Abstract

Formation of disinfection byproducts (DBPs) in drinking water treatment (DWT) as a result of pathogen removal has always been an issue of special attention in the preparation of safe water. DBPs are formed by the action of oxidant-disinfectant chemicals, mainly chlorine derivatives (chlorine, hypochlorous acid, chloramines, etc.), that react with natural organic matter (NOM), mainly humic substances. DBPs are usually refractory to oxidation, mainly due to the presence of halogen compounds so that advanced oxidation processes (AOPs) are a recommended option to deal with their removal. In this work, the application of catalytic ozonation processes (with and without the simultaneous presence of radiation), moderately recent AOPs, for the removal of humic substances (NOM), also called DBPs precursors, and DBPs themselves is reviewed. First, a short history about the use of disinfectants in DWT, DBPs formation discovery and alternative oxidants used is presented. Then, sections are dedicated to conventional AOPs applied to remove DBPs and their precursors to finalize with the description of principal research achievements found in the literature about application of catalytic ozonation processes. In this sense, aspects such as operating conditions, reactors used, radiation sources applied in their case, kinetics and mechanisms are reviewed.

1. Introduction

Safety of drinking water has always been a concern for humankind from at least 500 BC when natural materials were used to purify water [1]. However, it was not until the end of the Middle Age when significant steps in the treatment of water were noticed. In fact, the discovery of the microscope at the end of the 16th century was, years later in 1850, the milestone to know the reason of pandemic problems associated to the use of water. With the aid of microscopes the presence of pathogens in drinking water was discovered and the use of disinfectants would become soon later. Specifically, in 1854 chlorine was first used in London to remove bad odors coming from sewers. Although at that time the disinfectant power of chlorine was not yet well known, the role of contaminated water to spread pandemic illnesses had already been confirmed with the cholera epidemic of London [2]. In 1879 chlorine was first used as a disinfectant also for sewage and in 1903 in drinking water treatment plants [3]. Since then, chlorine has been widely used for some other operations in drinking water treatment such as taste and odor removal, keeping safe water distribution systems, biofouling control, and color removal, to cite a few. For more than 70 years, chlorine was used with great success as a water disinfectant. However, water chlorination began to be questioned after the US National Organics Reconnaissance Survey [4] that revealed the presence of halogenated compounds in 80 USA drinking water plants in 1975. This survey was based on previous studies of Rook [5] and Bellar et al. [6] in 1974 sponsored by the United States Environmental Protection Agency (USEPA) that initiated a work on the analysis of contaminants in rivers such as the Mississippi River at New Orleans [7]. In these works, six main halogenated compounds were identified: Four trihalomethanes (CHCl3, CHCl2Br, CHClBr2, and CHBr3), CCl4 and 1,2-dichloroethane [8]. Soon after, many more halogenated compounds, both of volatile and non-volatile nature, were detected in chlorine disinfected water and municipal wastewater secondary effluents. These compounds were not previously present in the untreated waters. For instance, Glaze and Henderson, in 1975, [9] detected in a municipal secondary effluent 39 halogenated compounds of aromatic and aliphatic type with one to at least four chlorine atoms in their molecules to give a total 3 to 4 mg L−1 of Cl. These halogenated compounds took the name of disinfection byproducts (DBPs) and the concern about their possible toxic character prompt the development of four questions and subsequent research lines: Which were the organic precursors of DBPs? what kind of alternative disinfectants could be applied? which different groups of DBPs were formed? and what toxicity these compounds have? A brief description about the findings of these research lines is presented below.

2. Nature of Chlorinated DBPs Precursors

There are multiple and variable natural substances present in surface waters that mainly come from plant degradation and animal wastes. Most of them are constituted by macromolecules containing numerous aromatic and aliphatic structures to which other simpler compounds, both of natural or anthropogenic origin, can be linked such as sugars, amino acids, metals, or pesticides [10,11].

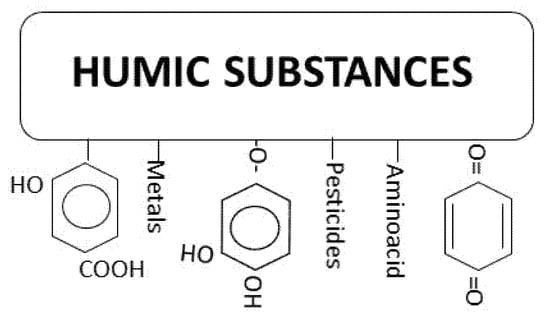

These macromolecules are called humic substances that are mainly formed by three fractions: Humic and fulvic acids and humin [12,13]. Humin is not soluble in water and the acid fractions can be separated after precipitation of humic acid at pH = 1. They are mostly colored from yellow to black and of high molecular weight. Up to 90% of total dissolved organic carbon (DOC) in surface waters is due to humic substances with fulvic acid as the major contributing fraction with about 80%. In surface waters, DOC can reach up to 60 mg L−1 but the usual concentration ranges from 1 to 6 mg L−1 [14]. Figure 1 shows an example of this type of macromolecules where it can be seen the presence of polyphenol structures.

Figure 1.

General structure of humic acids.

These polyphenol structures contain nucleophilic points where electrophilic substances such as chlorine can react. These reactions are responsible of halogenated compounds formation [15]. For instance, the molecule of resorcinol that can be found forming part of some humic macromolecule reacts with chlorine as shown in Scheme 1:

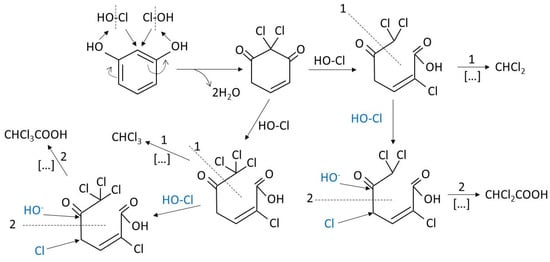

Scheme 1.

Mechanism of halogenated compounds formation from the reaction of hypochlorous acid with resorcinol in water: (Way 1): Volatile Chloroform and dichloroethane and (way 2): Non-volatile dichloro and trichloroacetic acids.

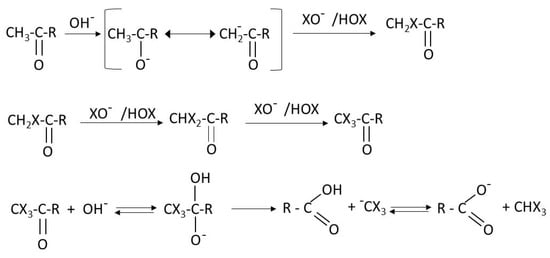

As it is seen from Scheme 1 the electrophilic agent (chlorine or hypochlorous acid) attacks the ortho position in the benzene molecule with respect to both hydroxyl groups. This position is strongly activated by the hydroxyl groups becoming a nucleophilic point. Also, chlorine reacts with simpler molecules such as ketones through the well-known haloform reaction [16] shown in Scheme 2.

Scheme 2.

Reaction of haloform formation (from [16]).

It should be noted that there are other compounds formed during the treatment of water when oxidants or disinfectants (chlorine, ozone, advanced oxidation processes, etc.) are applied. Precursors of these compounds are other pollutants, most of them of anthropogenic origin, such as pesticides, polynuclear aromatics, pharmaceutical compounds, and products of personal care [17,18,19]. These reaction products are also called DBPs because the reactive agent is a disinfectant. In this work, however, only DBPs coming from disinfection of drinking waters originated in reactions of disinfectants with humic and fulvic acids or generally called natural organic matter (NOM) are considered [20].

3. Alternative Disinfectants to Chlorine

The first possible disinfectant agents to be applied in water treatment alternatives to chlorine were ozone ([21]) and UV radiation. Table 1 shows the oxidation potential of main oxidants that can be used in drinking water treatment and their relative value with respect to that of ozone.

Table 1.

Oxidation power of some oxidizing-disinfectants of drinking water 1.

It can be seen that ozone has the highest oxidizing power among these disinfectants and its oxidation potential is 1.39, 1.52, 1.62, and 1.78 times more oxidant than hypochlorous acid, chlorine, chlorine dioxide, and monochloramine, respectively [22]. These values are in accordance with the CT parameter that gives a measure of the disinfectant power. CT is the product of the disinfectant concentration and the detention time [23]. This reaction time is that needed for the 10% of the water flow through the disinfection contactor be in contact with the indicated disinfectant concentration. CT varies with the nature of pathogen, disinfectant, and disinfection level to be reached. Accordingly, the lower the concentration or the detention time the higher the disinfection power. Table 2 shows, as an example, CT values for the four drinking water chemical oxidants to remove from water two logs or 99% of some microorganisms. It can be seen that in all cases ozone presents the lowest CT values with monochloramine as the weakest disinfectant [23]. Below some comments about chlorine alternative oxidant-disinfectants are given with special emphasis on ozonation.

Table 2.

CT values of drinking water disinfectants to inactivate 99% of some pathogens 1.

