Abstract

Bio-oil is a potential source for the production of alternative fuels and chemicals. In this work, Ni-V bimetallic zeolite catalysts were synthesized and evaluated in in situ catalytic hydrodeoxygenation (HDO) of pyrolysis volatiles of pine nut shell for upgraded bio-oil products. The pH and lower heating value (LHV) of the upgraded bio-oil products were improved by in situ catalytic HDO, while the moisture content and density of the oil decreased. The O/C ratio of the upgraded bio-oil products decreased significantly, and the oxygenated compounds in the pyrolysis volatiles were converted efficiently via deoxygenation over Ni-V zeolite catalysts. The highest HDO activity was obtained with NiV/MesoY, where the obtained bio-oil had the lowest O/C atomic ratio (0.27), a higher LHV (27.03 MJ/kg) and the highest selectivity (19.6%) towards target arenes. Owing to the more appropriate pore size distribution and better dispersion of metal active sites, NiV/MesoY enhanced the transformation of reacting intermediates, obtaining the dominant products of phenols and arenes. A higher HDO temperature improved the catalytic activity of pyrolysis volatiles to form more deoxygenated arenes. Higher Ni loading could generate more metal active sites, thus promoting the catalyst’s HDO activity for pyrolysis volatiles. This study contributes to the development of cost-efficient and eco-friendly HDO catalysts, which are required for producing high-quality biofuel products.

1. Introduction

With the continuous increase in the consumption of fossil fuels, environmental concerns about CO2 emissions and air pollution have attracted more and more attention from all over the world [1,2]. To address these issues, renewable and green energy resources are urgently needed to partially replace the conventional fossil fuels [3,4]. In recent decades, biomass has been considered as a potential source for the production of alternative fuels and chemicals, and renewable bio-oil has raised a lot of research interest [5,6,7]. However, the crude bio-oil produced from biomass pyrolysis has a high oxygen content, causing many issues, such as high acidity, a lower LHV, poor storage stability, etc. [8,9,10] Therefore, catalytic hydrodeoxygenation (HDO) upgrading of bio-oil is necessary before its utilization [11,12].

Catalysts play an essential role in HDO reactions. The noble metal catalysts, such as Pt [13], Pd [14], Ru [15], etc., are reported to have great activity in bio-oil HDO [16]. However, the high cost of noble metals limits their utilization. On the other hand, the non-noble metal catalysts, including Ni, Mo, Cu, etc., are more abundant and economical [17,18]. And the Ni-based bimetallic catalysts supported on zeolites, as non-noble transit metal catalysts, have attracted increasing attention. For instance, Ni-based bimetallic catalysts supported on hexagonally structured mesoporous SBA-15 (NiCu/SBA-15, NiMn/SBA-15, NiZn/SBA-15) were demonstrated to be highly effective for HDO of bio-oil at 250–350 °C for 45 min with 3 MPa H2 pressure, leading to significantly enhanced fuel properties of the heavy oil products, although with decreased yields of light oils [19]. Du et al. prepared Ni-Mo2C/MCM-41 catalysts and showed that those exhibited a great catalytic performance, with an 83.9 wt.% biofuel yield and 95.2% C15–C18 selectivity in HDO of jatropha oil [20]. Miao et al. synthesized Ni-based bimetallic NixCuy/γ-Al2O3 catalysts and evaluated those in an HDO reaction of methyl laurate, reporting that the Ni3Cu7/γ-Al2O3 catalyst achieved outstanding activity, with 87.4% C11 alkane selectivity [21].

Similarly, Sangnikul et al. prepared Cu- or Ce-modified NiMo/γ-Al2O3 catalysts and evaluated those in HDO of guaiacol, and it was found that the addition of Cu or Ce promoters affected the physicochemical properties of the NiMo catalyst [22]. Hewer et al. also prepared Ni-Mo bimetallic catalysts supported on different zeolites, including SAPO-11, SBA-15 and γ-Al2O3, and tested those in HDO reactions; the results showed that the dispersion of the metallic sites and the proportion of Lewis/Bronsted acid sites strongly influenced the selectivity [23]. Ni-based zeolite catalysts were widely investigated in HDO upgrading of bio-oil; however, the prior research predominantly investigated HDO of post-pyrolysis bio-oil refining with energy-intensive separation steps, and the utilization of such catalysts in the in situ direct upgrading of pyrolysis volatiles for value-added chemicals still needs further research.

In this study, Ni-V bimetallic catalysts supported on various zeolites were synthesized (NiV/γ-Al2O3, NiV/HZSM-5, NiV/USY, NiV/MesoY) and tested for catalytic pyrolysis of pine nut shell, where the pyrolysis volatiles were in situ upgraded by two-step HDO reactions. Here, the first step was carried out in a continuous pyrolysis reactor, and the second step was carried out in catalytic HDO reactor. The yields, compositions, element properties, moisture contents, pH values, densities and LHVs of the bio-oil products were evaluated, along with the effects of catalysts, reaction temperature and Ni loading. By pioneering an advanced in situ catalytic HDO strategy integrated with biomass pyrolysis processes, this work not only enhances the upgrading efficiency of pyrolysis volatiles but also helps to develop a cost-efficient and eco-friendly Ni-based zeolite catalyst for generating high-quality bio-oil products.

2. Results and Discussion

The catalytic HDO of pine nut shell pyrolysis volatiles was carried out in a two-stage reactor, where the continuous pyrolysis temperature was set as 550 °C to obtain volatiles, and the HDO temperature was set as 375/400/425 °C to obtain upgraded bio-oil. Different Ni-based bimetallic zeolite catalysts were evaluated in HDO reactions for deoxygenated products like arenes.

