Abstract

Fly ash is the main waste as a result of combustion in coal fired power plants. It represents about 40% of the wastes of coal combustion products (fly ash, boiler ash, flue gas desulphurization gypsum and bottom ash). Currently, coal waste is not fully utilized and waste disposal remains a serious concern despite tremendous global efforts in reducing fossil fuel dependency and shifting to sustainable energy sources. Owing to that, employment of fly ash as reinforcement particles in metallic matrix composites are gaining momentum as part of recycling effort and also as a means to improve the specifications of the materials that are added to it to form composite materials. Many studies have been done on fly ash to study composite materials wear characteristics including the effects of fly ash content, applied load, and sliding velocity. Here, particular attention is given to studies carried out on the influence FA content on physical, mechanical, and the thermal behavior of Aluminium-FA composites. Considerable changes in these properties are seen by fly ash refinement with limited size and weight fraction. The advantage of fly ash addition results in low density of composites materials, improvement of strength, and hardness. It further reduces the thermal expansion coefficient and improve wear resistance.

1. Introduction

In a recent report by the US Energy Information Administration, for the year 2020, coal power plants account for 19.3% of energy source for US, ranked third behind natural gas (40.3%) and nuclear (19.7%) [1]. On a global scale, it represents a bigger share of 36.4% and projected will reduce to 20–25% by 2040 [2] driven by global energy transition policies that promote carbon-free energy sources and reduced dependence on fossil fuels. Coal waste production is recycled and utilized in varying degree for instance, near to 100% in UK, Germany, France and Japan, 80% in China, ranging around 70% in USA, 10% in Russia and Africa whereas for other regions of developing countries, the consumption are lower [3]. Therefore, for the next two decades, coal waste recycling remains as a major relevant concern in many countries.

Waste management covers the aspects of waste reduction, reusing as well as recycling for other practical purposes. Increased global concern on carbon emission prompted the emergence of green policies that dictate the shift towards sustainable energy solutions as well as sustainable waste management approaches. In many less developed nations, coal waste accumulation required acres of land space and pose serious environmental hazards. Contrariwise, fly ash is considered as valuable secondary raw materials Typical examples are in highway engineering applications such as concrete fillers, road bases, flowable and structural fills, soil modifiers, mineral fillers and stabilizers [4]. Fly ash is an excellent substitute for Portland cement, a main ingredient in concrete. Apart from construction applications, fly ash has also made progress into geopolymers and zeolites production owing to its high silica and aluminium content. Fly ash global market is firmly ingrained in the construction sector, with top fly ash vendors are global market leaders in the production of building materials.

Alternatively, there are also numerous studies available evaluating the potential of fly ash as particulate reinforcement in metal- and polymer-matrix composite. This paper presents summary of recent literatures on the processing of metal matrix composites employing fly ash fillers and in particular for light weight metals such as AMCs and the effects of its addition on the improvement of mechanical and tribological properties. The approaches of reinforcement in metal matrix composite are explained, followed by a discussion on particulate reinforcement in aluminium matrix composites. Thereafter, the main body of this paper highlights relevant researches in the processing, mechanical testing and wear evaluation of fly ash reinforcement in AMCs.

2. Metal Matrix Composites

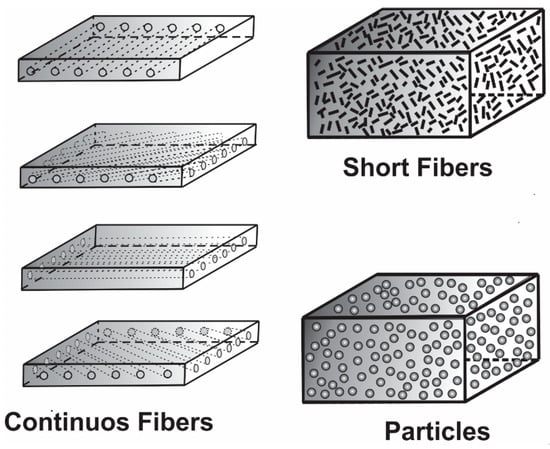

Reinforcement materials can be categorized as continuous or discontinuous fibers; whiskers [5], particles, and laminated reinforcement [6,7,8] as shown in Figure 1. Recently, particulate reinforced metal matrix composites have received great attention owing to their economic viability, isotropic properties, and ease of machinability with the same technology used for the unreinforced materials. Moreover, the liquid state processing method i.e., melt stirring process can be easily employed in the preparation of the particulate reinforced Al composites, Melt stir casting has in recent times dominated the manufacturing space because of its relatively low cost and ability to offer a wide range of materials selection and processing conditions [9].

Figure 1.

Types of composites reinforcements [10].

The choice of reinforcement is dictated by several factors: primarily, the density and modulus of the reinforcements (low density and high modulus) are important parameters to be considered for the composites to be used in structural application. More so, the particle geometry may be an essintial factor, angular particles can raise local stress and subsequently reduce ductility. Due to their great influece on the strength of composites, the coefficient of thermal expansion and thermal conductivity are important parameters to be considered for the composites to be used in thermal management application [11]. The contributions of different strengthening mechanisms of the composite were evaluated [12]. In general, the selection criteria must be made according to their intrinisc propeties including the chemical composition, melting point, volume shrinkage, density, shape and size, crystal structure, elasticity modulus, diffusivity, hardness, distribution in the matrix among others and finally, availability, ease of prodcution and use. It is noteworthy that oxides from carbides, nitrides, and borides are suitable as reinforcements [13,14,15].

Meanwhile, several investigations have reported the advantages of employing discontinuous ceramic particulates or whiskers over continuous ceramic fibers for the preparation of aluminum matrix composites AMCs [9,13,16,17]. Nevertheless, the major setbacks encountered in the production of discontinuously reinforced aluminum matrix composites (DRAMCs) are high cost, inferior ductility, low fracture toughness, and low availability of conventional ceramic reinforcing materials especially in developing countries [17,18,19].

So far, the studies conducted to address these setbacks have largely concentrated on the appropriate selection of suitable reinforcement materials. This indicated of the significance of the reinforcements in estimating the overall performance of the composites. Thus far, the performance of DRAMCs has been improved by three approaches aimed at sourcing for alternative and low cost reinforcements in the development of DRAMCs as well as giving solution to setbacks that posed expensive measures and limited availability of traditional ceramic reinforcement materials [20,21,22,23]. Alternative reinforcements that have been studied are industrial and agricultural wastes [21,23,24]. The results from the investigations conducted on the alternative reinforcements showed appreciable improvement in the properties of developed composites relative to the unreinforced alloy. Nonetheless, their properties are inferior to that of DRAMCs fabricated with conventional synthetic reinforcements [25,26].

The second approach involved the optimization of the properties of DRAMCs through particle size reduction (from micro to nano scale) of the synthetic ceramic materials [27,28,29,30]. The fracture toughness and ductility of DRAMCs improved without significant drop in strength upon the utilization of nano-particulates as reinforcing materials [27,31,32,33,34]. In spite of their marked mechanical property improvement capacity, factors such as high cost and low availability especially for developing countries limits the utilization of nano-particulates. More so, there seems to be an inclusive evidence on the substantial of the mechanisms of ductility and fracture toughness enhancement in nano-particulate reinforced composites. Some investigations have reported strength and wear resistance enhancement at the expenses of ductility [32,33]. The third approach was aimed at developing DRAMCs by using multiple reinforcement materials (hybrid composite). By employing this approach cost reduction and property optimization in DRAMCs can be achieved. Some investigations have reported comparable or improved performance of hybrid AMCs relative to the single reinforced AMCs [35,36].

