Abstract

In this study, pull-out tests were conducted to investigate the bond behavior of a rebar embedded in cementitious composites with polyvinyl alcohol (PVA) fibers and carbon nanotubes (CNTs). In the cementitious composites, the binder consisted of ordinary Portland cement, blast furnace slag, and fly ash, with a weight ratio of 39.5, 21.0 and 39.5%, respectively, while the nonbinder consisted of quartzite sand, lightweight aggregate, superplasticizer, and shrinkage-reducing admixture. The water/binder ratio and volume fractions of the PVA fibers were 32.9% and 2.07%, respectively. In the test program, the rebar diameter (D13, D16, and D19) and CNTs mix ratio (0.0, 0.1, 0.2, and 0.3 wt.%) were considered as the test variables. The test results showed that the bond strength of a rebar increased as the rebar diameter decreased or as the CNTs mix ratio increased. Based on the test results, a new, simple model has been proposed with consideration of the rebar diameter, as well as the CNTs mix ratio. Comparing the test results, it was investigated that the proposed model generally represented the bond behavior well, including the bond strength and the corresponding slip of a rebar embedded in PVA cementitious composites, with or without CNTs.

1. Introduction

Due to the demand for securing the safety of large structures, many studies are being conducted to improve the structural performance of reinforced concrete. In line with these demands, research on fiber-reinforced concrete has been actively conducted to overcome the shortcomings of concrete exhibiting brittle behavior after cracking. Owing to fibers bridging a crack, fiber-reinforced concrete can exhibit ductile behavior, even after cracking, with either tension softening behavior or strain hardening behavior [1]. In addition to improving the concrete performance after cracking, research on improving the concrete matrix itself has recently been conducted by adding carbon nanotubes (CNTs) to the concrete mixture. Recently, several types of research have been conducted to utilize the advantages of fibers and CNTs together. However, most of the research has focused on the material properties of fiber-reinforced concrete with CNTs.

To use fiber-reinforced concrete with CNTs as a structural member, it is necessary to investigate the interaction between the reinforcing bars and fiber-reinforced concrete with CNTs. In this study, as a part of the research for the structural behavior of CNTs-mixed fiber-reinforced concrete with reinforcing bars, the bond behavior of the steel rebar embedded in the PVA cementitious composites with CNTs is investigated through an extensive pull-out test program. Based on the test results, a conventional model for the bond stress-slip behavior of a rebar is modified to reflect the effect of PVA cementitious composites with CNTs. The test results and the proposed model will help the investigations of the effect of CNTs on structural behaviors, such as rebar development length, tension-stiffening behavior, etc.

2. Literature Review

2.1. Literature Review on Fiber-Reinforced Concrete

To apply fiber-reinforced concrete as a structural member, several models have been developed to describe the material behaviors. Some research groups have developed a tensile stress-crack width relationship to represent the tensile behavior of fiber-reinforced concrete. Martie et al. [2] proposed the tensile model for fiber reinforced concrete, based on the uniform bond stress along a fiber. Voo and Foster [3] proposed the Variable Engagement Model (VEM) by introducing the engagement length of a fiber so that the tensile behavior of concrete reinforced with straight steel fibers was reasonably predicted. Leutbecher and Fehling [4] presented a model considering the effect of fibers on crack widths in steel fiber-reinforced concrete containing rebars. Stroeven [5] developed a formulation that could consider fiber type on the tensile behavior. Lee et al. [6,7] proposed the Diverse Embedment Model (DEM), considering the mechanical anchorage effect of end-hooked steel fibers, as well as the frictional bond behavior of fibers. Later, the DEM was simplified by eliminating the double numerical integration in the DEM [8]. Meanwhile, others have proposed compressive stress-strain relationships to represent the compressive behavior of fiber-reinforced concrete. Ezeldin and Balaguru [9] presented a compression model for fiber reinforced concrete based on the test results. Hsu and Hsu [10] also proposed an empirical equation to describe the compressive behavior of fiber-reinforced concrete. Someh and Saeki [11] proposed a model for steel fiber-reinforced concrete under compression. Mansur et al. [12] conducted the compression test for high-strength fiber-reinforced concrete. Nataraja et al. [13] derived a simple analytical model to describe the compressive stress-strain response. Experimental programs [14,15,16] have also been actively conducted to investigate the tensile behavior of fiber-reinforced concrete with reinforcing bars. Based on the test results, Lee et al. [17] proposed the tension stiffening model, which was beneficial for analyzing the tensile behavior of fiber-reinforced concrete members with reinforcing bars. Recently, with the development of a rigorous analysis procedure, it has become possible to predict the nonlinear structural behavior of fiber-reinforced concrete members or structures [18,19,20].

2.2. Literature Review on Cementitious Composites with CNTs

Types of CNTs are generally divided into two groups: single-walled CNTs (SWCNTs) and multi-walled CNTs (MWCNTs). Kang et al. [21] showed the differences between SWCNTs and MWCNTs in their characteristics, including diameter, length, modulus of elasticity, tensile strength, electrical conductivity, and heat conductivity, as shown in Table 1. The table shows that MWCNTs were relatively better in terms of their tensile strength than SWCNTs, while SWCNTs were better in thermal and electrical conductivity than MWCNTs. Many studies [22,23,24,25,26] also investigated the effect of CNTs on cement composite or concrete performance when CNTs were additionally mixed. Silvestro and Gleize [22] reviewed the existing studies regarding the effect of CNTs on the compressive strength and flexural strength of cement-based material. They investigated, through the literature, whether incorporating CNTs increased the strength of cement-based materials if the CNTs were adequately dispersed. Through an experimental program, Cerro-Prada et al. [23] showed that the flexural and compressive strength increased as the MWCNTs mix ratio increased. Amin et al. [24] investigated, through an experimental program, that the addition of 0.1 wt.% of CNTs showed an improvement in the thermal and mechanical properties of the hardened Homra/OPC blended cement composites. Zhang et al. [25] investigated the effect of CNTs on the thermal and electrical conductivity of cementitious composites. They showed that the thermal resistivity increased up to a specific temperature as the CNTs were additionally mixed. Nam et al. [26] showed that the EM-wave-shielding performance was enhanced when MWCNTs were mixed into the cement matrix.