2.1. Effects of Different Ni-Based Bimetallic Zeolite Catalysts

The yields of pyrolysis products, including solid char, liquid oil and gas products, are shown in Table 1. In the typical pyrolysis process without HDO reaction at 400 °C, the yields of solid char, liquid oil and gas products were 36.8%, 38.7% and 24.5%, respectively. And for the blank run with SiO2, the yield of solid char decreased, while the yield of gas increased slightly. After the HDO process with Ni-based bimetallic zeolite catalysts, the yield of liquid oil decreased, while there was an increase in gas products. The results indicated that Ni-based bimetallic zeolite catalysts promoted the transformation of biomass pyrolysis volatiles.

Table 1.

Yields of pyrolysis products with different catalysts.

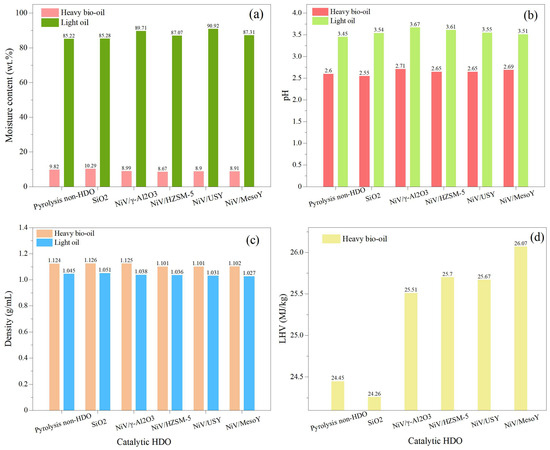

In this work, the collected liquid products were centrifuged sufficiently with a high-speed centrifuge and then separated using a separatory funnel to obtain aqueous light oil and target heavy oil with abundant chemicals. The properties of bio-oil products generated with different catalysts are shown in Figure 1, including the moisture content, pH value, density and LHV. According to this, the moisture content of crude pyrolysis heavy bio-oil and blank SiO2 heavy bio-oil was higher than that of Ni-based bimetallic zeolite catalysts. After catalytic HDO with Ni-based bimetallic catalysts, the moisture content of heavy bio-oils decreased while the moisture content of light oil increased, indicating that the H2O was generated in HDO reactions and transferred to the light oil products, thereby improving the quality of target heavy bio-oils. As for the pH value, a higher pH was achieved in the catalytic HDO bio-oils, whether in light oil or heavy bio-oil, which also showed less acidity and a higher quality. The density of pyrolysis non-HDO bio-oil was relatively higher, and after the catalytic HDO with NiV/HZSM-5, NiV/USY and NiV/Meso-Y, the density of catalytic bio-oil was decreased significantly.

Figure 1.

The moisture content (a), pH value (b), density (c) and LHV (d) of bio-oil produced by different HDO catalysts.

Meanwhile, the moisture content of aqueous light oil was too high, consistently exceeding 85%; thus, the LHV of light oil was no longer tested in this work. Instead, the LHV of heavy bio-oils was tested and analyzed. From Figure 1d, it can be seen that the LHVs of pyrolysis non-HDO bio-oil and blank SiO2 bio-oil were only 24.45 MJ/kg and 24.26 MJ/kg, respectively. After HDO with Ni-based bimetallic zeolite catalysts, the LHV of upgrading bio-oil increased significantly, especially for the NiV/Meso-Y catalyst, for which the LHV was improved to 26.07 MJ/kg. Overall, the quality of bio-oil was improved by HDO reaction with the catalytic effect of Ni-V bimetallic zeolite catalysts.

The elemental analysis results for heavy bio-oils produced by different catalysts are shown in Table 2. The C content in pyrolysis non-HDO bio-oil was only 62.3%. After the catalytic HDO, the C content in upgraded bio-oil increased, with the NiV/MesoY obtaining the highest C content of 65.8%. A similar increase was also observed in H content. On the contrary, the O content decreased significantly in the catalytic upgraded bio-oil, from 28.3% for pyrolysis non-HDO bio-oil to 24.5% for NiV/MesoY catalytic bio-oil. The contents of N and S were maintained at about 1.1% and 0.3%, respectively. On the other hand, similar H/C atomic ratios were obtained in different bio-oils. Furthermore, the O/C atomic ratios of catalytic HDO bio-oils were lower than that of pyrolysis non-HDO bio-oil, indicating that the oxygenated compounds in pyrolysis crude bio-oil were decreased efficiently with the catalytic effect of Ni-V bimetallic zeolite catalysts via deoxygenated reactions, and the NiV/MesoY catalyst had the highest HDO activity, while NiV/MesoY showing the lowest O/C atomic ratio of 0.28. The decrease in oxygen content in bio-oil will promote the wide utilization of sustainable biofuels [24].

Table 2.

Elemental analysis of heavy bio-oils produced by different catalysts.

