Abstract

This study investigates the impact of digitalization on sustainability, resilience, risk management, integration, and performance within supply chains. It addresses gaps in the existing literature concerning the role of digitalization in fostering sustainable supply chains. Drawing upon Innovation Diffusion Theory, the Triple Bottom Line (TBL), Risk Theory (RT), Organizational Information Processing Theory (OIPT), and the Resource-Based View (RBV), a comprehensive structural model was developed to examine the interrelationships among these constructs. A quantitative research design was employed, with data collected through an online survey of 420 supply chain practitioners. Data analysis, conducted using SPSS 28 and Smart PLS 4, tested the relationships between digitalization and supply chain performance. The findings demonstrate that digitalization exerts a significant positive influence on sustainability, resilience, risk management, and integration, thereby enhancing overall supply chain performance. Results further underscore the importance of aligning supply chain strategies with the unique characteristics of different organizational contexts in order to maximize efficiency and adaptability. In today’s dynamic business environment, digitalization emerges as a critical driver of competitiveness, enabling supply chains to achieve greater responsiveness and long-term sustainability. This study contributes to theory and practice by integrating multiple perspectives to provide nuanced insights into digital transformation, while also offering practical guidance for enterprises seeking to optimize supply chain strategies.

1. Introduction

Geopolitical disruptions, economic crises, extreme weather events, cyber threats, population migration, modern slavery, and other factors have increasingly undermined supply chain stability, rendering them more vulnerable to risks and interruptions. The COVID-19 pandemic had a profound impact across all sectors of the global economy, causing significant disruptions in supply chains, production processes, transportation, and the delivery of both raw materials and finished products. The magnitude of its impact on business operations was difficult to anticipate due to the inherent complexity and uncertainty of the situation. These supply chain disruptions, heightened uncertainty, sudden shifts in market demand, and unforeseen operational interruptions compelled businesses to adopt more flexible approaches and to continuously adjust their strategies and business models to address emerging challenges [1].

Ivanov (2024) [2] observed a shift among researchers and practitioners towards analyzing supply chain resilience in the context of the pre- and post-pandemic periods. Previous studies emphasize the need to adopt digital technologies, enhance blockchain visibility, and develop interconnected networks to mitigate disruptions and improve supply chain performance [3,4]. Research on the impact of resilience on supply chain performance remains limited. The results of assessing supply chain resilience capacity and its effect on performance provide businesses with the opportunity to develop innovative strategies and formulate effective plans and measures for risk management [5].

The war in Ukraine has caused significant new disruptions in global supply chains since 22 February 2022, directly impacting trade flows, production, and the transportation of raw materials and goods. The conflict has severely affected key sectors of the economy, such as agriculture, energy, metallurgy, transportation, and healthcare, leading to numerous interruptions and problems. In this context, Medvediev et al. (2024) [6] emphasizes the necessity of anticipating risks and uncertainties that may arise along new routes, as well as the need to develop proactive risk assessment models to reduce delivery times and identify anticipated risk factors. Few studies have evaluated risk management and its effect on supply chain performance [7,8,9]. Future research should focus on reducing uncertainty in logistics processes, identifying alternative risk mitigation strategies, and developing more precise and efficient solutions for optimizing supply chain management.

Climate change and natural disasters are significant vulnerability factors for the supply chain, considerably disrupting operations and the global flow of goods and services [10,11]. In this context, supply chains must find new solutions for strategic planning, risk management, improving logistics infrastructure, and implementing information and quality management systems. Bag et al. (2024) [12] observed that climate change and extreme weather events have intensified concerns among specialists regarding the analysis and reinforcement of supply chain resilience, emphasizing adaptive leadership, visibility, flexibility, communication, and collaboration, as well as the integration and enhancement of sustainability practices. Their results demonstrate that resilience directly contributes to improving supply chain performance when sustainability practices are integrated. Furthermore, supply chain resilience has significant positive effects on the sustainability triad and a strong impact when combined with IT.

