Dynamic Analysis of a Long Run-Out Rockslide Considering Dynamic Fragmentation Behavior in Jichang Town: Insights from the Three-Dimensional Coupled Finite-Discrete Element Method

Abstract

:1. Introduction

2. Background

2.1. Study Area

2.2. Geological and Topographical Conditions

2.3. Rainfall Condition

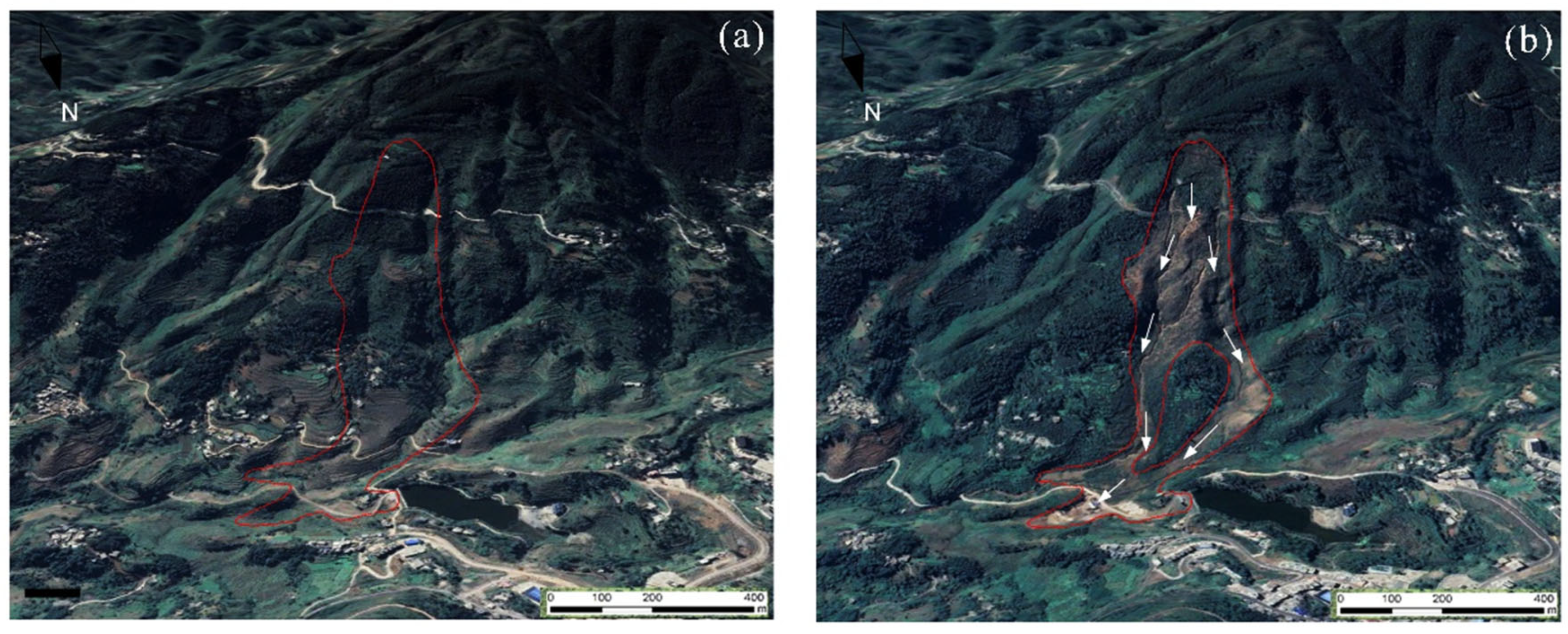

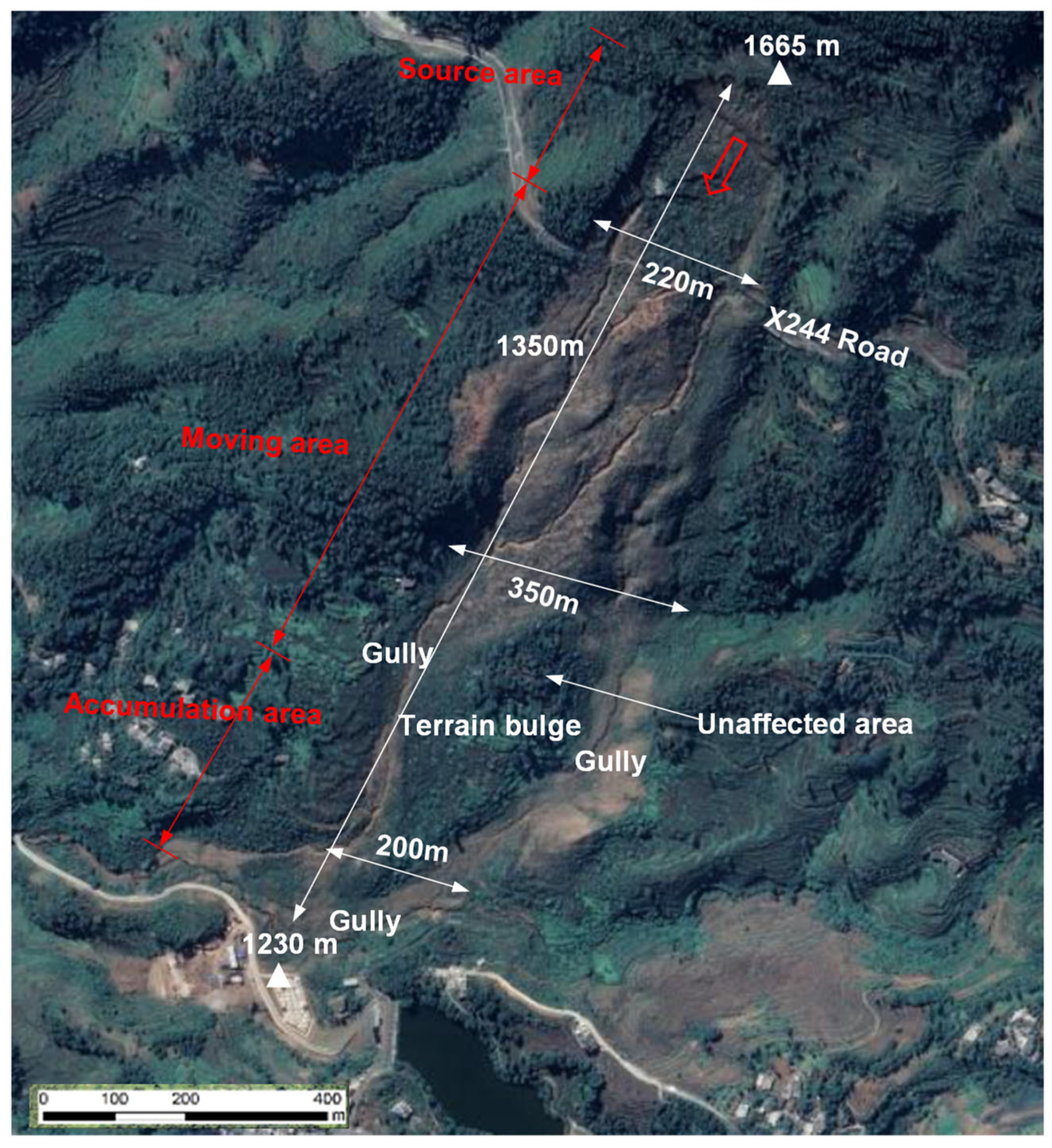

2.4. Jichang Rockslide

3. Methodology

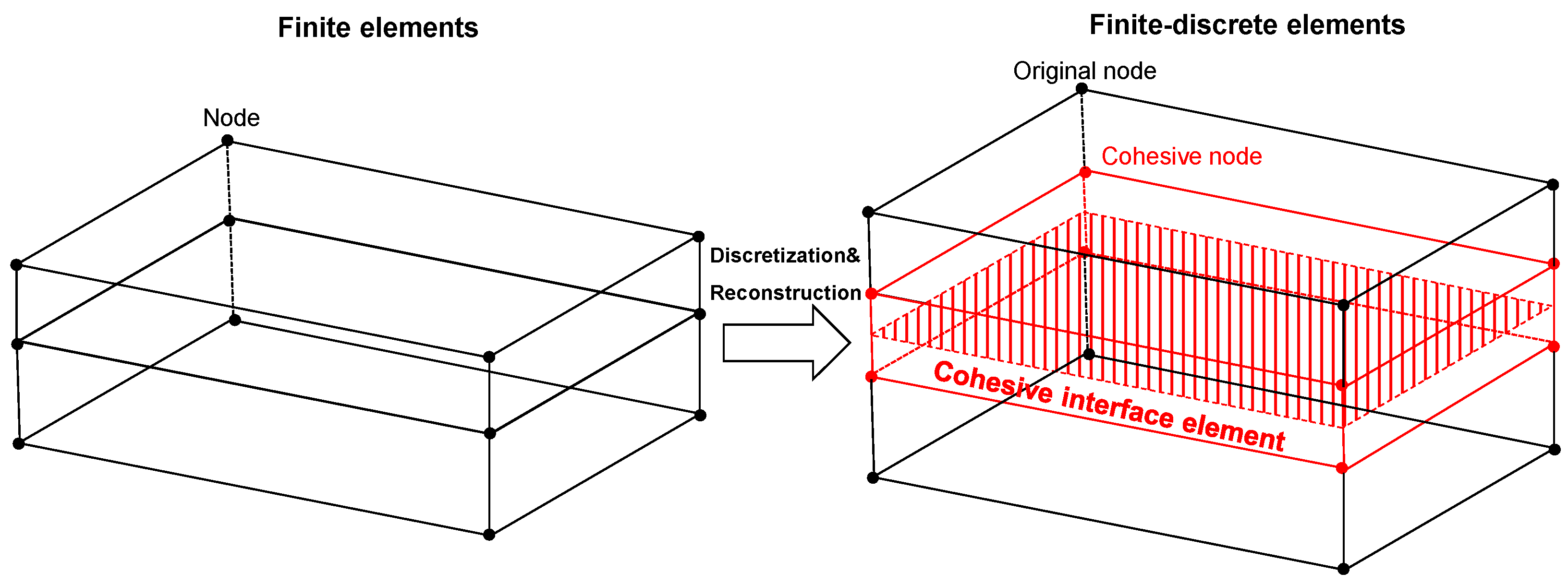

