A Mini-Two-Path Mach–Zehnder Interferometer Sensor with High Curvature Sensitivity Based on Four-Mode Fiber

Abstract

1. Introduction

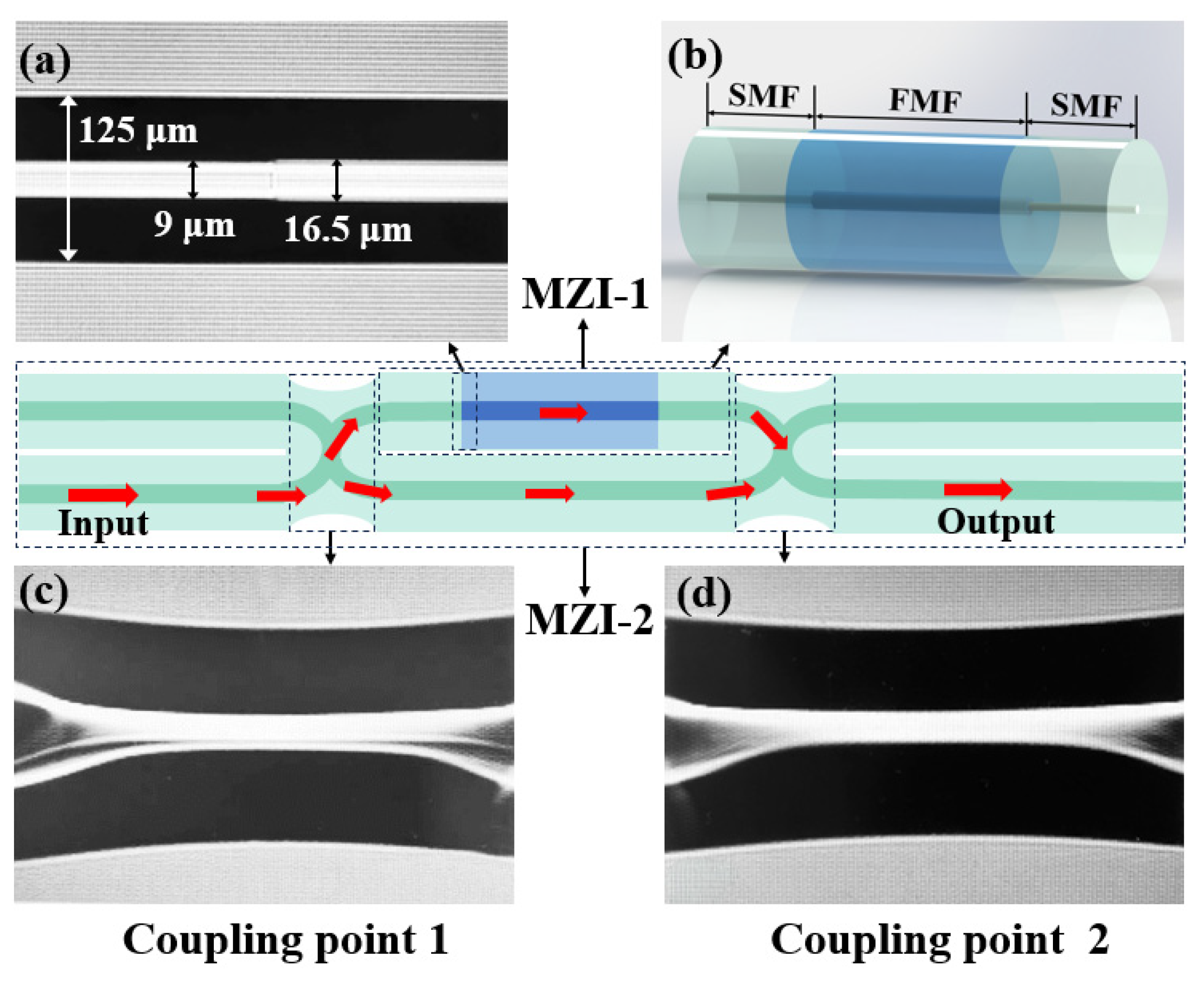

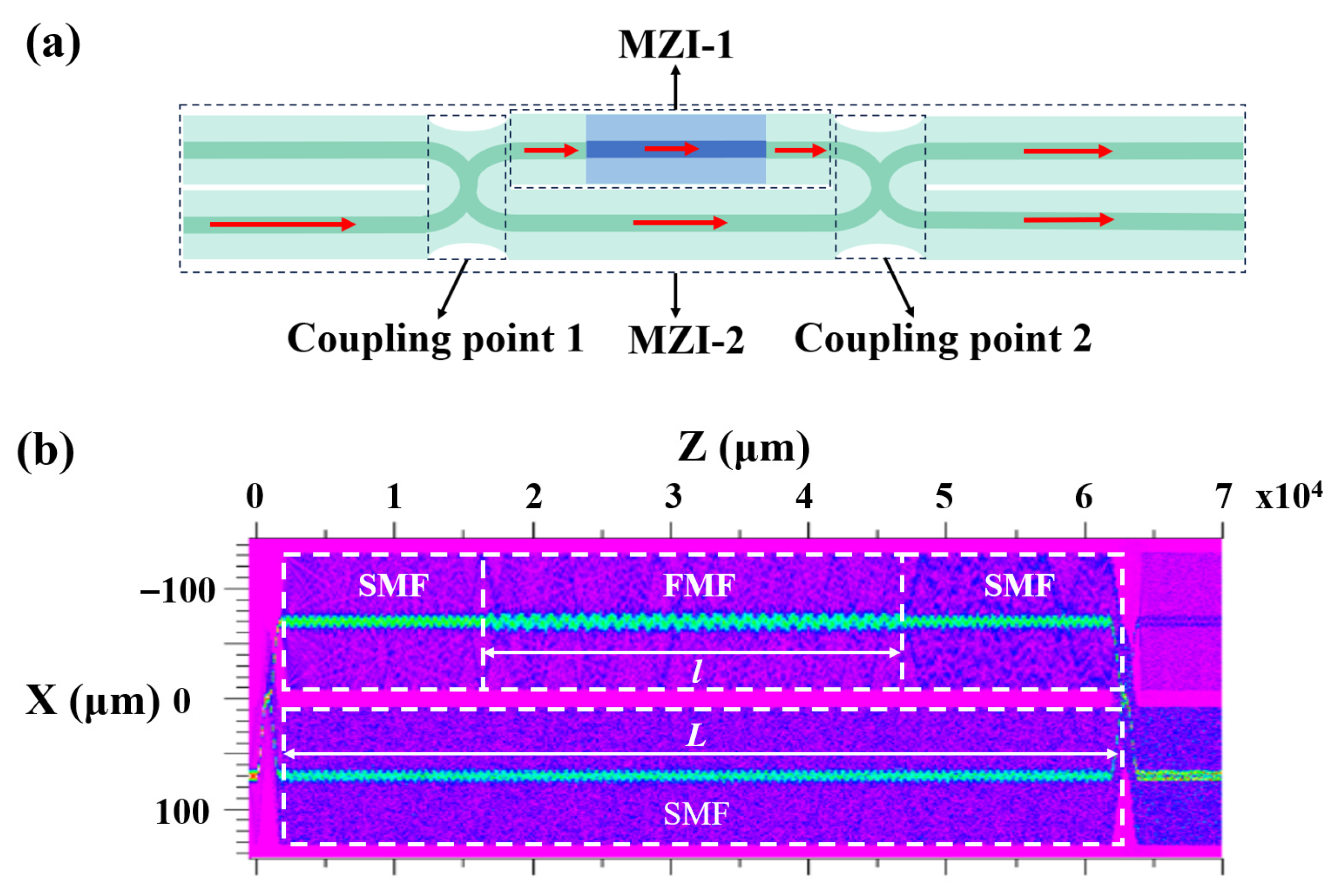

2. Structure Design and Principle of the Sensor

