Abstract

Fast-growing Chinese fir wood has shortfalls such as loose structure and low strength because it grows faster than natural trees. Resin impregnation is a great way to increase the strength of fast-growing fir. However, the resin used for impregnation is a kind of urea-formaldehyde resin, phenolic formaldehyde resin, melamine formaldehyde resin, and the like, which introduce harmful substances such as formaldehyde or phenolic into the wood. In this paper, Chinese fir wood was impregnated with natural shellac polymer, and the effects of impregnation variables on the mechanical properties of the wood were examined. The increase in strength in compression perpendicular to grain (SCPG) of wood samples impregnated with 15% shellac solution achieved a maximum value of 39.01%, but the modulus of rupture (MOR) was slightly reduced. The effects of the impregnation pressure, time, and their interaction were investigated by the response surface method (RSM). ANOVA analysis revealed that the impregnation pressure and time and the interaction between the two seemed to have a significant effect on ∆SCPG. Based on the response face model, the corresponding optimal parameters obtained are 1.0 MPa and 16.0 min for impregnation pressure and time, respectively. By impregnating fir wood with the above optimal conditions, the SCPG increased by 85.78%, whereas the MOR decreased by the least amount.

1. Introduction

The Chinese fir (Cunninghamia lanceolata (Lamb.) Hook) is a principal coniferous species in the subtropical regions of China, distributed in 16 subtropical provinces, municipalities, and autonomous regions in China [1]. The Chinese fir has had a long plantation history for more than 3000 years in China, according to the historical records [2]. Currently, the national Chinese fir plantation area is 8.95 × 106 ha, with a stock volume of 6.25 × 108 m3, providing up to 30% of the logs for China’s timber industry [3,4]. It became China’s most important commercial timber species due to its fast-growing, high-yielding, straight trunk, uniform structure with excellent anti-fungi resistance [5,6]. However, some disadvantages, including loose structure, low strength, and dimensional instability, of fast-growing Chinese fir wood seriously affect the service performance, limiting its utilization in the form of solid timber in engineering constructions, such as furniture and floors [7]. Researchers have attempted to reduce these disadvantages through thermal modification, mechanical compression, resin impregnation, and chemical modification processes [8]. Thermal modification of Chinese fir wood can enhance its performance by reducing water absorption and improving dimensional stability and biological durability, but it reduces its mechanical strength [9]. Although mechanical compression may increase the density, modulus of rupture (MOR), and modulus of elasticity (MOE) of the low-density wood, there will always be a certain recovery of compressive deformation after absorption [10,11]. Using a combined process of thermomechanical densification and heat treatment, Li et al. [12] significantly reduced the recovery of Chinese fir wood. Chemical modification methods such as acetylation, esterification, and furfurylation can alter the relationship between wood and moisture, making the wood hydrophobic, thereby improving dimensional stability and reducing decay susceptibility [13]. The resin impregnation method (RIM) has been shown to be one of the most effective solutions for improving the mechanical properties of Chinese fir wood [14,15]. Various synthetic thermosetting resins are commonly used for impregnating wood, such as urea-formaldehyde resin (UF), phenolic formaldehyde resin (PF), melamine formaldehyde resin (MF), etc. [16,17,18]. To improve the physical and mechanical properties of Chinese fir wood, Ma et al. [19] impregnated it with unsaturated polyester resin. However, the RIM either introduces some harmful chemicals into the wood or produces waste that pollutes the environment. As a result, several inorganic chemicals, such as sodium silicate, have been used to impregnate wood [20,21,22], they it will change the pH of the wood and corrode metal furniture hardware. Replacing synthetic resins with natural polymers that are less harmful to wood and the environment is a significant step forward.

Shellac is a natural biocompatible polymer that is commonly used as a protective coating for food and other products [23]. Shellac is a mixture of polyesters and monoesters that are insoluble in water but soluble in ethanol or ether [24]. Because of its excellent film-forming, strong adhesion to the wood surface, and protective properties, shellac is used as a varnish to preserve the surface of wooden products in the fields of wooden furniture restoration and musical instruments [25]. In this article, natural shellac polymer was used instead of synthetic resin to impregnate Chinese fir wood in order to use an environmentally friendly modifier. It was also investigated whether wood could be impregnated with a shellac solution to improve its mechanical properties.

2. Materials and Methods

2.1. Materials

Twenty-one year old fast-growing Chinese fir logs were purchased from Nanan City, Fujian, China. The fir logs were 5 m long, and the diameter of the small head was about 320~400 mm. The air-dried density of the fir logs was about 0.36 g/cm3. The fir logs were sawn by the rift-sawing method into square-section wood strips with a section size of 30 mm × 30 mm in a lumber mill. Bleached shellac with an average molecular weight of about 765 Da was bought from Yunnan Lvchun Shellac Co., Ltd, in Honghe Hani and Yi Autonomous Prefecture of China. Alcohol with a concentration of 95% was purchased from a chemical store in Fuzhou, China, and was produced by Guangzhou Chongwen Chemical Co., Ltd, in Guangzhou, China.