In recent years, supply chains have been exposed to a high number of cyber risks, including third-party supplier vulnerabilities, data breaches, phishing, ransomware attacks, and operational disruptions [13]. To mitigate these threats, businesses have had to adopt proactive measures such as continuous employee training, encryption, regular backups, and collaboration with business partners. Sindiramutty et al. (2024) [14] observed that with the advancement of emerging technologies, supply chains have become increasingly vulnerable to cyber threats and attacks. Few studies have examined how digitalization affects risk management, resilience, and supply chain performance [15,16]. These studies have shown that digitalization, through information processing and increased visibility, has a significant impact on risk management and supply chain resilience, while risk management acts as a positive mediator in the relationship between digitalization and supply chain performance.

Population migration, whether forced or voluntary, significantly affects supply chain vulnerability by causing workforce disruptions and regional labor imbalances. In the context of global changes, Scheel et al. (2024) [17] highlights the importance of reorganizing supply chains to accommodate migrant labor. This transformation should include building partnerships, sharing experiences, and fostering collaboration among supply chain members to improve long-term performance. Some previous studies have demonstrated the significant positive effect of supply chain integration on risk management [18], resilience [19], and performance [20].

In Romania, supply chains across various sectors face multiple challenges that hinder their efficiency and competitiveness. These challenges include limited access to financing, trade barriers, underdeveloped infrastructure, and market volatility. According to the World Bank (2023) [21], institutional weaknesses, administrative capacity constraints, and inefficient policies create a business environment that restricts supply chain performance. Additionally, OECD (2022) [22] highlights that limited access to long-term financing and underdeveloped capital markets further constrain investments in infrastructure and technological upgrades necessary for efficient supply chain operations. Together, these factors underscore the need for targeted policy measures and strategic interventions to enhance supply chain resilience and performance in Romania.

On the other hand, the adoption of new technologies such as precision agriculture, blockchain, and the Internet of Things (IoT), together with the implementation of coherent and sustainable policies, contributes to optimizing production, distribution, and commercialization processes [23]. Ionescu et al. (2023) [24] demonstrated that implementing advanced technologies and specialized software solutions, combined with proactive strategies, can significantly enhance supply chain performance. This improvement facilitates adaptation to the demands of the digital economy and strengthens long-term competitiveness.

In recent years, the digital transformation process in Romania’s industrial sector has been supported through government initiatives, including the Industrial Strategy of Romania 2023–2027 [25] and the National Action Plan for the Digital Decade 2030 [26]. These initiatives emphasize the importance of digitalization in the Romanian industrial sector and include proposals for integrated solutions in the agri-food, manufacturing, and services domains. By the end of 2023, Romania registered the lowest level of digitalization among European Union countries, with over 72% of enterprises classified as having very low digital intensity [27]. Beyond digitalization, Romanian enterprises also face challenges in implementing sustainability practices, risk management, and supply chain integration. Analysis of innovation trends in Romanian supply chain management, Puica (2021) [28] highlights that while digitalization can improve supply chain performance, its implementation remains challenging. This context makes Romania a pertinent case for analyzing how digitalization affects supply chain performance, while also providing an opportunity to explore the particularities of an emerging economy in Eastern Europe.

Given the considerations outlined above, as well as the need for a deeper under-standing of practitioners’ perspectives on the impact of digitalization on supply chain performance, this study aims to analyze the relationship between these two variables, with mediators such as sustainability, resilience, risk, and integration.

The originality of this study lies in integrating multiple theoretical constructs—digitalization, sustainability, resilience, risk management, and integration—within a unified framework, while assessing their mediated effects on supply chain performance. This study expands the existing literature by investigating the complex relationships between these constructs and their influence on supply chain performance, offering new insights into how implementing advanced digital products and services can improve performance.

