Abstract

The objective of this work was to assess the use of biomass fly ash (BFA) as cement replacement material or as an alkalinity source in high volume fly ash mortar and concrete. Mortar formulations were prepared with different types of cement replacement: fly ash from thermal power plants, BFA, a blend of two pozzolans, and small amounts of BFA or/and hydrated lime (HL). Mortar formulations were tested both in the fresh and hardened state. The replacement of cement by the two fly ashes led to a decrease in the mechanical strength. The best strength values were obtained when higher HL content was introduced in mortars, however, mortars with the lower BFA content presented the best results for the majority of the tests. In general, BFA has a similar effect on cementitious mortars to coal fly ash, having good performance as cement replacement.

1. Introduction

Nowadays, the Green and Circular Economy is gaining standing among academics and policy markets worldwide [1,2]. This green economy results in “improved human well-being and social equity, while significantly reducing environmental risks and ecological scarcities” [2]. This means that a Green and Circular Economy is low-carbon, resource-efficient, and socially inclusive, leading to a development state that reduces carbon emissions and pollution, increases resource efficiency, and prevents the loss of biodiversity and ecosystems [2]. The use of clean and affordable renewable sources is one of the main achievements of this Green and Circular Economy.

The increase in energy supply by renewable sources is a key issue to achieve and adopt sustainable development in several countries, and among these sources is biomass [1,3]. Its utilization leads to a direct reduction in greenhouse gases emission when substituting fossil fuels [3,4]. Biomass combustion is taken as a sustainable and renewable resource of energy when the rate of consumption is lower than the rate of natural raw materials production and very important in this context is the use of residual biomass from several forestry and industrial operations [5]. A great number of biomass resources are used in several industrial sectors to produce heat and power process applications and the national electric grid, as it happens, in the pulp and paper production and wood and furniture industry. In those sectors, the raw biomass feedstock preparation generates significant amounts of residual biomass that is then valorized in energetic applications as fuel in thermochemical conversion processes, mostly combustion [3,6,7,8,9,10].

During thermochemical valorization of biomass for energy different types of ashes are produced, and these are dependent on the characteristics of the boiler and the treatment system of the fuel gases [3,10]. Usually, two types of ashes are produced (bottom and fly ash) and according to the European List of Waste [11], they are considered as non-hazardous wastes. Several strategies have been adopted for ash management, such as the addition to forest soils and its incorporation in cement production [3,12]. Its utilization on the soil is limited by regulations, usually, biomass fly ash is enriched in heavy metals (e.g., Cr, Cd, Zn, and Pb) [10], when compared to the bottom ashes, those elements are leachable to the soil, and this could lead to the soil and groundwater contamination [13,14,15]. Thus, it is important to study alternative applications for specific types of ashes from biomass combustion.

Several types of biomass originate fly ash with similar pozzolanic activity as coal fly ash (CFA), such as rice husk, wheat straw, sugar cane straw, and wood [5,16,17,18,19]. The physical-chemical characteristics of ashes from biomass combustion are strongly influenced by the biomass type used as fuel [5,19,20]. Moreover, the same type of biomass may lead to different types of ashes, as the fly ash properties depend on growth and production parameters such as weather, season, storage, and geographic factors [19,21,22,23]. In Portugal, the BFA resulting from heat and power production in industrial combustion facilities has been increasing in recent years [24]. Portugal has no guidelines for biomass fly ash management; thus, the ashes are classified as industrial waste [10]. The chemical and physical characteristics of BFA are significantly different than coal fly ash. Usually, they are more alkali (higher Na and K content), have less alumina content, have a higher loss-on-ignition, and their mineralogical composition is very different than CFA [19,25,26].

Several studies [3,27,28,29,30,31,32] dealt with the use of BFA alone or blended with CFA and concluded that BFA may lead to similar or even better performances in cement-based mortars and ultimate strength and durability of concrete. Wang et al. [19] studied the properties of concrete with BFA ash and compared them with concrete containing coal fly ash. The results showed that 25% of cement replacement by BFA led to mechanical properties that could be considered statistically similar to those achieved with CFA concrete [19,33].

Several authors [12,25,34,35,36,37,38] studied the workability of cement materials. Results showed that the slump values decreased with the increase in cement replacement by BFA, which led to a decrease in the workability of fresh mixtures. Coelho [39], Rajamma et al. [29], and Barbosa et al. [3] studied the effect of the incorporation of wood fly ashes in the mechanical strength of concrete. The studies reported a decrease in the mechanical resistance with the increase in ash incorporation in concrete. Barbosa et al. [3] also studied the compressive strength for different curing periods and observed that BFA delayed the hydration. The authors verified that during the cure period, the concrete with a lower replacement level of cement had higher values for compressive strength [3]. It was possible to observe that, for 28 days of curing, concrete with 30–40%wt of cement replacement by BFA presented values for compressive strength between 20 to 30 MPa [29,39,40].

Udoeyo et al. [41] measured the water absorption capacity of concrete produced with 5, 10, 15, 20, 25, and 30%wt by weight replacement of binder. An increase in the water absorption with the increase of ash content was reported.

Despite several reported results on the use of BFA as cement replacement material, few studies that focus on its use in concrete with high volume of cement replacement by BFA, alone or blended with CFA. The main goal of this study was to understand the effect of using BFA in high volume fly ash (HVFA) mortar alone or blended with CFA. On the other hand, one of the issues related to HVFA concrete is the possibility of reinforcement corrosion that may be associated with its lower carbonation resistance. As BFA is more alkaline, with higher calcium content than CFA, an experimental study was carried out concerning the utilization of BFA on mortars to evaluate its effect on the carbonation of mortars. A comparison with the utilization of hydrated lime (HL) for the same purpose was also carried out.

2. Materials and Methods

2.1. Raw Materials

A CEM I 42.5R (from Outão, Secil, Portugal) cement and a commercial Portuguese river rolled sand 0/4 mm were used as main binder and aggregate, respectively. BFA was collected in a Portuguese pulp and paper industry, which uses forest residues, such as eucalyptus and pine bark, as fuel to produce heat and power in a bubbling fluidized bed combustor. The bubbling fluidized bed reactor used sand as the bottom bed. The fly ash was collected in an electrostatic precipitator used for air pollution control concerning the particulate matter. CFA was sampled from a Portuguese thermoelectric power plant (from Pegop, Pego, Portugal) using coal as fuel. The ashes were used in the mixtures as received, without any pre-treatment. In the preparation of some mortar and concrete formulations, hydrated lime (from the Lusical industry) was used as an addition, with the main goal of providing the alkalinity lost due to the cement replacement by high amounts of coal fly ash.

The physical and chemical characterization of CFA and BFA is shown in Table 1. The loss-on-ignition and the chemical composition were obtained by X-Ray Fluorescence using a Panalytical Axios spectrometer. The density was determined according to the ASTM C188-1995 standard [42].

Table 1.

Chemical and physical characteristics of used materials.

BFA showed the highest value for LOI, followed by CFA, cement, and sand. The silica compounds were present in higher content in sand, CFA, and BFA. But the calcium compounds were present in higher concentrations in cement and also in BFA. This higher content of calcium is also observed in several other studies [12,32,43,44], but not all biomass fly ash presents such a high content [14,19,29]. The differences in calcium concentration in fly ashes are related to the technology used for biomass combustion, biomass composition [45,46,47,48], and the operation conditions [33,49,50]. FA and BFA also presented considerable content of aluminum, magnesium, and potassium compounds.

