Abstract

High temperature would dramatically worsen rheological behaviors and increase filtration loss volumes of drilling fluids. Synthetic polymers with high temperature stability have attracted more and more attention. In this paper, a novel quadripolymer was synthesized using 2-acrylamido-2-methylpropanesulfonic acid (AMPS), acrylamide (AM), sodium styrene sulfonate (SSS), and dimethyl diallyl ammonium chloride (DMDAAC). Firstly, the molecular structure was studied by Fourier transform–infrared spectroscope (FT-IR) and nuclear magnetic resonance (1H-NMR) analysis. It was shown that the synthetic polymer contained all the designed functional groups. Moreover, the effect of temperature and the quadripolymer concentration on the rheological behavior and filtration loss of the bentonite-free drilling fluid were investigated. It was experimentally established that when the adding amount of the quadripolymer was 0.9 wt%, the prepared drilling fluid systems exhibited relatively stable viscosities, and the filtration losses could be controlled effectively after hot rolling aged within 180 °C. Further, it was confirmed that the bentonite-free drilling fluid containing the synthesized quadripolymer had good reservoir protection performance. In conclusion, the synthetic quadripolymer is a promising rheology modifier and a filtrate reducer for the development of the bentonite-free drilling fluid at high temperature.

1. Introduction

Drilling fluid is indispensable in oil and gas drilling engineering to maintain wellbore stability, carry and transport drilled cuttings, and reduce water loss. It is divided into water-based drilling fluid system (WBDF), oil-based drilling fluid system (OBDF), and gas-based drilling fluid system (GBDF) [1]. Among them, a water-based working fluid is the most commonly used one because of its environmental friendliness and low cost, and it is mainly composed of bentonite clay and different functional polymer treating agents [2,3,4]. Bentonite as the most essential component in drilling fluid exhibits incomparable advantages in viscosity and filtration loss control [5,6]. Furthermore, clay particles can plug pores and fractures in the near wellbore area and form a thin and low-permeability filtration cake. However, as the number of deep and ultra-deep wells increases, one of the inevitable problems is that drilling fluid must endure high temperatures [7]. It is worth noting that high bentonite content of water-based drilling fluids at high temperatures would give rise to serious detrimental effects [8,9,10], for example, deterioration of rheological behavior, increase in filtration volume seeping into formation, particularly formation damages caused by dispersive clay particles. Thus, less or no bentonite in drilling fluids capable of providing necessary performance in harsh operating conditions should be contained to maintain the desired properties [11]. Xiao et al. prepared a bentonite-free drilling fluid with amphoteric polymer (FA367) as the main treating agent, and the filed application results in the shallow formations of Anpeng oilfield showed that the drilling speed greatly increased, and the complex conditions such as leakage and sticking were effectively alleviated [12].

In order that a drilling fluid with low or no bentonite could be appropriate for deep well drilling project, one or more polymers are required to take place of bentonite and provide satisfactory performance, such as proper rheological parameters, low filtration loss volume, and good salt tolerance at high temperature conditions [13,14,15]. However, one disadvantage of polymers is related to the thermal degradation at elevated temperatures (above 150 °C) [16,17], which gives rise to the rheology and filtration loss being difficult to meet the demands of field application. Thus, it is necessary to develop novel polymers with high temperature resistance to contribute to rheological stability and low filtration loss for bentonite-free drilling fluids.

Synthetic polymers have attracted researchers’ attentions for a long time. Water soluble polymers are universally used in water based drilling fluids. The rheological behavior and filtrates of drilling fluid can be adjusted primarily by adding them However, with the increase of well depth, one disadvantage of natural polymer is related to the thermal degradation and oxidation under high temperature (150 °C) [18,19] which could not control the rheology and filtration loss to meet the demands of the field application. Thus, regarding these disadvantages of natural polymer, some researchers were directed to synthetic polymer that could contribute to rheological stability and low fluid loss in water based fluids at HTHP conditions. Perricone et al. used acrylamido-methylpropanesulfonic acid (AMPS), acrylamide (AM), and alkyl acrylamide monomers to synthesize a copolymer (named COP) through inverse micro-emulsion polymerizations [20]. In the field application, the drilling fluid with this synthetic product showed good high temperature resistance. Furthermore, Tao et al. (2011) synthesized a terpolymer of AM/acrylic acid/sodium styrene sulfonate (SSS) and evaluated its high temperature and high pressure rheological property with various salt concentrations [21]. Wu et al. synthesized AM/AMPS/itaconic acid (IA)/N-vinyl caprolactam (NVCap) by solution polymerization. It is reported that drilling fluid containing this terpolymer could control fluid loss and rheological properties after aging at 220 °C [22]. Some other synthetic polymers were developed and were used as rheology modifiers and filtrate reducers, which indicated that the sulfonate structure can be resistant to high temperature and salt [23,24,25]. The excellent performance of the drilling fluid decides the formation protection and drilling efficiency in deep wells [26].