2.2. Wood Samples Preparation

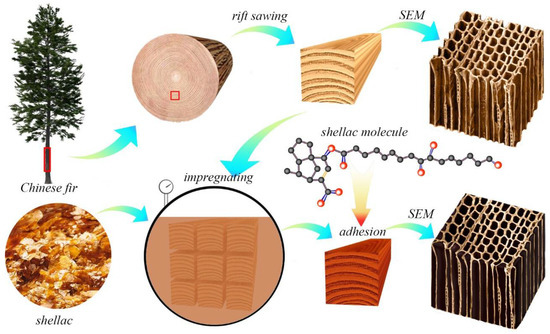

The wood strips were planed on all four sides and processed into wooden bars with a cross-sectional dimension of 20 mm × 20 mm (the error is 0~2 mm). Next, defects such as cracks, knots, rot, etc., were cut off, and some 300 mm long defect-free wood samples were cut from the wood bars. A pair of wood samples were cut from adjacent locations on the same wood bar: one for the impregnation treatment and the other for the control. The preparation and processing of the specimens is shown in Figure 1.

Figure 1.

Schematic of the impregnation with shellac polymer.

2.3. Microwave Pretreatment

In accordance with the literature, the wood samples were pretreated by microwave [26]. They were immersed in water at 25 °C for 24 h for the impregnation treatment. Subsequently, the wood samples were taken out of the water, and the surface water was wiped away with filter paper. The samples were then pretreated for 100 s in a microwave machine with a microwave power of 4 kW and a frequency of 2.45 GHz.

2.4. Impregnation with Shellac Solution of Different Concentrations

Shellac was dissolved in 95% alcohol to prepare 3000 mL shellac solutions with concentrations of 10%, 15%, and 20%.

After drying for 5 h in an oven at 103 ± 2 °C, the wood samples were placed in a pressure kettle. After locking the kettle lid, the pressure in the kettle was reduced to −0.1 MPa by vacuuming, and the shellac solution was sucked into the kettle. Next, the pressure in the kettle was raised to 1.2 MPa using an air compressor. After maintaining the pressure for 30 min, the outlet valve was opened to reduce the pressure and discharge the shellac solution. While the pressure in the kettle was being lowered to atmospheric pressure, the lid of the kettle was opened and the wood samples were taken out. After 24 h of storage at room temperature, both the wood samples and the controls were placed in a constant temperature (20 °C) and humidity (65%) chamber for more than 48 h.

2.5. Interaction of Impregnation Pressure and Time

The response surface method (RSM) with two factors and five levels was employed to optimize the experimental conditions of impregnation pressure and time. The concentration of the shellac solution was 15% for RSM analysis, and the specific RSM design is shown in Table 1. The increase rate of the strength in compression perpendicular to grain (ΔSCPG), increase rate of the modulus of rupture (ΔMOR), and weight gain percent (WGP) were used as the response of the RSM. Other parameters and procedures were the same as described above.

Table 1.

Test factors and level schedule for RSM.

2.6. Performance Testing

2.6.1. Strength in Compression Perpendicular to Grain

In accordance with ISO 13061-5:2020, the strength in compression perpendicular to grain (SCPG) of the wood samples was determined by the radial loading. The loading direction is the radial direction of the wood, and the loading speed is 5 mm/min. The ΔSCPG between an impregnated sample and its control sample was calculated by Equation (1):

where was the SCPG increase for the th pair wood samples; was the SCPG of the th treatment sample (MPa); and was the SCPG of the control sample adjacent to the th treatment sample.

2.6.2. Modulus of Rupture

In accordance with ISO 13061-3:2014, the modulus of rupture (MOR) of the wood samples was determined by an electromechanical universal testing machine (E44.304, MTS systems Co. Ltd., Eden Prairie, MN, USA). The radius of the support roller and the loading head were 30 mm, and the span was 240 mm. The loading direction was the radial direction of the wood, and the loading speed was 10 mm/min. The ΔMOR between an impregnated sample and its control sample was calculated by Equation (2):

where was the MOR increase for the th pair wood samples; was the MOR of the th treatment sample (MPa); and was the MOR of the control sample adjacent to the th treatment sample.

2.6.3. Weight Gain Percent

Before impregnation treatment with the shellac solution, the wood samples were dried to absolute dryness in an oven at 103 ± 2 °C, and the mass () of each wood sample was weighed by an electronic balance. After impregnation, they were dried to absolute dryness again and their masses () were determined. The WGP was computed by Equation (3):

2.6.4. Scanning Electron Microscopy (SEM)

After cutting a 5 mm × 5 mm × 2 mm slice from the impregnated wood sample, the distribution of shellac in the wood samples was observed under a scanning electron microscope (SU8010 produced by Hitachi, Tokyo, Japan).

