Abstract

In this study, we applied microbial induced calcium carbonate precipitation (MICP) technology to improve the undesirable characteristics of Pisha sandstone weathered soil that collapses easily upon environmental erosion. Through disintegration tests and wind erosion tests, the anti-water scour and anti-sand erosion performance of the weathered soil was tested before and after the improvement. Combined with an analysis of the physical properties and pore structure of the samples, this paper analyzes the internal mechanism by which MICP technology improves the poor characteristics of the soil. The results show that after improvement with the use of MICP technology, effective cementation is formed between the soil particles to form a solidified material with a strength of up to 1 MPa with a precipitated carbonate content of up to 15%, which effectively improves the water erosion resistance and wind erosion resistance. The disintegration rate of the improved soil sample was only 1.95% at the 30th minute, the remolded soil completely disintegrated, and the undisturbed soil reached 39.64%. The wind erosion resistance of the improved sample is improved, and its coefficient at a 30° erosion angle is increased roughly 20-fold on average when the wind speed is 31 m/s. The internal mechanism of the improved soil when it comes into contact with water and wind is that the induced calcium carbonate crystals fill the pores of the soil particles and adhere to and bridge between soil particles for effective cementation. When the soil expands after water invasion or the soil is destroyed after external erosion, the cementation of mineral crystals on the particles can resist the expansion force and punching force so as to improve the soil’s overall anti-erosion performance.

1. Introduction

Pisha sandstone is a kind of loose rock strata commonly encountered by local people in the Shanxi, Shaanxi and Inner Mongolia regions of China, which is concentrated in the Ordos Plateau in the north of the Loess Plateau. It specifically refers to the rock interbedding composed of thick sandstone, sand shale, and argillaceous sandstone from the Paleozoic Permian (about 250 million years) and Mesozoic, Triassic, Jurassic, and Cretaceous periods. Although it is called a rock, it often presents in a powder like state due to its small thickness of overburden, low degree of diagenesis, and poor structural strength. Once there is heavy rain, it will turn into sediment in an instant, flow down with the river, and merge into ditches, becoming an important source of coarse sediment of the Yellow River [1]. The survey data show that although the distribution area of Pisha sandstone only accounts for about 2% of the Yellow River Basin, the annual amount of coarse sediment, which is the most harmful to the lower reaches of the Yellow River, accounts for about 25% of the siltation. The core area where the coarse sediment of the Yellow River is most concentrated and also the most difficult area in which to control soil erosion in the Basin. The new methods for environmental management of the Pisha distribution area has always been a research hotspot.

Since the 1950s, many measures have been taken to resist wind and water erosion in the Pisha sandstone area. Biological measures based on vegetation planting include farming crops, forest belt, windbreak, sand fixation forest, seabuckthorn flexible dam, etc. [2,3,4]. Engineering measures include the construction of terraces, slope concrete protection, trenching, etc. [5]. In recent years, research on methods for erosion control not only consider the control effect, but also take into account ecological protection and environmental restoration with the emergence of new green and safe methods. Scholars at home and abroad have proposed the use of environmentally friendly spraying materials, including W-OH (a kind of hydrophilic polyurethane modified composite material that uses water as a curing agent) and W-OH-SF (a high-concentration, non-toxic, strong permeability, water-soluble, and colorless transparent organic solvent with a pungent odor that reacts with water.) [6,7]. Improvement methods of compound soil mixed with Pisha sandstone and sand have been used in engineering practice [8,9,10,11]. Additionally, some researchers have proposed that converting Pisha sandstone into geopolymer cement product to realize the resource utilization of Pisha sandstone for local engineering construction in order to reduce water loss and soil erosion is a very effective method [12]. The preparation technology of Pisha sandstone cement soil solves the problems of collapsing and strength reducing when coming into contact with water [13,14]. Further, improvement by NaOH activation and the control of hydrophilic substances or the use of EN-1 (ionic soil stabilizer) curing agents for sandstone slope protection has been discussed [5,15,16,17]. Unfortunately, the anti-erosion performance of the above protection and improvement measures is limited, and most of the methods use chemical modifiers to change the chemical composition and structure of the original rock and soil, so it is difficult to achieve the expected comprehensive goals of promoting vegetation growth and stabilizing steep slopes [18], and they are also not conducive to the restoration and sustainable development of the broader ecological environment.

With the advantages of potentially environmentally friendly, in situ operability, little disturbance to soil, low energy consumption and high reinforcement effect, etc. [19,20,21,22], this technology has been used by relevant scholars to explore new technologies in the fields of soil reinforcement, soil remediation and environmental treatment, and has gradually become a popular research direction [19,21,23,24,25]. In addition, the effect of surface treatment using calcium carbonate precipitation to solidify soil mass to inhibit sand movement and dust is also verified by experimental research [26,27,28]. Some bacteria in nature release urease during the metabolism process and the urease hydrolyzes urea in the environment to produce carbonate ions. When calcium ions exist in the environment, the calcium ions are adsorbed into the surrounding bacteria and combine with carbonate ions to precipitate calcium carbonate crystals. The deposited crystals envelop the bacteria more and more, and eventually form a calcium carbonate cement with the bacteria as the nucleus, which has a biological cementation effect, thereby solidifying the rock and soil matrix. Inspired by the application of MICP technology in soil improvement and remediation, this study introduces the improvement method of Pisha sandstone weathered soil based on MICP technology and conducts an in-depth study on the improvement of the soil resistance to water and wind erosion.

2. Materials, Methods and Experiments

2.1. Materials

2.1.1. Bacteria

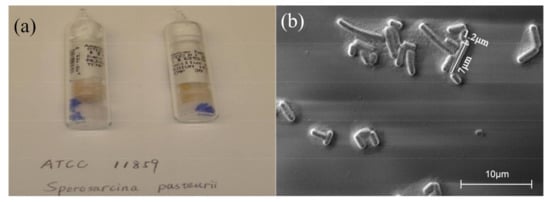

The microorganism used in this study is the bacterium Sporosarcina pasteurii (American Type Culture Collection 11859), which has the ability to produce urease stably. It was purchased from the American type culture collection (ATCC, Manassas, VA, USA), which was established in 1925, the largest organization of its kind in the world with the largest number of microorganisms. Sporosarcina pasteurii is a kind of non-pathogenic, rod-shaped aerobic bacteria widely found in soils (Figure 1). In view of its harmlessness to the human body, strong adaptability, rapid growth, rapid reproduction, and good environmental weather resistance, it is easy to use it to induce mineralization.

Figure 1.

Sporosarcina pasteurii (ATCC 11859): (a) test strain; (b) SEM images of the bacteria.

In order to ensure the activity and purity of bacteria, the freeze-dried powder of bacteria stored in a vacuum bottle was purchased. Firstly, the bacteria are activated in the liquid culture medium that is prepared according to the ATCC 1376 NH4-YE medium formula recommended by the ATCC (Table 1). Transfer the bacteria freeze-dried powder into the liquid culture medium for inoculation and shake the culture for 24 h in a bacterial shaker with a rotation speed of 200 rpm at 30 °C (to achieve the best turbidity). If the turbidity is not enough at 24 h, activate it again with the 5% inoculation amount. In order to determine whether the composition of Pisha sandstone will affect the ability of bacteria to produce urease, we oscillate and culture bacteria in the liquid medium added to the Pisha sandstone weathered soil and measure the conductivity change caused by the bacterial solution decomposing urea per minute during the oscillation culture for 24 h to evaluate the ability of decomposing urea. The results show that the ability of the bacterial solution to decompose urea after adding Pisha sandstone weathered soil is 3413.7 μS/min, and the ability of the original medium is 1902.4 μS/min. This indicates that urease production and urease activity can be maintained in Pisha sandstone weathered soil.

