Abstract

This study presents the development and first manufacturing realization of the ECOTIRE concept, a modular and sustainable tire system featuring a removable tread mechanically interlocked with a reusable casing. The concept aims to reduce rubber waste and improve recyclability by eliminating adhesive bonding and enabling tread replacement. Building on previous experimental and numerical studies that validated the interlocking performance, this work focuses on producing a scaled prototype using a low-cost molding process, which can serve as the basis for accessible and sustainable manufacturing. VMQ silicone rubber was selected as an eco-friendly material due to its durability, thermal stability, and processing versatility. A custom two-part aluminum mold was designed to replicate the optimized interlocking geometry, enabling accurate casting, curing, and assembly. The resulting prototype achieved precise fit, dimensional uniformity, and easy disassembly, confirming the manufacturing feasibility of the ECOTIRE concept and demonstrating its potential to support circular economy strategies through reduced material waste and extended tire component lifetimes.

1. Introduction

Modern mobility increasingly demands solutions that balance performance, safety, and sustainability. Among all vehicle components [1,2,3,4], the tire remains one of the most material-intensive and environmentally challenging elements to produce and dispose of [5]. Each year, millions of end-of-life tires are discarded worldwide, creating issues related to waste management, microplastic emissions, and energy-intensive recycling [6,7,8,9,10]. Despite advances in tread compounds and rolling resistance optimization, the fundamental structure of tires has changed little for decades, and the linear model of manufacture–use–discard still dominates [11]. This persistent gap has motivated the search for modular, repairable, and recyclable tire architectures that can extend service life and minimize material loss [12].

Globally, more than one billion tires reach their end of life each year, generating tens of millions of tons of rubber waste, a large fraction of which is still landfilled, stockpiled, or downcycled rather than fully recycled. The complex multi-material structure and permanent bonding between tire components significantly hinder efficient material recovery, making end-of-life tires a persistent environmental challenge. These figures highlight the urgent need for alternative tire architectures that facilitate disassembly, reuse, and circular material flows.

In response to these limitations, the ECOTIRE project was conceived as a new approach to tire sustainability. The concept introduces a removable tread that mechanically interlocks with a long-life casing, allowing worn treads to be replaced without discarding the entire structure. By focusing on a mechanical rather than chemical bond between components, ECOTIRE aims to simplify recycling, reduce waste, and enable local re-treading with minimal tooling. Earlier studies [12,13,14,15] established the theoretical framework and initial experimental validation, showing that properly designed interlocking geometries can maintain structural stability under combined normal and tangential loads.

The environmental footprint of tire production is strongly influenced by the choice and processing of raw materials [16]. Conventional tires are primarily composed of synthetic rubbers derived from petroleum, reinforcing fillers such as carbon black, and various chemical additives that complicate recycling and reuse [17]. In recent years, considerable research has been devoted to developing eco-friendly and resource-efficient elastomeric materials to reduce tire waste and carbon emissions [18,19,20,21,22]. Approaches based on bio-derived natural rubbers, silica-reinforced compounds, and recycled crumb-rubber composites have demonstrated potential for reducing rolling resistance and material usage while preserving acceptable durability. Nevertheless, once vulcanized, most tire materials remain difficult to separate or regenerate, limiting their suitability for modular or reconfigurable tire architectures (Figure 1).

Figure 1.

United Nations Sustainable Development Goals (SDGs) directly addressed by the ECOTIRE project, highlighting its contribution to resource efficiency, responsible production, and sustainable mobility [14]. This work primarily addresses SDG 12 (Responsible Consumption and Production) by enabling component reuse and waste reduction, and SDG 9 (Industry, Innovation, and Infrastructure) through sustainable manufacturing design.

Within this context, the ECOTIRE framework introduces a different material philosophy (Figure 2). Instead of focusing solely on incremental improvements in conventional compounds, ECOTIRE explores materials that are inherently recyclable, reprocessable, and compatible with mechanical assembly rather than chemical bonding. Several environmentally benign elastomers, including EPDM, silicone, and EPDM–silicone hybrids, have been investigated as potential candidates for the tread and casing components [14,15]. These materials offer the dual advantage of flexibility for assembly and removal, and sufficient stiffness to withstand operational loading without permanent deformation or delamination.

Figure 2.

Conceptual overview of the ECOTIRE system, illustrating the modular tire architecture based on a mechanically interlocked, removable tread and a reusable casing. The figure highlights the key principles of the ECOTIRE concept, including component separability, mechanical interlocking, and the intended support for reuse, replacement, and circular material strategies [14].

Among the candidate materials, silicone rubber was selected for initial prototyping due to its dimensional stability, thermal resistance, and ease of casting in laboratory-scale molds. Its smooth surface finish and controllable curing behavior enable accurate evaluation of interlocking geometry, while its inherent reusability and compatibility with fillers offer clear pathways for future optimization toward enhanced strength and wear resistance.

To further refine the interface behavior, surface modification techniques such as atmospheric plasma treatment (APPT) and thin functional coatings have been employed to tailor the local friction and adhesion properties between the tread and casing surfaces [23,24]. These treatments allow the ECOTIRE modules to achieve a balanced interaction, strong enough to prevent slippage during operations yet sufficiently low to permit manual disassembly when replacement is required.

Overall, the ECOTIRE material strategy integrates sustainability, mechanical performance, and manufacturability by prioritizing materials that can be molded, detached, and reused without degradation, enabling a practical pathway toward circular tire design and future hybrid formulations. Building on this foundation, the next step was to verify whether the ECOTIRE system could be physically manufactured with sufficient precision and repeatability to produce a testable scaled prototype. This transition from simulation and bench-scale studies to physical realization introduces manufacturing challenges, namely mold geometry optimization, curing uniformity, dimensional tolerances, and demolding behavior, that ultimately govern interlock quality and the feasibility of industrial-scale implementation.