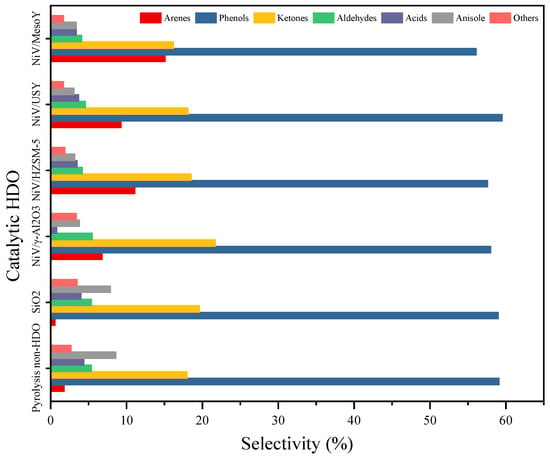

Based on the results of elemental analysis, the main components of heavy bio-oils produced by different HDO catalysts under 400 °C were further investigated. As shown in Figure 2, phenols, arenes, ketones, aldehydes, acids, anisole and other compounds were obtained in all bio-oils. For pyrolysis non-HDO bio-oil and blank SiO2 bio-oil, the oxygenated phenols, ketones and anisole were the dominant components, reaching about 85–90%, while the arenes made up only 1.8% and 0.6%, respectively. After catalytic HDO of pyrolysis volatiles over Ni-V bimetallic zeolite catalysts, it was observed that the formation of non-oxygenated arenes, including benzene, toluene, xylene, etc., was significantly improved. The arene content of different bio-oils increased in the order of SiO2 (0.6%) < non-HDO (1.8%) < NiV/γ-Al2O3 (6.8%) < NiV/USY (9.3%) < NiV/HZSM-5 (11.1%) < NiV/MesoY (15.1%). The NiV/MesoY catalyst had the highest HDO activity, allowing it to produce more target arenes and improve the bio-oil quality.

Figure 2.

Components of heavy bio-oil produced by different HDO catalysts.

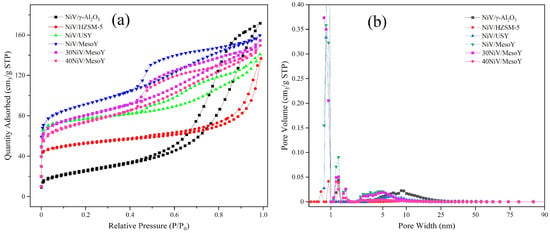

Furthermore, the characterization of Ni-V bimetallic zeolite catalysts was carried out to investigate the catalysts’ properties, as shown in Table 3. Ni and V metal loadings measured by ICP-MS were close to the nominal value for all catalysts; except for higher Ni-loading 30NiV/MesoY and 40NiV/MesoY catalysts, Ni and V loading were both slightly lower than the nominal value. The textural characteristics are shown in Table 3, and the N2 adsorption–desorption isotherms and pore distribution are shown in Figure 3. After metal loading, the surface areas of the Ni-V bimetallic zeolite catalysts decreased in the order of NiV/MesoY > NiV/USY > NiV/HZSM-5 > NiV/γ-Al2O3. Moreover, for the NiV/MesoY, 30NiV/MesoY and 40NiV/MesoY catalysts, the surface areas also decreased with higher Ni loading.

Table 3.

Physicochemical properties of Ni-V bimetallic zeolite catalysts.

Figure 3.

N2 isotherm linear plot (a) and pore size distribution (b) of Ni-V bimetallic zeolite catalysts.

A mesoporous structure was dominant in the NiV/γ-Al2O3 catalyst, while a microporous structure was mostly observed in the NiV/HZSM-5 catalyst. The NiV/USY catalyst showed the lowest SBET and pore volume. On the contrary, the NiV/MesoY catalyst exhibited the most developed pore structure, with the highest SBET (338 m2/g) and pore volume (0.239 cm3/g). Moreover, from the pore size distribution of NiV/MesoY, the mesoporous and microporous structures could be both detected, which presented a multistage pore distribution. According to this, the more developed pore structure and more appropriate pore size distribution were obtained in the NiV/MesoY catalyst, which was conducive to the dispersion of metal active sites as well as the transformation of HDO reacting intermediates [25].

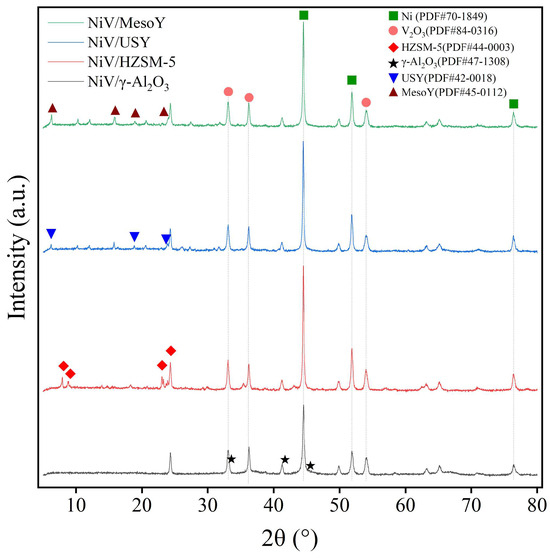

From the XRD patterns in Figure 4 and the coherent scattering region size of Ni in Table 3, the Ni diffraction peaks at 2θ = 44.48°, 51.83° and 76.35° as well as the V2O3 peaks at 2θ = 32.98°, 36.22° and 54.12° were identified in all Ni-V bimetallic zeolite catalysts, which was indicative of the effective loading of Ni0 and V3+ active sites. Moreover, the coherent scattering region size of Ni of the Ni-V bimetallic zeolite catalysts increased in the order of NiV/MesoY (33.6 nm) < NiV/γ-Al2O3 (39.9 nm) < NiV/HZSM-5 (41.8 nm) < NiV/USY (43.3 nm). This indicated that the better dispersion of Ni metal active sites was achieved in the NiV/MesoY catalyst, consistent with N2 adsorption–desorption results. It was reported that the more dispersed metal distribution and smaller Ni active sites were conducive to promoting HDO reactivity [26]. Therefore, the NiV/MesoY catalyst generated the higher HDO activity, allowing it to produce more target non-oxygenated arenes, including benzene, toluene, xylene, etc.