Table 1.

ATCC 1376 NH4-YE medium formula.

Part of this batch of bacteria after activation can be expanded and cultivated to put into the experiment directly, and the other part should be refrigerated and frozen to be used as the preservation strain.

2.1.2. Calcium Source Solution

The essence of microbial-induced mineralization is a series of chemical reactions. The final chemical reaction is the precipitation reaction of carbonate and calcium ions to form calcium carbonate crystals. In the process of inducing the mineralization reaction in the laboratory, in addition to providing bacterial liquid and soil matrix, it also needs a liquid environment of urea and calcium ions. This liquid environment not only provides the reactants generated by the crystals, but also the place where the ions move and transport during the mineralization reaction. In this study, the carbon source in the calcium source solution is urea that can be hydrolyzed by urease, and the calcium source is calcium chloride dihydrate that promotes better mineralization (Table 2). It is a slightly yellow transparent solution, and its pH value is adjusted to 9 with 1 M hydrochloric acid solution.

Table 2.

Calcium source solution.

2.1.3. Pisha Sandstone and Its Weathered Soil

The research team went to the Pisha sandstone distribution area to obtain undisturbed rock samples and weathered soil samples. The soil samples were taken from Ordos City, Inner Mongolia Autonomous Region, China, and two different sampling sites were selected. Table 3 summarizes coordinates, colors, exposure conditions and some basic physical indicators of four samples. Sampling site No.1 is located in Longkou Town, the southern end of Zhungeer Banner, Ordos City, which is adjacent to the Yellow River. The local area presents a typical loess landform with vertical ravines, exposed arsenic, and a unique geological landscape. However, the soil erosion is serious here, and a large amount of sediment has been imported into the Yellow River. Therefore, the weathered soil taken from sampling site No.1 is selected as the soil matrix material to improve in this study. Pisha sandstone has unique characteristics: when it comes into contact with water, it turns into mud, when it comes into contact with wind, it turns into sand. The water sieve method was used for particle analysis of samples, and the plastic limit was determined from soil samples obtained by crushing rock samples. In order to obtain the particle distribution data as accurately as possible, the water sieve sieving method (d > 0.075 mm) and the laser particle size distribution analyzer (d ≤ 0.075 mm) were used to determine the particle size composition as shown in Table 4. According to the particle size composition of four samples, the cumulative content of each particle group is calculated, and a grading curve is drawn (Figure 2).

Table 3.

Basic physical properties of soil samples.

Table 4.

Particle size composition.

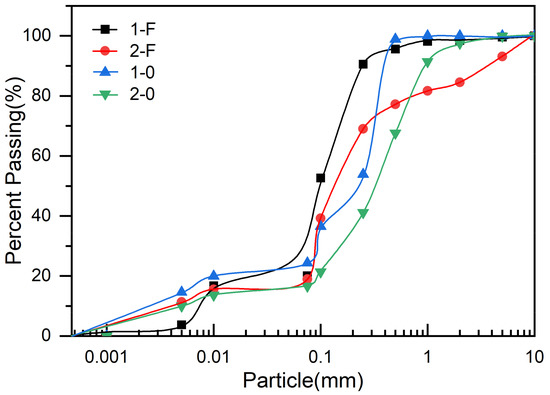

Figure 2.

Grading curve.

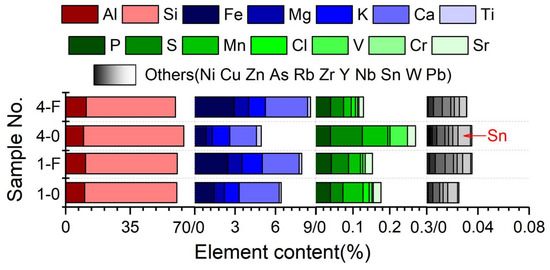

As shown in Figure 2, the particles of different soil samples are mainly distributed between 0.001–0.075 mm, indicating that the silt clay particles are widely distributed in different types of Pisha sandstone. According to the grading curve, the d50 of 1-F, 1-0, 2-F, and 2-0 are 0.0867, 0.2297, 0.1351, and 0.3256 mm, respectively. Through X-ray fluorescence spectroscopy analysis (Figure 3), it is known that Pisha sandstone and its weathered soil mainly contain oxides of silicon, aluminum, iron, magnesium, potassium, and calcium, and small amounts of oxides of titanium and phosphorus. Among them, the oxide content of silicon and aluminum is relatively high.

Figure 3.

Element content of Pisha sandstone.

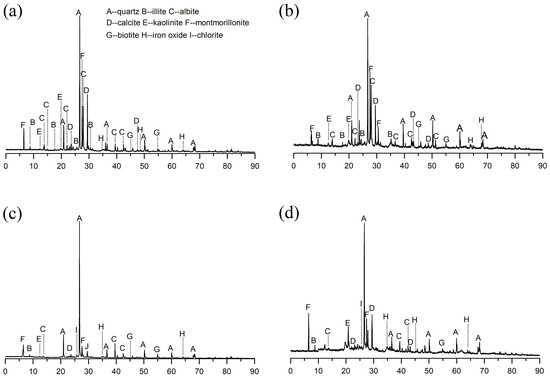

An X-ray diffractometer was used to determine the mineral composition of soil samples (Figure 4). Take the 1-F soil sample as an example. The minerals contained mainly quartz, calcite, albite, illite, kaolinite, montmorillonite, biotite, and iron oxide. In addition to the abovementioned minerals, the soil samples of sampling site No.2 are also rich in chlorite.

Figure 4.

XRD analysis of soil samples: (a) 1-0; (b) 1-F; (c) 2-0; and (d) 2-F.

According to different physical and chemical properties, the abovementioned minerals can be divided into three categories. The first category is large-particle substances composed of hard and stable quartz, feldspar, calcite, and other primary minerals with good crystallinity. The second category is fine particulate matter composed of secondary clay minerals such as montmorillonite, kaolinite, illite, and biotite. The third category is clay minerals such as iron oxide and chlorite that are rich in free oxides. Using TOPAS (Total Pattern Solution, released by Bruker, Karlsruhe, Germany) analysis software, a semi-quantitative analysis of minerals was performed on the diffraction pattern obtained by XRD test, and a quantitative calculation was performed. The results are shown in Table 5. Montmorillonite, quartz, and calcite are the main contents in samples. The content of montmorillonite in particular reaches 20–30%. Montmorillonite is a typical small clay mineral that easily absorbs water. When a large number of clay minerals meet with water to expand their volume, the cementation between the soil particles cannot withstand the swelling force and will cause the connection between the particles to be broken and collapse. This is the main reason why Pisha sandstone is easily eroded. The annual rainfall in the Pisha sandstone distribution area is concentrated in June to September, accounting for about 78% of the annual rainfall, especially in July and August with heavy rainfall and concentrated rainstorms. Coupled with the dense distribution of ravines, the water erosion caused by precipitation has become an important factor of soil erosion in the area. Moreover, The Ordos region from which the soil is taken belongs to a typical continental arid and semi-arid climate, with more wind and less rain throughout the year. The maximum annual wind speed can reach about 23 m/s, and the minimum wind speed is also above 10 m/s. When the climate temperature is high in spring, coupled with the lack of rainfall on the Mongolian Plateau and the weak vegetation, it is easy to cause sandstorms, which leaves sandstone areas severely eroded by wind and sand.

