Energy Storage, Power Management, and Applications of Triboelectric Nanogenerators for Self-Powered Systems: A Review

Abstract

1. Introduction

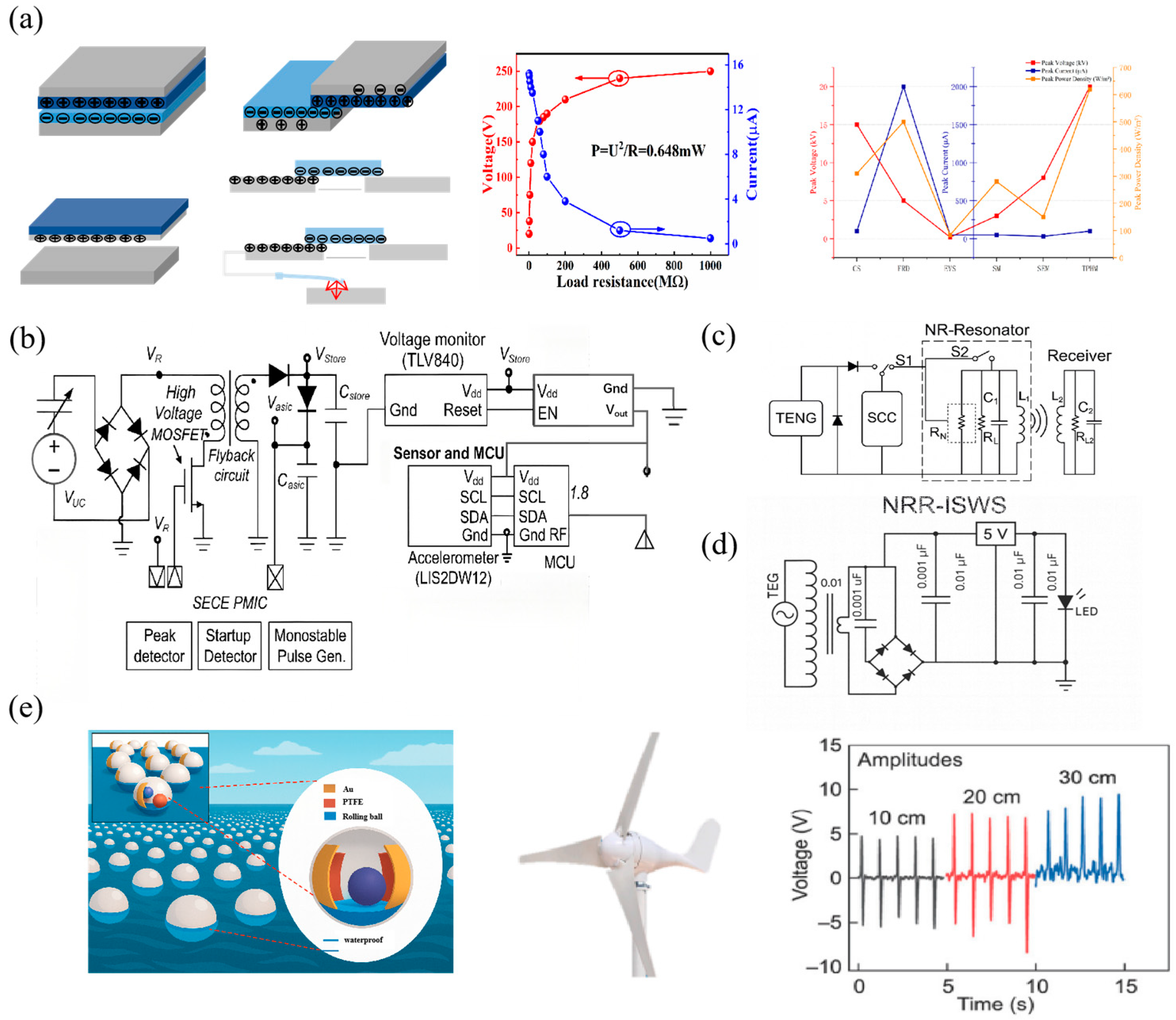

2. Basic Contradiction Between TENG Output Characteristics

2.1. High-Voltage/Low-Current Characteristics

| Working Modes | Voltage Range | Current Range | Peak Power Density | Applicable Scenarios |

|---|---|---|---|---|

| CS [43] | 1–15 kV | 1–100 μA | 310 W/m2 | Vibration Energy Harvesting |

| FRD [44] | 0.5–5 kV | 0.1–2 mA | 500 W/m2 | Wind/water harvesting |

| EVS [45] | 50–200 V | 10–50 μA | 83.6 W/m2 | Micropower Management Circuits |

| Sliding Mode [52] | 0.1–3 kV | 5–50 μA | 280 W/m2 | Linear motion energy harvesting |

| Single-Electrode Mode [53] | 0.5–8 kV | 0.5–30 μA | 150 W/m2 | Wearable device |

| Triboelectric- Piezoelectric Hybrid Mode [54] | 2–20 kV | 10–100 μA | 620 W/m2 | High frequency mechanical vibration |

