Abstract

At present, Al matrix composites (AMCs) have drawn much attention owing to their light weight, high specific strength, high thermal conductivity, and superior excellent wear resistance, which endows them with great potential in the aerospace, automobile and military industries. In this study, AMCs with different Ti contents (0, 5 and 10 vol.%) were prepared by powder metallurgy. During the sintering, Al3Ti particles were in situ formed in the Al matrix. It was found that the Ti completely reacted with the Al matrix and formed fine in situ Al3Ti particles in Al-10Ti, while some large Ti-Al3Ti core-shell formed in Al-5Ti due to the incomplete reaction between the Ti and the Al matrix. Furthermore, the hardness of the composites was significantly improved by the in situ formed Al3Ti particles, reaching 143.3 HV in Al-5Ti and the highest value at 331.2 HV in Al-10Ti, respectively. The wear resistance of the composites is remarkably enhanced by Al3Ti particles compared to the unreinforced Al. Al-5Ti has the highest wear resistance among the samples. The wear resistance of the Al-10Ti composite becomes slightly deteriorated compared to Al-5Ti due to the brittle nature of Al3Ti, which leads to a three-body abrasive wear.

1. Introduction

In recent decades, composites have been extensively applied in the construction, automobile, aerospace, biotechnology and electronic industries, etc. [1,2,3] Composites have been defined as a mixture or combination of two or more materials to achieve the combined properties of each material [4,5,6]. Currently, AMCs have drawn much attention owing to the lightweight, high specific strength, high thermal conductivity, and superior wear resistance, which endows them with great potential in the aerospace, automobile, and military industries [7,8,9]. Although a large number of studies have been conducted on the development of AMCs [10,11,12], novel and more competitive AMCs need to be developed in order to satisfy the increasing requirements for the mechanical properties and wear resistance of composites in the relevant industries, such as with the pistons and fuselage for aerospace applications.

AMCs reinforced with particulate reinforcements, such as ceramic particles and intermetallic particles, have been broadly studied owing to their extraordinary mechanical and tribological properties [13,14,15,16]. Among the particulate reinforcements, Al3Ti has attracted much attention as a promising reinforcement in AMCs as a result of its high Young’s modulus and high hardness, as well as its low density [17,18,19]. In particular, in situ formed Al3Ti particles can have a strong and robust interface with the Al matrix [20,21]. At present, an increasing number of studies focus on AMCs reinforced with in situ Al3Ti particles. Ma et al. [22] fabricated 5 vol.% in situ Al3Ti reinforced Al-7 wt.% Si alloy matrix composites by casting, and the influences of in situ Al3Ti particles on the microstructure and mechanical properties of the composite were studied. The microstructure and mechanical properties of the Al-7Si/Al3Ti composite were then further improved by adding the Sr element. Their results show that in situ formed Al3Ti particles with a blocky morphology were observed in the Al grains, and a coarse interdendritic eutectic Si phase was formed. With the formation of Al3Ti, the yield strength of the composite was improved by ~20 MPa, but with a significant decrease in ductility. With the further addition of Sr, the eutectic Si phase was refined, and the stress concentration resulting from the coarse eutectic Si was relieved. Accordingly, both the strength and ductility of the Al-7Si/Al3Ti were improved. Gong et al. [23] further investigated the tribological properties of the Al-7 wt.%Si alloy/5 vol.% in situ Al3Ti composites based on the studied results of Ma et al. [22]. They found that the formation of Al3Ti and the refined microstructure by the addition of Sr in the Al-7Si-Sr/Al3Ti composite can significantly increase the hardness and reduce the stress concentration in the wear process. This is conducive to increasing the wear resistance of the composite with a low coefficient of friction and a low specific wear rate.

Zeng et al. [19] prepared in situ Al3Ti/Al composites by using a high shear technology, during which the Ti powders reacted with the liquid Al matrix. Their results show that as the size of the Ti powders increases, the required reaction time increases, and relatively large Al3Ti phases are obtained. In addition, the enhanced strength of the composites can be ascribed to the uniform distribution of the Al3Ti phase in the matrix and grain refinement effect. Yang et al. [18] developed a technique combining combustion synthesis and melt dilution for the fast fabrication of Al3Ti/Al composites. It was found that the liquid-solid combustion in powder compacts could be activated by the high heating rate. In addition, the formation process of Al3Ti consists of three stages, including where the Al and Ti powders closely contact each other, molten Al spreads over Ti to form a thin Al3Ti layer, and the Ti atoms cross the Al3Ti layer to form fine Al3Ti particles in the molten Al. Ma et al. [24] fabricated in situ Al3Ti/Al composites from Al and Ti fibres using various electromagnetic induction heating processes with different heating powers. The reaction and diffusion zones surrounding the Ti fibres can be observed. Moreover, the wear resistance of the composite is improved with the increase of heating power due to the formation of more Al3Ti particles in the composite.

However, limited studies focus on the preparation of the in situ Al3Ti/Al composites by a solid-state powder metallurgy route, and the effects of raw Ti content on the microstructure and the improvement of wear resistance of in situ Al3Ti/Al composites. In this study, in situ Al3Ti reinforced Al matrix composites were produced with different fractions of raw Ti powders through high-energy ball milling, followed by spark plasma sintering. This study aims to develop novel in situ Al3Ti reinforced Al matrix composites with superior mechanical and tribological properties by a solid-state powder metallurgy technique, and to investigate the effects of the Ti content on the in situ formation of Al3Ti, microstructures, and the wear resistance of the composites.

2. Experimental Section

2.1. Composites Fabrication

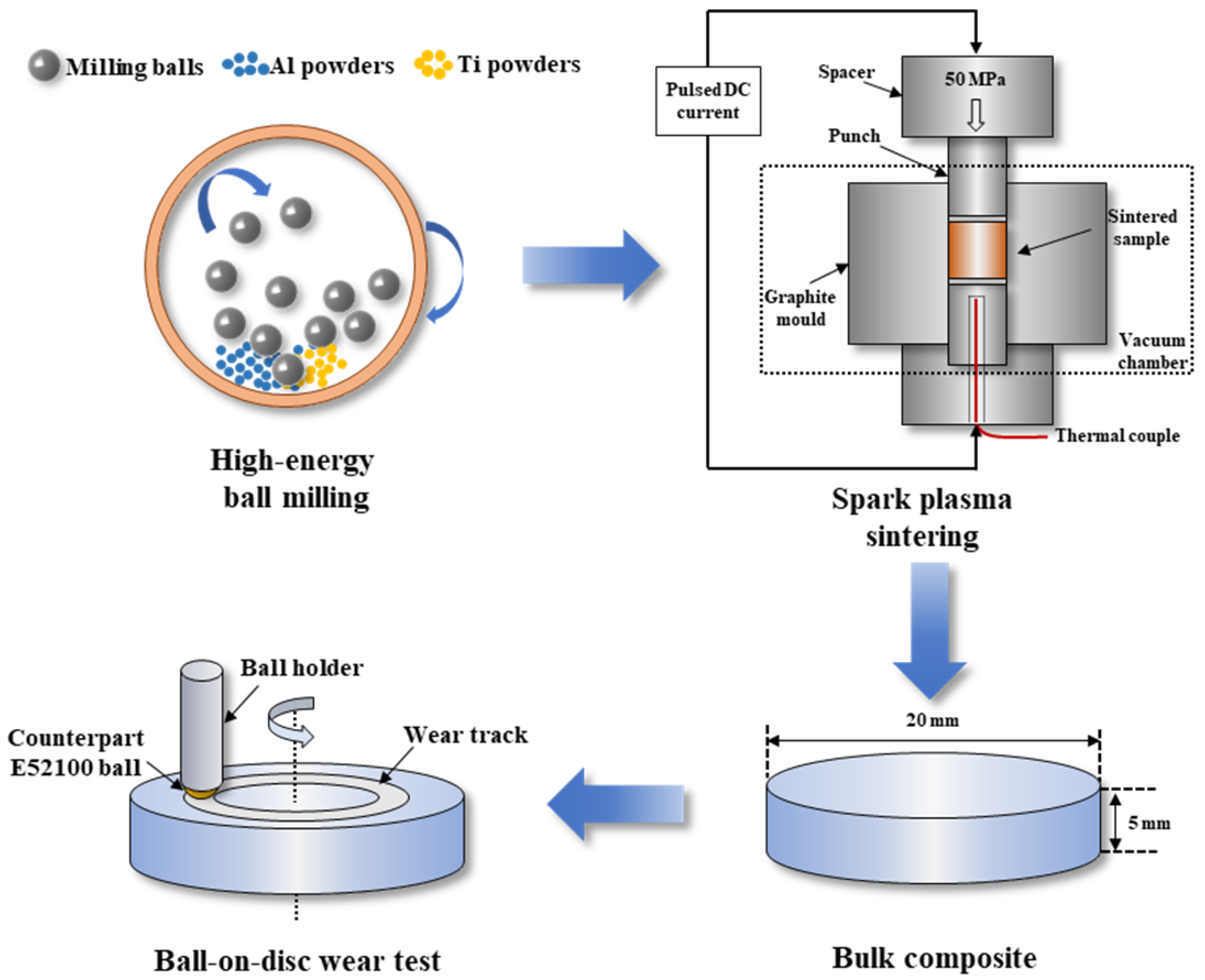

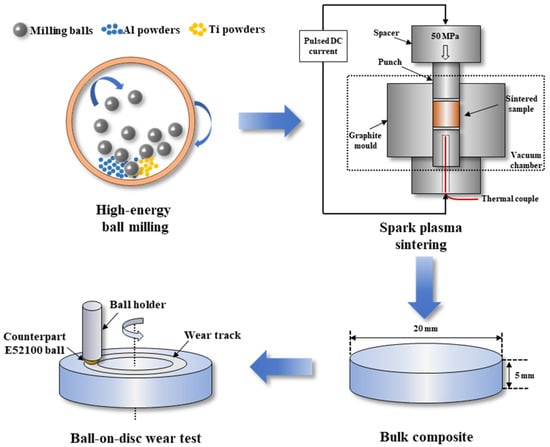

The composites were produced by a powder metallurgy process. First, pure Al powders (~20 μm) and Ti powders (<45 μm) were mechanically mixed for 20 h by high-energy ball milling in argon at 300 rpm with a ball-to-powder weight ratio of 20:1. A 2.0 wt.% stearic acid was introduced to prevent the cold-welding of Al powders. Subsequently, the milled powders were sintered by spark plasma sintering at 580 °C and 50 MPa for 30 min. Figure 1 shows the preparation process of the composite. Two composites with different volume fractions (5 vol.% and 10 vol.%) of Ti powders were made, and the corresponding sample was named as Al-5Ti and Al-10Ti, respectively. Pure Al was also produced through the same process as the reference sample.