Table 5.

Mineral composition of soils.

2.2. Method

2.2.1. Unconfined Compressive Strength Test

The improvement effect of the improved soil is evaluated by unconfined compressive strength test. Specimens prepared in unconfined compressions strength tests were 100 mm in height and 50 mm in diameter. The unconfined compressive strength is measured by the GCTS STX-100 bidirectional vibration triaxial testing machine (GCTS Testing Systems, Tempe, AZ, USA) with the loading rate set to 1.5 %/min. When the reading of the axial force reaches the peak value or the reading reaches a stable value, stop the test with an additional 3% axial strain value. When the reading has no stable value, stop the test until the strain value is 10%. The average value of three parallel specimens is taken. The maximum axial pressure of the GCTS STX-100 bidirectional vibration triaxial testing machine is 25 kN, and the displacement measurement accuracy can reach 0.01 mm.

2.2.2. XRD Test

X-ray diffraction (XRD) technology is a research method to obtain information such as the composition of the material or the structure or morphology of the atoms or molecules inside the material by X-ray diffraction analysis of its diffraction pattern. In order to determine the main components of the bio-crust on the surface of the improved soil, a Philips vertical X-ray diffractometer (PW3050/60, MPSS, Malvern Panalytical, Mavern, UK) is used to analyze it with Cu-K α (I = 1.54056 A) radiation. The 2θ range is 0–90°, and the step size is 0.02°.

2.2.3. Infrared Spectroscopy Test

In order to determine the functional group composition of the bio-crust, the KBr compression method was used, and the IR-affinity-1 Fourier transform infrared spectrometer (Shimadzu, Kyoto, Japan) is in the wave number range of 4000–500 cm−1. The ATR-FTIR is selected for infrared spectrum testing where the total reflection prism is a ZnSe prism (45°) with a 4000–700 cm−1 scanning range, 200 s scanning time, and 4 cm−1 resolution.

2.2.4. Nuclear Magnetic Resonance Test

The pore size distribution and porosity of improved samples were determined using a Newmark MacroMR12-150h-1 nuclear magnetic resonance (NMR, Suzhou Niumag analytical instrument corporation, Suzhou, China) analysis system. The resonance frequency is 12.53 MHz and the temperature of the magnet is 32.00 ± 02 °C where the coil diameter of the probe is 60 mm and the RF power is 300 W. NMR was used to calculate the pore size by detecting the water content in the improved sample.

2.2.5. Determination of Salt Content

The concentration of calcium ions in the calcium source solution during the mineralization reaction was determined by titration. The weights of different curing time samples that were dried and ground were measured. Then, excess dilute hydrochloric acid was added and the samples were cleaned using purified water. The reduced solid substance was the amount of calcium carbonate in the sample.

2.3. Experiments

2.3.1. Improvement of Pisha Sandstone Weathered Soil Based on MICP Technology

The experimental steps to improve the Pisha sandstone’s weathering are as follows:

- Weigh the matrix: calculate the volume of the sample according to the size of the test sample and determine the quality of the Pisha sandstone weathered soil.

- Making the mold: the unimproved weathered soil is a loose, granular material. In order to obtain an improved soil sample that meets the size specified in the specification, the specimens were prepared in full contact flexible molds (FCFM) as described in Li et al. [29], which were made of geotextile.

- Prepare the calcium source solution: calcium chloride dihydrate will produce a lot of bubbles in the dissolution process, it should be prepared one hour before soaking the samples and put into the box of the MICP reactor to give sufficient time to dissipate the bubbles.

- Dilute the bacterial liquid: there are two quantitative indicators for bacterial liquid, one is volumetric consumption, and the other is bacterial liquid concentration. In this study, the concentration of the bacterial solution was measured with a visible light spectrophotometer. The quantitative index is OD600, which generally refers to the absorbance of a certain solution at a wavelength of 600 nm. The OD600 of the bacterial solution obtained by the expanded culture is between 1.6 and 2.0, and the concentration used in the experiment is 1.2, so it should be diluted to a certain concentration with the fresh liquid culture medium for use. In order to ensure the urease production capacity of the bacterial liquid and the activity of urease, before diluting the bacterial liquid, a conductivity meter should be used to determine the activity of urease in the bacterial liquid. According to the method in the literature [30], use a conductivity meter to test the amount of hydrolysis of urea per minute by the activated bacterial solution to characterize the urease activity. The measured urease activity value of the bacterial solution should be greater than 6 mmol/(L·min) to meet the requirements for use.

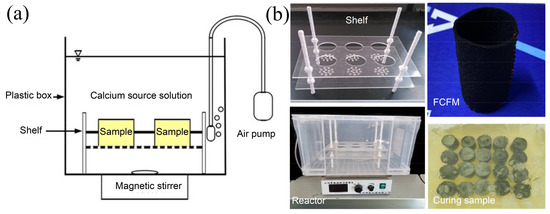

- Make the sample: the adjusted concentration of the bacterial liquid is mixed into the soil and then loaded into the sewn molding mold, and the upper cover of the mold is quickly stitched to the sample. After the stitching is completed, move samples into a reactor filled with calcium source solution to soak and cure. Sample volume: bacterial liquid volume: calcium source solution liquid volume = 5:1:20.The MICP reactor is a device designed and manufactured by the research group to provide a reaction place for the mineralization (as shown in Figure 5). It consists of a plastic box, a magnetic stirrer, a sample carrier, and an oxygen pump. Among them, during the operation of the magnetic stirrer, the entire liquid environment is agitated to make the ion distribution in the solution more uniform, making the mineralization reaction more complete; the oxygen pump continuously injects oxygen into the calcium source solution, and the abundance of oxygen is in order to provide the necessary oxygen for bacterial life and metabolism.

Figure 5. Schematic drawings of MICP reactor: (a) reactor; (b) MICP reactor.

Figure 5. Schematic drawings of MICP reactor: (a) reactor; (b) MICP reactor. - Cure the sample: soak the stitched sample in a mineralization reactor for eight days. During the curing process, ensure the normal operation of the oxygen pump. When the curing reaches the end of the third day, turn the sample upside down once.

- Air-dry the sample: the sample after curing for seven days can be taken out of the MICP reactor. After removing the shaping mold, take out the improved soil sample. The obtained sample should be dried naturally in an environment of 10–20% air humidity at 10–20 °C. After seven days, various tests are carried out.

2.3.2. Disintegration Experiments

Soil disintegration refers to the phenomenon whereby a certain volume of soil absorbs water, disperses, and disintegrates into fragments and particles in still water. The determination of disintegration can quantitatively evaluate the water stability of soil. The disintegration is quantitatively analyzed by the disintegration rate. The greater the disintegration rate, the weaker the soil’s resistance to water washing. In order to study the effect of improvement, the disintegration rate of the undisturbed Pisha sandstone rock, the remolded soil sample of weathered soil and the improved sample were tested.