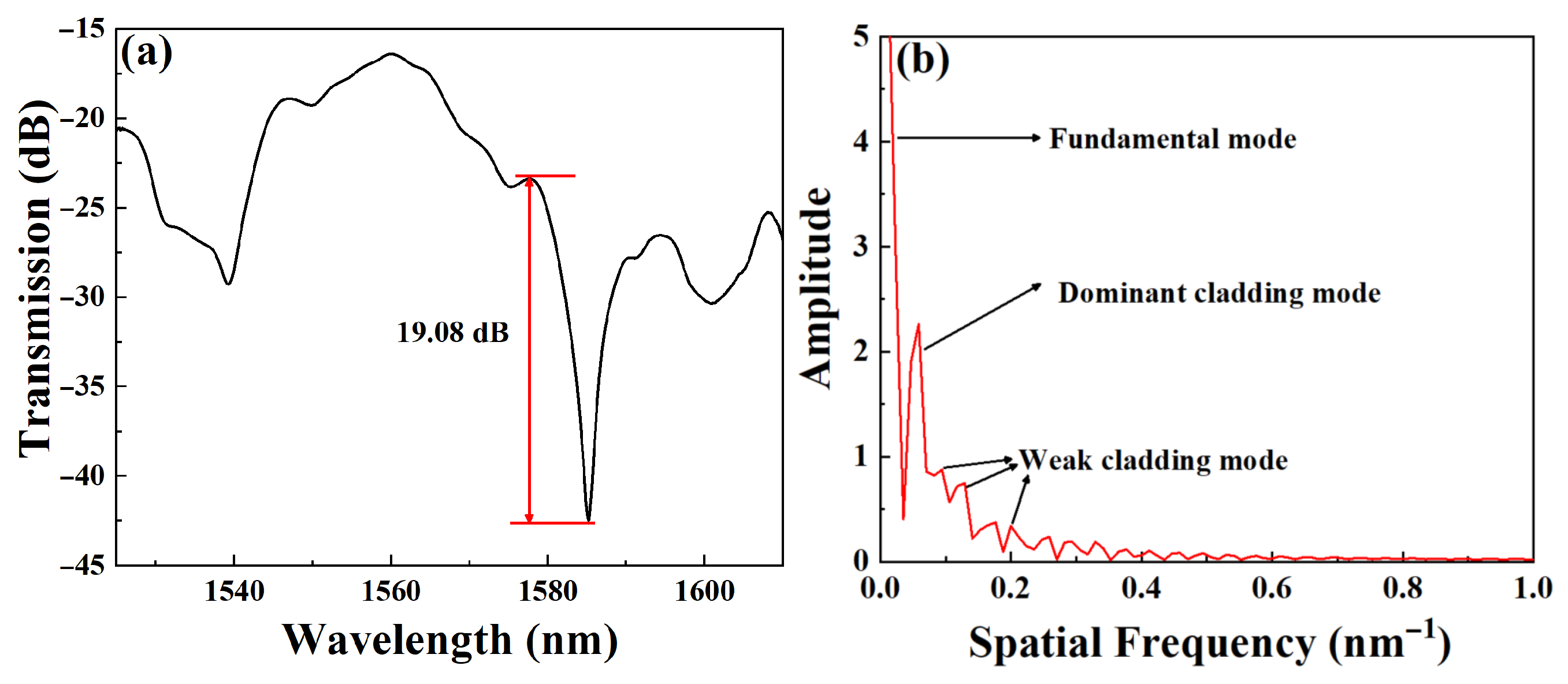

3. Experimental Results and Discussion

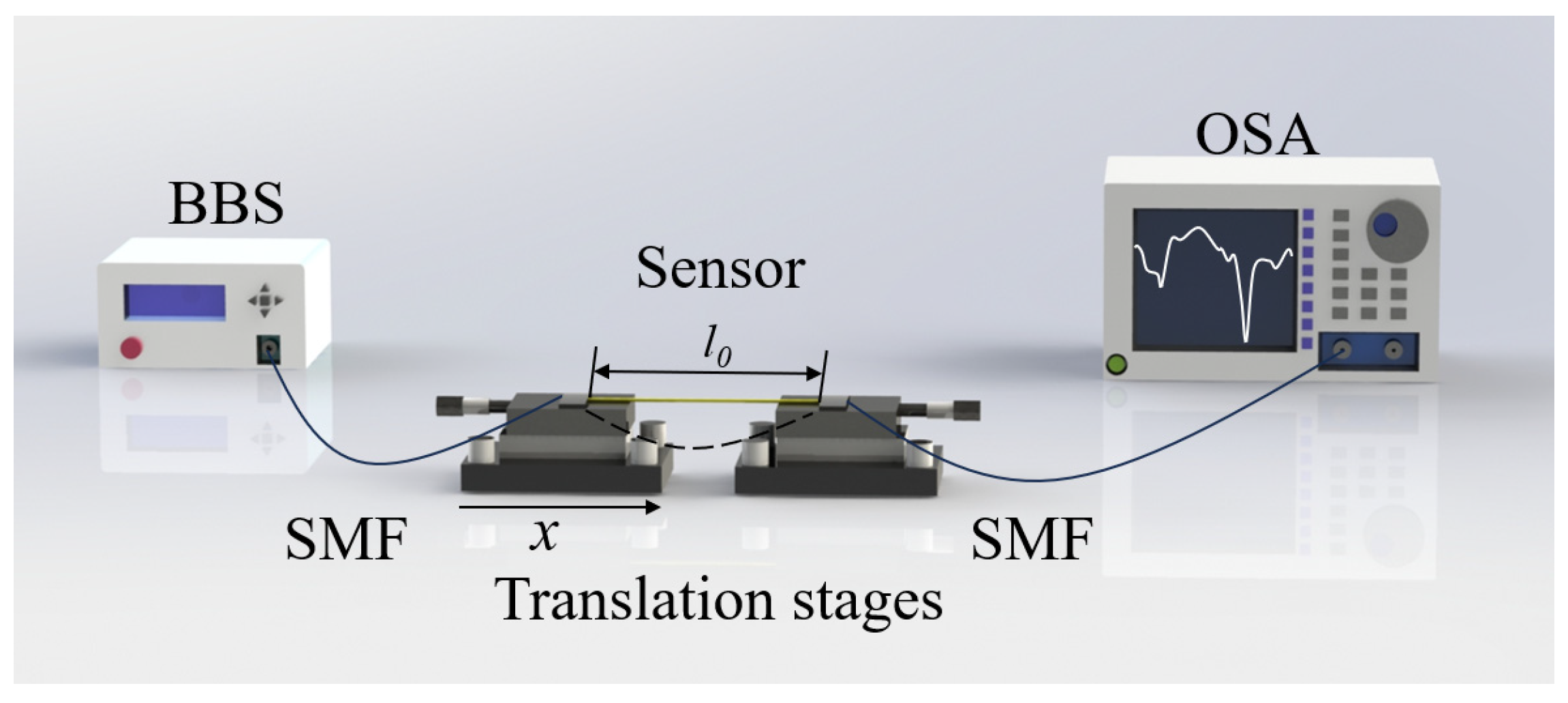

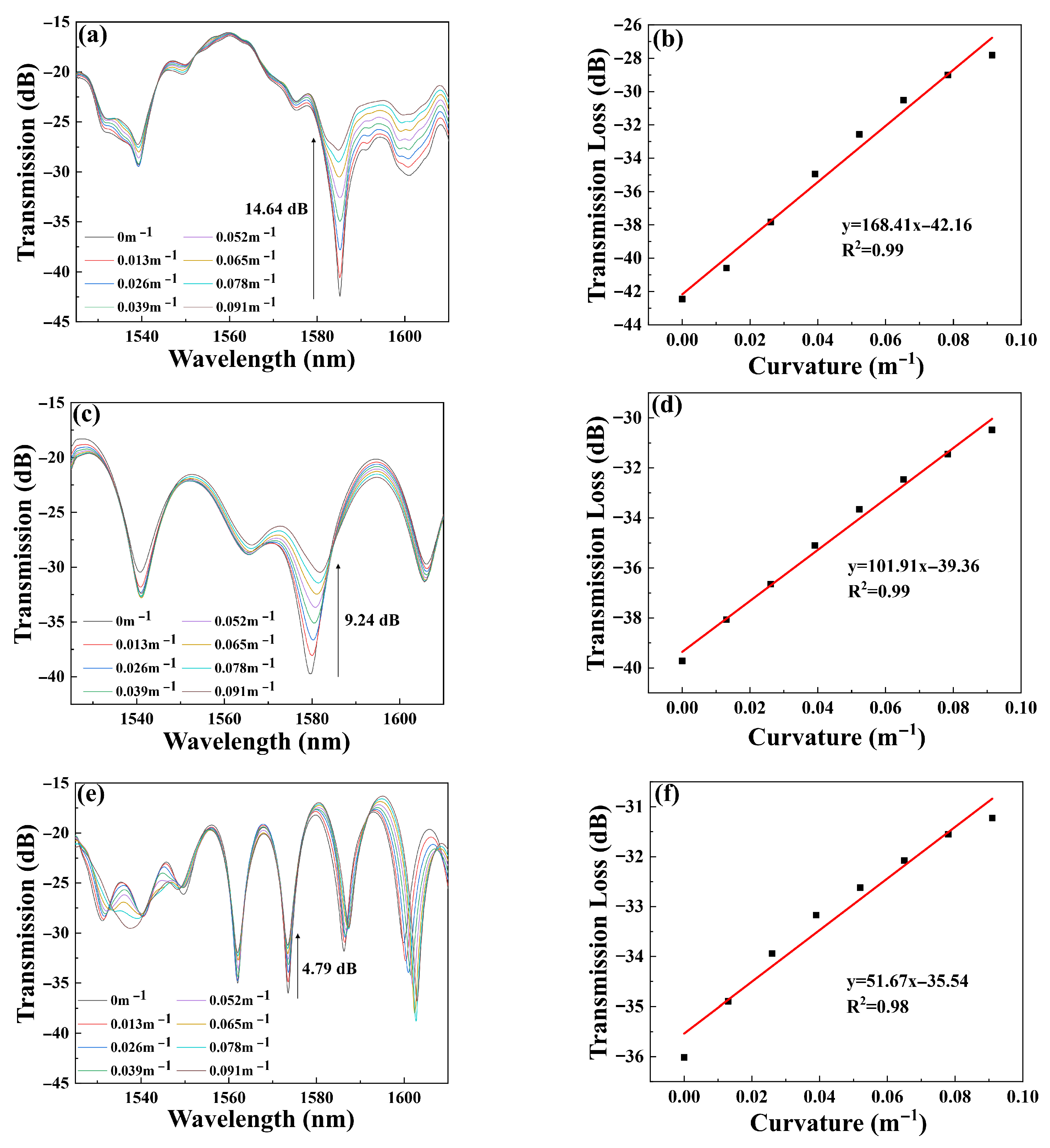

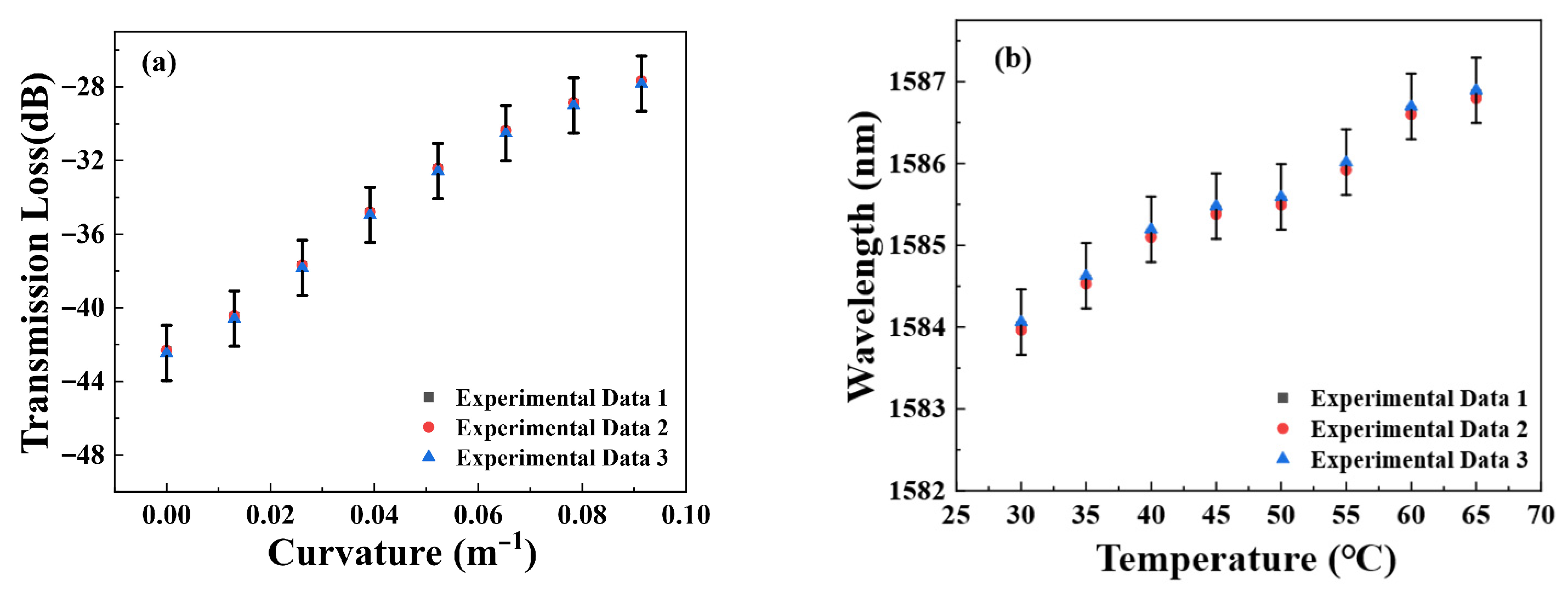

3.1. Curvature Measurement

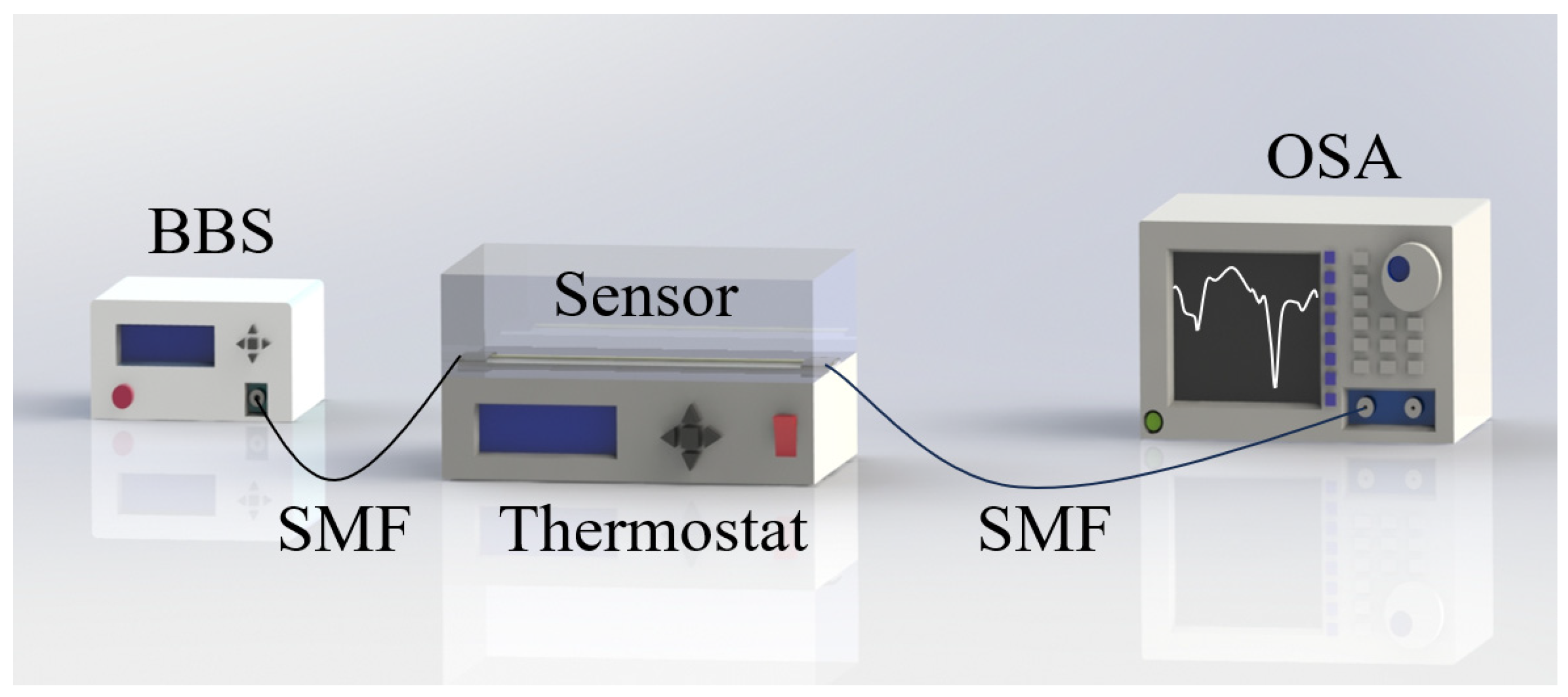