Figure 1.

Schematic illustration of the preparation process and wear tests of the AMCs.

2.2. Characterisation

The milled powder and sintered samples were characterised by X-ray diffraction (XRD) using a GBC MMA XRD diffractometer. The density of the sintered samples was determined based on the Archimedes’ principle. Vickers hardness measurements of the sintered samples were conducted on a Matsuzawa Via-F Vickers hardness tester at a load of 200 gf with a dwelling time of 10 s. Each sample was measured five times to obtain the average hardness. Ball-on-disc wear tests were conducted on an Rtec MFT-5000 Muti-functional Tribometer (Rtec Instruments, San Jose, CA, USA) at a load of 10 N for 2000 s with each disc sample against an E52100 steel ball. The rotation speed of the disc was 60 rpm, and the radius of wear track was 5 mm. 3D morphologies of the wear tracks were observed on a Keyence VK-X100 3D laser scanning microscope (KEYENCE, Itasca, IL, USA). The specific wear rates were then determined based on Equation (1).

where ΔV is the wear volume, mm3; FN is the applied load, and N; S is the sliding distance, m.

W = ΔV/FN·S

The morphologies of milled powders were observed on a JEOL JSM6490LA scanning electron microscope. The microstructures of the sintered samples were observed on a Nikon Eclipse LV100NDA optical microscope (OM) and a JEOL JSM-7001 F scanning electron microscope. The worn surfaces were observed using a JEOL JSM-7001F scanning electron microscope equipped with an energy dispersion spectrometer (EDS).

3. Results and Discussion

3.1. Microstructure Characterisation

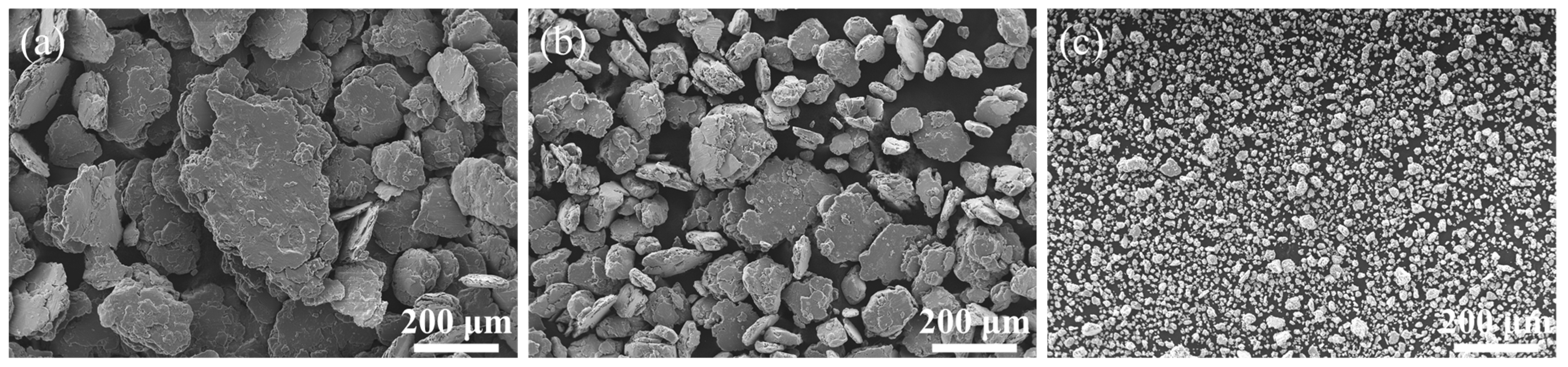

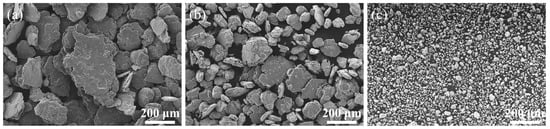

Figure 2 shows secondary electron microscopy (SEM) images of the milled powder samples. High-energy ball milling is commonly employed as a technique for uniformly mixing Al matrix powders and additives. During the ball milling, Al powders go through severe plastic deformations, including flattening, cold welding, fracturing, and re-welding due to the high-impact energy from the milling balls under the high centrifugal force [25,26]. The morphologies of pure Al powders after the ball milling were flattened into flakes, which were then cold welded into a lamella structure, as shown in Figure 2a. This indicates that the flattening and cold welding predominate the severe plastic deformation of the Al powders during the ball milling. Compared to the milled powders of pure Al, the milled powders of Al-5Ti show a mixed lamella and equiaxed structure, and the powders of Al-5Ti are much smaller, with sizes mostly less than 100 μm, as shown in Figure 2b. This indicates that the fracture mechanism of Al powders during the ball milling becomes more prominent, which may be related to the reasons below. First, the added Ti powders can be employed as an additional milling medium for Al matrix powders during the ball milling. Furthermore, the Ti powders can embed into Al matrix powders during the ball milling, and then make the Al matrix powders strengthened at the expense of plasticity of the Al matrix powders [27,28]. Therefore, the fracture mechanism of Al matrix powders is enhanced during the ball milling, and the decrease in the sizes of the milled powders is then obtained. With the further increase of the Ti content in the composite, the morphologies of milled powders of Al-10Ti are much different from the morphologies of other samples, and the milled powders are equiaxed with a much smaller size of less than 50 μm. This suggests that the fracture mechanism, which dominates the severe plastic deformation process of Al-10Ti powders, is further promoted with the increase of the Ti content.

Figure 2.

SEM images of milled powders of (a) Al, (b) Al-5Ti and (c) Al-10Ti.

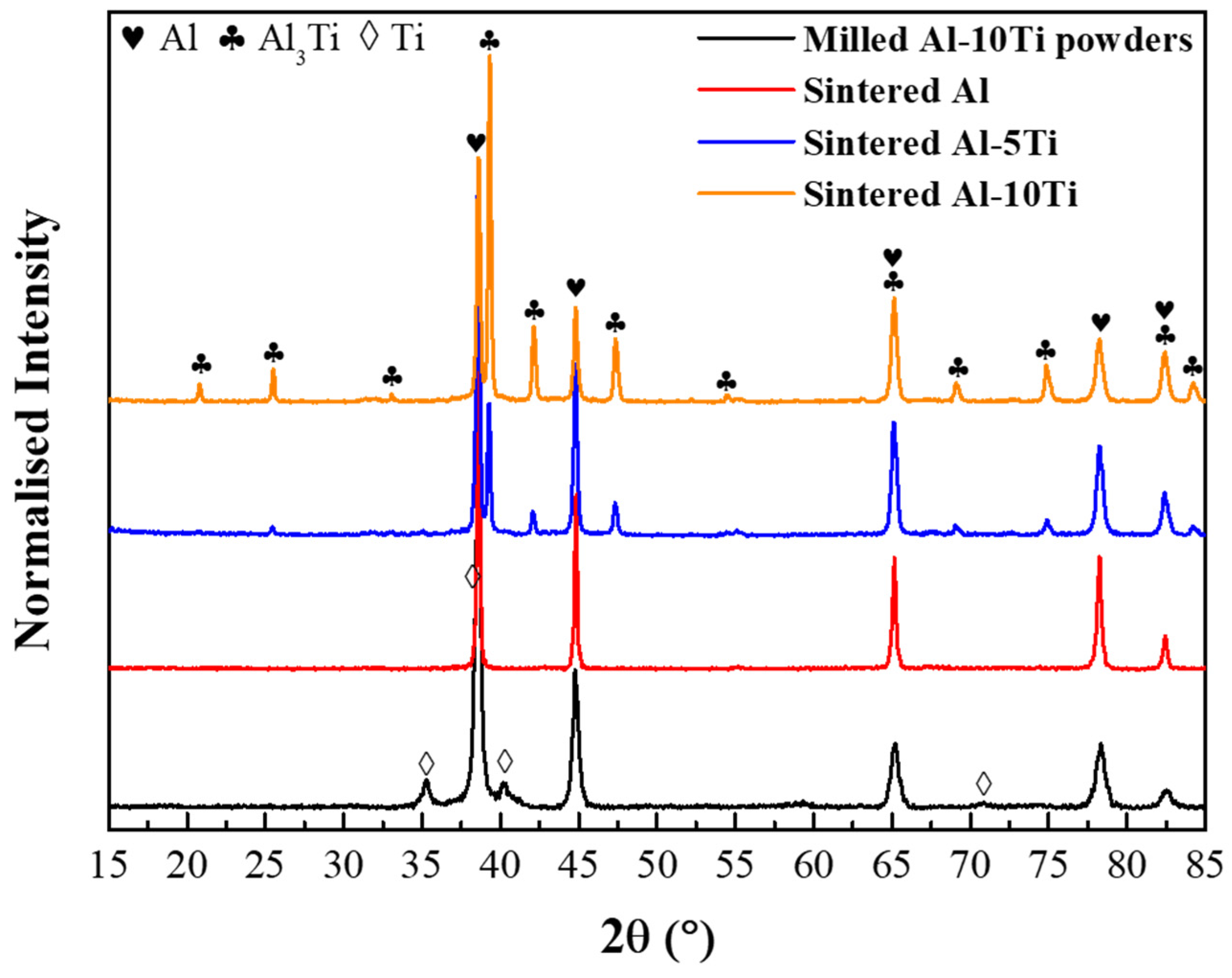

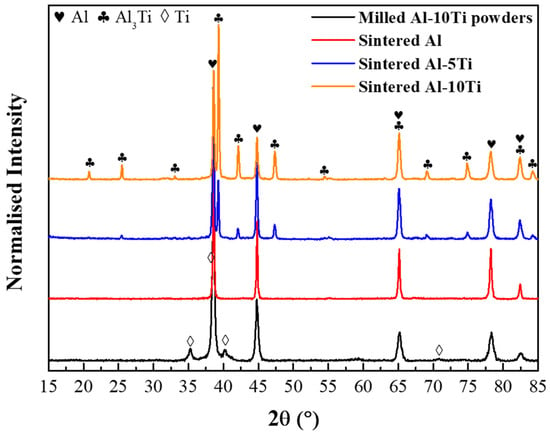

Figure 3 shows the XRD patterns of the milled Al-10Ti powders before the sintering and the bulk samples after the sintering. The peaks of Al are determined as (111), (200), (220), (311) and (222) in all of the samples. In the XRD pattern of the milled powders of Al-10Ti, only the peaks of Al and Ti are identified without any peak of Al3Ti, which indicates that the Al3Ti may not form during the ball milling or is of too small an amount to be detected. The XRD patterns of the sintered Al-5Ti and Al-10Ti composites show both the peaks of Al and the peaks of Al3Ti. This suggests that the Ti particles reacted with the Al matrix, resulting in the in situ formation of Al3Ti during the sintering process.