In this study, the undisturbed soil is the rock block retrieved from sampling site No.1. The remolded soil sample is a cylinder with a height of 50 mm and a diameter of 50 mm. The improved soil sample is a cylinder with a height of 100 mm and a diameter of 50 mm.

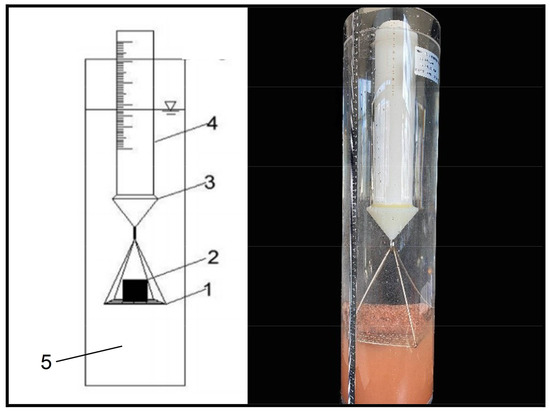

The disintegration test device is as shown in Figure 6. It consists of a beaker, a wire mesh bag, and a pontoon. The degree of disintegration is reflected by the change in the scale value of the pontoon. In the diagram, 1 is a 10 cm × 10 cm metal grid on which the sample is placed, with a mesh size of 1 cm × 1 cm; 2 is the sample; 3 is a plumb bob; 4 is a float, with a minimum scale of 1 mm; 5 is a cylindrical glass water tank with a diameter of 16cm and a height of 60 cm filled with distilled water. Before the start of the test, pour a sufficient amount of distilled water into the beaker, hang the wire mesh containing the soil sample to be tested on the lower hook of the float, and adjust the water level of the distilled water until the initial scale value is appropriate. In the test, the scale value of the float is recorded every 2 min until the sample is completely disintegrated, and the data of the disintegration of the soil sample is recorded for the longest 30 min.

Figure 6.

Disintegration test device.

The formula to define the index of disintegration rate At and disintegration velocity vt is as follows:

At = (Rt − R1)/(R0 − R1)

vt = At/t

In the formula, At and vt are the disintegration rate (%) and disintegration velocity (%/min) at time t, respectively, Rt is the float scale reading at time t (mm), R1 is the float scale reading at t = 0 (mm), and R0 is the buoy scale reading (mm) when the buoy and the wire mesh bag are empty at t = 0.

2.3.3. Wind Sand Erosion Test

The annual maximum wind speed in the entire Ordos area can reach about 23 m/s, and the minimum and maximum wind speed is also above 10 m/s. The wind energy is sufficient throughout the year, so the wind is an important dynamic factor of erosion in the Pisha sandstone area.

The test scheme of wind erosion is shown in Table 6, in which the erosion angle is the angle between the incident direction of sand particles and the erosion surface, of which the values are 30°, 60°, 75°, and 90°. The wind speed was set to 10, 16, 19, 23, and 30 m/s. The sediment discharge is 10 g/min. The diameter of the test sample is 5 cm and the height is 5 cm.

Table 6.

Wind erosion test program.

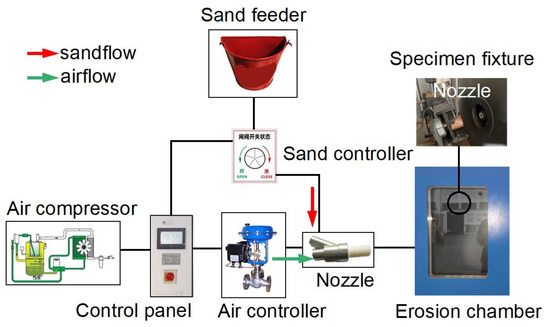

A wind erosion test system was adopted, as shown in Figure 7. The wind erosion test device is a “wind environmental erosion test system” produced by Shandong Luda Test Instrument Co., Ltd. in the structural laboratory of Inner Mongolia University of Technology. The test system consists of five parts: an air pressure system, a high-speed air blast system, a control system, a test system and a recovery system. The system can simulate wind speeds of 0–60 m/s and sediment discharges of 0–60 g/min. During the test, the center of the sample’s erosion surface is 10 cm away from the nozzle so the wind speed value at 10 cm away from the nozzle should be calibrated before the test. The sample is placed on a fixture with adjustable distance and angle from the nozzle. The area of the flow section of the sand blasting gun is 0.02 m2.

Figure 7.

Schematic diagram of the wind erosion test system.

The total erosion time is 30 min, and the mass loss was measured every 5 min during the test. Set three parallel samples for each test and take the average value.

The wind erosion resistance coefficient Re is defined to characterize the erosion resistance and defines the erosion resistance as the ratio of the volume consumption of solid particles to the volume of the target material to be removed. That is, the volume of sandy soil consumed by removing a unit volume of the target material.

Re = (ρM × mP)/(ρP × δm)

In the formula, ρM (which is 1.3287 g/cm3) is the density of the target material; mP = erosion time × sediment discharge, namely the consumption of aeolian sand; ρP (which is 1.4400 g/cm3) is the density of the aeolian sand; δm is the target material’s measured quality loss. The aellian sand used in the experiment was from the Hobq Desert located in the Ordos Plateau, Inner Mongolia, which is one of the main sources of sand and dust weather in the north of China [31].

The following section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

3. Results and Discussion

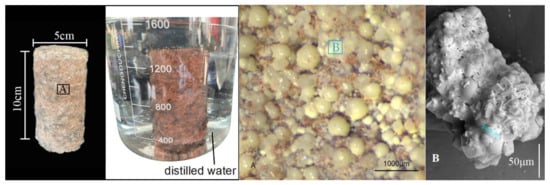

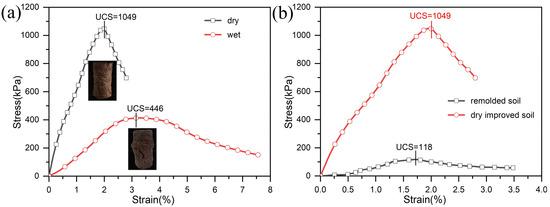

3.1. Mechanical Properties of Improved Samples

The improved sample is shown in Figure 8. It can be seen that the originally fragmented soil particles are stuck together by the white mineral precipitation. When putting the sample into the water, it can still maintain the original shape without collapsing. Test the unconfined compressive strength (UCS) of the improved soil samples before and after immersion and draw the stress–strain curve as shown in Figure 9a. The stress–strain curve of samples before and after improvement is shown in Figure 9b. It can be seen that the strength of weathered soil increases obviously after improvement and the failure strain increases. The UCS of the sample reaches 1MPa, which fully demonstrates the feasibility of improving the Pisha sandstone weathered soil based on the MICP technology. After the sample is soaked with water, the UCS decreases to 446 kPa, and its brittleness is weakened, with its strength remaining at 43.6%. Compared with the remolded soil with 0 strength after immersion, the improvement effect is also significant. The results show that the improvement method of Pisha sandstone weathered soil based on MICP technology solves the collapsing problem when it is in water. When the sample is broken, there are obvious diagonal cracks that penetrate the upper and lower sides, which is similar to the shear failure of normal soil.

Figure 8.

Improved soil samples of Pisha sandstone weathered soil before and after immersion. (A and B are the location of SEM test points respectively).