Table 1.

Differences between SWCNTs and MWCNTs.

Lee et al. [27] stated that the mechanical properties of concrete with steel fibers and CNTs were superior to those with only steel fibers or CNTs. Azhari and Banthia [28] noted that the electrical conductivity of carbon fiber-reinforced cementitious composites with MWCNTs considerably increased, and similar results have been reported by Park et al. [29]. Jang et al. [30] investigated the strain-detecting of cementitious composite with synthetic polyethylene (PE) and steel fibers. They found that adding MWCNTs improved the self-sensing performance for the strain measurements. Lee et al. [31] showed that the compressive behavior of polyvinyl alcohol (PVA) fiber-reinforced concrete was enhanced by adding CNTs to the mixture. Nuaklong et al. [32] demonstrated significant improvements in the residual compressive and flexural strengths around the heating temperature of 400 ℃ for cementitious composites with both PP fibers and MWCNTs.

2.3. Literature Review on the Bond Behavior of a Rebar

Many studies [33,34,35,36,37] have proposed simple models to represent the bond stress-slip behavior of deformed steel rebars embedded in ordinary concrete. This section reviews and discusses the conventional bond stress-slip models, followed by their applicability to PVA cementitious composites with CNTs. It is noted that bond behavior with the pull-out failure is discussed here because no splitting crack was observed in the test program of this study.

2.3.1. CEB-FIP Model Code 2010 [37]

The CEB-FIP Model Code 2010 (MC10) [37] adopted the bond stress-slip model for the deformed steel rebar proposed by Eligehausen et al. [35]. The MC10 bond stress-slip model consists of three phases: an ascending branch, plateau, and descending branch. For the case with a good bond condition under a pullout failure, each phase is expressed as the following equations:

where MPa, , , , is the clear distance between ribs, , and is the mean of the concrete compressive strength.

2.3.2. Soroushian et al. [34]

Soroushian and Choi [33] conducted the pullout tests for a rebar embedded in confined concrete. The test program considered 16 mm, 22 mm, and 25 mm diameter deformed steel rebars embedded in concrete with a compressive strength of 30 MPa. Through the tests, they investigated whether the bond strength decreased as the rebar diameter increased. With the additional pullout test to consider high-strength concrete, Soroushian et al. [34] proposed the bond stress-slip model for the ascending part with the following equation:

where MPa, , , , and α = 0.4.

In contrast to the MC10 model, this model considered the rebar diameter in the bond strength.

2.3.3. Harajili et al. [36]

Harajili et al. [36] proposed the bond stress-slip model for a rebar embedded in plain or fiber-reinforced concrete. In contrast to the models above, they proposed the model considering the effect of the rebar diameter on the slip. They adopted the same format as the MC10 model, but they considered different values, with MPa, MPa, mm, mm, mm, , and is the clear distance between the ribs.

2.3.4. Comparison of Existing Models

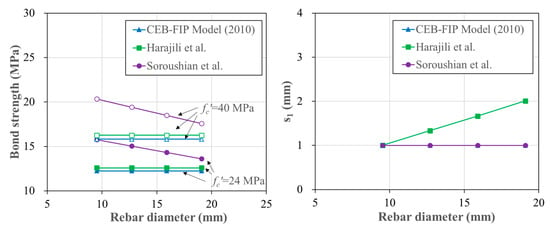

Figure 1 compares the existing models for the bond strength and its corresponding slip for a rebar embedded in concrete. To investigate the effect of the concrete compressive strength, 24 and 40 MPa of concrete compressive strengths were considered in the comparison. As the figure shows, Soroushian et al. presented higher bond strength than the other two models when the rebar diameter was smaller than 20 mm. They reported that the bond strength decreased as the rebar diameter increased. On the other hand, MC10 and Harajili et al. did not reflect the effect of the rebar diameter on the bond strength. For the slip corresponding to the bond strength (), the effect of the concrete compressive strength was ignored in the tree models. Regarding the effect of the rebar diameter, Harajili et al. considered that the increased as the rebar diameter increased, while the other two models presented that the was constant to 1.0 mm regardless of the rebar diameter.

Figure 1.

Comparison of the previous models on the bond strength and the slip corresponding to the bond strength [34,36,37].

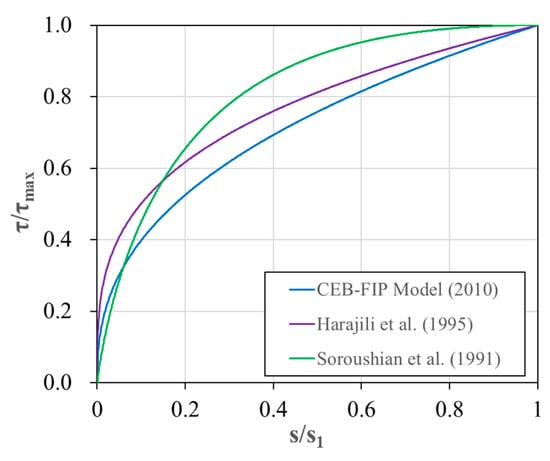

The comparison of the bond stress-slip responses until the bond strength is reached is depicted in Figure 2. To standardize the results, the bond stress and slip are normalized by the bond strength and its corresponding slip, respectively. The results show that the MC10 model and the model proposed by Harajili et al. exhibit similar trends in their curve shapes. However, the results of Harajili et al. reveal higher bond stress, with α = 0.3, which is a lower value than the α value of 0.4 in the MC10 model. On the other hand, the model proposed by Soroushian et al. displays a less steep initial slope compared to the other models, but exhibits higher bond stress values beyond the range of s/s1 = 0.1~0.2.