In this paper, a new quadripolymer was synthesized with monomers of AMPS, AM, DMDAAC, and SSS by aqueous solution polymerization. Among these, amide group provided by AM monomer is mainly responsible for forming the main chain structure. The sulfonic acid group of AMPS plays a role of hydration, and the side group -(CH3)2CH2SO3Na can enhance the rigidity of the molecular chain, thus improving the thermal stability of the product. The rigid group of benzene ring contained in SSS monomer has a strong hindering effect [27,28]. Then, two double bonds in the molecule of DMDAAC contribute to form mesh structure. Thus, such a quadripolymer was characterized with Fourier transform infrared spectroscopy and nuclear magnetic resonance. Firstly, the ability of the quadripolymer in adjusting rheological and filtration performance of bentonite-free fluids at elevated temperatures were studied by thermal aging test. Meanwhile, the salt tolerance of the bentonite-free drilling fluid was evaluated through an investigation of the viscosity change of the fluid system in different salinity of sodium chloride solution. Additionally, the reservoir protection performance of the bentonite-free drilling fluid containing the quadripolymer was evaluated experimentally.

2. Materials and Methods

2.1. Materials and Experiment Instruments

Acrylamide(AM), 2-acrylamido-2-methylpropanesulfonic acid (AMPS), dimethyl diallyl ammonium chloride(DMDAAC), sodium styrene sulfonate (SSS), chemical grade, were purchased from Aladdin Reagent Co., Ltd. (Shanghai, China); Ammonium persulfate ((NH4)2S2O8) and sodium hydrogen sulfite (NaHSO3), sodium hydroxide (NaOH), sodium carbonate (Na2CO3), analytical grade, were employed without further purification.

Drispac and HE150 were purchased from Chevron Phillips Chemical Company, Texas, America; 80A51, PAM, LOCKSEAL, PAC-LV and sized CaCO3 were collected from Jiahua Technology Co., Ltd., Jingzhou City, China. The experiment instruments used for this study are listed in Table 1.

Table 1.

Experiment instruments and the providers.

2.2. Methods

2.2.1. Synthesis of Quadripolymer

The quadripolymer of AM, AMPS, SSS, DMDAAC was synthesized by solution free radical polymerization. The effect of molar ratio of four monomers, dosage of initiator, pH and reaction temperature on optimizing the best synthesis condition was determined (AM: AMPS: SSS: DMDAAC is 10:3:3:2, redox initiator dosage((NH4)2S2O8) is 0.2 wt%, temperature is 80 °C and reactants system pH is 7) by dosage experiment.

Firstly, a desired amount of mixture monomers was mixed well in a reaction flask and deoxygenated with nitrogen. Secondly, sodium hydroxide was used to adjust the pH value (pH = 7) of the reaction system. The whole reaction process took place in a constant temperature oil bath. Next, a redox initiator ((NH4)2S2O8) dosage of 0.2 wt% was added into the above solution with a constant stirring speed of 200 r/min. After 5 h of reaction time, the white product was filtered off and extracted with acetone and methanol for three times, and finally dried powders were obtained.

2.2.2. Characterization of Molecular Structure

FT-IR spectrum of the quadripolymer was recorded on a Nicolet 6700 Fourier Transform Infrared Spectrometer. A pellet sample made from a mixture of 1 mg quadripolymer and about 100 mg of potassium bromide (KBr) was prepared under a pressure of 100 psi and tested in the optical range of 400–4000 cm−1.

1H NMR spectrum of the quadripolymer was measured by Angilent 400 MHz Nuclear magnetic resonance spectrometer. Mass of 10 mg of sample powder was dissolved into a test tube containing 0.65 mL D2O, and then transferred to a sample cavity. 1H NMR spectrum measurement was carried out with controlled heating and cooling steps.

Thermal stability: The thermal stability of the quadripolymer was tested with HCT-1 Differential Thermobalance analyzer (Beijing Henven Instrument Plant, Beijing, China) in nitrogen gas atmosphere. The heating rate was 10 °C/min, and the temperature was in the range of 30–600 °C.

2.2.3. Sample Preparation

Base formula of bentonite-free drilling fluid (marked as formula1#) was prepared as follows: 1000 mL deionized water, 0.1 wt% NaOH, 0.15 wt% Na2CO3, desired amount of polymer (the quadripolymer or Drispac), 2 wt% PAC-LV, 2 wt% LOCKSEAL, 4 wt% super-fine CaCO3, 0.5 wt% Na2SO3 were weighted and added sequentially at high speed stirring for 20 min with a GJSS-B12K multi-spindle mixer, and then the solution was stood still for 24 h at room temperature for complete dissolution.

2.2.4. Drilling Fluid Performance Measurements

Rheological and filtration properties of bentonite-free drilling fluid were evaluated according to the American Petroleum Institute test program [29], Formulas (1)–(3) were applied to calculate the rheological parameters, including apparent viscosity (AV), plastic viscosity (PV) and yield point (YP), for the fluid system. The readings at 600 rpm and 300 rpm obtained with a ZNN-D6 six-speed rotational viscometer were marked as Φ600 and Φ300, respectively. The initial and final gel strength were also measured and marked as G1 and G2. Before thermal stability evaluation, the bentonite-free drilling fluid was required to be heated at a given temperature for 16 h with a XGRL-4A hot roller oven and then cooled to ambient temperature.