2.2. Mortar Formulations and Characterization

A set of mortars were prepared, and their formulations are shown in Table 2. All mixtures were made with 1 wt. part of binder (considered as the sum of cement plus fly ash and hydrated lime): 2.5 wt. parts of aggregate and water–binder mass ratio (w/b) of 0.5. These proportions were chosen as the main aim of this study is to find a solution for the conventional concretes, and usually the cement dosage on a conventional plain cement concrete is around 300 kg/m3 and the content of sand is equal to 750 kg/m3 with a water/binder ratio of 0.5. These proportions for mortar production were chosen considering published studies that show that the results obtained for the properties of conventional concrete are coincident with the results obtained in the corresponding mortars [51,52,53,54,55]. On the other hand, one of the issues related to HVFA concrete is the possibility of reinforcement corrosion that may be associated with its worst carbonation behavior. As BFA is more alkaline than CFA, an experimental study was carried out concerning the use of BFA on mortars to evaluate its effect on the carbonation of mortars. A comparison with the utilization of hydrated lime for the same purpose was also carried out as it was shown in other studies [56] that the introduction of lime minimizes the issues related to pH decreased by preventing the loss of alkalinity. Small amounts of HL (0.5, 1.3, and 5%wt) were studied, as these amounts of hydrated lime led to an increase in carbonation resistance [57]. For each mixture, three specimens were prepared, to guarantee the statistical representativeness of the results. Mortar mixtures were prepared according to the following procedure: (i) solid and liquid weighing, (ii) addition of water to the solids, (iii) mixing for 1 min at a low rotation speed, (iv) stopping for 1 min, (v) mixing again for 1 min at a high rotation speed, and (vi) testing the fresh properties of the mixture, according to EN 1015-2:1998 [58].

Table 2.

Mortar formulations.

The tests carried out for mortar characterization are presented in Table 3. The workability of fresh samples was determined via the flow spread test, by the measurement of diameters (in mm) in two perpendicular directions after 15 strokes on the flow table, according to EN 1015-3:1998 [59]. The density was determined according to EN 1015-2:1998 [58] and the air volume content of fresh mortar was measured according to EN 1015-7:1998 [60]. The bulk density was determined by the measurement of the mass of fresh mortar and the volume which it occupies when it was introduced and compacted into a vessel of a given capacity. For the air volume determination, a volume of mortar was placed in a vessel of 1L, water was introduced on top of the mortar surface, and pressurized air was forced into the mortar displacing air from within any pores. The water level falls and reflects the volume of air displaced from the mortar.

Table 3.

Tests carried out in mortars in the fresh and hardened state.

For the tests in the hardened mortar, the mixtures were placed in 40 × 40 × 160 mm3 molds. First, the molds were half-filled and then compacted for 60 s. After that, the molds were filled and compacted again. To avoid the loss of water, the molds were covered with plastic film and stored in a humidity control chamber (21 °C – 87% RH) for 24 h. Then, the samples were demolded, and mortars were cured in water immersion, at an environment temperature (±20 °C), the periods of curing are expressed in Table 3.

Several non-destructive tests were carried on the mortar specimens, such as electric resistivity and ultrasonic pulse velocity (UPV). These tests estimate the mechanical properties and the quality and the homogeneity of mortar materials and make the correlation with the destructive tests, such as compressive strength [61,62]. The electric resistivity was measured using Resipod Proceq equipment, which is composed of four equidistant (38 mm) electrodes. During this test, an alternating current between the external electrodes was provided and the electric potential difference between the internal electrodes was measured. The electric resistivity is measured through the Ohm law and computed by the equipment used.

The UPV was measured in the specimens prepared for the flexural test, according to EN 12504-4:2007 [63], in two directions, direct and semi-direct, with cells with 54 kHz. Before each analysis, a calibration (25.4 µS) of the UPV equipment was carried out. The samples were 160 mm long and 40 mm wide. The results are an average of the results obtained for the three specimens. The measure of UPV in direct position was obtained with the transmitter and receiver transducers positioned on top and bottom of each specimen, corresponding to a distance of 160 mm between transducers. The semi-direct measures were carried out placing the transmitter on one side and the receiver on a side perpendicular to the first one, leading to 80 mm distance between the two transducers. To mitigate the influence of voids between the transducers and specimens, an appropriate coupling gel was applied to the transducers. Three independent readings for each sample were registered.

The ultrasonic pulse velocity was calculated by dividing the time of the first wave arrival by the length of the specimen. Each result value corresponds to an average of five measurements done for three specimens for each mortar formulation (which correspond to fifteen measurements).

The dynamic modulus of elasticity was determined by ultrasonic pulse velocity and calculated through Equation (1), according to the works in [64,65].

where

Edn = ρc2(((1 + υ)(1 − 2υ))/(1 − υ)),

- Edn is the dynamic modulus of elasticity of mortars (GPa),

- ρ is the hardened mortar density (kg/m3),

- c is the UPV (km/s), and

- υ is the Poisson’s ratio was assumed as 0.2 for all mortar mixtures.

The samples for mechanical strength, water absorption, and carbonation tests were prepared based on EN 1015-11:1999 [66]. The flexural strength was carried out in a LLOYDS Instruments universal testing machine, with a maximum capacity of 50 kN. The compressive strength was performed in an ELE Auto Test press, with a capacity between 5 to 110 kN. The mechanical strength was measured at the curing ages listed in Table 3.

To measure the water absorption, the 40 × 40 × 160 mm3 samples were previously subjected to be resulting from the 3-point flexural test. Then, one part of the specimen was used for the capillarity test and the other was used for the immersion test. All the mortar parts were dried at 60 ± 5 °C until a constant mass was reached before the water absorption tests [67]. The determination of open porosity was carried out at atmospheric pressure and the samples were immersed in water for 24 h. After that period, the specimen’s surface was wiped with a cloth to remove any adsorbed water from the surface, and then the samples were weighed. The specimens were immersed for 24 h periods until no further increase in apparent mass was observed. This was considered reached when two consecutive weight measurements do not differ by more than 0.1% wt. The open porosity was determined according to the works in [67,68,69] following Equation (2).

where

Ai = (m1 − m3)/(m1 − m2) × 100,

- Ai—open porosity (%),

- m1—weight of water saturated specimen (g),

- m2—weight of saturated specimen immersed in water (g), and

- m3—weight of specimen (g).

The water absorption coefficient by capillarity was measured by placing the specimens in a box with the broken face of the prism downwards and immersed in water with a depth of 5 mm during the test; the other faces were covered with silicone to ensure that the water just enters in the sample by the capillaries of the face in contact with water. The water level was maintained through the test. Several weight measures were done: 0, 0.08, 0.17, 0.25, 0.33, 0.5, 0.75, 1, 1.5, 2, 2.5, 3–7, 24, 48, 72, 96, 120, 144, and 168 h. After 168 h of testing, the specimens were weighed every 7 days until a constant weight was reached. The water absorption by capillarity is determined by the calculation of the slope of the linear regression line that linked the points related to the measures carried out between 10 and 90 min [67,70].

For the carbonation test, the cured samples were preconditioned in an isolated container subjected to a constant temperature and relative humidity (RH) (88.0 ± 4.0% and 17.5 ± 1.6 °C) for 14 days, to ensure the stabilization of humidity within the samples. After this period, the samples were sealed with paraffin, except for two opposed faces, and placed in a chamber to test the accelerated carbonation (4.2 ± 0.1%wt of CO2, 52.6 ± 8.3% RH, and 20.0 ± 0.8 °C). To measure the carbonation depth, several cross sections were taken by diametric compression, and after they were sprayed with a phenolphthalein indicator.

3. Results and Discussion

3.1. Fresh Properties

The flow spread values obtained for each mortar formulation are shown in Table 4. One may observe that mortars with 50%wt of cement replaced by BFA and with cement replaced by BFA (48.5%wt) and HL (1.25%wt) presented flow spread values similar to those observed for the reference formulation, and in some cases lower than reference. These results are according to those achieved in other research studies [12,71]. They are related to the physical characteristics of biomass fly ash from wood. Wood fly ash presents a heterogeneous distribution of particles, with irregular shape and fineness, that determine the high specific surface area and control the compactness of mixtures [71,72]. Besides that, the high organic matter (Table 1) leads to the adsorption of water molecules, which leads to a decrease in the free water available for workability purposes [12,29,71]. The incorporation of CFA on the mixtures, alone or blended with BFA or/and HL, increased the value of spread flow when compared with the reference mixture and with the mixtures containing only biomass fly ash.