Figure 2.

Normalized bond stress-slip curve for the ascending part of the previous models [34,36,37].

3. Research Significance

Recently, several types of research have been conducted to investigate the material behavior of cementitious composites with fibers and CNTs together in order to take all of the advantages before and after cracking. However, there are few studies on the bond behavior of a rebar in cementitious composites containing both fibers and CNTs. In this study, an experimental program was conducted to investigate the bond behavior of a rebar embedded in PVA cementitious composites with CNTs. From the pull-out test, the bond stress-slip behavior was measured so that the effect of the rebar diameter and CNTs mix ratio could be evaluated. Based on the test results, a new simple bond stress-slip model has been proposed. As the interaction between the cementitious composites and the rebar is significant in the structural behavior, the test results and the proposed model will help to predict the structural behavior of PVA cementitious composites with CNTs.

4. Test Program

4.1. Materials

The mix proportions of the PVA cementitious composites used in this study are summarized in Table 2. In the mix proportions, the binder consisted of Ordinary Portland Cement (OPC), blast furnace slag (BFS), and fly ash (FA) with a weight ratio of 39.5%, 21.0%, and 39.5%, respectively. The nonbinder consisted of quartzite sand (particle size 0.1~1.7 mm), lightweight aggregate (LA), superplasticizer (SP), and shrinkage-reducing admixture (SRA). The water/binder ratio and volume fractions of the PVA fibers were 32.9%, and 2.07%, respectively, which were constant throughout all of the test specimens. The geometric configuration and mechanical properties of the PVA fibers are presented in Table 3. To investigate the effect of the CNTs on the bond behavior of a rebar, four CNTs mix ratios were considered, from 0.0 wt.% to 0.3 wt.% to the binders, referred to in the previous studies [38,39,40,41,42]. The mix proportions were named CNT-0.0 through CNT-0.3 according to the CNTs’ mix ratio.

Table 2.

Mix proportions of PVA cementitious composites with CNTs.

Table 3.

Properties of PVA fibers.

In this study, MWCNTs were used as they are easier to produce, relatively inexpensive, and more dispersed than SWCNTs [38,43]. In addition, MWCNTs have better mechanical properties than SWCNTs [44]. To suppress aggregation by van der Waal`s force and achieve the uniform dispersion of the CNTs, a 5% polycarboxylate superplasticizer was added to the 3% CNTs aqueous solution and sonicated, as presented in the literature [38,45].

Three rebar sizes of D13, D16, and D19 were considered in the test program to investigate the effect of a rebar size. All of the rebars have a grade of SD400 according to the Korean standard (KS) [46]. The geometric properties of the rebar, including the cross-sectional area, perimeter, and the distance and height of the ribs, are presented in Table 4.

Table 4.

Properties of steel rebars.

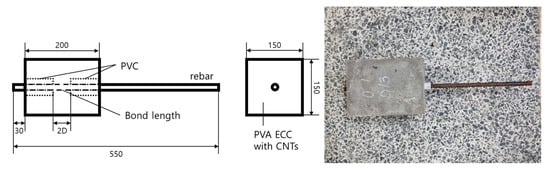

4.2. Pullout Test Specimens

To investigate the bond behavior of a deformed steel rebar embedded in the PVA cementitious composites with CNTs, the pullout test was conducted considering the test variables, the rebar diameter and the CNTs mix ratio. For the pull-out test, 150 × 150 × 200 mm prismatic specimens were fabricated, as shown in Figure 3. As presented in the figure, the embedment length was two times the rebar diameter placed in the specimen’s center. The PVC pipe was implemented to make the unbonded part of the rebar, as the previous studies adopted for the pull-out test [47,48,49].

Figure 3.

Pullout test specimen and its geometrical configuration.

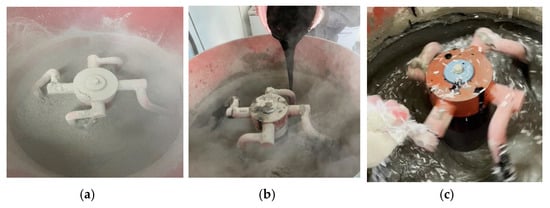

4.3. Fabrication

When the specimens were fabricated, the cementitious composites were first dry-mixed. Then, water, 3% CNTs aqueous solution, and PVA fibers were added and mixed in the order presented in Figure 4. It is noted that the mix order was referred to in the previous study [31], so that the workability was attained even after the CNTs were added.

Figure 4.

Mix procedure of PVA cementitious composites with CNTs. (a) Dry mix, (b) Addition of water and CNTs, (c) Addition of PVA fibers.

The pullout test specimens were fabricated following the order presented by Yoo and Shin [50]. First, the molds were made with wood, and holes were drilled in the middle of both sides in order to place the steel rebar. When the steel rebar was placed in the mold, the embedment length was set to two times the rebar diameter by covering the unbonded parts with PVC pipes. The embedded part was placed in the center of the specimen. Then, the PVA cementitious composites with CNTs were filled in the mold. Three specimens were fabricated for each test variable to obtain reliable test results. ϕ100 × 200 mm cylindrical specimens, to measure the compressive behavior, were also prepared in the same order. All of the specimens were vibrated on a vibration table, then dry-cured for 28 days.

Table 5 presents the slump and slump flow measured after mixing the PVA cementitious composites with CNTs. As presented in the table, both the slump and slump flow decreased as the CNTs mix ratio increased. It can be inferred that the lower workability was mainly due to the high surface area and surface tension property of the CNTs [51,52,53].

Table 5.

Slump and slump flow.