Figure 4.

XRD patterns of Ni-V bimetallic zeolite catalysts.

2.2. Effects of HDO Reaction Temperature

The influence of the reaction temperature was further investigated over the optimized NiV/MesoY catalysts. Here, 375 °C, 400 °C and 425 °C were set as the different HDO temperatures, and the results are shown in Table 4 and Figure 5. From the catalytic HDO bio-oil properties under different reaction temperatures in Table 4, it can be seen that with the increasing HDO temperature, the moisture content and density decreased gradually, whereas the pH and LHV improved. Similarly, an increase in C and H contents was also obtained with the increasing HDO temperature, accompanied by a significantly decreased O content. Lower O/C atomic ratios (0.27) of bio-oil could be obtained under a 425 °C HDO temperature. It was illustrated that the catalytic HDO activity of pyrolysis volatiles could be enhanced by applying an appropriately higher temperature, thus improving the quality of bio-oil [27,28].

Table 4.

Catalytic HDO bio-oil properties under different reaction temperatures.

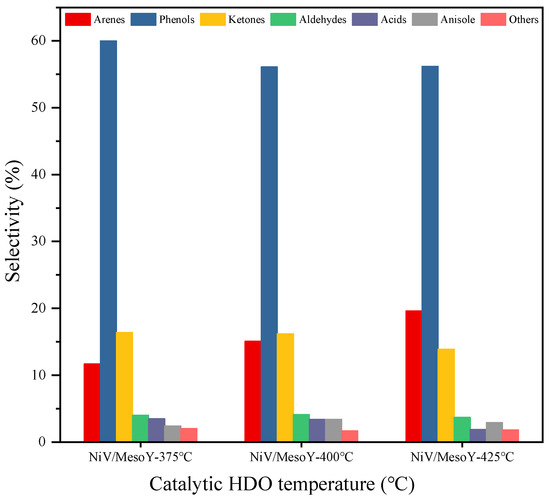

Figure 5.

Components of HDO bio-oil under different reaction temperatures.

The catalytic HDO reaction temperature influenced the components of bio-oil as well. At different HDO temperatures, the selectivity to phenol and ketones decreased slightly with increasing temperature, resulting in the decline of oxygenated compounds. And the selectivity to arenes increased when the temperature rose from 375 to 425 °C. A higher arene selectivity of 19.6% was achieved under 425 °C, indicating that the HDO activity of biomass pyrolysis volatiles was highly temperature-dependent over the NiV/MesoY catalyst [29,30].

2.3. Effects of Ni Metal Loading

In addition to the HDO reaction temperature, active metal loading is also an important factor in optimizing the catalyst and improving HDO activity [31]. In this work, Ni metal loading influenced the catalytic HDO performance of pyrolysis volatiles as well, as shown in Table 5 and Figure 6. With the increase in Ni loading, the moisture content and density decreased slightly. On the contrary, the pH and LHV of HDO bio-oil were improved. However, in the results of elemental analysis of HDO bio-oil, no obvious changes were observed in C content, which was maintained at 65.8%, while the H content slightly increased with increasing Ni loading. In addition, the O/C atomic ratios in HDO bio-oil gradually decreased to 0.27 with a higher Ni loading, indicating that a higher HDO activity could be obtained, offering the chance to upgrade bio-oil quality with higher Ni loading.

Table 5.

Catalytic HDO bio-oil properties over catalysts with different Ni loading levels.

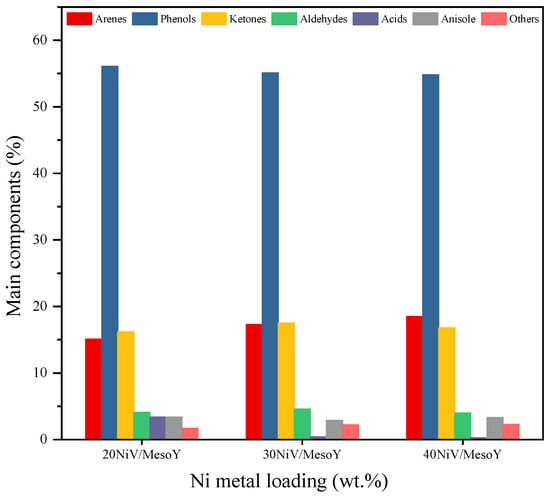

Figure 6.

Components of HDO bio-oil over catalysts with different Ni loading levels.

From the results in Figure 6, it can be seen that phenols, deoxygenated arenes and ketones were the dominant components in HDO bio-oil over different Ni loading catalysts. With increasing Ni loading, the selectivity to phenols and acids decreased, while the selectivity to ketones increased slightly. As for the target arene products, a higher arene selectivity of 18.5% was obtained over the 40NiV/MesoY catalyst with higher Ni loading. These results indicated that more metal active sites were formed by higher Ni loading, which could improve the catalytic HDO activity of pyrolysis volatiles to some extent. However, it should be considered that a higher Ni loading will also raise the cost of catalysts.