Table 4.

Flow spread, density, and air content of fresh mixtures.

In terms of the density of the fresh mixture, no significant differences were observed between the different mixtures (Table 4). On the other side, significant differences were observed in the amount of air content. The reference mixture presented more voids (almost 3% of air content) than the other mixtures. Once again, the mixtures with a high content of BFA present a similar behavior when compared with the reference. Mixtures with a high content of CFA presented lower values (below than 1%). Similar results were found in other studies [73,74,75,76,77]. In some of those studies, the results were explained by the smooth surface characteristics and the spherical shape of CFA which improved the fresh properties of concrete [75].

3.2. Hardened Properties

3.2.1. Electric Resistivity and Ultrasonic Velocity Pulse

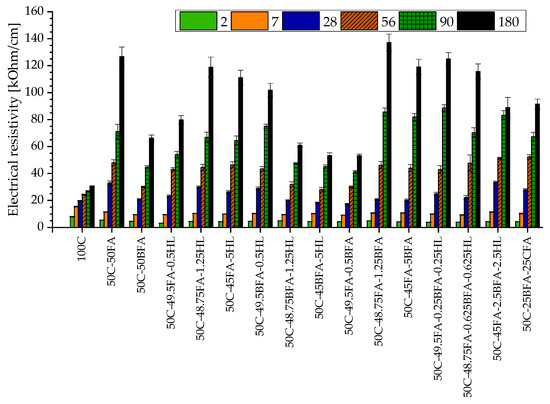

The electric resistivity was measured for each mortar formulation, and its results are presented in Figure 1. The electric resistivity is affected by several parameters such as the free water content, the origin and the concentration of ionic species in the pore solution, the amount of hydration products, the particle size, and the specific surface area of raw materials [71].

Figure 1.

Electric resistivity evolution of mortars for 2, 7, 28, 56, 90, and 180 of curing.

The electric resistivity evolution is similar for all mortar formulations, increasing with the curing period. At early ages, reference mortar presents higher resistivity values in comparison with the mortars containing ashes (Figure 1). Similar results were found in other researches, and this behavior is explained by the fact that a higher content of cement (like in reference mortar) leads to a faster setting [71]. The time needed for the pozzolanic reaction between CFA or BFA and calcium hydroxide resulting from cement hydration leads to longer setting periods in these mortars. Besides, there is a delay in the gain of resistivity on mortars with ashes at the early ages, the values observed after 28 days of curing are higher than those registered in the reference mortar (Figure 1). The mortars with CFA alone or blended with BFA presented a higher electric resistivity and similar results were found in [78].

The electric resistivity is an important parameter to control the initiation and propagation of the corrosion of steel reinforcement in concrete [79,80,81,82]. The use of CFA and BFA and ternary binder on concrete may contribute to decrease this risk of corrosion and improve the durability of concrete, as the objective of using pozzolan in concrete is mainly for concrete durability improvement [79], namely, to increase the resistance to chloride diffusivity [81].

Mortars with 50% cement replaced by BFA presented lower electric resistivity values when compared with CFA mortar, however they presented higher values than those observed in cement mortars.

The introduction of HL in a mortar with high volume fly ash content (CFA and BFA) has a different effect in electric resistivity. In mortars with CFA or with BFA, the increase of HL led to a decrease in the electric resistivity of mortars. The electric resistivity values of the three compositions are lower than the value for the mortar produced only with ashes (Figure 1). However, the values of electric resistivity of BFA/HL mortars were lower than those of CFA/HL mortars. The replacement of HL by BFA, in mortars with 50% of cement replaced by CFA, leads to an increase in the resistivity. The higher values were observed in the formulation with lower BFA content (50C-49.5CFA-0.5BFA, Figure 1). These results showed that the lack of cement is compensated by the synergistic effect between CFA with BFA [78].

The mixture of the three materials (CFA, BFA, and HL) with cement as a binder does not lead to a significant gain of electric resistivity, which shows that the synergetic effect of these four materials is not very effective.

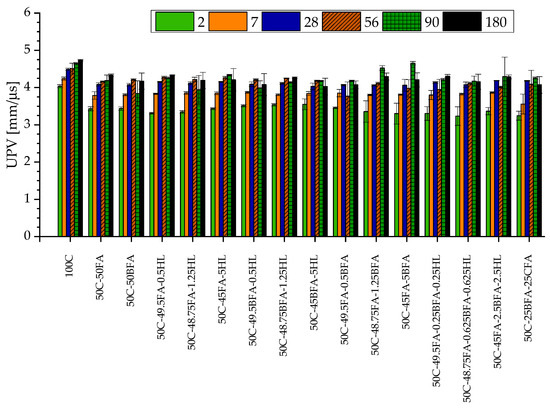

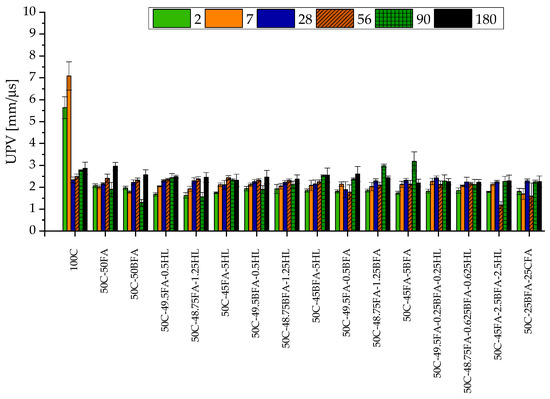

The UPV increased with curing time in all samples until 90 days of curing. The maximum velocity was obtained in the reference sample for all curing periods. The decrease in velocity for mortars with the fly ashes reveals that the compressive strength of samples with ashes had lesser compressive strength than the plain cement mortars. The UPV depends on the density and elastic properties of the building materials [62,83,84]. As the UPV is influenced by the heterogeneity of samples, such as the presence of voids, the reduction of this parameter in mortars with BFA (Figure 2 and Figure 3) showed that these samples were more heterogeneous. The UPV is related to the strength of the material, so a decrease in this parameter indicates a decrease in its mechanical strength [85].

Figure 2.

UPV values from the direct method for the different mortar formulations for 2, 7, 28, 56, 90, and 180 of curing.

Figure 3.

UPV values from the semi-direct method for the different mortar formulations for 2, 7, 28, 56, 90, and 180 of curing.

In terms of UPV measured in a semi-direct direction, significant differences may be observed when comparing the plain cement reference mortar and those containing ashes at early curing ages. A significant decrease in the UPV in mortars containing ashes may be noticed (Figure 3). However, with the increase in the curing age, UPV measured is similar for all mortars.

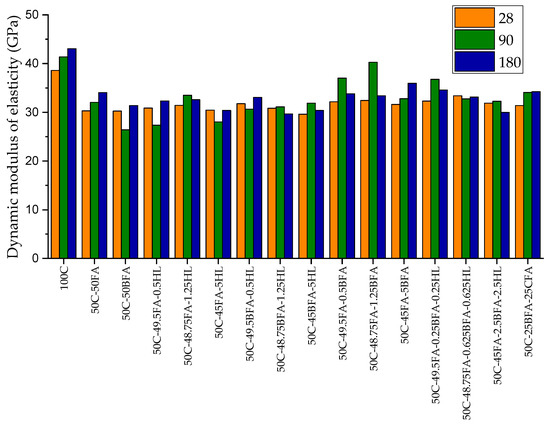

The dynamic modulus of elasticity determined by Equation (1) vs. curing time is presented in Figure 4.

Figure 4.

Dynamic modulus of elasticity for the different mortar formulations for 2, 7, 28, 56, 90, and 180 of curing.