4.4. Pull-Out Test Set-Up and Procedure

Figure 5 shows the setup for the pull-out test. As presented in the figure, two linear variable differential transducers (LVDTs) were attached to the free end of the rebar and the top surface of the specimen to measure the free-end slip. In contrast, one LVDT was attached to the rebar at the loaded end. The pull-out load was applied to the rebar at a rate of 0.5 mm/min using a 2000 kN capacity universal testing machine (UTM) to ensure static loading. The pullout test was conducted until the applied load decreased to 50% of the peak load due to the limitation of the test equipment configuration.

Figure 5.

Pull-out test setup.

5. Test Results

5.1. Material Properties

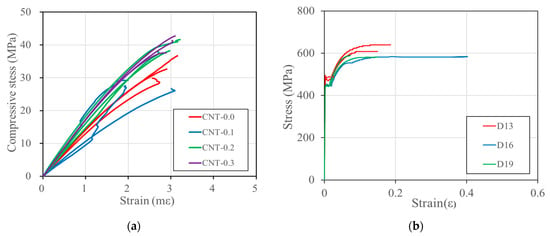

Table 6 presents the material properties of the PVA cementitious composites with CNTs. It is noted that the material properties were measured through the compression test, which followed the procedure presented in ASTM C39 [54]. During the compression tests, the strains were measured through two LVDTs attached to the side of the cylindrical specimen so that the modulus of elasticity could be evaluated from the stress-strain responses, as presented in Figure 6a. As presented in the table, it was observed that the compressive strength and the modulus of elasticity generally increased as the CNTs ratio increased, with the exception of CNT-0.1. On the other hand, the strain corresponding to the compressive strength was not much affected by the CNTs mix ratio. The direct tension test results of the rebars are presented in Figure 6b. The yield strength and the elastic modulus are evaluated from the stress-strain responses, as presented in Table 6.

Table 6.

Summary of the compression test results.

Figure 6.

Stress-strain relations of the materials. (a) PVA cementitious composites with CNTs, (b) the rebars.

5.2. Pullout Test Results

5.2.1. Failure Mode

Figure 7 shows one of the specimens after the pull-out test. As seen in the figure, all of the specimens exhibited pull-out failure, with neither a splitting crack nor rebar yielding. This is mainly due to the short embedment length of the rebar, the sufficiently thick cementitious composite cover thickness, and the PVA fibers.

Figure 7.

Pull-out test failure observed after the test.

5.2.2. Bond Stress-Slip Responses

From the load-slip responses, measured through the pull-out test, the bond stress-slip responses were evaluated. The following equation evaluated the bond stress:

where is bond stress (MPa), is applied load (N), is the rebar diameter (mm), and is the embedment length (mm). It is noted that the slip measured at the loaded end was considered in the same manner as conducted by Wardeh et al. [55] because the slip at the free end exhibited inconsistent results.

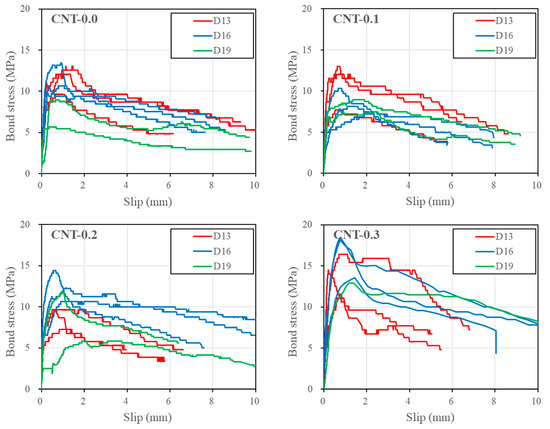

Figure 8 shows the bond stress-slip responses of a rebar evaluated from the pull-out test results. When one of the three test results was too scattered from the other two, it was excluded from the analysis of the test results. As seen in the figure, the bond stress-slip responses could appear to be divided into three phases: ascending, plateau, and descending. However, some specimens exhibited a plateau of very short duration.

Figure 8.

Bond stress-loaded end slip responses of a rebar embedded in PVA cementitious composites with CNTs.

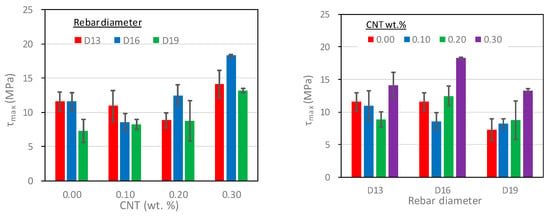

5.2.3. Bond Strength

The bond strengths () evaluated from the bond stress-slip responses are presented in Table 7 and Figure 9. It is noted that the bond strengths were evaluated to the average of the test results of two or three specimens. As seen in the table and figure, the bond strength increased as the CNT mix ratio increased, with the exception of CNT-0.10, which exhibited relatively low compressive strength. Therefore, it can be seen that the bond strength is highly affected by the compressive strength of PVA cementitious composites. In addition, the bond strength decreased as the rebar diameter increased. This tendency was consistent with the test results presented by many studies [52,56] and the analytical model [33].

Table 7.

Summary of the pullout test results.

Figure 9.

The effect of CNTs mix ratio and rebar diameter on the rebar bond strength.

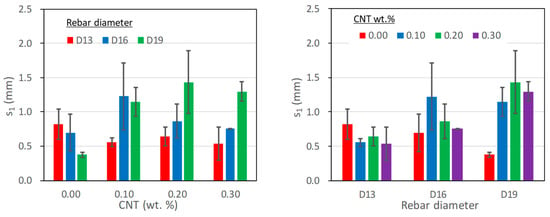

5.2.4. Slip Corresponding to the Bond Strength

The slips corresponding to the bond strengths () are presented in Table 7 and Figure 10. As compared in the table and figure, except for the specimens without CNTs, the slip corresponding to the bond strength generally increased as the rebar diameter increased, which was consistent with the test results presented by many other studies [52,56] and the analytical model [33]. On the other hand, it was observed that the effect of the CNTs mix ratio on the slip upon the bond strength was not consistent.