Figure 9.

Stress–strain curve of samples: (a) improved sample before and after immersion; (b) sample before and after improvement.

3.2. Analysis of Disintegration Characteristics

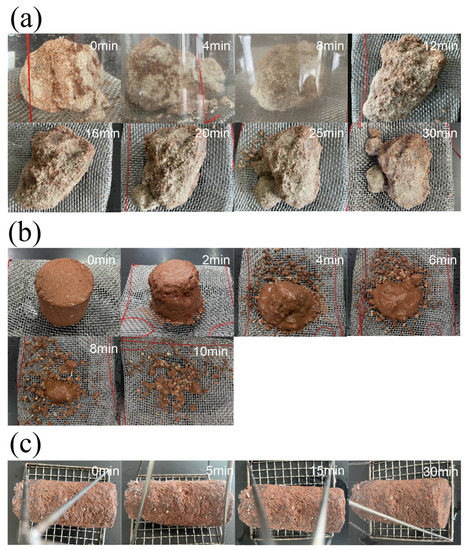

During the disintegration test, a large number of bubbles appeared on the surface of each sample after being immersed in water, and the particles on the surface diffused into the liquid environment. Among them, the surface of the undisturbed soil has flaky disintegration and cracks. With an increase in curing time, the cracks on the surface gradually expand and the width of the cracks become larger and larger. The sample gradually transforms into mud in the later stage of disintegration. Looking the morphological image of the disintegration process, it can be seen that the degree of disintegration of the remolded soil is more severe than that of the undisturbed soil. The specific characteristics of the disintegration process are shown in Figure 10. The disintegration of remolded soil is softened and collapsed, and the flakes that peeled off during the disintegration are smaller. This is because the undisturbed soil structure has been destroyed, and the original cementation between particles has become uniform after remolding. In contrast, the improved soil maintained good resistance during the entire disintegration test. After the 30th minute of the test, the sample remained intact and did not collapse.

Figure 10.

Photograph of sample disintegration process: (a) 1-0; (b) 1-F; (c) improved samples.

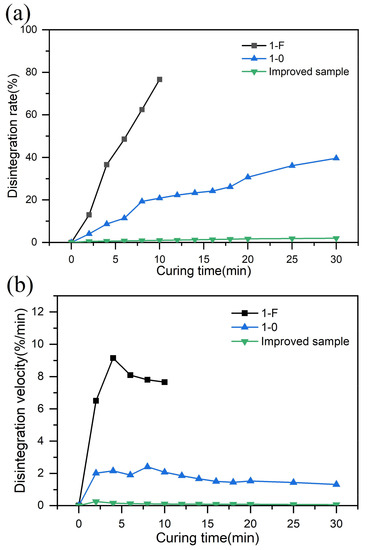

The disintegration rate is calculated as shown in Table 7. The development curve of the disintegration rate with curing time is shown in Figure 11a. The disintegration rate of undisturbed soil is less than that of remolded soil. The remodeled soil disintegrates almost completely at the 10th minute. The disintegration rate of undisturbed soil at the 30th minute is less than 50%, reaching 39.64%. In comparison, the disintegration rate of the improved soil is only 1.95% at the 30th minute. Not only is the water erosion resistance greatly improved over that of the remolded soil, but also that of the undisturbed soil, and the performance improvement is obvious.

Table 7.

Disintegration rate and disintegration velocity of samples.

Figure 11.

Disintegration characteristic development curve: (a) disintegration rate; (b) disintegration velocity.

The disintegration velocity is calculated as shown in Table 7. The development curve of the disintegration velocity with curing time is shown in Figure 11b. Similar to the curve law of the disintegration rate, the disintegration velocity pits remolded soil, undisturbed soil, and improved soil in decreasing order. The disintegration velocity curves of three samples all show the pattern of first increasing and then decreasing.

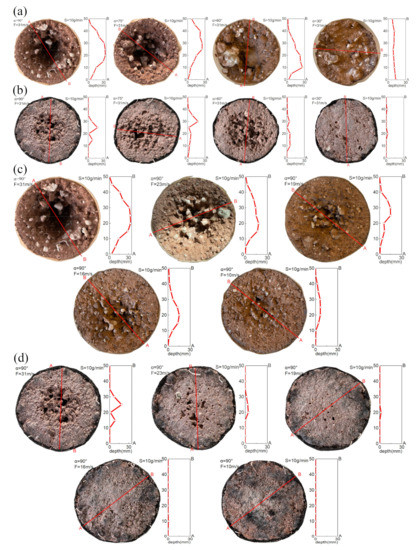

3.3. Observational Evidence of the Wind Erosion Test Samples

Observing the erosion surface of the sample after wind erosion, it can be seen that there is a deep erosion pit on the erosion surface of the remolded soil (Figure 12a,c). The difference is that the bio-crust at the erosion surface of the improved soil sample has holes after being eroded by wind and sand. After the holes appear on the surface of the crust, undercutting will occur on the lower part of the crust, which is not good. It can be seen from the erosion pit morphology map of the remolded soil sample with different erosion angles that the erosion surface is eroded to form a large pit. The larger the erosion angle, the larger the erosion pit. Comparing the erosion pit morphology of the remolded soil samples with different wind speeds when the erosion angle α = 90°, it can be seen that with an increase in wind speed, the erosion pits formed become larger and deeper.

Figure 12.

Images of erosion pits: (a) remolded soil; (b) improved soil; (c) remolded soil; (d) improved soil.

It can be seen from the erosion pit morphology of the improved soil sample at different erosion angles that the erosion surface of the sample is eroded to form many holes, but not pits. When the erosion angle is 75°, the holes are at their biggest, and when the erosion angle is 30°, the holes are at their smallest. Comparing the erosion pit morphology of the improved samples with different wind speeds when the erosion angle α = 90°, it can be seen that as the wind speed increases, the formation of erosion holes is greater in terms of both number and depth.

After improvement, the erosion morphology of weathered soil changes. The MICP technology forms a mineralized bio-crust with strong inter-particle cementation on the surface of the sample. This crust can effectively resist the erosion of wind and sand and will not be eroded by wind and sand to form a large erosion pit on the erosion surface.

3.4. Wind Erosion Resistance

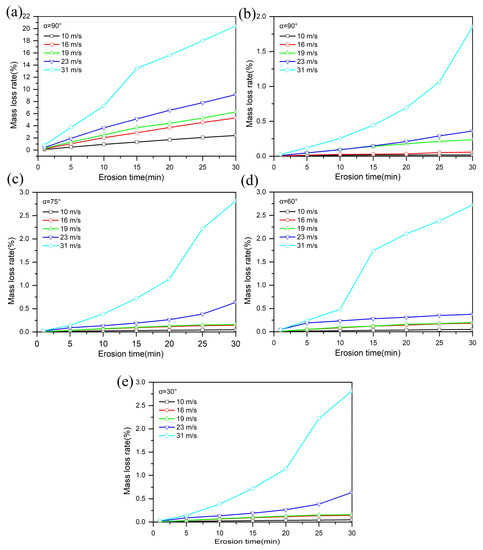

Table 8 lists the mass loss of samples after the wind erosion test. The curve of the mass loss rate of the samples with different erosion angles and different wind speeds as a function of wind erosion over time is shown in Figure 13.

Table 8.

