Early Warning of AC Salt Fog Flashover on Composite Insulators Using Fiber Bragg Grating Sensing and Visible Arc Images

Abstract

1. Introduction

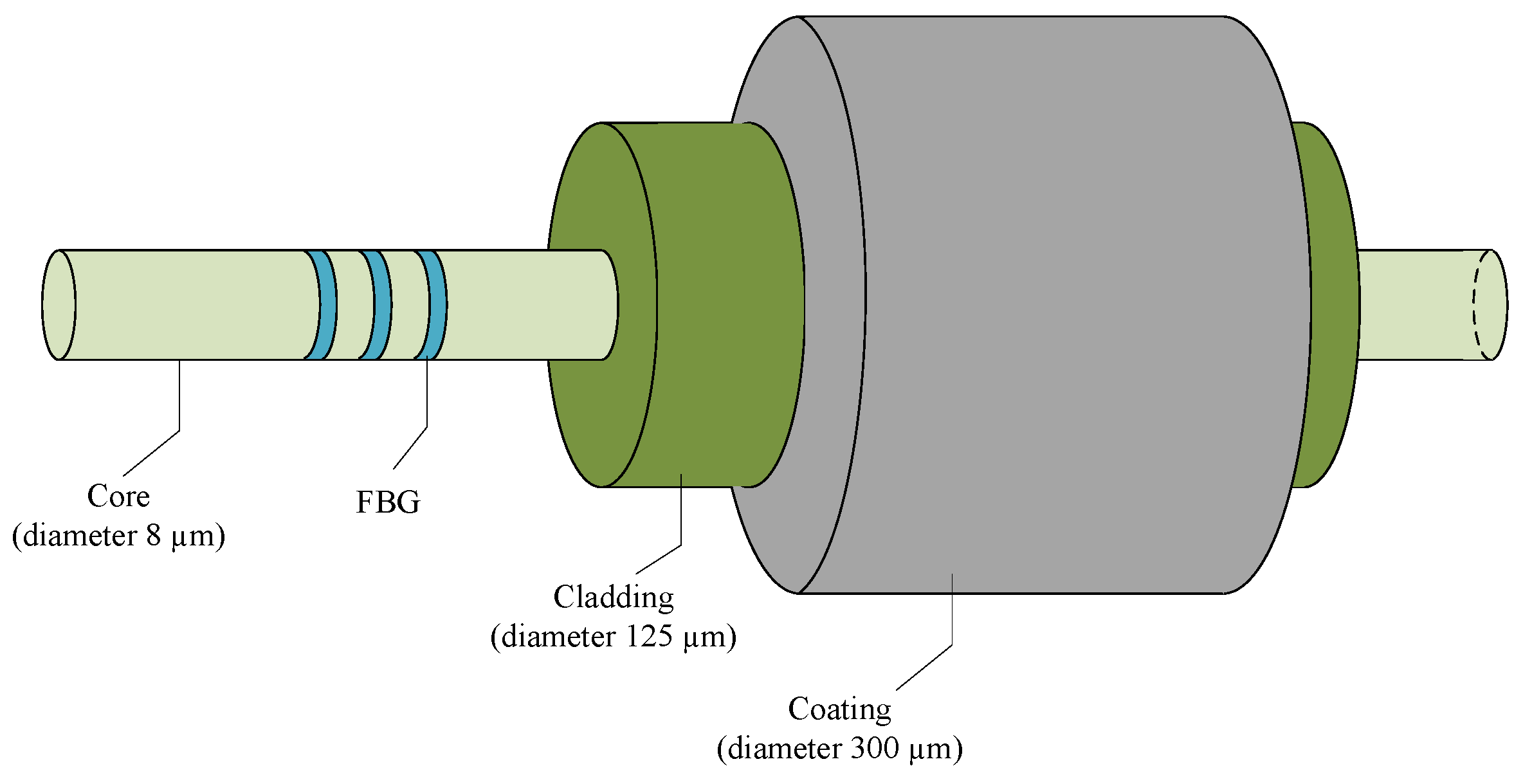

2. Temperature Detection Principle of FBG

3. Fabrication Method of Fiber-Optic Composite Insulators

- (1)

- The epoxy resin–glass fiber core rod should be polished at first, to maximize adhesion strength, with positions for composite insulator sheds are marked on its surface.

- (2)

- Five optical fibers with Bragg gratings (customized by Zhongke Sensing Technology Co., Ltd., Shenzhen, China), the sensing length of each FBG is 10 mm.) were bonded to the core rod surface using epoxy (Kafuter K-703, Evergrande New Materials Technology Co., Ltd., Huizhou, China) adhesive with low shrinkage rate, high toughness, and excellent resistance to hygrothermal aging, aiming at effectively mitigating the internal stresses arising from the coefficient of thermal expansion mismatch among the Fiber-Reinforced Plastic (FRP), epoxy, and the optical fiber. The customized optical fiber with a total length of approximately 3.5 m was used. Among this, about 0.29 m was precisely positioned within the core rod-silicone rubber sheath interface of the composite insulator, serving as the strain-sensing region, while the remaining approximately 3.21 m served as the pigtail to ensure the measurement equipment could be located in a safe zone during high-voltage experiments. Fiber 1# and Fiber 4# were placed at identical positions to verify data accuracy. Layout of fiber gratings is shown in Figure 2a.

- (3)

- Room-temperature vulcanized (RTV) silicone rubber (Kafuter K-704, Evergrande New Materials Technology Co., Ltd., Huizhou, China) was uniformly applied to the core rod surface. The resulting core rod–fiber grating–RTV silicone rubber bonding structure is shown in Figure 2b.

- (4)

- Crimping of metal fittings was performed after initial RTV silicone rubber curing.