Figure 10.

The effect of CNTs mix ratio and rebar diameter on the slip corresponding to the bond strength.

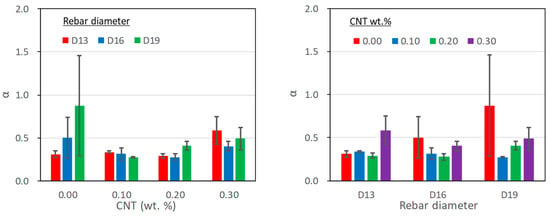

5.2.5. α Coefficient

To represent the ascending part of the bond stress-slip response, several models [35,36,37] adopted the type of the following equation:

where is a coefficient for the shape of the ascending curve.

Table 7 and Figure 11 present the coefficient α, which was evaluated through regression with the least square error when comparing the test results and equation (4) for the ascending part. It is noted that it is chosen between 0 to 1; a smaller value is closer to higher initial stiffness in the bond stress-slip response. As the table and figure shows, the effect of the CNTs mix ratio and the rebar diameter could have been more obvious on the α coefficient. The average value for the entire test results was calculated at 0.42, slightly larger than the 0.4 generally adopted for the bond behavior of a deformed rebar embedded in ordinary concrete [37]. If the test result with the D19 rebar and no CNTs is excluded, the coefficient was averaged to 0.38. Therefore, the coefficient for the PVA cementitious composite with CNTs can be similar to that for ordinary reinforced concrete.

Figure 11.

The effect of CNTs mix ratio and rebar diameter on coefficient.

6. Proposed Model and Its Verification

6.1. Proposed Model

As the test results showed that the bond strength of a rebar in PVA cementitious composite with CNTs decreased with the increase in the rebar diameter, this study assumes that the bond strength is inversely proportional to the rebar diameter. With the consideration of the square root of the concrete compressive strength, similar to the MC10 [37] and Harajili’s models [36], the following equation has been developed:

It is noted that the coefficient 28 in the above equation was derived through regression based on the least square error method for the differences in the bond strengths between the model predictions and the test results.

This study adopted four piecewise equations similar to MC10 and Harajili’s models to represent the bond stress-slip relationship. The proposed bond stress-slip model is expressed with the following equations:

In the above equation, based on the test results in this study, it was suggested that MPa, mm, mm, mm, and . As a result of the test in this study, and are smaller than those of Harajili et al. [36], considering that the slip corresponding to the bond strength and the plateau was smaller for the rebar embedded in PVA cementitious composites with CNTs than those of the ordinary reinforced concrete.

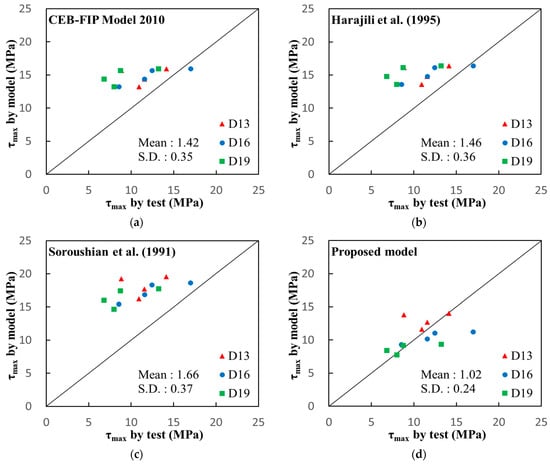

6.2. Verifications

The bond strengths predicted by the proposed model have been compared with the test results, as presented in Table 8 and Figure 12. The previous models have also been compared in the table and figure. As presented in the table and figure, it was investigated that the previous models significantly overestimated the bond strength of the rebar embedded in the PVA cementitious composites with or without CNTs. The ratio of the predicted values to the test results averaged as 1.42, 1.46, and 1.66 for MC10, Harajili et al., and Soroushian et al., respectively. It is inferred that the previous models overestimated the bond strength because there was no coarse aggregate in the PVA cementitious composites. On the other hand, the proposed model showed good agreement with the test results, with a mean of 1.02 and a standard deviation of 0.24 for the ratio of the predicted values to the test results. Although there was some deviation from the test results, the proposed model showed a much smaller standard deviation than the previous models. In more detail, the proposed model reflected the effect of the rebar diameter on the rebar bond strength well. In the proposed model, the effect of the CNTs’ mix ratio on the bond strength was taken into account with the concrete compressive strength. Therefore, it can be concluded that the proposed model predicted the actual bond strength of a rebar embedded in PVA cementitious composites with or without CNTs well.

Table 8.

Comparison on the bond strength between the test results and the models.

Figure 12.

Comparison of the test results and the models on the bond strength of rebar embedded in PVA cementitious composites with CNTs: (a) CEB-FIP Code Model 2010 [37] (b) Harajili et al. (1995) [36] (c) Soroushian et al. (1991) [34] (d) Proposed model.