Figure 3.

XRD patterns of milled Al-10Ti powder and sintered samples.

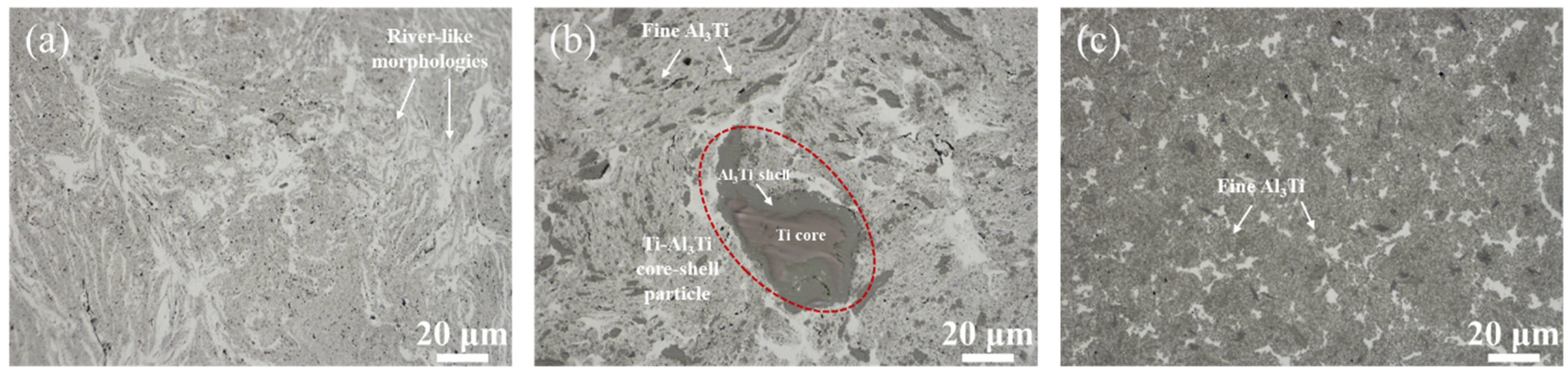

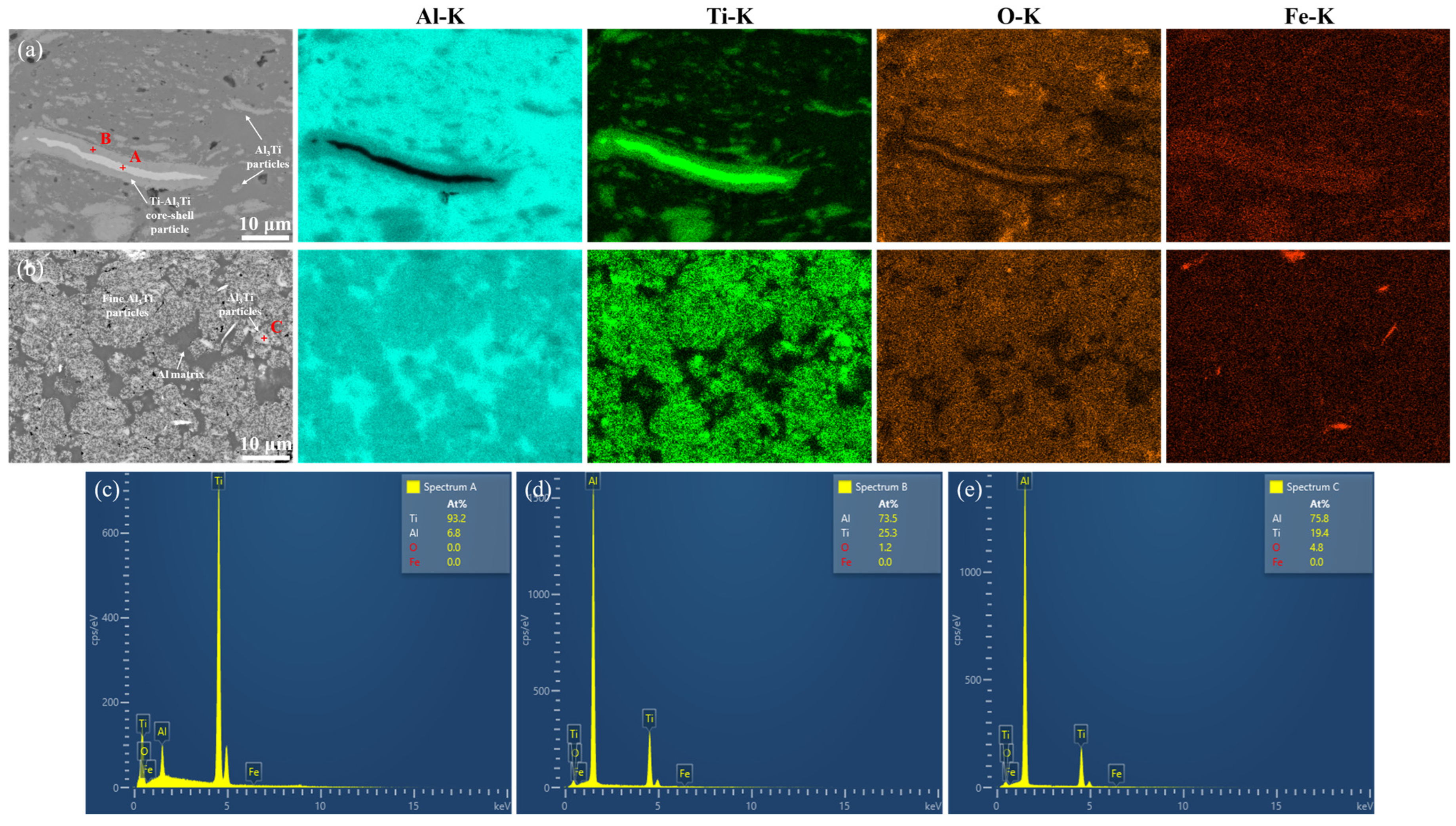

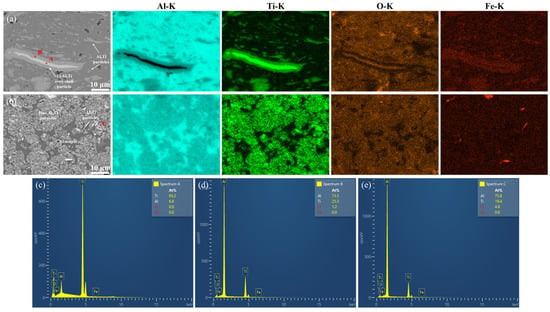

Figure 4 shows the sintered microstructures of the samples. In the OM microstructure of Al, as shown in Figure 4a, a river-like morphology is observed, which can be ascribed to the lamella structures of the milled powders. In the microstructure of Al-5Ti, fine Al3Ti particles and large Ti-Al3Ti core-shell particles are observed, as indicated in Figure 4b. This suggests that the Ti particles in Al-5T did not react with the Al matrix completely to form Al3Ti particles, and there is still some unreacted Ti, which represents the cores of the Ti-Al3Ti core-shell particles. In comparison, Ti-Al3Ti core-shell particles are not observed in the microstructure of the Al-10Ti. Furthermore, the Al3Ti particles in Al-10Ti are much finer. The cross-sectional microstructures of the Al-5Ti and Al-10Ti composites are further characterised by back-scattered electron (BSE) images and EDS, as shown in Figure 5. The Ti-Al3Ti core-shell particle in a large flake shape in Al-5Ti can be further identified by the BSE images and related EDS mappings, as shown in Figure 5a. The EDS spot analysis of spots A and B shown in Figure 5c,d also confirms that the unreacted Ti acts as the core, while the outer shell is the Al3Ti in the core-shell particle. The Ti-Al3Ti core-shell particle is about 40–50 μm in diameter, and about 5–10 μm in thickness, and this observation is consistent with the OM observation. In addition, some relatively small Al3Ti particles less than 10 μm are observed in Al-5Ti, which are uniformly distributed in the Al matrix. Figure 5b shows the BSE images and the related EDS mappings of Al-10Ti. Combined with the EDS spot analysis of spot C shown in Figure 5e, Al3Ti particles less than 5 μm are observed in Al-10Ti, which are finer than those in Al-5Ti, and their homogeneous distributions in the matrix can be confirmed. In this regard, the possible mechanisms for the formation of Al3Ti in the different samples are proposed by considering the morphologies of milled powders and the microstructures of the sintered samples. Due to the different Ti contents in the composite powders, the refining efficiency of the Al matrix powders in the different composites during the ball milling is different. It can be deduced that some large Ti particles still remain in the Al-5Ti powders after the ball milling, while the Ti particles are much finer in the milled Al-10Ti powders. This can be explained by the fact that with the refinement of the Al matrix powders, the Ti powders can also be refined by the high-energy impact from the milling balls. The higher Ti content in Al-10Ti makes the milled powders of Al-10Ti even finer than those of the Al-5Ti. During the sintering, the reaction between the Al and Ti was initiated by the high temperature, and the inter-diffusion between the Al and Ti atoms occurred [18]. Sufficient inter-diffusion between the Al and Ti in Al-10Ti was achieved because of the fine particles’ large specific area and short diffusion distance. Therefore, the fine Ti particles in both Al-5Ti and Al-10Ti completely reacted with the Al matrix to form the fine in situ Al3Ti particles, while the relatively larger Ti particles tended to form the Ti-Al3Ti core-shell structures.

Figure 4.

OM images of sintered microstructures of (a) Al, (b) Al-5Ti and (c) Al-10Ti.

Figure 5.

BSE images of the cross-sectional microstructure of the sintered (a) Al-5Ti and (b) Al-10Ti, and EDS spot analysis of (c) spot A, (d) spot B, and (e) spot C.