2.4. Proposed HDO Reaction Pathways

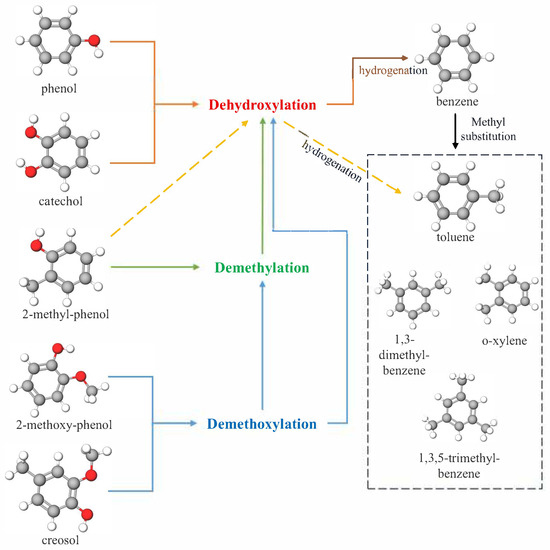

The detailed properties and catalytic HDO performance over all catalysts in this work are shown in Tables S1 and S2. The catalytic HDO pathways of biomass pyrolysis volatiles are extremely complex. Herein, we focus on the conversion pathways of dominant phenols and target arene products. Phenols were the main compounds in crude pyrolysis heavy bio-oil, typically including 2-methoxy-phenol, creosol, phenol, catechol, 2-methyl-phenol, etc., while the obtained arenes made up only 1.8%. After the HDO reaction over NiV/MesoY catalyst under 425 °C, the obtained arenes improved to 19.6%, including benzene, toluene, o-xylene, 1,3-dimethyl-benzene, 1,3,5-trimethyl-benzene, etc. The proposed HDO reaction pathways over NiV/MesoY catalyst are shown in Figure 7. In the HDO of phenol and catechol, dehydroxylation was the main deoxygenation pathway, and the target benzene was generated after further hydrogenation. Based on the methylation of benzene, further target products such as toluene and o-xylene were obtained. For the HDO of methyl-phenols, the demethylation and the subsequent dehydroxylation and hydrogenation were performed to produce the target arenes. As for the 2-methoxy-phenol and creosol with a higher oxygen content, demethoxylation/demethylation and the further dihydroxylation and hydrogenation were conducted to form arenes efficiently. Overall, through the in situ catalytic HDO of pyrolysis volatiles over NiV/MesoY catalysts, the quality of heavy bio-oil was significantly improved. Moreover, from the textural results in Table S1, a pore blockage was observed in spent catalysts caused by carbon deposition, resulting in catalyst deactivation to a certain extent [32]. The catalyst deactivation and regeneration mechanisms will be further investigated in future research.

Figure 7.

Proposed HDO reaction pathways over NiV/MesoY catalysts.

3. Materials and Methods

3.1. Materials

Zeolites HZSM-5 (SiO2/Al2O3 = 25, crystallinity 96%, surface area 348 m2/g), USY (SiO2/Al2O3 = 43, crystallinity 90%, surface area 670 m2/g) and MesoY (SiO2/Al2O3 = 10.7, crystallinity 55%, surface area 710 m2/g) were purchased from the Catalyst Factory of Nankai University (Tianjin, China). Material γ-Al2O3 (surface area 210 m2/g) was purchased from the Nanjing XFNANO Materials Tech. Co., Ltd. (Nanjing, China). Ni(NO3)2·6H2O and SiO2 were provided by Guangzhou Chemical Reagent (Guangzhou, China). NH4VO3 was provided by Macklin Co., Ltd. (Shanghai, China). Pine nut shell was obtained from a processing factory in Yichun City, China and then crushed to 20–80 meshes and dried for 24 h at 110 °C.

3.2. Catalyst Preparation

The catalysts were prepared by a co-impregnation method, at a metal loading of 20, 30 or 40 wt.% Ni and 10 wt.% V, respectively. Typically, 12 g zeolite support was impregnated with the mixed aqueous solution of 200 g deionized water, Ni(NO3)2·6H2O and NH4VO3. After shaking (50 °C for 2.5 h) and sonicating (20 kHz, 150 w for 0.5 h), the sample was dried for 24 h at 110 °C in air, and then ex situ reduced for 2 h at 650 °C in H2/N2 (10%/90%, 200 mL/min) flow to obtain the fresh catalyst. After that, the fresh catalyst was cooled in N2 flow and sieved to 20-mesh particles, denoted as NiV/γ-Al2O3, NiV/HZSM-5, NiV/USY, NiV/MesoY, 30NiV/MesoY and 40NiV/MesoY. Herein, in order to investigate the effect of different Ni metal loading levels, three catalysts (NiV/MesoY, 30NiV/MesoY, 40NiV/MesoY) with gradient-increasing Ni loading levels were synthesized.

3.3. Characterization of Catalyst and Bio-Oil

The contents of Ni and V were detected by inductively coupled plasma mass spectrometry (ICP-MS, Agilent 7700X, Agilent Technologies, Santa Clara, CA, USA). The porous structure of catalysts was analyzed by means of N2 adsorption–desorption at −196 °C on a Micromeritics ASAP 2460 analyzer (Micromeritics Corporation, Norcross, GA, USA), about 100 mg of sample was degassed for 10 h at 150 °C and the specific surface area was calculated based on the desorbed N2 area using the single-point BET equation.

X-ray Powder Diffraction (XRD) of catalysts was recorded by a Rigaku Ultima-IV diffractometer (Rigaku, Tokyo, Japan) in the 2θ range of 5° to 80°, with a Cu Kα radiation source (λ = 0.1542 nm) and a scanning rate of 10°/min.

The composition of bio-oil products was analyzed by GC-MS (Shimadzu QP2010 Ultra, Shimadzu Corporation, Kyoto, Japan) equipped with an RTX-Wax column (30 m × 0.25 mm × 0.25 μm), where acetophenone served as the internal standard.

The elemental content (CHNS-O) of bio-oil was determined by elemental analysis (EA) using an Elementar Vario EL cube instrument (Elementar Analysensysteme GmbH, Hanau, Germany). The moisture content of bio-oil was detected by a Karl-Fischer moisture tester (AKF2010V, Shanghai Hegong Instrument, Shanghai, China). Moreover, the pH value, density and LHV of the bio-oil sample were also obtained.