AV (Apparent viscosity) = Φ600/2, mPa·s,

PV (Plastic viscosity) = Φ600−Φ300, mPa·s,

YP (Yield point) =0.511(Φ300−PV), Pa,

API filtration loss (FLAPI) was determined by a SD-4 API filtration apparatus with a pressure difference of 100 psi at ambient temperature for 30 min. HTHP filtration loss (FLHTHP) was measured with a GCS71-A HTHP filtration apparatus at 150 °C and 500 psi for 30 min. After the test, the filtrate was collected into the measuring cylinder and the volume was recorded.

HTHP rheology test: After placing the drilling fluid inside the rheometer, the sample was heated up to the desired temperature and meanwhile pre-shear at 100 s−1 was performed before rheological measurement. The pressure was adjusted to 500 psi and the shear stress was measured at the shear rate of 511 s−1.

Reservoir protection test: The core original kerogen permeability K0 was measured as follows, Formula (4), wherein, Q, flow rate; μ, Kerosene viscosity; l, Core length; , Differential pressure before and after flow through the core; A, core, end surface area.

In step 1, the core saturated with simulated groundwater is placed into the core holder and repelled with filtered and dewatered kerosene at 0.4 times the critical flow rate; subsequently, repelled at 0.8 times the critical flow rate until no water flows out and the pressure is stable. According to the above formula, K0 can be calculated.

In step 2, the core tested for K0 is quickly loaded into the core holder of JHDS high temperature and high pressure dynamic water loss instrument, and the formulation drilling fluid is injected in the reverse direction at 90 °C and 3.5 MPa differential pressure, and cycled at a shear rate of 300 s−1 for 125 min. The core is loaded into the gripper and repelled at the same flow rate as in step 1, and the contaminated permeability K1. is calculated after the pressure and flow rate are stabilized.

In step 3, the end face of the core contaminated by drilling fluid in step 2 is cut off for about 1 cm, and step 2 is repeated to obtain the core permeability K2.

3. Results and Discussion

3.1. Characteristic

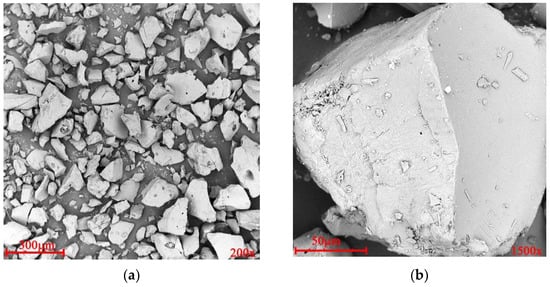

The quadripolymer used in this study was milky white dispersion. The scanning electron microscopy (SEM) picture is shown in Figure 1. The microstructure of the quadripolymer had the following characteristic: irregular shapes, different sizes (Figure 1a), and smooth surface (Figure 1b) of the particles were easily recognizable. Among them, the particle size is relatively widely distributed. The largest is around 200 microns and the smallest is just under 10 microns.

Figure 1.

Microscopic images of the quaripolymer particles: (a) 200 times, (b) 1500 times.

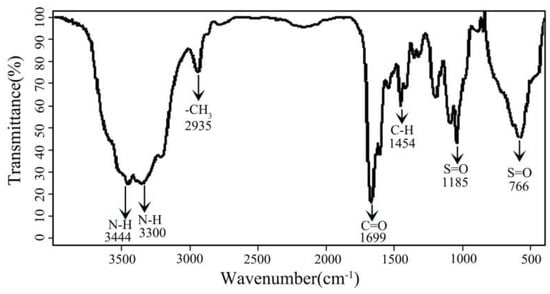

The FT-IR spectrum of the quadripolymer is presented in Figure 2. Moreover, 3444 cm−1 and 3300 cm−1 are assigned to the N-H stretching vibration of AM and AMPS, respectively. The absorbency at 2935 cm−1 results from the characteristic peak of the methyl group. The stretching vibration of C=O at 1699 cm−1 is attributed to AM and AMPS. The absorption peak observed at 1454 cm−1 is due to the C-H bending vibration from DMDAAC unit. Bands recorded at 1185 cm−1 and 1044 cm−1 assigned to S=O stretching vibration in the sulfonic group correspond to SSS unit. The absorption peaks at 766 cm−1 reveal the bending vibration of a benzene ring of the SSS unit.

Figure 2.

FT−IR spectrum of quadripolymer (AM/AMPS/DMDAAC/SSS).