The values observed, for each curing age, represent the average of three measurements on each sample. Mortars with CFA or/and BFA present lower values for the dynamic modulus of elasticity than that of reference mortar, for all curing ages. These results showed that the introduction of ashes as cement substitution has a significant effect on some mortar properties, such as the reduction of the hardened concrete density and the increase of heterogeneity of the resulting mortar [64].

An important observation is that the utilization of BFA as a reservoir of alkalinity in mortars with CFA presented higher values of dynamic modulus of elasticity when compared with the other mortars containing ashes. This phenomenon is particularly noticed at 90 days of curing (Figure 4). This can be related to a good synergic behavior between the two types of ash.

3.2.2. Flexural and Compressive Strength Results

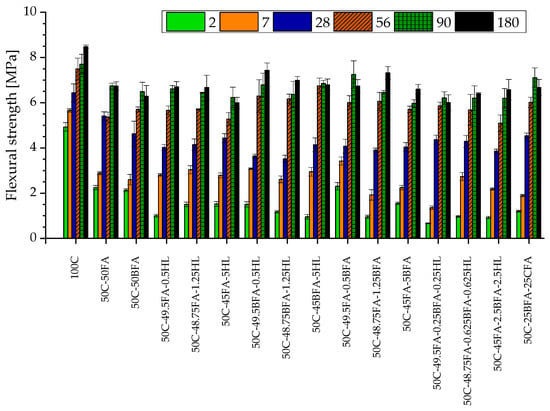

In Figure 5, the values obtained for the flexural mechanical strength of the different mortars may be observed. The results showed an increase in flexural strength with the curing age. The replacement of cement by CFA, BFA, or/and a blend of the two ashes led to a decrease in the flexural strength when compared with the reference mortar. This was expected, because of the higher percentage of cement substitution, and it is known that higher contents of pozzolans in mortars or concrete contribute to decreasing the strength of materials, despite the pozzolanic reaction, not sufficient to fulfill the lack of cement. Similar results were observed in other studies [29,31,85,86,87,88].

Figure 5.

Evaluation of flexural strength values of mortars with the curing period for 2, 7, 28, 56, 90, and 180 of curing.

In terms of the utilization of HL, in the mortar with CFA and BFA, the best results were observed for the composition with the higher lime content. On the other side, when it is used BFA in mortars with CFA, the mortars with the lower biomass content present the best results. The utilization of the two ashes and HL has different effects on the flexural strength in the different periods of curing.

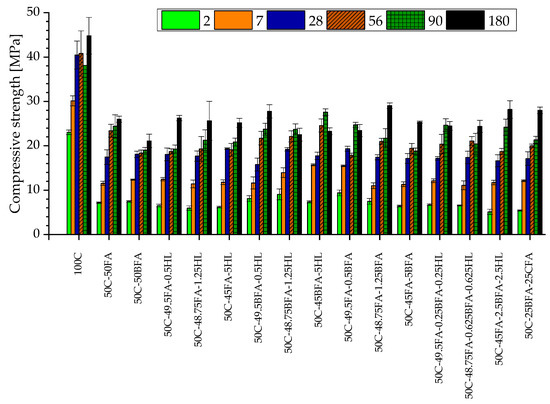

Similar results to those observed for flexural were also noticed for the compressive strength (Figure 6). A significant decrease was observed with the incorporation of ashes and HL as cement replacement in the compressive strength, when compared with the reference mixture (100C), was observed in some cases a 50% reduction on the values (e.g., for 28 days in 50C-50CFA) (Figure 6). An increase in the compressive strength with the curing age was also observed and similar results were found in [38,44,86,89,90,91,92]. The use of BFA as cement replacement led to a mortar with lower strength than the mortar with CFA after 56 days of curing (Figure 6), with values between 18.4 and 21.1 MPa for 50C-50BFA samples and 23.4 and 26.0 Mpa for 50C-50CFA. Several studies showed that the use of BFA from wood as partial cement replacement in concrete leads to a decrease in the compressive strength [12,29,31,35,93].

Figure 6.

Evaluation of compressive strength values of mortars with the curing period for 2, 7, 28, 56, 90, and 180 of curing.

The introduction of HL in mortars with CFA does not have a significant improvement in the strength of mortar when compared to the plain cement one. An increase in the compressive strength at early ages was observed for mortars with HL and CFA. This can be due to the breaking down of CFA particles at the high calcium hydroxide content and the inner silicate phase becoming suitable for the hydration reaction with the production of more calcium silicate hydrates [94]. However, its introduction in mortars with BFA leads to an increase in the mortar strength, being the cement substitution of 1.25% by HL, the content that provides the best results for the different curing ages.

The introduction of BFA as a reservoir of alkalinity on the CFA mortar did not show a significant effect on the compressive strength at early ages. However, for 90 and 180 days curing, mortars with CFA and BFA presented the best results (50C-45CFA-5BFA-90 days and 50C-49.5CFA-1.25BFA) and similar results were observed when the two fly ashes were used together with HL.

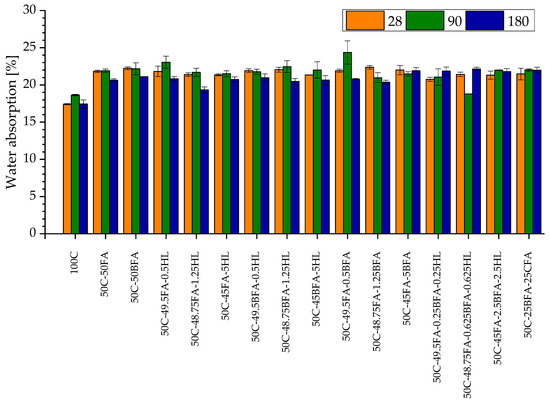

3.2.3. Water Absorption by Immersion and by Capillarity

The water absorption by immersion is relevant for the concrete durability because it allows assessing the open porosity of concrete, by indirect measurement of the mass of the samples immersed in water for 24 h periods. This test is affected by several factors that control the porosity of concrete/mortar, and one of them is the water/binder relation and the content of cement replacement by pozzolanic materials. The water immersion was determined at 28, 90, and 180 days (Figure 7). All mortars containing ashes have a higher water immersion coefficient than cement mortar. BFA mortars have similar behavior in terms of water absorption to CFA mortars. In general, the porosity decreases with the curing age. This is due to the increase of hydrated compounds content and latent hydration during the pozzolanic reaction of ashes in the presence of calcium hydroxide [82].

Figure 7.

Open porosity of mortar samples determined by water absorption for 28, 90, and 180 days of curing.

The introduction of HL in mortars with CFA does not have a different effect on the water absorption coefficient, for the early ages, when compared with the mortar containing only CFA. However, for 180 days curing, the coefficient for mortar with 0.5% of cement replacement by lime has a lower value than that observed in the mortar with CFA, but still higher than the reference one. On the other side, the introduction of lime in mortars with BFA does not have a different effect on the open porosity when compared with the mortars made only with BFA.

The use of 0.5% of BFA on mortars with CFA leads to a decrease in the open porosity for mortar with 90 and 180 days curing, when compared with mortars made only with cement and CFA. The other replacements did not lead to an improvement in the open porosity when compared with the mortar containing CFA. The use of the two pozzolans and lime together did not allow an improvement on the open porosity of mortars when compared with the reference ones or with mortars containing only one pozzolan or with the two pozzolans.