Metal matrix composites reinforcements have a manifold demand profile, which is determined using production and processing and by the matrix system of the composites material. The following demands are generally applicable [15,37]:

- Low density.

- High service temperature.

- Thermal stability.

- Chemical compatibility.

- High young’s modulus.

- Economic efficiency.

- High tensile and compression strength.

- Good processability.

- Minimum ductility.

- Increase fatigue strength.

- Improved wear and abrasive resistance.

- Improve thermal shock resistance.

- Increase in creep resistance at higher temperatures.

- Improved damping capabilities.

These sets of demands are only achievable by utilizing nonmetal inorganic reinforcement materials [15].

3. Particulate Reinforcement

In recent years, particulates reinforced AMCs have shown tremendous potential as structural materials for emerging technologies in aerospace [38], military and transportation industries [39]. The major reason for utilizing particles is to promote the production of low cost composites; hence the reinforcement has to be readily available at an affordable price [11]. Reinforcemnt types play a vital role in the mechanical reliablity of the MMCs. However, they should be nonreactive and stable in the desired operating temperature. Some of the common reinforcements include silicon cirbide(SiC) and aluminum oxide (Al2O3), griphite(Gr), cubic boron nitride(CBN), hexagonal boron nitride (HBN), titanium diboride(TiB2), molybdenum disulfide(MoS2), carbon nanotubes(CNT), carbon fibers, FA cenosphers, graphene and numerous nanoparticles. Reinforcements can be in the form of fibers, particles, or flakes [40].

SiC reinforcement enhances the tensile strength, hardness, wear resistance and density of Al and its alloys [41,42] whereas the Al2O3 reinforcement exhibited high compressive strength and wear resistance. The boron carbide (B4C) is among the hardest elements in existence which has high elastic and fracture toughness. However, B4C inclusion into Al matrix increases the hardness, but doesn’t enhance the wear resistance markedly well [43]. As a hybrid reinforcement, zircon enhances the wear resistance remarkable well [44].

In recent years, the utilization of FA reinforcements is due to their low cost and availability as a waste by product in thermal power plants. More so, electromagnetic shielding effect of the Al-MMC was reported to have remarkably improved by utilizing FA reinforcements [40,41,45,46].

4. FA as Reinforcement in Aluminum Composites

FA is produced at 1200–1700 °C from several organic and inorganic constituents of the feed coal during the combustion of pulverized coal in coal fired power stations; as such it is an industrial by product that must be resourcefully utilized so it doesn’t become harmful to the environment [47]. Meanwhile, it is on record that the direct utilization of this material in construction projects not only provides solution to the waste management challenges, but it is also an economical alternative to the use of traditional materials. Therefore, the present work is focused on the exploitation of FA waste as a reinforcement phase in the development of the aluminum matrix composite.

The existence of environment regulations industries has promoted the proper management of lightweight ash particles such as FA which is a waste residue from coal burning power plants. A typical Power plant produces 1620 tonnes per day of FA from 18,000 tons of coal burning (9%) [48]. A possible cost effective solution is to utilize FA as composite fillers [49]. Even though, the chemical constituents (SiO2, Fe2O3, CaO, and Al2O3) of FA are dependent on several impurities in burnt coal [40]. Mineralogically, the FA constitutes the aluminosilicate glasses containing quartz, magnetite, spinel, hematite, mullite, ferrite, anhydride and alumina [50].

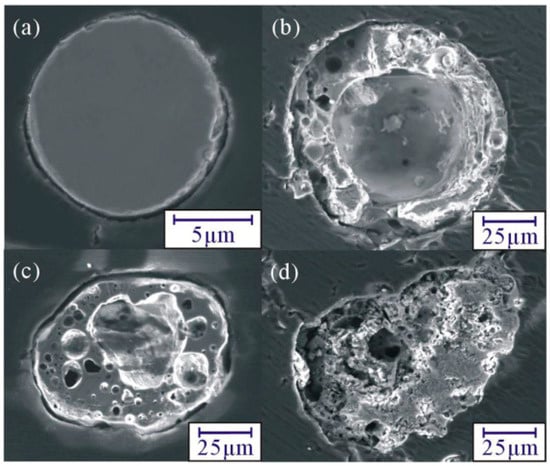

FA particles can be categorized into solid (precipitator), hollow (cenosphere), porous, and irregular particles as shown in Figure 2 [51]. In general terms, the solid spherical particles of FA are known as precipitator FA and the hollow spherical particles with a density below 1 g/cm3 are known as cenosphere FA. The precipitator FA with a density range of 2–2.5 g/cm3 can trigger the enhancement of several properties in selected matrix materials, such as stiffness, strength, wear resistance and density reduction.

Figure 2.

SEM micrographs showing FA structures of (a) solid spheres, (b) hollow spheres, (c) porous spheres and (d) irregular particles [51].

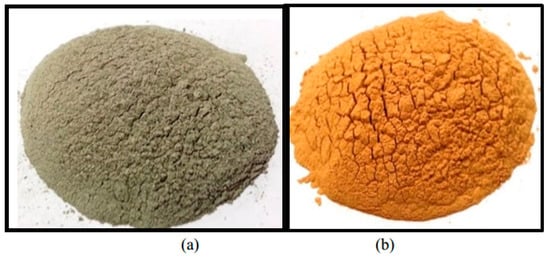

Depending on its chemical and mineral constituents, the FA has a tan and or dark grey which can be linked to a high lime content. More so, brownish and dark grey colours can be attributed to the iron content and the elevated unburned carbon content respectively. Figure 3 presents the appearance of FA before and after heat treatment. As presented, it can be evidenced that after heat treatment (preheated in the furnace at 800 °C for 3 h) the colour was changed from dark grey to brownish owing to the removal of unburnt carbon content present in the as-received condition [52]. The thermal expansion coefficient of FA is 6.6 × 10−6 °C [53].

Figure 3.

The FA powder used for synthesis of AL-FA composites (a) as-received condition, (b) after heat treatment condition [52].

Shueiwan et al. [54] fabricated ADC6 that was filled with 5 wt.% FA by stir casting. Preheated fly ash at various temperatures, 400, 500, 600, 660, 700, and 800 °C were added to molten ADC6 at 0.1, 0.15, 0.2 g/s of flow rate. Then, they used the mold Immersed Rapid Solidifications (MIRS) which is a new method to evaluate fly ash composite slurry and create casting specimen for revealing particles distribution in the matrix. Their experimental results revealed the avoidance or minimization of porosity which was made possible by lower addition of FA and higher preheating temperature caused by particle agglomerate in matrix.

The addition of FA particles as reinforcement has lots of benefits for obtaining high structural homogeneity in AMCs [41], and enhances hardness, wear resistance, stiffness, damping properties, and density reduction in Al alloys. Recently, utilization of FA as a reinforcement material in Al alloys has been showcased to be suitable due to its economic viability and resourceful utilization as a waste material [55]. Also, the small particles size (<45 µm) of FA will go a long way in the properties of AMCs [56,57].