- (5)

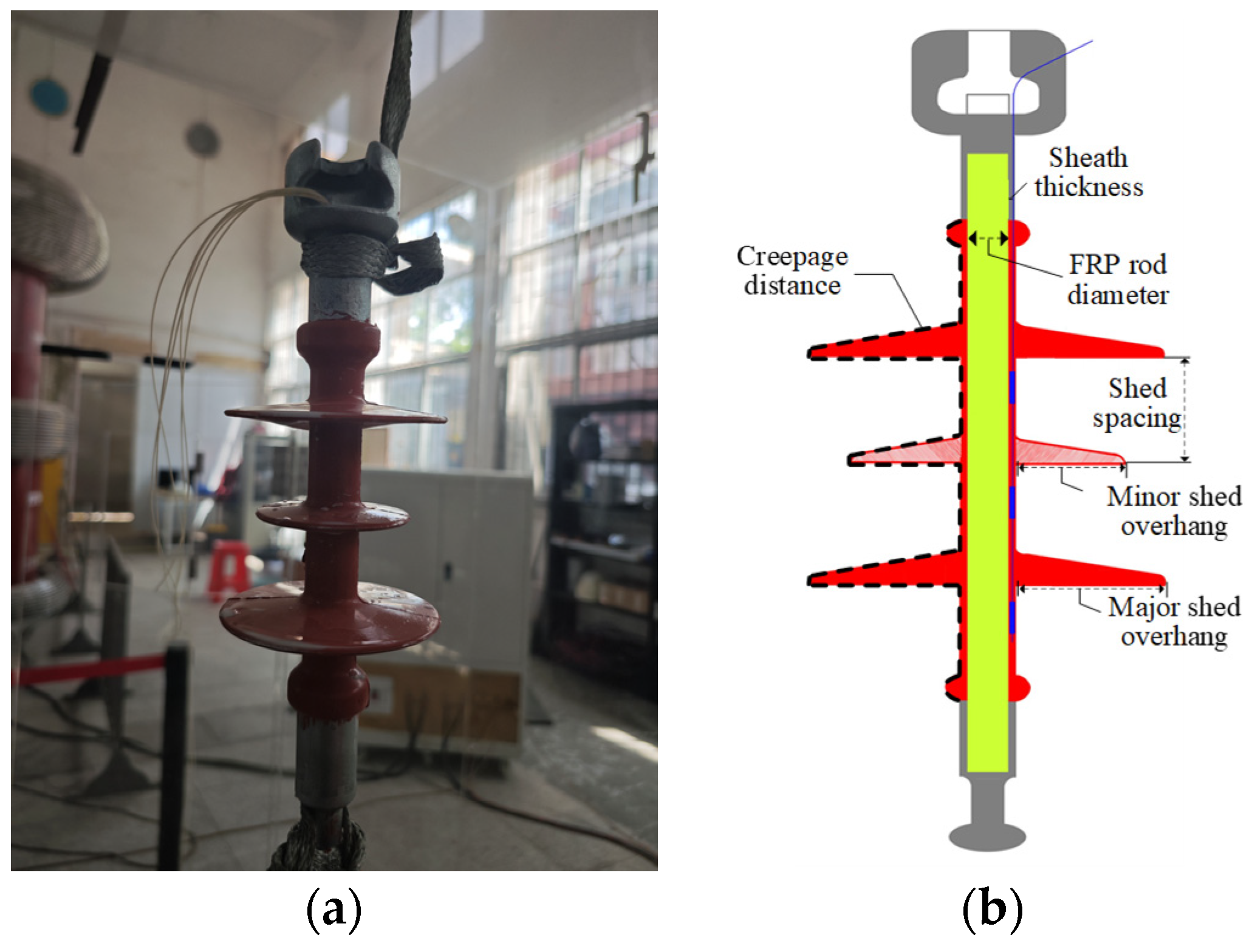

- Following complete RTV silicone rubber curing and consistent with the standard manufacturing process for conventional composite insulators using High-Temperature Vulcanizing (HTV) silicone rubber encapsulation, the core rod was baked at a temperature of 140 °C for a duration of over 30 min. Final sealing was then carried out with adhesive to complete fabrication of the fiber-optic composite insulator, as shown in Figure 3a.