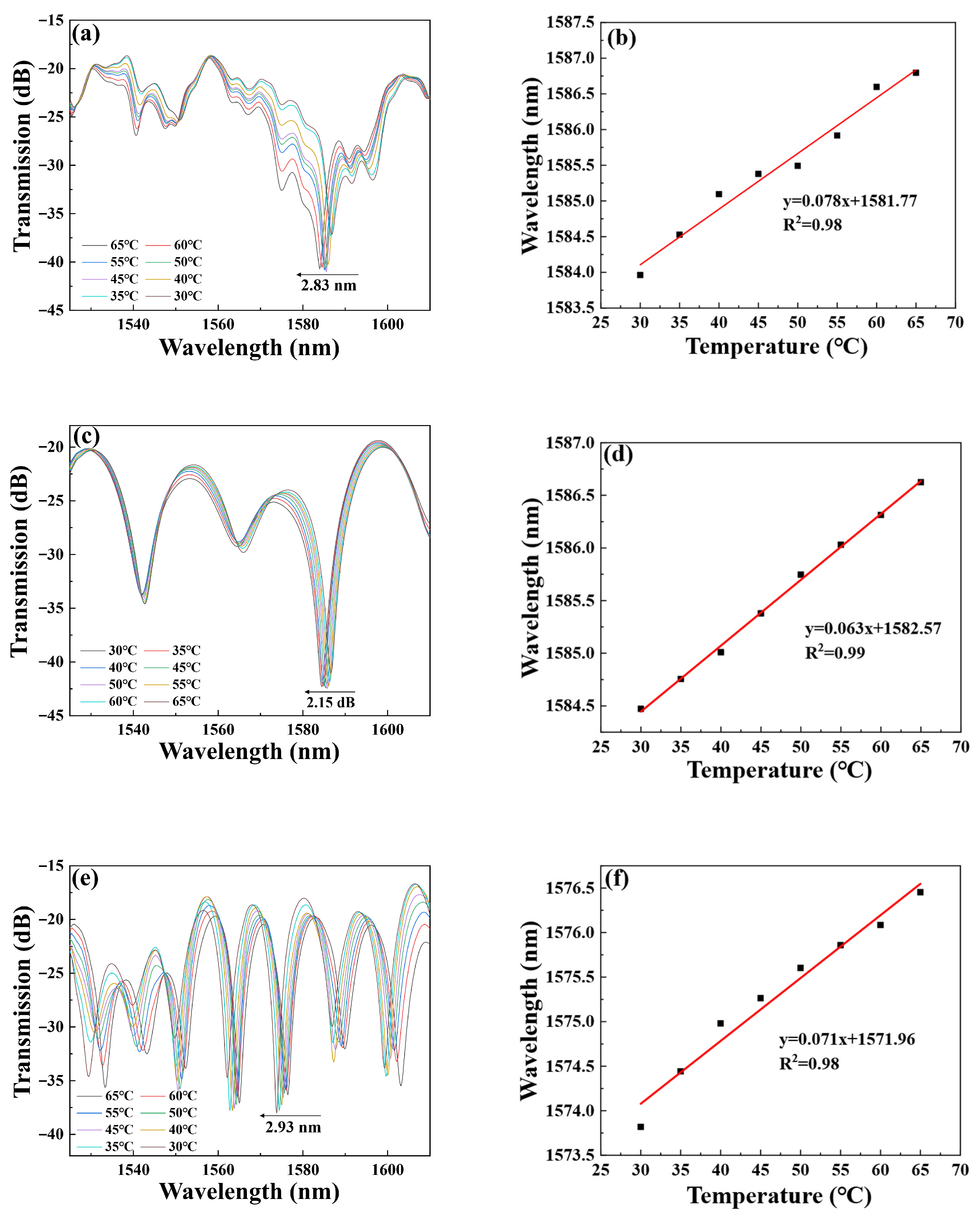

3.2. Temperature Measurement

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Lami, S.S.; Atea, H.K.; Salman, A.M.; Al-Janabi, A. Adjustable optical fiber displacement-curvature sensor based on macro-bending losses with a coding of optical signal intensity. Sens. Actuators A Phys. 2024, 373, 115403. [Google Scholar] [CrossRef]

- Cloud, B.A.; Zhao, K.D.; Breighner, R.; Giambini, H.; An, K.N. Agreement between fiber optic and optoelectronic systems for quantifying sagittal plane spinal curvature in sitting. Gait Posture 2014, 40, 369–374. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Erduran, E.; Gonen, S. Contact point accelerations, instantaneous curvature, and physics-based damage detection and location using vehicle-mounted sensors. Eng. Struct. 2024, 304, 117608. [Google Scholar] [CrossRef]

- White, E.L.; Case, J.C.; Kramer, R.K. Multi-mode strain and curvature sensors for soft robotic applications. Sens. Actuators A Phys. 2017, 253, 188–197. [Google Scholar] [CrossRef]