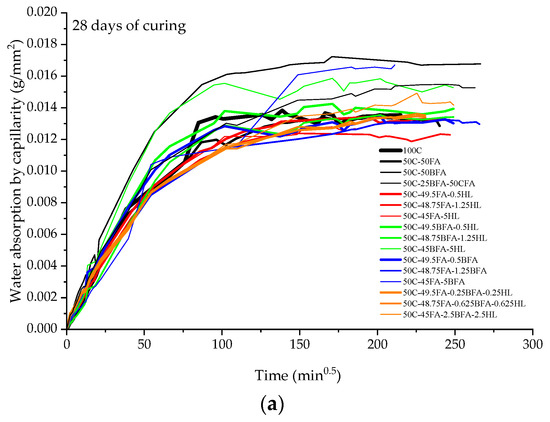

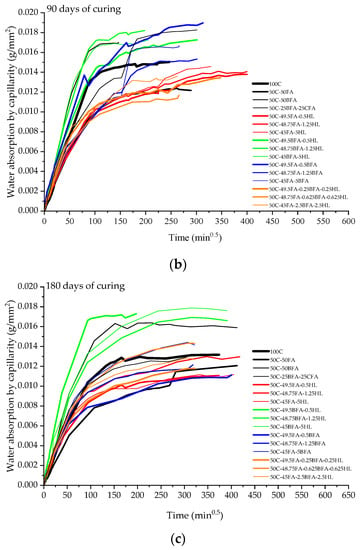

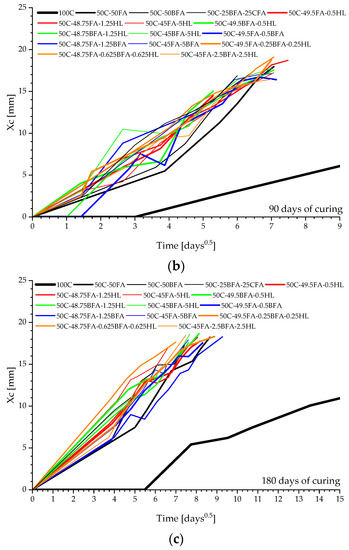

The capillarity absorption curves are shown in Figure 8 and capillarity absorption coefficient is shown in Table 5.

Figure 8.

Curves for the capillarity absorption of mortars cured for (a) 28, (b) 90, and (c) 180 days of curing.

Table 5.

Coefficient of water absorption by capillarity of mortars.

In general, the coefficient of water absorption decreased with the curing age, and this was expected as during the curing, the reaction of hydration occurs, leading to a decrease in the voids and the physical structures of mortars. Similar results were found in Silva and Brito (2015) [95]. Mortar with CFA had a lower capillarity coefficient than the reference mortar. On the other side, mortars with BFA had a higher coefficient than the reference and CFA mortars, for all curing ages. It was observed that CFA mortars with lime had higher values for the coefficients (Table 5) than the mortars made only with cement and CFA. The higher results were achieved in the mortar with the higher lime content (50C-45CFA-5HL).

As can be seen from Figure 8, the replacement of cement by CFA did not have a significant impact on the mortar in terms of water absorption by capillarity. However, at 90 and 180 days curing, the values for the water absorption for mortars with CFA were lower than those observed in the reference. The presence of BFA led to mortars with higher absorption than the reference, for all curing ages. One interesting observation is the fact that for 180 days curing, mortars with the two pozzolans presented lower values than the reference mortar.

Mortars with CFA and HL present lower water absorption than the reference. The lower values were achieved for the mortar with 1.25% of HL for 28 days curing, with 0.5% for 90 days, and with 5% of HL for 180 days of curing. In the case of mortars with BFA and HL, the mixtures with 0.5% and 5% presented higher values than the reference, but the composition with 1.25% presented lower values, for 28 days curing. However, all the formulations presented lower values than the mortars made only with BFA. In mortars with 90 days of curing, the best results were achieved for mortars with 0.5% of HL. At 180 days of curing, all the mortars with BFA and HL presented higher values than the reference and mortars made only with BFA. This phenomenon is contrary to the results observed for 28 days of curing.

Similar results to the mortars with CFA and HL were achieved when HL was replaced by BFA. In this case, the best results were achieved for 1.25 and 5% of BFA mortars, at 28 days of curing. However, at 90 and 180 days of curing, mortars with CFA and BFA presented higher values than mortars containing only CFA. The use of the two pozzolans together with HL did not lead to better results than mortars made only with CFA, but they perform better than mortars made only with BFA, for all curing ages, except for the mortar with 0.625% of BFA and HL for 90 days curing (Figure 8).

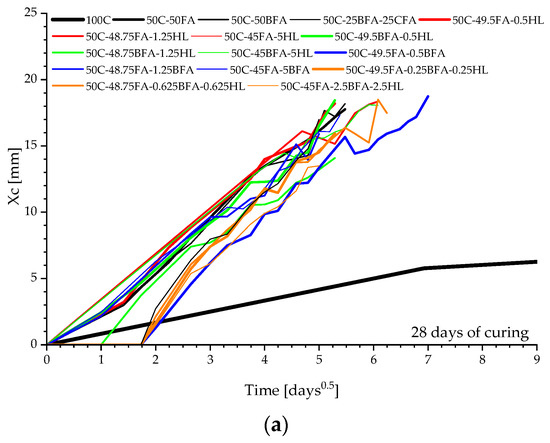

3.2.4. Carbonation

The carbonation depth for the different mortars is expressed in Figure 9. As it can be seen, for 28 days of curing the reference mortar did not present carbonation zones. For 90 and 180 days of curing, plain cement reference mortar presented the lowest carbonation depth values of all studied mortars. All mortars presented increased values of carbonation depth along the test period. As it can be seen, mortars with BFA presented lower values of carbonation depth at the beginning of the test. However, at 30 days of the test, mortar with BFA presented higher values.

Figure 9.

Carbonation depth measured in mortars with (a) 28, (b) 90, and (c) 180 days of curing.

The use of HL to minimize the carbonation phenomena in mortars with CFA did not present good results for mortars with 28 days of curing. However, in mortars with 90 days of curing, all formulations with the HL exhibited better results in the beginning of the test when compared with CFA mortar, and similar results at 30 days of testing. Mortars with 180 days of curing showed that the formulation that has similar and good results in terms of carbonation is the 50C-49.5CFA-0.5HL when compared with CFA mortar that presents the best results. On the other side, HL use in mortars with BFA led to better results when compared with mortars made only with BFA. In this case, the best results were achieved for the 50C-45BFA-5HL at 28 days of curing; 50C-49.5BFA-0.5HL and 50C-45BFA-5HL at 90 days of curing; and 50C-49.5BFA-0.5HL for mortars with 180 days of curing.

The use of BFA and CFA in mortars showed good results at the beginning of the accelerated test but, with its development, CFA mortar had better behavior in terms of carbonation depth, for 28 days of curing. Mortars with 90 and 180 days of curing and with the two selected pozzolans presented good results along with the entire accelerated carbonation test, similar or better than mortars made only with CFA. Mortars with 180 days showed that the small quantity of BFA improved the performance. Similar results were observed when the two pozzolans and HL were used.

4. Conclusions

This study focused on mortars, due to the fact of mortars used less raw materials and allows to study a greater number of different mixes; however, the design of these mortar mixes was done considering the properties of the corresponding concrete mixes. It was notorious that biomass fly ash cannot be used as a supplementary cementitious material like coal fly ash as its incorporation decreases the mechanical and carbonation resistance and increased the porosity and the absorption of water. However, the use of small amount of biomass fly ash blended with coal fly ash in high volume fly ash mortar has better mechanical performance and similar water absorption and carbonation behavior than a high-volume coal fly ash mortar, which in terms of the concrete is a type of concrete very used at an industrial level. However, with an important significant difference, biomass fly ash is a more sustainable material than coal fly ash, and therefore the high volume of coal/biomass fly ash concrete will be also more sustainable then the high-volume coal fly ash concrete. Therefore, one of the solutions to minimize the problems of the high volume of fly ash concrete seems to be the utilization of a small amount of biomass fly ash blended with coal fly ash. The results obtained show that the synergic effect obtained by the simultaneous use of these two materials allows achieving better performance than the use of each one alone.