2.2. Impedance Mismatch Loss

2.3. Mechanical Incentive Irregularity

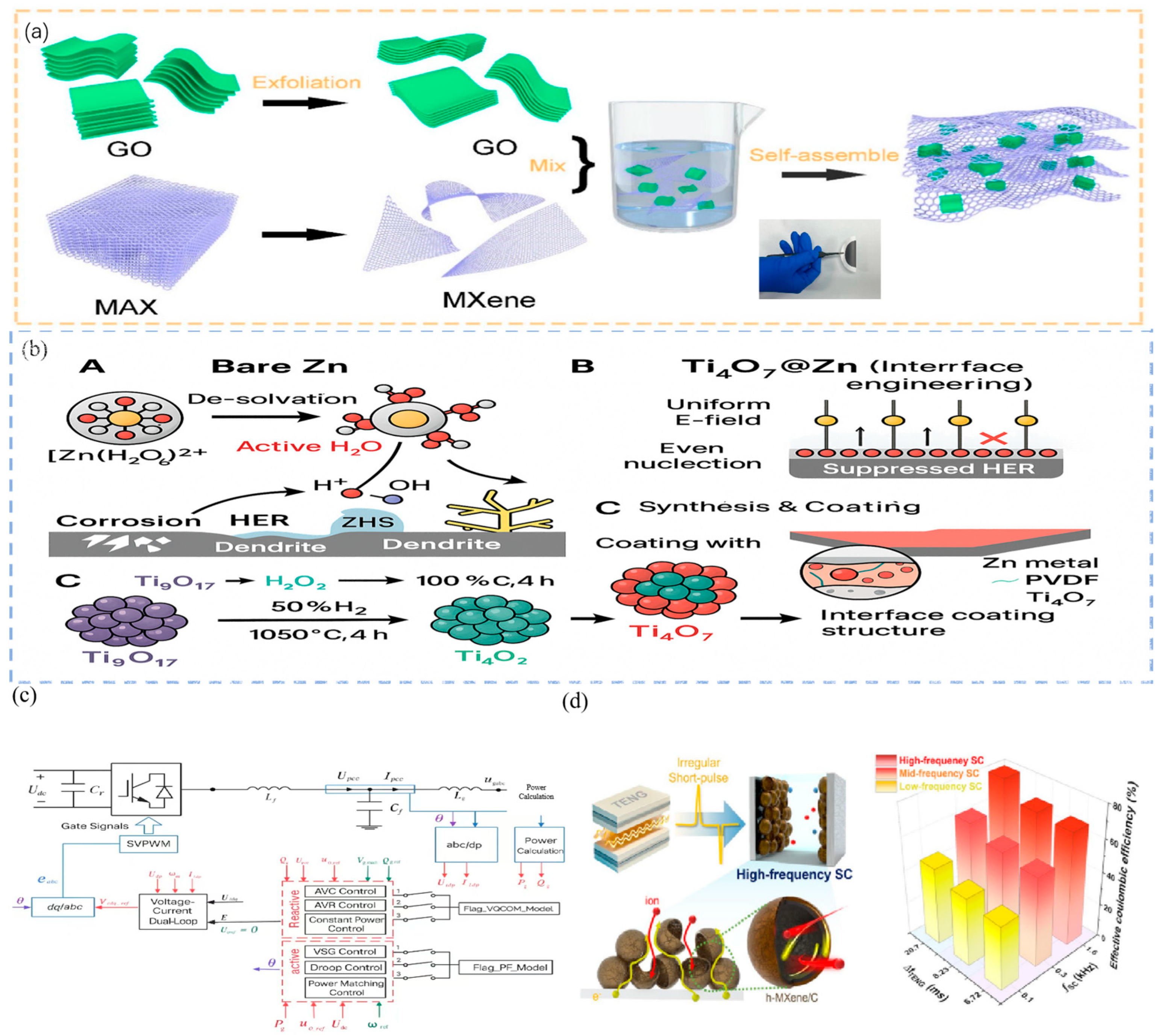

3. Energy Storage Technologies for TENGs

3.1. Capacitive Energy Storage

3.2. Battery-Based Storage

3.3. Hybrid Storage Energy Systems

| Method | Storage Type and Material | Frequency and Pulse Response | Charging Efficiency and Output | Result Summary |

|---|---|---|---|---|

| Hybrid TENG-SC with MXene Electrodes [80] | Supercapacitor with hollow MXene structure | High-frequency compatible with TENG pulses | Charging efficiency doubled; improved power density | Fast response, good matching but electrode cost. Suitable for wearable and short-pulse environment charging. Fast charging systems. |

| Flexible Self-Charging SCs [80] | Wearable supercapacitors | <1 ms response; suits high-frequency TENG | 30–70% | High flexibility but poor deployment stability and temperature and humidity sensitivity. Suitable for flexible devices and portable sensing. |

| Hybrid Battery-SC Energy Units [81] | Integrated SC and lithium battery | Handles low-frequency steady-state; high-frequency bursts | Stable delivery, energy-power balanced | Strong continuous power supply capability and stable efficiency but bulky and complex; For edge IoT, uninterruptible power systems. |

| Technology | Energy/Power Density | Cycle Life/Pulse Response | Efficiency/ESR | Self-Discharge | Compatibility with TENG | Disadvantages |

|---|---|---|---|---|---|---|

| Dielectric capacitors [82] | 0.1~1 J·cm−3/extremely high power density | >107 cycles/μs-level pulse capture | >95%/very low ESR | Very low | Excellent: as first-stage buffer for high-voltage pulses | Very low energy density; volume limits |

| Supercapa- citors [83] | 2~8 Wh·kg−1/1–10 kW·kg−1 | 104~105+ cycles/ms-level response | 90~95%/low ESR | Significant | High: suitable as second-stage cache and stabilizer | High self-discharge; balancing and over-voltage issues |

| Lithium-ion batteries [84] | 150~270 Wh·kg−1/moderate power | 500~2000 cycles/slow pulse acceptance | ~90%/moderate ESR | Low | Medium: long-term energy buffer with front-end management | Poor direct match with high-impedance pulse sources; needs buffer/SECE |

| Hybrid Supercapa- citors [85] | 20~80 Wh·kg−1/1~5 kW·kg−1 | 103~104 cycles/1 ms~100 ms response | High | Moderate | Medium–High: balances energy and power; suitable for wearables | Materials cost; self-discharge in some systems |

| Battery–supercapa citor hybrids [86] | Tunable by ratio and EMS/peak power from capacitor | Improved lifetime/ frequency-domain synergy | Depends on EMS | Governed by capacitor side | High: optimal for TENG | Higher system complexity, cost, and volume |

4. Power Management Circuit (PMC) Design

| Classification | Switch Type | Pressure Range | Response Time | Conduction Loss | TENG Adaptation Scenarios |

|---|---|---|---|---|---|

| Passive Switches | Diodes [94] | <100 V | 10–100 ns | 0.7 V | Low-voltage and rectification |

| GDTs [95] | 0.1–20 kV | 0.1–1 ms | 0.1 V | High-voltage pulse capture | |

| MEMS plasma [96] | 0.3–5 kV | 13.2 ns | 0.05 V | High-frequency LC resonant circuit | |

| Spark switch [90] | 0.1–20 kV | 3–7 ns | 0.1–0.12 V | High-voltage pulse capture, industrial environmental monitoring | |

| Active Switches | Memristors [89] | ±1–3 V | <0.1 ns | <1 fJ/bit | Brain-like energy management, adaptive control |

| GaN HEMT [92] | 100–650 V | 2–5 ns | <0.1 Ω | High-frequency Buck conversion | |

| 2D GAAFETs [91] | <100 V | <0.1 ns | 0.05 V | High-frequency LC resonance, sense and memory integration | |

| Trigger Switch | Mechanical synchronous [96] | <1 kV | µs–ms (depending on trigger) | High efficiency at peak conduction | Pulse energy extraction, proof-of-concept demonstrations |

| Electrostatic Vibration Switch [97] | <500 V | ms-level | Ultra-low static loss | Micro-energy harvesting, low-power sensing | |

| Gas Discharge Trigger Switch [98] | 0.1–20 kV | 3–7 ns | Low conduction loss | High-voltage pulse capture, industrial applications |

