules 2017, 18, 1387–1392. [Google Scholar] [CrossRef]

- Ushimaru, K.; Morita, T.; Fukuoka, T. Bio-based, flexible, and tough material derived from ε-Poly-l-lysine and fructose via the maillard reaction. ACS Omega 2020, 5, 22793–22799. [Google Scholar] [CrossRef]

- Songer, J. Adopting Who Guidance on Fabric Masks for COVID-19. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3632531 (accessed on 10 July 2024).

- Zhang, W.; Li, J.X.; Tang, R.C.; Zhai, A.D. Hydrophilic and antibacterial surface functionalization of polyamide fabric by coating with polylysine biomolecule. Prog. Org. Coat. 2020, 142, 105571. [Google Scholar] [CrossRef]

- Ojha, S.S.; Afshari, M.; Kotek, R.; Gorga, R.E. Morphology of electrospun nylon-6 nanofibers as a function of molecular weight and processing parameters. J. Appl. Polym. Sci. 2008, 108, 308–319. [Google Scholar] [CrossRef]

- ASTM D7334-08; Standard Practice for Surface Wettability of Coatings, Substrates and Pigments by Advancing Contact Angle Measurement. ASTM International: Philadelphia, PA, USA, 2022.

- Almasian, A.; Giahi, M.; Fard, G.C.; Dehdast, S.A.; Maleknia, L. Removal of heavy metal ions by modified PAN/PANI-nylon core-shell nanofibers membrane: Filtration performance, antifouling and regeneration behavior. Chem. Eng. J. 2018, 351, 1166–1178. [Google Scholar] [CrossRef]

- Cay, A.; Miraftab, M. Properties of electrospun poly (vinyl alcohol) hydrogel nanofibers crosslinked with 1, 2, 3, 4-butanetetracarboxylic acid. J. Appl. Polym. Sci. 2013, 129, 3140–3149. [Google Scholar] [CrossRef]

- ASTM D882-09; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International: Philadelphia, PA, USA, 2009.

- AATCC TM147-2011; Test Method for Antibacterial Activity of Textile Materials: Parallel Streak Method. Microchem Laboratory: Round Rock, TX, USA, 2011.

- Koombhongse, S.; Liu, W.; Reneker, D.H. Flat polymer ribbons and other shapes by electrospinning. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 2598–2606. [Google Scholar] [CrossRef]

- Itoh, H.; Li, Y.; Chan, K.H.; Kotaki, M. Morphology and mechanical properties of PVA nanofibers spun by free surface electrospinning. Polym. Bull. 2016, 73, 2761–2777. [Google Scholar] [CrossRef]

- Şener, A.G.; Altay, A.S.; Altay, F. Effect of voltage on morphology of electrospun nanofibers. In Proceedings of the 2011 7th International Conference on Electrical and Electronics Engineering (ELECO), Bursa, Turkey, 1–4 December 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 1–324. [Google Scholar]

- Haider, A.; Haider, S.; Kang, I.K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Han, Y.; Shi, C.; Cui, F.; Chen, Q.; Tao, Y.; Li, Y. Solution properties and electrospinning of polyacrylamide and ε-polylysine complexes. Polymer 2020, 204, 122806. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Hsu, C.P. Infrared spectroscopy. In Handbook of Instrumental Techniques for Analytical Chemistry; Prentice-Hall, Inc.: Upper Saddle River, NJ, USA, 1997; pp. 247–283. [Google Scholar]

- Zhang, S.; Chen, H.; Shi, Z.; Liu, Y.; Liu, L.; Yu, J.; Fan, Y. Preparation of amino cellulose nanofiber via ε-poly-L-lysine grafting with enhanced mechanical, anti-microbial and food preservation performance. Ind. Crops Product. 2023, 194, 116288. [Google Scholar] [CrossRef]

- Rotter, G.; Ishida, H. FTIR separation of nylon-6 chain conformations: Clarification of the mesomorphous and γ-crystalline phases. J. Polym. Sci. Part B Polym. Phys. 1992, 30, 489–495. [Google Scholar] [CrossRef]

- Gunaratne, L.M.; Shanks, R.A. Multiple melting behaviour of poly (3-hydroxybutyrate-co-hydroxyvalerate) using step-scan DSC. Eur. Polym. J. 2005, 41, 2980–2988. [Google Scholar] [CrossRef]

- Asran, A.S.; Razghandi, K.; Aggarwal, N.; Michler, G.H.; Groth, T. Nanofibers from blends of polyvinyl alcohol and polyhydroxy butyrate as potential scaffold material for tissue engineering of skin. Biomacromolecules 2010, 11, 3413–3421. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Xu, Y.; Zhang, S.; Li, T.; Ramakrishna, S.; Liu, Y. Progress of improving mechanical strength of electrospun nanofibrous membranes. Macromol. Mater. Eng. 2020, 305, 2000230. [Google Scholar] [CrossRef]