2.6.5. Fourier Transform Infrared (FTIR) Spectroscopy

The samples were pulverized with a ball mill, passed through a 200-mesh sieve, and prepared by KBr tableting method. FTIR spectroscopy was performed on a Fourier transform infrared spectrometer (VERTEX 70, produced by Bruker, Berlin, Germany) to investigate the state of the shellac in the wood. The scanning wavelength range was 4000–500 cm−1, the number of scans was 32, and the spectral resolution was 4 cm−1.

2.6.6. X-ray Diffraction (XRD)

The crystallinity of the wood samples was characterized by an X-ray diffractometer on a Bruker D8 Advance diffractometer (Cu-K, Bragg-Brentano Geometry, Billerica, MA, USA). The diffraction angle range was 5°~40° (2θ), and the scanning rate was 10°/min. The crystallinity index was calculated from the heights of the amorphous and the total intensity with Segal’s method [27].

2.6.7. X-ray Photoelectron Spectroscopy (XPS)

After drying the sample to absolute dryness with a vacuum dryer, XPS scans were performed by Thermo Scientific (Waltham, MA, USA) K-Alpha to study the shellac molecules present in wood. The vacuum pressure of the analysis chamber was about 5 × 10−7 mbar, and the X-ray source was the monochromatic AlKa, 1486.6 eV energy, 12 kV voltage, and 6 mA beam current.

3. Results and Discussion

3.1. Effect of the Concentration of the Shellac Solution

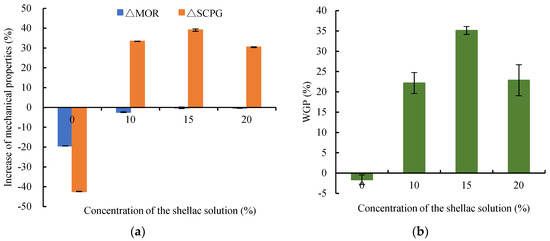

As shown in Figure 2a, wood samples impregnated with different shellac concentrations improved both MOR and SCPG. When impregnated with pure industrial alcohol (0% concentration, as shown in Figure 2), the MOR and SCPG were reduced by 19.40% and 42.43%, respectively. The WGP of wood samples was reduced by 1.61% due to the extraction of alcohol-soluble aliphatic and terpenoids (Figure 2b). Comparing wood samples impregnated with different shellac concentrations, wood samples impregnated with 15% shellac had the highest ΔSCPG of 39.01%. The corresponding WGP as high as 35.12% was achieved. A quite slight but noticeable decrease in MOR was observed as the concentration of shellac solution increased in the impregnated wood samples.

Figure 2.

The mechanical strength and weight gain of wood samples impregnated with different concentrations: (a) increase in mechanical properties; (b) WGP.

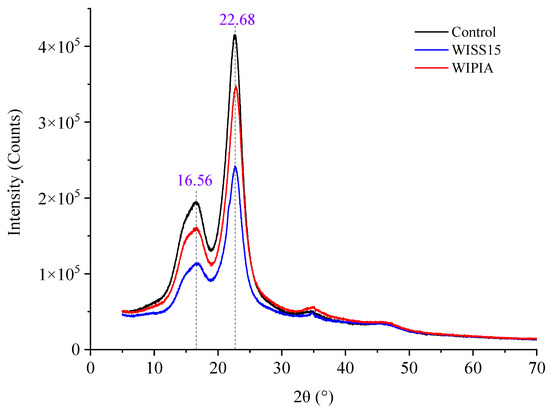

Figure 3 shows the XRD spectra of the wood samples impregnated with 15% shellac solution (WISS15), pure industrial alcohol (WIPIA), and a control. There are typical characteristic peaks of cellulose I-type structure at diffraction angles of 16.56° and 22.68° for all the samples [28,29]. WISS15 and WIPIA both exhibit decreased appearance in their diffraction peaks compared with the control sample. The crystallinity of WISS15, WIPIA, and control samples were 53.08%, 52.99%, and 53.49%, respectively. In comparison to control samples, wood samples impregnated with pure industrial alcohol showed a maximum reduction of 0.77% in crystallinity due to the strong permeability of alcohol. The alcohol molecules can enter the interior of the wood under high pressure, even around the crystallization area in the cell wall, and dissolve the alcohol-soluble substances, thereby reducing the crystallinity and mechanical properties. Impregnated with the shellac solution, the solvent alcohol had a similar effect, but the shellac could fill the cell lumen or adhere to the cell wall to improve its resistance to compression. As a result, the ΔSCPG of wood samples impregnated with 15% shellac solution increased by 39.01%.

Figure 3.

XRD spectra of the wood samples.

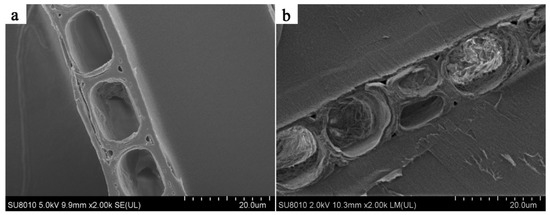

The SEM micrographs of the Chinese fir wood samples are shown in Figure 4. The tracheids and ray cells of the wood were clean and free of sediment (Figure 4a). When impregnated with the shellac solution, some shellac was deposited in the microcapillaries, such as the wood ray cell cavity. However, there was no visible deposit in the tracheid cavity, as shown in Figure 4b.