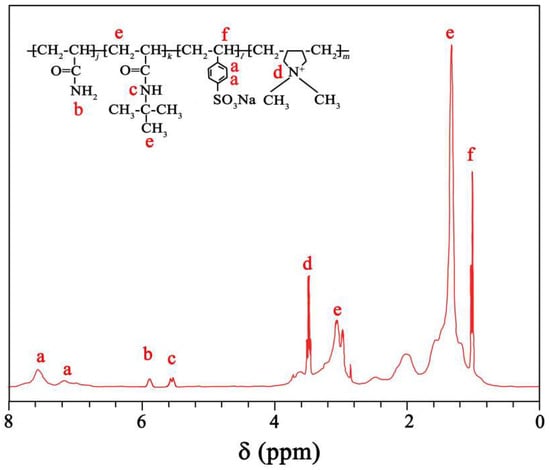

The 1H-NMR spectrum of the quadripolymer is shown in Figure 3. Bands recorded at 7.48 ppm (a1) and 7.24 ppm (a2) indicate the chemical shift in the benzene ring of SSS units. The N-H proton from 5.87 to 5.92 ppm (b) are related to AM. The peaks between 5.51 and 5.63 ppm (c) are due to the N-H proton vibration of AMPS. The characteristic peak at 4.79 ppm belongs to the chemical shift of D2O protons. Broad peaks between 3.45 and 3.53 ppm (d) are assigned to N-C proton of DMDAAC. Respectively, the peaks at 2.76 ppm and 1.65 ppm correspond to the chemical shift of –CH2 and –CH3 of AMPS (e). The board peak at 2.93 ppm and 1.45 ppm are related to the -CH- linked with the benzene ring and the main chain of SSS, respectively (f). Combined with the FT-IR spectrum, the quadripolymer molecular structure is consistent with the designed one.

Figure 3.

1H−NMR spectrum of quadripolymer (AM/AMPS/DMDAAC/SSS).

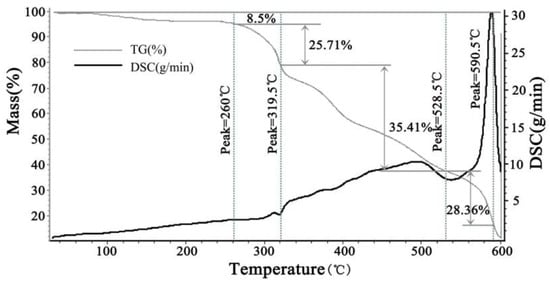

From the TG curve (Figure 4), it can be found that the four stages of the thermal degradation process, first stage, the quadripolymer has 8.5% of mass losses before 260 °C, indicating slightly thermal degradation from chain scissionThe second stage is from 260 °C to 319.5 °C, apparent mass loss of the quadripolymer occurs (27.71%) in the TG curve and the fastest mass loss temperature emerges at 300.5 °C in the DSC curve. The third stage is from 319.5 °C to 528.5 °C, the mass loss declines constantly (35.43%). the release of the non-cyclic anhydrides formation acrylic acid repeat unit or the carboxylic acid pendant group. Moreover, accordingly, there is no significant fluctuation on the DSC curve. The last stage is from 528.5 °C to 600 °C, 28.36% mass is left. This might be due to the thermal degradation of C=C decomposition in the main chain of AM and SSS segments and the breakage of benzene ring in SSS monomers. From the above analysis, the thermal degradation of the quadripolymer is not obvious before 260 °C and only 27.7%, which demonstrates the quadripolymer has strong heat-resistance ability.

Figure 4.

TG- DSC curve.

The data of quadripolymer molecular weight is follow in Table 2. Based on the molecular structure of the quadripolymer. The weight-average molecular weight is 1161,000 g/mol, and the number-average molecular weight is 684,000 g/mol. Besides, the viscosity-average molecular weight is 1090,000 g/mol calculated with Mark–Houwink–Sakurada equation (Mη = 802*[η]1.25), among which the η value is 3.236 dL/g measured by Ubbelohdo viscometer (the flowing time of 0.1 wt% quadripolymer solution). Moreover, the molecular weight distribution index PDI is 1.6974, indicating that the quadripolymer has narrow molecular weight distribution.

Table 2.

Molecular weight indexed of copolymer.

3.2. Performance Evaluation of Bentonite-Free Drilling Fluid with the Quadripolymer

3.2.1. Rheological Behavior

A drilling fluid having good rheological properties (low plastic viscosity value, suitable gel strength, and high yield point) will provide good cuttings transportation efficiency in drilling operation. To investigate the influence of the quadripolymer on the rheological behavior of the bentonite-free drilling fluid, various amount (from 0.3 to 0.9 wt%) of two polymers were added to the base formula and the rheological parameters, such as the apparent viscosity (AV), plastic viscosity (PV), and yield point (YP), were measured and compared.

As illustrated in Table 3, the two polymer drilling fluids display a remarkable increase in rheological parameters (AV, PV, and YP), as the concentration of polymer increases in the range from 0.3 to 0.9 wt%, which is mainly because that polymer contributes to forming the network structure of fluids and consequently improving the rhelogical properties. Compared with Drispac, PV values of the quadripolymer containing bentonite-free fluid system are relatively lower at the same polymer concentrations on the whole, while YP show relatively higher values. Moreover, the quadripolymer system exhibits a dynamic ratio (YP/PV) of up to 0.80, significantly larger than that of Drispac, at polymer concentration of 0.9 wt%, indicating that the quadripolymer has good shear thinning property. Lastly, gel strength of drilling fluid describes the capacity to suspend the drilling cuttings when the pump is shut down. It can be observed that the increase in concentration of the quadripolymer contributes to a more dramatic increase than Drispac in G1 and G2. The enhanced gel strength is attributed to the interactions among polymer molecules. Therefore, the bentonite-free drilling fluid with the quadripolymer has excellent cuttings suspending and carrying capacity.