3.1. Finite-Discrete Element Method

3.2. Numerical Model Construction and Setting

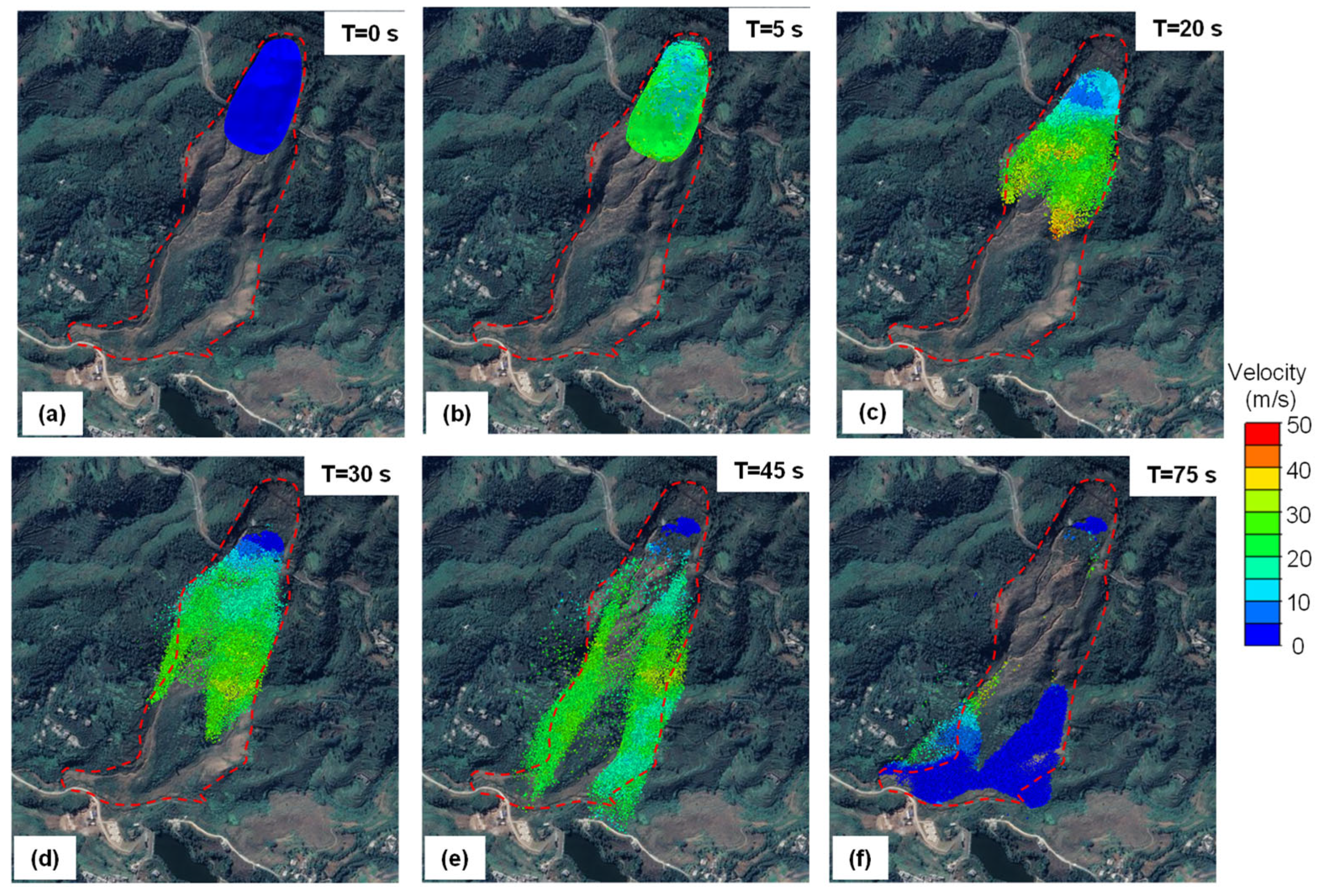

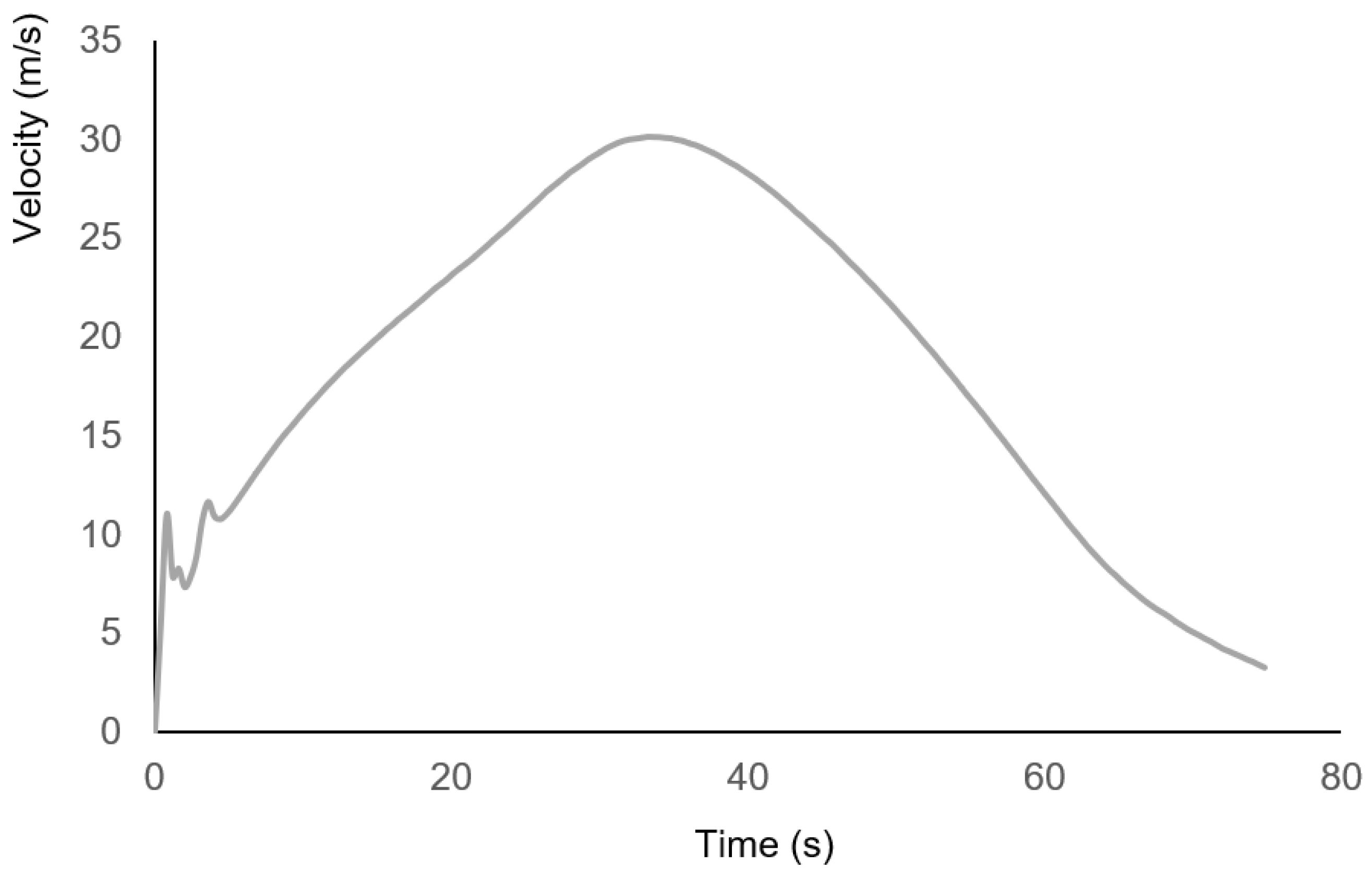

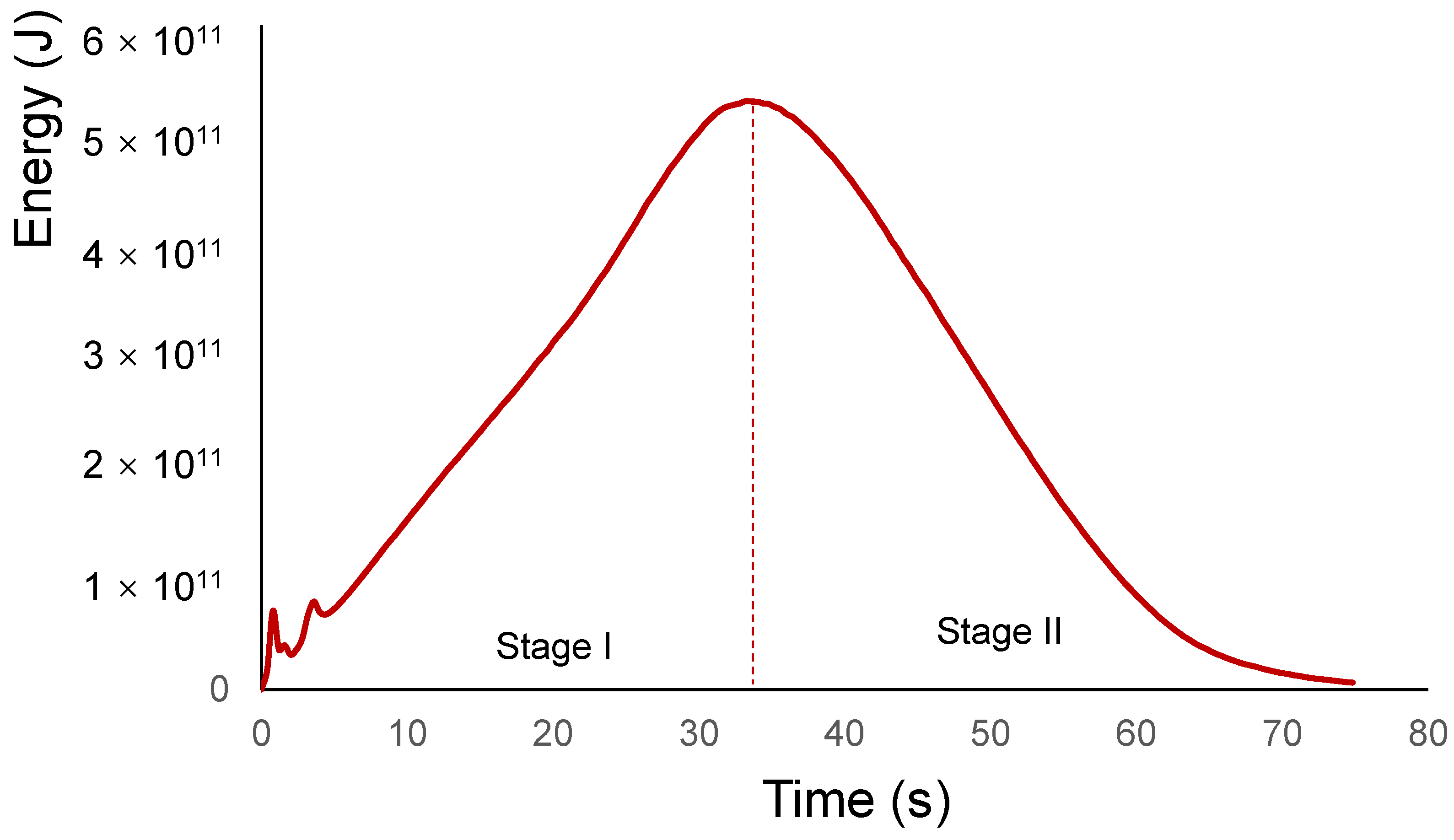

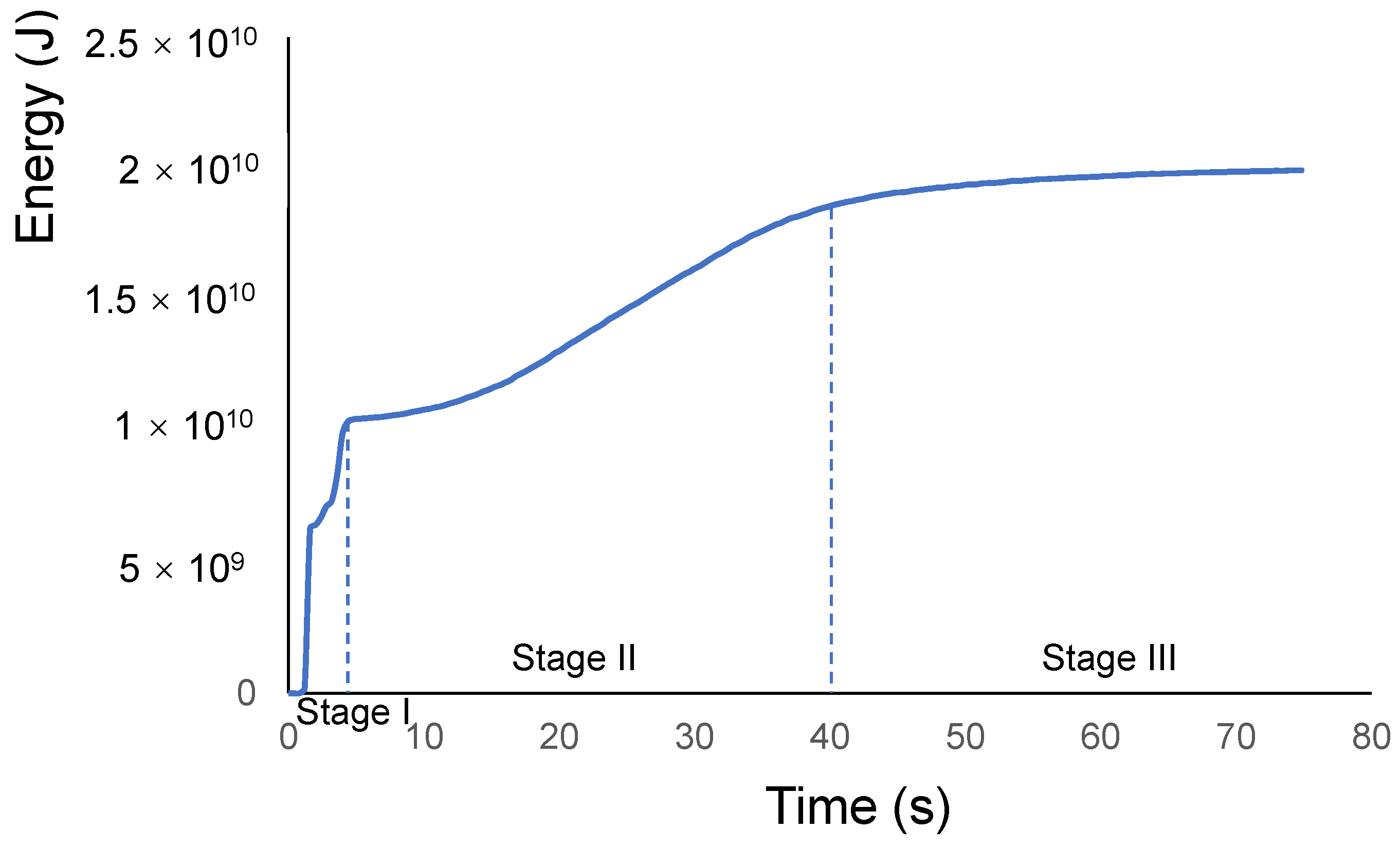

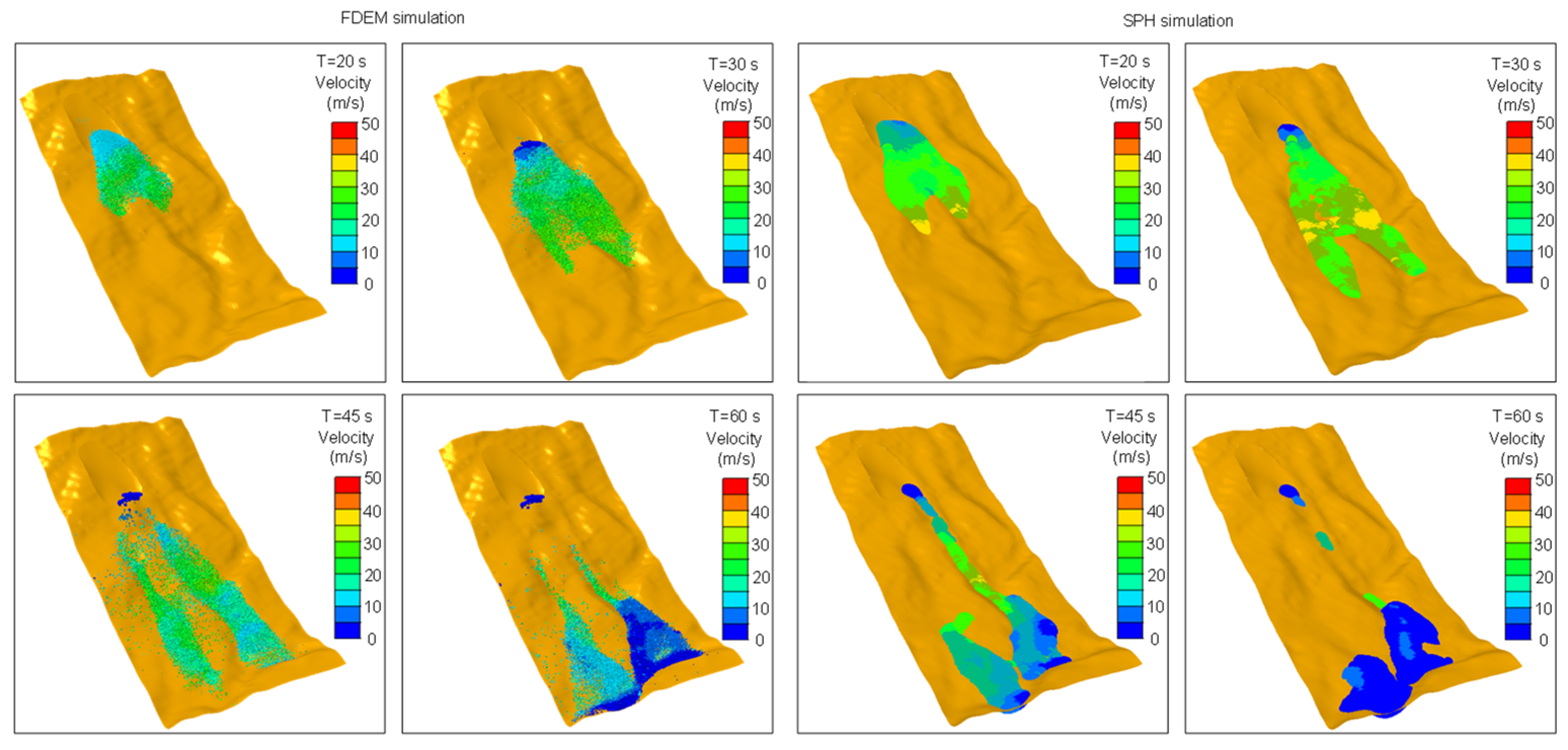

4. Numerical Simulation Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Plafker, G.; Ericksen, G.E. Nevados Huascaran avalanches, Peru. In Rockslides and Avalanche; Voight, B., Ed.; Elsevier: Amsterdam, The Nertherland, 1987; pp. 277–314. [Google Scholar]