Figure 4.

SEM photos of wood sample: (a) control; (b) impregnated.

3.2. Interaction Effect of Impregnation Pressure and Time

Table 2 presents the results of 16 experiments based on the RSM experiment model. Subsequently, depending on the statistics parameters, various statistical analysis approaches were utilized to select a fitting model. According to the sequential model sum of squares, the models were selected based on the highest order polynomials where the additional terms were significant and the models were not aliased. The quadratic model was suggested for all three responses of ΔSCPG, ΔMOR, and WGP by the software due to the sequential p-value (Table 3). The quadratic models of ΔSCPG, ΔMOR, and WGP were obtained by analysis software and given as follows:

Table 2.

Results of the response surface experiment.

Table 3.

Model summary statistics.

Table 4 shows the ANOVA data of the quadratic models. The ANOVA data for the quadratic model of ΔSCPG revealed that it had a very low probability (p < 0.00001), high R-squared coefficient (R2 = 0.9629), adjusted R-squared coefficient (Adj-R2 = 0.9444), and adequate precision (19.84). The polynomial equation of ΔMOR was analyzed by ANOVA with a very low probability value (p < 0.0001), high R-squared coefficient (R2 = 0.9696), adjusted R-squared coefficient (Adj-R2 = 0.9545), and adequate precision (18.92). Additionally, the quadratic model of WGP had a very low probability (p < 0.00001), high R-squared coefficient (R2 = 0.9371), adjusted R-squared coefficient (Adj-R2 = 0.9056), and adequate precision (16.15).

Table 4.

Analysis of variance (ANOVA) for the quadratic models of ΔMOR, ΔSCPG, and WGP.

By analyzing the F-value and p-values from Table 3, it can be found that all regression models were statistically significant (p < 0.0001) and the lack of fit was not significant. The ΔSCPG of the wood samples was profoundly (p < 0.0001) affected by the impregnation time (B), the interaction between the impregnation pressure and time (AB), and the quadratic term of time (B2). At the p < 0.005 level, impregnation pressure (A) significantly affected the ΔSCPG. With a p-value less than 0.1, the quadratic term of the pressure (B2) had less effect on the ΔSCPG. The impregnation time (B) and the quadratic terms of pressure (A2) and time (B2) all exhibited a very significant (p < 0.0001) effect on the ΔMOR. The impregnation pressure (A) had a modest (p < 0.05) influence on the ΔMOR, whereas the pressure and time interaction (AB) had a significant (p < 0.001) effect on the ΔMOR. At p < 0.0001, both the impregnation time (B) and its quadratic term (B2) had a significant effect on the WGP. The impregnation pressure significantly affected WGP at p < 0.005, and its quadratic term (A2) had a moderate impact on the WGP at p < 0.005. However, the interaction impact of impregnation pressure and time (AB) on the WGP was not significant (p > 0.5).

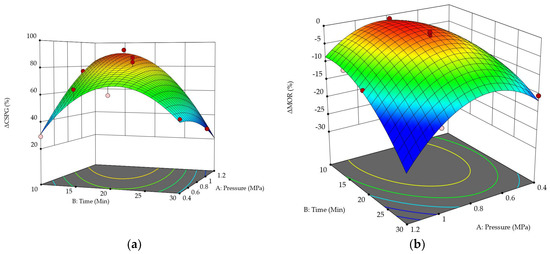

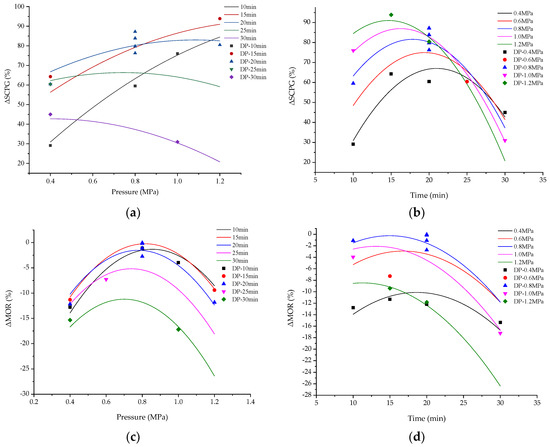

3.3. Effect of the Impregnation Pressure

The interactions between the impregnated pressure and time on the ΔSCPG and ΔMOR of wood samples can be shown by response surface 3-dimensional (3D) plots (Figure 5). Figure 5a depicts the interaction between the impregnation pressure and time on ΔSCPG of the wood samples. With the impregnation time was constant, the variation of ΔSCPG with different impregnation pressure is shown in Figure 6a. When the impregnation time was short, the ΔSCPG increased significantly with an increase in the impregnation pressure, but the increase in ΔSCPG gradually decreased with the extension of impregnation time. When the impregnation time was 30 min, ΔSCPG decreased with the increase in impregnation pressure. With the impregnation pressure constant, the change of ΔSCPG with different impregnation times is shown in Figure 6b. It can be seen that the curves of ΔSCPG as a function of impregnation time at different pressures were basically parabolas, and their extreme values were approximately in the range of impregnation time of 15–20 min. With the increase in the impregnation pressure, the extreme point of the ΔSCPG curve moved to the left, that is, the impregnation time gradually shortened, and the ΔSCPG decreased faster after passing the extreme point.