- Pinho, E.; Magalhães, L.; Henriques, M.; Oliveira, R. Antimicrobial activity assessment of textiles: Standard methods comparison. Ann. Microbiol. 2011, 61, 493–498. [Google Scholar] [CrossRef]

- Tofail, S.A.; Bauer, J. Electrically Mediated Interactions at the Materials/Biology Interface. In Electrically Active Materials for Medical Devices; Imperial College Press: London, UK, 2016; pp. 1–18. [Google Scholar] [CrossRef]

- Monticello, R.A.; Askew, P.D. Antimicrobial textiles and testing techniques. In Russell, Hugo & Ayliffe’s: Principles and Practice of Disinfection, Preservation and Sterilization; Wiley-Blackwell: Hoboken, NJ, USA, 2013; pp. 520–529. [Google Scholar] [CrossRef]

| Sample Code | Polyamide-6 Concentration | ε-Poly-L-lysine Concentration |

|---|---|---|

| Control | 30% (w/v) of formic acid | 0 |

| PA/PL1 | 30% (w/v) of formic acid | 0.5% (w/w) of PA |

| PA/PL2 | 30% (w/v) of formic acid | 1.33% (w/w) of PA |

| PA/PL3 | 30% (w/v) of formic acid | 10% (w/w) of PA |

| PA/PL4 | 30% (w/v) of formic acid | 25% (w/w) of PA |

| PA/PL5 | 30% (w/v) of formic acid | 40% (w/w) of PA |

| PA/PL6 | 30% (w/v) of formic acid | 65% (w/w) of PA |

| PA/PL7 | 15% (w/v) of formic acid | 100% (w/w) of PA |

| Sample | Feed Rate | Supply Voltage | Spinning Distance | Collection Time |

|---|---|---|---|---|

| Control and PA/PL1 to PA/PL6 | 1 mL/h | 20 KV | 12 cm | 4 h |

| PA/PL7_A | 1 mL/h | 18 KV | 12 cm | 4 h |

| PA/PL7_B | 1 mL/h | 16 KV | 12 cm | 4 h |

| PA/PL7_C | 1 mL/h | 16 KV | 14 cm | 4 h |

| Sample Code | Diameter (Microns) |

|---|---|

| Control | 0.22 ± 0.14 ab |

| PA/PL1 | 0.18 ± 0.10 ab |

| PA/PL2 | 0.16 ± 0.05 b |

| PA/PL3 | 0.18 ± 0.05 ab |

| PA/PL4 | 0.21 ± 0.05 ab |

| PA/PL5 | 0.43 ± 0.07 c |

| PA/PL6 | 1.06 ± 0.50 d |

| PA/PL7_A | 0.24 ± 0.05 ab |

| PA/PL7_B | 0.26 ± 0.07 ab |

| PA/PL7_C | 0.28 ± 0.12 a |

| Sample Code | Average Static Water Contact Angle | Average Swelling Ratio (g/g) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| Control | 82.44 ± 9.72 a | 7.63 ± 3.98 a | 0.36 ± 0.03 a | 3.00 ± 0.84 a |

| PA/PL1 | 40.44 ± 1.59 b | 13.92 ± 2.79 ab | 0.33 ± 0.21 a | 7.83 ± 3.85 b |

| PA/PL2 | 18.25 ± 4.02 c | 13.87 ± 0.61 ab | 0.53 ± 0.05 a | 6.46 ± 1.19 ab |

| PA/PL3 | 0 d | 14.86 ± 1.75 ab | 0.72 ± 0.26 ab | 5.60 ± 1.01 ab |

| PA/PL4 | 0 d | 15.20 ± 1.69 ab | 0.75 ± 0.19 ab | 5.13 ± 0.40 ab |

| PA/PL5 | 0 d | 18.10 ± 2.29 b | 1.02 ± 0.25 b | 2.33 ± 0.50 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Purandare, S.; Li, R.; Xiang, C.; Song, G. Development of Innovative Composite Nanofiber: Enhancing Polyamide-6 with ε-Poly-L-Lysine for Medical and Protective Textiles. Polymers 2024, 16, 2046. https://doi.org/10.3390/polym16142046

Purandare S, Li R, Xiang C, Song G. Development of Innovative Composite Nanofiber: Enhancing Polyamide-6 with ε-Poly-L-Lysine for Medical and Protective Textiles. Polymers. 2024; 16(14):2046. https://doi.org/10.3390/polym16142046

Chicago/Turabian StylePurandare, Saloni, Rui Li, Chunhui Xiang, and Guowen Song. 2024. "Development of Innovative Composite Nanofiber: Enhancing Polyamide-6 with ε-Poly-L-Lysine for Medical and Protective Textiles" Polymers 16, no. 14: 2046. https://doi.org/10.3390/polym16142046

APA StylePurandare, S., Li, R., Xiang, C., & Song, G. (2024). Development of Innovative Composite Nanofiber: Enhancing Polyamide-6 with ε-Poly-L-Lysine for Medical and Protective Textiles. Polymers, 16(14), 2046. https://doi.org/10.3390/polym16142046