The main objectives of the study are as follows:

O1: Assessing the impact of the exogenous variable supply chain digitalization on the endogenous variables supply chain sustainability, resilience, risk, and integration.

O2: Examining the relationships among the five latent variables of the supply chain, namely sustainability, resilience, risk, integration, and performance.

O3: Identifying potential differences between practitioner segments based on the relationships among the variables proposed in the structural model.

This study offers several significant contributions. First, it develops a complex, robust, and valid conceptual model that can be expanded in future studies by incorporating additional latent variables. Second, the study deepens and extends the existing literature on the impact of digitalization on key supply chain components such as sustainability, resilience, risk, and integration. Previous studies have focused on evaluating the effects of digitalization on supply chain sustainability and resilience. Other studies have only analyzed the interconnections between digitalization, integration, and resilience in different industries. In the context of uncertain and volatile markets, digital transformation is becoming a priority for supply chain decision-makers across all sectors. By enhancing visibility, transparency, and real-time responsiveness, and by integrating ecological and social practices while streamlining information flows and processes among stakeholders, and identifying and mitigating risks associated with political, economic, social, environmental, and operational uncertainties, business managers can ensure greater efficiency and resilience within supply chains. Third, this study uniquely highlights the complexity of the relationships between supply chain sustainability, resilience, risk, and integration in the context of a dynamic and constantly changing economic environment. Finally, through a comprehensive review and integration of specialized literature on supply chain performance, this study underscores the need for performance measurement systems adapted to contemporary challenges. These systems should include not only traditional indicators but also additional metrics that reflect essential aspects of sustainability, resilience, risk, and supply chain integration. Such systems must enable the continuous assessment and monitoring of supply chain performance in the face of political, economic, social, technological, and environmental changes.

2. Literature Review

2.1. Supply Chain Digitalization (SCD)

SCD involves transforming the analog data and processes of the supply chain into digital formats using advanced technologies and software. At the supply chain level, data flows from both internal and external sources are systematically integrated and automated. Through process optimization, end-to-end data visibility is ensured, thereby contributing to improved decision-making and business performance. To facilitate this transformation, customized or standardized platforms and software solutions leveraging automation and business intelligence are employed. According to Aamer et al. (2023) [29], there is growing interest in digitalization within supply chain management, while the specialized literature reveals a gap regarding the drivers of supply chain digitalization. The study results highlight a gap between studies on digital transformation and those on its implementation across different sectors. Bigliardi et al. (2022) [30] showed that the integration of blockchain, IoT, Machine Learning (ML), etc., contributes to increasing the efficiency of supply chains by enhancing the ability to optimize planning, sourcing, and procurement strategies. Sarfraz et al. (2023) [31] emphasized that businesses should not limit themselves to adopting sustainable strategies but should integrate advanced technologies (IoT and blockchain) and new transformation practices to maintain the competitive advantage gained in today’s dynamic market landscape. Atieh Ali et al. (2024) [32], analyzing the interaction between digitalization and supply chain sustainability, highlighted that managers who wish to improve their performance within the supply chain must adopt innovative technologies, implement agile processes, and collaborate with stakeholders. Existing literature has not paid much attention to the interaction between supply chain sustainability and performance. Numerous studies provide bibliometric analyses in the form of an inventory of publishing activity in the field of supply chain digitalization [33,34]. However, few studies correlate sustainability with supply chain performance [35,36].