In conventional tire production, mold design is a critical stage that defines the final geometry, tread pattern accuracy, and curing efficiency of the product [25,26,27]. Industrial tire molds are typically made of segmented steel or aluminum sections that allow the vulcanized tire to be released after curing [28,29]. Their design must account for thermal expansion, venting, surface finish, and parting line control, as these directly influence the dimensional fidelity and surface texture of the final tread. Numerous studies have investigated the optimization of tire mold temperature distribution, curing cycle, and airflow management to improve uniformity and minimize defects in conventional vulcanization processes [27,29,30,31,32]. However, these systems are tailored for continuous industrial production and fixed geometries, where the tire is formed as a single-bonded structure.

By contrast, the ECOTIRE concept requires molds capable of producing modular interlocking components that must achieve high dimensional precision while remaining fully detachable for maintenance or replacement. This imposes new mold-design constraints, particularly regarding draft angles, alignment accuracy, cavity depth, and demolding strategy, that are largely absent in conventional tire manufacturing. To address these challenges at the scaled-prototype level, a custom mold was developed to accurately reproduce the optimized interlocking geometry and preserve the fine features essential for reliable mechanical coupling. The mold enables controlled casting and curing of elastomeric materials while ensuring dimensional consistency across multiple tread and casing modules. The successful fabrication and assembly of the prototype under these constraints constitutes a critical milestone in demonstrating the manufacturability of the ECOTIRE concept, effectively bridging the gap between conceptual modeling and practical implementation.

Building on earlier stages of this research line that established the mechanical feasibility and interlocking performance of the ECOTIRE concept, the present study delivers its first practical manufacturing realization. The objective is to demonstrate that the optimized modular architecture can be physically produced using an accessible, cost-efficient fabrication process, with silicone adopted as an initial eco-friendly material. A scaled ECOTIRE prototype is successfully manufactured, marking a decisive step beyond numerical and laboratory-scale validation. In contrast to previous works focused on interlocking optimization and mechanical characterization, this study provides the first complete translation of the optimized geometry into a detachable tread–casing prototype [15]. The novelty lies in demonstrating mold design feasibility, dimensional fidelity, and repeatable assembly through a low-cost casting route. The paper details the selected materials, mold design and fabrication, and modular assembly process. While comprehensive mechanical testing is deferred to future work, the results presented here establish the manufacturing feasibility, scalability, and sustainability potential of modular tire construction, effectively bridging conceptual design and physical realization.

2. Materials and Methods

2.1. Material Selection and Surface Treatment

For the ECOTIRE concept to achieve both mechanical performance and sustainability targets, the choice of tread material is as crucial as the geometric design of the interlocking system. The selected material must combine strength, durability, and environmental compatibility, ensuring that the tread can be replaced or recycled without compromising safety or service life. Addressing these challenges has prompted a growing focus on surface modification and coating technologies capable of improving polymer–rubber interfaces and extending material longevity. A specific surface protection for the rubber has been studied, allowing it to continue serving as the base material in a casing with an extended lifespan, while ensuring its compatibility with new materials applied to the tread. This optimizes the casing for longevity and the removable tread to reduce its environmental impact throughout its expected wear, facilitating simple replacement at the end of its life cycle.

Among these methods, atmospheric pressure plasma torch (APPT) treatment has shown significant promise in enhancing the surface energy and adhesion of polymers by introducing polar functional groups—particularly beneficial for low-energy materials such as polyolefins [23,24]. Related approaches have also been applied to elastomeric systems to improve coating durability and bonding efficiency. In synthetic and natural SBR rubbers, for instance, APPT promotes oxidation and partial removal of surface carbon black, confirmed by XPS detection of hydroxyl (C–OH) and carbonyl (C=O) groups. The addition of silica fillers, commonly used to reinforce elastomers and reduce weight, benefits further from silane coupling agents that enhance filler dispersion and matrix compatibility. Despite these advances, polyurethane coatings, which are often used as protective layers, still suffer from limited UV resistance and yellowing, even with silane modifications.

By contrast, silicone-based materials exhibit excellent weathering and UV resistance, thermal stability, and mechanical resilience, making them strong candidates for sustainable tire applications. Their inherent recyclability, reusability, and processing versatility align closely with the goals of the ECOTIRE framework. Previous research in this line confirmed that silicone maintains stable and repeatable mechanical behavior under both longitudinal and lateral loading, supporting its potential for modular tread–casing assemblies.

In this work, VMQ (methyl vinyl silicone rubber) was therefore selected as the base material for the first ECOTIRE prototype. The compound, FDA-compliant with a hardness of 59 Shore A, was chosen for its favorable curing characteristics and low processing cost. The tread modules were molded at 171 °C for 10 min, followed by a post-cure at 200 °C for 4 h. VMQ offers an operating temperature range of −60 °C to 220 °C (up to 250 °C short term), exceptional weathering stability, and self-extinguishing behavior when exposed to flame. It is chemically resistant to water, glycols, esters, and alcohols, while limited resistance to acids and aromatic hydrocarbons is not critical in tire applications.

Beyond its technical advantages, VMQ’s widespread use in sealing, insulation, and medical-grade components demonstrates its durability and safety. Within the ECOTIRE framework, it served as an initial eco-friendly material for manufacturing the first scaled prototype, confirming that the concept can be realized using a low-cost and reproducible fabrication route. The main mechanical and surface properties of the tested silicone are presented in Table 1.

Table 1.

Mechanical and surface properties of the VMQ silicone used in the ECOTIRE prototype.

2.2. Methodology

2.2.1. Mold Design and Fabrication

The scaled ECOTIRE prototype required a custom mold system capable of reproducing the new interlocking geometry with high precision and consistent dimensional accuracy. The mold was designed as a two-part assembly, allowing the formation of both male and female interlock features while ensuring proper alignment during casting. Key geometric parameters, such as draft angles, cavity depth, and interlock spacing, were optimized based on previous experimental findings to balance ease of demolding with mechanical fit tolerance [15].