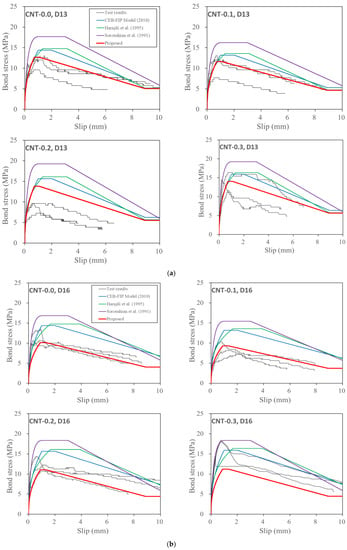

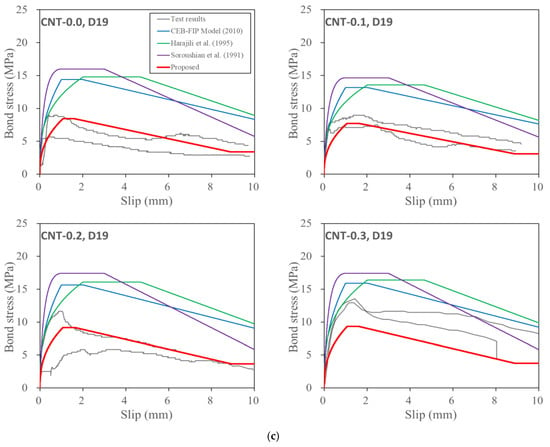

For the detailed investigation, the bond stress-slip responses measured through the test were compared with the proposed and previous models. As is compared in Figure 13, it was investigated that the previous models overestimated the bond stress overall, and they overestimated more with the increase in the rebar diameter. On the other hand, the proposed model represented the actual bond stress-slip response, in general, well, although there was some deviation between the predictions and the test results. Therefore, the proposed model helps to predict the bond behavior of a rebar embedded in PVA cementitious composites with CNTs.

Figure 13.

Comparison of the test results and bond stress-slip model: (a) D13 (b) D16 (c) D19, [34,36,37].

7. Conclusions

In this study, a total of 36 pull-out specimens were tested to investigate the bond behavior of a rebar embedded in PVA cementitious composites with or without CNTs. The test program considered the rebar diameter and CNTs mix ratio as the test variables. From the test results, the effect of the test variables was investigated on the bond stress-slip behavior, including the bond strength and the corresponding slip. To reasonably represent the bond behavior of a rebar embedded in PVA cementitious composites, a new simple proposed model has been proposed in this study. The proposed model has been verified through the comparison with the test results. The main results obtained through this study can be summarized as follows:

- All of the specimens exhibited pull-out failure with neither a splitting crack nor rebar yielding, so the bond behavior of the rebar embedded in the PVA cementitious composites could be rigorously measured.

- Regarding the effect of the rebar, the bond strength of the rebar embedded in PVA cementitious composites increased as the rebar diameter increased. Meanwhile, it was demonstrated that the slip corresponding to the bond strength increased as the rebar diameter increased.

- The bond strength of the rebar embedded in PVA cementitious composites generally increased with the increasing CNTs mix ratio because the compressive strength of the PVA cementitious composites was increased. Therefore, it can be concluded that the bond strength of a rebar embedded in PVA cementitious composites can be improved with CNTs.

- The existing models overestimated the test results for the bond behavior of the rebar embedded in PVA cementitious composites with no CNTs. The main reason for the overestimation is inferred to be because the existing models are designated for the bond behavior of a rebar embedded in ordinary concrete containing coarse aggregate. In contrast, the PVA cementitious composites contain no coarse aggregate.

- By comparing the test results and the existing models, it was shown that the existing models generally overestimated the bond strength of a rebar embedded in PVA cementitious composites by 42~66% as they were initially designated for a rebar embedded in ordinary concrete with coarse aggregated. In addition, the previous models generally overestimated the bond stress of a rebar embedded in cementitious composites, and this tendency was more severe as the rebar diameter increased.

- Through the regression with the test results, a new simple model has been proposed to represent the bond stress-slip behavior of a rebar embedded in PVA cementitious composites with or without CNTs. The bond strength and the corresponding slip were evaluated in the proposed model considering the rebar diameter. The effect of the CNTs’ mix ratio was considered with the compressive strength of the PVA cementitious composites. Through the comparison with the test results, the proposed model predicted the actual bond strength of the rebar well, with an average of 1.02 and a standard deviation of 0.24 for the ratio of the model predictions to the test results.

- It is expected that the results of this study can be used in research on the anchorage length of a rebar and crack control in PVA cementitious composites with or without CNTs. In addition, this study can be helpful in the relevant research area on the structural behavior of PVA cementitious composites with or without CNTs.

Author Contributions

Conceptualization, S.-C.L. and S.-W.Y.; methodology, D.L. and S.-C.L.; software, D.L.; validation, D.L. and S.-C.L.; formal analysis, D.L. and S.-C.L.; investigation, D.L. and S.-C.L.; resources, S.-W.Y.; data curation, D.L. and S.-W.Y.; writing—original draft preparation, D.L.; writing—review and editing, D.L. and S.-C.L.; visualization, D.L.; supervision, S.-C.L. and S.-W.Y.; project administration, S.-C.L. and S.-W.Y.; funding acquisition, S.-C.L. and S.-W.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2020R1I1A3073831) and the Korea Agency for Infrastructure Technology Advancement (KAIA) grant funded by the Ministry of Land, Infrastructure and Transport (Grant 21NANO-B156177-02).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data including the test results can be accessed through the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Naaman, A.E.; Namur, G.G.; Alwan, J.M.; Najm, H.S. Fiber Pullout and Bond Slip I: Analytical Study. J. Struct. Eng. ASCE 1991, 117, 2769–2790. [Google Scholar] [CrossRef]

- Marti, P.; Pfyl, T.; Sigrist, V.; Ulaga, T. Harmonized Test Procedures for Steel Fiber-Reinforced Concrete. ACI Mater. J. 1999, 96, 676–685. [Google Scholar] [CrossRef]

- Voo, J.Y.L.; Foster, S.J. Variable Engagement Model for Fibre Reinforced Concrete in Tension; Uniciv. report no. r-420; University of New South Wales, School of Civil and Environmental Engineering: Sydney, Australia, 2003; p. 86. [Google Scholar]

- Leutbecher, T.; Fehling, E. Crack Width Control for Combined Reinforcement of Rebars and Fibers Exemplified by Ultra-High-Performance Concrete. In Ultra High Performance Fibre Reinforced Concrete—UHPFRC. fib Task Group 8. 2008, Volume 6, pp. 1–28. Available online: https://www.bau.uni-siegen.de/subdomains/massivbau/publikationen/download/crack_width_control_for_combined_reinforcement_of_rebars_and_fibres_exemplified_by_ultra-high-performance_concrete.pdf (accessed on 5 January 2023).