2.2. Supply Chain Sustainability (SCS)

SCS refers to managing the economic, social, and environmental impacts and applying governance practices throughout the life cycle of goods and services. Its goal is to create, protect, and enhance economic, social, and environmental value for all businesses involved in the supply chain. SCS is particularly important because it enables the rapid delivery of goods and services worldwide, ensuring communication and connectivity across geographical areas, diverse industries, cultures, and regulatory standards. Moreover, by meeting consumer needs, applying ethical business principles, managing economic, social, and environmental performance, and creating jobs, it contributes to societal development and maximizes the positive impact on economic networks and the global community. Okoye et al. (2024) [37] explored sustainable supply chain practices and observed that businesses in the Americas and Africa are increasingly adopting eco-friendly logistics strategies. They use renewable energy in distribution and transportation, integrate advanced technologies such as IoT and blockchain to facilitate transparency and traceability in supply chains, utilize alternative materials from local sources and eco-friendly packaging, and ensure communication and collaboration between entities and local communities to create a positive impact on society and the environment. In analyzing the relationship between sustainable supply chain management (SSCM) and business performance, Fu et al. (2022) [38] found a positive and significant link between the two variables. Business performance improves as supply chain performance, network design, organizational structure, and information systems are enhanced. Other studies have shown a positive and significant correlation between SCS and business performance, highlighting that sustainable procurement, investment recovery, and the application of social and environmental practices contribute to increased competitiveness, improved operational efficiency, and enhanced organizational reputation [39,40]. Attia (2023) [41] showed that the successful implementation of SCS contributes not only to operational performance but also to improving customer relationship management and gaining a competitive advantage. Although the current literature reveals numerous studies on SCS, only two highlight the combined effect of digitalization and sustainability on supply chain performance [42,43].

2.3. Supply Chain Resilience (SCR)

SCR refers to the ability to prevent and quickly recover from operational disruptions through flexible planning and forecasting actions, starting with the supply of raw materials, materials, components, and goods to logistics, and ending with the final delivery of products and services. Due to the increase in global uncertainties and vulnerabilities, Ivanov et al. (2024) [2] demonstrated the need to adopt new management practices that strengthen SCR, ensuring their continuity and adaptability in the face of disruptions. By integrating digital technology, ensuring the viability of the supply chain, creating an inter-sectoral ripple effect, and interconnecting networks, businesses can enhance their capacity to mitigate most supply chain disruptions and/or limit those that may arise over time. Syed Jamaludin et al. (2024) [44] emphasize that in the context of an ever-changing, volatile, and uncertain climate, supply chain businesses should prioritize sustainability, adaptability, and resilience. Lakhouil and Soulhi (2024) [45] assessed SCR by including elements such as agility, innovation, coordination, and visibility. Furthermore, they demonstrated that by integrating digital technologies such as the IoT, Artificial Intelligence (AI), Machine Learning (ML), Additive (3D) Printing, Modern Databases, etc., businesses can improve resilience, flexibility, and efficiency in supply chains, adapting more easily to changes in the global environment. Jaller et al. (2024) [46] developed a tool for monitoring and evaluating the vulnerability, resilience, and sustainability of the supply chain based on macro and microeconomic parameters. The purpose of this tool is to provide a comprehensive and data-driven approach for identifying and managing supply chain risks to improve operational resilience and promote sustainability by providing valuable information that contributes to making the best decisions in the strategic process. Wang and Wang (2024) [47] found that adopting agility has a positive effect on both relationships and the sustainability of the supply chain. Moreover, applying sustainability practices mitigates the impact of crises on supply chains, contributing to the increased resilience and ability of supply chains to quickly adapt to unforeseen changes. Atieh Ali et al. (2024) [32] emphasized that SCR has a positive and significant effect on SCS, leading to improved operational performance, reduced risks, and strengthened long-term competitive advantage. Some authors, when analyzing the literature on supply chain risk management, have highlighted gaps in exploring its impact on supply chain performance, especially under the influence of the moderating factor of supply chain disruption, which involves disruptions in the supply process, catastrophic disturbances, and infrastructure disruptions [48,49].