3.1. Ozone

Ozone, similar to chlorine, was first used as bactericide at the end of the 19th century. The first drinking water treatment plant (DWTP) using ozone as disinfectant was in the small city of Oudshorrn in Holland in 1893. After that, ozone was applied, always for disinfection purposes in other cities, such as Wiesbaden, Germany, in 1901, but the first important city using ozone was Nice, France, in 1906. This plant, called Bon Voyage, has been using this oxidant-disinfectant since then [21]. Application of ozone in DWTP, however, experienced a great boost after trihalomethanes (THMs) discovery in chlorinated drinking water and, also, years later, from 1987, when Glaze et al. defined the advanced oxidation processes (AOPs) after studying the combination of ozone, hydrogen peroxide and UVC radiation to yield hydroxyl free radicals [24]. During the second part of the 20th century most of the fundamentals of ozone chemistry in water had already been uncovered [25]; and consequently, its possible application for water treatment [23]. Ozone can react with DOM through two possible routes: Direct reactions on nucleophilic points or addition reactions on unsaturated moieties (double and triple carbon bonds) that form H2O2:

At high pH it predominates the indirect reaction or reaction with hydroxyl radicals formed in ozone decomposition [26].

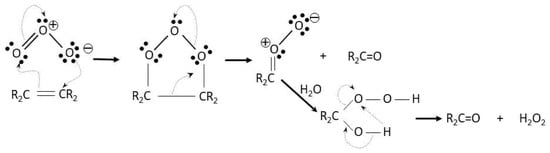

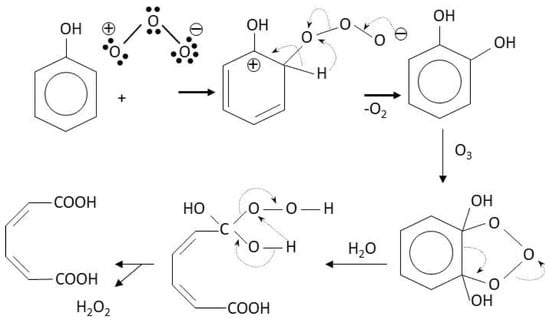

Many ozone reactions with humic substances are of the electrophilic substitution type. These reactions are faster than those with chlorine because the highest oxidizing power and oxidation kinetics of/with ozone [27,28,29]. In Scheme 3 and Scheme 4, the Criegge mechanism, the reaction of ozone with a double carbon bond, and an electrophilic aromatic substitution reaction of ozone with the carbon hydrogen bond in ortho position with respect to the hydroxyl group of a phenol molecule are, respectively, shown [30].

Scheme 3.

Cycloaddition of ozone to a carbon double bond.

Scheme 4.

Electrophilic aromatic substitution reaction of O3 with phenol.

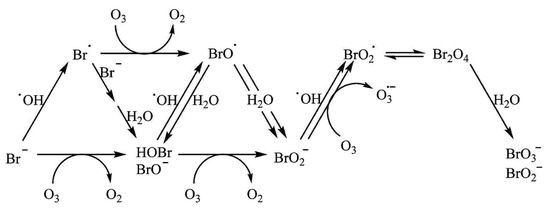

These are selective fast reactions of ozone with unsaturated compounds and nucleophilic points of organics. Furthermore, in these reactions hydrogen peroxide is formed. The reaction of the ionic form of this oxidant with ozone constitutes the main initiation step of hydroxyl radical formation mechanism in ozone involving advanced oxidation processes [27]. Regarding Scheme 4, after hydroxyl substitution in the phenol molecule, aromatic ring breaking is followed due to the cycloaddition of another ozone molecule and, finally, other ozone addition reactions to unsaturated carboxylic acids formed lead to low molecular weight saturated carboxylic acids. These acids, aldehydes and, in some cases, ketones are usually the end products of ozone reactions which are not precursors of halogenated compounds with the exception of some ketones. Then, previous utilization of ozone to chlorination allows significant reduction of trihalomethane formation potential (THMFP) or halogenated compounds formation potential (TOXFP). In case of high alkalinity, hydroxyl radical oxidation takes place to also yield similar byproducts that direct ozone reactions. Another advantage of ozone is its high capacity for being combined with other agents (oxidants, catalysts, and/or radiation) to yield more hydroxyl radicals, what are called ozone AOPs. This has implications even on THMs or TOX removal since ozone alone is not reactive with many halogenated compounds. On the contrary, hydroxyl radicals generated in ozone AOPs can react with THMs or TOX. However, some ozone DBPs can also be harmful, for instance, when water contains bromide ion. In this case, bromoform and hypobromous acid are formed and, eventually, depending on the conditions, bromate ion, an important priority pollutant. Then, the levels of bromide in surface water needs surveillance if ozone is used for THMFP and TOXFP control. Some considerations about bromate control have been specifically reviewed in Section 9. Also, the ozone dose has to be controlled because if added very low, it could increase the precursors concentration due to partial oxidation of first TOX precursors. For instance, water samples containing 1 mg L−1 1,3-cyclohexanedione, a DBP precursor, treated with an ozone dose of 30 mg L−1 during 15 and 30 min and then diluted 100 times and chlorinated (1 mg L−1 Cl2 dose) led to CHCl3 concentrations of 77 and 15 μg L−1, respectively, while without preozonation, CHCl3 formation was 50 μg L−1 [31]. Ozone added at very high dose could form bromoform and other brominated organics such as bromohydrines [32]. In spite of its faster kinetics through two possible routes and high disinfectant and oxidizing power application of ozone also present another drawback: It cannot be used as residual disinfectant and chlorine or another residual disinfectant has to be used at the end of a DWTP. In any case, the residual disinfectant dose needed in a DWTP with a pre-ozonation step is much lower than in a conventional process without pre-ozonation, especially when a biological activated carbon step is placed after ozonation. For example, Langlais et al. [23] reported that chlorine demand was reduced from 4.5 mg L−1 to 3.5 and 2.7 mg L−1 when water from St. Rose treatment plant in Laval (Canada) was treated with rapid sand filtration, rapid sand filtration and ozonation, and rapid sand filtration plus ozonation and biological activated carbon, respectively. The savings in chlorine dose were in some case comparable to the cost of ozonation [23].

3.2. Chlorine Dioxide

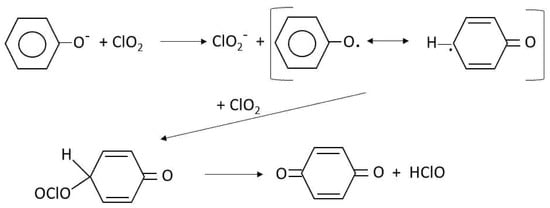

Chlorine dioxide started to be used in DWTP in 1944, that is, much later than chlorine or ozone. The first application of chlorine dioxide in DWTP was for taste and odor control in Niagara Falls, State of New York. Then, it was most commonly used for bleaching in textile industries [21]. Depending on the way of synthesis, concentration and presence or not of chlorine, chlorine dioxide may lead to THMs or TOX formation while reacting with humic substances. Chlorine dioxide when used alone no THMs or TOX is formed but accompanied by chlorine, which could be formed in its preparation method, halogenated compounds can appear in the treated water. In a detailed studied, Rav-Acha [33] already described the main reactions and mechanisms of chlorine dioxide with many organics including humic substances. He concluded that since the main way of chlorine dioxide reaction with these substances is as one electron acceptor, its reactions a more selective and mainly yield quinones, hydroquinones and low molecular weight aldehydes and carboxylic acids. For instance, Scheme 5 shows a proposed mechanism of reaction of chlorine dioxide and phenolate, also a precursor molecule of TOX [33].

Scheme 5.

Reaction of chlorine dioxide and phenol, from [23].

It is shown that the final products are p-benzoquinone and hypochlorous acid but some amount of chlorite is also formed. The presence of hypochlorous acid is likely responsible of TOX formation when precursor molecules are in excess [34]. More information about chlorine dioxide DBPs and toxicity is given in Section 4 and Section 5.

3.3. Chloramines

Chloramines are formed in the reaction of chlorine with amine in a three consecutive steps where mono, di and trichloramine are formed:

For practical cases, it is monochloramine the species used as disinfectant. The way of chloramine formation, from addition of chlorine to amine or vice versa, already present in water or by adding a previously prepared monochloramine solution to the water, highly affects the appearing of chlorinated byproducts because of the free chlorine remaining in the first two cases [35]. However, even in the case of monochloramine solution application to water, hypochlorite (at alkaline pH) or hypochlorous acid (at acid pH) eventually will appear in water due to monochloramine hydrolysis. Then, using monochloramine as disinfectant always leads to chlorinated organics. Monochloramine is the less effective disinfectant and oxidant species among the four reviewed in this work but its capability of forming chlorinated organics is also the lowest. As a consequence, chloramines, depending on the TOXFP of the water, can be recommended as secondary disinfectant for the control of DBPs because their residual disinfectant property. A different question arises when talking about nitrogen containing disinfection byproducts (NDBPs) such as haloacetamides (HAcAm). In this case, chloramination may result in a higher formation potential of these compounds than chlorination.

3.4. UV Disinfection

Although chemical disinfectants are used in DWTPs because of the need of a residual disinfectant and DBPs control, the use of UV disinfection of water is highly extended due to some advantages over chemical oxidants as reported by Song et al. [36]. These advantages are the absence of DBPs, low health risk, easy operation and maintenance, minimum reaction time, and high disinfection power. However, problems associated to UV disinfection arise when treating natural waters containing humic substances. Efficiency of disinfection highly depends on the transparency of water and the presence of colored water due to humics reduces the UV absorption and lower pathogen removal rates. This negative effect could be reduced by increasing the energy dose and lowering the wavelength of emitted radiation but at a higher cost.