Figure 5.

Three-dimensional surface and contour plot showing the effects of impregnation pressure and impregnation time on ΔSCPG and ΔMOR: (a) ΔSCPG; (b) ΔMOR.

Figure 6.

Effect of variables on ΔSCPG and ΔMOR: (a) effect of pressure on ΔSCPG; (b) effect of time on ΔSCPG; (c) effect of pressure on ΔMOR; (d) effect of time on ΔMOR. Note: The mark of “DP” in the legend indicates the design point in the RSE.

Figure 5b shows the interaction between the impregnation pressure and time on ΔMOR of the wood samples. As the pressure increased from 0.4 MPa to 0.8 MPa, the ΔMOR increased from −12.17% to −0.81%, whereas it declined from −0.81% to −11.83% as the pressure increased from 0.8 MPa to 1.2 MPa. With the impregnation time constant, the variation of ΔMOR with different impregnation pressure is shown in Figure 6c. It was found that the ΔMOR increased as the impregnation pressure rose from 0.4 MPa to 0.8 MPa, whereas it reduced as the impregnation pressure increased from 0.8 MPa to 1.2 MPa, with the extreme points being around 0.8 MPa. Furthermore, when the impregnation time was extended, the extreme point shifted closer to the coordinate’s origin. This indicates that it is necessary to reduce the impregnation pressure to maintain the MOR if the impregnation time is prolonged. With the impregnation pressure constant, the variation of ΔMOR with different impregnation time is shown in Figure 6d. If the impregnation pressure was less than or equal to 1.0 MPa, the extreme points of the ΔMOR curve were between 15 min and 20 min. If the pressure was 1.2 MPa, ΔMOR decreased dramatically as the impregnation time increased.

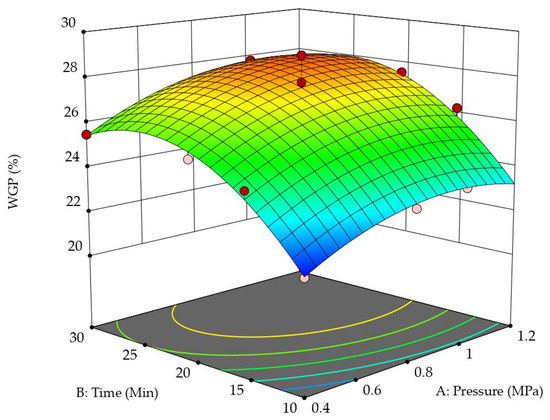

As seen in Figure 7, WRP increased with both impregnation pressure and time. This occurs because the number of shellac molecules entering the wood interior through the tracheid lumens and pit canals increases with increasing impregnation pressure and time. However, a continuous increase in WGP does not necessarily improve the SCPG and MOR of the wood samples.

Figure 7.

Three-dimensional surface and contour plot showing the effects of impregnation pressure and impregnation time on WGP.

3.4. Optimization and Validation

Based on the fit models of ΔCSPG and ΔMOR, the impregnation pressure of [0.4, 1.2] and the impregnation time [10,30] were optimized to obtain the maximum of ΔCSPG and ΔMOR. The corresponding conditions were 0.99 MPa and 16.10 min for the impregnation pressure and the impregnation time, respectively. For verification, 12 groups of Chinese fir wood samples were impregnated with the optimized impregnation pressure and time. In order to facilitate the immersion process, the impregnation pressure was adjusted from 0.99 MPa to 1.0 MPa, and the impregnation time was adjusted from 16.10 min to 16 min. The confirmatory experiment results (Table 5) show that the ΔSCPG and ΔMOR are close to the model predicted values with low standard deviation. The measured value of ΔSCPG is within the 95% confidence interval. Although the mean of ΔMOR is outside the 95% confidence interval, the ΔMOR is higher than the predicted mean.

Table 5.

Statistical parameters of confirmatory test results.