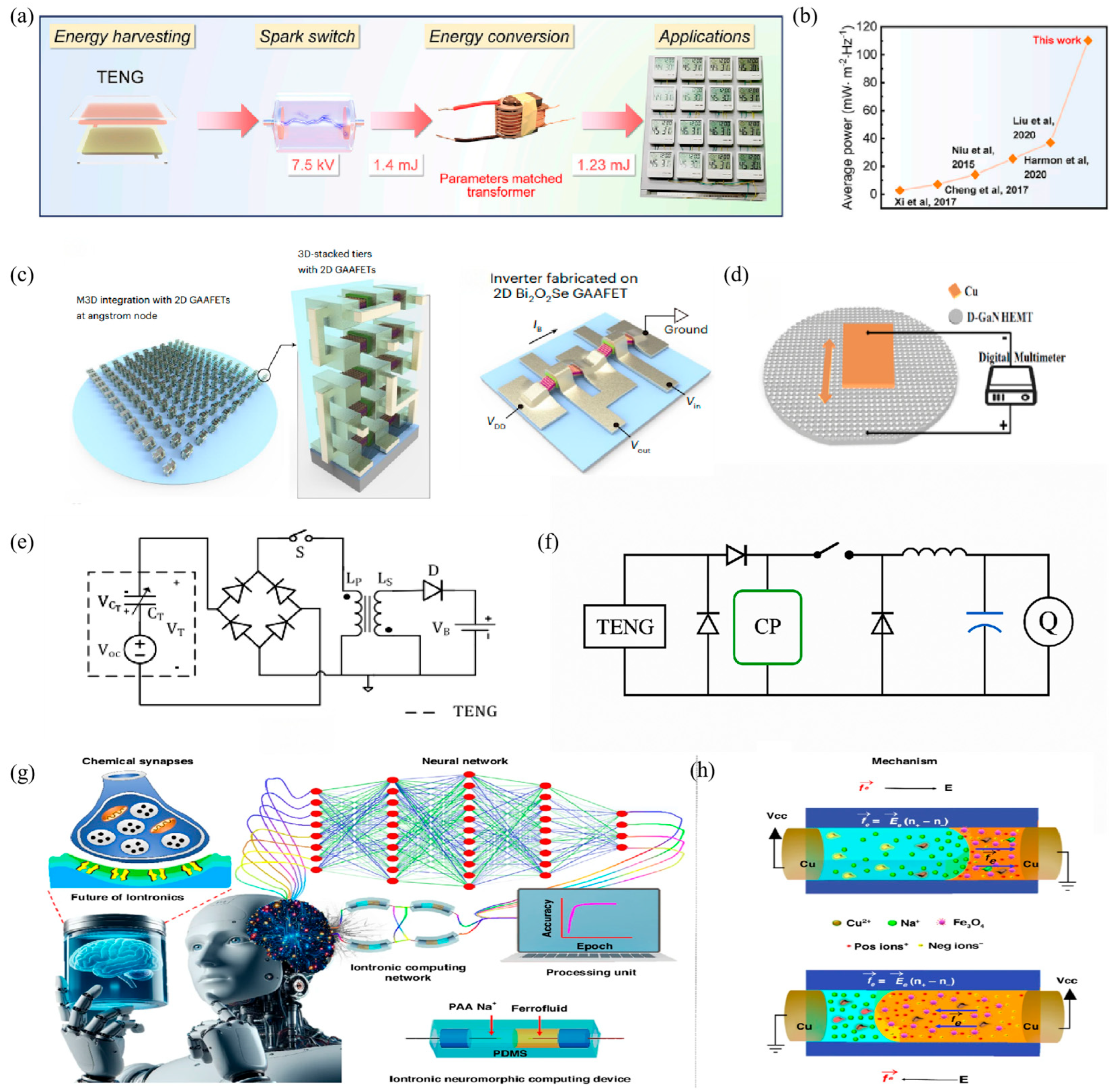

4.1. Switch Device Selection

4.1.1. Passive Switches

4.1.2. Active Switches

4.1.3. New Switching Technology

4.2. Energy Extraction Topology

4.3. Adaptive and Intelligent Circuits

4.3.1. Mechanical-Electrical Feedback to Regulate Variable Impedance

4.3.2. Machine Learning and Hardware Co-Optimization

4.4. Energy Storage Efficiency Calculation Methods for TENG

| Method | Calculation Formula | Applicable Scenarios | Advantages | Limitations/Error Sources |

|---|---|---|---|---|

| Capacitor voltage method [105] | Capacitor/supercapacitor charging | Simple, widely used | Neglects initial energy, self-discharge, and ESR tends to overestimate | |

| Instantaneous power integration [106] | Various circuits and storage ports | Accurate, can separate different losses | Complex measurement requires high-bandwidth sampling | |

| Coulombic efficiency [107] | Batteries/electrochemical capacitors | Reflects charge reversibility | Does not directly reflect energy loss | |

| Per-cycle normalization [108] | Periodic excitation of TENG | Suitable for comparison across frequencies/amplitudes | Large fluctuation in single cycle requires statistical averaging | |

| Peak/pulse-capture method [106] | Energy ratio per pulse | SECE, triggered switches, pulsed circuits | Highlights peak energy capture | May be misleading if only peak value is reported without average power |

| End-to-end efficiency [109] | Whole system performance evaluation | Most realistic reflection of actual efficiency | Complex measurement, requires synchronous mechanical–electrical testing |

5. TENG Energy Storage System Integration Design

5.1. Energy Supply–Sensing Co-Optimization

| Method | ML Algorithm | Training Data and Features | Accuracy and Real-Time Performance | Result Summary |

|---|---|---|---|---|

| ML-enhanced Self-powered TENG Sensors [112] | SVM, CNN, RF, LSTM | Signal features: amplitude, frequency, waveform; samples >10 k | Accuracy >90%; latency <100 ms | Robust to complex signals but High training cost; suitable for motion recognition, environmental monitoring, human–computer interaction. |

| Rotary TENG and NN for RPM detection [113] | Soft-coded NN classifier | RPM range training dataset; 100 s of samples | >90% prediction; 6.6 mW peak; lights 65 LEDs | Real-time stable output but limited to known mechanics; for machine speed monitoring, industrial automation. |

| GNN-guided Electrode Material Discovery [114] | GNN material prediction model | Doping ratio, structure, energy yield | Output improvement 65–85%, peak 1.12 J/cm2 | Fast screening, low experiment cost but model dependence; for the direction of material design and performance optimization. |

5.2. Design for Environmental Adaptation

5.3. Energy Scheduling and Management

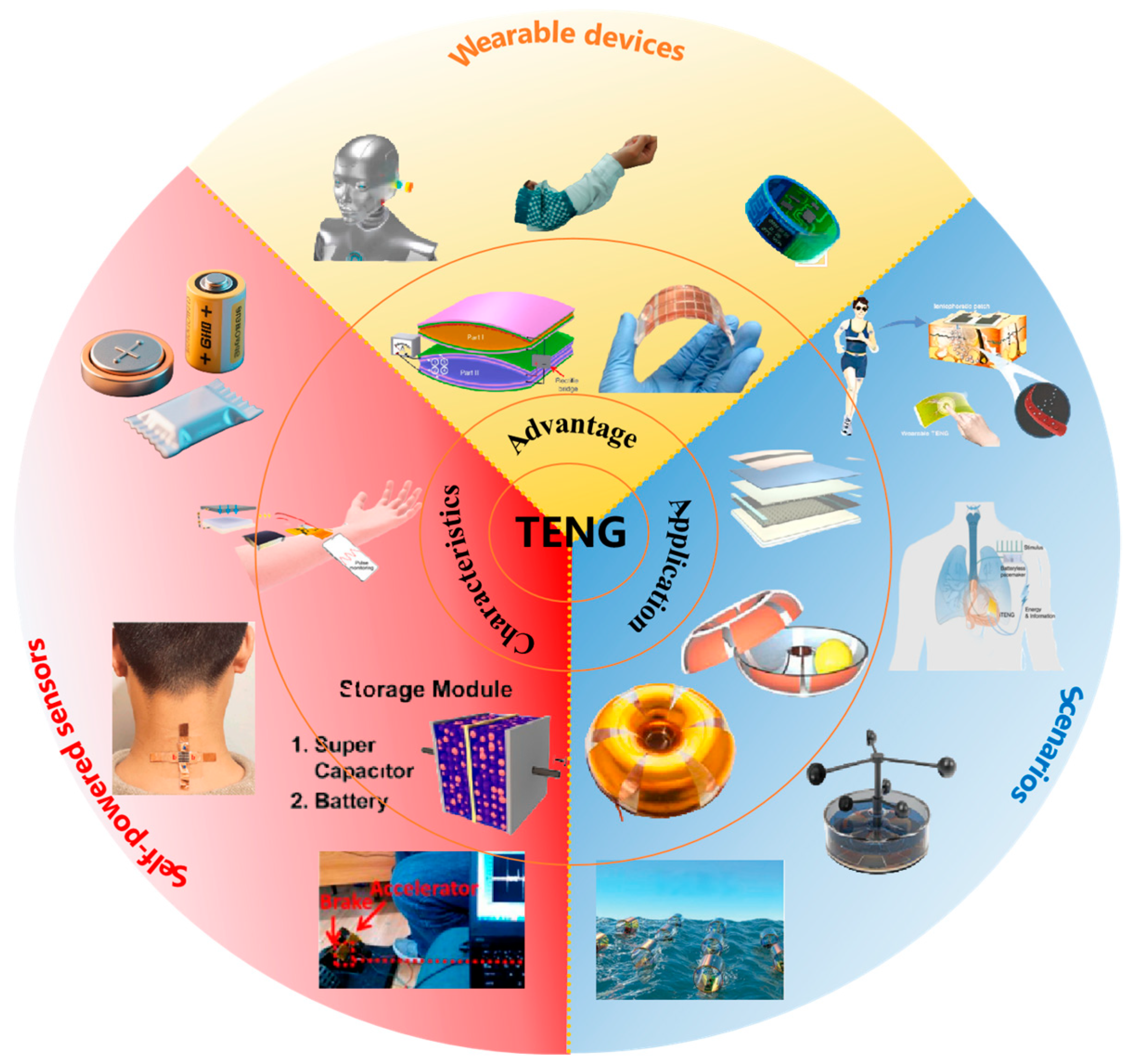

6. Application of Cases and Technology Adaptation

6.1. TENG Applications in Wearable Devices

| Method | Integration Strategy | Environmental Adaptivity | Output Parameters | Result Summary |

|---|---|---|---|---|

| MR-TENG with Rolling Drum Design [121] | Multi-roller and series/parallel scheduling | Saltwater-proof encapsulation | Voc ≈166 V; Isc ≈2.06 μA; 602 μJ in 100 s | High power density, adapted to the marine environment but the installation structure is complex and costly; applicable to blue energy collection, ocean monitoring. |

| Moisture-resistant PDMS Surface Structuring [117] | 3D microstructure and hydrophobic packaging | Stable in humid/rainy environments | Output degradation ≤10% to maintain stable performance | Highly reliable, suitable for wet outdoor environments but encapsulation limits contact crimping; suitable for outdoor wearable, wet area deployment. |

| TENG-Electrochemical Hybrid for Marine Fuel [116] | Integrated TENG and water splitting | Corrosion- and humidity-resistant design | 1910 W/m3 volume power; Fuel yield 7.1 mL/min | Integration of energy harvesting, storage and clean fuel extraction but with high system complexity; suitable for ocean energy platforms, ocean sensing and clean fuel production. |