3.5. Other Disinfection Processes

Literature also gives examples of water disinfection processes different from the use of chemical oxidants or radiation though some of them are intimately related with them. This happens, for example, with the simultaneous use of radiation and a semiconductor catalyst, that is, photocatalytic oxidation [37]. This process has the attractive possibility of using solar light to excite the catalyst [38,39]. In photocatalytic oxidation, an AOP process, hydroxyl radicals generated can inactivate microorganisms, including viruses, bacteria, spores, and protozoa. However, since hydroxyl radicals are strong oxidants, DBPs similar to those found in ozone processes can be produced and cytotoxicity of catalyst particles requires further studies. Other examples of disinfection processes are based on membranes [40], hydrodynamic cavitation [41], nanoparticles such as in photocatalysis or in membranes [42], or with magnetic materials [43]. However, more work is needed so that these processes can be put into practice.

4. Nature of DBPs from Classical Oxidant-Disinfectants Agents Used in DWTPs

Soon after the uncover of THMs in chlorinated drinking water many works were carried out to ascertain the nature of generated products not only from chlorine but also from the application of the other alternative oxidants commented before. One of the first studies on this matter was carried out by Coleman et al. in 1980 [44] who identified 400 compounds from a chlorinated fulvic acid extract. Among these compounds, polynuclear chlorinated aromatic hydrocarbons and polychlorinated biphenyls represented an important fraction. Also, regarding DBPs of alternative oxidants, Glaze in 1986 [45] published a review on ozonation DBPs, highlighting the formation of hydroperoxidic byproducts, unsaturated aldehydes and hypobromous acid or even permanganate ions, the two later from the oxidation of bromide and manganous ions, respectively. Regarding chlorine dioxide DBPs, at that time, Werdehoff and Singer in 1987 [46] reported some TOX and THMs formation from chlorine dioxide oxidation of humics. They also checked that these chlorinated organic compounds were mainly due to residual chlorine formed accompanying the synthesis of chlorine dioxide. They also reported the formation of chlorite ion as main inorganic byproduct. Throughout these last three decades, a lot of work has been done on DBPs identification [32] and some reviews on this matter have been published [47]. Also, published studies report works not only on DBPs identified from chlorination [48], but also from chloramination [49,50], ozonation [32], and chlorine dioxide NOM oxidation [51,52]. Most of identified DBPs come from water chlorination and mainly involve organochlorine compounds but some treat the presence of brominated (Br-DBPs) and iodinated (I-DBPs) DBPs formed from chlorine, ozone or chlorine dioxide when natural waters contain bromide or iodide, respectively [32,53]. In these works, oxidation of bromide and iodide yields hypobromous and hypoiodous acids, respectively, which in turn oxidize NOM to form Br-DBPs and I-DBPs. Also, from the oxidation of chlorine, ozone or chlorine dioxide, bromite, and iodite are formed that in a fast step are oxidized to bromate and iodate, respectively.

DBPs are classified as regulated (R-DBPs) and non-regulated (NR-DBPs) whether or not some maximum contaminant level (MCL) has been imposed from official government environmental organizations such as USEPA or the European Chemical Agency (ECA), (called standard values in this case). Regulated DBPs are among the most halogen organics identified. These are four out of ten THMs: Those containing chlorine and bromine and five out of nine haloacetic acids (HAAs) (only with chlorine and bromine atoms): Mono, di and trichloroacetic acids and mono and dibromoacetic acids. For total THM, USEPA, and ECA have imposed MCL (or standard values) of 80 and 100 µg L−1, respectively, while for total HAAs, MCL are 60 µg L−1 imposed for both official organisms. Regarding inorganic DBPs, bromate has 10 µg L−1 and chlorite 1000 and 250 µg L−1, also from these organizations, USEPA and ECA, respectively. The rest of the identified DBPs are non-regulated and main family groups are listed in Table 3 with some representative example compound. Many of these DBPs are formed from chlorination but also from chloramination, ozonation and chlorine dioxide application. Richardson et al. [54] in an extensive and detailed review gives numerous examples of DBPs from the oxidation with the four mentioned disinfectants and from sequential oxidations such as ozonation or chlorine dioxide treatment followed by chlorination or chloramination. New DBPs are continuously being identified as Pan et al. [55] did in 2017. These authors reported 13 new polar phenolic chlorinated and brominated DBPs or How et al., also in 2017 [56], about organic chloramines. Literature shows detailed explanations about the formation mechanisms of these DBPs which are out of the scope of this work.

Table 3.

Family groups of unregulated DBPs identified in water during disinfection processes, representative compounds and average detection concentration levels (ADC) 1.

5. Issues Related to DBPs Toxicity

As it was reported in the 1970s the reason for applying alternative disinfectants to chlorine was the potential toxic character of THMs and other halogenated organics found in finished chlorinated drinking water [59]. Specifically, the US National Cancer Institute in 1976 published that chloroform was carcinogenic in rodents [60]. Soon after, epidemiological studies suggested some relation between chlorinated drinking water and the occurrence of bladder, colon, and rectal cancer [61,62]. Since then, many studies on the evaluation of safety and hazard of DBPs have been reported [63]. According to DeMarini [64], at present, 20 out of 22 DBPs are rodent carcinogens, more than 100 genotoxic and 1000 water samples have been found to be mutagenic. It has been shown that brominated DBP are more carcinogenic than the chlorinated ones [54] and genotoxicity and cytotoxicity decrease in the following order for halogenated DBPs: Iodinated > brominated > chlorinated [65]. Generally, every DBP evaluated is genotoxic [64]. Comparing chlorinated and ozonated DBPs, the former are more genotoxic than the latter, at least, with Salmonella [66]. Regarding the way of DBPs exposure, some works [67] have reported higher cancer risk with the inhalation/dermal way than with oral intake. From inhalation or dermal way, volatile DBPs go directly to the blood stream, bypassing the liver, and once in the bladder they can be activated by some mutagen. From oral intake, DBPs go first to the liver where they could be detoxified. This is particularly important in swimming pool water and bath spa water where, in addition, many nitrogen containing DBPs (N-DBPs) have been found likely due to urine present in these waters. N-DBPs like nitrosamines have been found even more cytotoxic and genotoxic than their corresponding halogenated organics [68].

6. The Role of AOPs in the Removal of Precursors and DBPs

Different AOPs have been applied to eliminate NOM or formed DBPs in a refinement stage focused on drinking water production. AOPs are capable to completely mineralize organic contaminants at mild operating conditions of pressure and temperature though the balance between cost and mineralization requirements is a key issue. At moderate conditions, partial oxidation of NOM components into more reactive compounds to form DBPs can occur. In contrast, a very high mineralization is usually expensive and may not be economically feasible. This section reviews some of the main issues concerning the application of different AOPs for NOM and DBPs removal.

6.1. Elimination of Precursors or DBPs Formation Potential

Advanced oxidation processes have been studied for DBPs precursor removal due to their oxidation ability through hydroxyl radical (HO•) fast and non-selective reactions with organic compounds [69,70]. However, research efforts are needed in terms of improved efficiency, development of less expensive installation and operating conditions [70].

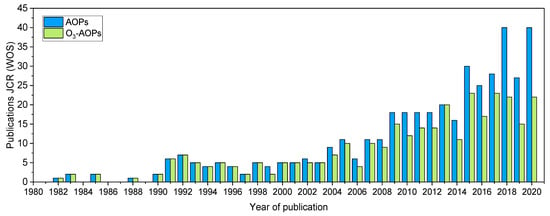

DBP formation potential (DBPFP) represents the level of the formation of different DBPs (or total TOX) in the worst scenario using high excess of disinfectant. This a useful tool to assess the effectiveness of a specific treatment to remove the DBPs precursors, mainly NOM. Since 1980 the number of publications related to AOPs applied to NOM or surrogate removal to reduce DBPFP has progressively increased. The search presented in Figure 2 shows the number of publications in JCR (source WOS) between 1980–2020 and includes different combinations of the keywords: Advanced oxidation, natural organic matter, disinfection by-products, trihalomethanes, haloacetic acids, halonitromethanes, haloketones, haloacetamides, ozone; and their abbreviations, for drinking water treatment.

Figure 2.

Reports in AOPs and ozone-AOPs for DBPFP or NOM removal for drinking water in the last 40 years.

Matilainen and Sillanpää [71] and Sillanpää et al. [70] comprehensively reviewed the application of AOPs for the removal of NOM in the periods between 2006–2009 and 2010–2016, respectively. This section is focused on the abatement DBPs precursors, mainly NOM, highlighting the formation of DBPs and some key factors in the application of AOPs for DBPFP removal without the aim of compiling all the research found. The application of these processes to the elimination of other microcontaminants in surface water such as pharmaceuticals or personal care products without subsequent DBPs analyses are not reviewed here.