Despite this, these results show a good contribution of biomass fly ash as a reservoir of alkalinity for high-volume fly ash concrete. This needs to be verified in concrete compositions, and it will be done in a near future. Thus, the work developed in this study can be complemented to test the concrete in a more complete way, carrying out tests such as shrinkage, flexural strength, resistance to acids attack, alkali–silica reaction test, freeze–thaw resistance, porosity, and leaching tests. Those tests can be important to complement the study on concrete with a high volume of coal/biomass fly ash and to have a better understanding of biomass fly ash’s benefits, risks, and applicability.

Author Contributions

Conceptualization, E.R.T.; methodology, E.R.T., A.C. and F.G.B.; validation, A.C.; formal analysis, A.C. and F.G.B.; investigation, E.R.T.; resources, E.R.T., A.C. and F.G.B.; writing—original draft preparation, E.R.T.; writing—review and editing, A.C., J.C.M. and F.G.B.; supervision, A.C. and F.G.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Portuguese Foundation for Science and Technology (FCT) and the Eco-Construction and Rehabilitation Doctoral Program for supporting the PhD scholarship (reference PD/BD/52661/2014). This work was partly financed by FCT/MCTES through national funds (PIDDAC) under the R&D Unit Institute for Sustainability and Innovation in Structural Engineering (ISISE), under reference UIDB/04029/2020.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gasparatos, A.; Doll, C.N.; Esteban, M.; Ahmed, A.; Olang, T.A. Renewable energy and biodiversity: Implications for transitioning to a Green Economy. Renew. Sustain. Energy Rev. 2017, 70, 161–184. [Google Scholar] [CrossRef]

- UNEP. Towards a Green Economy: Pathways to Sustainable Development and Poverty Eradication; UNEP: Nairobi, Kenya, 2011. [Google Scholar] [CrossRef]

- Barbosa, R.; Lapa, N.; Dias, D.; Mendes, B. Concretes containing biomass ashes: Mechanical, chemical, and ecotoxic performances. Constr. Build. Mater. 2013, 48, 457–463. [Google Scholar] [CrossRef]

- Morais, J.B.; Barbosa, R.; Lapa, N.; Mendes, B.; Gulyurtlu, I. Environmental and socio-economic assessment of co-combustion of coal, biomass and non-hazardous wastes in a Power Plant. Resour. Conserv. Recycl. 2011, 55, 1109–1118. [Google Scholar] [CrossRef]

- Wang, S.; Baxter, L. Comprehensive study of biomass fly ash in concrete: Strength, microscopy, kinetics and durability. Fuel Process. Technol. 2007, 88, 1165–1170. [Google Scholar] [CrossRef]

- Sami, M.; Annamalai, K.; Wooldridge, M. Co-firing of coal and biomass fuel blends. Prog. Energy Combust. Sci. 2001, 27, 171–214. [Google Scholar] [CrossRef]

- Haykırı-Açma, H. Combustion characteristics of different biomass materials. Energy Convers. Manag. 2003, 44, 155–162. [Google Scholar] [CrossRef]

- Al-Kassir, A.; Gañán-Gómez, J.; Mohamad, A.; Cuerda-Correa, E.M. A study of energy production from cork residues: Sawdust, sandpaper dust and triturated wood. Energy 2010, 35, 382–386. [Google Scholar] [CrossRef]

- González, J.F.G.; Ledesma, B.; Alkassir, A.; González, J. Study of the influence of the composition of several biomass pellets on the drying process. Biomass Bioenergy 2011, 35, 4399–4406. [Google Scholar] [CrossRef]

- Tarelho, L.; Teixeira, E.; Silva, D.; Modolo, R.; Labrincha, J.; Rocha, F. Characteristics of distinct ash flows in a biomass thermal power plant with bubbling fluidised bed combustor. Energy 2015, 90, 387–402. [Google Scholar] [CrossRef]

- European Commission. Commission Decision on the European List of Waste (COM 2000/532/EC). Off. J. Eur. Communities 2000, D0532, 1–31. [Google Scholar]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of woody biomass fly ash in cement-based materials. Constr. Build. Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

- Lima, A.T.; Ottosen, L.M.; Pedersen, A.; Ribeiro, A. Characterization of fly ash from bio and municipal waste. Biomass Bioenergy 2008, 32, 277–282. [Google Scholar] [CrossRef]

- Sarabèr, A.; Haasnoot, K. Recycling of Biomass Ashes in The Netherlands; Ash Utilisation; Springer: Berlin/Heidelberg, Germany, 2012; pp. 25–27. [Google Scholar]

- Kröppl, M.; Lanzerstorfer, C. Acidic extraction and precipitation of heavy metals from biomass incinerator cyclone fly ash. E3S Web Conf. 2013, 1, 16007. [Google Scholar] [CrossRef]

- Biricik, H.; Akoz, F.; Berktay, I.; Tulgar, A.N. Study of pozzolanic properties of wheat straw ash. Cem. Concr. Res. 1999, 29, 637–643. [Google Scholar] [CrossRef]

- Yu, Q.; Sawayama, K.; Sugita, S.; Shoya, M.; Isojima, Y. The reaction between rice husk ash and Ca(OH)2 solution and the nature of its product. Cem. Concr. Res. 1999, 29, 37–43. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Valencia-Morales, E.; González-Rodríguez, R.; Hernández-Ruíz, J. Kinetics of the pozzolanic reaction between lime and sugar cane straw ash by electrical conductivity measurement: A kinetic–diffusive model. Cem. Concr. Res. 2003, 33, 517–524. [Google Scholar] [CrossRef]

- Wang, S.; Miller, A.; Llamazos, E.; Fonseca, F.; Baxter, L. Biomass fly ash in concrete: Mixture proportioning and mechanical properties. Fuel 2008, 87, 365–371. [Google Scholar] [CrossRef]

- Lokare, S.S.; Dunaway, J.D.; Moulton, D.; Rogers, D.; Tree, D.R.; Baxter, L.L. Investigation of Ash Deposition Rates for a Suite of Biomass Fuels and Fuel Blends. Energy Fuels 2006, 20, 1008–1014. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Darvell, L.I.; Jones, J.M.; Williams, P.T.; Fahmi, R.; Bridgwater, A.V.; Barraclough, T.; Shield, I.; Yates, N.; Thain, S.C.; et al. Influence of particle size on the analytical and chemical properties of two energy crops. Fuel 2007, 86, 60–72. [Google Scholar] [CrossRef]

- Wiselogel, A.; Agblevor, F.; Johnson, D.; Deutch, S.; Fennell, J.; Sanderson, M. Compositional changes during storage of large round switchgrass bales. Bioresour. Technol. 1996, 56, 103–109. [Google Scholar] [CrossRef]

- Lewandowski, I.; Clifton-Brown, J.C.; Scurlock, J.M.O.; Huisman, W. Miscanthus: European experience with a novel energy crop. Biomass Bioenergy 2000, 19, 209–227. [Google Scholar] [CrossRef]

- Rafael, S.; Tarelho, L.; Monteiro, A.; Sá, E.; Miranda, A.I.; Borrego, C.; Lopes, M. Impact of forest biomass residues to the energy supply chain on regional air quality. Sci. Total. Environ. 2015, 505, 640–648. [Google Scholar] [CrossRef]

- Wang, S.; Llamazos, E.; Baxter, L.; Fonseca, F. Durability of biomass fly ash concrete: Freezing and thawing and rapid chloride permeability tests. Fuel 2008, 87, 359–364. [Google Scholar] [CrossRef]

- Thy, P.; Jenkins, B.; Grundvig, S.; Shiraki, R.; Lesher, C. High temperature elemental losses and mineralogical changes in common biomass ashes. Fuel 2006, 85, 783–795. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Wu, Y.; Wang, Y.; Wang, Y. Evaluation of the improved properties of SBR/weathered coal modified bitumen containing carbon black. Constr. Build. Mater. 2009, 23, 2678–2687. [Google Scholar] [CrossRef]

