An Electrochemical Tilt Sensor with Double-Band Electrodes Fabricated by Wire Winding

Abstract

:1. Introduction

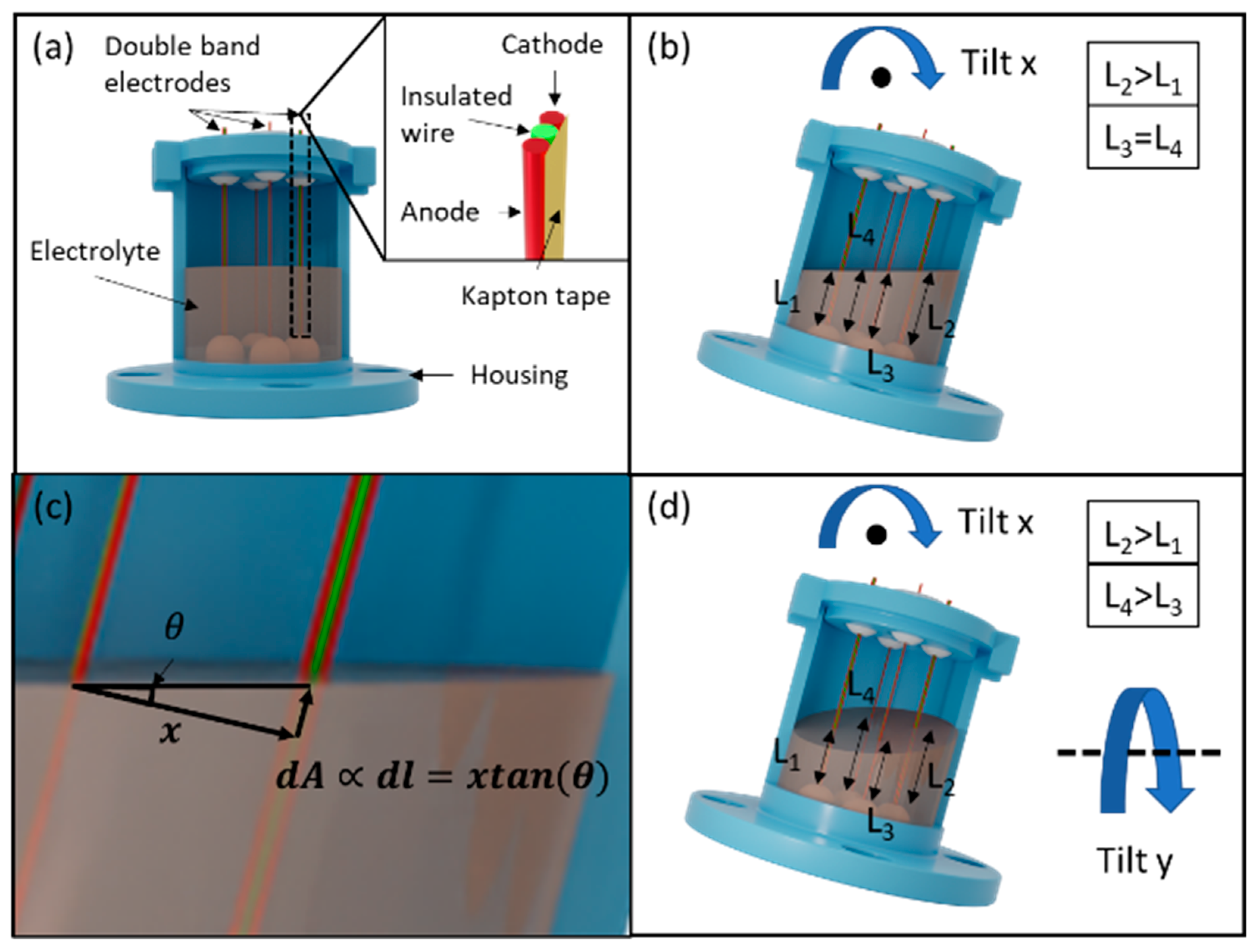

Sensing Principle

2. Materials and Methods

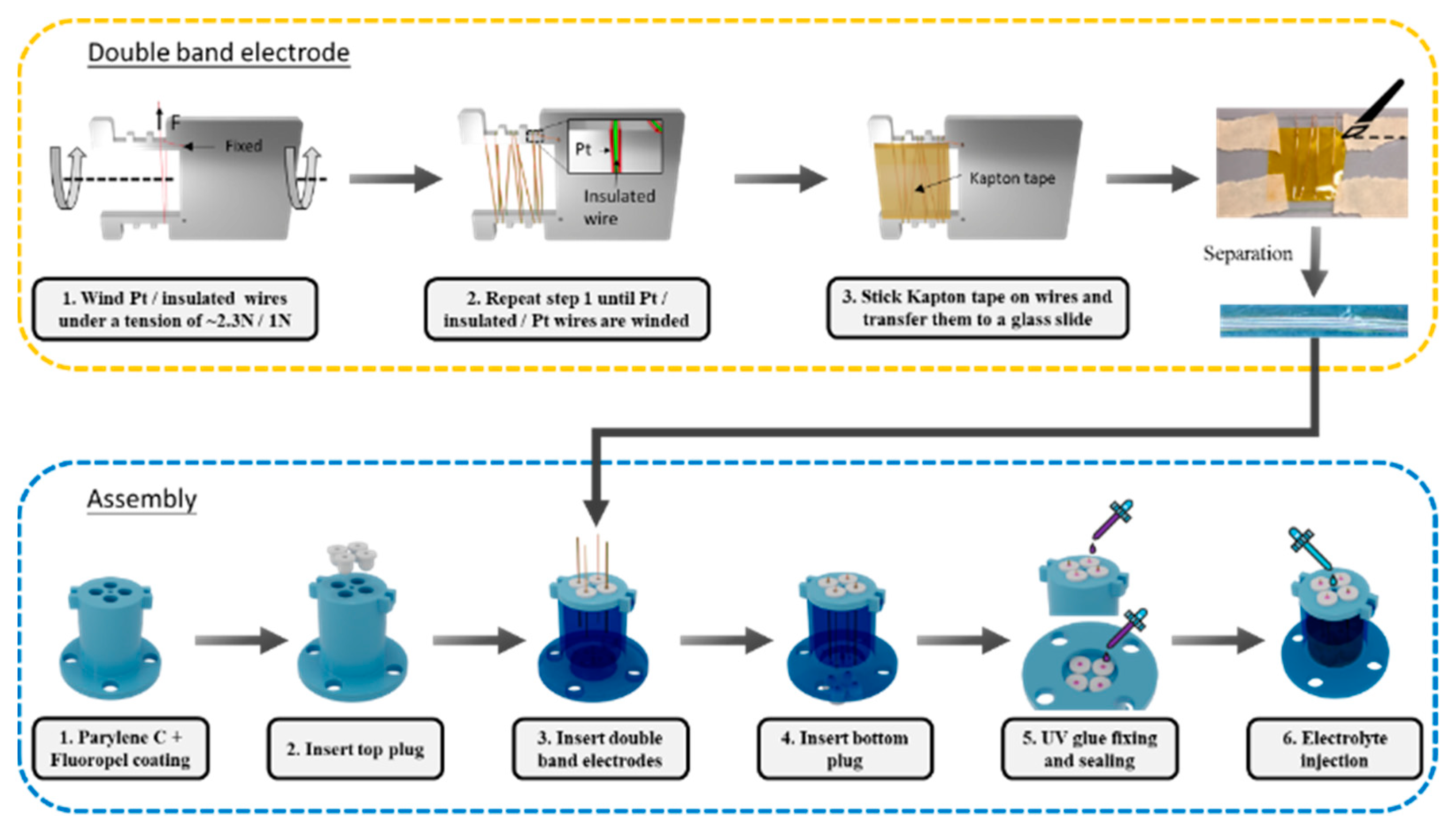

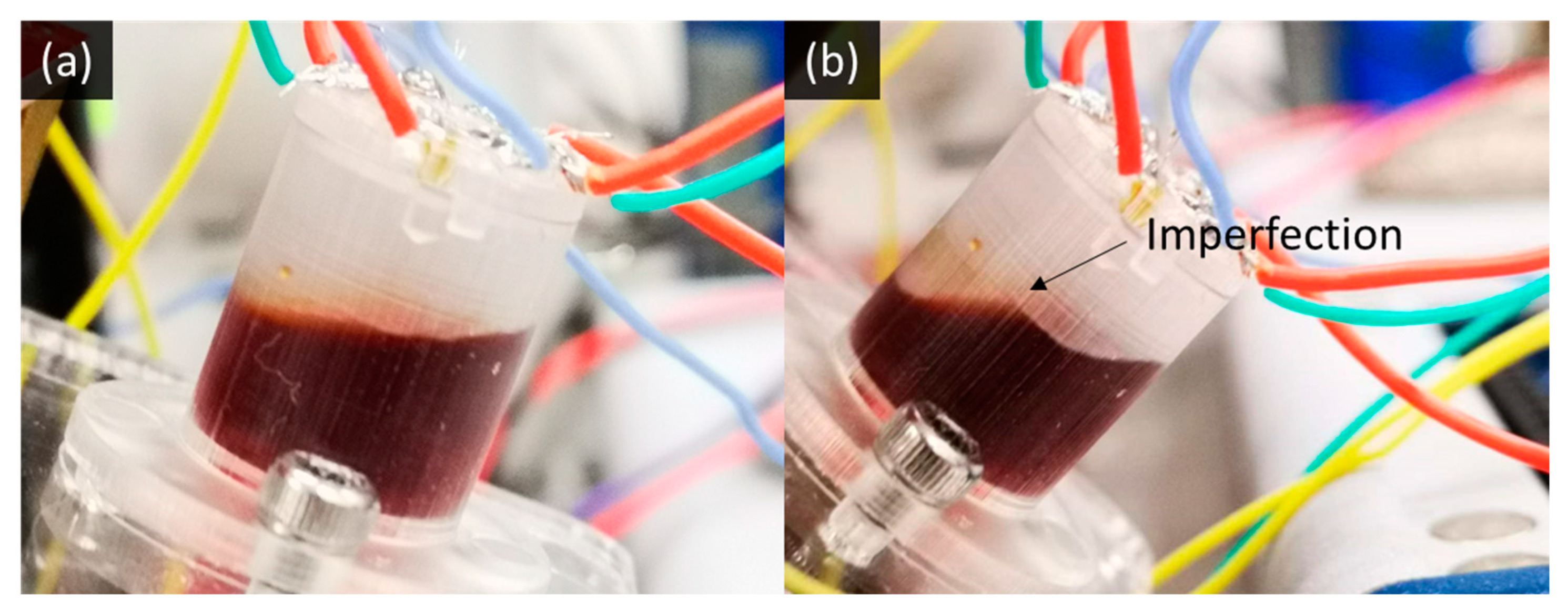

2.1. Fabrication

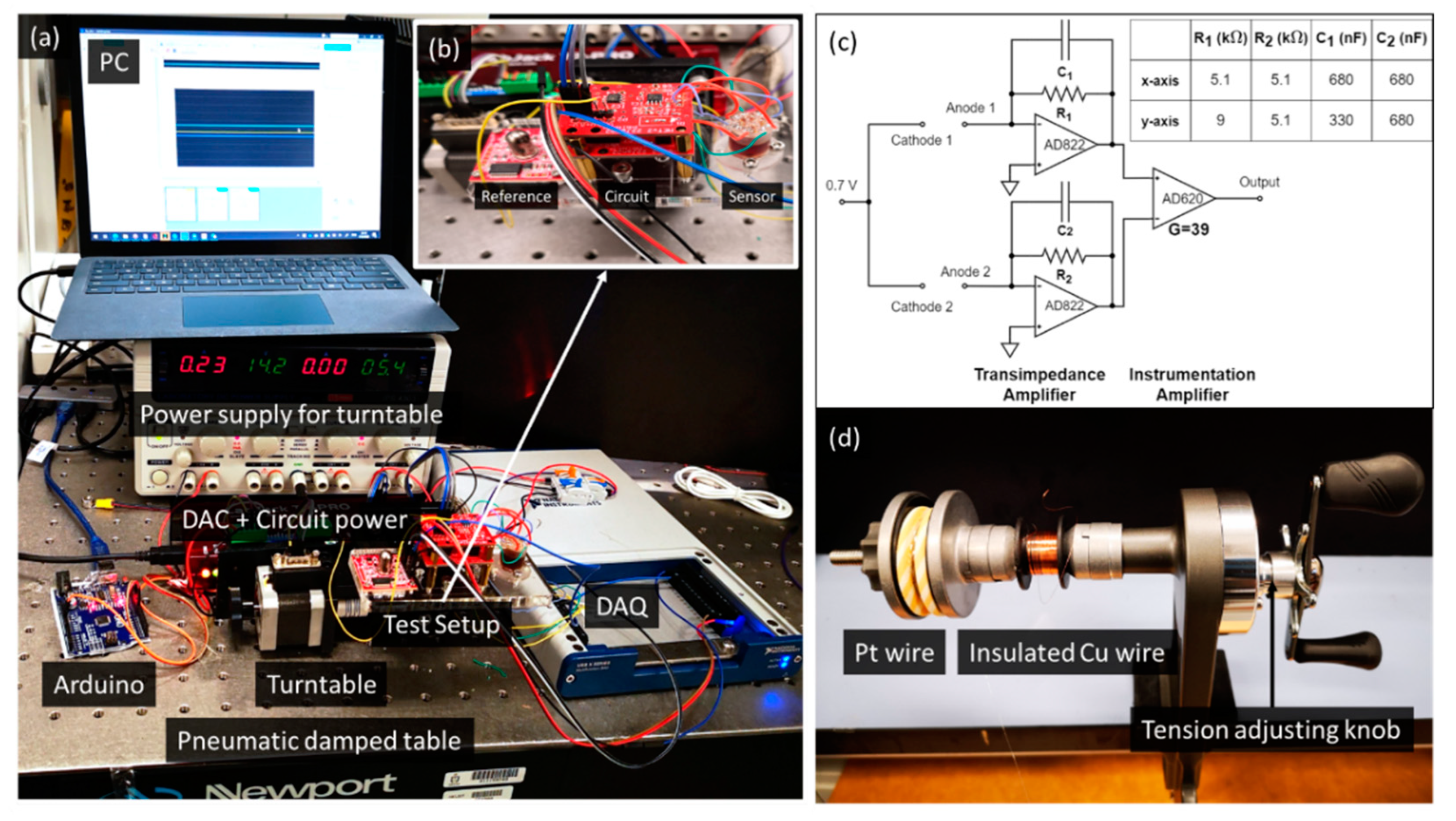

2.2. Setup

3. Results

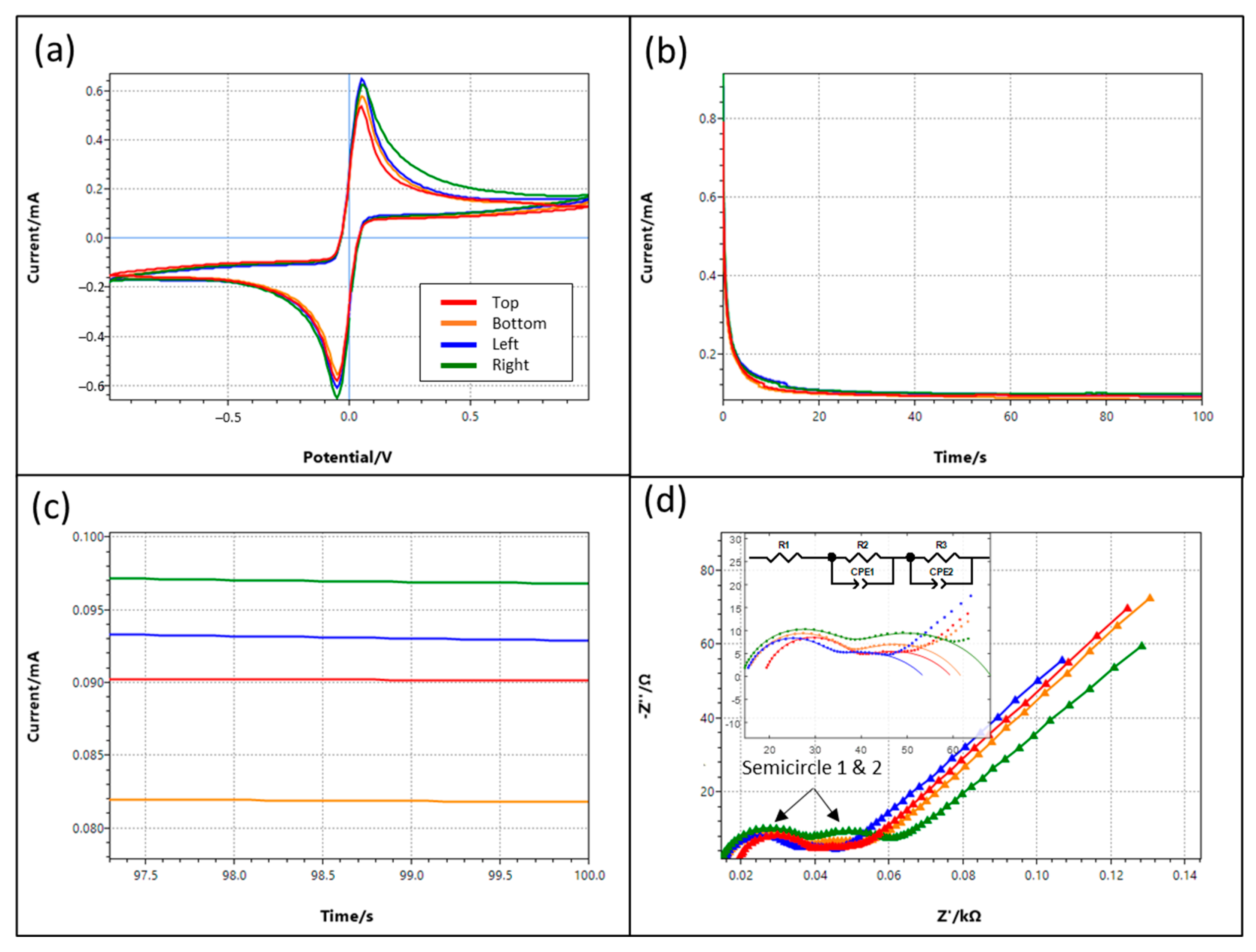