6.1.1. Classic Ozonation Processes

The first study published by Glaze et al. [72] was focused on the degradation of natural trihalomethane precursors by O3 and O3/UVC processes in raw waters with high DOC levels. They found that secondary precursors of greater refractivity were produced by ozonation but they could be simultaneously destroyed by UVC combined with ozone. This was due to the formation of high concentration of hydroxyl radicals in the combined process, less selective than ozone, favoring indirect reactions to some extent. Since then, the works in the last two decades of the 20th century have been mainly related to classical ozone based-AOPs, with the main aim of increasing the production of hydroxyl radicals compared to O3 alone, O3/H2O2, O3/UVC, O3/H2O2/UVC and also the process H2O2/UVC [73]. These processes are well established and have been deeply investigated at lab scale, pilot scale and even at full-scale [74]. In general, the oxidation changes the nature of NOM structures into more hydrophilic compounds, being hydrophobic fractions (humic and fulvic structures) the main responsible for THMs and trihaloacetic acid formation, whereas the more hydrophilic ones are related to dichloroacetic acid generation and the formation of higher concentration of brominated DBPs [75,76,77]. In this line, even with the highest THMs and HAAs formation potential removal by combined O3/UV treatment, bromine-containing DBPs present increased toxicity being the conditions between oxidant and UV dose crucial to minimize the risks [78]. Also, the particular characteristics of the NOM play a key role in the suitability of a specific treatment [70,79].

In addition to the classical ozonation and ozone-AOPs, homogeneous and heterogeneous catalytic treatments such as Fenton-related, photocatalytic oxidation or persulfate processes, have been studied for NOM or surrogates elimination in drinking water [69,70,71].

6.1.2. Fenton Related Processes

Fenton reaction involves the combination of hydrogen peroxide and a metal salt or oxide catalyst, commonly iron, to produce hydroxyl radicals responsible for NOM oxidation and mineralization through the following main reactions:

The presence of radiation in photo-Fenton process accelerates the reduction of Fe3+ improving the yield of HO• generation:

Murray and Parsons [80] studied the elimination of NOM through Fenton and photo-Fenton using UVC as radiation source. They found that the three treatments at optimum conditions reached 90% removal of DOC (DOC0 = 7.5 mg L−1), dropping THMFP from 140 to below 10 µg L−1. The economic assessment disfavored these processes compared to conventional treatments but neither the use of a different radiation source nor the possibility of a more restrictive regulation (not only THMs), were considered. In this line, Moncayo-Lasso et al. [81] treated surface water by solar photo-Fenton in a CPC reactor (compound parabolic collector) using natural sunlight. They demonstrated the performance of the process to mineralize up to 80% of NOM (TOC0 = 7.44–7.81 and 4.12–5.02 mg L−1) from surface water containing dissolved iron or with Fe2+ supplement at pH = 5. They found a beneficial effect of photoactive natural components present in the natural water on the process leading to a more efficient mineralization than using dihydroxy-benzene as a model compound. Unfortunately, the DBPFP before and after chlorine disinfection was not analyzed in this work either the formation of other oxidation by-products. Moncayo-Lasso et al. [82] also studied the photo-Fenton process using simulated solar radiation to eliminate NOM at pH = 6.5, which introduces an advantage with respect to Fenton related treatments usually carried out at pH near 3. They used Fe3+ at low concentration for the treatment of surface water with TOC0 = 7.1 mg L−1, demonstrating the effectiveness of the system for the transformation and partial mineralization of NOM previously treated with a sand filter system. The THMFP dropped from 160 to 20 µg L−1 at the optimum conditions. However, the transformation of NOM can lead to different DBPs precursors that have not been considered in these works.

6.1.3. Photocatalytic Oxidation

Heterogeneous photocatalysis based in the interaction of a semiconductor, mainly TiO2, with radiation to produce reactive oxidizing species (ROS) is a complex mechanism that can be generally described by the following reactions:

where organic molecules can react both in the catalyst surface with photogenerated holes (h+) or in the liquid phase with hydroxyl radicals or other ROS.

Photocatalytic oxidation using suspended TiO2 for NOM removal has been studied by different authors. Lee and Ohgaki [83] observed an initial increase in THMFP at short treatment times with the system TiO2/UVC and different surface waters with DOC0 = 1.1–3.5 mg L−1. This effect has been subsequently observed by different authors with different surface waters using TiO2/UVA [84,85]), TiO2/UVC [86] and even TiO2/solar radiation [87]; concluding, in general, that sufficient radiation doses are needed to achieve the desired elimination, depending on raw water characteristics, and an initial negative impact of photocatalysis on DBPFP is expected at low UV doses.

Apart from suspended TiO2, Murray and Parsons [88] studied different supported TiO2 demonstrating that can be effective combined with UVC for NOM removal. Later, Murray et al. [89] studied pelletized TiO2 to adsorb NOM from different surface waters (DOC0 = 17.0–5.4 mg L−1) at bench scale and then used UVC to regenerate the TiO2 pellets by oxidation. They observed a reduction of DOC concentration of source water by 70% with the subsequent THMFP reduction in a multistage process. Also Kent et al. [90] compared the efficiency of suspended and fixed TiO2 using nanostructured thin films and UVC with river water (DOC0 = 5.34 mg L−1). No complete DOC elimination was reached but they obtained removals of total trihalomethane formation potential (TTHMFP) and total haloacetic acid formation potential (THAAFP) of approximately 20% and 90%, respectively, being fixed TiO2 configuration less effective than suspended TiO2.

6.1.4. Sulfate-Radical Processes

Sulfate radical-based AOPs are based on the generation of SO4•− radicals from persulfate (PS) or peroxymonosulfate (PMS) activation by temperature, metal ions, solid catalysts, radiation, ultrasound, etc. For NOM removal and DBPFP reduction, mainly homogeneous metal ions or UV activation have been used:

Lu et al. [91] studied the system Co2+-PMS and reported the NOM reconfiguration upon exposure to sulfate radicals with a great increase in the DBPFP, concretely chloroform, trichloroacetic acid, and dichloroacetic acid. Also, the formation of reactive bromine species through SO4•− and Br− reaction was demonstrated.

Hua et al. [92] studied the DBP alteration from NOM and model compounds after UV/PS treatment and subsequent chlorination. They found that the yields of THMs and dichloroacetonitrile (DCAN) from NOM decreased by 50% and 54%, respectively, after UV/PS followed with chlorination, whereas those of chloral hydrate (CH), 1,1,1-trichloropropanone and trichloronitromethane (TCNM) increased by 217%, 136%, and 153%, respectively. They demonstrated the impact of different structures of the precursors on DBP formation through different surrogates (benzoic acid, resorcinol or methylamines). Wang et al. [93] also studied Br-DBPs during UV/PS oxidation demonstrating the potential negative effects of Br− on sulfate radical-AOPs, which need to be considered if this technology is applied in practice. In the same line, Wang et al. [94] studied the formation of iodinated DBPs during heat activated PS using phenol as model compound in the presence of iodide. They concluded that I− was transformed into free iodine leading to iodinated DBPs that can further be degraded by additional SO4•− and transformed to iodate. All these works highlight the crucial impact of sulfate radicals in the presence of bromide, iodide or chloride.

6.1.5. Chlorine/UV Process

The combination of chlorine/UV has been recently studied for NOM degradation. With radiation of sufficient energy, the photolysis of hypochlorous acid and hypochlorite can lead to hydroxyl and chlorine radicals as follows:

Pisarenko et al. [95] investigated the generation of DBPs during NOM degradation by combination of chlorine (electrochemically generated or from hypochlorite solution) with UVC and UVA radiation. They found that Cl• and HO• radicals generated oxidized NOM from river water (DOC0 = 2.6 mg L−1) and different surrogates (o-methoxybenzoic acid and 4,6-dioxoheptanoic acid) increasing HAA formation but with no negative impact on THM formation. UVC resulted in lower overall DBP formation than UVA. Also, Wang et al. [96] studied the process at pilot scale with river water (DOC0 = 1.5–3.5 mg L−1). They concluded that the treatment was effective and the DBPs formed were comparable to that from H2O2/UV also tested. The main drawback was the formation of chlorate during the treatment up to 17% of the total chlorine used. Liu et al. [97] reported the formation of DBPs in the system chlorine-chloramine/UVC. They found that the mass ratio of HOCl to NH2Cl played a key role in the control of DBPs formation and that the presence of Br− increased DBPFP but it can be reduced with higher radiation doses (Br− transformed to bromate).

6.1.6. Electrochemical AOPs

Electrochemical AOPs (EAOPs) have been mainly applied for wastewater more than for drinking water treatment due to technical and economic aspects [98]. Trellu et al. [99] studied the removal of humic acids from drinking water by anodic oxidation and electro-Fenton processes. They concluded that EAOPs are promising processes for the production of high quality organic-free water, particularly when BDD anode is used but no disinfection by-products were analyzed. Mao et al. [100] compared conventional ozonation with electro-peroxone (E-peroxone, E-H2O2/O3) in the removal of NOM (DOC0 = 3.2 mg L−1). They found that E-peroxone was less efficient at reducing chlorination DBPs. However, the formation of bromate was significantly reduced in the combined treatment. More research is needed in these processes and their combinations to boost the application in real conditions.

6.1.7. Some Considerations on AOPs for DBPFP Removal

Many studies have determined that the application of AOPs operating with limited energy or chemical inputs can lead to an increase in the DBPFP as compiled Mayer et al. [101]. Therefore, intensified treatments with high enough oxidant concentration or exposure time are required. In this scenario, the effectiveness of ozone-based AOPs for DBPFP depletion for drinking water treatment has led to the investigation of other catalytic and photocatalytic ozone treatments with the aim of improving the use of ozone. These processes are deeply reviewed in Section 7 and Section 8.