- Zheng, Y.; Jensen, P.A.; Jensen, A.D.; Sander, B.; Junker, H. Ash transformation during co-firing coal and straw. Fuel 2007, 86, 1008–1020. [Google Scholar] [CrossRef]

- Rajamma, R.; Ball, R.J.; Tarelho, L.A.; Allen, G.C.; Labrincha, J.A.; Ferreira, V.M. Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef]

- Wieck-Hansen, K.; Overgaard, P.; Larsen, O.H. Cofiring coal and straw in a 150 MWe power boiler experiences. Biomass Bioenergy 2000, 19, 395–409. [Google Scholar] [CrossRef]

- Cheah, C.B.; Ramli, M. The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: An overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- Esteves, T.; Rajamma, R.; Soares, D.; Silva, A.S.; Ferreira, V.; Labrincha, J. Use of biomass fly ash for mitigation of alkali-silica reaction of cement mortars. Constr. Build. Mater. 2012, 26, 687–693. [Google Scholar] [CrossRef]

- Tarelho, L.A.C.; Teixeira, E.R.; Silva, D.F.R.; Modolo, R.C.E.; Silva, J.J.F. Characteristics, management and applications of ashes from thermochemical conversion of biomass to energy. In Proceedings of the World bioenergy 2012, Conference & Exhibition on Biomass for Energy, Jonkopin, Sweden, 29–31 May 2012. [Google Scholar]

- Cordeiro, G.C.; Filho, R.D.T.; Tavares, L.M.; Fairbairn, E.D.M.R. Ultrafine grinding of sugar cane bagasse ash for application as pozzolanic admixture in concrete. Cem. Concr. Res. 2009, 39, 110–115. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Mahmood, Y.A. Ash from timber waste as cement replacement material. Cem. Concr. Compos. 2002, 24, 219–222. [Google Scholar] [CrossRef]

- Shearer, C.R.; Yeboah, N.; Kurtis, K.E.; Burns, S.E. The Early Age Behavior of Biomass Fired and Co-fired Fly Ash in Concrete; World Coal Ash: Denver, CO, USA, 2011; Available online: http://www.flyash.info/2011/017-Shearer-2011.pdf (accessed on 22 November 2020).

- Barathan, S.; Gobinath, B. Evaluation of Wood Ash As a Partial Replacement To Cement. Int. J. Sci. Eng. Technol. Res. 2013, 2, 2009–2013. [Google Scholar]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Influence of pozzolan from various by-product materials on mechanical properties of high-strength concrete. Constr. Build. Mater. 2007, 21, 1589–1598. [Google Scholar] [CrossRef]

- Coelho, A.M.S.L. Gestão de Cinzas produzidas em centrais de cogeração operadas com biomassa (Management of ashes produced in biomass co-generation industries). Master’s Thesis, Department of Environment and Planning, University of Aveiro, Aveiro, Portugal, 2010. [Google Scholar]

- Tkaczewska, E.; Małolepszy, J. Hydration of coal–biomass fly ash cement. Constr. Build. Mater. 2009, 23, 2694–2700. [Google Scholar] [CrossRef]

- Udoeyo, F.F.; Inyang, H.; Young, D.T.; Oparadu, E.E. Potential of Wood Waste Ash as an Additive in Concrete. J. Mater. Civ. Eng. 2006, 18, 605–611. [Google Scholar] [CrossRef]

- ASTM C188-95. Standard Test Method for Density of Hydraulic Cement; ASTM: West Conshohocken, PA, USA, 2003. [Google Scholar] [CrossRef]

- Dahl, O.; Nurmesniemi, H.; Pöykiö, R.; Watkins, G. Comparison of the characteristics of bottom ash and fly ash from a medium-size (32 MW) municipal district heating plant incinerating forest residues and peat in a fluidized-bed boiler. Fuel Process. Technol. 2009, 90, 871–878. [Google Scholar] [CrossRef]

- Maschio, S.; Tonello, G.; Piani, L.; Furlani, E. Fly and bottom ashes from biomass combustion as cement replacing components in mortars production: Rheological behaviour of the pastes and materials compression strength. Chemosphere 2011, 85, 666–671. [Google Scholar] [CrossRef]

- Girón, R.; Ruiz, B.; Fuente, E.; Gil, R.; Suarezruiz, I. Properties of fly ash from forest biomass combustion. Fuel 2013, 114, 71–77. [Google Scholar] [CrossRef]

- Liao, C.; Wu, C.; Yan, Y. The characteristics of inorganic elements in ashes from a 1 MW CFB biomass gasification power generation plant. Fuel Process. Technol. 2007, 88, 149–156. [Google Scholar] [CrossRef]

- Latva-Somppi, J.; Moisio, M.; I Kauppinen, E.; Valmari, T.; Ahonen, P.; Tapper, U.; Keskinen, J. Ash formation during fluidized-bed incineration of paper mill waste sludge. J. Aerosol Sci. 1998, 29, 461–480. [Google Scholar] [CrossRef]

- Latva-Somppi, J.; I Kauppinen, E.; Valmari, T.; Ahonen, P.; Gurav, A.S.; Kodas, T.T.; Johanson, B. The ash formation during co-combustion of wood and sludge in industrial fluidized bed boilers. Fuel Process. Technol. 1998, 54, 79–94. [Google Scholar] [CrossRef]

- Miller, B.; Dugwell, D.; Kandiyoti, R. The Fate of Trace Elements during the Co-Combustion of Wood-Bark with Waste. Energy Fuels 2006, 20, 520–531. [Google Scholar] [CrossRef]

- Steenari, B.-M.; Fedje, K.K. Addition of kaolin as potassium sorbent in the combustion of wood fuel—Effects on fly ash properties. Fuel 2010, 89, 2026–2032. [Google Scholar] [CrossRef]

- Daczko, J.J. Mortar Testing for Estimating Strength. Concr. Int. 1999, 21, 63–67. [Google Scholar]

- Camões, A.; Aguiar, J.; Jalali, S. Estimating Compressive Strength of Concrete by Mortar Testing. In Proceedings of the INCOS’05, International Conference on Concrete for Structures, Coimbra, Portugual, 7–8 July 2005; Available online: https://www.academia.edu/21562504/Estimating_compressive_strength_of_concrete_by_mortar_testing (accessed on 26 February 2021).

- Strain-Rate Sensitive Behavior of Cement Paste and Mortar in Compression. ACI Mater. J. 1990, 87, 508–516. [CrossRef]

- Maroof, N.; Karim, H.; Hasan, A. Relationship between properties of cement mortar with that of concrete mix. Proj. Prod. Light. Therm. Insul. Clay Bricks Using Pap. 2016, 6, 391–404. [Google Scholar]

- Camões, A. Betões de Elevado Desempenho Com Elevado Volume de Cinzas Volantes. Restor. Ecol. 2005, 23, 55–64. [Google Scholar] [CrossRef]

- Vimmrová, A.; Keppert, M.; Michalko, O.; Černý, R. Calcined gypsum–lime–metakaolin binders: Design of optimal composition. Cem. Concr. Compos. 2014, 52, 91–96. [Google Scholar] [CrossRef]

- Reis, R.; Camões, A.; Ribeiro, M.; Malheiro, R. Matrizes Cimentíceas Com Elevado Volume de Cinzas Volantes e Hidróxido de Cálcio: Estudo da Carbonatação; 5as Jornadas Port. Eng. Estruturas; LNEC: Lisbon, Portugal, 2014; pp. 1–12. [Google Scholar]

- EN1015-2:1998. Methods of Test for Mortar for Masonry—Part 2: Bulk Sampling of Mortars and Preparation of Test Mortars; CEN: Brussels, Belgium, 1998; Available online: https://shop.bsigroup.com/ProductDetail?pid=000000000030151072 (accessed on 26 February 2021).