6.2. TENG Applications in Agricultural and Environmental Monitoring

6.3. Application of TENG in Smart Home and Security Systems

6.4. Application of TENG in Smart Interfaces and Multidirectional Pressure Sensing

7. Challenges and Future Developments

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, W.; Xu, L.; Bu, T.; Yang, H.; Liu, G.; Li, W.; Pang, Y.; Hu, C.; Zhang, C.; Cheng, T. Torus structured triboelectric nanogenerator array for water wave energy harvesting. Nano Energy 2019, 58, 499–507. [Google Scholar] [CrossRef]

- Chen, J.; He, T.; Du, Z.; Lee, C. Review of textile-based wearable electronics: From the structure of the multi-level hierarchy textiles. Nano Energy 2023, 117, 108898. [Google Scholar] [CrossRef]

- Lei, R.; Shi, Y.; Ding, Y.; Nie, J.; Li, S.; Wang, F.; Zhai, H.; Chen, X.; Wang, Z.L. Sustainable high-voltage source based on triboelectric nanogenerator with a charge accumulation strategy. Energy Environ. Sci. 2020, 13, 2178–2190. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, D.; Wang, J.; Wang, Z.L. Triboelectric nanogenerators: Fundamental physics and potential applications. Friction 2020, 8, 481–506. [Google Scholar] [CrossRef]

- Guo, H.; Pu, X.; Chen, J.; Meng, Y.; Yeh, M.-H.; Liu, G.; Tang, Q.; Chen, B.; Liu, D.; Qi, S.; et al. A highly sensitive, self-powered triboelectric auditory sensor for social robotics and hearing aids. Sci. Robot. 2018, 3, eaat2516. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.; Zhang, C.; Han, C.B.; Fan, F.R.; Tang, W.; Wang, Z.L. Woven structured triboelectric nanogenerator for wearable devices. ACS Appl. Mater. Interfaces 2014, 6, 14695–14701. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.; Nie, Y.; Xiang, G. Facile fabrication of highly porous nylon-11 layer for flexible high-performance triboelectric nanogenerator. J. Appl. Phys. 2022, 131, 165002. [Google Scholar] [CrossRef]

- Li, M.; Wan, Z.; Zou, T.; Shen, Z.; Li, M.; Wang, C.; Xiao, X. Artificial intelligence enabled self-powered wireless sensing for smart industry. Chem. Eng. J. 2024, 492, 152417. [Google Scholar] [CrossRef]

- Mehamud, I.; Marklund, P.; Björling, M.; Shi, Y. Machine condition monitoring enabled by broad range vibration frequency detecting triboelectric nano-generator (TENG)-based vibration sensors. Nano Energy 2022, 98, 107292. [Google Scholar] [CrossRef]

- Jiang, H.; Lv, X.; Wang, K. Application of triboelectric nanogenerator in self-powered motion detection devices: A review. APL Mater. 2024, 12, 070601. [Google Scholar] [CrossRef]

- Lu, Z.-Q.; Zhao, L.; Fu, H.-L.; Yeatman, E.; Ding, H.; Chen, L.-Q. Ocean wave energy harvesting with high energy density and self-powered monitoring system. Nat. Commun. 2024, 15, 6513. [Google Scholar] [CrossRef]

- Song, Y.; Wang, H.; Cheng, X.; Li, G.; Chen, X.; Chen, H.; Miao, L.; Zhang, X.; Zhang, H. High-efffciency self-charging smart bracelet for portable electronics. Nano Energy 2019, 55, 29–36. [Google Scholar] [CrossRef]

- Yong, S.; Wang, J.; Yang, L.; Wang, H.; Luo, H.; Liao, R.; Wang, Z.L. Auto-switching self-powered system for efficient broad-band wind energy harvesting based on dual-rotation shaft triboelectric nanogenerator. Adv. Energy Mater. 2021, 11, 2101194. [Google Scholar] [CrossRef]

- Jiang, T.; Pang, H.; An, J.; Lu, P.; Feng, Y.; Liang, X.; Zhong, W.; Wang, Z.L. Robust swing-structured triboelectric nanogenerator for efficient blue energy harvesting. Adv. Energy Mater. 2020, 10, 2000064. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, H.; Wang, T.; Lee, C. Self-powered liquid triboelectric microfluidic sensor for pressure sensing and finger motion monitoring applications. Nano Energy 2016, 30, 450–459. [Google Scholar] [CrossRef]

- Kim, W.-G.; Kim, D.-W.; Tcho, I.-W.; Kim, J.-K.; Kim, M.-S.; Choi, Y.-K. Triboelectric nanogenerator: Structure, mechanism, and applications. ACS Nano 2021, 15, 258–287. [Google Scholar] [CrossRef]

- Meng, X.; Cheng, Q.; Jiang, X.; Fang, Z.; Chen, X.; Li, S.; Li, C.; Sun, C.; Wang, W.; Wang, Z.L. Triboelectric nanogenerator as a highly sensitive self-powered sensor for driver behavior monitoring. Nano Energy 2018, 51, 721–727. [Google Scholar] [CrossRef]

- Khandelwal, G.; Raj, N.P.M.J.; Kim, S.-J. Triboelectric nanogenerator for healthcare and biomedical applications. Nano Today 2020, 33, 100882. [Google Scholar] [CrossRef]

- Xia, K.; Liu, J.; Li, W.; Jiao, P.; He, Z.; Wei, Y.; Qu, F.; Xu, Z.; Wang, L.; Ren, X.; et al. A self-powered bridge health monitoring system driven by elastic origami triboelectric nanogenerator. Nano Energy 2023, 105, 107974. [Google Scholar] [CrossRef]

- Vallejo, D.D.; Corstvet, J.L.; Fernández, F.M. Triboelectric nanogenerators: Low-cost power supplies for improved electrospray ionization. Int. J. Mass Spectrom. 2024, 495, 117167. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Shan, C.; Fu, S.; Li, K.; Wang, J.; Xu, S.; Li, G.; Zhao, Q.; Guo, H.; Hu, C. Efficient energy conversion mechanism and energy storage strategy for triboelectric nanogenerators. Nat. Commun. 2024, 15, 6558. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Zhang, P.; Li, J.; Mao, X. Recent progress of triboelectric nanogenerator-based power management and information processing circuit. Mater. Today Sustain. 2023, 23, 100426. [Google Scholar] [CrossRef]

- Paranjape, M.V.; Manchi, P.; Kurakula, A.; Kavarthapu, V.S.; Lee, J.K.; Graham, S.A.; Yu, J.S. Generalized utilization of energy harvesting ability of TENG for concurrent energy storage and motion sensing application with effective external circuitry. Nano Energy 2024, 129, 109983. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, J.; Xu, N.; Chen, M.; Lee, J.-H.; Wang, Y.; Sun, Q.; Liu, B.; Gao, Z. Self-powered flexible sensors: From fundamental mechanisms toward diverse applications. Int. J. Extreme Manuf. 2024, 7, 012011. [Google Scholar] [CrossRef]