To maintain structural rigidity and thermal uniformity, the mold was machined from aluminum alloy using CNC milling (Adventaria, Madrid, Spain). The molds for the male and female parts of the joint were manufactured with a height difference of 0.1 mm to ensure a proper fit, considering the permissible tolerance in mold manufacturing. The pyramidal shape thus guarantees a fit up to the contact of the joint walls. Alignment pins and venting channels were incorporated to ensure accurate closure and air escape during casting. Before each use, the internal surfaces were cleaned with ethanol and coated with a silicone-compatible release agent to facilitate smooth demolding. The final design provided sufficient flexibility for future adaptation to different module geometries and elastomer formulations. The manufactured and fabricated molds are shown in Figure 3, illustrating the segmented cavity layout and parting-line configuration.

Figure 3.

Custom aluminum mold designed by ADVANTARIA for manufacturing the scaled ECOTIRE prototype, showing cavity layout and parting-line configuration.

The final CAD geometry of the ECOTIRE mold and interlocking features was developed using Autodesk Inventor (2021.2), following initial conceptual iterations created with various CAD tools. The finalized design was directly employed for manufacturing, and CNC toolpaths were generated using Inventor CAM (Adventaria, Madrid, Spain), ensuring consistency between the digital model and the machined geometry. Mold fabrication was performed on a DMG CMX 600 3-axis CNC milling machine (15,000 rpm spindle, internal coolant, automatic tool changer, DMG MORI, Pfronten, Munich). The molds were primarily manufactured from 7075 aluminum alloy, selected for its high hardness and ability to maintain surface integrity and dimensional accuracy over repeated casting cycles. Several prototypes were produced using these molds without observable surface degradation. Comparative trials were also conducted using 5083 aluminum, which offers faster machining and lower tool wear; although satisfactory results were obtained, 7075 aluminum was found to be more suitable for repeated use where a precise surface finish is required. Aluminum molds were selected as a cost-effective and easily machinable alternative to steel molds, which, while offering higher durability, would significantly increase manufacturing complexity and cost.

To ensure accurate reproduction of the complex interlocking geometry, the mold cavities were machined using CNC milling directly from the final CAD model, with toolpaths generated via CAM to minimize geometric deviation. Alignment between the two mold halves was achieved using precision alignment pins, ensuring consistent cavity registration and maintaining the specified height difference of 0.1 mm across repeated casting cycles. A uniform demolding draft angle of approximately 2–3° was applied to the interlocking walls to facilitate part removal while preserving geometric fidelity.

2.2.2. Casting and Curing Process

The silicone compound (VMQ) was prepared according to the manufacturer’s specifications and mixed at a 10:1 ratio of base to catalyst by weight. The mixture was degassed under vacuum to eliminate entrapped air bubbles and poured into the mold cavities under controlled conditions to avoid void formation. Filling was performed gradually from the lowest point using a thin stream to ensure uniform flow and minimize turbulence.

Casting and curing were intentionally conducted using a simple, low-cost procedure to evaluate the robustness of the manufacturing approach. All molds were used at ambient conditions (approximately 25 °C), and no active monitoring of mold temperature uniformity or thermal gradients was applied. After filling, the mold assembly was placed in a curing oven at 171 °C for 10 min, followed by a post-curing step at 200 °C for 4 h to complete crosslinking and stabilize the mechanical properties, remaining within the supplier-recommended temperature range.

The manufacturing process was carried out manually, and five complete ECOTIRE prototype units were successfully produced. Minor surface defects, such as air bubbles or local surface imperfections at sharp interlocking edges, were observed only during the initial trials, while subsequent prototypes exhibited surface finishes suitable for assembly. Once cooled to room temperature, the mold halves were separated, and the cured modules were carefully demolded and visually inspected for surface quality, edge completeness, and potential defects. These observations indicate that the proposed casting and curing procedure is tolerant to moderate variations in mixing, degassing, and handling.

2.2.3. Evaluation and Next Steps

The primary goal of this stage was to verify the manufacturability and assembly feasibility of the ECOTIRE design rather than perform exhaustive mechanical testing. The prototype will serve as a baseline for future investigations involving dynamic testing, multi-material configurations, and surface-optimized interlocks. The successful realization of this scaled model confirms that the ECOTIRE concept can transition from simulation to a physical, manufacturable product, supporting future studies on durability and scaling to full-size applications.

2.3. End-of-Life and Recyclability Considerations (VMQ ECOTIRE vs. Conventional Tires)

From an end-of-life perspective, conventional passenger-car tires are multi-material, reinforced, and vulcanized structures, which complicates material separation and limits true closed-loop recycling. Typical routes for end-of-life tires include mechanical grinding into ground tire rubber, devulcanization for partial material recovery, and thermochemical processes such as pyrolysis to recover oil and recovered carbon black, each with different environmental trade-offs reported in the literature.

In contrast, the ECOTIRE architecture is designed to enable physical separation between tread and casing, which can reduce dismantling effort and improve material sorting. For the present prototype, VMQ silicone is a crosslinked elastomer, so direct melt reprocessing is not possible; however, silicone wastes can be mechanically recycled by size reduction and reused as a filler in new silicone formulations, and chemical recycling routes for silicones (e.g., depolymerization) are increasingly being developed and assessed.

While a full LCA is outside the scope of this work, these established end-of-life routes and the modular separability of ECOTIRE support the concept’s potential to reduce waste and enable more circular strategies compared with conventional bonded tire structures.

3. Prototype Realization and Observations

The cured tread modules were then assembled with the casing unit by manually aligning and pressing the interlocking features into position. The mechanical engagement was designed to ensure sufficient normal and tangential contact without the need for adhesives or bonding agents. The fitting process also served as a practical validation of the dimensional accuracy and repeatability of the manufacturing process.

The design and manufacturing process of the scaled prototype followed a sequential workflow, beginning with digital modeling and CNC machining of the mold, followed by silicone casting and curing, and concluding with manual assembly of the modules. This workflow is summarized in Figure 3, Figure 4, Figure 5, Figure 6 and Figure 7, which collectively illustrate the fabrication route and resulting product quality. The dimensional and surface inspection confirmed that the interlocking features were precisely reproduced and the modules could be repeatedly assembled without surface damage, supporting the feasibility of scaling the process to industrial applications.