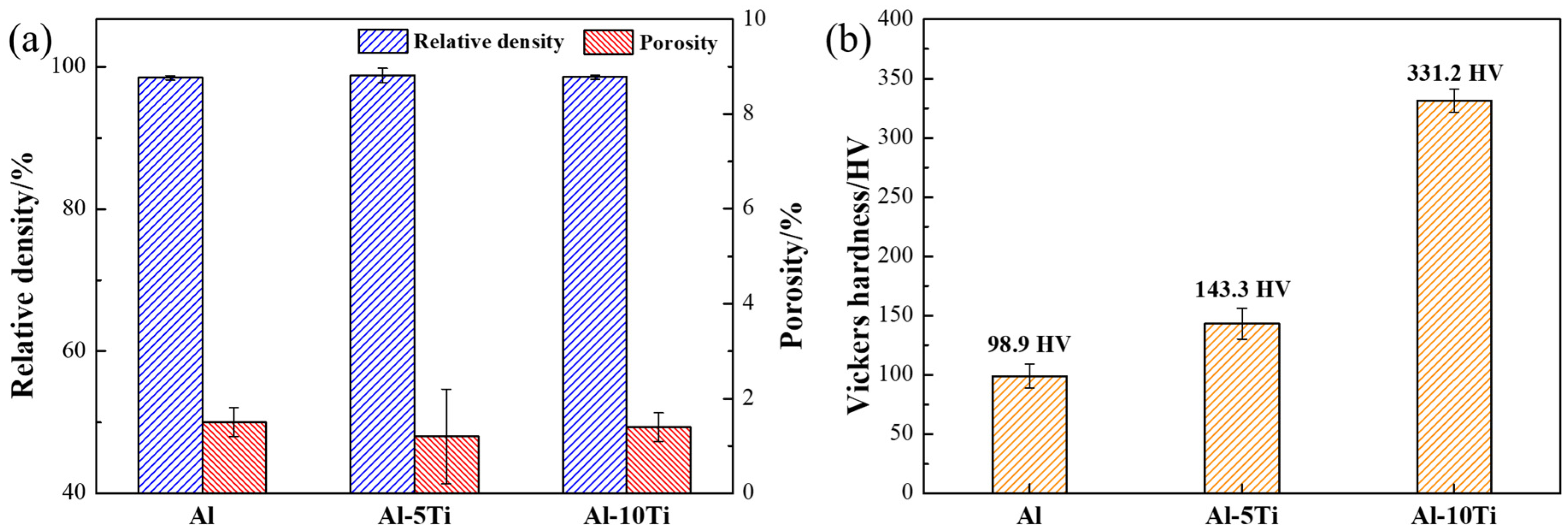

3.2. Density and Vickers Hardness

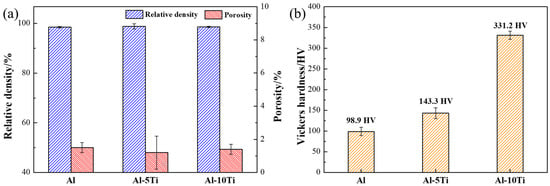

Figure 6a shows the relative density and porosity of the sintered samples. All of the samples were well densified, with a relative density higher than 98.0% and a porosity less than 2.0%. Figure 6b shows the Vickers hardness measurements of the bulk samples after sintering. The Vickers hardness of pure Al is measured as 98.9 HV. After introducing 5 vol.% Ti, the Vickers hardness of the Al-5Ti composite rises to 143.3 HV, which is 44.9% higher than that of Al. The increase in hardness may be related to the following explanations. Firstly, the introduction of Ti powders increases the plastic deformation of the Al matrix powders during the ball milling, which brings a more prominent work-hardening effect on the Al matrix powders [29,30]. In addition, the in situ formation of Al3Ti particles in the composite during the sintering process, especially fine Al3Ti particles in Al-10Ti, can increase the load-bearing ability of the composite upon indentation owing to the high Young’s modulus and high hardness of the Al3Ti particles [19]. With the further increase of Ti content in the composite, the above mechanisms are further enhanced, and then Al-10Ti shows a much higher Vickers hardness at 331.2 HV, which is 234.9% and 131.1% higher than that of Al and Al-5Ti, respectively.

Figure 6.

(a) Relative density and porosity, and (b) Vickers hardness of the sintered samples.

3.3. Tribological Properties

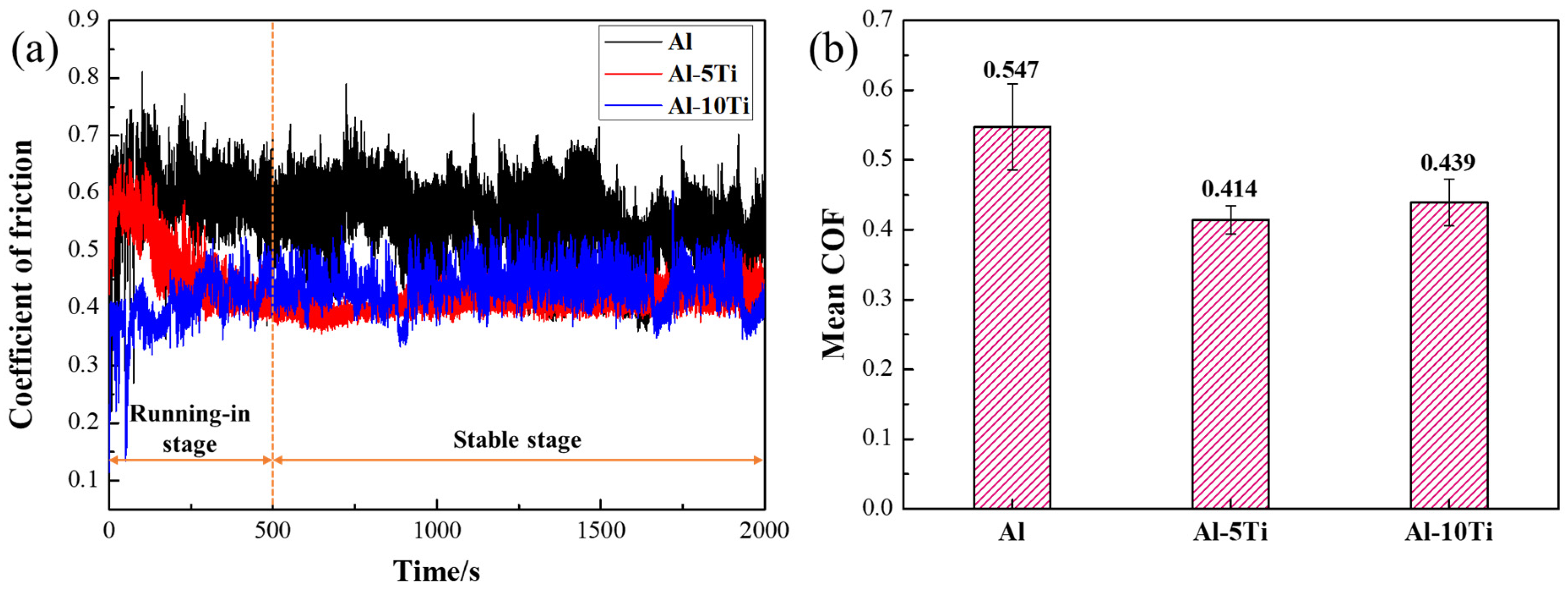

3.3.1. Coefficient of Friction (COF) and Wear Rates

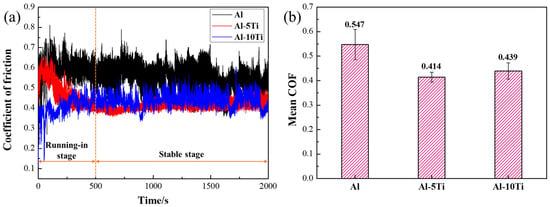

Coefficient of friction (COF) is a dimensionless number that is defined as the ratio of the frictional force between two surfaces to the normal force acting on one of the surfaces. During the wear tests, the frictional and normal forces were measured in real time by load cells, and the COF was then calculated and recorded. Figure 7a shows the variation of COF as the time continues during the wear tests. The initial running-in stage lasts for ~500 s in all of the samples, and then the COF values tended to become relatively stable. Clearly, the fluctuation in the COF value of Al is much more significant than that of the two composites, since the counterpart ball kept penetrating and ploughing deeper during the wear test due to the soft quality of the Al. The mean COF values obtained from the stable stages of the samples are summarised and compared in Figure 7b. It can be seen that Al has the highest mean COF value at 0.547, which can also be observed from the COF vs. time curves directly. This further suggests the more severe ploughing deformation in the wear of Al than in Al-5Ti and Al-10Ti. In addition, it was found that the mean COF value of Al-10Ti was slightly higher than that of Al-5Ti, which may be attributed to the higher fraction of Al3Ti particles in Al-10Ti. This will be further discussed in the subsequent paragraphs with the observations of worn surfaces and wear tracks.

Figure 7.

(a) COF vs. time curves of the samples during wear tests and (b) mean COF values of the samples.