- Sheng, H.; Ma, Y.; Zhang, H.; Yuan, J.; Li, F.; Li, W.; Xie, E.; Lan, W. Integration of Supercapacitors with Sensors and Energy-Harvesting Devices: A Review. Adv. Mater. Technol. 2024, 9, 2301796. [Google Scholar] [CrossRef]

- Meng, J.; Zhao, Z.; Cao, X.; Wang, N. The integration of triboelectric nanogenerators and supercapacitors: The key role of cellular materials. Materials 2023, 16, 3751. [Google Scholar] [CrossRef]

- Chen, J.; Sun, L.; Wang, K.; Zhang, Y. Research and applications of rechargeable seawater battery. J. Energy Storage 2024, 76, 109659. [Google Scholar] [CrossRef]

- Mishra, P.; Singh, G. Energy management systems in sustainable smart cities based on the internet of energy: A technical review. Energies 2023, 16, 6903. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Q.; Zhang, F. Electrochemical triboelectricity: A comprehensive survey of current research and future prospects. Nano Energy 2024, 130, 110180. [Google Scholar] [CrossRef]

- Pu, X.; Zhang, C.; Wang, Z.L. Triboelectric nanogenerators as wearable power sources and self-powered sensors. Natl. Sci. Rev. 2023, 10, nwac170. [Google Scholar] [CrossRef]

- Qin, S.; Chen, J.; Yang, P.; Liu, Z.; Tao, X.; Dong, X.; Hu, J.; Chu, X.; Wang, Z.L.; Chen, X. A piezo-tribovoltaic nanogenerator with ultrahigh output power density and dynamic sensory functions. Adv. Energy Mater. 2024, 14, 2303080. [Google Scholar] [CrossRef]

- Xu, G.; Li, C.; Chen, C.; Fu, J.; Hou, T.; Zi, Y. Dynamics of triboelectric nanogenerators: A review. Int. J. Mech. Syst. Dyn. 2022, 2, 311–324. [Google Scholar] [CrossRef]

- Long, W.; Xiaogang, X.; Lingpeng, K.; Yueliang, L.; Zhimin, X.; Tianchen, Y.; Teng, X. Research on Inertia and Additional Power Compensation Control of PV-Storage DC Microgrid. In Proceedings of the 2024 6th International Conference on Power and Energy Technology (ICPET), Beijing, China, 12–15 July 2024; IEEE: New York, NY, USA, 2024; pp. 804–809. [Google Scholar]

- Baburaj, A.; Jayadevan, S.; Aliyana, A.K.; Sk, N.K.; Stylios, G.K. AI-Driven TENGs for Self-Powered Smart Sensors and Intelligent Devices. Adv. Sci. 2025, 12, 2417414. [Google Scholar] [CrossRef]

- Somkuwar, V.U.; Garg, H.; Maurya, S.K.; Kumar, B. Influence of relative humidity and temperature on the performance of knitted textile triboelectric nanogenerator. ACS Appl. Electron. Mater. 2024, 6, 931–939. [Google Scholar] [CrossRef]

- Sachdev, D.; Gupta, S.; Bhullar, N.K.; Verma, G. Recent Progress on the Correlation Between Hydrophobicity and the Water Absorption of Different Materials. J. Inorg. Organomet. Polym. Mater. 2025, 1–26. [Google Scholar] [CrossRef]

- Gao, J.-H.; Wan, B.; Zheng, M.-S.; Luo, L.; Zhang, H.; Zhao, Q.-L.; Chen, G.; Zha, J.-W. High-toughness, extensile and self-healing PDMS elastomers constructed by decuple hydrogen bonding. Mater. Horiz. 2024, 11, 1305–1314. [Google Scholar] [CrossRef] [PubMed]

- Qin, H.; Gu, G.; Shang, W.; Luo, H.; Zhang, W.; Cui, P.; Zhang, B.; Guo, J.; Cheng, G.; Du, Z. A universal and passive power management circuit with high efficiency for pulsed triboelectric nanogenerator. Nano Energy 2020, 68, 104372. [Google Scholar] [CrossRef]

- Yu, Y.; Gao, Q.; Zhang, X.; Zhao, D.; Xia, X.; Wang, J.; Li, H.; Wang, Z.L.; Cheng, T. Contact-sliding-separation mode triboelectric nanogenerator. Energy Environ. Sci. 2023, 16, 3932–3941. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, M.; Zhang, Z.; Min, H.; Wang, C.; Hu, G.; Yang, T.; Luo, S.; Yu, B.; Huang, T.; et al. Highly Durable Bidirectional Rotary Triboelectric Nanogenerator with a Self-Lubricating Texture and Self-Adapting Contact Synergy for Wearable Applications. Small 2023, 19, 2300890. [Google Scholar] [CrossRef]

- Deng, H.-C.; Li, Y.; Tian, S.-S.; Zhang, X.-X.; Xiao, S. Dielectric materials for high-performance triboelectric nanogenerators. Acta Phys. Sin. 2024, 73, 070702. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, D.; Shi, J.; Yang, P.; Li, S.; Zhao, Z.; Guo, Z.; Gao, Y.; He, L.; Zhao, J.-S.; et al. An ultra-high voltage (>10 kV) direct-current triboelectric nanogenerator realized by structural and material optimizations. Nano Energy 2024, 124, 109517. [Google Scholar] [CrossRef]

- Peng, W.; Du, S. The advances in conversion techniques in triboelectric energy harvesting: A review. IEEE Trans. Circuits Syst. I Regul. Pap. 2023, 70, 3049–3062. [Google Scholar] [CrossRef]

- Radfar, M.; Nakhlestani, A.; Le Viet, H.; Desai, A. Battery management technique to reduce standby energy consumption in ultra-low power IoT and sensory applications. IEEE Trans. Circuits Syst. I: Regul. Pap. 2019, 67, 336–345. [Google Scholar] [CrossRef]

- Dien, X.; Ramli, N.; Thio, T.H.G.; Linfeng, C.; Lin, Z.; Jiang, Y.; Zhuanqing, Y. High-performance energy harvesting and continuous output using nylon-11/BaTiO3-PVDF triboelectric nanogenerators with strong dielectric properties. PLoS ONE 2025, 20, e0319802. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, J.; Li, J.; Zhang, K.; Xu, L.; Liu, Y.; Xuan, W.; Chen, J.; Ong, H.; Jin, H.; et al. A self-powered instantaneous wireless sensing platform based on integrated triboelectric nanogenerator and negative resistance LC resonator. Measurement 2024, 235, 115032. [Google Scholar] [CrossRef]

- Liu, D.; Luo, J.; Huang, L.; Chen, M.; Ji, M.; Wang, Z.L.; Kang, J. Triboelectric Nanogenerators as a Practical Approach for Wind Energy Harvesting: Mechanisms, Designs, and Applications. Nano Energy 2025, 136, 110767. [Google Scholar] [CrossRef]

- Zhu, G.; Chen, J.; Zhang, T.; Jing, Q.; Wang, Z.L. Radial-arrayed rotary electrification for high performance triboelectric generator. Nat. Commun. 2014, 5, 3426. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Gong, X.; Li, X. Material selection and performance optimization strategies for a wearable friction nanogenerator (W-TENG). J. Mater. Chem. A 2023, 11, 24454–24481. [Google Scholar] [CrossRef]

- Wu, Y.-S.; Liu, Q.; Cao, J.; Li, K.; Cheng, G.-G.; Zhang, Z.-Q.; Ding, J.-N.; Jiang, S.-Y. Design and output performance of vibration energy harvesting triboelectric nanogenerator. Acta Phys. Sin. 2019, 68, 190201. [Google Scholar] [CrossRef]

- Kannabiran, K.; Rabi, B.R.M.; Jayapalan, B.; Palani, L.T. Harnessing energy from low-frequency and low-amplitude vibrating sources using triboelectric nano generator. Appl. Phys. A 2025, 131, 316. [Google Scholar] [CrossRef]