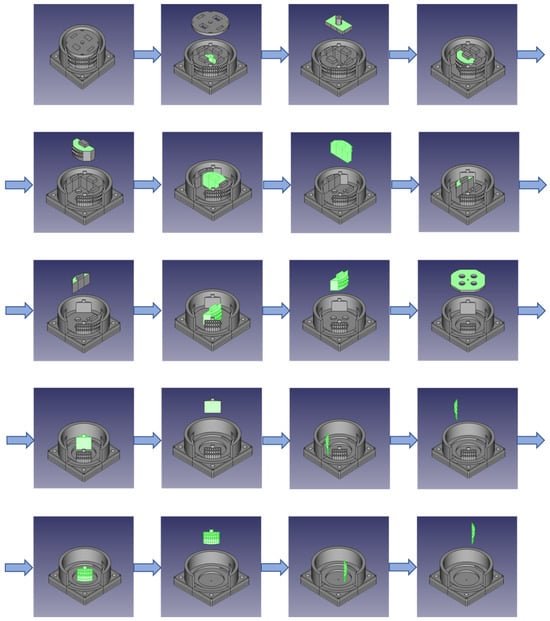

Figure 4.

Assembly sequence of the ECOTIRE tread mold, as designed by ADVANTARIA, demonstrating the alignment and mechanical engagement of interlocking tread and casing modules (Graphics: ADVANTARIA).

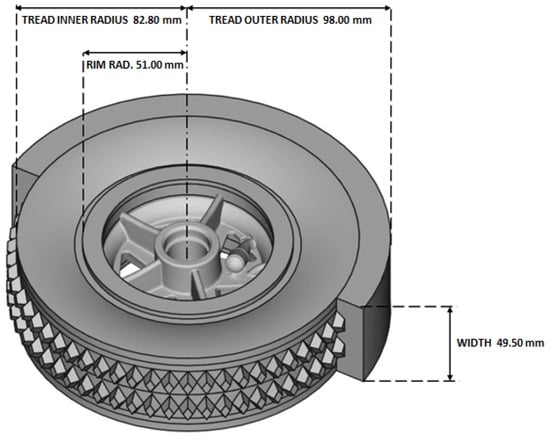

Figure 5.

Dimensional overview of the scaled ECOTIRE prototype, indicating the principal geometric parameters of the interlocking connection.

Figure 6.

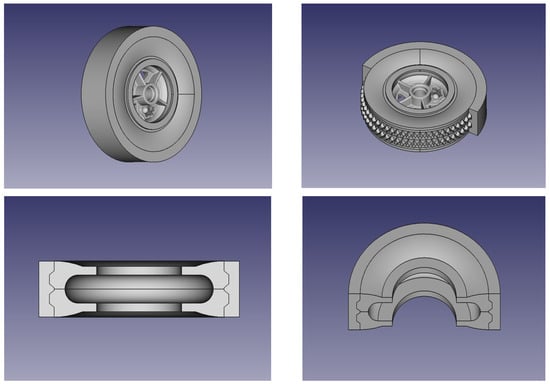

Detailed views of the designed ECOTIRE model highlighting the interlocking geometry and cavity arrangement prior to casting.

Figure 7.

Assembled scaled ECOTIRE prototype illustrating accurate alignment of interlocking modules and dimensional uniformity achieved through the molding process.

Figure 4 illustrates the assembly process of the scaled ECOTIRE prototype, highlighting the accurate alignment and engagement between the tread and casing modules. The interlocking features, produced through precision aluminum molding, exhibited uniform geometry and consistent dimensional accuracy across all modules. During assembly, the male and female interlocks fitted together smoothly with minimal insertion force, confirming the reliability of the designed tolerances and the mechanical compatibility of the VMQ silicone material. The elastic flexibility of the silicone aided in compensating for small geometric deviations while maintaining firm contact once seated, resulting in stable mechanical coupling without the need for adhesives or external fasteners.

Repeated assembly and disassembly cycles were carried out to assess fit repeatability and potential surface wear at the contact regions. No visible tearing, deformation, or loss of interlock integrity was observed, indicating that the material and geometry combination is suitable for reusable modular operation. The resulting prototype demonstrated a continuous, uniform tread surface with precise alignment along the circumferential direction, validating the manufacturing precision and structural stability of the concept. The visual inspection and tactile feedback confirmed that the interlocking mechanism performs as predicted in earlier simulation studies, achieving both secure engagement under normal load and easy manual removal when replacement is required.

Figure 5 presents the dimensional overview of the scaled ECOTIRE prototype, summarizing the principal geometric parameters that define the interlocking connection between the tread and casing modules. The measured dimensions closely matched the digital CAD model, confirming that the CNC-machined mold accurately replicated the intended cavity geometry. The interlock angle, tip radius, and cavity spacing were preserved within a deviation of less than ±0.1 mm, demonstrating excellent dimensional fidelity of the manufacturing process.

This dimensional validation is essential for ensuring consistent mechanical performance, since the strength and stability of the modular connection depend directly on the accuracy of these parameters. The controlled tolerances achieved during machining and casting prevented any perceptible gaps or excessive compression at the contact regions, resulting in a smooth load transfer path across the interface. Moreover, the dimensional uniformity among modules enables interchangeability and repeatable assembly, which are key requirements for future large-scale or automated production.

The overview shown in Figure 5, therefore, confirms that the manufacturing workflow, from CAD design to mold fabrication and silicone casting, can maintain tight geometric control while reproducing complex interlocking shapes. This outcome validates both the design for manufacturability principles applied to the ECOTIRE system and the feasibility of scaling the concept to industrial tire dimensions.

Figure 6 provides a detailed view of the ECOTIRE interlocking geometry and the corresponding cavity configuration used for mold fabrication. The design follows a male–female interlock concept consisting of truncated pyramid-shaped features distributed across the tread–casing interface. This configuration was derived from previous numerical optimization studies, which identified the geometry that maximizes tangential grip while minimizing local stress concentrations at the tips of the interlocks. The chosen shape ensures smooth assembly, uniform stress transfer, and stable contact during deformation under rolling or lateral loads.