5. Fabrication Methods of Aluminum Matrix Composites

Metal matrix composites can be made via liquid, or solid state processes [16,58]. Technically, the development of MMCs using the liquid metallurgy method is more important than the powder metallurgy method [14,15,59]. The method is economical viable and has the capacity of being able to employed in existing casting process for the fabrication of MMCs [60]. Some of the factors to be considered in selecting the processing route include the type and level of reinforcement loading, the matrix alloy, application type, and the degree of microstructure integrity desired [16]. The liquid phase technique involves the introduction of the reinforcement (discontinuous phase) into the metal matrix (continuous phase) which is in liquid state. Through the utilization of conventional casting, the molten metal can be cast into several mold of desired shapes. On the other hand, the solid state process involves the production of particulate-reinforced MMCs through the stepwise blending of the elemental powders followed by consolidation [16]. Several tradtional methods as well as specific patened methods have been utilized in fabrcating AMCs reinforced with varying ceramic particles which include but not limited to powder metallurgy [61], mechanical alloying [62], stir casing [63], squeeze casting [64], compocasting [65] and spray deposition [66]. The mechanical and tribological performance of AMCs are greatly influenced by the processing technique. Improvement of AMCs properties requires an optimal inclusion of ceramic particles into the aluminum matrix. A significant number of processing approaches have been reported on the fabrication of composites by K. Morsi. Approaches discussed include bulk deformation processes such as rolling, 2D forging, equal channel angular pressing, (laser and non-laser-based) additive manufacturing [67]. A Ti-15Mo/TiB metal matrix composite was produced by the spark plasma sintering process [68,69].

Some of the important merits of the melt processing involving the stirring of ceramic particles into melt include, superior matrix bonding, easier control of matrix structure, simplicity, less expensive processing and nearer net shape with wide range of materials for this processing technique [70]. The adhesion between the matrix and the reinforcement phase results in the interfacial bonding. For adhesion to take place in the course of the composites manufacture, the matrix and the reinforcement must be in a close connection with each other. During the developmental stage of composite, the matrix is often in a state wherein it has a high tendency of flowing towards the reinforcement and this behaviour is similar to that of a liquid flow. A key concept in this contact is wettability. Bonding occurs when an intimate contact is established between the matrix and the reinforcement which is due to adequate wetting of the matrix on the reinforcement particles. Many methods have been proposed to overcome the problem of the poor wettability: Preheating the reinforcement particles, Wettability Agents Addition, Fluxes Addition, Coating the Reinforcement Particles, and Compocasting Technique [71].

6. FA Effect on Mechanical Physical Properties of Aluminum Composites Material

Several factors such as type, size, shape, and volume fraction of the reinforcement, matrix material and reaction at the interface affect the mechanical integrity of composites [72]. Hence, it is important to have adequate understanding of the mechanical behaviour of the developed composites so that they can be employed in different areas of applications [73,74]. The complex structure of FA particles makes its usage in FA–reinforced aluminum AMCs very complicated. However, the lowering of density, improvement in elastic modulus, tensile strength and wear resistance of the resulting composites are properties that have increased research interest in the development of FA- reinforced aluminum AMCs.

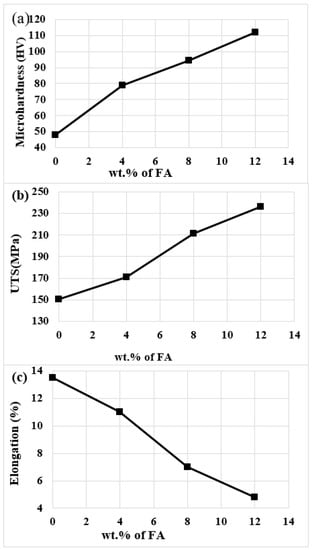

Rajan et al. [50] evaluated the effect of the manufacturing method on the properties and structure of Al-7si-0.35Mg reinforced with FA particles. They used three different stir casting techniques which are modified compocasting, modified compocasting followed by squeeze casting routes, and liquid metal stir casting. They were well dispersed for fly ash particles distribution by using of modified compocasting cum squeeze, and relatively agglomerate. It enhances the compression strength but it reduces the tensile strength due to particle fracture and particle-matrix debonding. Selvam et al. [75] used composting method to reinforce aluminum alloy AA6061 with volume fraction (0, 4, 8 and 12%) of FA particles for fabrication of composite material. The scanning electronic microscope was used to analyze the aluminum matrix composites AMCs which revealed homogeneous dispersion of the FA with AMCs and there was good bonding associated with clear interface. They reported an improvement in ultimate tensile strength UTS by 132.21% and micorhardness of the AMCs by 56.95% as shown in Figure 4a–c, but the elongation of the AMCs decreased by 63% due to the grain refinement and the ductility reduction of the AMCs.

Figure 4.

(a) Effect of FA content on microhardness (b) tensile strength and (c) elongation of AA6061-FA compocast composites [75].

Dou et al. [76] used two types of FA which are the cenosphere fly ash CFA and the precipitator to reinforce Al2024 alloy and they found that the tensile strength of matrix aluminum reduced by the particles added owing to the inferior mechanical properties of the FA particulate. More so, the fractography studies indicated that AA2024-CFA experienced brittle fracture while AA2024-PFA fractured in a micro ductile manner. Rohatgi et al. [77,78] reported a density decrease in the Al-FA composite after synthesizing cenosphere particles into Al alloy, but observed that pores and cracks in the ash promoted the deterioration of hardness, Young’s modulus, and compressive strength.

Anilkumar et al. [23] investigated particle size effect of FA on the mechanical behaviour of AA6061 alloy. Three sets of composites had FA particle size of 4–25, 45–50, and 75–100 µm and reinforcement weight fractions of 10, 15, and 20% were used. Their conclusion revealed that the tensile strength increased with increasing weight content of FA. More so, the tensile strength, compressive strength and hardness of the AA6061 aluminum alloy composites were observed to have decreased with increasing particle size of reinforcement FA. Increasing the weight fractions of the FA particles led to increase in the ultimate tensile strength, compressive strength, hardness, and ductility reduction of the composite. The scanning electron micrographs of the samples indicated uniform distribution of the FA particles in the matrix without any voids. Sudarshan and Surappa [79] prepared A356 Al–FA particle composites by stir cast to reinforce by 6 and 12 vol.% fly ash particles. They observed remarkable increase in micro and macro hardness, as well as excellent mechanical properties with narrow size range of fly ash particles (53–106 μm) performed better than the size range of 0.5 to 400 μm. Suresh et al. [80] reported that by increasing the content of FA, hardness and ultimate tensile strength of LM6-FA composites increased by 34.7% and 44.3% respectively, while the density decreased by 13.2%. The wear loss decreased by 33% at the highest sliding distance.

Fan et al. [51] fabricated the Al–3Mg/5 wt.% FA composites to study the effect of the period of time for interaction between FA and pure aluminum which contained 3% Mg on the microstructure and mechanical properties. Stir casting method was used to manufacture aluminum composite at 850 °C for different durations (0, 10, 30 and 40 h). They observed reduction of porosity with increasing time, whereas BHN and density increased. They obtained 46.7% improvement of hardness when the duration of reaction was 40 h. θ-Al2O3, MgAl2O3 was obtained by the decomposition of FA particles with prolong time of reactions, Si and Mg formed Mg2Si. The porosity decreased after 30 h reaction due to the decomposition of FA and melt fill by particles. Guo and Rohatgi [81] used pure aluminum as a matrix to fabricate aluminum-FA composites by powder metallurgy techniques. They observed a slight increase in hardness up to 10 wt.% FA, whereas beyond the 10 wt.% mark, a decrease was reported. Mahendra et al. [82] observed higher hardness for Al–4.5% Cu alloy–fly ash based composites with improvement percentages of 6.7%, 16%, 49%, 128% for hardness, tensile strength, compression strength and impact strength respectively, which increased with an increasing percentage of FA particulates. However, the density decreased with increasing FA content. The maximum density value was 2752 kg/m3 for base alloy, while the minimum value was 2643 kg/m3 for composite material at 15 wt.% of FA.