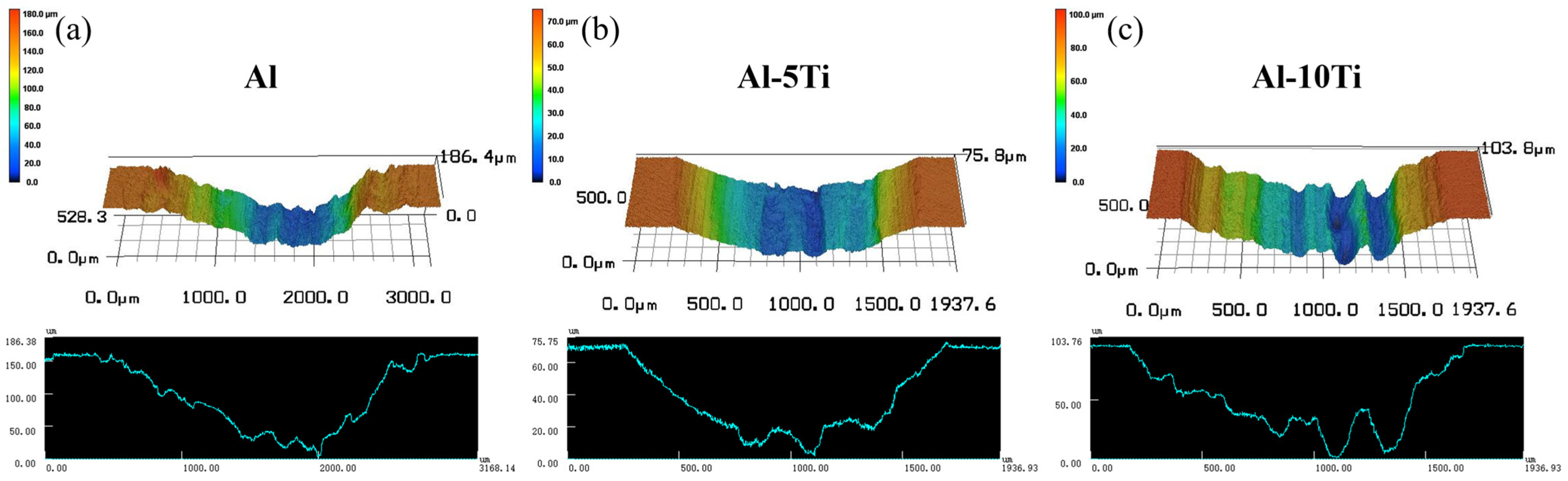

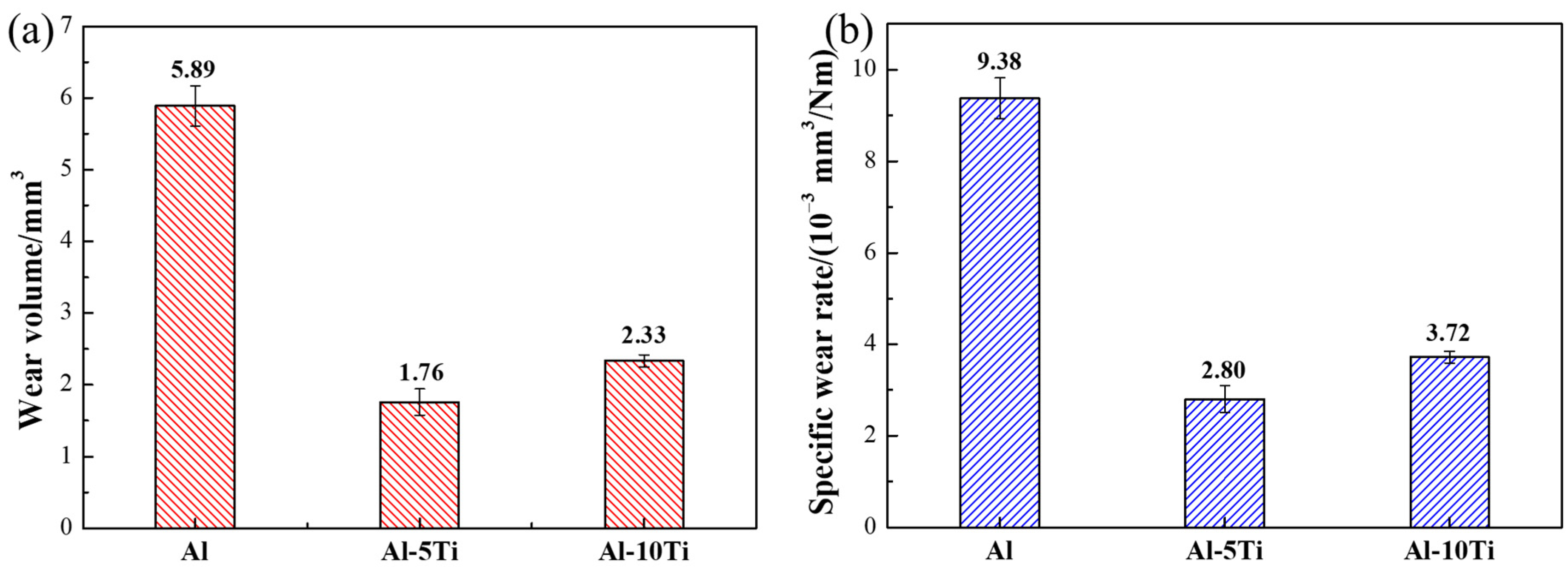

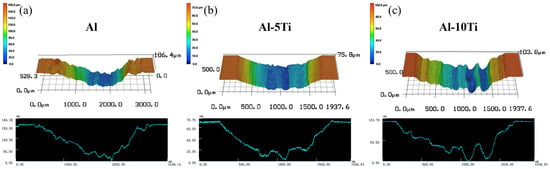

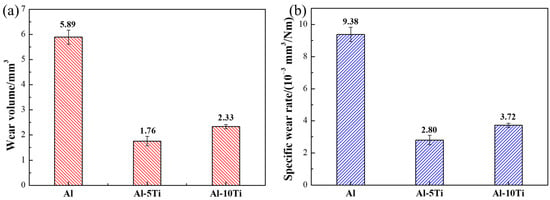

Figure 8 shows the 3D morphologies and the representative cross-sectional profiles of the wear tracks of the samples. It was found that the pure Al obtained the deepest and broadest wear track with a depth of ~160 μm and a width larger than 2000 μm. In contrast, the wear track of Al-5Ti is a fair bit smaller, with a depth of ~70 μm and a width of ~1500 μm. However, with the increase of Ti content in the composite, the wear track of Al-10Ti with a depth of ~100 μm and a width of ~1500 μm is slightly larger than that of Al-5Ti, although it is still much smaller than that of Al. In addition, deep grooves can be seen in the wear track of Al-10Ti, which are not observed in the wear track of Al-5Ti. It was deduced that the formation of the deep grooves in the wear track of Al-10Ti may be related to the effects of Al3Ti particles on the wear process. Figure 9 shows the wear loss and wear rates of the samples after the wear tests. As expected, Al has the highest wear loss, with a wear volume of ~5.89 mm3, corresponding to the highest specific wear rate of 9.38 × 10−3 mm3/Nm; the wear loss then decreased significantly to ~1.76 mm3 for Al-5Ti, and the specific wear rate of Al-5Ti reached 2.80 × 10−3 mm3/Nm as a result. As the Ti content in the composite increases, the wear volume and specific wear rate of the Al-10Ti composite slightly increase to 2.33 mm3 and 3.72 × 10−3 mm3/Nm, compared to the Al-5Ti composite, respectively.

Figure 8.

3D morphologies and representative cross-sectional profiles of wear tracks of (a) Al, (b) Al-5Ti, and (c) Al-10Ti.

Figure 9.

(a) Wear volumes and (b) specific wear rates of the samples after wear tests.