The figure also illustrates the arrangement of interlocking units and the cavity layout within the mold. Each cavity was carefully aligned along the circumferential direction to preserve periodic symmetry and avoid cumulative alignment errors during module assembly. The spacing between adjacent interlocks was optimized to prevent overlapping of deformation zones while maintaining sufficient contact area for load transmission. This balance between engagement depth and spacing allows the system to achieve both mechanical stability and ease of disassembly, two essential criteria for modular tire operation.

From a manufacturing perspective, the cavity geometry shown in Figure 6 confirms that the interlocking features were designed with adequate draft angles and surface transitions, enabling smooth demolding without structural damage or residual stresses. These design-for-manufacturing refinements ensured that the final cast parts retained sharp interlocking edges and accurate surface finishes, which are critical for both performance consistency and aesthetic quality.

The complete scaled ECOTIRE prototype, shown in Figure 7, demonstrates the feasibility of producing detachable tread modules through a simple and low-cost casting approach. Dimensional checks confirmed uniform joint alignment and consistent interlock engagement, indicating that the manufacturing tolerances achieved were sufficient for a functional proof-of-concept.

Post-manufacturing dimensional inspection indicated that the deviations of key interlocking features relative to the CAD geometry remained within ±1.0 mm across multiple samples.

Mechanical Stability of the Interlocking Interface

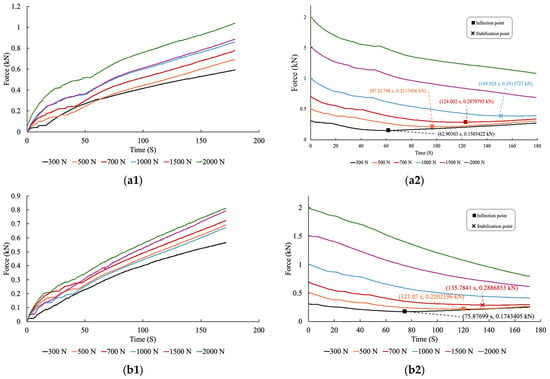

To verify the mechanical consistency of the detachable interface and confirm that the interlocked tread–casing samples remain engaged under loading, additional tests were performed on specimen-scale segments representing the contact-patch region. The experiments were conducted under two loading categories (longitudinal and lateral), while monitoring both normal and tensile force components. The applied displacement was imposed at a constant rate, resulting in a linear relationship between time and displacement; therefore, the recorded force–time curves can be directly interpreted as force–displacement behavior.

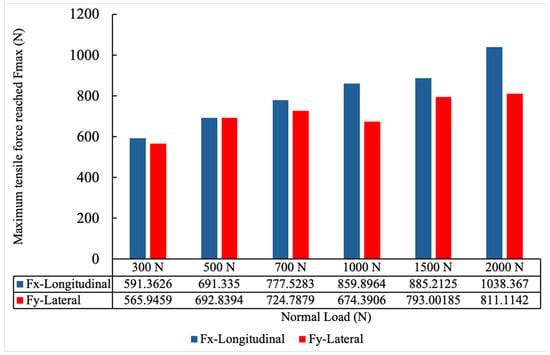

Across all tested specimens, the interface remained fully engaged throughout the test duration (170 s), and no climbing, separation, or detachment of the interlocked components was observed under any loading condition (Figure 8). The maximum forces reached during these tests, therefore, represent conservative lower-bound estimates of the interface retention capacity (Figure 9).

Figure 8.

Specimen-scale interface loading tests on interlocked ECOTIRE samples: (a1) applied tangential force in the longitudinal direction; (a2) corresponding evolution of normal force during longitudinal loading; (b1) applied tangential force in the lateral direction; (b2) corresponding evolution of normal force during lateral loading. No disengagement or separation of the interlocking interface was observed during the test duration [15].

Figure 9.

Maximum tangential force sustained by the interlocked ECOTIRE interface as a function of normal load for longitudinal and lateral loading cases. The values represent lower-bound interface retention capacities.

The applied normal load range was intentionally selected to span from low to relatively high interface-level loads in order to capture the mechanical response and load-dependent trends of the detachable interlock across a broad operating window. Further details on the experimental setup, loading protocol, and test conditions are provided in [15].

Overall, the specimen-scale loading results demonstrate that the mechanically interlocked ECOTIRE interface can sustain representative normal and tangential loads without disengagement. The absence of detachment throughout the applied loading range confirms that the detachable tread–casing connection is mechanically meaningful and stable at the interface level, providing quantitative support for the manufacturability and assembly feasibility claims of the ECOTIRE concept.

4. Discussion

The successful manufacturing of the scaled ECOTIRE prototype confirms that the proposed modular tire concept can be physically realized through conventional, low-cost molding techniques without adhesive bonding or complex vulcanization. The selected VMQ silicone material effectively replicated the intricate interlocking geometry while maintaining dimensional stability after curing and assembly. These results demonstrate that both the material formulation and manufacturing approach are suitable for producing sustainable tire components capable of being repeatedly separated, replaced, and reused.

Observations during the casting stage highlighted the importance of air evacuation, vent design, and controlled mold vibration to achieve defect-free surfaces, particularly at sharp interlocking edges where air entrapment is most likely. These issues, commonly encountered in elastomeric casting, were successfully mitigated through gradual filling and optimized venting channels. The high reproducibility of the interlocking features across multiple samples confirmed that the adopted mold design and curing parameters yielded consistent results, establishing a robust process foundation for future scaling to larger or multi-material configurations.

From a design and functional standpoint, the prototype’s assembly and disassembly behavior verified the mechanical integrity and geometric precision of the interlocking connection. The modules engaged smoothly under moderate manual pressure, forming a continuous tread surface with no visible gaps or misalignment. Repeated assembly–disassembly cycles revealed no tearing, permanent deformation, or surface wear, demonstrating that the material’s elasticity and optimized geometry ensured both stable mechanical grip and easy release. This reversible connection mechanism supports the concept’s goal of localized tread replacement, allowing worn sections to be renewed independently while the casing remains in service, thereby minimizing waste generation and material consumption compared to conventional full-tire replacement.