Efzan et al. [57] employed the compocasting method to reinforce LM6 aluminum alloy with different amounts (0, 4 and 6 wt.%) of FA particle. They observed that the inclusion of FA particles enhanced the physical and mechanical properties of the AMCs. Thus leading to the improvement of the energy consumption in automotive parts. The developed AMCs having 6 wt.% of FA reinforcement demonstrated approximately 50 % improvement compared to the unreinforced LM6 alloy. Many researches have used FA as a reinforcement with various grades of aluminum alloy as shown in Table 1.

Table 1.

Effect FA on physical and mechanical properties of Al-FA composites.

Based on the existing literature review, several research works have focused on the aluminum alloy based composites such as LM6, LM25, A349, AA356, AA357, AA359, AA2024, AA2618, AA2214, AA6061 and AA7075 [76,83,96,97,98,99]. However, few investigations have been conducted on the utilization of AA6063 alloy as a base material for the improvement of aluminum matrix composites by FA particles addition [100,101].

7. Effect of FA on Wear Behaviour

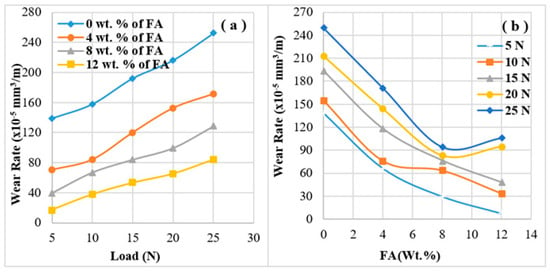

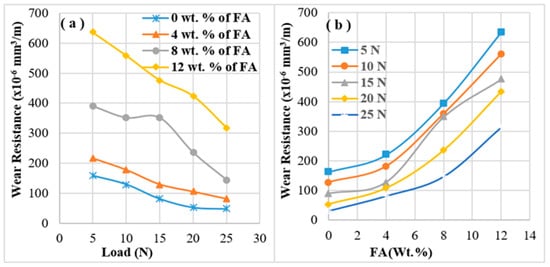

Wear resistance of the commercial Al significantly improved with inclusion of FA particles and the wear resistance of the composites was much superior to the aluminum without reinforcement across the board for the load range tested dry sliding conditions [102]. This may be as a result of the favourable effect of the FA particles which was a prevailing factor that affected the wear resistance [103]. However, the inclusion of 20 wt.% FA particle to the Al was very effective in promoting wear loss reduction [84]. Samrat Mohanty and Chugh [104] reported the inclusion of FA particles in automotive brake lining friction composites. The developed brake lining composites demonstrated a reasonable level of consistency in both the wear rates and coefficient of friction. Elsewhere, Al-4.5% Cu-FA composite bush was developed by the stir casting technique [105]. The developed composites bush exhibited more resistance to wear as a compared to the aluminum alloy under lubricated conditions for 200 h. A cylinder liner was cast from the composite and thereafter, it was tested in a two stroke petrol engine. No seizure was detected in the cylinder liner even after 400 h of testing. In their investigation, Selvam et al. [53] observed a rise in the wear rate of FA reinforced AA6061 Al alloy with increasing applied load but decreased with increasing FA content as shown in Figure 5. More so, they observed that the load bearing capacity of AA6061 alloy during dry sliding wear increased in the presence of FA particles. The composites demonstrated superior wear resistance relative to the unreinforced alloy up to a load of 24.5 N as shown in Figure 6. Generally, the wear rate reduced with increasing particle size of FA particles [56].

Figure 5.

Wear rate of AA 6061 alloy-based MMCs as a function of (a) normal load applied; (b) wt.% FA [53].

Figure 6.

Wear resistance of AA 6061 alloy-based MMCs as a function of (a) normal load applied; (b) wt.% fly ash [53].

Ravi Kumar et al. [106] investigated the influence of FA particle size and percentages FA content on the wear volume for constant load, speed, and time period. The wear of composites was less than that of the unreinforced aluminum alloy owing to the inclusion of hard FA particles. An increase in the percentage of FA decreased the wear volume at all speeds and loads. This increase can best be explained by the ductility reduction in the composites caused by an increase in hardness owing to the addition of hard FA particles. They discovered that for a given load and speed, rise in FA particle size resulted in the wear volume reduction and vice versa. The possibility for small FA particles to be pulled out from the matrix was greater, hence resulting in an increased wear volume. The matrix held the coarse particles tightly till the particles became fragmented; hence, the wear volume was lower in composites with coarse fly ash particles. In summary, for a given load and speed, the wear volume of the composites decreased with an increasing percentage of FA and particle size.

8. The Coefficient of Friction

Coefficient of friction can be defined as the ratio of the force of friction between two bodies and the force pressing them together [107]. Ravi Kumar et al. [106] studied the influence of particle size, reinforcement content, load and speed on the coefficient of friction at constant load and speed. They observed that the coefficient of friction decreased with an increase in fly ash content at a constant load and speed. The coefficient of friction of composite materials was greater than that of the aluminum alloy. The coefficient of friction also increased with an increase in FA particle size. The rise in the abrasive resistance by coarse particles most likely explained the increase in coefficient of friction and therefore decreased the wear volume. They observed for a constant FA particle size and percentage of FA, a rise in load and speed decreased the coefficient of friction. Rao and Das [108] investigated the influence of SiC content and sliding speed on wear performance of aluminum composites. They observed that the coefficient of friction increased with increasing of SiC content, but decreased with rising sliding speed. In summary, the coefficient of friction decreased with an increase in the percentage of FA, load, and speed and increased with an increase in particle size. Table 2 show many studies have been conducted to investigate the frictional and wear behaviour.

Table 2.

Investigations regarding wear behavior of Al-FA composites.

Many types of aluminum matrix alloy were used to fabricate aluminum composites material for the study of wear behavior, however, it was difficult to establish a general relationship for the wear of composites and sliding velocity. The tribolayers were separated and metal to metal contact initialized. At high sliding speed, large frictional heat emerged and it led to large plastic deformation. These factors promoted the bulk removal of materials from the wear surface and the wear tracks have been observed in some of the investigations. The effect of the parameters (load, sliding velocity) must be simultaneously evaluated in order to determine the wear behaviour of AA6063-FA composites under increasing weight FA contents precisely.

9. Conclusions

There exists a broad data base in the literature for various reinforcements, however that of utilizing FA reinforcement is rarely reported. The addition of FA particles as reinforcement is beneficial in obtaining high structural homogeneity in AMCs, and enhances tensile strength, hardness, stiffness, wear resistance, and reduced thermal expansion, density, and impact energy of Al alloys. Recently, it has been reported the utilization of FA as a reinforcement in Al alloys is desirable from both environmental and economic owing to its availability as low cost waste material. It was found that smaller particle size (less than 45 µm) of FA can easily give superior properties. AA6063 alloy can be considered as preferred matrix for the fabrication of particles reinforced aluminum based composites. So far, few investigations have been carried out on the employment of AA6063 alloy as a base material for the improvement of aluminum matrix composites by FA powder addition. More studies revealed that wear and coefficient friction of composites were influenced by reinforcement content, sliding speed, and applied load. Reinforcement particle size was also a factor that influences the wear and mechanical properties of MMCs. Few investigations are available on the impact of FA reinforcement on the mechanical, the thermal, and the wear behaviour of AA6063-FA composites.

A key benefit of the low temperature of liquid state fabrication of AMCs is that some unwanted reactions can be eliminated from the interface between the matrix and diapered reinforcing phases. Compocasting as semisolid melt process prevents the particles from sinking or floating. The particle movements within the semisolid aluminum alloy after stirring was minimal relative to stir casting owing to the enhanced viscosity of the composite slurry. Limited studies reported reactions by FA addition during the composites fabricated by compocasting processing.