- An, S.; Fu, S.; He, W.; Li, G.; Xing, P.; Du, Y.; Wang, J.; Zhou, S.; Pu, X.; Hu, C. Boosting output performance of sliding mode triboelectric nanogenerator by shielding layer and shrouded-tribo-area optimized ternary electrification layered architecture. Small 2023, 19, e2303277. [Google Scholar] [CrossRef]

- Jeong, J.; Ko, J.; Kim, J.; Lee, J. Asymmetric voltage amplification using a capacitive load energy management circuit in a triboelectric nanogenerator. Nanoscale Res. Lett. 2024, 19, 52. [Google Scholar] [CrossRef]

- Pang, Y.; Cao, Y.; Derakhshani, M.; Fang, Y.; Wang, Z.L.; Cao, C. Hybrid energy-harvesting systems based on triboelectric nanogenerators. Matter 2021, 4, 116–143. [Google Scholar] [CrossRef]

- Guo, X.; Wang, Y.; Feng, Y.; Yu, Y.; Wang, J.; He, S.; Zhu, J.; Li, H.; Cheng, T.; Wang, Z.L.; et al. Enhance Charge Transfer and Reduce Internal Resistance for Triboelectric Nanogenerator via Switching Charge Shuttling. Adv. Energy Mater. 2025, 15, 2405116. [Google Scholar] [CrossRef]

- Du, S.; Basset, P.; Guo, H.; Galayko, D.; Karami, A. Power management technologies for triboelectric nanogenerators. MRS Bull. 2025, 50, 305–314. [Google Scholar] [CrossRef]

- Zhao, X.; Xu, Z.; Kang, Y.; Ou, Z.; Ling, Y.; Xu, S.; Wang, X. A Triboelectric-Powered Continuous Wireless Communication Microsystem with Synchronous Electric Charge Extraction Power Management. In Proceedings of the 2025 IEEE 38th International Conference on Micro Electro Mechanical Systems (MEMS), Kaohsiung, Taiwan, 19–23 January 2025; IEEE: New York, NY, USA, 2025; pp. 791–794. [Google Scholar]

- Lee, K.; Kim, J.; Oh, S.; Yoo, H.; Lee, J.; Oh, I.; Lee, C.H. DC Power Boosting Circuit for Freestanding-Sliding Triboelectric Nanogenerators with High Intrinsic Impedance and Multi-Harmonic Output. Adv. Mater. Technol. 2024, 9, 2400225. [Google Scholar] [CrossRef]

- Yu, Y.; Gao, Q.; Zhao, D.; Li, X.; Wang, Z.L.; Cheng, T. Influence of mechanical motions on the output characteristics of triboelectric nanogenerators. Mater. Today Phys. 2022, 25, 100701. [Google Scholar] [CrossRef]

- Jiang, Y.; Liang, X.; Jiang, T.; Wang, Z.L. Advances in triboelectric nanogenerators for blue energy harvesting and marine environmental monitoring. Engineering 2024, 33, 204–224. [Google Scholar] [CrossRef]

- Zhang, B.; Gao, Q.; Li, W.; Zhu, M.; Li, H.; Cheng, T.; Wang, Z.L. Alternating Magnetic Field-Enhanced Triboelectric Nanogenerator for Low-Speed Flow Energy Harvesting. Adv. Funct. Mater. 2023, 33, 2304839. [Google Scholar] [CrossRef]

- Chen, L.; He, M.; Gong, W.; Hu, P.; Yuan, S.; Chen, A.; Wei, L.; Zhang, Q.; Li, Q. Robust salt-shelled metal halide for highly efficient photoluminescence and wearable real-time human motion perception. Nano Energy 2023, 112, 108235. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.; Yang, Z.; Zhu, J.; Zhang, P.; Yu, X.; Li, H.; Yu, Y.; Zhang, Y.; Wang, Z.L.; et al. A universal self-triggered passive management strategy for enhancing the output power of triboelectric nanogenerators. Energy Environ. Sci. 2025, 18, 3761–3772. [Google Scholar] [CrossRef]

- Wang, J.; Xu, S.; Hu, C. Charge generation and enhancement of key components of triboelectric nanogenerators: A review. Adv. Mater. 2024, 36, e2409833. [Google Scholar] [CrossRef]

- Zi, Y.; Wang, J.; Wang, S.; Li, S.; Wen, Z.; Guo, H.; Wang, Z.L. Effective energy storage from a triboelectric nanogenerator. Nat. Commun. 2016, 7, 10987. [Google Scholar] [CrossRef]

- Cui, J.; Bai, S.; Li, X.; Jia, L.; Li, G.; Zheng, Y.; Xue, C. Integration of triboelectric sensing and electromagnetic energy harvesting for self-adaptive vibration suppression. Nano Energy 2023, 113, 108525. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, T.; Zou, X.; Zhu, Y.; Chi, M.; Wu, D.; Jiang, K.; Zhu, S.; Zhai, W.; Wang, S.; et al. Real-time data visual monitoring of triboelectric nanogenerators enabled by deep learning. Nano Energy 2024, 130, 110186. [Google Scholar] [CrossRef]

- Kwon, Y.H.; Meng, X.; Xiao, X.; Suh, I.-Y.; Kim, D.; Lee, J.; Kim, S.-W. Triboelectric energy harvesting technology for self-powered personal health management. Int. J. Extreme Manuf. 2024, 7, 022005. [Google Scholar] [CrossRef]

- Trinh, V.-L.; Chung, C.-K. Advances in triboelectric nanogenerators for sustainable and renewable energy: Working mechanism, tribo-surface structure, energy storage-collection system, and applications. Processes 2023, 11, 2796. [Google Scholar] [CrossRef]

- Luo, X.; Zhu, L.; Wang, Y.; Li, J.; Nie, J.; Wang, Z.L. A Flexible Multifunctional Triboelectric Nanogenerator Based on MXene/PVA Hydrogel. Adv. Funct. Mater. 2021, 31, 2104928. [Google Scholar] [CrossRef]

- Dutta, W.; Reece, C.; Mallik, A. A comparative analysis of power pulsating buffer architectures for mitigating high-frequency and low-frequency ripple in PV microinverter applications. IET Power Electron. 2024, 17, 1262–1286. [Google Scholar] [CrossRef]

- Shu, B.; Huang, Z.; Ren, W.; Wu, Y.; Li, H. Learning-Based Model Predictive Control for Legged Robots with Battery–Supercapacitor Hybrid Energy Storage System. Appl. Sci. 2025, 15, 382. [Google Scholar] [CrossRef]

- Yang, W.; Cai, X.; Guo, S.; Wen, L.; Sun, Z.; Shang, R.; Shi, X.; Wang, J.; Chen, H.; Li, Z. A high performance triboelectric nanogenerator based on MXene/graphene oxide electrode for glucose detection. Materials 2023, 16, 841. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 576–584. [Google Scholar] [CrossRef]

- Zheng, W.; Qu, D.; Sun, Z.; Niu, L. Research progress of zinc ion batteries in zinc metal electrodes and electrolytes. J. Chin. Soc. Corros. Prot. 2024, 45, 548–562. [Google Scholar]

- Ming, J.; Guo, J.; Xia, C.; Wang, W.; Alshareef, H.N. Zinc-ion batteries: Materials, mechanisms, and applications. Mater. Sci. Eng. R Rep. 2019, 135, 58–84. [Google Scholar] [CrossRef]

- Lee, K.-H.; Kim, M.-G.; Kang, W.; Park, H.-M.; Cho, Y.; Hong, J.; Kim, T.-H.; Kim, S.-H.; Cho, S.-K.; Kang, D.; et al. Pulse-Charging Energy Storage for Triboelectric Nanogenerator Based on Frequency Modulation. Nano-Micro Lett. 2025, 17, 210. [Google Scholar] [CrossRef]