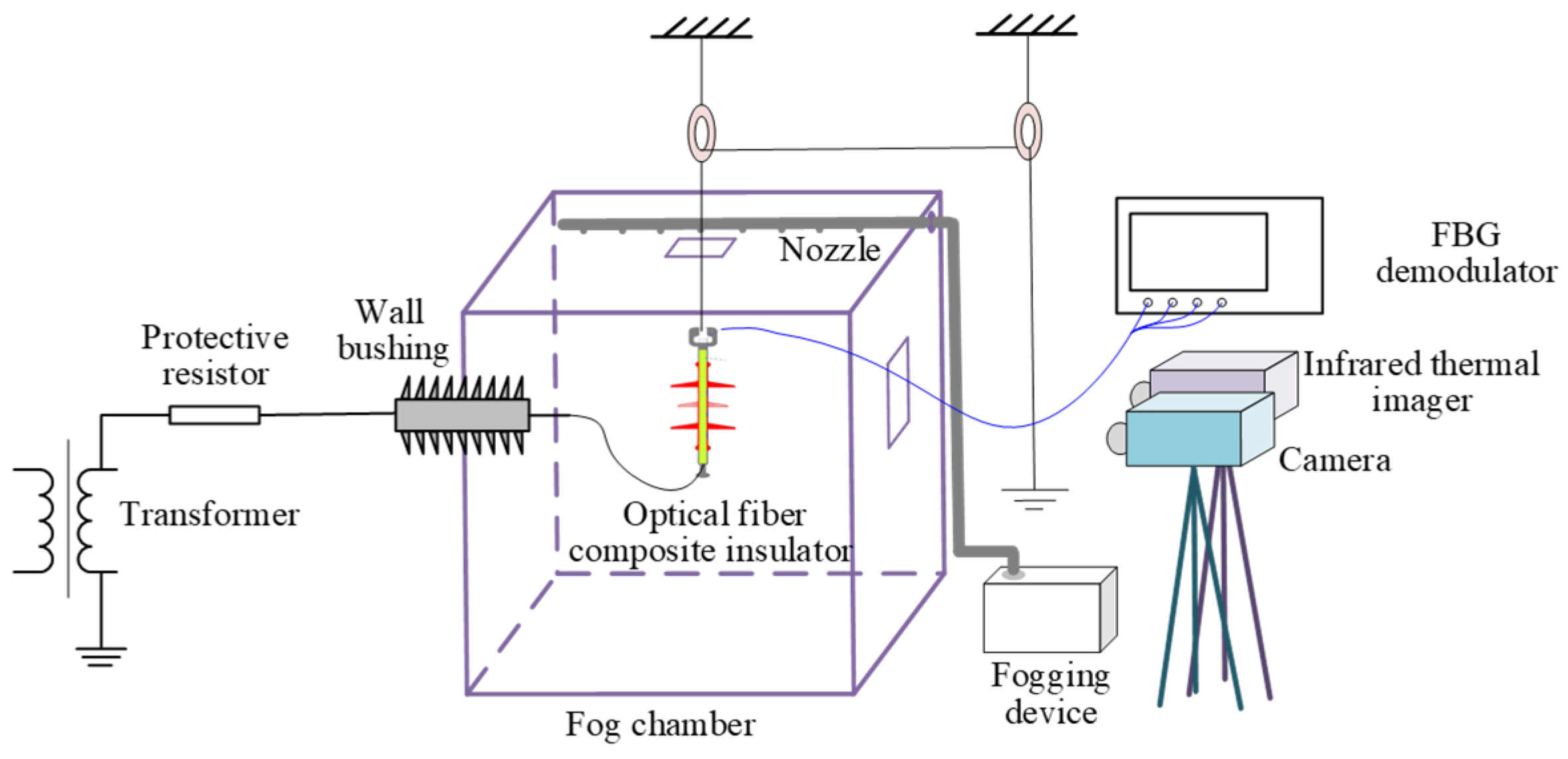

4. Experimental Methodology

4.1. Testing System

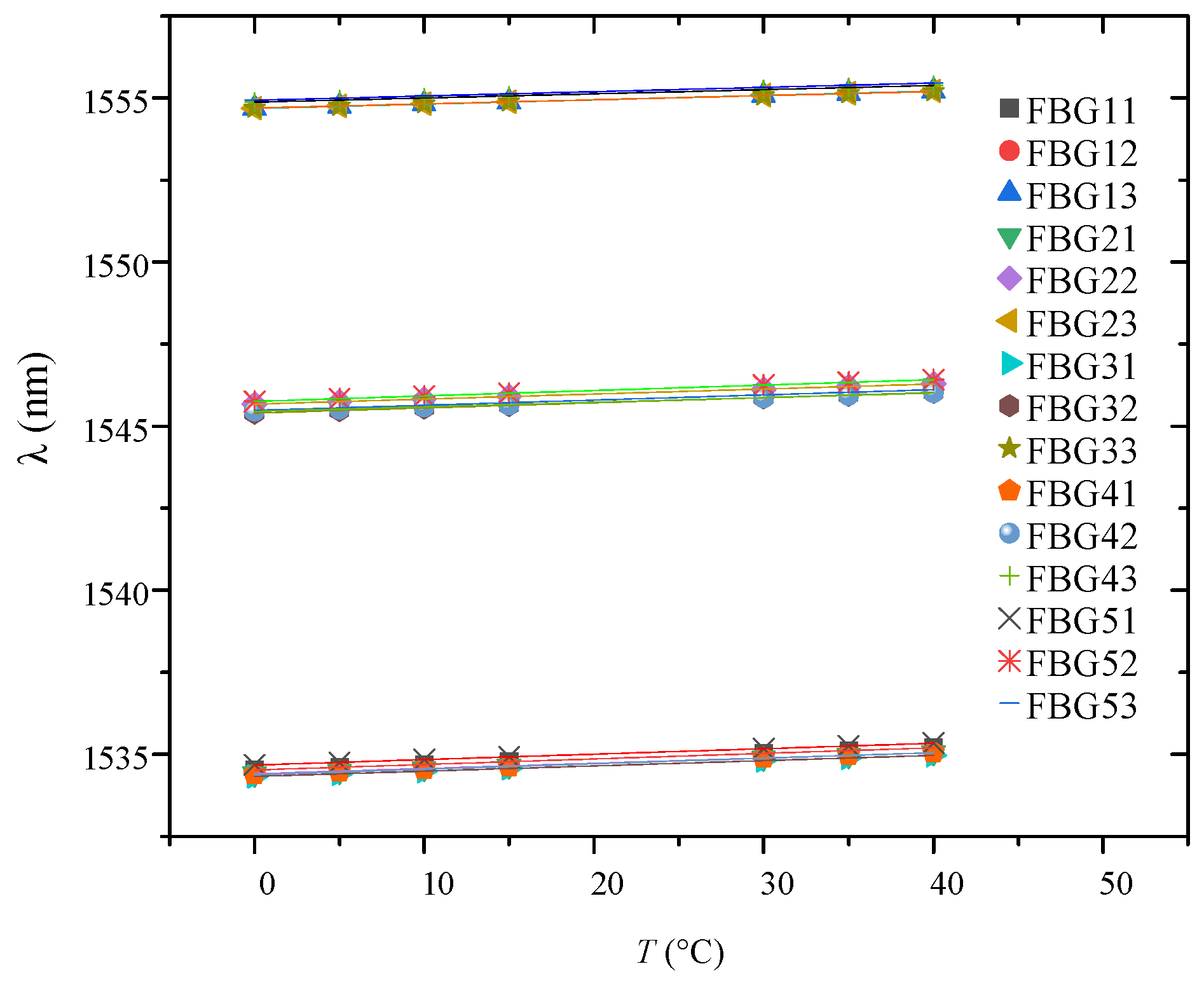

4.2. Fiber-Grating Temperature Calibration Experiment

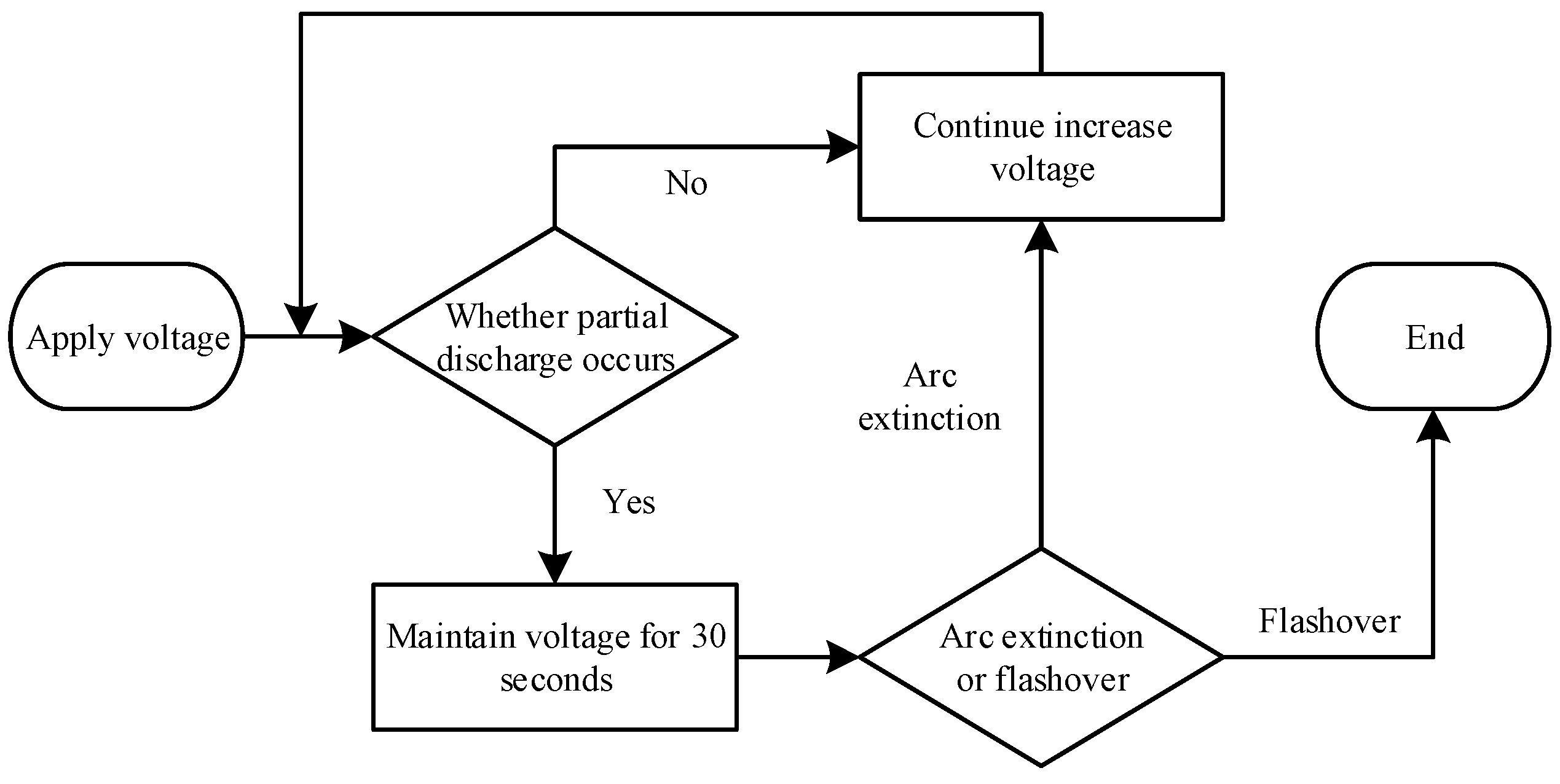

4.3. Experimental Procedure

5. Results and Analysis

5.1. Fiber-Grating Temperature Calibration Results

5.2. FBG Temperature and Visible Images During Flashover of Fiber-Optic Composite Insulator

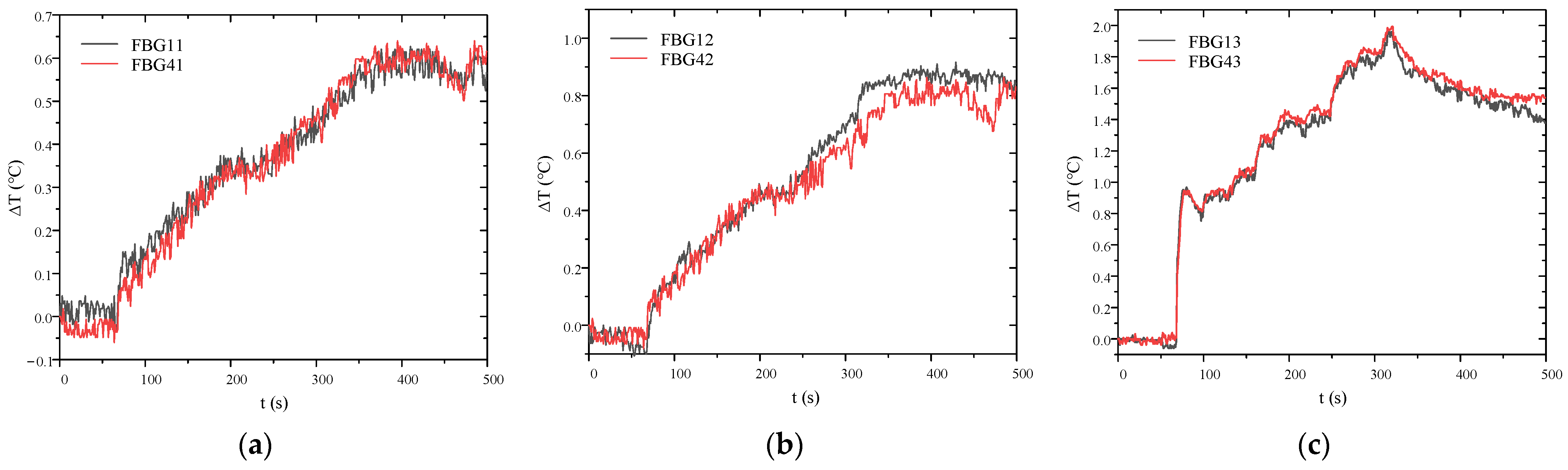

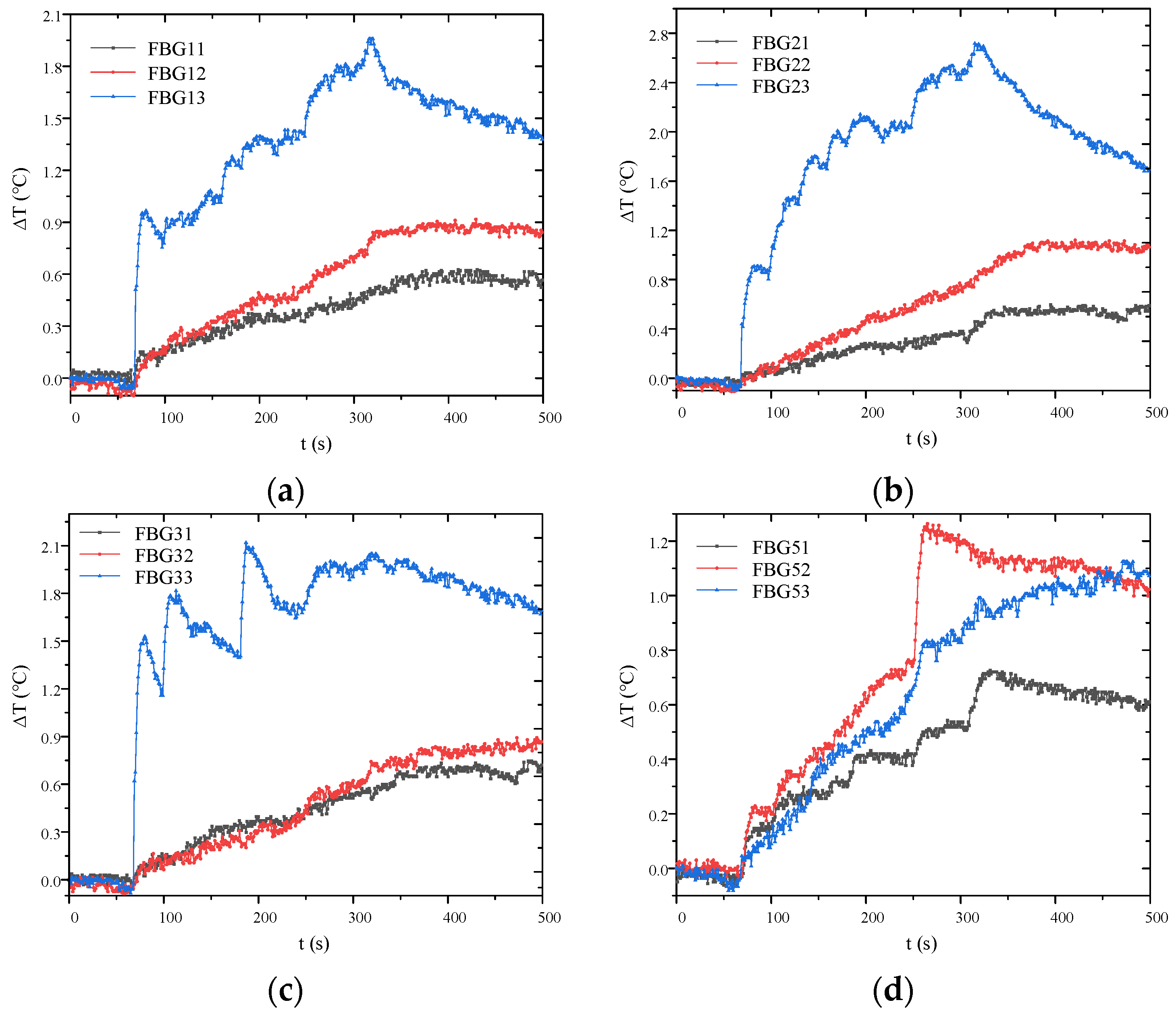

5.2.1. FBG Temperature

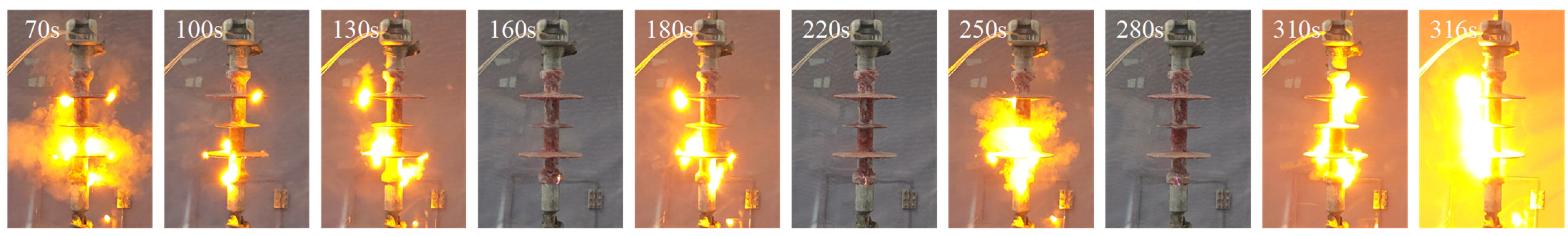

5.2.2. Arc Visible-Light Images

5.3. Early Warning for AC Salt Fog Flashover of Fiber-Optic Composite Insulator