Mass loss of samples after wind erosion test.

Figure 13.

Development curve of sample mass loss rate with wind erosion time: (a) remolded soil; (b) improved soil; (c) improved soil; (d) improved soil; (e) improved soil.

With an increase in wind erosion time, the mass loss rate of improved soil samples and remolded soil samples continues to increase. For the same wind erosion time, the greater the wind speed, the greater the mass loss rate. After the weathered soil is improved, the mass loss rate is reduced by nearly 10 times, and the soil’s resistance to wind and sand erosion is significantly improved after improvement.

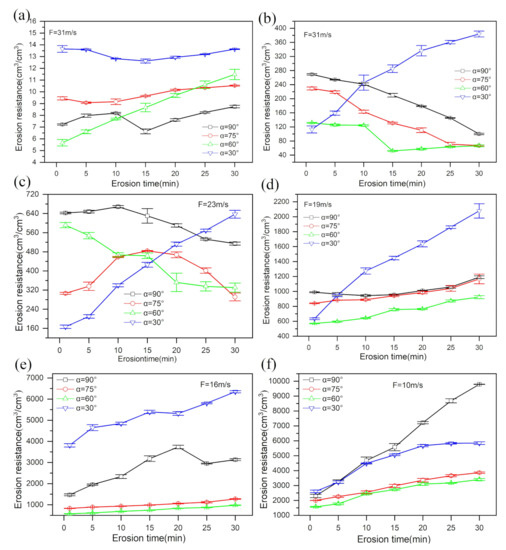

The calculation of the wind erosion resistance coefficient and the development curve of the wind erosion time is shown in Figure 14. The larger the wind speed, the smaller the wind erosion coefficient. At different erosion angles, when the wind speed is 31 m/s, the wind erosion resistance coefficient Re of the remolded soil samples generally increases with the wind erosion time. Except for 30°, the wind erosion resistance coefficient Re values at other erosion angles are relatively close.

Figure 14.

Development curve of wind erosion resistance with wind erosion time: (a) remolded soil; (b) improved soil (c) improved soil; (d) improved soil; (e) improved soil; (f) improved soil.

When the wind speed is below 16 m/s, the wind erosion resistance coefficient Re of different erosion angles increases with an increase in wind erosion time. When the wind speed is 23 m/s, except for the erosion angle of 30°, the wind erosion resistance coefficient Re at other erosion angles begins to decrease after 15 min, indicating that the limit of resistance to wind and sand erosion has been reached. When the wind speed reaches 31 m/s, except for the erosion angle of 30°, the wind erosion resistance coefficient Re at other erosion angles all decrease. The erosion resistance Re at a 30° erosion angle was the highest. When the erosion time is 30 min, the Re at a 30° erosion angle before and after curing are 13.6 and 383, respectively, which is a 28-fold increase. When the erosion time is 1 min, the Re before and after curing are 13.5 and 112, respectively, which is an 8.3-fold increase. The Re is increased by about 20 times on average. Additionally, the erosion resistance Re at a 60° erosion angle was the lowest. When the erosion time is 30 min, the Re before and after curing are 11.5 and 66.6, respectively, which is an increase of only 5.8 times. In general, except for the case where the wind speed is 10 m/s, at the same wind erosion time, the wind erosion resistance coefficient (Re) from large to small corresponds to the pattern that the erosion angles are 30°, 90°, 75°, and 60°.

Combined with the image of the erosion surface morphology in Section 3.4, it can be seen that when the erosion angle is 30°, the erosion of wind and sand will cause little damage to the erosion surface, and the erosion holes formed are small and shallow. The distribution is uneven, and the damage caused by erosion is mainly concentrated on the lower side of the erosion surface, that is, the side closer to the sandblasting gun. The damage caused by sand erosion on the eroded surface is mainly caused by the punching of the eroded surface by sand particles. When the erosion angle is 60°, the punching damage of the improved soil by moving sand particles is the greatest.

Analyzing the above results, we can provide a mechanical explanation regarding these phenomena. In the test, the distance from the sandblasting gun to the center of the erosion surface for different erosion angle erosion tests is the same, so it can be assumed that the energy of the sand particles reaching the erosion surface is the same, and the impact force of the sand particles on the erosion surface is the same. When the blow angle is not 0°, the impact force caused by the sand particles on the eroded surface will form two components; one is the normal stress on the eroded surface, and the other is the shear stress on the eroded surface. Of course, the damage of the eroded surface is the result of the combined action of two stresses.

When the erosion angle gradually decreases from 90°, σ gradually decreases, τ gradually decreases and then becomes larger, and the external force caused by the impact of sand particles on the surface of the sample becomes more and more dispersed. The damage of the eroded surface is firstly caused by the cementation between the normal stress failure particles to form pits, and then the pits continue to develop under the action of shear stress. Therefore, when the erosion angle is 60°, the erosion is greater than when there is no shear stress at 90°, and the erosion is greater than when the normal stress is too small at 30°.

σ = (f/A) sin α

σ = (f/A) cos α

In the formula, f/A is the impact force of the sand particles on the erosion surface, σ is the normal stress, and τ is shear stress.

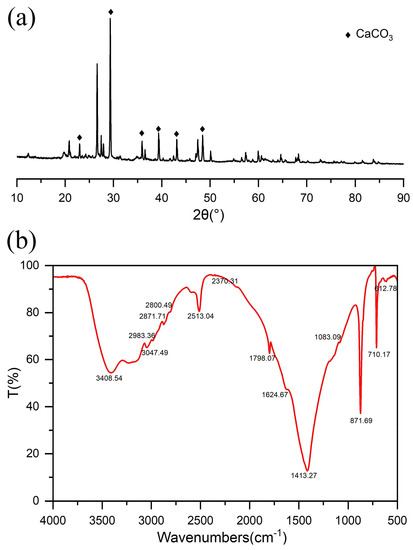

3.5. Improvement Mechanism of Pisha Sandstone Weathered Soil

Using XRD and infrared spectroscopy testing methods to determine the composition of the white matter formed after the mineralization reaction on the improved soil sample, the test results are shown in Figure 15. It can be seen that the white substance of the adhesion particles on the surface of the sample is mainly calcium carbonate crystals, but the test results of infrared spectroscopy show that organic substances such as lipids are detected in the minerals. The FT-IR spectra also showed peaks corresponding to biomolecules. It can be seen that the white mineral precipitate is a mixture of carbonate minerals and a small amount of organic matter (Table 9). Bacterial cells and extracellular polysaccharides affect the morphology of early induced minerals by acting as nucleation templates of carbonate particles [32]. The final mineral precipitate contains bacteria and organic matter. These organic substances are mixed with calcium carbonate crystals, which makes the mineral crystal obtained by induced mineralization different from the pure crystal generated by chemical reactions in terms of their functional and mechanical properties. After being modified by MICP technology, the soil particles are cemented together by the induced mineral crystals to form a solid material with a certain amount of strength, and the problem of collapsing in water will not occur after saturation.

Figure 15.

Physical property analysis of cement: (a) XRD pattern; (b) FT-IR spectrum of mineral.

Table 9.

Assignment of infrared bands identified in the EPS minerals.