Table 3.

Influence of polymer concentration on rheological behavior of base formula.

3.2.2. Salt Resistance

It is shown from Table 4 that all bentonite-free polymer drilling fluids with NaCl have lower rheological parameters than that without salt. Furthermore, as the salt content increases, all the rheological parameters display a remarkable decreasing trend. This is mainly because of charge shielding effect. Na+ has strong ability to compress electric double layer of polymer and neutralize negative charge on ionized polymer, which could reduce an electrostatic repulsion force between particles to lower viscosity values, thus destroying network structure between polymer molecules. Furthermore, with a further increase in salt, large amount of Na+ will increase the polarity of solution and enhance the hydrophobic associate effect, which can compensate the decrease of viscosity to a certain extent [30]. However, it could be seen clearly that compared with Drispac containing fluids, the quadripolymer shows a less variation in rheological parameters and has higher YP and gel strength values at the same salt concentration of 5 wt% and 10 wt%, respectively, suggesting that the quadripolymer has better salt resistance than Drispac.

Table 4.

Influence of salt concentration on rheological behavior of bentonite-free drilling fluid.

3.2.3. Filtration Property

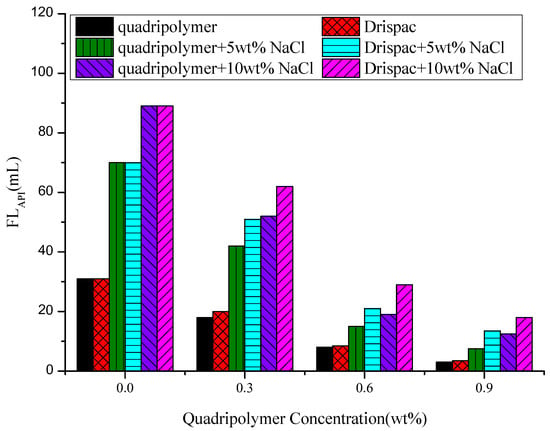

For filtration property, the API filtration (FLAPI) experiments were performed under a pressure of 100 psi and room temperature. The effect of salinity and polymers on filtration performance of bentonite-free drilling fluid is presented in Figure 5.

Figure 5.

Effect of salinity and polymers on filtration property of bentonite-free drilling fluid.

Dramatic decreases in FLAPI of both fresh and salt fluid samples are seen as the dosage of polymer increases from 0 to 0.9 wt%. Firstly, in deionized water, FLAPI of the bentonite-free fluids with 0.9 wt% quadripolymer and Dispac decrease to 3 mL and 3.5 mL, respectively. The two polymers have approximately equal ability to control the filtration loss in fresh water environment. Similarly, in electrolyte solution, the filtration loss variations also present a declining trend with increasing polymer concentration, but the volumes are considerably higher than those in fresh water solution. This is mainly because that the molecular chains of polymer cannot be fully stretched in salt water, and subsequently the repulsive forces between molecular reduce and a high permeable filtration cake is formed. For all that, compared with FLAPI of Drispac containing salt system (18 mL), at 0.9 wt%, FLAPI of bentonite-free drilling fluid with the quadripolymer can be controlled within 12.5 mL, which demonstrates that the quadripolymer has better filtration loss control property in brine drilling fluid.

3.2.4. Thermal Stability

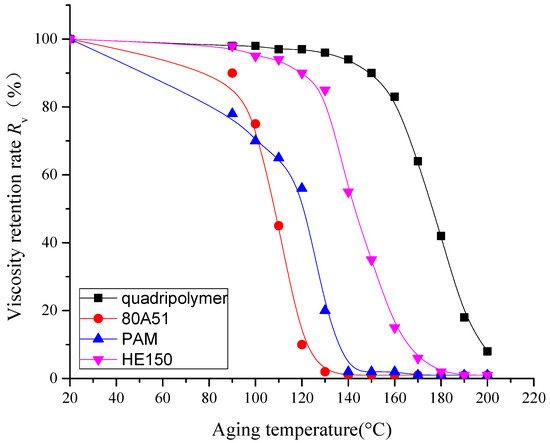

In petroleum industry, it is well known that high temperature would dramatically worsen rheological property and increase filtration volume loss of drilling fluids. Therefore, common used polymers PAM, 80A51, HE150 were compared with the quadripolymer to investigate their high temperature resistance. The initial viscosity was recorded as V1 when polymer solutions were prepared at 0.9 wt%. Then, the polymer solutions were hot rolling aged at different temperatures for 16 h, and the residual viscosity was marked as V2. The viscosity retention rates at different temperatures are shown in Figure 6.

Figure 6.

Viscosity retention rate of polymers at different aging temperature.