5.3.1. Flashover Early Warning Based on FBG Interfacial Temperature Rise

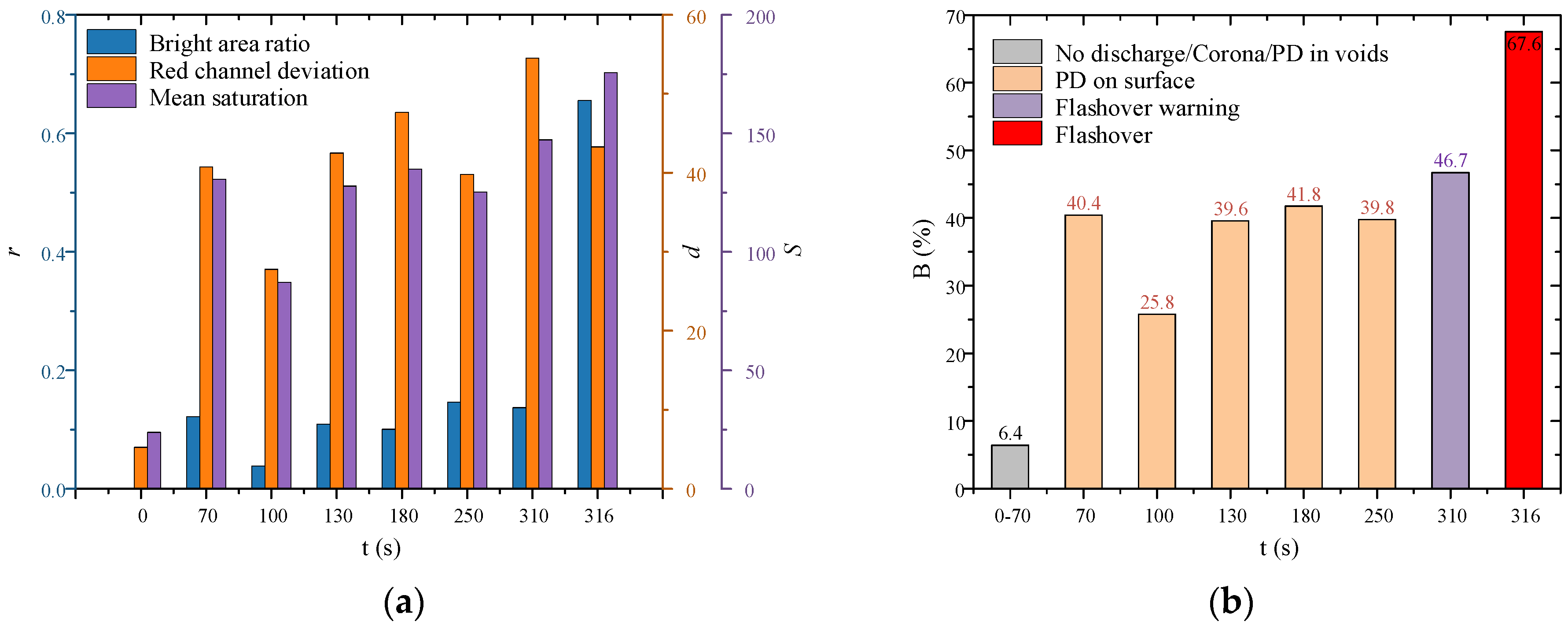

5.3.2. Flashover Early Warning Based on Visible Images of Arc

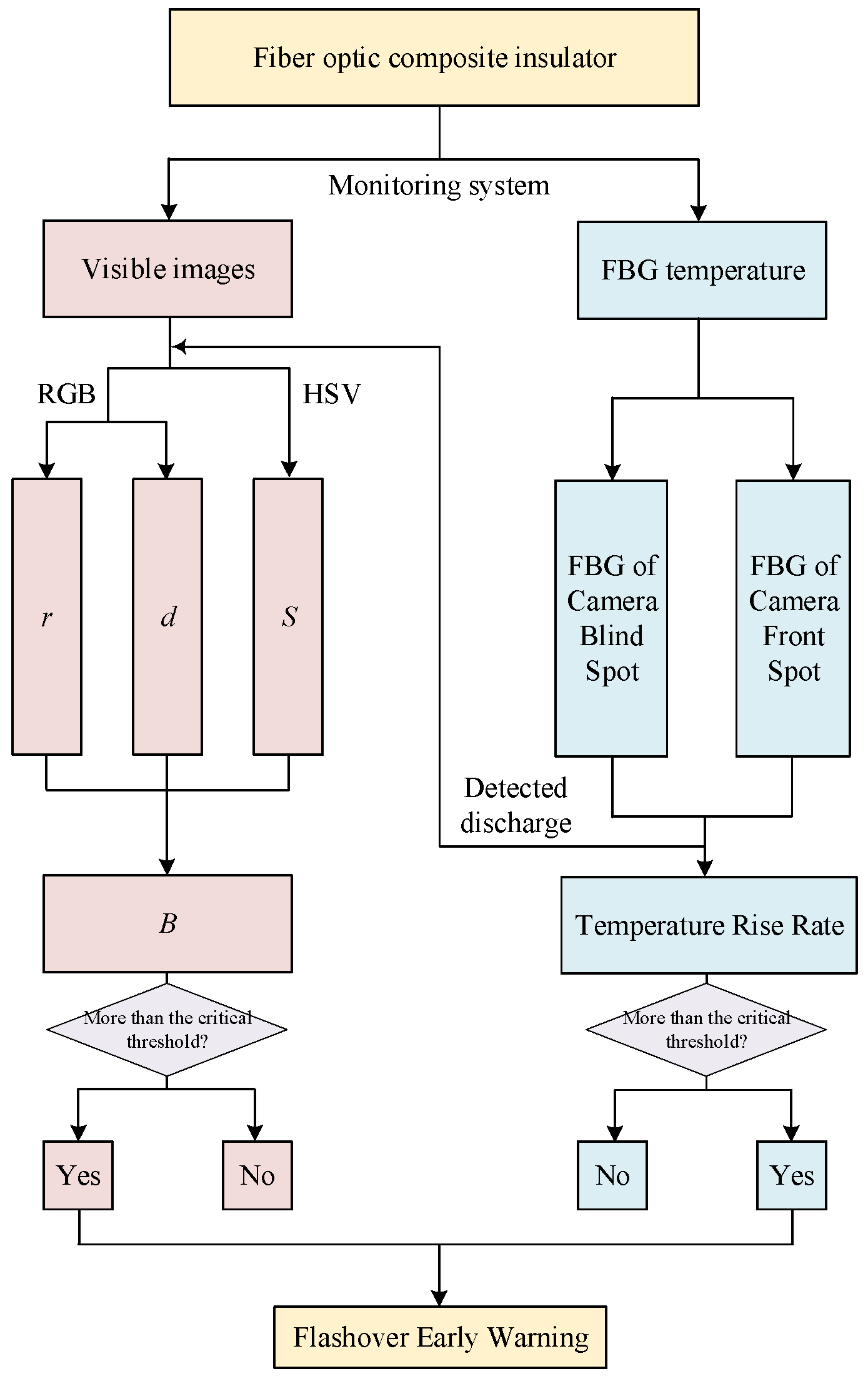

5.3.3. Dual-Parameter Collaborative Flashover Early Warning

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, X.; Chi, Y.; Ma, S.; Fan, Y.; Li, Y.; Wang, C. Research and Application of Key Technologies and Technical Standards for Large-scale Offshore Wind Farms Connecting to Power Grid. Power Syst. Technol. 2022, 46, 2589–2870. [Google Scholar]

- Aouabed, F.; Bayadi, A.; Boudissa, R. Flashover voltage of silicone insulating surface covered by water droplets under AC voltage. Electr. Power Syst. Res. 2017, 143, 66–72. [Google Scholar] [CrossRef]