3.3.2. Worn Surfaces and Wear Mechanisms

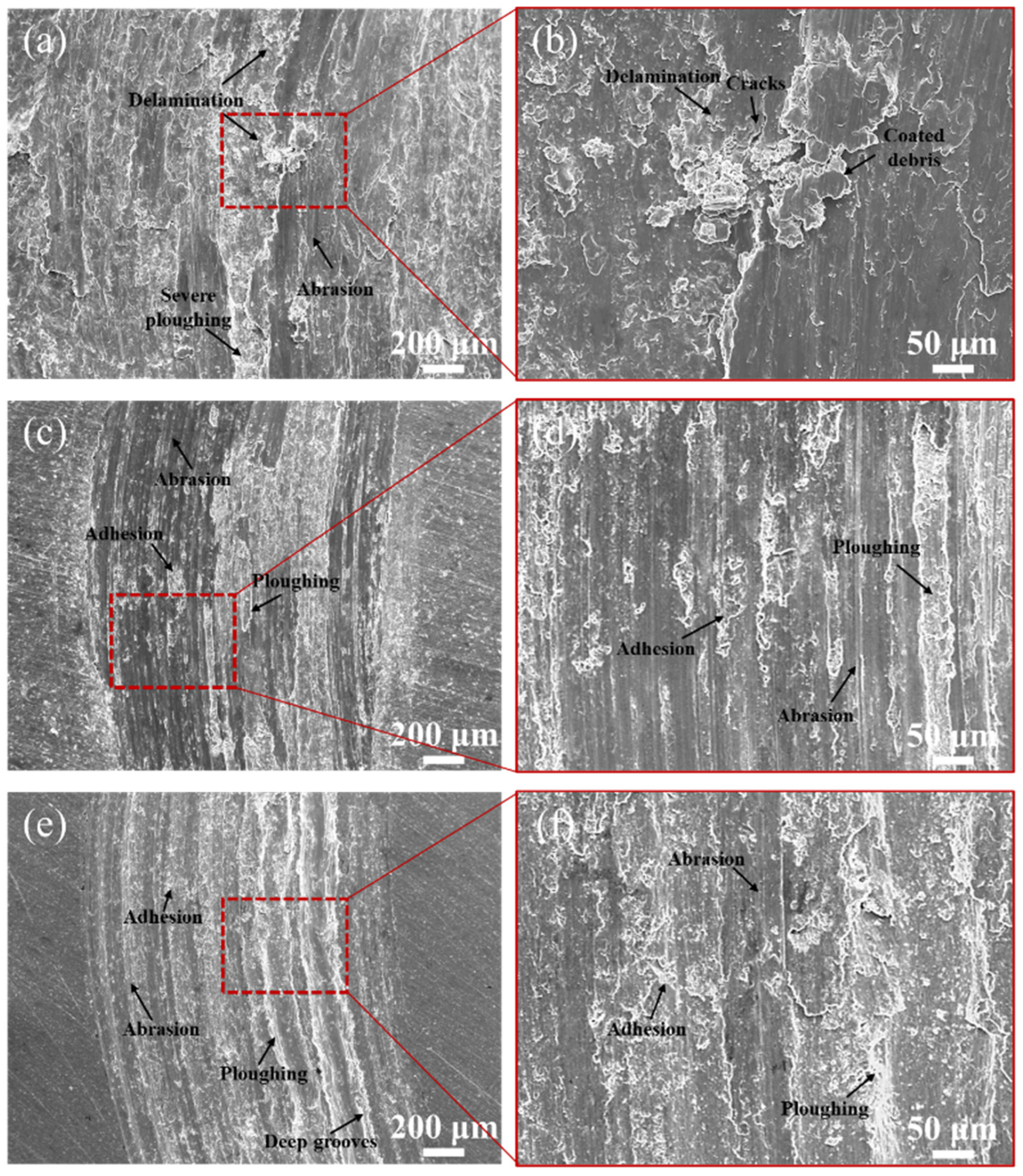

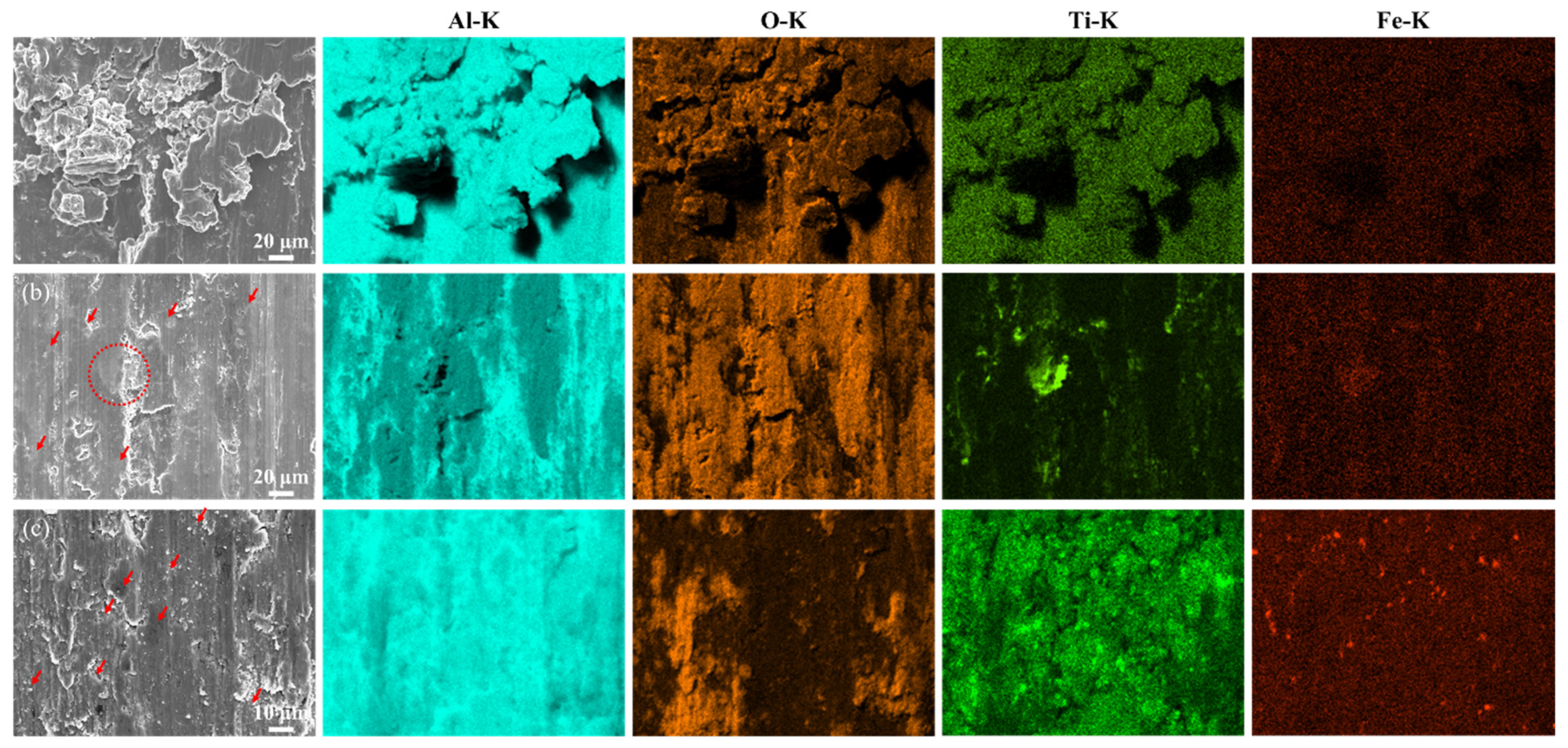

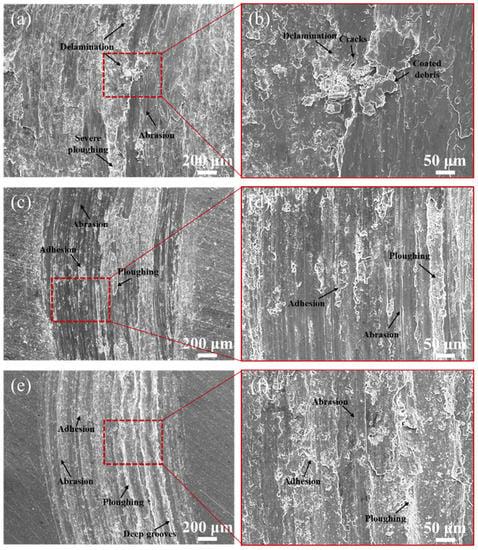

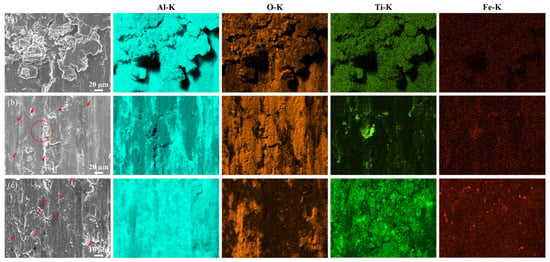

Figure 10 shows the SEM images of worn surfaces of the samples after the wear tests. Mixed wear modes can be found in all of the samples. The worn surfaces of Al show the most severe wear among all of the samples, which is consistent with the above-obtained results of wear rates. Due to the soft nature of Al, the hard micro asperities on the counterpart ball tend to penetrate the Al and then slide along the wear direction as the wear test continues. Abrasion wear, delamination, and severe ploughing from the counterpart ball are observed on the worn surfaces shown in Figure 10a. As further observed in Figure 10b, the particle which is about to be delaminated is identified along with the cracks. In addition, the coated large wear debris on the worn surface is also observed, which was compacted by the repeated sliding of the counterpart ball. The delamination and coated wear debris are observed more clearly in the SEM image with a higher magnification and relevant EDS mappings, shown in Figure 11a. It was determined that severe ploughing and delamination dominate the wear process of Al.

Figure 10.

SEM images of worn surfaces of (a,b) Al, (c,d) Al-5Ti, and (e,f) Al-10Ti after wear tests.

Figure 11.

High-magnification SEM images and EDS mappings of wear tracks of (a) Al, (b) Al-5Ti, and (c) Al-10Ti, in which Al3Ti particles are labelled by the red circle and arrows.

SEM images of the worn surfaces of Al-5Ti are shown in Figure 10c,d. Compared to Al, the severe delamination and ploughing are significantly alleviated. Instead, abrasion wear becomes the predominant wear mode in the wear of Al-5Ti. Moreover, some adhesion is found on the worn surfaces of Al-5Ti. This is because frictional heat was produced by the repeated sliding of the counterpart ball on the composite, leading to local adhesion between the counterpart ball and the composite. Figure 11b shows a high-magnification SEM image and the relevant EDS mappings of worn surfaces of Al-5Ti, in which the presence of Al3Ti particles in the tribolayer is identified, confirming the involvement of Al3Ti particles in the wear of Al-5Ti. Figure 10e,f show the worn surfaces of Al-10Ti, where the adhesion becomes more prominent compared to Al-5Ti. In addition, deep grooves and ploughing can be seen on the worn surfaces of Al-10Ti. This may be ascribed to the presence of hard Al3Ti particles with a high content of Al-10Ti, which largely deteriorates the toughness of the Al-10Ti composite. The local failure would occur at local areas with poor toughness as the counterpart ball slid, and then the formation of deep grooves was initiated. Furthermore, the severe three-body abrasion by the pulled-out Al3Ti particles or wear debris containing a considerable amount of Al3Ti during the wear of Al-10Ti occurred [31,32], which could further accelerate the formation of deep grooves. Compared to Al-5Ti, the deep grooves shown in Figure 10e,f can account for the increased wear loss of Al-10Ti, and the higher content of Al3Ti particles was involved in the wear of Al-10Ti compared to Al-5Ti, which can be further demonstrated by the EDS mappings shown in Figure 11c. An optimised composite design, such as the optimised composition and fabrication process, could be helpful for improving the wear resistance of the composite and serve to alleviate the formation of deep grooves. In addition, the increased presence of Fe particles in the wear track of the Al-10Ti composite was observed. This may be related to the three-body abrasion by the pulled-out Al3Ti particles. Those pulled-out hard Al3Ti particles presented between the Al-10Ti and the steel ball would scratch both the surface of the Al-10Ti and the surface of the steel ball during the sliding process. Some small steel pieces were then scratched off the steel ball and compacted onto the worn surfaces of the Al-10Ti during the sliding, thereby increasing the presence of Fe on the worn surfaces.