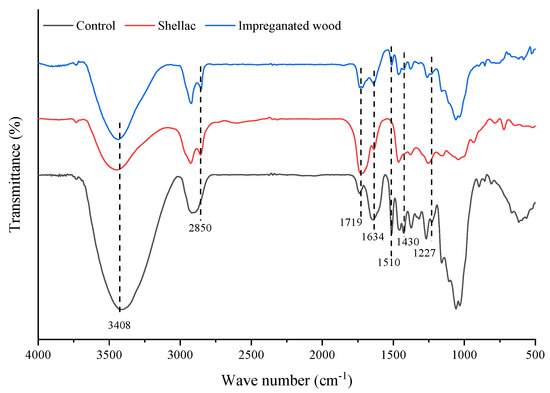

3.5. FTIR Spectroscopy Analysis

The FTIR spectra of the wood sample impregnated with shellac solution are shown in Figure 8. A comparison between the impregnated wood, pure shellac, and control wood sample reveals that the FTIR spectra of the impregnated sample have an alkane –CH2 stretching vibration absorption peak at 2850 cm−1. The -C=O stretching vibration absorption peak at 1719 cm−1 was enhanced. However, the 3408 cm−1 -OH stretching vibration peak, the 1634 cm−1 C=O stretching vibration absorption peak, the aromatic ring skeleton stretching vibration absorption peak at 1510 cm−1, the 1430 cm−1 -OH bending vibration peak, and the 1227 cm−1 aromatic ring ether bond stretching vibration absorption peak were all weakened significantly. These results mean that the penetration of shellac introduced the alkane –CH2, reducing the relative amounts of -OH and C=O in the wood, whereas other chemical groups did not obviously change. The results of FTIR spectrum analysis showed that there was no chemical reaction between the shellac molecules and the wood components, and the shellac molecules filled the wood cell cavity or adhered to the cell wall, which improved the compressive strength of the impregnated wood.

Figure 8.

FTIR spectroscopy of the wood samples impregnated with shellac solution.

3.6. X-ray Photoelectron Spectroscopy (XPS) Analysis

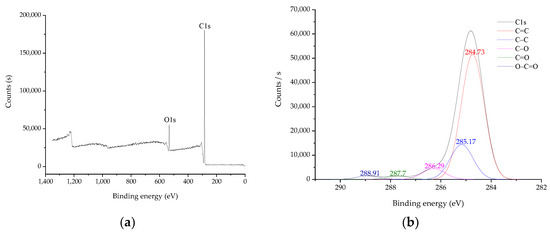

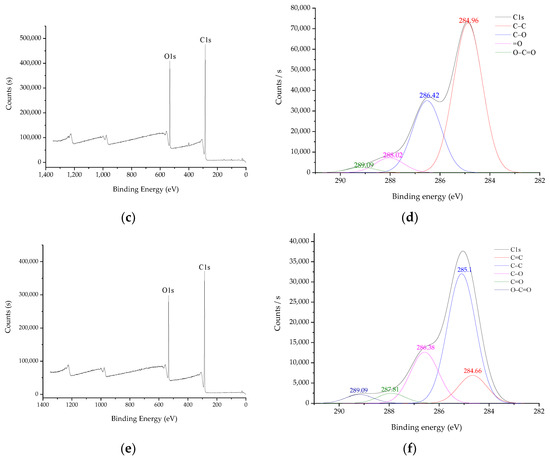

The full-spectrum scanning photoelectron spectra of the shellac, control wood sample, and impregnated wood sample obtained by scanning with Thermo Scientific K-Alpha photoelectron spectrometer are shown in Figure 9a, Figure 9c, and Figure 9e, respectively. There are two main elements, C and O, on the full spectrum. The results of the C1s peak fitting showed five distinctive peaks at 284.73 eV, 285.17 eV, 286.29 eV, 287.7 eV, and 288.91 eV, which are the characteristic peaks of shellac chemical structure C=C, C-C, C-O, C=O, and O-C=O [30,31], respectively, as shown in Figure 9b.

Figure 9.

XPS spectra of shellac and Chinese fir impregnated with shellac solution under vacuum: (a) full spectrum of shellac; (b) C1s spectrum of shellac; (c) the full spectrum of the control wood sample; (d) C1s spectrum of the control wood sample; (e) the full spectrum of the impregnated wood sample; (f) C1s spectrum of the impregnated wood sample.

The untreated wood sample exhibited four peaks around 284.96 eV, 286.42 eV, 288.02 eV, and 289.09 eV, which are characteristic peaks of C-C, C-O, C=O, and O-C=O (Figure 9d). After impregnation with the shellac solution, the wood sample has a characteristic peak derived from C=C of shellac. The proportion of each C1s peak area of impregnated and unimpregnated wood was calculated, as shown in Table 6. Because the penetration of shellac introduced the C=C chemical structure, the proportion of C-C, C-O, and C=O peak areas of the wood samples impregnated with shellac solution relatively decreased by 21.90%, 22.93%, and 30.00%, respectively. The shellac molecules impregnated into wood samples and adhered tightly to the cell wall, effectively increasing the SCPG of wood samples despite having no positive effect on the MOR.

Table 6.

The ratio of chemical structure and C1s peak of the wood impregnated with shellac solution.