- Mohammadnabi, S.; Rahmani, K. Influence of humidity and contamination on the leakage current of 230-kV composite insulator. Electr. Power Syst. Res. 2021, 194, 107083. [Google Scholar] [CrossRef]

- Su, Z. Influences of Fog-Haze on External Insulation of Transmission and Distribution Equipments. Power Syst. Technol. 2013, 37, 2284–2290. [Google Scholar]

- Li, J.; Wang, X.; Huang, Z.; Zhao, X.; Wang, F. Research of Preparation, Anti-icing and Anti-pollution of Super Hydrophobic Insulation Coatings. Trans. China Electrotech. Soc. 2017, 32, 61–75. [Google Scholar]

- Su, H.; Jia, Z.; Guan, Z.; Li, L. Mechanism of contaminant accumulation and flashover of insulator in heavily polluted coastal area. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1635–1641. [Google Scholar] [CrossRef]

- Guan, Z.; Wang, S.; Liang, X.; Wang, L.; Fan, J. Application and Prospect of Polymeric Outdoor Insulation in China. High Volt. Eng. 2000, 26, 37–39. [Google Scholar]

- Cui, J.; Su, Z.; Che, W.; Fan, J.; Liu, X.; Wu, G.; Zhao, F. Analysis of large area flashover accidents in Northeast, North China and Henan power grids in early 2001. Electr. Equip. 2001, 2, 6–20. [Google Scholar]

- Yang, L.; Bi, J.; Zhang, F.; Hao, Y.; Li, L.; Liao, Y.; Zhang, F. Effects of structure and material of polluted insulators on the wetting characteristics. IET Sci. Meas. Technol. 2019, 13, 131–138. [Google Scholar] [CrossRef]