Author Contributions

A.M.R. and D.L.M. conceived and designed the theoretical structure of the paper; A.M.R. and U.M.B. compared and analyzed the data; A.M.R. wrote the paper and reviewed by A.M.R., D.L.M., U.M.B. and H.S.S.A. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by Dana Penerbitan Jurnal UPM.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Not Applicable.

Acknowledgments

The authors would like to thank the support of Universiti Putra Malaysia (UPM), especially the Department of Aerospace Engineering.

Conflicts of Interest

The authors declare no conflict of interest.

References

- U.S. Energy Information Administration. Electric Power Monthly. U.S. Energy Information Administration. Available online: https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=ep mt_6_07_b (accessed on 24 July 2018).

- IEA. Power Generation in the New Policies Scenario, 2000–2040; IEA: Paris, France; Available online: https://www.iea.org/data-andstatistics/charts/power-generation-in-the-new-policies-scenario-2000-2040 (accessed on 6 August 2021).

- Marinina, O.; Nevskaya, M.; Jonek-Kowalska, I.; Wolniak, R.; Marinin, M. Recycling of coal fly ash as an example of an efficient circular economy: A stakeholder approach. Energy 2021, 14, 3597. [Google Scholar] [CrossRef]

- American Coal Ash Association. Fly Ash Facts for Highway Engineers. Report No. FHWA-IF-03-019; Federal Highway Administration, U.S. Department of Transportation, 2003. Available online: https://www.fhwa.dot.gov/pavement/recycling/fach00.cfm (accessed on 8 October 2021).

- Koo, M.Y.; Park, J.S.; Park, M.K.; Kim, K.T.; Hong, S.H. Effect of aspect ratios of in situ formed TiB whiskers on the mechanical properties of TiBw/Ti–6Al–4V composites. Scr. Mater. 2012, 66, 487–490. [Google Scholar] [CrossRef]

- Bhaskar, K.; Johri, N.; Kumar, N.; Srivastava, A. Effect of industrial/agricultural waste materials as reinforcement on properties of metal matrix composites. Mater. Today: Proc. 2021, 26, 2333–2336. [Google Scholar]

- Li, H.-y.; Zeng, C.-t.; Han, M.-s.; Liu, J.-j.; Lu, X.-C. Time–temperature–property curves for quench sensitivity of 6063 aluminum alloy. Trans. Nonferrous Met. Soc. China 2013, 23, 38–45. [Google Scholar] [CrossRef]

- Nemati, J.; Majzoobi, G.H.; Sulaiman, S.; Baharudin, B.T.; Hanim, M.A. Effect of equal channel angular extrusion on Al-6063 bending fatigue characteristics. Int. J. Miner. Metall. Mater. 2015, 22, 395–404. [Google Scholar] [CrossRef]

- Yigezu, B.S.; Mahapatra, M.M.; Jha, P.K. Influence of reinforcement type on microstructure, hardness, and tensile properties of an aluminum alloy metal matrix composite. J. Miner. Mater. Charact. Eng. 2013, 1, 124. Available online: https://publons.com/journal/21441/journal-of-minerals-and-materials-characterization/ (accessed on 8 October 2021).

- Tiwari, S.K.; Soni, S.; Rana, R.S.; Singh, A. Effect of heat treatment on mechanical properties of aluminium alloy-fly ash metal matrix composite. Mater. Today Proc. 2017, 4, 3458–3465. [Google Scholar] [CrossRef]

- Lloyd, D. Particle reinforced aluminium and magnesium matrix composites. Int. Mater. Rev. 1994, 39, 1–23. [Google Scholar] [CrossRef]

- Ozerov, M.S.; Klimova, M.V.; Stepanov, N.D.; Zherebtsov, S.V. Microstructure evolution of a Ti/TiB metal-matrix composite during high-temperature deformation. Mater. Phys. Mech 2018, 38, 54–63. [Google Scholar]

- Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H. Aluminium matrix hybrid composites: A review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef] [Green Version]

- Sayuti, M. Properties of Titanium Carbide Reinforced Aluminium Silicon Alloy Matrix. Ph.D. Thesis, Universiti Putra Malaysia, Seri Kembangan, Malaysia, 2012. [Google Scholar]

- Kainer, K.U. Basics of metal matrix composites. In Metal Matrix Composites, 1st ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2006; pp. 1–54. [Google Scholar]

- Surappa, M. Aluminium matrix composites: Challenges and opportunities. Sadhana 2003, 28, 319–334. [Google Scholar] [CrossRef]

- Kok, M. Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J. Mater. Process. Technol. 2005, 161, 381–387. [Google Scholar] [CrossRef]

- Bhandakkar, A.; Prasad, R.; Sastry, S.M. Fracture toughness of AA2024 aluminum fly ash metal matrix composites. Int. J. Compos. Mater. 2014, 4, 108–124. [Google Scholar]

- Oghenevweta, J.; Aigbodion, V.; Nyior, G.; Asuke, F. Mechanical properties and microstructural analysis of Al–Si–Mg/carbonized maize stalk waste particulate composites. J. King Saud Univ.-Eng. Sci. 2016, 28, 222–229. [Google Scholar] [CrossRef] [Green Version]

- Fatile, O.B.; Akinruli, J.I.; Amori, A.A. Microstructure and mechanical behaviour of stir-cast Al-Mg-Sl alloy matrix hybrid composite reinforced with corn cob ash and silicon carbide. Int. J. Eng. Technol. Innov. 2014, 4, 251–259. [Google Scholar]

- Loh, Y.; Sujan, D.; Rahman, M.; Das, C. Sugarcane bagasse—the future composite material: A literature review. Resour. Conserv. Recycl. 2013, 75, 14–22. [Google Scholar] [CrossRef]

- Madakson, P.; Yawas, D.; Apasi, A. Characterization of coconut shell ash for potential utilization in metal matrix composites for automotive applications. Int. J. Eng. Sci. Technol. 2012, 4, 1190–1198. [Google Scholar]

- Anilkumar, H.; Hebbar, H.; Ravishankar, K. Mechanical properties of fly ash reinforced aluminium alloy (Al6061) composites. Int. J. Mech. Mater. Eng. 2011, 6, 41–45. [Google Scholar]

- Aigbodion, V.; Hassan, S.; Dauda, E.; Mohammed, R. The development of mathematical model for the prediction of ageing behaviour for Al-Cu-Mg/bagasse ash particulate composites. J. Miner. Mater. Charact. Eng. 2010, 9, 907. [Google Scholar] [CrossRef]

- Prasad, D.S.; Krishna, R. Production and mechanical properties of A356. 2/RHA composites. Int. J. Adv. Sci. Technol. 2011, 33, 51–58. [Google Scholar]

- Alaneme, K.K.; Akintunde, I.B.; Olubambi, P.A.; Adewale, T.M. Fabrication characteristics and mechanical behaviour of rice husk ash–alumina reinforced Al-Mg-Si alloy matrix hybrid composites. J. Mater. Res. Technol. 2013, 2, 60–67. [Google Scholar] [CrossRef] [Green Version]

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nano-particles—A review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Liu, Y.; Cong, H.; Wang, W.; Sun, C.; Cheng, H. AlN nanoparticle-reinforced nanocrystalline Al matrix composites: Fabrication and mechanical properties. Mater. Sci. Eng. A 2009, 505, 151–156. [Google Scholar] [CrossRef]