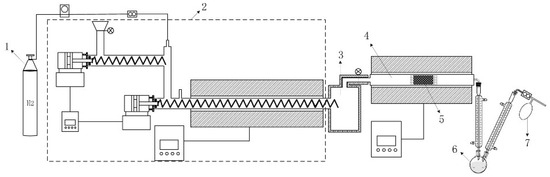

3.4. Catalytic Performance

The catalytic pyrolysis of pine nut shell was carried out under atmospheric pressure in a two-stage reactor, consisting of a first-stage continuous pyrolysis reactor and a second-stage catalytic HDO reactor, as shown in Figure 8. In a typical run, 100 g pine nut shell was fed into a first-stage continuous pyrolysis reactor over 40 min at 550 °C under H2 atmosphere, and the biomass pyrolysis resident time was approximate 650 s. Next, 10 g of catalyst was loaded into a second-stage catalytic HDO reactor (conditions: 375, 400, 425 °C; WHSV = 1.48 h−1, H2: volatile molar ratio was set as 40:1). After the reactions, solid char was collected in a char chamber, and the gas sample was collected with a gas bag. Liquid products were condensed at −5 °C for collection, then centrifuged and separated to obtain aqueous light oil and heavy bio-oil. In this work, we mainly focused on the heavy bio-oil with abundant chemicals. For a reference, blank tests of pyrolysis without catalysts and with SiO2 were also carried out. The yield [33] and product selectivity [34] were defined as follows:

Figure 8.

Two-stage reactor for catalytic HDO reactions of pine nut shell pyrolysis volatiles. 1. Hydrogen gas; 2. first-grade continuous pyrolysis reactor; 3. char box; 4. second-grade catalytic HDO reactor; 5. Ni-based bimetallic catalysts; 6. condenser; 7. gas bag.

4. Conclusions

In this study, Ni-V bimetallic zeolite-supported catalysts were synthesized and evaluated in in situ catalytic HDO of pine nut shell pyrolysis volatiles. The catalytic process promoted the HDO of biomass pyrolysis volatiles, resulting in a decreased yield of liquid oil but an increased yield of gas products, while improving the quality of the bio-oil products: The pH and LHV of HDO bio-oil increased, while the moisture content and density of HDO bio-oil decreased. Moreover, the O/C atomic ratio of the upgraded bio-oils decreased significantly, owing to the conversion of oxygenated compounds in pyrolysis volatiles via a deoxygenation reaction over Ni-V zeolite-supported catalysts. The NiV/MesoY catalyst showed the highest HDO activity and we obtained an HDO bio-oil with the lowest O/C atomic ratio of 0.27, an LHV of 27.03 MJ/kg and the highest selectivity of 19.6% to target arenes in upgraded bio-oil products, which was developed owing to its more appropriate pore size distribution and better dispersion of metal active sites. It was observed that the catalytic HDO activity of the catalyst improved at a higher temperature, and higher arene selectivity was achieved under 425 °C over the NiV/MesoY catalyst. As expected, the catalytic HDO performance of the catalyst was improved by increasing Ni loading. This work contributes toward developing cost-efficient and eco-friendly HDO catalysts suited for producing high-quality bio-oil products.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/catal15050498/s1, Table S1: Detailed properties of all catalysts in this work; Table S2: Detailed catalytic HDO performance over all catalysts in this work.

Author Contributions

Y.W., X.X. and E.J. conceived and designed this study. Y.W. and X.F. provided the materials and prepared the catalysts. Y.W., Y.S. and R.T. performed the catalytic HDO experiments. Y.W., X.F. and X.X. wrote the paper. C.C.X. and Q.X. reviewed and edited the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Program for Scientific Research Start-up Funds of Guangdong Ocean University (Grant No. 060302072302); Zhanjiang Marine Youth Talent Innovation Project (Grant No. 2024R3002); National Natural Science Foundation of China (Grant No. 52476190); National Natural Science Foundation of China (Grant No. 51706075); National Key Research and Development Project, China (Grant No. 2019YFD1100602); Rural Revitalization Strategy Special Fund (“Special Project+Task List”) project in Yunfu City, Guangdong Province, China (Grant No. 2020020203).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to thank the Joint Training Demonstration Base Project for Graduate Students of “Guangzhou Institute of Energy Conversion, Chinese Academy of Sciences” in Guangdong Province, thank Shiyanjia Lab (www.shiyanjia.com) for the support with catalyst measurements, and thank the Guangdong Provincial Key Laboratory of Intelligent Equipment for the South China Sea Marine Ranch and the Instrumental Analysis and Research Center of Guangdong Ocean University for the support with GC-MS tests.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

The list of abbreviations and corresponding full names.

| Abbreviations | Full names |

| Dmean | Most probable pore size |

| EA | Elemental analysis |

| HDO | Hydrodeoxygenation |

| ICP-MS | Inductively coupled plasma mass spectrometry |

| LHV | Lower heating value |

| meso | Mesopore |

| micro | Micropore |

| VS | Total pore volume |

| Vm | Micropore volume |

| XPS | X-ray photoelectron spectroscopy |

| XRD | X-ray powder diffraction |

| Sorted in alphabetical order | |

References

- Valizadeh, S.; Valizadeh, B.; Lee, J.; Park, Y. Catalytic guaiacol hydrodeoxygenation in supercritical fluids: A Review. ChemCatChem 2025, 17, e202401390. [Google Scholar] [CrossRef]