- Stroeven, P. Stereological Principles of Spatial Modeling Applied to Steel Fiber-Reinforced Concrete in Tension. ACI Mater. J. 2009, 106, 213–222. [Google Scholar] [CrossRef]

- Lee, S.-C.; Cho, J.-Y.; Vecchio, F.J. Diverse Embedment Model for Steel Fiber-Reinforced Concrete in Tension: Model Development. ACI Mater. J. 2011, 108, 516–525. [Google Scholar] [CrossRef]

- Lee, S.-C.; Cho, J.-Y.; Vecchio, F.J. Diverse Embedment Model for Steel Fiber-Reinforced Concrete in Tension: Model Verification. ACI Mater. J. 2011, 108, 526–535. [Google Scholar] [CrossRef]

- Lee, S.-C.; Cho, J.-Y.; Vecchio, F.J. Simplified Diverse Embedment Model for Steel Fiber-Reinforced Concrete Elements in Tension. ACI Mater. J. 2013, 110, 403–412. [Google Scholar] [CrossRef]

- Ezeldin, A.S.; Balaguru, P.N. Normal and high strength fiber reinforced concrete under compression. J. Mater. Civ. Eng. 1992, 4, 415–429. [Google Scholar] [CrossRef]

- Hsu, L.S.; Hsu, C.T.T. Stress-strain behavior of steel-fiber high-strength concrete under compression. ACI Mater. J. 1994, 91, 448–457. [Google Scholar] [CrossRef]

- Someh, A.K.; Saeki, N. Prediction for the stress-strain curve of steel fiber reinforced concrete. Proc. Jpn. Concr. Inst. 1996, 18, 1149–1154. [Google Scholar]

- Mansur, M.A.; Chin, M.S.; Wee, T.H. Stress-strain relationship of high-strength fiber concrete in compression. J. Mater. Civ. Eng. 1999, 11, 21–29. [Google Scholar] [CrossRef]

- Nataraja, M.; Dhang, N.; Gupta, A. Stress-strain curves for steel-fiber reinforced concrete under compression. Cem. Concr. Compos. 1999, 21, 383–390. [Google Scholar] [CrossRef]

- Noghabai, K. Behavior of Tie Elements of Plain and Fibrous Concrete and Varying Cross Sections. ACI Struct. J. 2000, 97, 277–285. [Google Scholar] [CrossRef]

- Bischoff, P.H. Tension Stiffening and Cracking of Steel FiberReinforced Concrete. J. Mater. Civ. Eng. 2003, 15, 174–182. [Google Scholar] [CrossRef]

- Deluce, J.R.; Vecchio, F.J. Cracking Behavior of Steel Fiber-Reinforced Concrete Members Containing Conventional Reinforcement. ACI Struct. J. 2013, 110, 481–490. [Google Scholar] [CrossRef]

- Lee, S.-C.; Cho, J.-Y.; Vecchio, F.J. Tension-Stiffening Model for Steel Fiber-Reinforced Concrete Containing Conventional Reinforcement. ACI Struct. J. 2013, 110, 639–648. [Google Scholar] [CrossRef]

- Spinella, N.; Colajanni, P.; La Mendola, L. Nonlinear analysis of beams reinforced in shear with stirrups and steel fibers. ACI Struct. J. 2012, 109, 53–64. [Google Scholar] [CrossRef]

- Kim, K.S.; Lee, D.H.; Hwang, J.H.; Kuchma, D.A. Shear behavior model for steel fiber-reinforced concrete members without transverse reinforcements. Compos. Part B Eng. 2012, 43, 2324–2334. [Google Scholar] [CrossRef]

- Lee, S.C.; Cho, J.Y.; Vecchio, F.J. Analysis of Steel Fiber-Reinforced Concrete Elements Subjected to Shear. ACI Struct. J. 2016, 113, 275–285. [Google Scholar] [CrossRef]

- Kang, J.; Al-Sabah, S.; Théo, R. Effect of single-walled carbon nanotubes on strength properties of cement composites. Materials 2020, 13, 1305. [Google Scholar] [CrossRef]

- Silvestro, L.; Gleize, P.J.P. Effect of carbon nanotubes on compressive, flexural and tensile strengths of Portland cement-based materials: A systematic literature review. Constr. Build. Mater. 2020, 264, 120237. [Google Scholar] [CrossRef]

- Cerro-Prada, E.; Pacheco-Torres, R.; Varela, F. Effect of multi-walled carbon nanotubes on strength and electrical properties of cement mortar. Materials 2020, 14, 79. [Google Scholar] [CrossRef]

- Amin, M.S.; El-Gamal, S.M.A.; Hashem, F.S. Fire resistance and mechanical properties of carbon nanotubes–clay bricks wastes (Homra) composites cement. Constr. Build. Mater. 2015, 98, 237–249. [Google Scholar] [CrossRef]

- Zhang, L.W.; Kai, M.F.; Liew, K.M. Evaluation of microstructure and mechanical performance of CNT-reinforced cementitious composites at elevated temperatures. Compos. Part A Appl. Sci. Manuf. 2017, 95, 286–293. [Google Scholar] [CrossRef]

- Nam, I.W.; Lee, H.K.; Sim, J.B.; Choi, S.M. Electromagnetic characteristics of cement matrix materials with carbon nanotubes. ACI Mater. J. 2012, 109, 363. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, S.; Yoo, D.Y. Hybrid effects of steel fiber and carbon nanotube on self-sensing capability of ultra-high-performance concrete. Constr. Build. Mater. 2018, 185, 530–544. [Google Scholar] [CrossRef]

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Park, H.M.; Kim, G.M.; Lee, S.Y.; Jeon, H.; Kim, S.Y.; Kim, M.; Kim, J.W.; Jung, Y.C.; Yang, B.J. Electrical resistivity reduction with pitch-based carbon fiber into multi-walled carbon nanotube (MWCNT)-embedded cement composites. Constr. Build. Mater. 2018, 165, 484–493. [Google Scholar] [CrossRef]