A key novelty of this work lies in demonstrating, to the authors’ knowledge, the first experimental manufacturing realization of a fully detachable, mechanically interlocked tread–casing interface produced using a scalable, low-cost process, as distinct from bonded retreading technologies and conceptual or non-detachable modular designs reported in the literature [12,13]. Conventional retreading processes rely on permanent bonding between tread and casing and do not allow repeated disassembly or localized tread replacement [33,34]. The segmented or modular tread concepts reported in the literature typically focus on assembly concepts without demonstrating a reusable casing combined with mechanically interlocked, detachable tread elements produced through scalable manufacturing routes [35,36]. In this context, the present work distinguishes itself by experimentally demonstrating a fully detachable tread–casing interface realized through physical manufacturing rather than conceptual design alone.

This experimental realization goes beyond previous simulation-based or small-sample studies in the ECOTIRE line, providing direct evidence that complex interlocking geometries can be reproduced with high-dimensional fidelity and assembled repeatedly without degradation. The successful replication of these intricate features establishes a practical foundation for scalable, modular tire systems, distinguishing this approach from traditional retread or segmented designs.

From a durability and end-of-life perspective, conventional tires based on SBR compounds are optimized for mechanical performance but exhibit well-documented sensitivity to environmental ageing, particularly under prolonged exposure to elevated temperatures, ozone, and moisture [37]. Reviews on tire-derived rubber recycling report that ageing-induced degradation affects the mechanical integrity of SBR materials and limits reuse options, with most end-of-life strategies relying on mechanical grinding, devulcanization, or thermochemical processes such as pyrolysis, often associated with material downcycling and significant energy demand [38].

In contrast, VMQ silicone elastomers are widely recognized for their excellent thermal stability, UV resistance, and resistance to oxidative and environmental ageing, making them suitable for applications exposed to severe temperature variations and weathering. While VMQ materials generally do not match the abrasion and fatigue resistance of tire-grade SBR compounds, their superior ageing resistance can support extended service life in non-traditional tire architectures, particularly when combined with modular and replaceable designs.

In the context of ECOTIRE, the removable tread architecture allows durability requirements to be decoupled between components: the casing material can prioritize environmental stability and reuse, while the tread can be replaced or reformulated as needed. Although quantitative fatigue and accelerated ageing tests were beyond the scope of the present manufacturing-focused study, the reviewed literature supports the rationale that VMQ-based modular systems may offer durability advantages at the system level through improved ageing resistance and facilitated end-of-life handling.

In parallel, ongoing work within the ECOTIRE research program is addressing wear and surface durability of both conventional tire materials and candidate elastomers, including VMQ-based formulations, with initial results reported in recent literature [39].

To provide a first-order sustainability perspective without performing a full life cycle assessment, a qualitative comparison between a conventional tire and the ECOTIRE concept is presented based on material flow and end-of-life logic. This screening-level comparison focuses on component replacement, disassembly, and recycling complexity, which are key drivers of environmental impact in tire systems.

As summarized in Table 2, the ECOTIRE architecture alters the material replacement and end-of-life logic of conventional tires by enabling casing reuse and reducing material flows per service cycle, which supports circular economy strategies.

Table 2.

Screening-level qualitative comparison between a conventional tire and the ECOTIRE concept based on material replacement, disassembly, and end-of-life considerations. The comparison highlights system-level differences relevant to circular economy strategies rather than quantified life cycle impacts.

Beyond technical feasibility, the manufacturing success of ECOTIRE reinforces its alignment with the United Nations Sustainable Development Goals (SDGs), particularly those promoting responsible production (SDG 12) and sustainable industry innovation (SDG 9). The process reduces material waste, energy demand, and production complexity, enabling future local manufacturing and recycling strategies.

Future developments will focus on dynamic and durability testing to validate the prototype under operational loads, as well as hybrid-material combinations to further balance stiffness, elasticity, and wear resistance. In parallel, the automation of module assembly and demolding operations will be investigated to evaluate the scalability of the concept for industrial implementation. Overall, the insights gained from this first manufacturing realization establish a strong foundation for developing next-generation, sustainable, and modular tire technologies that combine engineering functionality with environmental responsibility.

The main limitation of this study is that it focuses solely on manufacturability and assembly feasibility. Mechanical durability, dynamic performance under rolling and lateral loading, and long-term wear behavior were not evaluated at this stage and will be addressed in future work. Additionally, the current prototype uses a single material (VMQ silicone) and a scaled geometry; therefore, full-scale implementation and hybrid-material configurations will require further validation. Despite these constraints, the findings provide the necessary experimental foundation for advancing the ECOTIRE concept toward operational testing.

5. Conclusions

This work presented the first complete manufacturing realization of the ECOTIRE concept, a modular and sustainable tire design that enables tread replacement through a mechanical interlocking connection with a reusable casing. The key findings can be summarized as follows:

- VMQ silicone rubber was confirmed as a suitable, eco-friendly material for modular tire applications, combining durability, dimensional stability, and processability using standard molding equipment.

- A custom two-part aluminum mold successfully replicated the complex interlocking geometry with high accuracy and consistent surface quality, validating the feasibility of a low-cost, reproducible manufacturing process.

- The scaled ECOTIRE prototype achieved precise interlock engagement and repeatable assembly behavior, demonstrating the structural and practical viability of the modular approach.

- The results provide experimental evidence that the ECOTIRE system can be physically produced and assembled without adhesives, supporting its potential for circular and sustainable tire production.

- Future work will focus on durability and ageing characterization under representative thermal and mechanical loading, evaluation of alternative and hybrid tread materials, and dynamic testing of full-size ECOTIRE prototypes. While the concept was initially driven by sustainability objectives, the development of a simple and economical manufacturing process also enables short production runs and potential deployment in regions with limited industrial infrastructure.

Overall, the manufacturing success of the ECOTIRE prototype bridges the gap between conceptual modeling and real-world application, marking a key step toward sustainable and reconfigurable tire technologies.