6.2. DBPs Removal

Although DBPs can be controlled through removing NOM in the drinking water treatment process, it is not only difficult to remove NOM completely, but DBPs are inevitably produced when the remaining chlorine is released to rivers and reacts with NOM. Because of variability in DBPs characteristics, complete elimination from drinking water by single technique is impossible. A quick search in database Scopus with key words “disinfection by-products removal AND oxidation processes” give more than two hundred entries.

6.2.1. Ozone Based Processes

Ozone-based processes, other than catalytic/photocatytic ozonation, have been used for removing DBPs from water supplies. As it can be inferred from Table 4, N-nitrosamines and chloroacetic acids (CAAs) are the main disinfection by-products investigated. N-nitrosamines are highly toxic disinfection by-products formed in drinking water treatment process. More than 80% of N-nitrosamines are carcinogenic, teratogenic and mutagenic. USEPA has classified N-nitrosodimethylamine (NDMA) as a probable human carcinogen [102]. N-nitrosamines cannot be sufficiently removed during conventional water and wastewater treatment processes and could permeate through reverse osmosis (RO) membrane filtration in water reclamation systems. In this sense, NDMA degradation by ozone-based AOPs has been investigated. However, these works indicated that conventional ozonation had very limited effect on NDMA oxidation [102]. Zhang et al. [102] found that, compared with UV irradiation, ozone was less effective for the abatement of N-nitrosamines. Less than 20% of N-nitrosamines were oxidized after ozonation. However, when 2 mg L−1 of H2O2 was added into ozonation system, the degradation efficiencies of N-nitrosamines were significantly improved. Xu et al. [103] investigated the removal efficiency of NDMA using UV/O3 and evaluated the ability of UV/O3 to diminish the regeneration of NDMA after degradation. It was showed that 99% NDMA removal was achieved both in UV and UV/O3 system, while the oxidized fraction of NDMA was only 10% at pH = 6 by ozone alone ([O3]0 = 6.6 mg L−1 (0.14 mM), [NDMA]0 = 0.1 mM). The introduction of ozone during the UV process had little influence on NDMA removal, but had a large impact on NDMA degradation products. Lee et al. [104] compared the efficiency of conventional ozonation and the AOP (O3/H2O2) for NDMA oxidation. The degradation effectiveness of NDMA was only 13% ([NDMA]0 = 1 mM) at pH = 7 and 12 min contact time, by 40 mM ozone alone. In contrast, 85% of NDMA was removed by the AOP (O3/H2O2, [O3]0 = 40 mM, [O3]0/[H2O2]0 = 2) under the same reaction conditions. It appeared that the reaction with HO• radicals dominated NDMA ozonation, and methylamine (MA) was the primary amino product of this NDMA oxidation. In this sense, Lv et al. [105] investigated the degradation of NDMA by ozonation. The effects of initial NDMA concentration (50–800 ng L−1), ozone dosage (0.02–0.2 mM), and pH (5–8) were studied in detail in the context of NDMA degradation. The amount of removed NDMA increased as the initial NDMA concentration rose ([O3]0 = 4.8 mg L−1, pH = 7.6). Higher ozone dosage ([NDMA]0 = 400 ng L−1, pH = 7.6) and pH enhanced removal efficiency. Increasing pH was favorable for NDMA oxidation ([O3]0 = 0.1 mM, [NDMA]0 = 400 ng L−1). Inhibition of NDMA degradation was observed when a hydroxyl radical scavenger, t-butanol, was added during the ozonation process. Hydroxyl radicals generated from ozone played a critical role in the degradation of NDMA.

Table 4.

Works on DBPs removal by ozone-based processes.

On the other hand, it is well known that CAAs are widely present in water treated by chlorination processes and are resistant against ozonation in the darkness. The results obtained by Hama Aziz [106] showed that single ozonation was an inefficient method for the destruction of the CAAs as only about 2% degradation was observed after 90 min treatment (pH = 3). However, increasing the pH of the solution to 11 showed a dramatic improvement in the degradation efficiency. The fast decomposition of ozone molecule in alkaline solution (pH > 9) to generate powerful and non-selective hydroxyl radicals resulted in efficient degradation of organic pollutants. The addition of hydrogen peroxide to ozonation process, also improved monochloroacetic acid (MCA) and dichloroacetic acid (DCA) degradation. Lovato et al. [107] studied DCA decomposition in aqueous media employing ozone and UVC radiation. The influence of various parameters, such as pollutant initial concentration (20–50 mg L−1), radiation photon fluency rate at the reactor window and ozone dissolved concentration (1.46 to 2.1 × 10−7 mol cm−3) was studied. Oozne or UVC by themselves did not result in appreciable decomposition of DCA within the studied reaction time (180 min). Conversely, the O3/UV combination can be considered a suitable process for degrading DCA in water. Also, the combination of ozone and UVC radiation produces a significant amount of hydrogen peroxide as an important reaction by-product. Finally, Wang et al. [108] studied the decomposition of DCA and trichloroacetic acid (TCA) from water by means of single oxidants: Ozone, UV radiation; and by the AOPs constituted by combinations of O3/UV radiation, O3/H2O2, O3/H2O2/UV radiation. Single O3 or UV did not result in perceptible decomposition of HAAs within the applied reaction time (30 min). O3/UV showed to be more suitable for the decomposition of DCA and TCA in water among the methods of oxidation tested.

6.2.2. Ozone Free Processes

Regarding other than classic ozonation treatments [109], Table 5 shows the most illustrative works dealing with advanced oxidation systems used for removal of DBPs in water supplies in the last 25 years.

Table 5.

Works on DBPs removal by ozone free processes.

As it can be seen from Table 5 among the various harmful DBPs removed from water supplies, HAAs are the most investigated. As it is known, they are the second most important DBPs after THMs and are highly stable and non-volatile compounds. Trichloroacetic acid (TCA) and dichloroacetic acid (DCA), the two main fractions of HAAs, are important because of their potential risks to human, aquatic, and plant life. Thus, realizing the danger of chloroacetic acids, different advanced oxidation techniques or electrochemical methods are proposed to eliminate them from water. A great deal of effort has been devoted to HAAs removal by biological activated carbon (BAC) processes. However, it has generally been found that while mono- and di-HAAs are relatively easily biodegradable, tri-HAAs are recalcitrant to biodegradation [121].

The breaking of C-Cl bond can result in the degradation of chloroacetic acids. TCA and degradation by-products can be reductively removed by zero valent iron (ZVI) or bimetallic particles. Reduction of HAAs through dehalogenation by using zero valent iron (Fe0) or other element-doped Fe0 (such as the bimetallic Pd/Fe, Cu/Fe and Si/Fe) have been reported [134]. In contrast to the order of HAAs biodegradability, the susceptibility of HAAs to Fe0 reduction normally follows the order of tri-HAAs, di-HAAs, and lastly mono-HAAs. Di- and mono-HAAs were usually observed as the dehalogenation intermediates or end-products [121]. However, the potential release of metal ions affects water quality, leading to secondary pollution in long term. Electrochemical reductive dechlorination is efficient for TCA, and the stepwise dechlorination from TCA and DCA to MCA is achieved [126]. Because the degradation of TCA, DCA, or MCA strictly depends on current density, electrodes are easily corroded by high current in this electrochemical process. To increase the degradation efficiency of TCA and simultaneously protect the electrodes, Esclapez et al. [123] have developed a hybrid sonoelectrochemical process at a low current density and obtained satisfying dechlorination efficiency. Summarily, the break of C-Cl bond is an efficient degradation channel for TCA in ultrasonic (and sono-photolytic degradation [133]) or electrochemical or special reductive reagents reaction, and Cl−, DCA, MCA and CO2 are the major by-products in aqueous solution [116].

In addition, the breakage of C-C bond can also produce the removal of chloroacetic acids. In this sense, decomposition of mono-, di-, and trichloroacetic acid in aqueous titania suspensions was studied by several researchers [111]. It has been concluded that two types of reactions may be responsible for the TiO2-mediated photodegradation of chloroacetic acids: (1) Direct reactions between the photogenerated charge carriers and the organic molecules and (2) reactions of hydroxyl radicals or other oxygen containing radicals with the organic molecules [125]. MCA and DCA are readily decomposed over UV-irradiated TiO2 catalyst in aqueous media to form CO2 and HCl. On the other hand, using bare TiO2, TCA is degraded with a very low efficiency [111]. TCA has no C–H bond, and such a molecule has been found to be hardly reactive in TiO2-based photocatalytic systems. For that reason, an efficient Fenton assisted TiO2 photocatalytic hybrid process have developed [116,118]. These works report that exists a noticeable synergetic effect dominantly caused by the oxidation– reduction recycling reaction of Fe3+ ↔ Fe2+ between Fenton and TiO2 photocatalytic oxidation. Also, an AOP based on combination of Ferrate with UV illumination was investigated in terms of kinetics, by-products analysis and application of surface methodology for degradation of CAAs [114].

On the other hand, the most significant group of DBPs formed during chlorination is THMs. Compounds of this group: Chloroform, bromodichloromethane, chlorodibromomethane, and bromoform, were recognized as potential human or animal carcinogens [119], as detailed before. AOPs are promising techniques to efficiently and effectively convert these compounds into better biodegradable or less harmful substances. Several types of AOPs have been developed using Fenton Reagent [129], photo-Fenton process [113], UV/ZnO nanocatalyst/H2O2 [119], photocatalysis with titanium dioxide [86], ultrasonic degradation [127,128,129,130], and sonophotolytic process [120].