- Sadeghian, Z.; Lotfi, B.; Enayati, M.; Beiss, P. Microstructural and mechanical evaluation of Al–TiB 2 nanostructured composite fabricated by mechanical alloying. J. Alloys Compd. 2011, 509, 7758–7763. [Google Scholar] [CrossRef]

- Zhang, Z.; Topping, T.; Li, Y.; Vogt, R.; Zhou, Y.; Haines, C.; Paras, J.; Kapoor, D.; Schoenung, J.M.; Lavernia, E.J. Mechanical behavior of ultrafine-grained Al composites reinforced with B 4 C nanoparticles. Scr. Mater. 2011, 65, 652–655. [Google Scholar] [CrossRef]

- Tjong, S.C. Processing and Deformation Characteristics of Metals Reinforced with Ceramic Nanoparticles, Nanocrystalline Materials Their Synthesis-Structure-Property Relationships and Applications, 2nd ed.; Elsevier: London, UK, 2014; pp. 269–304. [Google Scholar]

- Mazahery, A.; Shabani, M.O. Characterization of cast A356 alloy reinforced with nano SiC composites. Trans. Nonferrous Met. Soc. China 2012, 22, 275–280. [Google Scholar] [CrossRef]

- Mobasherpour, I.; Tofigh, A.; Ebrahimi, M. Effect of nano-size Al2O3 reinforcement on the mechanical behavior of synthesis 7075 aluminum alloy composites by mechanical alloying. Mater. Chem. Phys. 2013, 138, 535–541. [Google Scholar] [CrossRef]

- Poovazhagan, L.; Kalaichelvan, K.; Rajadurai, A.; Senthilvelan, V. Characterization of hybrid silicon carbide and boron carbide nanoparticles-reinforced aluminum alloy composites. Procedia Eng. 2013, 64, 681–689. [Google Scholar] [CrossRef] [Green Version]

- Rino, J.J.; Chandramohan, D.; Sucitharan, K.; Jebin, V.D. An overview on development of aluminium metal matrix composites with hybrid reinforcement. Int. J. Sci. Res. (IJSR) 2012, 2319, 7064. [Google Scholar]

- Shivaraja, H.; Praveen Kumar, B. Experimental determination and analysis of fracture toughness of MMC. Int. J. Sci. Res. (IJSR) 2014, 3, 887–892. [Google Scholar]

- Narasimha, B.G.; Krishna, V.M.; Xavior, A.M. A review on processing of particulate metal matrix composites and its properties. Int. J. Appl. Eng. Res. 2013, 8, 647–666. [Google Scholar]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley Online Library: Hoboken, NJ, USA, 2006. [Google Scholar]

- Ashish, B.; Saini, J.; Sharma, B. A review of tool wear prediction during friction stir welding of aluminium matrix composite. Trans. Nonferrous Met. Soc. China 2016, 26, 2003–2018. [Google Scholar]

- Macke, A.; Schultz, B.F.; Rohatgi, P.K.; Gupta, N. Metal matrix composites for automotive applications. In Advanced Composite Materials for Automotive Applications: Structural Integrity and Crashworthiness; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; pp. 311–344. [Google Scholar]

- Iqbal, A.A.; Nuruzzaman, D.M. Effect of the Reinforcement on the Mechanical Properties of Aluminium Matrix Composite: A Review. Int. J. Appl. Eng. Res. 2016, 11, 10408–10413. [Google Scholar]

- Ramnath, B.V.; Elanchezhian, C.; Annamalai, R.M.; Aravind, S.; Atreya, T.S.; Vignesh, V.; Subramanian, C. Aluminium metal matrix composites—a review. Rev. Adv. Mater. Sci 2014, 38, 55–60. [Google Scholar]

- Previtali, B.; Pocci, D.; Taccardo, C. Application of traditional investment casting process to aluminium matrix composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1606–1617. [Google Scholar] [CrossRef]

- Das, S.; Das, S.; Das, K. Abrasive wear of zircon sand and alumina reinforced Al–4.5 wt% Cu alloy matrix composites—A comparative study. Compos. Sci. Technol. 2007, 67, 746–751. [Google Scholar] [CrossRef]

- Kumar, S.H.; Suman, K.N.; Sekhar, S.R.; Bommana, D. Investigation of mechanical and tribological properties of aluminium metal matrix composites. Mater. Today Proc. 2018, 5, 23743–23751. [Google Scholar] [CrossRef]

- Kasar, A.K.; Gupta, N.; Rohatgi, P.K.; Menezes, P.L. A brief review of fly ash as reinforcement for composites with improved mechanical and tribological properties. JOM 2020, 72, 2340–2351. [Google Scholar] [CrossRef]

- Blissett, R.; Rowson, N. A review of the multi-component utilisation of coal fly ash. Fuel 2012, 97, 1–23. [Google Scholar] [CrossRef]

- Abubakar, A.U.; Baharudin, K.S. Potential use of malaysian thermal power plants coal bottom ash in construction. Int. J. Sustain. Constr. Eng. Technol. 2012, 3, 25–37. [Google Scholar]

- Vivekanandan, P.; Arunachalam, V.P. The Experimental Analysis of Stir Casting Method on Aluminium-Fly Ash Composites. IJCET 2013, 3, 215–219. [Google Scholar]

- Rajan, T.P.; Pillai, R.M.; Pai, B.C.; Satyanarayana, K.G.; Rohatgi, P.K. Fabrication and characterisation of Al–7Si–0.35 Mg/fly ash metal matrix composites processed by different stir casting routes. Compos. Sci. Technol. 2007, 67, 3369–3377. [Google Scholar] [CrossRef]

- Fan, L.-J.; Juang, S.H. Reaction effect of fly ash with Al–3Mg melt on the microstructure and hardness of aluminum matrix composites. Mater. Des. 2016, 89, 941–949. [Google Scholar] [CrossRef]

- Rao, J.B.; Rao, D.V.; Bhargava, N. Development of light weight ALFA composites. Int. J. Eng. Sci. Technol. 2010, 2. [Google Scholar] [CrossRef]

- Selvam, J.D.R.; Smart, D.R.; Dinaharan, I. Influence of fly ash particles on dry sliding wear behaviour of AA6061 aluminium alloy. Kov. Mater 2016, 54, 175–183. [Google Scholar]

- Juang, S.H.; Fan, L.-J.; Yang, H.P.O. Influence of preheating temperatures and adding rates on distributions of fly ash in aluminum matrix composites prepared by stir casting. Int. J. Precis. Eng. Manuf. 2015, 16, 1321–1327. [Google Scholar] [CrossRef]

- Selvam, J.D.R.; Smart, D.R.; Dinaharan, I. Synthesis and characterization of Al6061-fly Ashp-SiCp composites by stir casting and compocasting methods. Energy Procedia 2013, 34, 637–646. [Google Scholar] [CrossRef] [Green Version]

- Anilkumar, H.; Hebbar, H.S. Effect of particle size of fly ash on mechanical and tribological properties of aluminium alloy (Al6061) composites and their correlations. Int. J. Mech. Syst. Eng. 2013, 3, 3–6. [Google Scholar]

- Efzan, E.; Noor, M.; Siti Syazwani, N.; Emerson, J. Properties of Aluminum Matrix Composite (AMCs) for Electronic Packaging. Mater. Sci. Forum 2016, 857, 18–21. [Google Scholar] [CrossRef]

- Sharma, P.; Khanduja, D.; Sharma, S. Tribological and mechanical behavior of particulate aluminum matrix composites. J. Reinf. Plast. Compos. 2014, 33, 2192–2202. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M. The wettability of SiC particles by molten aluminium alloy. J. Mater. Process. Technol. 2001, 119, 324–328. [Google Scholar] [CrossRef]