- Nahirniak, S.; Ray, A.; Saruhan, B. Challenges and future prospects of the MXene-based materials for energy storage applications. Batteries 2023, 9, 126. [Google Scholar] [CrossRef]

- Liu, J.; Su, X.; Zhao, L.; Chen, Y.; Jin, Y. Simulation Analysis and Verification Research on the Hybrid-GFM Energy Storage System with “Lithium Batteries + Supercapacitors”. Energy Storage Sci. Technol. 2025, 14, 2675–2688. [Google Scholar]

- Lu, Y.; Wu, T.; Ma, Z.; Mi, Y.; Zhao, Z.; Liu, F.; Cao, X.; Wang, N. Integration of flexible supercapacitors with triboelectric nanogenerators: A review. Batteries 2023, 9, 281. [Google Scholar] [CrossRef]

- Rani, S.; Khandelwal, G.; Kumar, S.; Pillai, S.C.; Stylios, G.K.; Gadegaard, N.; Mulvihill, D.M. Flexible self-powered supercapacitors integrated with triboelectric nanogenerators. Energy Storage Mater. 2025, 74, 103977. [Google Scholar] [CrossRef]

- Zubairi, H.; Lu, Z.; Zhu, Y.; Reaney, I.M.; Wang, G. Current development, optimisation strategies and future perspectives for lead-free dielectric ceramics in high field and high energy density capacitors. Chem. Soc. Rev. 2024, 53, 10761–10790. [Google Scholar] [CrossRef]

- Helseth, L. The self-discharging of supercapacitors interpreted in terms of a distribution of rate constants. J. Energy Storage 2021, 34, 102199. [Google Scholar] [CrossRef]

- Frith, J.T.; Lacey, M.J.; Ulissi, U. A non-academic perspective on the future of lithium-based batteries. Nat. Commun. 2023, 14, 420. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Gao, L.; Liu, F.; Qi, J.; Gao, W.; Xu, G. Recent Advances and Challenges in Hybrid Supercapacitors Based on Metal Oxides and Carbons. Inorganics 2025, 13, 49. [Google Scholar] [CrossRef]

- Reveles-Miranda, M.; Ramirez-Rivera, V.; Pacheco-Catalán, D. Hybrid energy storage: Features, applications, and ancillary benefits. Renew. Sustain. Energy Rev. 2024, 192, 114196. [Google Scholar] [CrossRef]

- Wu, J.; Li, X.; Xue, N.; Wang, J.; Xu, G.; Chen, S.; Cui, H.; Zi, Y.; Wang, Z.L. Managing the two mode outputs of triboelectric nanogenerators to reach a pulsed peak power density of 31 MW m−2. Energy Environ. Sci. 2025, 18, 2381–2394. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, W.; He, W.; Guo, H.; Long, L.; Xi, Y.; Wang, X.; Liu, A.; Hu, C. Ultrahigh electricity generation from low-frequency mechanical energy by efficient energy management. Joule 2021, 5, 441–455. [Google Scholar] [CrossRef]

- Tang, J.; Jiang, J.; Gao, X.; Gao, X.; Zhang, C.; Wang, M.; Xue, C.; Li, Z.; Yin, Y.; Tan, C.; et al. Low-power 2D gate-all-around logics via epitaxial monolithic 3D integration. Nat. Mater. 2025, 24, 519–526. [Google Scholar] [CrossRef]

- Luo, Q.; Li, Y.; Ji, J.; Xiao, K.; Deng, J.; Zhang, J.; Hu, X.; Hou, Q.; Wang, Y.; Zeng, R.; et al. Enhancing power density in D-mode GaN HEMT direct-current triboelectric nanogenerators through ICP-etched surface engineering. Mater. Today Commun. 2024, 41, 111128. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Y.; Deng, L.; Zhu, X.; Xu, C.; Xie, L.; Yang, Q.; Zhang, H. Efficient electrical energy conversion strategies from triboelectric nanogenerators to practical applications: A review. Nano Energy 2024, 132, 110383. [Google Scholar] [CrossRef]

- Xiao, Z.; Luo, Y.; Yuan, H.; Zheng, T.; Xu, S.; Dai, G.; Yang, J. Coupling charge pump and BUCK circuits to efficiently enhance the output performance of triboelectric nanogenerator. Nano Energy 2023, 115, 108749. [Google Scholar] [CrossRef]

- Khan, M.U.; Hassan, B.; Alazzam, A.; Eissa, S.; Mohammad, B. Brain inspired iontronic fluidic memristive and memcapacitive device for self-powered electronics. Microsyst. Nanoeng. 2025, 11, 37. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, G.; Zhang, Z.; Ren, H.; Zhou, H.; Gui, Y.; Du, Z.; Cheng, G. Enhancing the output energy of triboelectric nanogenerator by adaptive arc discharge devices and its application in wireless weather sensing system. Nano Energy 2024, 129, 109987. [Google Scholar] [CrossRef]

- Zhen, D.; Xu, Z.; Yan, J.; Tu, Y.; Ding, C.; Zhang, C.; Chen, S.; Shan, L.; Wang, X.; Xu, S. A triboelectric energy harvesting ic with high-voltage synchronous electric charge extraction strategy and superior systematic efficiency. IEEE Trans. Circuits Syst. I Regul. Pap. 2024, 71, 5349–5361. [Google Scholar] [CrossRef]

- Shang, W.; Gu, G.; Zhang, W.; Luo, H.; Wang, T.; Zhang, B.; Guo, J.; Cui, P.; Yang, F.; Cheng, G.; et al. Rotational pulsed triboelectric nanogenerators integrated with synchronously triggered mechanical switches for high-efficiency self-powered systems. Nano Energy 2021, 82, 105725. [Google Scholar] [CrossRef]

- Yang, J.; Yang, F.; Zhao, L.; Shang, W.; Qin, H.; Wang, S.; Jiang, X.; Cheng, G.; Du, Z. Managing and optimizing the output performances of a triboelectric nanogenerator by a self-powered electrostatic vibrator switch. Nano Energy 2018, 46, 220–228. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, G.; Bu, T.; Wang, Z.; Cao, J.; Wang, Z.; Zhang, Z.; Dong, S.; Zeng, J.; Cao, X.; et al. Autonomous cantilever buck switch for ultra-efficient power management of triboelectric nanogenerator. Appl. Energy 2024, 357, 122475. [Google Scholar] [CrossRef]

- Macário, D.; Domingos, I.; Carvalho, N.; Pinho, P.; Alves, H. Harvesting circuits for triboelectric nanogenerators for wearable applications. iScience 2022, 25, 103977. [Google Scholar] [CrossRef]

- Wang, S.; Lin, L.; Wang, Z.L. Nanoscale triboelectric-effect-enabled energy conversion for sustainably powering portable electronics. Nano Energy 2015, 15, 578–601. [Google Scholar] [CrossRef]

- Xie, Z.; Teng, L.; Wang, H.; Liu, Y.; Fu, M.; Liang, J. A self-powered synchronous switch energy extraction circuit for electromagnetic energy harvesting enhancement. IEEE Trans. Power Electron. 2023, 38, 9972–9982. [Google Scholar] [CrossRef]

- Ra, Y.; Choi, J.H.; Choi, S.-J.; La, M.; Park, S.J.; Kim, M.-J.; Choi, D. Cold rolled robust metal assisted triboelectric nanogenerator for extremely durable operation. Extreme Mech. Lett. 2020, 40, 100910. [Google Scholar] [CrossRef]

- Shi, Y.; Li, H.; Fu, X.; Luan, R.; Wang, Y.; Wang, N.; Sun, Z.; Niu, Y.; Wang, C.; Zhang, C.; et al. Self-powered difunctional sensors based on sliding contact-electrification and tribovoltaic effects for pneumatic monitoring and controlling. Nano Energy 2023, 110, 108339. [Google Scholar] [CrossRef]

- Li, R.; Wei, D.; Wang, Z. Synergizing machine learning algorithm with triboelectric nanogenerators for advanced self-powered sensing systems. Nanomaterials 2024, 14, 165. [Google Scholar] [CrossRef]