Finally, from Table 5, it can be concluded that major ozone-free processes tested for DBPs removal have been photocatalysis and sonodegradation/sonophotolytic degradation. From an applied point of view, Gerrity et al. [86] studied different scenarios using a pilot-scale TiO2 photocatalysis reactor. DBPs may form in clear wells prior to distribution that could also be destroyed before the water is released into the distribution system. Since photocatalysis will destroy a chlorine residual, the water would have to be rechlorinated prior to discharge. The authors concluded that when focusing on photocatalytic destruction of DBPs rather than precursors and formation potential, several problems still exist. Optimization of this process should be considered in future studies to address some relatively high energy requirements and the need of rechlorination. In general, this technology has a number of promising aspects but should be considered on a case-by-case basis. Regarding to the high-frequency sonoelectrochemical methods for DPBs mitigation have been applied in a laboratory scale, Esclapez et al. [123] claim that the use of the electricity as unique reactant and the mineralization of the trichloroacetic acids and its by-products make the sonoelectrochemical technology a serious alternative to current technologies.

7. Elimination of DBP Precursors by Catalytic Ozonation Processes

In this section after description of some features about proposed mechanisms of catalytic ozonation, literature about removal of DBP precursors or what is called DPBFP is reviewed.

7.1. Catalytic Ozonation

Several strategies have been proposed to efficiently increase the generation of hydroxyl radicals during ozonation favoring indirect reactions. Many groups have started to investigate a new ozone advanced oxidation process named catalytic ozonation, that is, the simultaneous use of ozone and substances (catalysts) that activate its decomposition to increase the formation of hydroxyl radicals and also to increase not only the removal of pollutants from water but also the mineralization of the total organic carbon content [137]. Catalytic ozonation was starting, in fact, in the middle of 20th century, in 1949, with the use of soluble catalysts, that is, with metal cations such as Co2+ [138]. However, this kind of process was not feasible from health and environmental aspects since these catalysts, as heavy metals, are contaminants. Hence, studies were oriented to the use of solid materials of different nature, what it is called heterogeneous catalytic ozonation. It has to be highlighted; however, that also what is called homogeneous catalytic ozonation is a heterogeneous process since gaseous ozone is transferred to the water to react. Then, the catalytic ozonation process where the catalyst is a solid was named the heterogeneous catalytic ozonation process. According to WOS database in the last 10 years about 400 publications have been reported in literature about heterogeneous catalytic ozonation. Three main families of catalyst types have mainly been used since then: Metal oxide catalysts, carbonaceous materials and ceramic materials [139]. More recently, however, a new type of potential catalyst has appeared: Metal based organic frameworks (MOFs) of high specific surface area and tunable pore structure [140,141]. In addition to this number of publications some review works [142,143,144,145] have also appeared highlighting the main aspects concerning this process.

As a summary, it can be said that works already published deal with synthesis and characterization of catalysts, application of the new catalyst to remove some given organics taken as model compounds, mechanism of the process, a few of them study the kinetics and some also give data on toxicity, activity, and stability of the catalysts. In addition to the diversity of results obtained which is the consequence of the different methodologies, equipment, analytical procedures, etc., applied, the most relevant fact is the high variation in the reaction mechanism proposed which is also due to the variability of methods of catalyst preparation, analytical techniques, etc., and the lack of knowledge about catalyst stability, by-products formed and ecotoxicity. In fact, the mechanism of catalytic ozonation can be due to direct reactions of ozone or to reactions of hydroxyl radicals coming from the decomposition of ozone on the catalyst surface. Usually, it is expected that the mechanisms of catalytic ozonation fulfilled some of the following requirements:

- Ozone adsorbed on the surface of the catalysts is decomposed into reactive species.

- Organic molecules are adsorbed on the surface of the catalysts with subsequent ozone attacks.

- Both ozone and organic molecules are adsorbed on the catalyst surface and surface reactions take place.

Steps of these mechanisms follow the well-known LHHW or ER mechanisms [146]. These mechanisms, as indicated above, may imply both the formation of hydroxyl radicals or direct reactions between adsorbed ozone and target compounds. For instance, Liu et al. [147] proposed the following simple mechanism for the catalytic ozonation of nitrobenzene with a Zn/SiO2 catalyst:

where it is seen that hydroxyl radicals are formed as adsorbed species, then they are release to water bulk to oxidize the organic compound. On the contrary, Andreozzi et al. [148] for the catalytic ozonation of oxalic acid with a manganese oxide catalyst reported the adsorption of the target compound (oxalic acid) to form a manganese oxalate complex that then reacts with dissolved ozone, that is, as a surface direct reaction:

Other examples of catalytic ozonation mechanisms have been reported with hydroxyl radicals or ozone (adsorbed or in solution) as main oxidants. Martins and Quinta-Ferreira [149] proposed the following LHHW mechanism for the Mn-Ce-O catalytic ozonation of phenolic acids:

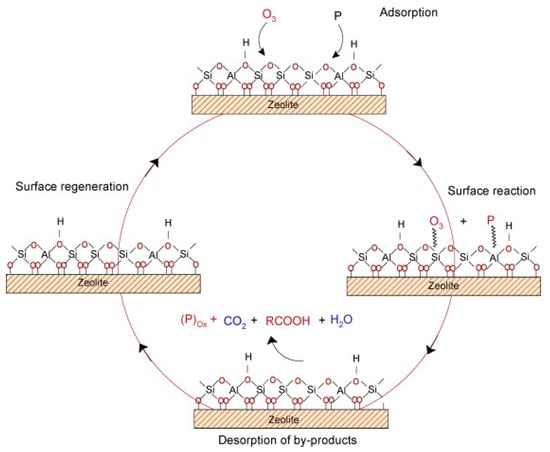

Mechanism proposals are not limited to metal oxide catalysts. For example, Ikhlaq et al. [150] studied the catalytic ozonation of some pharmaceuticals, volatile organic compounds and carboxylic acids with a ZSM-5 zeolite constituted by xSiO2/yAl2O3. They proposed a LHHW mechanism as shown in Scheme 6 where ozonation also goes through a direct surface reaction between ozone and organic adsorbed species.

Scheme 6.

Mechanism of catalytic ozonation over zeolite ZSM-5 [150] (Reprinted with permission of Appl. Catal. B: Environ, 154-155, Ikhlaq, A.; Brown, D.R.; Kasprzyk-Hordern, B., Catalytic ozonation for the removal of organic contaminants in water on ZSM-5 zeolites, pg110-122. Copyright (2014), with permission from Elsevier).

On the opposite side, Zao et al. [151] reported a hydroxyl radical formation and reaction when using a cordierite material (2MgO-2Al2O3-5SiO2) to catalyze the ozonation of nitrobenzene:

The authors confirmed the presence of hydroxyl radicals with the Spin trapping/EPR technique.

Many examples are also given in literature on the use of carbonaceous materials such as activated carbon, multi-walled carbon nanotubes, xerogels, and graphene oxide [152,153,154,155,156] where these materials were used as main catalyst or as support of metal oxides. Again, discrepancies are observed in the mechanism proposed. Thus, some authors have reported that some functional groups of the catalyst surface can be modified by ozone, by enhancing the specific surface area, and decreasing the total volume of the catalyst [157]. However, some others showed that, once the modified carbon was ozonated, its specific surface area was slightly diminished, and the total volume of the pores remained unchanged [158]. Another important issue is the in situ regeneration of the catalyst, or the predominance of catalytic properties and adsorption–oxidation processes in the catalytic ozonation process [157]. Other works have indicated that ozonation reduces the catalytic properties of activated carbon due to a decrease of basic groups and an increase in the number of oxygenated surface functional groups such as hydroxyl and carboxylic acid groups and nitro aromatic compounds [159].

Most of the research works have been carried out with the objective of wastewater treatment and with different organic pollutants such as dyes, pharmaceuticals, personal care products or model molecules such as oxalic and phenol. Regarding to DBP precursors or NOM removal, Table 6 summarizes the main results of reports on catalytic ozonation for drinking water highlighting those in which DBPs are analyzed.

Table 6.

Works on catalytic ozonation of DBPs precursors.

7.1.1. Catalysts

The main catalytic materials used for NOM or humic/fulvic acids removal were metal oxides, ceramic materials, and carbonaceous materials and the properties more frequently analyzed were composition (by XRD, XRF, or ICP), textural properties by N2 adsorption-desorption, pHpzc, and crystallinity by XRD. Some studies have also reported surface composition by XPS or FTIR.

Among metal oxides, titanium dioxide, TiO2 has been used both in slurry reactors in the form of suspended nanoparticles (mainly the commercial TiO2 P25) or supported in different materials. The characterization of powder TiO2 P25 has been widely studied and the main features were 50 m2 g−1 BET surface area, anatase/rutile ratio 80/20, crystallite size 21 nm and pHpzc = 6.7 [167]. These studies [175] probed that at the conditions used, no improvement was observed in THMFP removal from surface water compared to ozonation, but less brominated species were formed in catalytic ozonation. On the contrary, in another work [173], with higher catalyst loading but synthetic humic acid solution, a positive effect in the THMFP removal of water treated by catalytic ozonation was observed. The catalyst loading and the composition of NOM may play a key role in the process (more information in Section 7.1.3 and Section 7.1.4).