As illustrated in Figure 6, as the aging temperature increases, the viscosity retention rates of different polymers generally show downward trends, but the change degree varies. Among them, the viscosity of the two polymers, PAM and 80A51, has been basically lost after aging at 140 °C. In contrast, HE150 and the quadripolymer have higher viscosity retention rates at the same temperature, especially for the quadripolymer, the viscosity retention rate is as high as 40% even when the aging temperature reaches to 180 °C, and nearly 10% at 200 °C. Therefore, compared with other three polymers commonly used in drilling fluids, the quadripolymer has better temperature resistance.

In order to further study the effect of the quadripolymer on the thermal stability of the bentonite-free drilling fluid, the rheological and filtration properties were evaluated before and after hot rolling aging at various temperatures (25 °C, 100 °C, 120 °C, 140 °C, 160 °C, 180 °C, 200 °C), and the results are shown in Table 5.

Table 5.

Influence of thermal aging temperature on performance of bentonite-free drilling fluid.

As shown in Table 5, it can be clearly observed that in the aging temperature range of 100–180 °C, all parameters variation are within the acceptable range, showing a good thermal stability. PV value of the quadripolymer bentonite-free drilling fluid still remains at 20 mPa·s after aging at 180 °C. Meanwhile, FLAPI and FLHTHP are controlled within 8.6 mL and 24.8 mL, respectively. However, when the aging temperature rises to 200 °C, the rheological parameters of the bentonite-free drilling fluid with the quadripolymer show an obvious decreasing trend, and the amount of filtration loss markedly increases, indicating that the comprehensive properties of drilling fluid are out of control. Based on the above analysis, it can be demonstrated that the bentonite-free drilling fluid prepared by the quadripolymer possesses excellent ability to maintain viscosity and filtration loss at the temperature of 180 °C.

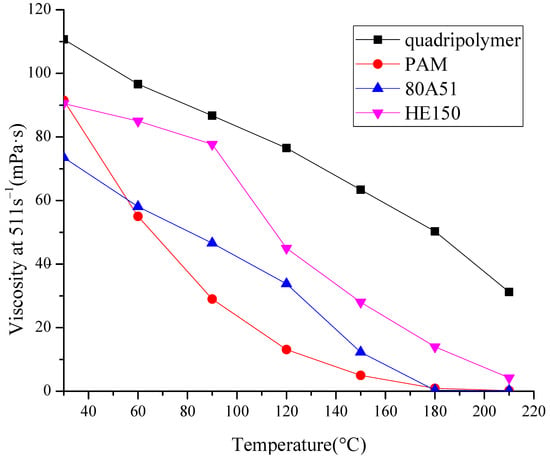

3.2.5. HTHP Rheology

In order to determine the rheological characteristics of the synthetic quadripolymer under high temperature and high pressure environment, the HTHP rheology test of four common high temperature resistant polymers were performed. A constant shear rate (511 s−1) was applied at different temperatures. Moreover, the curves of viscosity changing with temperature are presented in Figure 7.

Figure 7.

HTHP rheology curves of different polymer solutions.

As shown in Figure 6, heating causes the rapid drop in the viscosity of polymer solutions, especially for PAM, 80A51 and HE150. Among the four polymers, the viscosity reduction rates of the three polymers mentioned above are much higher than that of quadripolymer. When temperature rises to 180 °C, the viscosities of the PAM and 80A51 solution are close to 0. In contrast, the quadripolymer has higher viscosity values at each temperature point than those of the other three polymers in the temperature range of 200 °C, which further suggests that the quadripolymer has good temperature resistance at high temperatures.

3.2.6. Reservoir Protection Performance

ZDY50–180 core flow tester and oil reservoir cores taken from Well TK10 at the depth of 5298.83–5299.50 m, were used for reservoir protection evaluation of the bentonite-free drilling fluid with the new quadripolymer.

The degree of reservoir damage caused by drilling fluid can be characterized by the change of permeability before and after core contamination by drilling fluid, i.e., the lower permeability of core contamination means the higher degree of reservoir damage. It is clear that the permeability of both cores (sample a and sample b) after contamination is restored to more than 85% (Table 6). Moreover, the permeability recovery rate of two cores are obviously improved and reaches up as high as 95.7% and 94.2%, respectively, after cutting off 1 cm of contaminated core section, which indicates that the bentonite-free drilling fluid has a good protective effect on reservoir.

Table 6.

Reservoir protection performance test for bentonite-free polymer drilling fluid.

4. Conclusions

A novel hydrophilic polymer was prepared with AM, AMPS, DMDAAC, and SSS monomers via a method of free radical polymerization in aqueous solution. The new polymer was characterized by 1H NMR and FT-IR analysis. Results indicated the quadripolymer molecular structure was consistent with the designed one. Moreover, the rheological and filtration properties of the bentonite-free drilling fluid containing the quadripolymer and Drispac were examined in deionized and salt water at various temperatures. As a result, the rheological parameters regularly increased with increasing dosage of polymers. Simultaneously, the viscosity of the salt water fluid system was explicit smaller than that of the fresh water system. Additionally, when the adding amount was 0.9 wt%, it was confirmed that FLAPI of two polymers drilling fluid systems decreased to 3 mL and 3.5 mL, respectively, which are in acceptable range. The thermal stability test of bentonite-free drilling fluid showed that the quadripolymer drilling fluid could maintain a certain viscosity value, and FLAPI and FLHTHP were also controlled within 8.6 mL and 24.8 mL, respectively. In HTHP rheology test, the synthetic polymer showed superior resistance to high temperature than commonly used polymers. As for its damage to the reservoir, the permeability recovery of cores reached more than 95.72%. In general, the synthesized polymer has good properties of high temperature resistance and salt tolerance in controlling rheology and filtration loss of the bentonite-free drilling fluid system.