Author Contributions

Conceptualization, F.A. and D.G.-P.R. Ramos; Methodology, D.G.-P.R. Ramos; Software, F.A.; Validation, F.A. and D.G.-P.R. Ramos; Formal analysis, F.A. and D.G.-P.R. Ramos; Investigation, F.A. and D.G.-P.R. Ramos; Resources, D.G.-P.R. Ramos; Data curation, D.G.-P.R. Ramos; Writing—original draft, F.A.; Writing—review & editing, F.A. and D.G.-P.R. Ramos; Visualization, F.A.; Supervision, D.G.-P.R. Ramos; Project administration, D.G.-P.R. Ramos; Funding acquisition, D.G.-P.R. Ramos. All authors have read and agreed to the published version of the manuscript.

Funding

This publication is part of the R + D + i project: TED2021-129604B-100, funded by MCIU/AEI/10.13039 501100011033 and by the European Union NextGeneration EU PRTR.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The experimental data generated in this study are not publicly available, as they were obtained from laboratory-scale tests conducted for this research project and are not stored in a public repository. The CAD models used for mold design and prototype fabrication are also not publicly available, as they are part of ongoing research and design optimization. Both the experimental data and CAD files can be made available from the corresponding authors upon reasonable request.

Acknowledgments

The authors gratefully acknowledge the support provided by Universidad Carlos III de Madrid, which made this research possible, and the company ADVANTARIA for the conceptual contributions and the provided technical and industrial support, allowing the use of preexisting Industrial Property Rights.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Advantaria. Wheel with Mixed Damping and Increased Safety Structure. Patent No. ES2665819B2, 7 February 2019. [Google Scholar]

- Min, D.; Wei, Y.; Zhao, T.; He, J. A fusion estimation of tire vertical forces using model-based tire state estimators for a dual-sensor intelligent tire. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2024, 238, 2146–2159. [Google Scholar] [CrossRef]

- Zhang, J.; Fu, H.; Yang, B.; Ni, S.; Huo, R.; Lian, C. A spoke strain-based method to estimate tire condition parameters for intelligent tires. Sens. Actuators A Phys. 2024, 367, 115035. [Google Scholar] [CrossRef]

- Taiebat, M.; Brown, A.L.; Safford, H.R.; Qu, S.; Xu, M. A review on energy, environmental, and sustainability implications of connected and automated vehicles. Environ. Sci. Technol. 2018, 52, 11449–11465. [Google Scholar] [CrossRef]

- Mayer, P.M.; Moran, K.D.; Miller, E.L.; Brander, S.M.; Harper, S.; Garcia-Jaramillo, M.; Carrasco-Navarro, V.; Ho, K.T.; Burgess, R.M.; Hampton, L.M.T.; et al. Where the rubber meets the road: Emerging environmental impacts of tire wear particles and their chemical cocktails. Sci. Total Environ. 2024, 927, 171153. [Google Scholar] [CrossRef] [PubMed]

- Khan, F.R.; Rødland, E.S.; Kole, P.J.; Van Belleghem, F.G.A.J.; Jaén-Gil, A.; Hansen, S.F.; Gomiero, A. An overview of the key topics related to the study of tire particles and their chemical leachates: From problems to solutions. TrAC Trends Anal. Chem. 2024, 172, 117563. [Google Scholar] [CrossRef]

- Evaluation of the Potential Toxicity of Automobile Tires in the Aquatic Environment/Prepared by B.A.R. Environmental Inc.; Prepared for Environment Canada, National Water Research Institute. Available online: https://publications.gc.ca/site/eng/9.894617/publication.html (accessed on 16 December 2025).

- Root, T. Tires: The plastic polluter you never thought about. Natl. Geogr. 2019, 20, 47. [Google Scholar]

- Dabic-Miletic, S.; Simic, V. Smart and Sustainable Waste Tire Management: Decision-Making Challenges and Future Directions. Decis. Mak. Adv. 2023, 1, 10–16. [Google Scholar] [CrossRef]

- Piotrowska, K.; Kruszelnicka, W.; Bałdowska-Witos, P.; Kasner, R.; Rudnicki, J.; Tomporowski, A.; Flizikowski, J.; Opielak, M. Assessment of the Environmental Impact of a Car Tire throughout Its Lifecycle Using the LCA Method. Materials 2019, 12, 4177. [Google Scholar] [CrossRef] [PubMed]

- Laftah, W.A.; Rahman, W.A.W.A. A comprehensive review of tire recycling technologies and applications. Mater. Adv. 2025, 6, 4992–5010. [Google Scholar] [CrossRef]

- Rodríguez, I.R. Neumático Menos Contaminante y Con Mayor Vida Útil Solicitante. Patent No. ES2942787, 3 December 2021. [Google Scholar]

- Rodríguez, I.R.; García-Pozuelo, R.D.; Casanova, M.Á.M.; Ventura, J.M.P. Neumático con Banda de Rodadura Menos Contaminante y Unión Mediante Procedimientos No Termoquímicos. Patent No. ES1312633U, 22 January 2024. [Google Scholar]

- Garcia-Pozuelo, D.; Afshari, F.; Gutierrez-Moizant, R.; Martínez, M.A. ECOTIRE: A New Concept of a Smart and Sustainable Tire Based on a Removable Tread. Appl. Sci. 2025, 15, 3675. [Google Scholar] [CrossRef]

- Afshari, F.; García-Pozuelo, D.; Gutiérrez-Moizant, R.; Martínez, M.Á. Multiscale Surface and Friction Characterization of an ECOTIRE Modular Tire Interface: From Manufacturing to Measurement. Results Eng. 2025, 29, 108810. [Google Scholar] [CrossRef]

- Wu, S.; Wang, Z.; Guo, S.; Cai, Y.; Zhang, J.; Huangfu, C.; Huang, Y.; Ma, L.; Zhao, W. Life-cycle-based reconfiguration of sustainable carbon black production: Integrated conventional technique with waste tire pyrolysis and its future improvement potentials. J. Clean. Prod. 2024, 442, 141022. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, H.; Sablani, S.S.; Wu, Q. Recycling Functional Fillers from Waste Tires for Tailored Polystyrene Composites: Mechanical, Fire Retarding, Electromagnetic Field Shielding, and Acoustic Insulation Properties—A Short Review. Materials 2024, 17, 2675. [Google Scholar] [CrossRef]