2.4. Supply Chain Risk (SCK)

SCK refer to various threats that disrupt the flow of goods and services from suppliers to recipients within the supply chain network. To manage and reduce emerging risks, supply chain businesses can implement strategies such as supply chain mapping, supplier assessment and prioritization based on performance criteria, strengthening relationships with suppliers, optimizing inventories, and others. These measures contribute to increasing the resilience of the supply chain and ensuring the continuity of operations. Examining SCK management and resilience from the perspective of information processing theory, Rashid et al. (2024) [16] found that enterprises that quickly collect, analyze, and interpret information from the supply chain have the ability to develop strategies that effectively respond to external changes and challenges. In this regard, they gradually integrate advanced technologies to monitor supply chain operations in real time, providing better visibility and enabling the quick identification and management of disruptions. Furthermore, SCK mediates the relationship between information processing capability and supply chain digitalization. Analyzing the effect of adopting new technologies on risk management practices in supply chains, Odimarha et al. (2024) [50] highlighted those technological innovations such as blockchain, IoT, AI, and predictive analytics are reshaping traditional risk management approaches by providing real-time visibility, using data-driven information, and implementing proactive risk mitigation strategies. The study reveals the contributory role of new technologies in improving SCR, agility, and response to unforeseen disruptions. Christiana et al. (2024) [20] demonstrated that manufacturing businesses that use a continuous process control system improve the management of processes and ensure effective management of environmental risks, which significantly increases supply chain performance. Additionally, businesses can quickly identify potential threats and minimize their impact on operations by implementing risk detection systems and emergency procedures, ensuring continuity in the face of unforeseen changes, thereby contributing to enhanced resilience and overall performance of the organization. Senna et al. (2024) [8] highlight gaps in the literature regarding the analysis of SCK and the joint, positive, and significant effect of SCI and SCK management on SCP in the healthcare sector.

2.5. Supply Chain Integration (SCI)

SCI refers to the ability to organize and operate a supply chain as an association composed of customers and suppliers who, using management and marketing techniques and strategies, work together to enhance collective performance, starting from creation, production, and distribution, and ending with the support of the final products. Integration is the core of the supply chain process, and to ensure long-term success, it must be strategically planned. To acquire and understand all the details about the actions and interactions of the chains, the technological integration process must be closely coordinated with the functions and elements of the supply chain, as stated by [51]. A particularly important role of integration is data collection, storage, and processing. Ensuring the monitoring and security of the integration process requires effective coordination and control of communications throughout the entire network. At the same time, exploring and utilizing emerging technologies contributes to improving activities and communication, reducing errors, saving time and financial costs, as well as increasing the performance of the supply chain, thus creating a more complex and efficient structure. Kumar and Raj (2024) [52] demonstrated that the adoption of Big Data contributes to improving innovation capacity, and the integration and resilience of the supply chain effectively translate the influence of innovation capacity into organizational performance. Christiana et al. (2024) [20] found that the development and integration of new technologies allowed supply chains to, on the one hand, expand the number of internal and external partners working together in the network, and on the other hand, manage the volume of information efficiently and quickly for making the best, real-time, and reliable decisions. The results of the study show that SMEs that continuously improve their technologies and processes while using advanced process control systems benefit from a significant enhancement of ecological and SCK management, leading to a visible improvement in business performance. Shahadat et al. (2024) [53] emphasized that the SCI process is vital for improving supply chain performance. The study highlights that the relationship between integration and supply chain performance has been insufficiently explored by experts, even though digital integration of the supply chain has received significant attention in recent literature.