Author Contributions

Conceptualization, J.W. and W.Z.; methodology, J.W.; software, M.C.; validation, X.L. and J.W.; formal analysis, J.W.; investigation, X.Y.; resources, J.W.; data curation, X.Y.; writing—original draft preparation, J.W.; writing—review and editing, J.W. and X.L.; supervision, W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not application.

Informed Consent Statement

Not application.

Data Availability Statement

Not application.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that have appeared to influence the work reported in this paper.

References

- Caeen, R.; Darley, H.C.H.; Gray, G.R. Composition and Properties of Drilling and Completion Fluids, 7th ed.; Gulf Professional Publishing: Waltham, MA, USA, 2017; pp. 36–38. [Google Scholar]

- Yan, L.L.; Wang, C.B.; Xu, B.; Sun, J.S.; Yue, W.; Yang, Z.X. Preparation of a Novel Amphiphilic Comb–like Terpolymer as Viscosifying Additive in Low-solid Drilling Fluid. Mater. Lett. 2013, 105, 232–235. [Google Scholar] [CrossRef]

- Liu, F.; Jiang, G.C.; Peng, S.L.; He, Y.B.; Wang, J.X. Amphoteric Polymer as an Anti–calcium Contamination Fluid–loss Additive in Water-based Drilling Fluids. Energy Fuels 2016, 30, 7221–7228. [Google Scholar] [CrossRef]

- Yang, X.J.; Mao, J.C.; Chen, Z.X.; Chen, Y.N.; Zhao, J.Z. Clean fracturing fluids for tight reservoirs: Opportunities with viscoelastic surfactant. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 1446–1459. [Google Scholar] [CrossRef]

- Mahto, V.; Sharma, V.P. Rheological Study of a Water Based Oil Well Drilling Fluid. J. Petrol. Sci. Eng. 2004, 45, 123–128. [Google Scholar] [CrossRef]

- Gautam, S.; Guria, C.; Rajak, D.K.; Pathak, A.K. Functionalization of Fly Ash for the Substitution of Bentonite in Drilling Fluid. J. Petrol. Sci. Eng. 2018, 166, 63–72. [Google Scholar] [CrossRef]

- Sepehri, S.; Soleyman, R.; Varamesh, A.; Valizadeh, M.; Nasiri, A. Effect of Synthetic Water-Soluble Polymers on the Properties of the Heavy Water-based Drilling Fluid at High Pressure-High Temperature (HPHT) Conditions. J. Petrol. Sci. Eng. 2018, 166, 850–856. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Mohammed, A. Effect of Nanoclay on the Electrical Resistivity and Rheological Properties of Smart and Sensing Bentonite Drilling Muds. J. Petrol. Sci. Eng. 2015, 130, 86–95. [Google Scholar] [CrossRef]

- Azouz, K.B.; Bekkour, K.; Dupuis, D. Influence of the Temperature on the Rheological Properties of Bentonite. Appl. Clay Sci. 2016, 123, 92–98. [Google Scholar] [CrossRef]

- Song, K.L.; Wu, Q.L.; Li, M.C.; Wojtanowicz, A.K.; Dong, L.; Zhang, X.; Ren, S.; Lei, T. Performance of Low Solid Bentonite Drilling Fluids Modified by Cellulose Nanoparticles. J. Nat. Gas Sci. Eng. 2016, 34, 1403–1411. [Google Scholar] [CrossRef]

- Zhou, H.; Deville, J.P.; Davis, C.L. Novel Thermally Stable High-density Brine-based Drill-in Fluids for HP/HT Applications. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 8–11 March 2015. [Google Scholar]

- Xiao, J.F.; Li, Z.J.; Liu, Z.X. Application of Solid Free Drilling Fluid in Anpeng Oilfield. Drill. Fluid. Complet. Fluid 2002, 19, 82–84. [Google Scholar]

- Mustafa, V.K.; Tolga, A. Effect of polymers on the rheological properties of KCl/Polymer Type Drilling fluids. Energy Sources Part A Recovery Util. Environ. Eff. 2005, 27, 405–415. [Google Scholar] [CrossRef]

- Fink, J. Petroleum Engineer’s Guide to Oil Field Chemicals and Fluids, 2nd ed.; Gulf Professional Publishing/Elsevier: Waltham, MA, USA, 2012; pp. 1–60. ISBN 978-0-12-383844-5. [Google Scholar]