- McDougall, S.; Hungr, O. Dynamic modelling of entrainment in rapid landslides. Can. Geotech. J. 2005, 42, 1437–1448. [Google Scholar] [CrossRef]

- Ibañez, J.P.; Hatzor, Y.H. Rapid sliding and friction degradation: Lessons from the catastrophic Vajont landslide. Eng. Geol. 2018, 244, 96–106. [Google Scholar] [CrossRef]

- Aaron, J.; McDougall, S. Rock avalanche mobility: The role of path material. Eng. Geol. 2019, 257, 105126. [Google Scholar] [CrossRef]

- Shi, A.-W.; Wang, Y.-F.; Cheng, Q.-G.; Lin, Q.-W.; Li, T.-H.; Wünnemann, B. The largest rock avalanche in China at Iymek, Eastern Pamir, and its spectacular emplacement landscape. Geomorphology 2023, 421, 108521. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, J.; Su, L.; Zhang, W.; Zhan, J. A novel numerical approach for rockslide blocking river based on the CEFDEM model: A case study from the Samaoding paleolandslide blocking river event. Eng. Geol. 2023, 312, 106949. [Google Scholar] [CrossRef]

- Bao, Y.; Su, L.; Chen, J.; Ouyang, C.; Yang, T.; Lei, Z.; Li, Z. Dynamic process of a high-level landslide blocking river event in a deep valley area based on FDEM-SPH coupling approach. Eng. Geol. 2023, 319, 107108. [Google Scholar] [CrossRef]

- Fang, K.; Zhang, J.; Tang, H.; Hu, X.; Yuan, H.; Wang, X.; An, P.; Ding, B. A quick and low-cost smartphone photogrammetry method for obtaining 3D particle size and shape. Eng. Geol. 2023, 322, 107170. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Qin, W.; Wei, S.; Tian, H.; Fang, K. Behaviour of pile-anchor reinforced landslides under varying water level, rainfall, and thrust load: Insight from physical modelling. Eng. Geol. 2023, 325, 107293. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, Q.; Li, K.; Shi, A.; Li, T.; Cheng, Q. Review on Rock Avalanche Dynamics. J. Earth Sci. Environ. 2021, 43, 164–181. (In Chinese) [Google Scholar]