4. Conclusions

Compared to wood impregnated with different concentrations of shellac solution, wood impregnated with 15% shellac solution had a 39.01% higher SCPG. However, the MOR of the wood samples consistently decreased regardless of the concentration of the shellac solution, but the decrease in MOR was quite slight when impregnated with 15% shellac solution. The impregnation pressure and time were optimized by the use of response surface models. As a result of ANOVA analysis, ∆SCPG was significantly affected by impregnation pressure, time, and their interaction. In addition, the impregnation pressure and the interaction between impregnation time and pressure affected the ∆MOR of the wood samples significantly. As a result of optimization of the impregnation variables by response surface models, 1.0 MPa impregnation pressure and 16.0 min impregnation time were found to be the optimal parameters. The confirmatory experiments confirmed the response surface optimization results with low prediction errors and standard deviations, and the ∆SCPG was 85.78%. Shellac can be seen deposited inside the ray cell lumen and covering the inner wall of the tracheid, which could also explain the increase in the ∆SCPG.

Author Contributions

Conceptualization, Q.Z., W.Z. and N.W.; methodology, Q.Z., X.Y., Z.W., Q.L. and N.C.; investigation, X.Y., Q.Z. and Z.W.; writing—original draft preparation, Q.Z. and X.Y.; writing—review and editing, W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

The authors thank the 2018 Forestry Science and Technology Research Project by Forestry Department of Fujian Province (No. 2018-26), National Natural Science Foundation of China (31971593, 32071688), Science and Technology Innovation Special Fund Project of Fujian Agriculture and Forestry University (CXZX2019111S) for providing financial support for this research.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhao, Y.; Deng, X.; Xiang, W.; Chen, L.; Ouyang, S. Predicting potential suitable habitats of Chinese fir under current and future climatic scenarios based on Maxent model. Ecol. Inform. 2021, 64, 101393. [Google Scholar] [CrossRef]

- Li, M.; Chen, X.; Huang, M.; Wu, P.; Ma, X. Genetic diversity and relationships of ancient Chinese fir (Cunninghamia lanceolata) genotypes revealed by sequence-related amplified polymorphism markers. Genet. Resour. Crop Evol. 2017, 64, 1087–1099. [Google Scholar] [CrossRef]

- Wu, H.; Xiang, W.; Chen, L.; Ouyang, S.; Xiao, W.; Li, S.; Forrester, D.I.; Lei, P.; Zeng, Y.; Deng, X.; et al. Soil Phosphorus Bioavailability and Recycling Increased with Stand Age in Chinese Fir Plantations. Ecosystems 2020, 23, 973–988. [Google Scholar] [CrossRef]

- You, R.; Zhu, N.; Deng, X.; Wang, J.; Liu, F. Variation in wood physical properties and effects of climate for different geographic sources of Chinese fir in subtropical area of China. Sci. Rep. 2021, 11, 4664. [Google Scholar] [CrossRef]

- Yang, X.; Yu, X.; Liu, Y.; Shi, Z.; Li, L.; Xie, S.; Zhu, G.; Zhao, P. Comparative metabolomics analysis reveals the color variation between heartwood and sapwood of Chinese fir (Cunninghamia lanceolata (Lamb.) Hook. Ind. Crops Prod. 2021, 169, 113656. [Google Scholar] [CrossRef]

- Li, Y.; Deng, X.; Zhang, Y.; Huang, Y.; Wang, C.; Xiang, W.; Xiao, F.; Wei, X. Chemical Characteristics of Heartwood and Sapwood of Red-Heart Chinese Fir (Cunninghamia lanceolata). For. Prod. J. 2019, 69, 103–109. [Google Scholar] [CrossRef]

- Wang, J.; Yao, Y.; Huang, Y.; Ma, Y.; Xi, J.; Wang, X.; Li, H.; Yang, Z. Effects of the combination of compression and impregnation with phenolic resin on the dimensional stability in the multiscale wood structure of Chinese fir. Constr. Build. Mater. 2022, 327, 126960. [Google Scholar] [CrossRef]

- Spear, M.J.; Curling, S.F.; Dimitriou, A.; Ormondroyd, G.A. Review of Functional Treatments for Modified Wood. Coatings 2021, 11, 327. [Google Scholar] [CrossRef]

- Zhou, T.; Liu, H. Research Progress of Wood Cell Wall Modification and Functional Improvement: A Review. Materials 2022, 15, 1598. [Google Scholar] [CrossRef]

- Kutnar, A.; Kamke, F.A. Influence of temperature and steam environment on set recovery of compressive deformation of wood. Wood Sci. Technol. 2012, 46, 953–964. [Google Scholar] [CrossRef]

- Rautkari, L.; Properzi, M.; Pichelin, F.; Hughes, M. Properties and set-recovery of surface densified Norway spruce and European beech. Wood Sci. Technol. 2010, 44, 679–691. [Google Scholar] [CrossRef]