- Gladston, J.A.; Sheriff, N.M.; Dinaharan, I.; Selvam, J.D. Production and characterization of rich husk ash particulate reinforced AA6061 aluminum alloy composites by compocasting. Trans. Nonferrous Met. Soc. China 2015, 25, 683–691. [Google Scholar] [CrossRef]

- Rahimian, M.; Ehsani, N.; Parvin, N.; reza Baharvandi, H. The effect of particle size, sintering temperature and sintering time on the properties of Al–Al2O3 composites, made by powder metallurgy. J. Mater. Process. Technol. 2009, 209, 5387–5393. [Google Scholar] [CrossRef]

- Srinivasarao, B.; Suryanarayana, C.; Oh-Ishi, K.; Hono, K. Microstructure and mechanical properties of Al–Zr nanocomposite materials. Mater. Sci. Eng. A 2009, 518, 100–107. [Google Scholar] [CrossRef]

- Kalaiselvan, K.; Murugan, N.; Parameswaran, S. Production and characterization of AA6061–B 4C stir cast composite. Mater. Des. 2011, 32, 4004–4009. [Google Scholar] [CrossRef]

- Xiu, Z.; Yang, W.; Chen, G.; Jiang, L.; Ma, K.; Wu, G. Microstructure and tensile properties of Si3N4p/2024Al composite fabricated by pressure infiltration method. Mater. Des. 2012, 33, 350–355. [Google Scholar] [CrossRef]

- Amirkhanlou, S.; Rezaei, M.R.; Niroumand, B.; Toroghinejad, M.R. High-strength and highly-uniform composites produced by compocasting and cold rolling processes. Mater. Des. 2011, 32, 2085–2090. [Google Scholar] [CrossRef]

- Srivastava, V.; Ojha, S. Microstructure and electrical conductivity of Al-SiCp composites produced by spray forming process. Bull. Mater. Sci. 2005, 28, 125–130. [Google Scholar] [CrossRef]

- Morsi, K. titanium–titanium boride composites. J. Mater. Sci. 2019, 54, 6753–6771. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Ozerov, M.; Povolyaeva, E.; Sokolovsky, V.; Stepanov, N.; Moskovskikh, D.; Salishchev, G. Effect of hot rolling on the microstructure and mechanical properties of a Ti-15Mo/TiB metal-matrix composite. Metals 2020, 10, 40. [Google Scholar] [CrossRef] [Green Version]

- Zherebtsov, S.; Ozerov, M.; Stepanov, N.; Klimova, M.; Ivanisenko, Y. Effect of high-pressure torsion on structure and microhardness of ti/tib metal–matrix composite. Metals 2017, 7, 507. [Google Scholar] [CrossRef] [Green Version]

- Ezatpour, H.R.; Sajjadi, S.A.; Sabzevar, M.H.; Huang, Y. Investigation of microstructure and mechanical properties of Al6061-nanocomposite fabricated by stir casting. Mater. Des. 2014, 55, 921–928. [Google Scholar] [CrossRef]

- Razzaq, A.M.; Majid, D.L.A.A.; Ishak, M. A brief research review for improvement methods the wettability between ceramic reinforcement particulate and aluminium matrix composites. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017. [Google Scholar]

- Rohatgi, P.K. Low-cost, fly-ash-containing aluminum-matrix composites. JOM J. Miner. Met. Mater. Soc. 1994, 46, 55–59. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Jia, L.; Li, S.; Umeda, J.; Takahashi, M.; Kondoh, K. Length effect of carbon nanotubes on the strengthening mechanisms in metal matrix composites. Acta Mater. 2017, 140, 317–325. [Google Scholar] [CrossRef]

- Kala, H.; Mer, K.; Kumar, S. A review on mechanical and tribological behaviors of stir cast aluminum matrix composites. Procedia Mater. Sci. 2014, 6, 1951–1960. [Google Scholar] [CrossRef] [Green Version]

- Selvam, J.D.R.; Smart, D.R.; Dinaharan, I. Microstructure and some mechanical properties of fly ash particulate reinforced AA6061 aluminum alloy composites prepared by compocasting. Mater. Des. 2013, 49, 28–34. [Google Scholar] [CrossRef]

- Dou, Z.; Wu, G.; Huang, X.; Sun, D.; Jiang, L. Electromagnetic shielding effectiveness of aluminum alloy–fly ash composites. Compos. Part A: Appl. Sci. Manuf. 2007, 38, 186–191. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Kim, J.K.; Gupta, N.; Alaraj, S.; Daoud, A. Compressive characteristics of A356/fly ash cenosphere composites synthesized by pressure infiltration technique. Compos. Part A: Appl. Sci. Manuf. 2006, 37, 430–437. [Google Scholar] [CrossRef]

- Rohatgi, P.; Gupta, N.; Alaraj, S. Thermal expansion of aluminum–fly ash cenosphere composites synthesized by pressure infiltration technique. J. Compos. Mater. 2006, 40, 1163–1174. [Google Scholar] [CrossRef]

- Surappa, M. Synthesis of fly ash particle reinforced A356 Al composites and their characterization. Mater. Sci. Eng. A 2008, 480, 117–124. [Google Scholar]

- Suresh, N.; Venkateswaran, S.; Seetharamu, S. Influence of cenospheres of fly ash on the mechanical properties and wear of permanent moulded eutectic Al–Si alloys. Mater. Sci.-Pol. 2010, 28, 55–65. [Google Scholar]

- Guo, R.; Rohatgi, P.; Nath, D. Preparation of aluminium-fly ash particulate composite by powder metallurgy technique. J. Mater. Sci. 1997, 32, 3971–3974. [Google Scholar] [CrossRef]

- Mahendra, K.; Radhakrishna, K. Fabrication of Al-4.5% Cu alloy with fly ash metal matrix composites and its characterization. Mater. Sci.-Pol. 2007, 25, 57–68. [Google Scholar]

- Rohatgi, P.; Weiss, D.; Gupta, N. Applications of fly ash in synthesizing low-cost MMCs for automotive and other applications. JOM 2006, 58, 71–76. [Google Scholar] [CrossRef]

- Shanmughasundaram, P.; Subramanian, R.; Prabhu, G. Some studies on aluminium–fly ash composites fabricated by two step stir casting method. Eur. J. Sci. Res. 2011, 63, 204–218. [Google Scholar]

- Boopathi, M.M.; Arulshri, K.; Iyandurai, N. Evaluation of mechanical properties of aluminium alloy 2024 reinforced with silicon carbide and fly ash hybrid metal matrix composites. Am. J. Appl. Sci. 2013, 10, 219. [Google Scholar] [CrossRef]

- Arun, L.; Kulkarni, D.S.K.N.; Kuldeep, B. Characteristic studies on aluminium based silicon carbide and fly ash particulate metal matrix composite. Int. J. Eng. Res. Technol. 2013, 2, 2303–2306. [Google Scholar]

- Malhotra, S.; Narayan, R.; Gupta, R. Synthesis and Characterization of Aluminium 6061 Alloy-Flyash & Zirconia Metal Matrix Composite. Int. J. Curr. Eng. Technol. 2013, 3, 1716–1719. [Google Scholar]

- Kulkarni, S.; Meghnani, J.; Lal, A. Effect of fly ash hybrid reinforcement on mechanical property and density of aluminium 356 alloy. Procedia Mater. Sci. 2014, 5, 746–754. [Google Scholar] [CrossRef] [Green Version]