2.6. Supply Chain Performance (SCP)

Supply chain performance refers to the set of activities carried out within the chain that contribute to meeting customer requirements, starting with product availability, timely delivery, ensuring appropriate costs, efficient management of inventories and necessary resources, and achieving operational and strategic objectives in a responsive, adaptable, and effective manner. Numerous studies have analyzed the various dimensions and determinants of supply chain performance, highlighting factors such as digitalization, sustainability, agility, integration, resilience, and risk management, which influence its efficiency and effectiveness Zhao et al. (2023) [35] demonstrate the positive and significant mediating role of resilience, through absorption, response, and recovery capabilities, between digitalization and supply chain performance. Hamidu et al. (2023) [49] indicated that disruptions in supply chains, resulting from procurement processes, catastrophic disturbances, and infrastructure issues, significantly mediate the relationship between resilience and its performance. Bhattacharjee and Chakraborty (2025) [54] observed that in recent years, supply chains in Europe have become increasingly vulnerable due to offshore technology sourcing, inadequate logistical connectivity, cyberattacks, uniform supplier policies, and excessive reliance on raw materials supplied from other continents. Redesigning strategic alliances, developing infrastructure and innovation processes, and adopting partnership policies are essential actions to overcome these challenges and ensure supply chain performance. Khan and Emon (2025) [55] demonstrated that in the context of Industry 4.0, integration, innovation, and supply chain visibility collectively and significantly contributes to the overall performance growth of the supply chain.

2.7. Research Model and Hypothesis

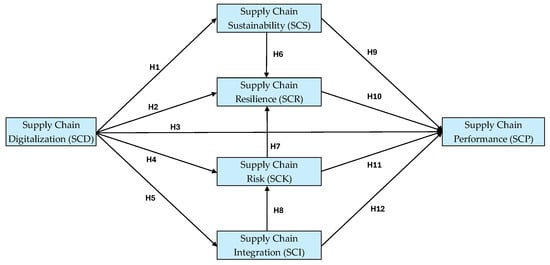

Figure 1 presents a new structural model that highlights the interconnected relationships between the latent variables SCD, SCS, SCR, SCK, SCI, and SCP.

Figure 1.

Proposed structural model. Source: Author owns work.

In line with the three objectives of the study, the following statistical hypothesis has been formulated:

The implementation of SCD through advanced technologies and innovative practices enables supply chains to enhance SCS by optimizing processes, improving real-time monitoring, and supporting predictive analytics. Supply chain practitioners may therefore perceive SCD as a key driver of SCS, fostering sustainability, facilitating collaboration, and ensuring better data security [31,32]. Thus, this argument suggests the following hypothesis.

H1.

SCD influences SCS significantly.

Adopting SCD through digital technologies and innovative management practices has been shown to strengthen SCR by enhancing the continuity, adaptability, and resilience of supply chains in the face of disruptions [2,44]. By integrating digital solutions, ensuring supply chain viability, interconnecting networks, and fostering inter-sectoral collaboration, practitioners can improve their capacity to anticipate, mitigate, and respond effectively to potential disruptions. Based on this reasoning, the following hypothesis is presented:

H2.

SCD influences SCR significantly.

Digitalization enables supply chains to improve resilience by enhancing visibility, monitoring vulnerabilities, establishing standardized processes, and implementing integrated operational strategies [32,33,34,35,36]. By transforming operations into more agile and responsive networks, digitalization is expected by supply chain practitioners to help reduce disruptions, optimize procurement and inventory management, and strengthen relationships with partners and customers. Based on this reasoning, the following hypothesis is presented:

H3.

SCD influences SCP significantly.

SCD strengthens SCK management by fostering a risk-aware culture, enhancing training and competencies, enabling real-time monitoring, and ensuring transparent communication and effective control of risks [16,50]. This could enable practitioners to anticipate, respond to, and mitigate emerging risks efficiently. Accordingly, the following hypothesis is formulated:

H4.

SCD influences SCK significantly.

SCD enhances SCI by enabling the use of integrated information systems, fostering direct communication among partners, aligning all parties with customer needs, and promoting collaborative relationships [20,53]. As a result, practitioners may be better equipped to enhance coordination, swiftly adapt to market fluctuations, streamline supply flows, lower operational expenses, and increase the supply chain’s responsiveness to present and future customer requirements. Based on this reasoning, the following hypothesis is proposed:

H5.

SCD influences SCI significantly.