- Ek-Ek, J.R.; Jauregui-Vazquez, D.; Korterik, J.P.; Benedictus, M.; Martinez-Pinon, F.; Offerhaus, H.L.; Alvarez-Chavez, J.A. Dual tapered optical fiber for simultaneous detection of curvature and strain. Opt. Fiber Technol. 2022, 69, 102843. [Google Scholar] [CrossRef]

- Jauregui-Vazquez, D.; Herrera-Piad, L.A.; Tentori, D.; Castro-Toscano, J.D.; Escalante-Sanchez, K.C.; Gallegos-Arellano, E.; Sierra-Hernandez, J.M. Visible range curvature fiber-optic sensor with low strain-temperature dependence. Opt. Commun. 2024, 563, 130601. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, B.; Wang, D.N.; Wang, Z. High-Resolution Sensing System Based on Fiber Bragg Grating Fabry–Perot Interferometer and Frequency-Domain Demodulation. IEEE Sens. J. 2019, 19, 4451–4457. [Google Scholar] [CrossRef]

- Zhu, C.; Huang, S.; Tang, C.; Li, H. Miniature Temperature-Independent Curvature Sensor Based on a Phase-Shifted Long-Period Fiber Grating Using Deep Tapering. IEEE Sens. J. 2023, 23, 14174–14181. [Google Scholar] [CrossRef]

- Palma, P.D.; Iadicicco, A.; Campopiano, S. Curvature Sensor Based on FBGs Embedded in 3D Printed Patches. IEEE Sens. J. 2021, 21, 17868–17874. [Google Scholar] [CrossRef]

- Zhu, X.; Qian, J.; Liu, W.; Cao, J.; Yang, Y.; Zhang, G.; Cai, Y.; Shi, Y.; Wu, W. Temperature and Curvature Microfiber Mach-Zehnder Interferometer Sensor Based on Double Peanut-Shaped Structures and Tapered Coreless Fiber. IEEE Photonics Technol. Lett. 2024, 36, 433–436. [Google Scholar]

- Monteiro, C.S.; Ferreira, M.S.; Silva, S.O. Fiber Fabry-Perot interferometer for curvature sensing. Photonic Sens. 2016, 6, 339–344. [Google Scholar] [CrossRef]

- Hofmann, M.; Xiao, Y.; Sherman, S. Asymmetric Mach-Zehnder interferometers without an interaction window in polymer foils for refractive index sensing. Appl. Op. 2016, 55, 1124–1131. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.R.; Huang, L.; Liu, C. Sensitivity-enhanced fiber temperature sensor based on Vernier effect and dual in-line Mach-Zehnder interferometers. IEEE Sens. J. 2019, 19, 7983–7987. [Google Scholar] [CrossRef]

- Marrujo-Garcia, S.; Hernandez-Romano, I.; Torres-Cisneros, M.; May-Arrioja, D.A.; Minkovich, V.P.; Monzon-Hernandez, D. Temperature-independent curvature sensor based on in-fiber Mach-Zehnder interferometer using hollow-core fiber. J. Light. Technol. 2020, 38, 4166–4173. [Google Scholar] [CrossRef]

- Zhu, X.; Liu, W.; Qian, J. A Novel Wearable Knee Joint Angle Monitoring Sensor Utilizing Mach–Zehnder Interferometer With Triple-Clad Fiber. IEEE Sens. J. 2024, 24, 2785–2791. [Google Scholar] [CrossRef]

- Gong, Y.; Zhao, T.; Rao, Y.-J. All-fiber curvature sensor based on multimode interference. IEEE Photonics Technol. Lett. 2011, 23, 679–681. [Google Scholar] [CrossRef]

- Ma, L.; Qi, Y.; Kang, Z. All-fiber strain and curvature sensor based on no-core fiber. IEEE Sens. J. 2014, 14, 1514–1517. [Google Scholar] [CrossRef]

- Wang, X.; Chen, D.; Li, H. In-line Mach–Zehnder interferometric sensor based on a seven-core optical fiber. IEEE Sens. J. 2017, 17, 100–104. [Google Scholar] [CrossRef]

- Su, D.; Qiao, X.; Bao, W. Orientation-dependent fiber-optics displacement sensor by a grating inscription within four-mode fiber. Opt. Laser Technol. 2019, 115, 229–232. [Google Scholar] [CrossRef]

- Ashry, I.; Mao, Y.; Trichili, A.; Wang, B.; Ng, T.K.; Alouini, M.-S.; Ooi, B.S. A Review of Using Few-Mode Fibers for Optical Sensing. IEEE Access 2020, 8, 179592–179605. [Google Scholar] [CrossRef]

- Cai, X.; Gao, S.; Wu, M.; Zheng, S.; Fu, H.; Chen, D. Temperature-insensitive curvature sensor with few-mode-fiber based hybrid structure. Opt. Laser Technol. 2024, 168, 109843. [Google Scholar] [CrossRef]

- Zhang, F.; Su, B.; Zhong, L.; Qi, B.; Xu, O.; Qin, Y. Ring core few-mode fiber sensor for curvature measurement. Appl. Opt. 2022, 61, 2598–2603. [Google Scholar] [CrossRef]