- EN 1015-3, European Standard. Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table); CEN: Brussels, Belgium, 1998. [Google Scholar]

- EN 1015-7, European Standard. Methods of Test for Mortar for Masonry—Part 7: Determination of Air Content of Fresh Mortar; CEN: Brussels, Belgium, 1998. [Google Scholar]

- Perez, J.A.V.; Guzmán, E.M.A.; Molina, W.M.; García, H.L.C.; Moreno, I.T.; Sánchez, M.A. Evaluation of the Electrical Resistivity, Ultrasonic Pulse Velocity and Mechanical Properties in Portland Cement Pastes Type II. Key Eng. Mater. 2020, 841, 198–202. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Utilization of high volumes of unprocessed lignite-coal fly ash and rice husk ash in self-consolidating concrete. J. Clean. Prod. 2014, 78, 184–194. [Google Scholar] [CrossRef]

- NP EN 12504-4. Portuguese Standard—Testing Concrete in Structures—Part 4: Determination of ultrasonic pulse velocity; NP: Lisbon, Portugal, 2007. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Andiç-Çakir, Ö.; Ramyar, K. Freeze–thaw resistance and transport properties of high-volume fly ash roller compacted concrete designed by maximum density method. Cem. Concr. Compos. 2013, 37, 259–266. [Google Scholar] [CrossRef]

- Cusens, A. Concrete technology. Build. Environ. 1976, 11, 215. [Google Scholar] [CrossRef]

- EN 1015-11, European Standard. Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; CEN: Brussels, Belgium, 1999. [Google Scholar]

- Teixeira, E.R.; Camões, A.; Branco, F.G.; Tarelho, L. Biomass and coal fly ash as cement replacement on mortar properties. In Proceedings of the ICCS16—II International Conference on Concrete Sustainability, Madrid, Spain, 13–15 June 2016; pp. 1–12. [Google Scholar]

- EN 1015-10, European Standard. Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar; CEN: Brussels, Belgium, 1999. [Google Scholar]

- LNEC E 394_1993. Determination of the Absorption of Water Immersion; LNEC: Lisbon, Portugal, 1993. [Google Scholar]

- EN 1015-18, European Standard. Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient due to Capillary Action of Hardened Mortar; CEN: Brussels, Belgium, 2002. [Google Scholar]

- Rajamma, R.; Senff, L.; Ribeiro, M.; Labrincha, J.; Ball, R.J.; Allen, G.; Ferreira, V. Biomass fly ash effect on fresh and hardened state properties of cement based materials. Compos. Part B Eng. 2015, 77, 1–9. [Google Scholar] [CrossRef]

- Modolo, R.; Ferreira, V.; Tarelho, L.; Labrincha, J.; Senff, L.; Silva, L. Mortar formulations with bottom ash from biomass combustion. Constr. Build. Mater. 2013, 45, 275–281. [Google Scholar] [CrossRef]

- Kayali, O.; Ahmed, M.S. Assessment of high volume replacement fly ash concrete – Concept of performance index. Constr. Build. Mater. 2013, 39, 71–76. [Google Scholar] [CrossRef]

- Bouzoubaâ, N.; Zhang, M.; Malhotra, V. Mechanical properties and durability of concrete made with high-volume fly ash blended cements using a coarse fly ash. Cem. Concr. Res. 2001, 31, 1393–1402. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yaman, I.O. Hybrid fiber reinforced self-compacting concrete with a high-volume coarse fly ash. Constr. Build. Mater. 2007, 21, 150–156. [Google Scholar] [CrossRef]

- Zhang, M.; Malhotra, V. Characteristics of a thermally activated alumino-silicate pozzolanic material and its use in concrete. Cem. Concr. Res. 1995, 25, 1713–1725. [Google Scholar] [CrossRef]

- Arezoumandi, M.; Volz, J.S. Effect of fly ash replacement level on the shear strength of high-volume fly ash concrete beams. J. Clean. Prod. 2013, 59, 120–130. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Kocabağ, M.E.; Bayram, V.; Mermerdaş, K. Fresh and hardened characteristics of self compacting concretes made with combined use of marble powder, limestone filler, and fly ash. Constr. Build. Mater. 2012, 37, 160–170. [Google Scholar] [CrossRef]

- Torgal, F.P.; Jalali, S. Eco-efficient Construction and Building Materials. 2011. Available online: https://www.sciencedirect.com/book/9780857097675/eco-efficient-construction-and-building-materials (accessed on 26 February 2021).

- Ferreira, R.M.; Jalali, S. Quality control based on electrical resistivity measurements. In Proceedings of the ESCS-2006: European Symposium on Service Life and Serviceability of Concrete Structures, Helnsink, Finland, 12 June 2006; pp. 325–332. [Google Scholar]

- Electrical Resistivity Measurements for Quality Control During Concrete Construction. ACI Mater. J. 2008, 105, 541–547. [CrossRef]

- Rajamma, R. Incorporação de cinzas volantes de biomassa em materiais cimentíceos (Biomass fly ash incorporation in cement based materials). Ph.D. Thesis, Department of Materials and Ceramic Engineering, University of Aveiro, Aveiro, Portugal, 2011. [Google Scholar]

- Sua-Iam, G.; Makul, N. Utilization of limestone powder to improve the properties of self-compacting concrete incorporating high volumes of untreated rice husk ash as fine aggregate. Constr. Build. Mater. 2013, 38, 455–464. [Google Scholar] [CrossRef]

- Zerbino, R.; Giaccio, G.; Isaia, G. Concrete incorporating rice-husk ash without processing. Constr. Build. Mater. 2011, 25, 371–378. [Google Scholar] [CrossRef]

- Turgut, P. Cement composites with limestone dust and different grades of wood sawdust. Build. Environ. 2007, 42, 3801–3807. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of wood ash in concrete manufacturing. Resour. Conserv. Recycl. 2012, 67, 27–33. [Google Scholar] [CrossRef]

- Elinwa, A. Experimental characterization of Portland cement-calcined soldier-ant mound clay cement mortar and concrete. Constr. Build. Mater. 2006, 20, 754–760. [Google Scholar] [CrossRef]

- Ramos, T.; Matos, A.M.; Sousa-Coutinho, J. Mortar with wood waste ash: Mechanical strength carbonation resistance and ASR expansion. Constr. Build. Mater. 2013, 49, 343–351. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Jaturapitakkul, C.; Chindaprasirt, P. Use of palm oil fuel ash as a supplementary cementitious material for producing high-strength concrete. Constr. Build. Mater. 2009, 23, 2641–2646. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Homwuttiwong, S.; Jaturapitakkul, C. Strength and water permeability of concrete containing palm oil fuel ash and rice husk–bark ash. Constr. Build. Mater. 2007, 21, 1492–1499. [Google Scholar] [CrossRef]

- Sukumar, B.; Nagamani, K.; Raghavan, R.S. Evaluation of strength at early ages of self-compacting concrete with high volume fly ash. Constr. Build. Mater. 2008, 22, 1394–1401. [Google Scholar] [CrossRef]

- Horsakulthai, V.; Phiuvanna, S.; Kaenbud, W. Investigation on the corrosion resistance of bagasse-rice husk-wood ash blended cement concrete by impressed voltage. Constr. Build. Mater. 2011, 25, 54–60. [Google Scholar] [CrossRef]

- Elinwa, A.; Ejeh, S. Effects of the Incorporation of Sawdust Waste Incineration Fly Ash in Cement Pastes and Mortars. J. Asian Arch. Build. Eng. 2004, 3, 1–7. [Google Scholar] [CrossRef]

- Barbhuiya, S.A.; Gbagbo, J.K.; Russell, M.I.; Basheer, P.A.M. Properties of fly ash concrete modified with hydrated lime and silica fume. Constr. Build. Mater. 2009, 23, 3233–3239. [Google Scholar] [CrossRef]

- Da Silva, P.R.; De Brito, J. Experimental study of the porosity and microstructure of self-compacting concrete (SCC) with binary and ternary mixes of fly ash and limestone filler. Constr. Build. Mater. 2015, 86, 101–112. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).