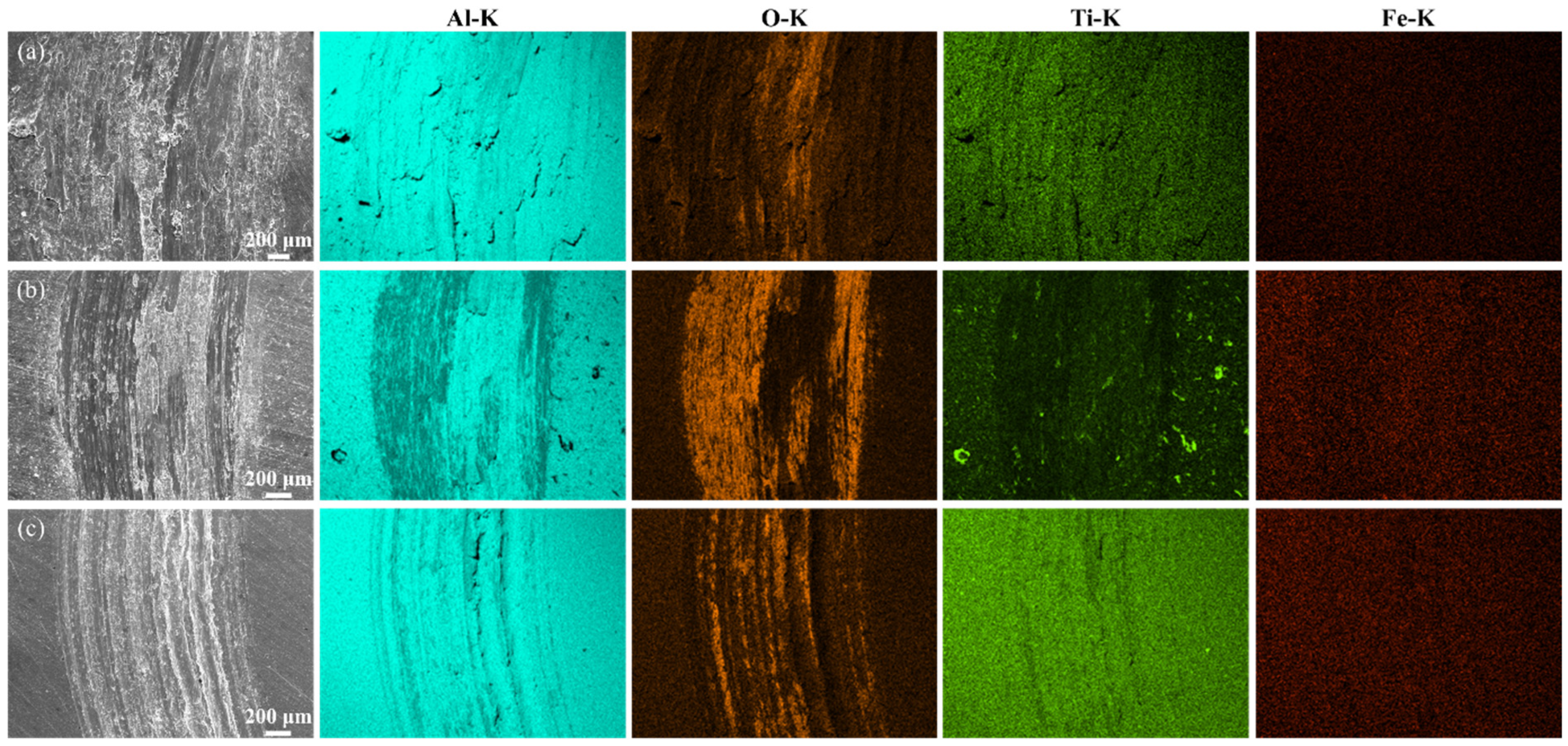

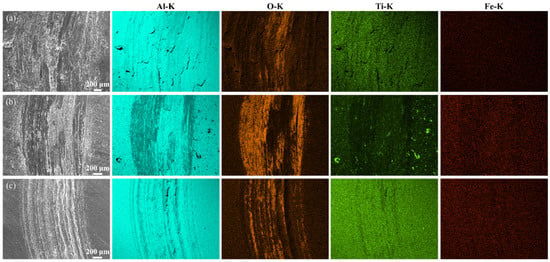

Figure 12 shows the low-magnification SEM images and relevant EDS mappings of wear tracks in order to comprehensively characterise the oxidation wear and the oxide formation on the worn surfaces. It was observed that oxygen was present on the worn surfaces of all of the samples. The oxidation of aluminium occurred because of the heat generated by the repeated sliding process, which then led to oxidation wear in the samples [33,34]. Generally, the AMCs with a larger fraction of reinforcements are more prone to the oxidation of aluminium due to their reduced resistance to oxidation [35]. However, the area of the formed oxide film on the worn surfaces of Al-10Ti is smaller than that of Al-5Ti, which further confirms the more severe abrasion or ploughing that occurred during the wear of Al-10Ti, and then brought about the fresh surfaces in Al-10Ti. The large-area oxide film with high hardness on the worn surfaces of Al-5Ti also contributed to the more excellent wear resistance compared to the other samples.

Figure 12.

Low-magnification SEM images and EDS mappings of wear tracks of (a) Al, (b) Al-5Ti and (c) Al-10Ti after wear tests.

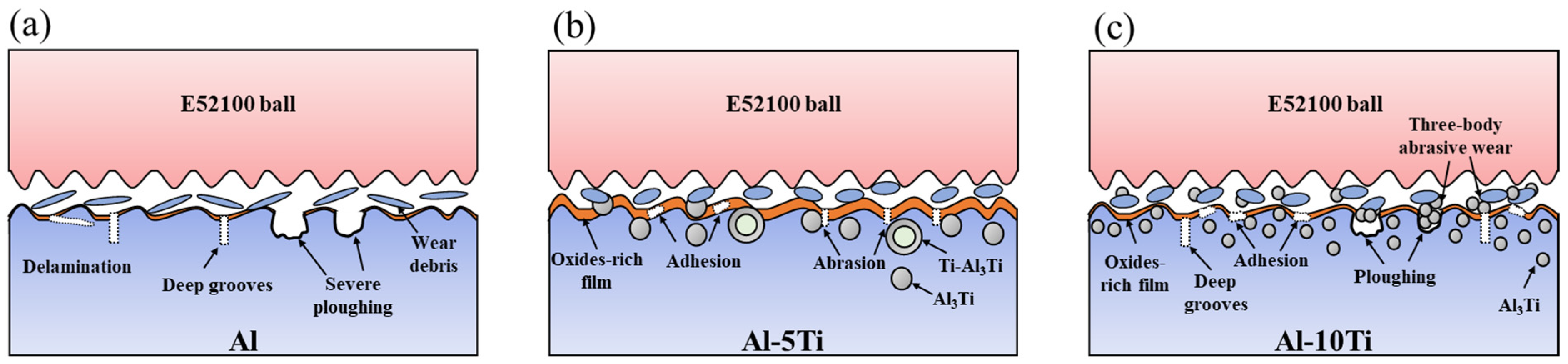

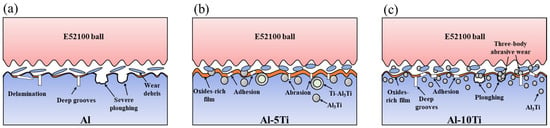

Overall, the wear mechanisms of pure Al and the composites regarding the influences of in situ Al3Ti particles in Al-5Ti and Al-10Ti can be summarized in a schematic illustration, as shown in Figure 13. Due to the soft nature of Al, the ability of the Al sample to resist the penetrating of the micro-asperities and the ploughing of the counterpart ball is poor. Therefore, deep grooves are formed as the counterpart ball slides, and large particles are delaminated as the cracks initiate and propagate during the wear process, as shown in Figure 13a. A relatively complete oxide-rich film cannot be formed, since the local materials are removed or transferred continuously. In the wear of Al-5Ti, the presence of Al3Ti particles and Ti-Al3Ti core-shell particles can help resist the plastic deformation caused by the sliding of the counterpart ball [36], as shown in Figure 13b. Furthermore, the frictional heat results in local adhesive wear and oxidation wear. The formed large-area oxide-rich film on the worn surfaces of Al-5Ti also improves the wear resistance compared to other samples. For the Al-10Ti composite, the large fraction of in situ formed Al3Ti particles leads to an extremely high hardness. However, this also makes the composite significantly more brittle and less tough. Therefore, the Al3Ti particles can either be pulled out, or wear debris containing a large amount of Al3Ti particles can be produced during the wear of Al-10Ti because of local fracture or failure [37]. These hard particles are then located between the composite and counterpart ball, leading to severe three-body abrasive wear, as shown in Figure 13c. In addition, due to the severe abrasion and the constant production of fresh surfaces, the area of oxide-rich film on the worn surfaces of Al-10Ti is smaller than that of Al-5Ti. Thus, Al-10Ti obtains a slightly higher wear rate than that of Al-5Ti, corresponding to a slightly lower wear resistance. Our results provide references for designing AMCs reinforced with in situ Al3Ti particles with superior wear resistance.

Figure 13.

Schematic illustration of wear mechanisms of (a) Al, (b) Al-5Ti and (c) Al-10Ti.

4. Conclusions

AMCs reinforced with in situ Al3Ti are fabricated via a powder metallurgy route in this work. The influences of raw Ti content on the in situ formation of Al3Ti particles, microstructures, Vickers hardness, and tribological properties of the samples have been investigated. The main conclusions are as follows.

(1) During the ball milling, the fracture of Al powders is promoted with the addition of Ti powders. The Al-10Ti powders are the finest after the ball milling. After sintering, fine Al3Ti particles and large Ti-Al3Ti core-shell particles form in the Al-5Ti, while only much finer Al3Ti particles are found in Al-10Ti. This is because sufficient inter-diffusion between the Al and Ti in Al-10Ti can be achieved due to the large specific area and short diffusion distance of the fine particles. However, for the large Ti particles in Al-5Ti, the inter-diffusion distance between the Al matrix and Ti was limited by the sintering time, and the central part of the large Ti particle remained as the Ti core.

(2) The Vickers hardness of the composites was significantly increased compared to the unreinforced Al. The Vickers hardness value rose to 143.3 HV for the Al-5Ti composite and reached the highest value at 331.2 HV for the Al-10Ti composite, which was 44.9% and 234.9% higher than that of the Al, respectively. The increased Vickers hardness can be attributed to the enhanced work hardening effects on the Al matrix powders during the ball milling and enhanced load-bearing ability upon indentation by the hard Al3Ti particles.

(3) The wear resistance of the composites was significantly improved compared to the unreinforced Al due to the presence of in situ formed Al3Ti particles in the composites. However, the wear resistance of the Al-10Ti composite is worse than that of the Al-5Ti composite due to the increased brittleness and decreased toughness of the composite with a large fraction of Al3Ti, as well as the result of the three-body abrasive wear during the sliding. Therefore, the Al-5Ti composite had the lowest specific wear rate among all of the samples, thus corresponding to the highest wear resistance.