SCD enables SCS by transforming supply chain processes and data into digital formats, improving real-time monitoring, resource optimization, predictive analysis, and collaboration among partners [12,52]. In this way, supply chain practitioners could anticipate enhancing sustainability, ensuring more accurate environmental reporting, and supporting overall supply chain performance. This reasoning leads to the following hypothesis:

H6.

SCS influences SCR significantly.

Effective supply chain risk management (SCK) enables enterprises to proactively identify, assess, and mitigate potential vulnerabilities, thereby strengthening resilience (SCR) and ensuring continuity under volatile conditions [8,16]. Supply chain practitioners are thus expected to view robust SCK practices as essential for enhancing overall resilience. Based on this rationale, the following hypothesis is presented:

H7.

SCK influences SCR significantly.

Technological innovations such as blockchain, IoT, AI, and predictive analytics enhance traditional risk management through real-time visibility, data-driven decisions, and proactive mitigation [50,51]. Simultaneously, SCI—aligning partners and information flows across customers, suppliers, and operations—enables coordinated, timely responses to potential disruptions. By fostering transparency and collaboration, SCI strengthens SCK, allowing practitioners to anticipate risks and implement cohesive mitigation strategies. In light of the above, the following hypothesis is put forward:

H8.

SCI influences SCK significantly.

Evidence suggests that enhancing network design, organizational structure, and information systems improves business performance, while SCS practices—through efficiency, innovation, and stakeholder engagement—further drive superior SCP [38,50]. Accordingly, practitioners are likely to perceive sustainability as a key driver of competitiveness and long-term profitability. Drawing from this reasoning, the following hypothesis is advanced:

H9.

SCS influences SCP significantly.

Building on prior research, adopting agility and sustainability practices has been shown to enhance SCR by enabling enterprises to maintain operational continuity during disruptions, rapidly recover, adjust capacity, and sustain delivery commitments, thereby preserving SCP, cost efficiency, service quality, and customer satisfaction [32,47]. Supply chain practitioners are therefore expected to view resilience as a key driver of sustainable performance and competitive advantage. Consequently, the subsequent hypothesis is suggested:

H10.

SCR influences SCP significantly.

Emerging technologies such as blockchain, IoT, AI, and predictive analytics enhance supply chain risk management by enabling real-time visibility, data-driven decisions, and proactive mitigation, while integration amplifies their positive impact on overall performance [8,50]. Thus, by systematically identifying, assessing, and mitigating potential vulnerabilities, supply chain practitioners may regard comprehensive risk frameworks as instrumental in strengthening adaptive capacity, ensuring continuity under volatile conditions, and achieving consistent performance and strategic growth. On this basis, the following hypothesis is proposed:

H11.

SCK influences SCP significantly.

The development and integration of new technologies allows supply chains to efficiently coordinate information, processes, and partners, thereby enhancing operational performance, ecological, and risk management capabilities [20,53]. Building on this, integration within the SCI further enhances SCP by aligning processes, technologies, and partner objectives toward shared efficiency goals. Collaborative planning and transparent communication enable faster adaptation to customer needs and market dynamics. As a result, practitioners are likely to perceive integration as a key driver of productivity, service quality, and financial performance across the entire supply chain ecosystem. Accordingly, the following hypothesis is formulated:

H12.

SCI influences SCP significantly.

Supply chain practitioners may hold heterogeneous views regarding the relationships among the key constructs of the proposed model (SCD, SCS, SCR, SCK, SCI, and SCP). Digitalization (SCD) can shape or moderate their perceptions of how supply chain performance (SCP) is achieved through the mediation of sustainability (SCS), resilience (SCR), risk management (SCK), and integration (SCI). From this perspective, it is reasonable to assume that significant differences might exist between practitioner segments with respect to the magnitude and direction of the path coefficients within the structural model, reflecting distinct organizational contexts, technological maturity levels, and strategic orientations toward digital transformation. Thus, the following hypotheses are advanced:

–.

There are no significant differences between practitioner segments regarding the path coefficients in the structural model.