- Jang, A.-Y.; Lim, S.-H.; Kim, D.-H.; Yun, H.-D.; Lee, G.-C.; Seo, S.-Y. Strain-Detecting properties of hybrid PE and steel fibers reinforced cement composite (Hy-FRCC) with Multi-Walled carbon nanotube (MWCNT) under repeated compression. Results Phys. 2020, 18, 103119. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.-C.; Yoo, S.-W. Workability and compressive behavior of PVA-ECC with CNTs. Geomech. Eng. 2022, 29, 311–320. [Google Scholar] [CrossRef]

- Nuaklong, P.; Boonchoo, N.; Jongvivatsakul, P.; Charinpanitkul, T.; Sukontasukkul, P. Hybrid effect of carbon nanotubes and polypropylene fibers on mechanical properties and fire resistance of cement mortar. Constr. Build. Mater. 2021, 275, 122189. [Google Scholar] [CrossRef]

- Soroushian, P.; Choi, K.B. Local bond of deformed bars with different diameters in confined concrete. Struct. J. 1989, 86, 217–222. [Google Scholar] [CrossRef]

- Soroushian, P.; Choi, K.B.; Park, G.H.; Aslani, F. Bond of deformed bars to concrete: Effects of confinement and strength of concrete. Mater. J. 1991, 88, 227–232. [Google Scholar] [CrossRef]

- Eligehausen, R.; Popov, E.P.; Bertero, V.V. Local bond stress-slip relationships of deformed bars under generalized excitations. Proc. Eur. Conf. Earthq. Eng. 1982, 4, 69–80. [Google Scholar] [CrossRef]

- Harajli, M.H.; Hout, M.; Jalkh, W. Local bond stress-slip behavior of reinforcing bars embedded in plain and fiber concrete. Mater. J. 1995, 92, 343–353. [Google Scholar] [CrossRef]

- Comite Euro-International Du Beton. CEB-FIP Model Code 2010; Thomas Telford Services Ltd., Thomas Telford House: London, UK, 2011. [Google Scholar]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Collins, F.; Lambert, J.; Duan, W.H. The influences of admixtures on the dispersion, workability, and strength of carbon nanotube–OPC paste mixtures. Cem. Concr. Compos. 2012, 34, 201–207. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Kim, G.M.; Naeem, F.; Kim, H.K.; Lee, H.K. Heating and heat-dependent mechanical characteristics of CNT-embedded cementitious composites. Compos. Struct. 2016, 136, 162–170. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Taha, R.; Taqa, A.A.; Shaat, A. Optimum carbon nanotubes’ content for improving flexural and compressive strength of cement paste. Constr. Build. Mater. 2017, 150, 395–403. [Google Scholar] [CrossRef]

- Lee, H.; Kang, D.; Kim, J.; Choi, K.; Chung, W. Void detection of cementitious grout composite using single-walled and multi-walled carbon nanotubes. Cem. Concr. Compos. 2019, 95, 237–246. [Google Scholar] [CrossRef]

- Hilding, J.; Grulke, E.A.; George Zhang, Z.; Lockwood, F. Dispersion of carbon nanotubes in liquids. J. Dispers. Sci. Technol. 2003, 24, 1–41. [Google Scholar] [CrossRef]

- Isfahani, F.T.; Li, W.; Redaelli, E. Dispersion of multi-walled carbon nanotubes and its effects on the properties of cement composites. Cem. Concr. Compos. 2016, 74, 154–163. [Google Scholar] [CrossRef]

- KATS. Steel Bars for Reinforcement; KS D 3504; KATS: Eumseong-gun, Korea, 2021. (In Korean)

- Kim, S.H. Evaluation of Crack Width and Remaining Service Life for RC Flexural Members under Repeated Loading. Ph.D. Thesis, Seoul National University, Seoul, Korea, 2004. [Google Scholar]

- Oh, B.H.; Kim, S.H. Realistic Models for Local Bond Stress-Slip of Reinforced Concrete under Repeated Loading. J. Struct. Eng. 2007, 133, 216–224. [Google Scholar] [CrossRef]

- Pishro, A.A.; Feng, X. Experimental Study on Bond Stress between Ultra High Performance Concrete and Steel Reinforcement. Civ. Eng. J. 2018, 3, 1235–1246. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Shin, H.O. Bond performance of steel rebar embedded in 80–180 MPa ultra-high-strength concrete. Cem. Concr. Compos. 2018, 93, 206–217. [Google Scholar] [CrossRef]

- Madani, H.; Bagheri, A.; Parhizkar, T. The pozzolanic reactivity of monodispersed nanosilica hydrosols and their influence on the hydration characteristics of Portland cement. Cem. Concr. Res. 2012, 42, 1563–1570. [Google Scholar] [CrossRef]

- Mudasir, P.; Naqash, J.A. The effect of water cement ratio on the characteristics of multi-walled carbon nanotube reinforced concrete. Mater. Today Proc. 2021, 43, 3852–3855. [Google Scholar] [CrossRef]

- Papayianni, I.; Pachta, V.; Stefanidou, M. Experimental study of nano-modified lime-based grouts. World J. Eng. 2013, 9, 501–508. [Google Scholar] [CrossRef]

- ASTM C39/C39M-18; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2018.

- Wardeh, G.; Ghorbel, E.; Gomart, H.; Fiorio, B. Experimental and analytical study of bond behavior between recycled aggregate concrete and steel bars using a pullout test. Struct. Concr. 2017, 18, 811–825. [Google Scholar] [CrossRef]

- De Larrard, F.; Shaller, I.; Fuchs, J. Effect of the bar diameter on the bond strength of passive reinforcement in high-performance concrete. ACI Mater. J. 1993, 90, 333–339. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).