- Li, X.; Zhang, C.; Gao, Y.; Zhao, Z.; Hu, Y.; Yang, O.; Liu, L.; Zhou, L.; Wang, J.; Wang, Z.L. A highly efficient constant-voltage triboelectric nanogenerator. Energy Environ. Sci. 2022, 15, 1334–1345. [Google Scholar] [CrossRef]

- Hou, H.; Xu, Q.; Pang, Y.; Li, L.; Wang, J.; Zhang, C.; Sun, C. Efficient storing energy harvested by triboelectric nanogenerators using a safe and durable all-solid-state sodium-ion battery. Adv. Sci. 2017, 4, 1700072. [Google Scholar] [CrossRef]

- Gao, Y.; He, L.; Liu, D.; Zhang, J.; Zhou, L.; Wang, Z.L.; Wang, J. Spontaneously established reverse electric field to enhance the performance of triboelectric nanogenerators via improving Coulombic efficiency. Nat. Commun. 2024, 15, 4167. [Google Scholar] [CrossRef] [PubMed]

- Pathak, M.; Kumar, R. Synchronous pre-biasing of triboelectric nanogenerator for enhanced energy extraction. IEEE Trans. Power Electron. 2022, 37, 11552–11566. [Google Scholar] [CrossRef]

- Wen, J.; Pan, X.; Fu, H.; Xu, B. Advanced designs for electrochemically storing energy from triboelectric nanogenerators. Matter 2023, 6, 2153–2181. [Google Scholar] [CrossRef]

- Khan, M.U.; Dumbre, D.; Abbas, Y.; Rezeq, M.; Alazzam, A.; Alamoodi, N.; Khaleel, M.; Mohammad, B. Triboelectric nanogenerator based on silane-coupled LTA/PDMS for physiological monitoring and biomechanical energy harvesting. Microsyst. Nanoeng. 2024, 10, 152. [Google Scholar] [CrossRef] [PubMed]

- Behera, S.A.; Hajra, S.; Panda, S.; Sahu, A.K.; Alagarsamy, P.; Mishra, Y.K.; Kim, H.J.; Achary, P.G.R. Synergistic energy harvesting and humidity sensing with single electrode triboelectric nanogenerator. Ceram. Int. 2024, 50, 37193–37200. [Google Scholar] [CrossRef]

- Zhang, R. Machine learning-assisted triboelectric nanogenerator-based self-powered sensors. Cell Rep. Phys. Sci. 2024, 5, 101888. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, J.; Shao, Y.; Ni, X.; Xie, J.; Luo, H.; Yang, T. Rotational Triboelectric Nanogenerator with Machine Learning for Monitoring Speed. Sensors 2025, 25, 2533. [Google Scholar] [CrossRef]

- Xu, G.; Zhao, Z.; Wang, Z.L.; Li, H.-F. Integrating machine learning with triboelectric nanogenerators: Optimizing electrode materials and doping strategies for intelligent energy harvesting. Nano Energy 2025, 142, 111131. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q.; Xia, Z.; Wang, J.; Yao, H.; Shen, Q.; Yang, H. A humidity-and environment-resisted high-performance triboelectric nanogenerator with superhydrophobic interface for energy harvesting and sensing. Nano Energy 2023, 109, 108300. [Google Scholar] [CrossRef]

- Wang, Y.; Du, H.; Yang, H.; Xi, Z.; Zhao, C.; Qian, Z.; Chuai, X.; Peng, X.; Yu, H.; Zhang, Y.; et al. A rolling-mode triboelectric nanogenerator with multi-tunnel grating electrodes and opposite-charge-enhancement for wave energy harvesting. Nat. Commun. 2024, 15, 6834. [Google Scholar] [CrossRef]

- Oh, J.; Kang, M.; Park, J.; Kim, T.Y.; Park, K.; Seo, J. Autonomously Self-healing, Adhesive, and Stretchable Triboelectric Nanogenerator Using Multifunctional Hydrogel-Elastomer Double Layer with a Power Management Circuit. Adv. Electron. Mater. 2024, 10, 2400013. [Google Scholar] [CrossRef]

- Xia, K.; Xu, Z.; Wang, L.; Yu, M. Multi-Roller Structure Triboelectric Nanogenerator for Enhanced Water Wave Energy Harvesting and Energy Management. arXiv 2024, arXiv:2409.03601. [Google Scholar] [CrossRef]

- Sheng, F.; Zhang, B.; Cheng, R.; Wei, C.; Shen, S.; Ning, C.; Yang, J.; Wang, Y.; Wang, Z.L.; Dong, K. Wearable energy harvesting-storage hybrid textiles as on-body self-charging power systems. Nano Res. Energy 2023, 2, e9120079. [Google Scholar] [CrossRef]

- Deng, X. A Wearable Triboelectric Nanogenerator Based on Polyester-Paper Cloth for Mechanical Energy Harvesting and Running Motion Sensing. ChemistryOpen 2025, 14, e202400373. [Google Scholar] [CrossRef]

- Dip, T.M.; Arin, R.A.; Anik, H.R.; Uddin, M.; Tushar, S.I.; Sayam, A.; Sharma, S. Triboelectric Nanogenerators for Marine Applications: Recent Advances in Energy Harvesting, Monitoring, and Self-Powered Equipment. Adv. Mater. Technol. 2023, 8, 2300802. [Google Scholar] [CrossRef]

- Guo, X.; He, J.; Zheng, Y.; Wu, J.; Pan, C.; Zi, Y.; Cui, H.; Li, X. High-performance triboelectric nanogenerator based on theoretical analysis and ferroelectric nanocomposites and its high-voltage applications. Nano Res. Energy 2023, 2, e9120074. [Google Scholar] [CrossRef]

- Qu, W.; Zhong, C.; Luan, P.; Shi, W.; Geng, L.; Shi, G.; Chen, R. Self-powered system based on triboelectric nanogenerator in agricultural groundwater pollution monitoring and control. Front. Energy Res. 2024, 12, 1324866. [Google Scholar] [CrossRef]

- Munirathinam, P.; Chandrasekhar, A. Self-powered triboelectric nanogenerator for security applications. Micromachines 2023, 14, 592. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Fu, H.; Xu, B. Advanced design of triboelectric nanogenerators for future eco-smart cities. Adv. Compos. Hybrid Mater. 2024, 7, 102. [Google Scholar] [CrossRef]

- Chen, J. Self powered triboelectric nanogenerator with enhanced surface charge density for dynamic multidirectional pressure sensing. In Sensors & Diagnostics; RSC Publishing: Cambridge, UK, 2024. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dien, X.; Ramli, N.; Thio, T.H.G.; Yang, Z.; Hu, S.; He, X. Energy Storage, Power Management, and Applications of Triboelectric Nanogenerators for Self-Powered Systems: A Review. Micromachines 2025, 16, 1170. https://doi.org/10.3390/mi16101170

Dien X, Ramli N, Thio THG, Yang Z, Hu S, He X. Energy Storage, Power Management, and Applications of Triboelectric Nanogenerators for Self-Powered Systems: A Review. Micromachines. 2025; 16(10):1170. https://doi.org/10.3390/mi16101170

Chicago/Turabian StyleDien, Xiong, Nurulazlina Ramli, Tzer Hwai Gilbert Thio, Zhuanqing Yang, Siyu Hu, and Xiang He. 2025. "Energy Storage, Power Management, and Applications of Triboelectric Nanogenerators for Self-Powered Systems: A Review" Micromachines 16, no. 10: 1170. https://doi.org/10.3390/mi16101170

APA StyleDien, X., Ramli, N., Thio, T. H. G., Yang, Z., Hu, S., & He, X. (2025). Energy Storage, Power Management, and Applications of Triboelectric Nanogenerators for Self-Powered Systems: A Review. Micromachines, 16(10), 1170. https://doi.org/10.3390/mi16101170