- Guang, Z.; Zhang, Y.; Zhu, P. Ultrashort laser pulse spatio temporal profile manipulation using a single-mode-few-mode optical fiber device. J. Opt. Soc. Am. B 2021, 38, F152–F160. [Google Scholar] [CrossRef]

- Tong, Z.; Zhong, Y.; Wang, X. Research on simultaneous measurement of refractive index and temperature comprising few mode fiber and spherical structure. Opt. Commun. 2018, 421, 1–6. [Google Scholar] [CrossRef]

- Liu, J.; Luo, C.; Yang, H. Mach-Zehnder interferometer for high temperature (1000 °C) sensing based on a few-mode fiber. Photonic Sens. 2021, 11, 341–349. [Google Scholar] [CrossRef]

- Zhu, X.; Zhuang, H.; Liu, Y. High-sensitivity robust Mach-Zehnder interferometer sensor in ultra-compact format. Measurement 2024, 236, 115051. [Google Scholar] [CrossRef]

- Shen, C.; Zhong, C.; You, Y.; Chu, J.; Zou, X.; Dong, X.; Jin, Y.; Wang, J.; Gong, H. Polarization-dependent curvature sensor based on an in-fiber Mach-Zehnder interferometer with a difference arithmetic demodulation method. Opt. Express 2012, 20, 15406. [Google Scholar] [CrossRef] [PubMed]

- Shao, M.; Cao, Z.; Gao, H. Large measurement-range and low temperature cross-sensitivity optical fiber curvature sensor based on Michelson interferometer. Opt. Fiber Technol. 2022, 72, 102990. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, L.; Ma, T. A high-sensitivity sensor based on tapered dispersion compensation fiber for curvature and temperature measurement. Opt. Commun. 2021, 481, 126534. [Google Scholar] [CrossRef]

- Wang, S.; Niu, P.; Liu, S. Curvature and temperature sensor based on anti-resonant effect combined with multimode interference. IEEE Photonics Technol. Lett. 2021, 33, 127–130. [Google Scholar] [CrossRef]

- Cheng, H.; Wu, S.; Wang, Q. In-line hybrid fiber sensor for curvature and temperature measurement. IEEE Photonics J. 2019, 11, 6803311. [Google Scholar] [CrossRef]

- Shao, M.; Liang, J.; Gao, H. Seven-core fiber based in-fiber Mach-Zehnder interferometer for temperature-immune curvature sensing. Opt. Commun. 2023, 528, 128989. [Google Scholar] [CrossRef]

- Yang, B.; Niu, Y.; Yang, B. High sensitivity curvature sensor with intensity demodulation based on single mode-tapered multimode-single mode fiber. IEEE Sens. J. 2017, 18, 1094–1099. [Google Scholar] [CrossRef]

| Structure | Curvature Sensitivity (dB/m−1) | Extinction Ratio (dB) | Curvature Range | Temperature Sensitivity (pm/°C) | Reference |

|---|---|---|---|---|---|

| SMF-MMF-SMF | −130.37 | −15 | 0.11–0.34 m−1 | / | [16] |

| SMF (MTP-MZI) | 112.6 | 1.856 | 0.005224–0.52245 m−1 | 162 | [26] |

| SMF-MMF-Fiber sphere | −1.812 | 22.03 | 0–12.2894 m−1 | 78 | [28] |

| SMF-DCF-SMF | 15.19 | 10 | 0.98–1.753 m−1 | 79.8 | [29] |

| SMF-MMF-Capillary-SMF | −9.25 | ~9 | 1.30–2.27 m−1 | 30 | [30] |

| SMF-HCF-SMF | −4.28 | ~3 | 10.72–11.60 m−1 | 25.76 | [31] |

| SMF-CLF-SCF-SMF | −26.5517 | ~23 | 0.527–1.395 m−1 | 75.3 | [32] |

| SMF-Tapered MMF–SMF | −21.734 | ~26 | 0.7064–1.9129 m−1 | 6.1 | [33] |

| This study | 168.41 | 19.08 | 0–0.091 m−1 | 78 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Qian, J.; Shi, Y.; Zhu, X. A Mini-Two-Path Mach–Zehnder Interferometer Sensor with High Curvature Sensitivity Based on Four-Mode Fiber. Micromachines 2025, 16, 1149. https://doi.org/10.3390/mi16101149

Wu W, Qian J, Shi Y, Zhu X. A Mini-Two-Path Mach–Zehnder Interferometer Sensor with High Curvature Sensitivity Based on Four-Mode Fiber. Micromachines. 2025; 16(10):1149. https://doi.org/10.3390/mi16101149

Chicago/Turabian StyleWu, Wuming, Jiayi Qian, Yuechun Shi, and Xiaojun Zhu. 2025. "A Mini-Two-Path Mach–Zehnder Interferometer Sensor with High Curvature Sensitivity Based on Four-Mode Fiber" Micromachines 16, no. 10: 1149. https://doi.org/10.3390/mi16101149

APA StyleWu, W., Qian, J., Shi, Y., & Zhu, X. (2025). A Mini-Two-Path Mach–Zehnder Interferometer Sensor with High Curvature Sensitivity Based on Four-Mode Fiber. Micromachines, 16(10), 1149. https://doi.org/10.3390/mi16101149