- Ambursa, M.M.; Juan, J.C.; Yahaya, Y.; Taufiq-Yap, Y.; Lin, Y.-C.; Lee, H.V. A review on catalytic hydrodeoxygenation of lignin to transportation fuels by using nickel-based catalysts. Renew. Sustain. Energy Rev. 2021, 138, 110667. [Google Scholar] [CrossRef]

- Paritosh, K.; Bose, A. Application of biogenic carbon in renewable energy vectors and devices: A step forward to decarbonization. Renew. Sustain. Energy Rev. 2024, 197, 114399. [Google Scholar] [CrossRef]

- Sayed, E.T.; Olabi, A.G.; Alami, A.H.; Radwan, A.; Mdallal, A.; Rezk, A.; Abdelkareem, M.A. Renewable energy and energy storage systems. Energies 2023, 16, 1415. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, Z.; Yang, L.; Li, J.; Wu, K.; Gouda, S.G.; Niu, W.; Yuan, Q. Co-hydrothermal treatment of chicken carcass and non-animal biomass for cleaner production. Chem. Eng. J. 2025, 513, 162789. [Google Scholar] [CrossRef]

- Ge, L.; Ali, M.M.; Osman, A.I.; Elgarahy, A.M.; Samer, M.; Xu, Y.; Liu, Z. A critical review on conversion technology for liquid biofuel production from lignocellulosic biomass. Renew. Sustain. Energy Rev. 2025, 217, 115726. [Google Scholar] [CrossRef]

- Pantawane, S.R.; Chaurasia, A.S.; Ekhe, J.D. Unveiling the potential of thermo catalytic fast pyrolysis for the production of higher quantities of bio-oil: Lignin-derived oxygenates. J. Anal. Appl. Pyrolysis 2025, 190, 107121. [Google Scholar] [CrossRef]

- Xue, X.; Liu, J.; Xia, D.; Liang, J. Hydrocarbon-rich bio-oil production from the coupling formaldehyde-pretreatment and catalytic pyrolysis of poplar sawdust. Biomass Bioenergy 2023, 173, 106807. [Google Scholar] [CrossRef]

- Qu, L.; Jiang, X.; Zhang, Z.; Zhang, X.-G.; Song, G.-Y.; Wang, H.-L.; Yuan, Y.-P.; Chang, Y.-L. A review of hydrodeoxygenation of bio-oil: Model compounds, catalysts, and equipment. Green Chem. 2021, 23, 9348–9376. [Google Scholar] [CrossRef]

- da Silva, T.L.; Dutra, F.; Marques, S.; Gomes, M.; Costa, P.; Paradela, F.; Ferreira, F.C.; Faria, N.T.; Mugica, P.; Pinheiro, H.M.; et al. Production of sustainable aviation fuel precursors using the oleaginous yeast Rhodotorula toruloides PYCC 5615 cultivated on eucalyptus bark hydrolysate. Biomass Bioenergy 2025, 197, 107790. [Google Scholar] [CrossRef]

- Rueda, A.C.; Granados-Reyes, J.; Delaunay, J.; Mora-Masià, P.; Cesteros, Y. Tuning the acid-base properties of layered double hydroxides for the selective obtention of cyclohexane and cyclohexanol in the hydrodeoxygenation of guaiacol. Chem. Eng. J. 2025, 512, 162226. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, F.; Feng, J.; Pan, H. Efficient hydrodeoxygenation of guaiacol to cyclohexanol over Ni–Co bimetallic nanoparticles supported on Al2O3–TiOx. Biomass Bioenergy 2025, 197, 107841. [Google Scholar] [CrossRef]

- Pastor-Pérez, L.; Jin, W.; Villora-Picó, J.J.; Wang, Q.; Pastor-Blas, M.M.; Sepúlveda-Escribano, A.; Reina, T.R. “H2-free” demethoxylation of guaiacol in subcritical water using Pt supported on N-doped carbon catalysts: A cost-effective strategy for biomass upgrading. J. Energy Chem. 2021, 58, 377–385. [Google Scholar] [CrossRef]

- Ding, W.; Li, H.; Zong, R.; Jiang, J.; Tang, X. Controlled Hydrodeoxygenation of Biobased Ketones and Aldehydes over an Alloyed Pd–Zr Catalyst under Mild Conditions. ACS Sustain. Chem. Eng. 2021, 9, 3498–3508. [Google Scholar] [CrossRef]

- Yan, P.; Mensah, J.; Drewery, M.; Kennedy, E.; Maschmeyer, T.; Stockenhuber, M. Role of metal support during ru-catalysed hydrodeoxygenation of biocrude oil. Appl. Catal. B Environ. 2021, 281, 119470. [Google Scholar] [CrossRef]

- Wang, X.; Wu, P.; Wang, Z.; Zhou, L.; Liu, Y.; Cheng, H.; Arai, M.; Zhang, C.; Zhao, F. Chlorine-modified Ru/TiO2 catalyst for selective guaiacol hydrodeoxygenation. ACS Sustain. Chem. Eng. 2021, 9, 3083–3094. [Google Scholar] [CrossRef]

- Dou, X.; Li, W.; Zhu, C.; Jiang, X. Catalytic waste Kraft lignin hydrodeoxygenation to liquid fuels over a hollow Ni-Fe catalyst. Appl. Catal. B Environ. 2021, 287, 119975. [Google Scholar] [CrossRef]

- Saraeian, A.; Burkhow, S.J.; Jing, D.; Smith, E.A.; Shanks, B.H. Catalyst property effects on product distribution during the hydrodeoxygenation of lignin pyrolysis vapors over MoO3/γ-Al2O3. ACS Sustain. Chem. Eng. 2021, 9, 6685–6696. [Google Scholar] [CrossRef]