- Ismail, H.; Rosnah, N.; Rozman, H.D. Effects of various bonding systems on mechanical properties of oil palm fibre reinforced rubber composites. Eur. Polym. J. 1997, 33, 1231–1238. [Google Scholar] [CrossRef]

- Lee, D.; Song, S.H. A Study of Silica Reinforced Rubber Composites with Eco-Friendly Processing Aids for Pneumatic Tires. Macromol. Res. 2019, 27, 850–856. [Google Scholar] [CrossRef]

- Ren, X.; Sancaktar, E. Use of fly ash as eco-friendly filler in synthetic rubber for tire applications. J. Clean. Prod. 2019, 206, 374–382. [Google Scholar] [CrossRef]

- Qin, X.; Wang, J.; Han, B.; Wang, B.; Mao, L.; Zhang, L. Novel design of eco-friendly super elastomer materials with optimized hard segments micro-structure: Toward next-generation high-performance tires. Front. Chem. 2018, 6, 400249. [Google Scholar] [CrossRef]

- Sutisna, N.A.; Gapsari, F. Rolling Resistance and Noise Estimation for Product Design and Development of Eco-Tyre using Finite Element and Numerical Method. IOP Conf. Ser. Mater. Sci. Eng. 2019, 494, 012021. [Google Scholar] [CrossRef]

- Encinas, N.; Abenojar, J.; Martínez, M.A. Development of improved polypropylene adhesive bonding by abrasion and atmospheric plasma surface modifications. Int. J. Adhes. Adhes. 2012, 33, 1–6. [Google Scholar] [CrossRef]

- Bahrami, M.; Lavayen-Farfan, D.; Martínez, M.A.; Abenojar, J. Experimental and numerical studies of polyamide 11 and 12 surfaces modified by atmospheric pressure plasma treatment. Surf. Interfaces 2022, 32, 102154. [Google Scholar] [CrossRef]

- Choi, S.H.; Lyu, M.Y. A study of rubber flow in a mold during the tire shaping process using experiment and computer simulation. Polym. Test 2017, 61, 258–268. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, B.; Liu, X.; Cheng, L.; Yan, H.; Ding, Q.; Tan, J.; Yang, W. Energy-Saving Performance and Production Accuracy of the Direct-Pressure Tire Curing Technology with an Expandable Steel Internal Mold. Appl. Sci. 2020, 10, 79. [Google Scholar] [CrossRef]

- Yoo, S.; Kim, H.; Kim, Y.; Sung, K.; Heo, H. Advanced Finite Element Analysis Process for Accurate Cured Tire Shape Forecasting. Polymers 2025, 17, 1546. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, Z.; Wang, X.; Xu, X.; Wu, Y.; Wu, D. Comparative Study of Anti-Sticking Properties of Coatings for Tire Molds. Coatings 2022, 12, 1740. [Google Scholar] [CrossRef]

- Xiao, W.; Cao, F.; Lin, J.; Wang, H.; Liu, C. Thermo-Mechanical Behavior Simulation and Experimental Validation of Segmented Tire Molds Based on Multi-Physics Coupling. Appl. Sci. 2025, 15, 4010. [Google Scholar] [CrossRef]

- Çağlıyan, A.Ç.; Akyüz, F.; Feyzioğlu, A.; Ersoy, S.; Festo, S.; Ve Ticaret, A.Ş.; İayosb, A. Thermal and flow optimization and generative design simulations of the curing press manifold used in tire production. J. Mechatron. Artif. Intell. Eng. 2024, 5, 191–198. [Google Scholar] [CrossRef]

- Xia, Z.; Gan, J.; Xia, H.; Chen, M.; Tang, R. Design and Temperature Uniformity Optimization of Electromagnetic Heating Hot Plate for Tire Vulcanizing Machine. Energies 2025, 18, 2695. [Google Scholar] [CrossRef]

- Zhao, C.; Cao, A.; Wang, L.; Chen, Z.; Wang, H.; Liu, Z.; He, S.; Gao, M. Analysis of effect on temperature field of tire curing process by initial temperatures and condensate discharging. Appl. Therm. Eng. 2024, 257, 124424. [Google Scholar] [CrossRef]

- Rackers, K.J.; Bateman, W.J. Wheel Assembly with Replaceable Tire. U.S. Patent USD917124S1, 20 April 2021. [Google Scholar]

- Kikuchi, N.; Hochi, K.; Horiguchi, T. Green Tire and Method of Manufacture. Patent 7,946,323 B2, 24 May 2011. [Google Scholar]

- Thomas, J.; Patil, R. The Road to Sustainable Tire Materials: Current State-of-the-Art and Future Prospectives. Environ. Sci. Technol. 2023, 57, 2209–2216. [Google Scholar] [CrossRef] [PubMed]

- Deng, S.; Chen, R.; Duan, S.; Jia, Q.; Hao, X.; Zhang, L. Research progress on sustainability of key tire materials. SusMat 2023, 3, 581–608. [Google Scholar] [CrossRef]

- Fathali, M.; Esmaeili, M.; Nejad, F.M. Influence of tire-derived aggregates mixed with ballast on ground-borne vibrations. J. Mod. Transp. 2019, 27, 355–363. [Google Scholar] [CrossRef]

- Kraśkiewicz, C.; Anysz, H.; Zbiciak, A.; Płudowska-Zagrajek, M.; Al Sabouni-Zawadzka, A. Artificial neural networks as a tool for selecting the parameters of prototypical under sleeper pads produced from recycled rubber granulate. J. Clean. Prod. 2023, 405, 136975. [Google Scholar] [CrossRef]

- Abenojar, J.; Martínez, M.A.; García-Pozuelo, D. Analysis of Wear Behavior Between Tire Rubber and Silicone Rubber. Appl. Sci. 2026, 16, 878. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.