Author Contributions

Conceptualization, F.L. and M.R.; methodology, F.L. and H.W.; validation, F.L. and M.R.; formal analysis, F.L., M.R., F.J. and Z.C.; investigation, F.L., M.R., H.W. and F.J.; resources, M.Y.; data curation, F.L.; writing—original draft preparation, F.L.; writing—review and editing, M.R., Z.C. and Z.J.; supervision, Z.C. and Z.J.; project administration, Z.J.; funding acquisition, Z.J. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Australian Research Council under the project of DP190100408. The first author appreciates China Scholarship Council (No. 201806080021) and the University of Wollongong for the scholarship support.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jagannatham, M.; Chandran, P.; Sankaran, S.; Haridoss, P.; Nayan, N.; Bakshi, S.R. Tensile properties of carbon nanotubes reinforced aluminum matrix composites: A review. Carbon 2020, 160, 14–44. [Google Scholar] [CrossRef]

- Ren, M.; Lin, F.; Jia, F.; Xie, H.; Yang, M.; Jiang, Z. Micro rolling fabrication of copper/SS304L micro composite channels. J. Manuf. Process. 2023, 90, 1–13. [Google Scholar] [CrossRef]

- Ren, M.; Xie, H.; Lin, F.; Jia, F.; Huo, M.; Wu, H.; Yang, M.; Jiang, Z. Evolutions of microstructure and mechanical properties of copper/SS304L composite micro channels during micro rolling. Mater. Sci. Eng. A 2023, 871, 144881. [Google Scholar] [CrossRef]

- Ramanathan, A.; Krishnan, P.K.; Muraliraja, R. A review on the production of metal matrix composites through stir casting—Furnace design, properties, challenges, and research opportunities. J. Manuf. Process. 2019, 42, 213–245. [Google Scholar] [CrossRef]

- Ren, M.; Xie, H.; Lin, F.; Jia, F.; Huo, M.; Wu, H.; Yang, M.; Jiang, Z. Effect of heat treatment on the microstructure and mechanical properties of copper/SS304L composite sheets. Vacuum 2022, 204, 111370. [Google Scholar] [CrossRef]

- Nie, J.; Chen, Y.; Chen, X.; Liu, X.; Liu, G.; Zhao, Y.; Zhu, Y. Stiff, strong and ductile heterostructured aluminum composites reinforced with oriented nanoplatelets. Scr. Mater. 2020, 189, 140–144. [Google Scholar] [CrossRef]

- Zhao, K.; Gao, T.; Yang, H.; Hu, K.; Liu, G.; Sun, Q.; Nie, J.; Liu, X. Enhanced grain refinement and mechanical properties of a high–strength Al–Zn–Mg–Cu–Zr alloy induced by TiC nano–particles. Mater. Sci. Eng. A 2021, 806, 140852. [Google Scholar] [CrossRef]

- Guo, B.; Du, Y.; Yan, N.; Song, M. Mechanical properties and microstructures of Al-10Mg-4.5Si matrix composites reinforced by carbon nanotubes. J. Alloys Compd. 2019, 792, 860–868. [Google Scholar] [CrossRef]

- Lin, F.; Jia, F.; Ren, M.; Wang, J.; Yang, M.; Chen, Z.; Jiang, Z. Microstructure, mechanical and thermal properties of ultrafine-grained Al2024–TiC-GNPs nanocomposite. Mater. Sci. Eng. A 2022, 841, 142855. [Google Scholar] [CrossRef]

- Lin, F.; Ren, M.; Jia, F.; Huo, M.; Yang, M.; Chen, Z.; Jiang, Z. Achieving balanced strength-ductility of heterostructured TiC/graphene nanoplatelets (GNPs) reinforced Al matrix composites by tuning TiC-to-GNPs ratio. Compos. Commun. 2023, 38, 101529. [Google Scholar] [CrossRef]

- Lin, Z.; Su, Y.; Qiu, C.; Yang, J.; Chai, X.; Liu, X.; Ouyang, Q.; Zhang, D. Configuration effect and mechanical behavior of particle reinforced aluminum matrix composites. Scr. Mater. 2023, 224, 115135. [Google Scholar] [CrossRef]

- Shen, Z.; Li, N.; Wang, T.; Wu, Z. Effects of SiC content on wear resistance of Al-Zn-Mg-Cu matrix composites fabricated via laser powder bed fusion. Crystals 2022, 12, 1801. [Google Scholar] [CrossRef]

- Gao, T.; Li, C.; Li, M.; Zhao, K.; Wu, Y.; Liu, X. Influence of heterogeneous microstructure on the tensile properties of (Al2O3+AlB2)/Al composites. Compos. Commun. 2022, 36, 101401. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoğlu, M.; Acarer, M. Effect of ball milling time on the structural characteristics and mechanical properties of nano-sized Y2O3 particle reinforced aluminum matrix composites produced by powder metallurgy route. Adv. Powder Technol. 2021, 32, 3826–3844. [Google Scholar] [CrossRef]

- Aydin, F. The investigation of the effect of particle size on wear performance of AA7075/Al2O3 composites using statistical analysis and different machine learning methods. Adv. Powder Technol. 2021, 32, 445–463. [Google Scholar] [CrossRef]

- Zeng, Y.; Himmler, D.; Randelzhofer, P.; Körner, C. Processing of in situ Al3Ti/Al composites by advanced high shear technology: Influence of mixing speed. Int. J. Adv. Manuf. Technol. 2020, 110, 1589–1599. [Google Scholar] [CrossRef]

- Tamizi Junqani, M.; Madaah Hosseini, H.R.; Azarniya, A. Comprehensive structural and mechanical characterization of in-situ Al–Al3Ti nanocomposite modified by heat treatment. Mater. Sci. Eng. A 2020, 785, 139351. [Google Scholar] [CrossRef]

- Yang, R.; Zhao, F.; Wang, L.; Zhang, Z.; Zhang, B. Fast fabrication of Al3Ti/Al composites using combustion synthesis and melt dilution. Mater. Lett. 2021, 298, 130036. [Google Scholar] [CrossRef]

- Zeng, Y.; Himmler, D.; Randelzhofer, P.; Körner, C. In situ Al3Ti/Al composites fabricated by high shear technology: Microstructure and mechanical properties. Mater. Sci. Technol. 2019, 35, 2294–2303. [Google Scholar] [CrossRef]

- Chen, G.; Jin, Y.; Zhang, H.; Han, F.; Chen, Q.; Xu, J.; Zhao, Z. Microstructures and mechanical properties of in-situ Al3Ti/2024Al composites after solution and subsequent aging treatment. Mater. Sci. Eng. A 2018, 724, 181–188. [Google Scholar] [CrossRef]

- Gupta, R.; Chaudhari, G.P.; Daniel, B.S.S. Strengthening mechanisms in ultrasonically processed aluminium matrix composite with in-situ Al3Ti by salt addition. Compos. Eng. 2018, 140, 27–34. [Google Scholar] [CrossRef]

- Ma, S.; Wang, Y.; Wang, X. The in-situ formation of Al3Ti reinforcing particulates in an Al-7wt%Si alloy and their effects on mechanical properties. J. Alloys Compd. 2019, 792, 365–374. [Google Scholar] [CrossRef]

- Gong, Y.P.; Ma, S.M.; Hei, H.J.; Ma, Y.; Zhou, B.; Wang, Y.S.; Yu, S.W.; Wang, X.; Wu, Y.C. Tailoring microstructure and its effect on wear behavior of an Al–7Si alloy reinforced with in situ formed Al3Ti particulates. J. Mater. Res. Technol. 2020, 9, 7136–7148. [Google Scholar] [CrossRef]

- Ma, J.; Niu, L.; Wu, H.; Gao, C.; An, Y. Formation and wear behaviors of in-situ Al3Ti/Al composites using aluminum and titanium fibers under electromagnetic induction heating. J. Cent. South Univ. 2020, 27, 3594–3602. [Google Scholar] [CrossRef]

- Wu, Y.; Luo, S.; Wu, J.; Guo, B.; Wu, Z.; Chen, B.; Yu, Z.; Zhang, Z.; Li, W. Development and characterization of CrCoNi medium entropy alloy particles reinforced aluminum matrix composite. Crystals 2022, 12, 1452. [Google Scholar] [CrossRef]

- Lin, F.; Wang, J.; Wu, H.; Jia, F.; Lu, Y.; Ren, M.; Yang, M.; Chen, Z.; Jiang, Z. Synergistic effects of TiC and graphene on the microstructure and tribological properties of Al2024 matrix composites. Adv. Powder Technol. 2021, 32, 3635–3649. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Al-Aqeeli, N. Mechanically alloyed nanocomposites. Prog. Mater. Sci. 2013, 58, 383–502. [Google Scholar] [CrossRef]

- Lin, F.; Ren, M.; Wu, H.; Jia, F.; Lu, Y.; Huo, M.; Yang, M.; Chen, Z.; Jiang, Z. Investigation of microstructure and tribological performances of high-fraction TiC/graphene reinforced self-lubricating Al matrix composites. Tribol. Int. 2023, 177, 108018. [Google Scholar] [CrossRef]

- Wang, W.; Heydari Vini, M.; Daneshmand, S. Mechanical and wear properties of Al/TiC composites fabricated via combined compo-casting and APB process. Crystals 2022, 12, 1440. [Google Scholar] [CrossRef]

- Feijoo, I.; Cabeza, M.; Merino, P.; Pena, G.; Pérez, M.C.; Cruz, S.; Rey, P. Estimation of crystallite size and lattice strain in nano-sized TiC particle-reinforced 6005A aluminium alloy from X-ray diffraction line broadening. Powder Technol. 2019, 343, 19–28. [Google Scholar] [CrossRef]

- Lin, F.; Ren, M.; Wu, H.; Lu, Y.; Huo, M.; Yang, M.; Chen, Z.; Jiang, Z. Fabrication of TiC-graphene dual-reinforced self-lubricating Al matrix hybrid nanocomposites with superior mechanical and tribological properties. Tribol. Int. 2022, 171, 107535. [Google Scholar] [CrossRef]

- Lin, F.; Ren, M.; Wu, H.; Lu, Y.; Yang, M.; Chen, Z.; Jiang, Z. Characterisation of microstructure, microhardness and tribological properties of Al matrix hybrid nanocomposites reinforced with B4C and in-situ GNSs. Wear 2023, 522, 204691. [Google Scholar] [CrossRef]

- Sharma, V.K.; Kumar, V.; Joshi, R.S. Effect of RE addition on wear behavior of an Al-6061 based hybrid composite. Wear 2019, 426–427, 961–974. [Google Scholar] [CrossRef]

- Wu, L.; Zhao, Z.; Bai, P.; Zhao, W.; Li, Y.; Liang, M.; Liao, H.; Huo, P.; Li, J. Wear resistance of graphene nano-platelets (GNPs) reinforced AlSi10Mg matrix composite prepared by SLM. Appl. Surf. Sci. 2020, 503, 144156. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; López, M.D.; Escalera, M.D.; Viejo, F. Influence of reinforcement content and matrix composition on the oxidation resistance of aluminum-matrix composites (A3xx.x/SiCp). Oxid. Met. 2003, 59, 1–21. [Google Scholar] [CrossRef]

- Umeda, J.; Nishimura, N.; Fujii, H.; Jia, L.; Kondoh, K. In-situ formed Al3Zr compounds reinforced Al composites and tribological application. Crystals 2021, 11, 227. [Google Scholar] [CrossRef]

- Gao, Y.-Y.; Qiu, F.; Zou, Q.; Chu, J.-G.; Dong, B.-X.; Han, X.; Yang, H.-Y.; Jiang, B.; Jiang, Q.-C. Controlling the sizes of in-situ TiC nanoparticles for high-performance TiC/Al–Cu nanocomposites. Ceram. Int. 2021, 47, 28584–28595. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).