- Senapati, A.K.; Mishra, P.C.; Routara, B.C. Use of waste flyash in fabrication of aluminium alloy matrix composite. Int. J. Eng. Technol 2014, 6, 905–912. [Google Scholar]

- Senapatia, A.; Senapatib, A.; Mishrac, O. Mechanical Properties of Fly Ash Reinforced Al-Si Alloy Based MMC. Int. J. Res. Advent Technol. 2014. [Google Scholar]

- Arun, L.R.; Suneel, K.N. Effect of AL2O3 and fly ash reinforced particulates for fatigue behavior of the AL6061T6 alloy matrix composites. Int. J. Eng. 2016, 5, 1129–1254. [Google Scholar]

- Ilandjezian, R.; Gopalakannan, S. Tensile fracture and compression failure behavior of cenosphere reinforced AA6061 metal matrix composite. Procedia Eng. 2017, 173, 1239–1245. [Google Scholar] [CrossRef]

- Verma, A.S.; Suri, N.; Kant, S. Effect of process parameter of Al-6063 based fly ash composites using taguchi. Int. J. Appl. Eng. Res. 2012, 7, 2012. [Google Scholar]

- Verma, A.S.; Kant, S.; Suri, N. Modelling of process variables for fly ash based Al-6063 composites using artificial neural network. Int. J. Sci. Res. Publ. 2013, 3, 1–5. [Google Scholar]

- Kumar, M.R.; Shunmuga Priyana, M.; Mani, A. Investigation of mechanical and wear properties of aluminum-fly ash composite material produced by stir casting method. Int. J. Sci. Eng. 2014, 5, 1261–1269. [Google Scholar]

- Suragimath, M.P.K.; Purohit, G. A study on mechanical properties of aluminium alloy (LM6) reinforced with SiC and fly ash. IOSR J. Mech. Civ. Engg 2013, 8, 13–18. [Google Scholar]

- Christy, T.; Murugan, N.; Kumar, S. A comparative study on the microstructures and mechanical properties of Al 6061 alloy and the MMC Al 6061/TiB2/12p. J. Miner. Mater. Charact. Eng. 2010, 9, 57. [Google Scholar]

- Pakdel, A.; Farhangi, H.; Emamy, M. Effect of extrusion process on ductility and fracture behaviour of SiCp/aluminum-alloy composites. In Proceedings of the 8th International Fracture Conference, Istanbul, Turkey, 7–9 November 2007; pp. 460–470. [Google Scholar]

- Hwu, B.-K.; Lin, S.-J.; Jahn, M.-T. Effects of process parameters on the properties of squeeze-cast SiCp-6061 Al metal-matrix composite. Mater. Sci. Eng. A 1996, 207, 135–141. [Google Scholar] [CrossRef]

- Khalifa, T.A.; Mahmoud, T.S. Elevated temperature mechanical properties of Al alloy AA6063/SiCp MMCs. In Proceedings of the World Congress on Engineering, London, UK, 1–3 July 2009. [Google Scholar]

- AlanemeaΨ, K.K.; Alukob, A.O. Production and age-hardening behaviour of borax premixed SiC reinforced Al-Mg-Si alloy composites developed by double stir-casting technique. West Indian J. Eng. 2012, 1, 2. [Google Scholar]

- Razzaq, A.M.; Majid, D.L.; Ishak, M.R.; Uday, M.B. Effects of Solid Fly Ash on Wear Behaviour of AA6063 Aluminum Alloy; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Mohammed Razzaq, A.; Majid, D.L.; Ishak, M.R.; Muwafaq Basheer, U. Mathematical modeling and analysis of tribological properties of AA6063 aluminum alloy reinforced with fly ash by using response surface methodology. Crystals 2020, 10, 403. [Google Scholar] [CrossRef]

- Mohanty, S.; Chugh, Y. Development of fly ash-based automotive brake lining. Tribol. Int. 2007, 40, 1217–1224. [Google Scholar] [CrossRef]

- Mahendra, K.; Radhakrishna, K. Castable composites and their application in automobiles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2007, 221, 135–140. [Google Scholar] [CrossRef]

- Kumar, K.R.; Mohanasundaram, K.; Arumaikkannu, G.; Subramanian, R. Analysis of parameters influencing wear and frictional behavior of aluminum–fly ash composites. Tribol. Trans. 2012, 55, 723–729. [Google Scholar] [CrossRef]

- Uthayakumar, M.; Kumaran, S.T.; Aravindan, S. Dry sliding friction and wear studies of fly ash reinforced AA-6351 metal matrix composites. Adv. Tribol. 2013, 2013, 365602. [Google Scholar] [CrossRef] [Green Version]

- Rao, R.; Das, S. Effect of SiC content and sliding speed on the wear behaviour of aluminium matrix composites. Mater. Des. 2011, 32, 1066–1071. [Google Scholar] [CrossRef]

- Ramachandra, M.; Radhakrishna, K. Effect of reinforcement of flyash on sliding wear, slurry erosive wear and corrosive behavior of aluminium matrix composite. Wear 2007, 262, 1450–1462. [Google Scholar] [CrossRef]

- Rao, J.B.; Rao, D.V.; Prasad, K.S.; Bhargava, N.R. Dry sliding wear behaviour of fly ash particles reinforced AA 2024 composites. Mater. Sci.-Pol. 2012, 30, 204–211. [Google Scholar]

- Moorthy, A.; Natarajan, D.N.; Sivakumar, R.; Manojkumar, M.; Suresh, M. Dry sliding wear and mechanical behavior of aluminium/fly ash/graphite hybrid metal matrix composite using taguchi method. Int. J. Mod. Eng. Res. (IJMER) 2012, 2, 1224–1230. [Google Scholar]

- Prasad, K.; Ramachandra, M. Effect of squeeze pressure on the hardness and wear resistance of aluminium fly ash composite manufactured by stir-squeeze casting. Int. J. Eng. Invent. 2013, 3, 1–8. [Google Scholar]

- Prasad, K.; Ramachandra, M. Evaluation of factors affecting sliding wear behaviour of Al-flyash metal matrix composites by using design of experiments. Int. J. Mod. Eng. Res. India 2013, 3, 2591–2599. [Google Scholar]

- Udaya, P.J.; Moorthy, T. Adhesive Wear Behaviour of Aluminium Alloy/Fly Ash Composites. Adv. Mater. Res. 2013, 622–623, 1290–1294. Available online: https://www.scientific.net/AMR.622-623.1290 (accessed on 8 October 2021). [CrossRef]

- Kumar, V.; Gupta, R.D.; Batra, N. Comparison of mechanical properties and effect of sliding velocity on wear properties of Al 6061, Mg 4%, fly ash and Al 6061, Mg 4%, graphite 4%, fly ash hybrid metal matrix composite. Procedia Mater. Sci. 2014, 6, 1365–1375. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Min, F.; Zhu, J. Microstructural characterization and mechanical property of Fly Ash/Al-25Mg composites. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2014, 29, 1019–1022. [Google Scholar] [CrossRef]

- Kountouras, D.T.; Stergioudi, F.; Tsouknidas, A.; Vogiatzis, C.A.; Skolianos, S.M. Properties of high volume fraction fly ash/Al alloy composites produced by infiltration process. J. Mater. Eng. Perform. 2015, 24, 3315–3322. [Google Scholar] [CrossRef]

- David Raja Selvam, J.; Dinaharan, I.; Mashinini, P. High temperature sliding wear behavior of AA6061/fly ash aluminum matrix composites prepared using compocasting process. Tribol.-Mater. Surf. Interfaces 2017, 11, 39–46. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).