- Wu, Z.; Ma, L.; Fan, L. Investigation of the characteristics of rock fracture process zone using coupled FEM/DEM method. Eng. Fract. Mech. 2018, 200, 355–374. [Google Scholar] [CrossRef]

- Wu, J.-H.; Hsieh, P.-H. Simulating the postfailure behavior of the seismically- triggered Chiu-fen-erh-shan landslide using 3DEC. Eng. Geol. 2021, 287, 106113. [Google Scholar] [CrossRef]

- Fang, K.; Tang, H.; Li, C.; Su, X.; An, P.; Sun, S. Centrifuge modelling of landslides and landslide hazard mitigation: A review. Geosci. Front. 2023, 14, 101493. [Google Scholar] [CrossRef]

- Do, T.N.; Wu, J.-H. Simulating a mining-triggered rock avalanche using DDA: A case study in Nattai North, Australia. Eng. Geol. 2019, 264, 105386. [Google Scholar] [CrossRef]

- Peng, X.; Liu, J.; Cheng, X.; Yu, P.; Zhang, Y.; Chen, G. Dynamic modelling of soil-rock-mixture slopes using the coupled DDA-SPH method. Eng. Geol. 2022, 307, 106772. [Google Scholar] [CrossRef]

- Tang, C.-L.; Hu, J.-C.; Lin, M.-L.; Angelier, J.; Lu, C.-Y.; Chan, Y.-C.; Chu, H.-T. The Tsaoling landslide triggered by the Chi-Chi earthquake, Taiwan: Insights from a discrete element simulation. Eng. Geol. 2009, 106, 1–19. [Google Scholar] [CrossRef]

- Han, X.; Chen, J.; Xu, P.; Zhan, J. A well-balanced numerical scheme for debris flow run-out prediction in Xiaojia Gully considering different hydrological designs. Landslides 2017, 14, 2105–2114. [Google Scholar] [CrossRef]

- Ouyang, C.; An, H.; Zhou, S.; Wang, Z.; Su, P.; Wang, D.; Cheng, D.; She, J. Insights from the failure and dynamic characteristics of two sequential landslides at Baige village along the Jinsha River, China. Landslides 2019, 16, 1397–1414. [Google Scholar] [CrossRef]

- Conte, E.; Pugliese, L.; Troncone, A. Post-failure stage simulation of a landslide using the material point method. Eng. Geol. 2019, 253, 149–159. [Google Scholar] [CrossRef]

- Li, X.; Yan, Q.; Zhao, S.; Luo, Y.; Wu, Y.; Wang, D. Investigation of influence of baffles on landslide debris mobility by 3D material point method. Landslides 2020, 17, 1129–1143. [Google Scholar] [CrossRef]

- Pastor, M.; Haddad, B.; Sorbino, G.; Cuomo, S.; Drempetic, V. A depth-integrated, coupled SPH model for flow-like landslides and related phenomena. Int. J. Numer. Anal. Methods Géoméch. 2009, 33, 143–172. [Google Scholar] [CrossRef]

- Bao, Y.; Su, L.; Chen, J.; Zhang, C.; Zhao, B.; Zhang, W.; Zhang, J.; Hu, B.; Zhang, X. Numerical investigation of debris flow–structure interactions in the Yarlung Zangbo River valley, north Himalaya, with a novel integrated approach considering structural damage. Acta Geotech. 2023, 18, 5859–5881. [Google Scholar] [CrossRef]

- Wang, Y.C.; Ju, N.P.; Zhao, J.J.; Xiang, X.Q. Formation mechanism of landslide above the mined out area in gentle inclined coal beds. J. Eng. Geol. 2013, 21, 61–68. [Google Scholar]

- Zhao, J.J.; Ma, Y.T.; Lin, B.; Lan, Z.Y.; Shi, W.B. Geomechanical mode of mining landslides with gently counter-inclined bedding—A case study of Madaling landslide in Guizhou Province. Chin. J. Rock Mech. Eng. 2016, 35, 2217–2224. [Google Scholar]

- Corominas, J.; Mavrouli, O.; Ruiz-Carulla, R. Magnitude and frequency relations: Are there geological constraints to the rockfall size? Landslides 2018, 15, 829–845. [Google Scholar] [CrossRef]

- Gili, J.A.; Ruiz-Carulla, R.; Matas, G.; Moya, J.; Prades, A.; Corominas, J.; Lantada, N.; Núñez-Andrés, M.A.; Buill, F.; Puig, C.; et al. Rockfalls: Analysis of the block fragmentation through field experiments. Landslides 2022, 19, 1009–1029. [Google Scholar] [CrossRef]

- Munjiza, A.; Owen, D.; Bicanic, N. A combined finite-discrete element method in transient dynamics of fracturing solids. Eng. Comput. 1995, 12, 145–174. [Google Scholar] [CrossRef]

- Bao, Y.; Wang, H.; Su, L.; Geng, D.; Yang, L.; Shao, P.; Li, Y.; Du, N. Comprehensive analysis using multiple-integrated techniques on the failure mechanism and dynamic process of a long run-out landslide: Jichang landslide case. Nat. Hazards 2022, 112, 2197–2215. [Google Scholar] [CrossRef]

- Gao, Y.; Li, B.; Gao, H.; Chen, L.; Wang, Y. Dynamic characteristics of high-elevation and long-runout landslides in the Emeishan basalt area: A case study of the Shuicheng “7.23” landslide in Guizhou China. Landslides 2020, 17, 1663–1677. [Google Scholar] [CrossRef]