TiO2 has also been used supported onto different materials, mainly Al2O3, clays, and zeolites. Many of these supports have also catalytic activity for ozone decomposition [143]. For the first time, Allemane et al. [187] studied TiO2/Al2O3 combined with ozone for the degradation of fulvic acid and, at high O3 doses, the catalytic activity was demonstrated but no DBPs were analyzed. In the same line, Volk et al. [186] observed higher mineralization of fulvic acid using TiO2/Al2O3 than ozone alone with a decrease in the chlorine demand of the treated water though no DBPs were detected. No characterization studies were reported here. On the contrary, Gracia et al. [184,185] compared the catalytic activity of TiO2 supported on Al2O3, attapulgyte (a clay) and silica gel for the degradation of NOM. The best results in terms of mineralization of precursors were obtained with the TiO2/Al2O3 catalyst whose main characteristics can be observed in Table 6, highlighting again the importance of adsorption mainly related with the role of Al2O3, BET surface area, pHpzc of the solid, characteristics of NOM and pH of the solution. Only the works reported by Chen et al. [177] and Chen and Wang [170], using the same experimental set up, checked the efficiency of TiO2/Al2O3 in the DBPs formation potential elimination from surface water, obtaining a significant reduction up to 50% of THMFP and HAAFP in the water treated by catalytic ozonation at the conditions tested (see Table 6).

Different iron oxides/hydroxides have been studied for catalytic ozonation mainly bare FeOOH, Fe2O3 and Fe3O4 or supported in different materials [143]. α-FeOOH-goethite has been used in other studies that reported SBET 60–97 m2 g−1 and pHpzc near 7. The properties of this material for catalytic ozonation have also been deeply discussed in Bai et al. [188]. In general, a higher efficiency in NOM mineralization was observed by catalytic ozonation compared to ozone alone. Only Wang et al. [171] analyzed post-chlorination DBPs in treated surface water and observed that THMs and HAAs were highly reduced by catalytic ozonation (combined with biofiltration).

Regarding the supported Fe-catalysts, Karnik et al. [181,182] used Fe2O3 over a ceramic membrane composed by Al2O3/ZrO2/TiO2 (no characterization reported) in the hybrid catalytic ozonation/ultrafiltration system and studied the decomposition of ozone in the membrane surface, obtaining a high removal of THMFP and HAAFP (higher than 85%) from surface water at the conditions shown in Table 6. Other authors supported FeOOH or Fe2O3 species over zeolite [163] or natural pumice [161] and observed an important catalytic effect of these materials in the degradation of synthetic humic acid solutions but no DBPs were analyzed in their works.

Other metal oxides and composite materials have been tested as catalysts. Turkay et al. [164,168] checked the effectiveness of CuO and ZnO nanoparticles with high crystallinity in the degradation of humic acid and NOM from surface water studying the possible mechanism by DFT modelling but no DBPs analyses. Wang et al. [166,178] studied the performance of RuO2 supported onto activated carbon, Al2O3 and ZrO2-CeO2 using oxalic acid, dimethyl phthalate as target compounds and also NOM from surface water. They fully characterized the catalysts (see Table 6) with main differences between SBET in AC supported catalyst. All the systems showed a high catalytic activity and improved ozonation results. THM precursors reacted fast with ozone alone but the THMFP and HAAFP were highly reduced in catalytic ozonation. Some aspects about the activity and stability of these catalytic systems are commented in the next sections.

Different manganese materials also showed catalytic activity for ozonation of NOM or humic and fulvic acids. Alsheyab and Muñoz [180] studied MnO2 and at the conditions tested TOC removal improved from 67% in single ozonation to 79% in catalytic ozonation (pH = 8.9). No characterization and no DBPs studies were reported. Recently, Salla et al. [160] tested Mn2O3 as catalyst for humic acid ozonation that resulted in rapid ozone decomposition, neither DBPs were studied. Only Chen and Wang [170] prepared a mixed Fe-Mn oxide (8.17% Mn) with high surface area (262 m2 g−1) for NOM removal and reduced THMs and nine HAA up to 70 and 75% respectively.

Cerium oxide have been used as support but also presented catalytic activity for the process. Zhang et al. [179] synthetized CeO2 with pHpzc = 6.6 and high SBET = 117 m2 g−1. The elimination of DOC from surface water was between 30–50% of different NOM fractions compared to 3–6% obtained in ozonation alone. On the contrary, a similar CeO2 material was tested by Wang et al. [165] that found that their adsorption capacity exerted a negative effect in mineralization (lower than ozonation alone). Later, Zhang and Wang [162] synthetized different CeO2-TiO2 composites and studied the Ce/Ti ratio effect. They found that CeO2 main phase was cubic fluorite and the positive effect of Ce content by increasing BET surface area because of lower crystallite sizes. An optimum Ce/Ti ratio of 0.8 was found due to the high surface area (expected) and low pHpzc that improved adsorption properties and lead to lower molecular weight organics from humic acid degradation. Unfortunately, no post-chlorination DBPs were analyzed.

Regarding the use of carbonaceous materials as catalysts, though they have been widely used in catalytic ozonation of different organic pollutants, a few studies have been found for humic acid and NOM removal with post-chlorination and DBPs analyses. Shioyama et al. [183] combined powder activated carbon with membrane filtration for surface water treatment, which improved the performance of the subsequent membrane system reducing DOC up to 59% and T-THMFP up to 75%. Gümüs and Akbal [163] also studied the degradation of humic acid with granular activated carbon reaching 48% compared to 21% in ozonation alone though no DBPs were analyzed.

7.1.2. Catalytic Activity, Stability, and Reusability

No straightforward conclusions can be reached about the catalytic activity of the different catalysts checked at different operating conditions. However, some of the previous reported studies in Table 6 compare different materials that can differ in the active phase or the support.

Allemane et al. [187] and Gracia et al. [184,185] compared different TiO2 catalytic systems. In their work, the relevance of the support was pointed out, being Al2O3 the best option that increased adsorption of NOM. The latter works also studied the stability of the TiO2/Al2O3 catalysts in four reaction cycles of NOM catalytic ozonation at the operating conditions in Table 6. A good stability was maintained with similar TOC, UV254, and pH results after the four experiments.

Chen and Wang [170] compared the behavior of TiO2/Al2O3 and a Fe-Mn oxide in the degradation of NOM and DBPFP of surface water. Fe-Mn presented the best performance in O3 decomposition, DOC, UV254, and DBPFP removals. This was attributed to the catalytic activity of Fe and Mn species and to the highest specific surface area of this catalyst which improved the adsorption of NOM.

Also, the series of Wang et al. [166] demonstrated the importance of the support in RuO2 supported catalysts. RuO2/ZrO2-CeO2 resulted highly efficient compared to Al2O3 or AC as support, although a high adsorption capacity can also mask mineralization results. HAAFPs improved from 38–57% and THMFPs from 50–64% when comparing catalytic ozonation and ozonation, but O3 alone reacts fast with THMs precursors. The best performance is ascribed to the efficiency of the redox Ce4+/Ce3+ couple in the material which enhances the catalytic activity of very well dispersed Ru species. This catalyst was also more stable in continuous operation (only 48 h were checked with no Ru leaching).

The three works by Turkay et al. [164,167] have been performed using the same experimental set up and with quasi-similar operating conditions but with different catalysts. They studied the catalytic behavior of CuO, TiO2 and ZnO nanopowders, respectively. All the materials presented an improved DOC removal (from humic acid with the same concentration and pH) which increased from 30% for ozone alone to 80% for CuO, 70% TiO2 and 60% ZnO. Thus, CuO seems the most active catalytic system but, in terms of stability, although not studied, probably TiO2 is a better candidate for future works since Zn and Cu ions are easily leachable.

On the other hand, Wang et al. [165] compared the catalytic activity of FeOOH, CeO2, and MgO. Whereas CeO2 presented a better UV254 removal, FeOOH and MgO showed the best DOC mineralization results. In this work, adsorption onto CeO2 seems to play a negative effect in its catalytic performance. The stability of all the materials was checked by ion leaching and SEM and XRD of the used catalysts with no significant changes in morphology or structural properties.

Recently, Salla et al. [160] compared classical Al2O3 with Mn2O3 catalysts in humic acid degradation. The favorable surface charge of Al2O3 led to a better performance in humic acid removal, but Mn2O3 promoted a faster decomposition of O3. This last catalyst led to higher ozone consumption. Catalytic stability was studied in four consecutive runs. Some catalyst deactivation is observed with changes in the oxidation state of Mn and Al and the surface hydroxylation of both catalysts was observed by XPS.

Therefore, some controversial effects are still unknown such as the role of the adsorption of some NOM species (NOM fractionation) onto the catalysts surface or the true catalytic activity of the active species in comparable conditions. In terms of stability, long term and deep characterization would be desirable to check the real applicability of these materials.