3.1. Electrochemical Characterization

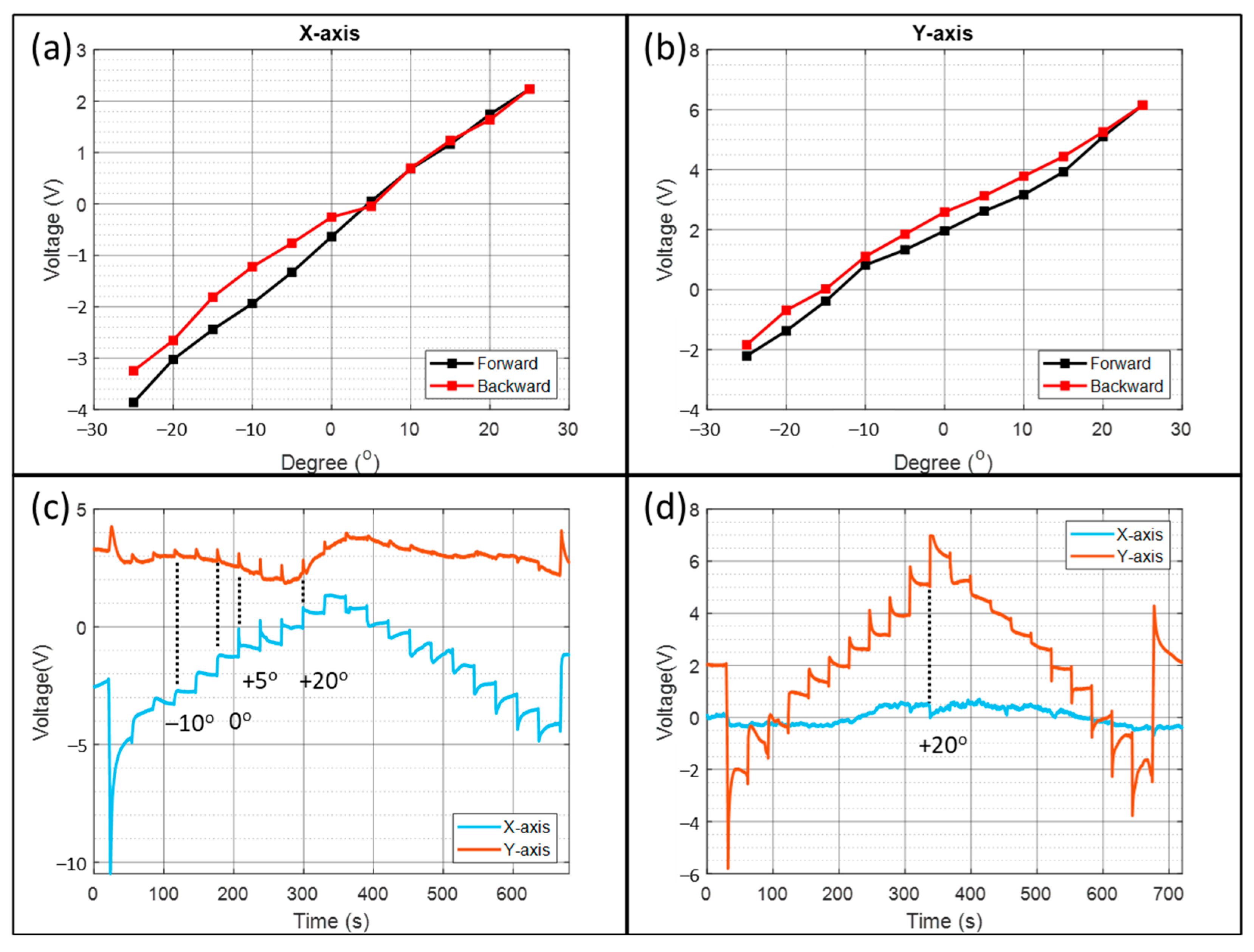

3.2. Sensor Performance

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sharbirin, A.S.; Zaini, M.K.A.; Brambilla, G.; Rahman, B.M.A.; Grattan, K.T.V.; Ismail, M.F.; Ahmad, H. 3D-Printed Tilt Sensor Based on an Embedded Two-Mode Fiber Interferometer. IEEE Sens. J. 2021, 21, 7565–7571. [Google Scholar] [CrossRef]