- Zhang, Y.; Xing, A.; Jin, K.; Zhuang, Y.; Bilal, M.; Xu, S.; Zhu, Y. Investigation and dynamic analyses of rockslide-induced debris avalanche in Shuicheng, Guizhou, China. Landslides 2020, 17, 2189–2203. [Google Scholar] [CrossRef]

- Ma, G.; Zhou, W.; Ng, T.-T.; Cheng, Y.-G.; Chang, X.-L. Microscopic modeling of the creep behavior of rockfills with a delayed particle breakage model. Acta Geotech. 2015, 10, 481–496. [Google Scholar] [CrossRef]

- Xi, X.; Yang, S.; Mcdermott, C.I.; Shipton, Z.K.; Fraser-Harris, A.; Edlmann, K. Modelling rock fracture induced by hydraulic pulses. Rock Mech. Rock Eng. 2021, 54, 3977–3994. [Google Scholar] [CrossRef]

- Dassault Systèmes Inc. Abaqus 6.14 Online Documentation. Abaqus Analysis User’s Guide; Dassault Systèmes Inc.: Velizy-Villacoublay, France, 2014. [Google Scholar]

- McDougall, S. 2014 Canadian Geotechnical Colloquium: Landslide runout analysis—Current practice and challenges. Can. Geotech. J. 2014, 54, 605–620. [Google Scholar] [CrossRef]

- Davies, T.R.; McSaveney, M.J.; Hodgson, K.A. A fragmentation-spreading model for long-runout rock avalanches. Can. Geotech. J. 1999, 36, 1096–1110. [Google Scholar] [CrossRef]

- Dufresne, A.; Davies, T. Longitudinal ridges in mass movement deposits. Geomorphology 2009, 105, 171–181. [Google Scholar] [CrossRef]

- Dufresne, A.; Davies, T.R.H.; Mcsaveney, M.J. Influence of runout-path material on emplacement of the round top rock avalanche, New Zealand. Earth Surf. Process. Landf. 2010, 35, 190–201. [Google Scholar] [CrossRef]

- Dufresne, A. Granular flow experiments on the interaction with stationary runout path materials and comparison to rock avalanche events. Earth Surf. Process. Landforms 2012, 37, 1527–1541. [Google Scholar] [CrossRef]

- Potyondy, D.; Cundall, P. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Lu, C.Y.; Tang, C.L.; Chan, Y.C.; Hu, J.C.; Chi, C.C. Forecasting landslide hazard by the 3D discrete element method: A case study of the unstable slope in the Lushan hot spring district, Central Taiwan. Eng. Geol. 2014, 183, 14–30. [Google Scholar] [CrossRef]

- Wei, J.; Zhao, Z.; Xu, C.; Wen, Q. Numerical investigation of landslide kinetics for the recent Mabian landslide (Sichuan, China). Landslides 2019, 16, 2287–2298. [Google Scholar] [CrossRef]

- Hu, W.; Huang, R.; McSaveney, M.; Yao, L.; Xu, Q.; Feng, M.; Zhang, X. Superheated steam, hot CO2 and dynamic recrystallization from frictional heat jointly lubricated a giant landslide: Field and experimental evidence. Earth Planet. Sci. Lett. 2019, 510, 85–93. [Google Scholar] [CrossRef]

- Hu, Y.-X.; Yu, Z.-Y.; Zhou, J.-W. Numerical simulation of landslide-generated waves during the 11 October 2018 Baige landslide at the Jinsha River. Landslides 2020, 17, 2317–2328. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, C.; Li, Z.; Bao, Y.; Ning, P.; Zhou, X.; Wang, M.; Wang, H.; Shi, W.; Chen, B. Dynamic Analysis of a Long Run-Out Rockslide Considering Dynamic Fragmentation Behavior in Jichang Town: Insights from the Three-Dimensional Coupled Finite-Discrete Element Method. Remote Sens. 2023, 15, 5708. https://doi.org/10.3390/rs15245708

Zhu C, Li Z, Bao Y, Ning P, Zhou X, Wang M, Wang H, Shi W, Chen B. Dynamic Analysis of a Long Run-Out Rockslide Considering Dynamic Fragmentation Behavior in Jichang Town: Insights from the Three-Dimensional Coupled Finite-Discrete Element Method. Remote Sensing. 2023; 15(24):5708. https://doi.org/10.3390/rs15245708

Chicago/Turabian StyleZhu, Chun, Zhipeng Li, Yiding Bao, Po Ning, Xin Zhou, Meng Wang, Hong Wang, Wenbing Shi, and Bingbing Chen. 2023. "Dynamic Analysis of a Long Run-Out Rockslide Considering Dynamic Fragmentation Behavior in Jichang Town: Insights from the Three-Dimensional Coupled Finite-Discrete Element Method" Remote Sensing 15, no. 24: 5708. https://doi.org/10.3390/rs15245708

APA StyleZhu, C., Li, Z., Bao, Y., Ning, P., Zhou, X., Wang, M., Wang, H., Shi, W., & Chen, B. (2023). Dynamic Analysis of a Long Run-Out Rockslide Considering Dynamic Fragmentation Behavior in Jichang Town: Insights from the Three-Dimensional Coupled Finite-Discrete Element Method. Remote Sensing, 15(24), 5708. https://doi.org/10.3390/rs15245708