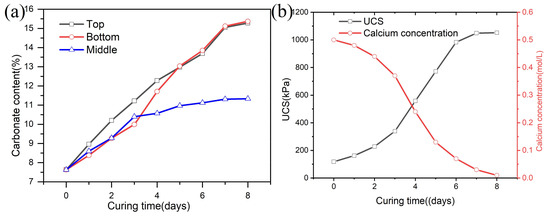

The data and change curves of carbonate content, the calcium concentration of calcium source solution (CSS), and the dry UCS at different curing times are shown in Table 10 and Figure 16. It can be proved that the calcium ions in the calcium source solution are consumed by mineralization to form calcium carbonate. The un-confined compressive strength of the sample is negatively correlated with the calcium ion concentration. As the calcium carbonate content in the sample increases, the non-lateral compressive strength of the sample increases, but the increase is small after the seventh day of treatment. It can be seen that the source of the sample’s strength is the cementation of calcium carbonate crystals. After the third day of treatment, the increase in calcium carbonate content in the sample was small, but the increase in calcium carbonate content on the surface of the sample was still large. This is because the crystals formed outside the sample block the ion migration channel and hinder the mineralization reaction inside the sample. After being immersed in water, the strength of the cured sample decreases. According to the recommendation of the reviewer, we measured the dry strength of the cured sample after cleaning in distilled water. The remaining strength is 1032 kPa. The strength is reduced by just 1.52% compared with that before cleaning. The decrease in strength is due to the dissolution of soluble salts in the sample, including both calcium chloride and ammonium chloride. Admittedly, the strength reduction is partly due to the dissolution of residual salt in the sample, but this is not the main reason. After the seventh day, calcium ions were almost completely consumed in the mineralization process, and the main reason for the decrease in strength was that the clay particles in the weathered Pisa sandstone lost their cementation with the soil. The effect of the soluble salt on the strength can be ignored.

Table 10.

The carbonate content, the calcium concentration of the calcium source solution (CSS), and the dry UCS at different curing times.

Figure 16.

(a) The carbonate content, (b) the calcium concentration of the calcium source solution (CSS), and the dry UCS at different curing times.

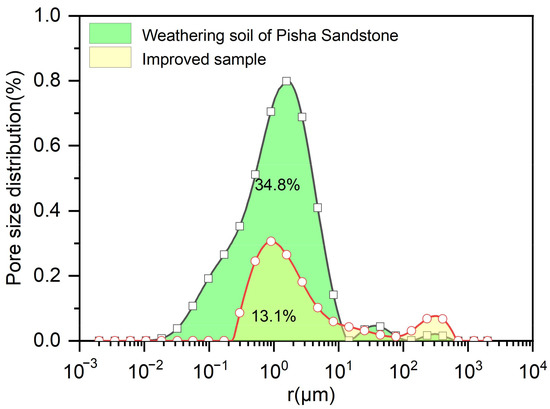

The pore size distribution curve of the soil by NMR test before and after improvement is shown in Figure 17. After the improvement by MICP technology, the porosity of the weathered soil is reduced from 34.8% to 13.1%, a reduction of 62.4%. After solidification, the soil becomes dense due to the filling of pores by calcium carbonate crystals, which increases the water erosion resistance of the sample.

Figure 17.

Pore size distribution of Pisha sandstone weathered soil before and after improvement.

3.6. Mechanism Analysis for Improving Resistance Ability

Improvement with the use of MICP technology can greatly improve soil resistance to water erosion and wind erosion. The crystallization of calcium carbonate minerals produced by mineralization induced by MICP technology fills the pores and adheres to the particles of the weathered soil for effective cementation, allowing for bridging to take place. The loose and expansive weathered soil particles are cemented together to form a certain strength. Whether it is water intrusion or wind sand erosion, the cementation of mineral crystallization in the weathered soil can resist the damage caused by erosion.

4. Conclusions

After improvement by MICP technology, the water erosion resistance and wind erosion resistance of Pisha sandstone weathering soil have been greatly improved. The main conclusions are as follows:

- Pisha sandstone and its weathered soil contain a large number of silty clay particles, especially montmorillonite with high water absorption and strong expansibility. When Pisha sandstone rock and soil are eroded by water or sand, the clay minerals that originally cemented large particles cannot resist the expansion force or external force and sometimes fail, leading to the collapse of the rock and the soil. After improvement, effective cementation was formed between particles, and solidified material with strength up to 1 MPa was formed.

- The disintegration rate and disintegration velocity of improved samples by MICP technology are greatly reduced, which can effectively stave off water erosion. The remolded soil sample almost completely disintegrates in the 10th minute, and the disintegration rate of undisturbed soil in the 30th minute was less than 50%, reaching 39.64%. For the sample improved by MICP technology, the disintegration rate of the sample in the 30th minute was only 1.95%.

- The wind erosion resistance of the improved soil is improved. Originally, the weathered soil formed large and deep erosion pits after being eroded by wind and sand, but after the improvement the mineralized bio-crust forms effective resistance, which changes the damage form of erosion surface and only forms erosion holes. The wind erosion resistance of the improved sample is improved, and its coefficient at a 30° erosion angle is increased about 20 times on average when the wind speed is 31 m/s.

- The internal mechanism of the MICP technology to improve the poor characteristics of the weathered soil in contact with water, mud, and aeolian sand is achieved by inducing calcium carbonate mineral crystals to fill the pores of the soil particles and adhere to and bridge between soil particles for effective cementation. When water invades the soil and expands or is destroyed by external erosion, the cementation of the mineral crystals on the particles resists the expansion force and punching force, thereby improving the erosion resistance.

This experimental study proposes an improvement method for Pisha sandstone weathered soil based on MICP technology. At the same time, in-depth research on the anti-erosion performance of the improved material has been carried out.

Author Contributions

Y.W. conceptualized the methodology and performed all the experiments, analyzed the data, and prepared part of the original draft of this manuscript; C.L. suggested how to improve the methodology, prepared part of the original draft of this manuscript, and edited the manuscript; C.W. and Y.G. were responsible for funding acquisition, supervision, partly conducting the experiments, and analyzing the data. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of China, grant number 51968057; the Major Science and Technology Projects of the Inner Mongolia Autonomous Region, grant number 2020ZD0021; the Natural Science Foundation of the Inner Mongolia Autonomous Region of China, grant number 2019MS05075; and the Science and Technology Plan of the Inner Mongolia Autonomous Region, grant number 2021GG0344.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, Y.C.; Wu, Y.H.; Li, M. Study on Soil Erosion and Its Control in Pisha Sandstone Area; Yellow River Water Conservancy Press: Shanghai, China, 2007. [Google Scholar]

- Yang, F.-S.; Cao, M.-M.; Li, H.-E.; Wang, X.-H.; Bi, C.-F. Simulation of Sediment Retention Effects of the Single Seabuckthorn Flexible Dam in the Pisha Sandstone Area. Ecol. Eng. 2013, 52, 228–237. [Google Scholar] [CrossRef]

- Yang, F.S.; Cao, M.M.; Li, H.E.; Wang, X.H.; Bi, C.F. Ecological Restoration and Soil Improvement Performance of the Seabuckthorn Flexible dam in the Pisha Sandstone Area of Northwestern China. Solid Earth Discuss. 2014, 6, 2803–2842. [Google Scholar]