- Hong, C.; Zhang, Y.; Lu, Z.; Yin, Z. A FBG Tilt Sensor Fabricated Using 3D Printing Technique for Monitoring Ground Movement. IEEE Sens. J. 2019, 19, 6392–6399. [Google Scholar] [CrossRef]

- Yang, Y.; Ma, X.; Chen, K.; Wang, E.; Yu, Z.; Yu, Q. A high-resolution dynamic fiber-optic inclinometer. Sens. Actuators Phys. 2018, 283, 305–312. [Google Scholar] [CrossRef]

- Osuch, T.; Markowski, K.; Manujło, A.; Jędrzejewski, K. Coupling independent fiber optic tilt and temperature sensor based on chirped tapered fiber Bragg grating in double-pass configuration. Sens. Actuators Phys. 2016, 252, 76–81. [Google Scholar] [CrossRef]

- Chiang, J.-S.; Chang, H.-Y.; Sun, N.-H.; Liu, W.-F. High Sensitive Two-Dimension Tilted-meter Based on Chirped Fiber Bragg Gratings. IEEE Sens. J. 2016, 16, 8477–8482. [Google Scholar] [CrossRef]

- Ismail, N.N.; Sharbirin, A.S.; Sa’ad, M.S.M.; Zaini, M.K.A.; Ismail, M.F.; Brambilla, G.; Rahman, B.M.A.; Grattan, K.T.V.; Ahmad, H. Novel 3D-printed biaxial tilt sensor based on fiber Bragg grating sensing approach. Sens. Actuators Phys. 2021, 330, 112864. [Google Scholar] [CrossRef]

- Xu, H.; Li, F.; Gao, Y.; Wang, W. Simultaneous Measurement of Tilt and Acceleration Based on FBG Sensor. IEEE Sens. J. 2020, 20, 14857–14864. [Google Scholar] [CrossRef]

- Yang, R.; Bao, H.; Zhang, S.; Ni, K.; Zheng, Y.; Dong, X. Simultaneous Measurement of Tilt Angle and Temperature With Pendulum-Based Fiber Bragg Grating Sensor. IEEE Sens. J. 2015, 15, 6381–6384. [Google Scholar] [CrossRef]

- Guan, B.-O.; Tam, H.-Y.; Liu, S.-Y. Temperature-Independent Fiber Bragg Grating Tilt Sensor. IEEE Photonics Technol. Lett. 2004, 16, 224–226. [Google Scholar] [CrossRef]