- Elkatatny, S. Enhancing the Stability of Invert Emulsion Drilling Fluid for Drilling in High-pressure High-temperature Conditions. Energies 2018, 11, 2393. [Google Scholar] [CrossRef] [Green Version]

- Tehrani, M.A.; Popplestone, A.; Guarneri, A.; Carminati, S. Water Based Drilling Fluid for HT/HP Applications. In Proceedings of the SPE International Symposium on Oilfield Chemistry, Houston, TX, USA, 28 February 2007. [Google Scholar]

- Stefano, G.D.; Stamatakis, E.; Young, S. Meeting the Ultrahigh-temperature/Ultrahigh-pressure Fluid Challenge. SPE Drill. Completion 2013, 28, 86–92. [Google Scholar] [CrossRef]

- Li, M.C.; Wu, Q.; Song, K.; Qing, Y.; Wu, Y. Cellulose Nanoparticles as Modifiers for Rheology and Fluid Loss in Bentonite Water-Based Fluids. ACS Appl. Mater. Interfaces. 2015, 7, 5006–5016. [Google Scholar] [CrossRef] [PubMed]

- Taye, S.O.; Johann, P. Preparation and Properties of a Dispersing Fluid Loss Additive Based on Humic Acid Graft Copolymer Suitable for Cementing High Temperature (200°C) Oil Wells. J. Appl. Polym. Sci. 2013, 129, 2544–2553. [Google Scholar] [CrossRef]

- Perricone, A.C.; Enright, D.P.; Lucas, J.M. Vinyl Sulfonate Copolymers for High-temperature Filtration Control of Water-based Muds. SPE Drill. Eng. 1986, 1, 358–364. [Google Scholar] [CrossRef]

- Tao, W.; Jie, Y.; Sun, Z.S.; Wang, L.; Wang, J. Solution and Drilling Fluid Properties of Water Soluble AM-AA-SSS Copolymers by Inverse Microemulsion. J. Petrol. Sci. Eng. 2011, 78, 334–337. [Google Scholar] [CrossRef]

- Wu, Y.M.; Zhang, B.Q.; Wu, T.; Zhang, C.G. Properties of the Forpolymer of N-Vinylpyrrolidone with Itaconic Acid, Acrylamide and 2-Acrylamido-2-Methyl-1-Propane Sulfonic Acid as a Fluid-Loss Reducer for Drilling Fluid at High Temperatures. Colloid Polym. Sci. 2001, 279, 836–842. [Google Scholar] [CrossRef]

- Munawar, K.; Munawar, J.B.K. Viscoplastic Modeling of a Novel Lightweight Biopolymer Drilling Fluid for Underbalanced Drilling. Ind. Eng. Chem. Res. 2012, 51, 4056–4068. [Google Scholar] [CrossRef]

- Bai, X.D.; Yang, Y.; Xiao, D.Y.; Pu, X.L.; Wang, X. Synthesis, Characterization, and Flocculation Performance of Anionic Polyacrylamide P (AM-AA-AMPS). J. Appl. Polym. Sci. 2013, 129, 1984–1991. [Google Scholar] [CrossRef]

- Wu, Y.M.; Sun, D.J.; Zhang, B.Q.; Zhang, C.G. Properties of High-Temperature Drilling Fluids Incorporating Disodium Itaconate-Acrylamide-Sodium 2-Acrylamido-2-Methyl-Propane Sulfonate Terpolymers as Fluid-Loss Reducers. J. Appl. Poly. Sci. 2002, 83, 3068–3075. [Google Scholar] [CrossRef]

- Peng, B.; Peng, S.; Long, B.; Miao, Y.; Guo, W.Y. Properties of High-Temperature Resistant Drilling Fluids Incorporating Acrylamide/(Acrylic Acid)/(2-Acrylamido-2-Methyl-1-Propane Sulfonic Acid) Terpolymer and Aluminum Citrate as Filtration Control Agents. J. Vinyl. Addit. Technol. 2010, 16, 84–89. [Google Scholar] [CrossRef]

- Huang, Y.M.; Zhang, D.Y.; Zheng, W.L. A Synthetic Copolymer (AM/AMPS/DMDAAC/SSS) as Rheology Modifier and Fluid Loss Additive at HTHP for Water-Based Drilling Fluids. J. Appl. Poly. Sci. 2019, 139, 47813. [Google Scholar] [CrossRef]

- Stamatakis, E.; Steve, Y.; Guido, D.S.; Swaco, M.-I. Meeting the Ultra HTHP Fluids Challenge. In Proceedings of the SPE Oil and Gas India Conference and Exhibition, Mumbai, India, 28–30 March 2012. [Google Scholar]

- API Recommended Practice. Recommended Practice for Field Testing Water–based Drilling Fluids. In API Recommended Practice13B–1, 3rd ed.; API Publishing Services: Washington, DC, USA, 2003; pp. 7–8. [Google Scholar]

- Guo, H.; Brûlet, A.; Rajamohanan, P.R.; Marcellan, A.; Sanson, N.; Hourdet, D. Influence of Topology of LCST-Based Graft Copolymers on Responsive Assembling in Aqueous Media. Polymer 2015, 60, 164–175. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).