- Liang, Z.S.; Wu, Z.R.; Yao, W.; Noori, M.; Yang, C.; Xiao, P.; Leng, Y.; Deng, L. Pisha sandstone: Causes, processes and erosion options for its control and prospects. Int. Res. Soil Water Conserv. 2019, 7, 1–8. [Google Scholar] [CrossRef]

- Liang, H.; Wu, Z.; Noori, M.; Yang, C.; Yao, W. A New Ecological Control Method for Pisha Sandstone based on Hydrophilic Polyurethane. J. Arid Land 2017, 9, 790–796. [Google Scholar] [CrossRef]

- Liang, Z.S.; Yang, C.Q.; Wu, Z.R. Study on Mechanical Properties of Pisha Sandstone Solidified Body with W-OH Composite. Yellow River 2016, 38, 30–34. [Google Scholar]

- Zhang, J.K. Study on W-OH Modification and its Performances for Pisha Sandstone Consolidation; Southeast University: Nanjing, China, 2017. [Google Scholar]

- Sun, Z.H.; Han, J.C.; Mao, Z.G.; Wang, H.Y.; Hu, Y. Simulation of Effects of Pisha Sandstone on Improving Corn Yield in Sandy Soil with RZWQM2 Model. Trans. Chin. Soc. Agric. Mach. 2018, 49, 235–243. [Google Scholar]

- Han, J.C.; Xie, J.C.; Zhang, Y. Potential Role of Feldspathic Sandstone as a Natural Water, Retaining Agent in Mu Us Sandy Land, Northwest China. Chin. Geogr. Sci. 2012, 22, 550–555. [Google Scholar] [CrossRef]

- Guo, H.; Han, J.C.; Zhang, Y.; Wang, H.Y.; Sun, Y.Y.; Li, X.C.; Zhang, H.O. Cementation Force of Compound Soil Mixed by Soft Rock and Sand: Raman Spectrum Study. Laser Optoelectron. Prog. 2017, 54, 436–442. [Google Scholar]

- Wang, N.; Xie, J.C.; Han, J.C. A Sand Control and Development Model in Sandy Land Based on Mixed Experiments of Arsenic Sandstone and Sand: A Case Study in Mu Us Sandy Land in China. Chin. Geogr. Sci. 2016, 23, 56–63. [Google Scholar] [CrossRef] [Green Version]

- Dong, J.; Wang, L.; Zhang, T. Study on the strength development, hydration process and carbonation process of NaOH-activated Pisha Sandstone. Constr. Build. Mater. 2014, 66, 154–162. [Google Scholar] [CrossRef]

- Chang, P.; Li, X.L.; Li, M.Y.; Chen, S.H.; Wu, S.G. Experimental study on hydraulic scouring characteristics of sheet flow in Pisha-sandstone. J. Drain. Irrig. Mach. Eng. 2019, 37, 55–61. [Google Scholar]

- Wu, S.Y. Experimental Study on the Mechanical Properties of Pisha-Sandstone and Pisha-Sandstone Cement Soil under Dry-Wet Cycle; Inner Mongolia Agricultural University: Huhhot, China, 2019. [Google Scholar]

- Dong, J.; Li, C.; Liu, H.; Zhang, L.; Liu, J. Investigating the mechanical property and reaction mechanism of geopolymers cement with red Pisha Sandstone. Constr. Build. Mater. 2019, 201, 641–650. [Google Scholar] [CrossRef]

- Su, T.; Zhang, X. Effects of EN-1 soil stabilizer on slope runoff hydraulic characteristics of Pisha sandstone stabilized soil. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2011, 42, 68–75. [Google Scholar]

- Huo, J.S.; Geng, Y.J.; Yu, Z.Q. Experimental Study on the Weathered Red Sandstone Soil Road Performance Stabilized with EN-1 Soil Stabilizer. Adv. Mater. Res. 2011, 255–260, 3190–3194. [Google Scholar] [CrossRef]

- Xiao, P.Q.; Yao, W.Y.; Liu, H. Research progress and harnessing method of soil and water loss in Pisha sandstone region. Yellow River 2014, 36, 92–94. [Google Scholar] [CrossRef]

- Phillips, A.J.; Gerlach, R.; Lauchnor, E.; Mitchelf, A.C.; Cunningham, A.B.; Spangler, L. Engineered applications of ureolytic biomineralization: A review. Biofouling 2013, 29, 715–733. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, C.S.; Yin, L.-Y.; Jiang, N.-J.; Zhu, C.; Zeng, H.; Li, H.; Shi, B. Factors affecting the performance of microbial-induced carbonate precipitation (MICP) treated soil: A review. Environ. Earth Sci. 2020, 79, 94. [Google Scholar] [CrossRef]

- Whiffin, V.S.; Van Paassen, L.A.; Harkes, M.P. Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Wang, X.X.; Miao, L.C.; Sun, X.H.; Wu, L.Y. Research progress of microbial induced solidification technology. J. Hunan Univ. 2021, 48, 70–81. (In Chinese) [Google Scholar]

- He, J.; Chu, J.; Liu, H.L.; Gao, Y.; Li, B. Research advances in biogeotechnologies. Chin. J. Geotech. Eng. 2016, 38, 643–653. [Google Scholar]

- Liu, H.L.; Xiao, P.; Xiao, Y.; Chu, J. State-of-the-art review of biogeotechnology and its engineering applications. J. Civil Environ. Eng. 2019, 41, 1–14. [Google Scholar]

- De Jong, J.; Soga, K.; Kavazanjian, E.; Burns, S.; van Paassen, L.; Al Quabany, A.; Aydilek, A.; Bang, S.; Burbank, M.; Caslake, L.; et al. Biogeochemical processes and geotechnical applications: Progress, opportunities and challenges. Geotechnique 2013, 63, 287–301. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Wang, S.; Wang, Y.X.; Gao, Y.; Bai, S. Field experimental study on stability of bio-mineralization crust in the desert. Chin. J. Rock Soil Mech. 2019, 40, 1291–1298. [Google Scholar]

- Meyer, F.D.; Bang, S.; Min, S.; Stetler, L.D.; Bang, S.S. Microbiologically-Induced Soil Stabilization: Application of Sporosarcina pasteurii for Fugitive Dust Control. ASCE Geo-Front. 2011, 4002–4011. [Google Scholar] [CrossRef] [Green Version]

- Hamdan, N.; Kavazanjian, E.J. Enzyme-induced carbonate mineral precipitation for fugitive dust control. Géotechnique 2016, 66, 546–555. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y.; Zhou, T.; Bai, S.; Gao, Y.; Yao, D.; Li, L. Sulfate Acid Corrosion Mechanism of Biogeomaterial Based on MICP Technology. J. Mater. Civil Eng. 2019, 31, 04019097. [Google Scholar] [CrossRef]

- Whiffin, V.S. Microbial CaCO3 Precipitation for the Production of Biocement. Ph.D. Thesis, Murdoch University, Perth, Australia, 2004. [Google Scholar]

- Shi, Y.; Shi, Z.M. Ultrasonic surface treatment for improving wind-blown sand erosion resistance of cementitious materials. WEAR 2020, 460, 108–203. [Google Scholar] [CrossRef]

- Zhang, C.; Li, X.; Lyu, J.; Li, F. Comparison of carbonate precipitation induced by Curvibacter sp. HJ-1 and Arthrobacter sp. MF-2: Further insight into the biomineralization process. J. Struct. Biol. 2020, 212, 107609. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).