- Au, H.Y.; Khijwania, S.K.; Fu, H.Y.; Chung, W.H.; Tam, H.Y. Temperature-Insensitive Fiber Bragg Grating Based Tilt Sensor With Large Dynamic Range. J. Light. Technol. 2011, 29, 1714–1720. [Google Scholar] [CrossRef]

- Albert, J.; Shao, L.-Y.; Caucheteur, C. Tilted fiber Bragg grating sensors: Tilted fiber Bragg grating sensors. Laser Photonics Rev. 2013, 7, 83–108. [Google Scholar] [CrossRef]

- Guo, Y.; Li, C.; Zhou, X.; Jiang, L.; Liu, H. Wide-Range Fiber Bragg Grating Tilt Sensor Based on a Cam Structure. IEEE Sens. J. 2020, 20, 4740–4748. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, E.; Chen, K.; Yu, Z.; Yu, Q. Fiber-Optic Fabry–Perot Sensor for Simultaneous Measurement of Tilt Angle and Vibration Acceleration. IEEE Sens. J. 2019, 19, 2162–2169. [Google Scholar] [CrossRef]

- Li, C.; Li, X.; Yu, X.; Peng, X.; Lan, T.; Fan, S. Room-Temperature Wide Measurement-Range Optical Fiber Fabry–Perot Tilt Sensor With Liquid Marble. IEEE Sens. J. 2018, 18, 170–177. [Google Scholar] [CrossRef]

- Welch, D.; Georgiou, J.; Christen, J.B. Fully differential current-mode MEMS dual-axis optical inclination sensor. Sens. Actuators Phys. 2013, 192, 133–139. [Google Scholar] [CrossRef]

- Lee, Y.-G.; Jang, H.-K.; Kim, D.-H.; Kim, C.-G. Development of a mirror mounted fiber optic inclinometer. Sens. Actuators Phys. 2012, 184, 46–52. [Google Scholar] [CrossRef]

- Hu, P.; Guo, J.; Tan, J. An Annular Planar-capacitive Tilt Sensor with a 360° Measurement Range. IEEE Trans. Ind. Electron. 2015, 63, 2469–2476. [Google Scholar] [CrossRef]

- Xu, H.; Zhao, Y.; Zhang, K.; Wang, Z.; Jiang, K. A liquid MEMS inclinometer sensor with improved sensitivity. Sens. Actuators Phys. 2019, 285, 369–377. [Google Scholar] [CrossRef] [Green Version]

- Łuczak, S.; Ekwińska, M. Electric-Contact Tilt Sensors: A Review. Sensors 2021, 21, 1097. [Google Scholar] [CrossRef]

- Buthe, L.; Vogt, C.; Petti, L.; Cantarella, G.; Munzenrieder, N.; Troster, G. Fabrication, Modeling, and Evaluation of a Digital Output Tilt Sensor With Conductive Microspheres. IEEE Sens. J. 2017, 17, 3635–3643. [Google Scholar] [CrossRef]

- Matsuda, R.; Zihao, S.; Kamoto, U.; Ota, H. Liquid-Based Digital Readable Tilt Sensor. Adv. Mater. Technol. 2021, 6, 2100490. [Google Scholar] [CrossRef]

- Garraud, A.; Giani, A.; Combette, P.; Charlot, B.; Richard, M. A dual axis CMOS micromachined convective thermal accelerometer. Sens. Actuators Phys. 2011, 170, 44–50. [Google Scholar] [CrossRef]

- Chen, S.J.; Shen, C.-H. A Novel Two-Axis CMOS Accelerometer Based on Thermal Convection. IEEE Trans. Instrum. Meas. 2008, 57, 1572–1577. [Google Scholar] [CrossRef]

- Lin, J.M.; Lin, C.H. A Novel Wireless Thermal Convection Type Inclinometer by Using Non-Floating Structure. Appl. Mech. Mater. 2014, 595, 243–249. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, C.; Bin, W.; Zheng, X.; San, H.; Hofmann, W. Dual-axis thermal convective inclinometer based on CNT/PDMS composite. J. Mater. Sci. Mater. Electron. 2018, 29, 18997–19004. [Google Scholar] [CrossRef]