- Sun, S.; Ma, F.; He, Y.; Niu, B.; Wang, C.; Dai, L.; Zhao, Z. An optimized PZT-FBG voltage/temperature sensor. Micromachines 2025, 16, 235. [Google Scholar] [CrossRef]

- Du, C.; Kong, D.; Xu, C. Development of a fault detection instrument for fiber bragg grating sensing system on airplane. Micromachines 2022, 13, 882. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, L.; Zheng, Z.; Quan, Y.; Chen, Z.; Cao, J.; Zhang, T.; Xie, X.; Liu, X.; Xiang, P. Bending strain progression and damage of asphalt beams based on distributed fibre optic sensors. Int. J. Pavement Eng. 2025, 26, 2479645. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, T.; Bao, Y.; Liu, R.; He, J. Experimental study on damage monitoring of FRP plate using FBG sensors. Micromachines 2025, 16, 649. [Google Scholar] [CrossRef]

- Chen, R.; He, J.; Xu, X.; Wu, J.; Wang, Y.; Wang, Y. High-quality fiber bragg gratings inscribed by femtosecond laser point-by-point technology. Micromachines 2022, 13, 1808. [Google Scholar] [CrossRef]

- Zhao, N.; Zhang, Z.; Lin, Q.; Yao, K.; Zhu, L.; Chen, Y.; Zhao, L.; Tian, B.; Yang, P.; Jiang, Z. Research on the high temperature and high pressure gold-plated fiber grating dual-parameter sensing measurement system. Micromachines 2022, 13, 195. [Google Scholar] [CrossRef]

- Trouillet, A.; Lepley, D.; Mure-Ravaud, A.; Marin, E. Integration of fibre bragg grating strain sensors into composite electrical insulators. In Proceedings of the Second European Workshop on Optical Fibre Sensors (SPIE), Santander, Spain, 9–11 June 2004; Volume 5502, pp. 92–95. [Google Scholar]

- Kerrouche, A.; Boyle, W.J.; Sun, T.; Grattan, K.T.; Schmidt, J.W.; Taljsten, B. Strain measurement using embedded fiber bragg grating sensors inside an anchored carbon fiber polymer reinforcement prestressing rod for structural monitoring. IEEE Sens. J. 2009, 9, 1456–1461. [Google Scholar] [CrossRef]

- Cai, W.; Zhou, G.; Yang, H.; Wang, X.; Ma, J.; Xiong, P. Study on the Optic Fiber Sensors Intelligent Monitoring Experiment with Composite Insulator. High Volt. Eng. 2010, 36, 1167–1171. [Google Scholar]

- Chen, W.; Dong, X.; Yang, F.; Zeng, X.; Ma, J.; Wang, X.; Ma, X. Theoretical analysis of temperature response of the fiber bragg grating embedded in composite insulator. In Proceedings of the Advanced Laser Manufacturing Technology (SPIE), Beijing, China, 19 October 2016; Volume 10153, pp. 229–234. [Google Scholar]

- Hao, Y.; Wang, Q.; Bi, J.; Yang, Z.; Pan, R.; Zheng, Y. Temperature Distribution and Transient Process of Interface Heat in Composite Insulators. High Volt. Eng. 2022, 48, 3497–3506. [Google Scholar]

- Hao, Y.; Bi, J.; Wang, Q.; Wei, J.; Chen, Y.; Yang, L. Method of quasi-distributed interface fiber bragg gratings monitoring dry band arc on the moist pollution layer of composite insulators. Electr. Power Syst. Res. 2022, 209, 107956. [Google Scholar] [CrossRef]

- Bi, J.; Hao, Y.; Zheng, Y.; Wu, X.; Wu, H.; Huang, L.; Chen, Y.; Yang, L. A method for detecting conductive droplet deformation and flashover using interface temperature based on electrothermal synergistic mechanism. Electr. Power Syst. Res. 2023, 218, 109212. [Google Scholar] [CrossRef]

- Fang, C.; Zhou, Y.; Wang, J.; Jia, B.; Sun, C.; Pan, M. Extraction of Insulator Discharge Arc Area Based on the Theory of Image Processing Techniques. Insul. Surge Arresters 2016, 2, 35–39. [Google Scholar]

- Li, F.; Ye, Q.; Wang, Y.; Guo, Z.; Dong, X.; Hu, J. Research on RGB Chromaticity of Corona Discharge Visible Digital Image. Proc. CSEE 2018, 38, 1881–1888. [Google Scholar]

- Thanh, P.N.; Cho, M.-Y.; Da, T.N. Insulator leakage current prediction using surface spark discharge data and particle swarm optimization based neural network. Electr. Power Syst. Res. 2021, 191, 106888. [Google Scholar] [CrossRef]

- Kumosa, M.; Han, Y.; Kumosa, L. Analyses of composite insulators with crimped end-fittings: Part I—Non linear finite element computations. Compos. Sci. Technol. 2002, 62, 1191–1207. [Google Scholar] [CrossRef]

- Rollinson, C.M.; Wade, S.A.; Dragomir, N.M.; Baxter, G.W.; Collins, S.F. Strain and temperature response of transmission dips at 2/3 of the bragg wavelength in type iand IIA fiber bragg gratings. In Proceedings of the 17th International Conference on Optical Fibre Sensors (SPIE), Bruges, Belgium, 23–27 May 2005; Volume 5855, pp. 310–313. [Google Scholar]

- Yücel, M.; Öztürk, N.F.; Göktaş, H.H.; Gündüz, A.E. Design of a fiber bragg grating based temperature sensor. In Proceedings of the 2016 24th Signal Processing and Communication Application Conference (SIU), Zonguldak, Turkey, 16–19 May 2016; pp. 669–672. [Google Scholar]

- GB/T 22707-2008; Artificial Pollution Tests on High-Voltage Insulators to Be Used on d.c. Systems. China Standard Press: Beijing, China, 2008.

- Peng, G.; Guan, Z.; Zhang, F.; Mei, H.; Wang, L. Test Method of DC Artificial Contaminated Composite Insulators. High Volt. Eng. 2011, 37, 513–519. [Google Scholar]

- Wu, H.; Hao, Y.; Wu, X.; Bi, J.; Yang, L.; Li, L. Research on Visible Light Criterion for AC Salt Fog Flashover of Composite Insulators. Guangdong Electr. Power 2024, 37, 60–68. [Google Scholar]

- IEC 60507; Artificial Pollution Tests on High-Voltage Insulators to Be Used on a.c. Systems. European Standards Institute: Berlin, Germany, 1993.