7.1.3. Reactors and Variables Studied

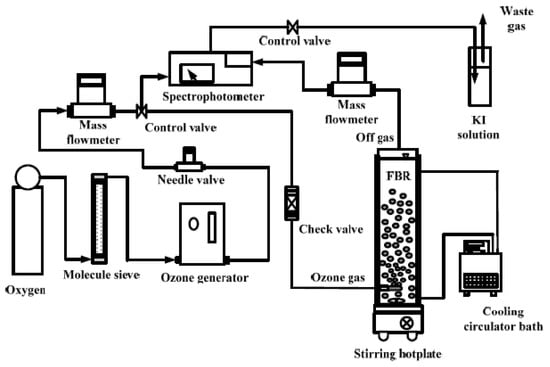

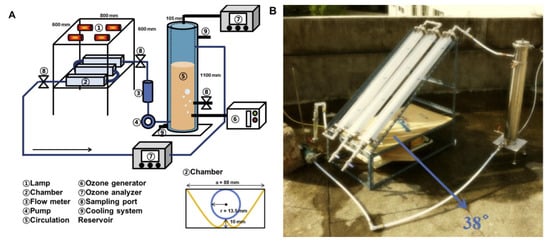

Bubble columns or vessels were used in semi-batch mode operation, batch for liquid phase, continuous for gas phase have been usually selected for catalytic ozonation processes. The catalyst, depending on the particle size, has been suspended in slurry or fluidized bed reactors, or packed in fixed bed reactors. In any case, they are three-phase reactors with gas–liquid–solid phases in which matter transfer will play a key role. Figure 3 shows a scheme of the typical ozonation experimental set up.

Figure 3.

Experimental set up for catalytic ozonation experiments at lab scale [171] (From Wang, Y.H.; Chen, K.C. Removal of disinfection by-products from contaminated water using a synthetic goethite catalyst via catalytic ozonation and a biofiltration system. Int. J. Environ. Res. Public Health 2014, 11, 9325–9344. doi.org/10.3390/ijerph110909325).

In general, the installation is composed by an air or oxygen cylinder, an ozone generator which sends the ozone gas into the reactor, in line ozone analyzers (at gas inlet and/or gas outlet), mass flow controllers, and ozone destruction systems (KI solution, AC filter or UV analyzers with catalytic destruction). The reactor usually comprises a glass or acrylic column or vessel with variable volume (mainly 1–2 L) provided with a bottom diffuser for ozone inlet which favors mass transfer, magnetic or mechanical stirring, gas inlet, and gas outlet and sampling port. Some reactors are provided with thermostatic baths for temperature control, and temperature or analytic probes (ozone, pH) can be included in the reactor. Usually, the reactor is filled with the water to treat having some head space for gas outlet. The catalyst is usually added, and a pre-adsorption or homogenization time is spent before ozonation. Then the containing ozone stream is bubbled into the reactor and the catalytic ozonation experiment begins.

Among the typical operating conditions studied are DOC concentration, pH, catalyst loading, and ozone dose (Table 6). Ambient temperature was used in most of the works. Regardless of natural surface water or synthetic humic or fulvic acid solutions, DOC values are usually in the range 2–10 mg L−1. Mortazavi et al. [176] detected a positive effect of DOC increasing the apparent reaction rate of catalytic ozonation as DOC increased.

It is well-known the role of pH on ozone reactions that has been usually described and commented in the introduction section. The application of the process for drinking water makes sense at the pH of natural waters (pH 6.0–8.5) and most of the studies are performed at natural pH. However, the relevance of pH in the NOM and catalyst charge has been evaluated. In this line, Salla et al. [160] assigned the best catalytic performance of Al2O3 with higher humic acid adsorption and lower ozone dosage due to favorable negative surface charge at the conditions studied (pH = 5.5 > pHpzc = 4.2). This also affects the adsorption capacity of the catalysts for different NOM fractions (acidic, neutral, hydrophilic or hydrophobic). On the other hand, Mortazavi et al. [176] in their study evaluated the influence of pH on the catalytic ozonation performance of bone charcoal to remove humic substances in the range of pH 2–12. They found that heterogeneous catalytic ozonation contribution was much higher at low pH and ozonation alone contribution increases with alkalinity due to the relative importance of indirect ozone reactions. In addition, at pH = 8 < pHpzc = 8.5 of the catalysts, a positive catalytic effect is still observed due to hydroxyl groups in the catalyst surface that act as Lewis acid sites for ozone decomposition. Therefore, depending on the catalyst nature, the catalytic effect could be improved also in alkaline solutions.

Catalyst loading is also an important parameter to optimize. The optimum dose is highly dependent on the catalyst nature and on the particle size used. The range used in the works reported in Table 6 for semi-batch experiments are as wide as 1 mg L−1 for TiO2 in slurry, 10 mg L−1 for activated carbon or 30 g L−1 of TiO2/Al2O3. In continuous operation, the space time (mass of catalyst/flow of water) ranged from 500–2000 g min L−1 [177]. In general, at sufficient ozone dose, the catalyst loading exerted a positive effect on the degradation rate of NOM. However, experimental check is needed in any different case.

In the same line, the optimization of ozone dose will mark the economic feasibility of the process in terms of ozone consumption/power energy required for ozone production. In general, research works reported in Table 6 applied high ozone dose and high ozone concentration in the gas phase with common values ca 10 mg L−1. However, ozone concentrations used were as varied as 2–90 mg L−1. Molnar et al. [175] observed that DOC removal did not improve at high ozone doses (0.1–3 mg O3/mg DOC) using TiO2/O3 catalytic ozonation compared to ozonation alone, but attributed this effect to the pH of the natural water and the scavenging effect of carbonate/bicarbonate. On the contrary, Wang et al. [173], found a positive effect in the ozone dosage in the permeated flux of their hybrid system. However, no relevant changes were observed in TOC or UV254 removal or THMFP.

7.1.4. Mechanisms and Kinetics for the Removal of DBPs Precursors

General mechanisms such as presented in reactions (21) to (31) have been accepted for NOM or humic/fulvic acids degradation by catalytic ozonation depending on the catalyst used.

In general, humic/fulvic substances are easily degraded by ozone direct reactions due to the presence of unsaturated bonds and aromatic rings to produce other compounds less reactive towards ozone but also with different reactivity towards subsequent chlorine treatment. These other compounds, carboxylic acids, or aliphatic molecules, can be degraded by reactive oxygen species formed by catalytic decomposition of ozone (hydroxyl radical, ozonide radical, etc.) both in the liquid phase or near the catalyst surface/adsorbed. They may react with organic molecules with low selectivity, thus leading to a high mineralization of NOM.

Considering the transformation of NOM in different species prior to mineralization, it is important to know the chlorine reactivity of the different fractions formed during catalytic ozonation. Thus, Zhang et al. [179] observed that ozonation alone decreases the aromaticity of humic-like structures and increases the generation of carboxylic groups. Catalytic ozonation with FeOOH and CeO2 catalysts also improved the destruction of humic-like structures and enhanced the destruction of the hydrophilic acid fraction destroying polycyclic aromatic structures. Unfortunately, no DBPFP was studied in this work.

Allemane et al. [187] proposed the adsorption of O3 and NOM onto TiO2/Al2O3 surface and the generation of oxidizing species in the surface. This trend has been observed in many of the studies dealing with TiO2/Al2O3 [184,185]. With respect to the contribution of adsorption, direct reactions, indirect reactions during catalytic ozonation, Alver and Kilic [161] studied the mechanism of humic acid removal by Fe coated pumice catalytic ozonation in the presence of different scavengers (t-BuOH and phosphate). They observed the high contribution of hydroxyl radicals in solution to the overall process. The studies of Turkay et al. [164,167] for the degradation of humic acid are based in DFT modelling calculations to stablish the interaction of reactants with the catalyst surface. They concluded that HO• radicals formed in the catalyst surface initiate the heterogeneous reaction in CuO with important contributions of adsorption-desorption and chelating [168]. For TiO2, HO• radicals are supposed to be formed from adsorbed O3 and its decomposition onto TiO2 surface in the presence of water molecules [167]. Finally, they proposed the O3 disproportionation over ZnO surface to form reactive oxygen species [164].

In the same line, Gümüs and Akbal [163] studied the degradation of humic acid using GAC and Fe-coated zeolite as catalysts. For GAC they proposed a general mechanism reported by Beltrán et al. for the degradation of diclofenac [189,190]. In this mechanism adsorbed ozone reacts with adsorbed organic compounds to yield hydrogen peroxide which eventually might react with adsorbed ozone to form hydroxyl radicals:

For Fe-coated zeolite (ICZ), they proposed the following mechanism:

In this mechanism ozone is adsorbed in terminal –OH groups of the catalyst and then reactive oxygen species are produced that eventually would react with organic compounds (adsorbed or in the bulk liquid phase).

Then, despite the variety of catalysts and the few studies directly dealing with the determination of the mechanisms involved in the catalytic ozonation of humic acid or NOM, some general steps can be hypothesized:

where Equations (42)–(45) represent heterogeneous reactions and Equations (46)–(48) are some of the well-known homogeneous ozone/hydroxyl radical reactions. This sequence will be completed by the general ozonation and HO• mechanisms in water [26,191,192]. DOC1 represents initial humic/fulvic substances that readily react with ozone or hydroxyl radicals to form organic compounds with lower molecular weight (DOC2 accounting for carboxylic, aldehydes, aliphatic compounds, etc.) usually refractory to direct ozone attack that can be further mineralized by hydroxyl radicals. The reactivity of different DOC fractions towards chlorine and their subsequent DBPFP is crucial to stablish the need of achieving an advanced oxidation degree or a high mineralization. Therefore, the importance of each reaction should be the objective of future works to tailor the catalytic properties and to modify operating conditions for the degradation of NOM of specific characteristics to reduce DBPFP. It is necessary to point out that the analysis of the latter will be mandatory regardless of the mineralization achieved.