- Billat, S.; Glosch, H.; Kunze, M.; Hedrich, F.; Frech, J.; Auber, J.; Sandmaier, H.; Wimmer, W.; Lang, W. Micromachined inclinometer with high sensitivity and very good stability. Sens. Actuators A Phys. 2002, 97, 125–130. [Google Scholar] [CrossRef]

- Han, M.; Bang, Y.; Kim, W.; Lee, G.S.; Jung, D. Thermal convective inclinometer using carbon nanotube yarn. Microelectron. Eng. 2017, 168, 50–54. [Google Scholar] [CrossRef]

- Andò, B.; Baglio, S.; Beninato, A. A ferrofluid inclinometer with a Time Domain Readout strategy. Sens. Actuators Phys. 2013, 202, 57–63. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, L.; Song, Y.; Zhao, L.; Zhao, Q. Design and Implementation of a Novel Tilt Sensor Based on the Principle of Variable Reluctance. Sensors 2019, 19, 5228. [Google Scholar] [CrossRef] [Green Version]

- Su, S.; Li, D.; Tan, N.; Li, G. The Study of a Novel Tilt Sensor Using Magnetic Fluid and Its Detection Mechanism. IEEE Sens. J. 2017, 17, 4708–4715. [Google Scholar] [CrossRef]

- Cheung, Y.K.; Yu, H. Electrochemical Tilt Sensors With Symmetric Concentric Electrode Pairs. IEEE Sens. J. 2021, 21, 21322–21329. [Google Scholar] [CrossRef]

- Liang, M.; Nickerson, S.; Dai, L.; Yu, H. Molecular Electronic Transducer Based Tilting Sensors. In Proceedings of the 2020 IEEE 33rd International Conference on Micro Electro Mechanical Systems (MEMS), Vancouver, BC, Canada, 18–22 January 2020; pp. 765–768. [Google Scholar] [CrossRef]

- Ejigu, A.; Lovelock, K.R.J.; Licence, P.; Walsh, D.A. Iodide/triiodide electrochemistry in ionic liquids: Effect of viscosity on mass transport, voltammetry and scanning electrochemical microscopy. Electrochim. Acta 2011, 56, 10313–10320. [Google Scholar] [CrossRef]

- Hernández, H.H.; Reynoso, A.M.R.; González, J.C.T.; Morán, C.O.G.; Hernández, J.G.M.; Ruiz, A.M. Electrochemical Impedance Spectroscopy (EIS): A Review Study of Basic Aspects of the Corrosion Mechanism Applied to Steels. In Electrochemical Impedance Spectroscopy; El-Azazy, M., Min, M., Annus, P., Eds.; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

| Element | Top | Bottom | Left | Right |

|---|---|---|---|---|

| ) | 18.75 | 15.07 | 14.63 | 14.01 |

| ) | 17.5 | 20.6 | 15.6 | 20.9 |

| |CPE1| (T) | 1.6458 × 10−6 | 2.0612 × 10−6 | 1.5877 × 10−6 | 2.571 × 10−6 |

| ) | 0.89479 | 0.86299 | 0.91045 | 0.86933 |

| ) | 23.34 | 26.09 | 23.38 | 33.36 |

| |CPE2| (T) | 0.0011689 | 0.0006357 | 0.0011073 | 0.00038612 |

| ) | 0.53648 | 0.60159 | 0.50492 | 0.62528 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheung, Y.-K.; Yu, H. An Electrochemical Tilt Sensor with Double-Band Electrodes Fabricated by Wire Winding. Micromachines 2022, 13, 1229. https://doi.org/10.3390/mi13081229

Cheung Y-K, Yu H. An Electrochemical Tilt Sensor with Double-Band Electrodes Fabricated by Wire Winding. Micromachines. 2022; 13(8):1229. https://doi.org/10.3390/mi13081229

Chicago/Turabian StyleCheung, Yik-Kin, and Hongyu Yu. 2022. "An Electrochemical Tilt Sensor with Double-Band Electrodes Fabricated by Wire Winding" Micromachines 13, no. 8: 1229. https://doi.org/10.3390/mi13081229

APA StyleCheung, Y.-K., & Yu, H. (2022). An Electrochemical Tilt Sensor with Double-Band Electrodes Fabricated by Wire Winding. Micromachines, 13(8), 1229. https://doi.org/10.3390/mi13081229