- Du, S.; Cai, W.; Deng, H.; Wen, S.; Deng, W.; Xiong, P. Production and Calibration Test of the Composite Insulator with Fiber Bragg Grating Embedded. High Volt. Eng. 2012, 38, 2274–2780. [Google Scholar]

| Creepage Distance (mm) | Sheath Thickness (mm) | FRP Rod Diameter (mm) | Shed Spacing (mm) | Shed Overhang (mm) | |

|---|---|---|---|---|---|

| Major Shed | Minor Shed | ||||

| 382 | 3.2 | 18 | 45 | 37.8 | 22.8 |

| Gratings | λ (nm) | ||||||

|---|---|---|---|---|---|---|---|

| 0 °C | 5 °C | 10 °C | 15 °C | 30 °C | 35 °C | 40 °C | |

| FBG11 | 1534.5273 | 1534.6102 | 1534.6932 | 1534.7761 | 1535.0365 | 1535.1177 | 1535.2012 |

| FBG12 | 1545.4765 | 1545.5556 | 1545.6347 | 1545.7138 | 1545.9523 | 1546.0295 | 1546.1097 |

| FBG13 | 1554.6813 | 1554.7469 | 1554.8126 | 1554.8782 | 1555.0771 | 1555.1396 | 1555.2072 |

| FBG21 | 1534.4093 | 1534.4908 | 1534.5722 | 1534.6537 | 1534.8885 | 1534.9694 | 1535.0541 |

| FBG22 | 1545.6679 | 1545.7469 | 1545.8258 | 1545.9048 | 1546.1223 | 1546.2042 | 1546.2896 |

| FBG23 | 1554.6867 | 1554.7527 | 1554.8188 | 1554.8848 | 1555.0775 | 1555.1439 | 1555.2116 |

| FBG31 | 1534.3274 | 1534.4093 | 1534.4911 | 1534.573 | 1534.8119 | 1534.8899 | 1534.973 |

| FBG32 | 1545.397 | 1545.4766 | 1545.5562 | 1545.6358 | 1545.864 | 1545.9439 | 1546.0261 |

| FBG33 | 1554.6934 | 1554.7578 | 1554.8223 | 1554.8867 | 1555.0723 | 1555.1344 | 1555.2024 |

| FBG41 | 1534.3819 | 1534.4647 | 1534.5475 | 1534.6303 | 1534.8889 | 1534.9708 | 1535.0545 |

| FBG42 | 1545.4586 | 1545.52 | 1545.5814 | 1545.6428 | 1545.8586 | 1545.9374 | 1546.0206 |

| FBG43 | 1554.8739 | 1554.9379 | 1555.0019 | 1555.0659 | 1555.2595 | 1555.3188 | 1555.3825 |

| FBG51 | 1534.6785 | 1534.7605 | 1534.8425 | 1534.9245 | 1535.1765 | 1535.2574 | 1535.3421 |

| FBG52 | 1545.7533 | 1545.8364 | 1545.9195 | 1546.0026 | 1546.2494 | 1546.3313 | 1546.4171 |

| FBG53 | 1554.9293 | 1554.9964 | 1555.0636 | 1555.1307 | 1555.3227 | 1555.3888 | 1555.4604 |

| Gratings | KT (pm/°C) | R2 | λ0 at 22.6 °C (nm) |

|---|---|---|---|

| FBG11 | 16.59 | 0.9986 | 1534.9022 |

| FBG12 | 15.82 | 0.9999 | 1545.834 |

| FBG13 | 13.13 | 0.9999 | 1554.978 |

| FBG21 | 16.29 | 0.9985 | 1534.7775 |

| FBG22 | 15.79 | 0.9943 | 1546.0248 |

| FBG23 | 13.21 | 0.9995 | 1554.9852 |

| FBG31 | 16.37 | 0.9989 | 1534.6974 |

| FBG32 | 15.92 | 0.9986 | 1545.7568 |

| FBG33 | 12.89 | 0.9993 | 1554.9847 |

| FBG41 | 16.56 | 0.9987 | 1534.7562 |

| FBG42 | 16.27 | 0.9998 | 1545.7361 |

| FBG43 | 12.80 | 0.9983 | 1555.1632 |

| FBG51 | 16.40 | 0.9995 | 1535.0491 |

| FBG52 | 16.62 | 0.9999 | 1546.1289 |

| FBG53 | 13.43 | 0.9992 | 1555.2328 |

| Gratings | β (°C/s) | ||||||

|---|---|---|---|---|---|---|---|

| 70 s | 100 s | 130 s | 180 s | 250 s | 310 s | 316 s | |

| FBG51 | 2.26 × 10−2 | 1.83 × 10−2 | 3.35 × 10−2 | 2.44 × 10−2 | 1.22 × 10−2 | 4.88 × 10−2 | 3.66 × 10−2 |

| FBG52 | 2.41 × 10−2 | 1.81 × 10−2 | 2.41 × 10−2 | 2.41 × 10−2 | 4.69 × 10−2 | × | 1.81 × 10−2 |

| FBG53 | 2.79 × 10−2 | 2.73 × 10−2 | 2.23 × 10−2 | × | 1.19 × 10−2 | × | 4.96 × 10−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Hao, Y.; Wu, Z.; Bi, J.; Wu, H.; Huang, L. Early Warning of AC Salt Fog Flashover on Composite Insulators Using Fiber Bragg Grating Sensing and Visible Arc Images. Micromachines 2025, 16, 1171. https://doi.org/10.3390/mi16101171

Wu X, Hao Y, Wu Z, Bi J, Wu H, Huang L. Early Warning of AC Salt Fog Flashover on Composite Insulators Using Fiber Bragg Grating Sensing and Visible Arc Images. Micromachines. 2025; 16(10):1171. https://doi.org/10.3390/mi16101171

Chicago/Turabian StyleWu, Xiaoxiang, Yanpeng Hao, Zijian Wu, Jikai Bi, Haixin Wu, and Lei Huang. 2025. "Early Warning of AC Salt Fog Flashover on Composite Insulators Using Fiber Bragg Grating Sensing and Visible Arc Images" Micromachines 16, no. 10: 1171. https://doi.org/10.3390/mi16101171

APA StyleWu, X., Hao, Y., Wu, Z., Bi, J., Wu, H., & Huang, L. (2025). Early Warning of AC Salt Fog Flashover on Composite Insulators Using Fiber Bragg Grating Sensing and Visible Arc Images. Micromachines, 16(10), 1171. https://doi.org/10.3390/mi16101171