- Li, T.; Cai, J.-b.; Zhou, D.-g. Optimization of the Combined Modification Process of Thermo-Mechanical Densification and Heat Treatment on Chinese Fir Wood. BioResources 2013, 8, 5279–5288. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. iForest-BioGeosci. For. 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Huang, Y.; Fei, B.; Yu, Y.; Zhao, R. Effect of Modification with Phenol Formaldehyde Resin on the Mechanical Properties of Wood from Chinese Fir. BioResources 2012, 8, 272–282. [Google Scholar] [CrossRef][Green Version]

- Yue, K.; Wu, J.; Xu, L.; Tang, Z.; Chen, Z.; Liu, W.; Wang, L. Use impregnation and densification to improve mechanical properties and combustion performance of Chinese fir. Constr. Build. Mater. 2020, 241, 118101. [Google Scholar] [CrossRef]

- Kohlmayr, M.; Stultschnik, J.; Teischinger, A.; Kandelbauer, A. Drying and curing behaviour of melamine formaldehyde resin impregnated papers. J. Appl. Polym. Sci. 2014, 131, 39860. [Google Scholar] [CrossRef]

- Shi, J.; Li, J.; Zhou, W.; Zhang, D. Improvement of wood properties by urea-formaldehyde resin and nano-SiO2. Front. For. China 2007, 2, 104. [Google Scholar] [CrossRef]

- Ali, R.A.M.; Ashaari, Z.; Lee, S.H.; Uyup, M.K.A.; Bakar, E.S.; Azmi, N.I.F. Low viscosity melamine urea formaldehyde resin as a bulking agent in reducing formaldehyde emission of treated wood. Bioresources 2020, 15, 2195–2211. [Google Scholar]

- Ma, Q.; Zhao, Z.; Yi, S.; Wang, T. Modification of fast-growing Chinese Fir wood with unsaturated polyester resin: Impregnation technology and efficiency. Results Phys. 2016, 6, 543–548. [Google Scholar] [CrossRef][Green Version]

- Lahtela, V.; Kärki, T. Effects of impregnation and heat treatment on the physical and mechanical properties of Scots pine (Pinus sylvestris) wood. Wood Mater. Sci. Eng. 2016, 11, 217–227. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Y.; Zuo, Y.; Lu, J.; Yuan, G.; Wu, Y. Preparation and characterization of sodium silicate impregnated Chinese fir wood with high strength, water resistance, flame retardant and smoke suppression. J. Mater. Res. Technol. 2020, 9, 1043–1053. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Y.; Zuo, Y.; Wu, Y.; Yuan, G.; Lu, J. Comparison of silicate impregnation methods to reinforce Chinese fir wood. Holzforschung 2021, 75, 126–137. [Google Scholar] [CrossRef]

- Bar, H.; Bianco-Peled, H. The unique nanostructure of shellac films. Prog. Org. Coat. 2021, 157, 106328. [Google Scholar] [CrossRef]

- Liu, M.; Xu, G.; Wang, J.; Tu, X.; Liu, X.; Wu, Z.; Lv, J.; Xu, W. Effects of Shellac Treatment on Wood Hygroscopicity, Dimensional Stability and Thermostability. Coatings 2020, 10, 881. [Google Scholar] [CrossRef]

- Weththimuni, M.L.; Capsoni, D.; Malagodi, M.; Milanese, C.; Licchelli, M. Shellac/nanoparticles dispersions as protective materials for wood. Appl. Phys. A 2016, 122, 1058. [Google Scholar] [CrossRef]

- Yu, X.; Wei, N.; Liu, Q.; Wu, Z.; Fan, M.; Zhao, W.; Zeng, Q. Study on Microwave Pretreatment Technology to Improve the Effect of Shellac Impregnation of Fast-Growing Chinese Fir. J. Renew. Mater. 2021, 10, 2041–2053. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance. Biotechnol. Biofuels 2010, 3, 10. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Ren, X.; Luo, K.; Xu, W.; Hou, Q.; Liu, W. From wood pulp fibers to tubular SiO2/C composite as anode for Li-ion battery: In-situ regulation of cellulose microfibrils by alkali solution. Ind. Crops Prod. 2020, 158, 113022. [Google Scholar] [CrossRef]

- Zhao, W.; Yan, W.; Zhang, Z.; Gao, H.; Zeng, Q.; Du, G.; Fan, M. Development and performance evaluation of wood-pulp/glass fibre hybrid composites as core materials for vacuum insulation panels. J. Clean. Prod. 2022, 357, 131957. [Google Scholar] [CrossRef]

- Zhou, Y.; Luo, L.; Yan, W.; Li, Z.; Fan, M.; Du, G.; Zhao, W. Controlled preparation of nitrogen-doped hierarchical carbon cryogels derived from Phenolic-Based resin and their CO2 adsorption properties. Energy 2022, 246, 123367. [Google Scholar] [CrossRef]

- Chen, T.; Luo, L.; Luo, L.; Deng, J.; Wu, X.; Fan, M.; Du, G.; Weigang, Z. High energy density supercapacitors with hierarchical nitrogen-doped porous carbon as active material obtained from bio-waste. Renew. Energy 2021, 175, 760–769. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).