- Oh, S.; Lee, J.H.; Choi, I.-G.; Choi, J.W. Enhancement of bio-oil hydrodeoxygenation activity over Ni-based bimetallic catalysts supported on SBA-15. Renew. Energy 2020, 149, 1–10. [Google Scholar] [CrossRef]

- Du, X.; Zhou, K.; Zhou, L.; Lei, X.; Yang, H.; Li, D.; Hu, C. Efficient catalytic conversion of jatropha oil to high grade biofuel on Ni-Mo2C/MCM-41 catalysts with tuned surface properties. J. Energy Chem. 2021, 61, 425–435. [Google Scholar] [CrossRef]

- Miao, C.; Zhou, G.; Chen, S.; Xie, H.; Zhang, X. Synergistic effects between Cu and Ni species in NiCu/γ-Al2O3 catalysts for hydrodeoxygenation of methyl laurate. Renew. Energy 2020, 153, 1439–1454. [Google Scholar] [CrossRef]

- Sangnikul, P.; Phanpa, C.; Xiao, R.; Zhang, H.; Reubroycharoen, P.; Kuchonthara, P.; Vitidsant, T.; Pattiya, A.; Hinchiranan, N. Role of copper- or cerium-promoters on NiMo/γ-Al2O3 catalysts in hydrodeoxygenation of guaiacol and bio-oil. Appl. Catal. A Gen. 2019, 574, 151–160. [Google Scholar] [CrossRef]

- Hewer, T.L.; Souza, A.G.; Roseno, K.T.; Moreira, P.F.; Bonfim, R.; Alves, R.M.; Schmal, M. Influence of acid sites on the hydrodeoxygenation of anisole with metal supported on SBA-15 and SAPO-11. Renew. Energy 2018, 119, 615–624. [Google Scholar] [CrossRef]

- Kim, S.; Kwon, E.E.; Kim, Y.T.; Jung, S.; Kim, H.J.; Huber, G.W.; Lee, J. Recent advances in hydrodeoxygenation of biomass-derived oxygenates over heterogeneous catalysts. Green Chem. 2019, 21, 3715–3743. [Google Scholar] [CrossRef]

- Yang, X.; Jenkins, R.W.; Leal, J.H.; Moore, C.M.; Judge, E.J.; Semelsberger, T.A.; Sutton, A.D. Hydrodeoxygenation (HDO) of biomass derived ketones using supported transition metals in a continuous reactor. ACS Sustain. Chem. Eng. 2019, 7, 14521–14530. [Google Scholar] [CrossRef]

- Yan, P.; Mensah, J.; Adesina, A.; Kennedy, E.; Stockenhuber, M. Highly-dispersed Ni on BEA catalyst prepared by ion-exchange-deposition-precipitation for improved hydrodeoxygenation activity. Appl. Catal. B Environ. 2020, 267, 118690. [Google Scholar] [CrossRef]

- Wu, Y.; Xu, X.; Sun, Y.; Jiang, E.; Fan, X.; Tu, R.; Wang, J. Gas-phase hydrodeoxygenation of guaiacol over Ni-based HUSY zeolite catalysts under atmospheric H2 pressure. Renew. Energy 2020, 152, 1380–1390. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, H.; Li, H.; Cai, B.; Lv, W.; Cai, C.-L.; Wang, C.; Yan, L.; Liu, Q.; Ma, L. Selective hydrodeoxygenation of 5-hydroxymethylfurfural to 2,5-dimethylfuran over alloyed Cu−Ni encapsulated in biochar catalysts. ACS Sustain. Chem. Eng. 2019, 7, 19556–19569. [Google Scholar] [CrossRef]

- Auersvald, M.; Shumeiko, B.; Vrtiška, D.; Straka, P.; Staš, M.; Šimáček, P.; Blažek, J.; Kubička, D. Hydrotreatment of straw bio-oil from ablative fast pyrolysis to produce suitable refinery intermediates. Fuel 2019, 238, 98–110. [Google Scholar] [CrossRef]

- Zhou, G.; Jensen, P.A.; Le, D.M.; Knudsen, N.O.; Jensen, A.D. Atmospheric hydrodeoxygenation of biomass fast pyrolysis vapor by MoO3. ACS Sustain. Chem. Eng. 2016, 4, 5432–5440. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, G.; Yang, L.; Zheng, L.; Li, F. Cooperative effects between Ni-Mo alloy sites and defective structures over hierarchical Ni-Mo bimetallic catalysts enable the enhanced hydrodeoxygenation activity. ACS Sustain. Chem. Eng. 2021, 9, 11604–11615. [Google Scholar] [CrossRef]

- Wu, Y.; Sun, Y.; Liang, K.; Yang, Z.; Tu, R.; Fan, X.; Cheng, S.; Yu, H.; Jiang, E.; Xu, X. Enhancing hydrodeoxygenation of bio-oil via bimetallic Ni-V catalysts modified by cross-surface migrated-carbon from biochar. ACS Appl. Mater. Interfaces 2021, 13, 21482–21498. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Chen, Z.; Xian, S.; Wu, Y.; Li, M. Sulfur release behavior and sulfur fixation mechanism during biomass microwave co-pyrolysis of Ascophyllum and rice straw. Bioresour. Technol. 2024, 407, 131073. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, J.; Li, H. Critical role of support crystal structures on highly selective hydrodeoxygenation of lignin-derived vanillin over Pd/ZrO2 catalysts. Fuel Process. Technol. 2023, 249, 107844. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).