The proposed structural model is based on several economic theories, which, when combined, contribute to the development of a holistic approach to supply chain performance through the lens of digitalization, as well as other essential components such as sustainability, resilience, risk, and integration. The theoretical framework of this study integrates multiple perspectives to provide a comprehensive understanding of the interrelationships between these latent variables.

Innovation Diffusion Theory (IDT) highlights that the characteristics of advanced technologies (such as blockchain or IoT) influence how enterprises collect information and perform analyses in order to make the best decisions within the supply chain. The integration of these innovative technologies helps reduce costs, build trust among participants, automate processes, and improve supply chain management, thereby reducing the risk of fraud and counterfeiting [56,57]. IDT interacts with RBV and OIPT by enabling enterprises to leverage technological resources for better integration, operational efficiency, and resilience across the supply chain. Moreover, the adoption of these technologies interacts with sustainability practices, resilience mechanisms, and risk management strategies, demonstrating that technological innovation is not only a driver of efficiency but also a key enabler of sustainable and integrated supply chain performance.

The triple bottom line (TBL) represents a specific sustainability framework based on three P’s: people, planet, and prof-it. By adopting and implementing sustainability practices, businesses within the supply chain can improve their financial performance, contribute significantly to the harmonious development of society, and play a crucial role in protecting the environment [58,59]. TBL principles complement RDT and RT by aligning resource dependence and risk management strategies with sustainability goals, ensuring that resilience and performance are achieved alongside environmental and social objectives.

Resource Dependence Theory (RDT) reveals that through dependence, communication, and collaboration, enterprises in the supply chain can achieve greater long-term performance. An important role is played by the sharing of resources (material, human, financial, etc.), technologies, information, as well as the acceptance of support or external consulting services. Intensifying collaboration between the enterprises and stakeholders contributes to building SCR and provides practical guidance for navigating through turbulent or disruptive periods more easily [60,61]. RDT interconnects with IDT, TBL, and RBV by showing how resource sharing and inter-organizational dependencies amplify the impact of digitalization and sustainability initiatives on supply chain performance.

Risk Theory (RT) provides the theoretical framework necessary for the organization and efficient management of businesses within supply chains, enabling them to cope with crisis situations, mitigate risks, and manage uncertainties. Since SCK stem from the external environment (natural disasters, climate change, economic crises) and are external to the businesses (risks from suppliers and customers), it becomes imperative to adopt proactive and re-active strategies that allow for the anticipation and/or reduction in the impact of these unforeseen events, contributing to the resilience and sustainable performance of supply chains [8,62]. RT is linked with OIPT and RBV by highlighting how risk-aware strategies rely on information processing and strategic resource deployment to enhance resilience and performance across the supply chain.

Organizational Information Processing Theory (OIPT) provides a valuable framework for supply chains as it explains how businesses can improve their information processing capacity and gain a competitive advantage through the implementation of strategies that focus on investments in new technologies, diversification of communication channels, and optimization of decision-making processes. All these actions can significantly contribute to strengthening resilience, reducing risks, and achieving higher levels of performance within the supply chain [63,64]. OIPT complements IDT, RT, and RBV by demonstrating that enhanced information flows and decision-making processes amplify the benefits of digitalization, risk management, and resource-based capabilities.

Resource-Based View (RBV), also known as the “resource-based vision of the enterprise,” is a managerial framework used for the selection and exploitation of strategic resources to enhance business performance. Access to and utilization of natural, financial, human, technological, organizational, social, and energy resources contribute to improving the performance of supply chains by enhancing the capacity to respond to fluctuations in demand and supply, increasing transparency and traceability throughout the supply chain, adopting sustainable practices, and stimulating collaboration and integration between partners, among other factors [65,66]. RBV integrates insights from IDT, TBL, RDT, RT, and OIPT by providing the strategic perspective through which digitalization, sustainability, resilience, risk management, and integration collectively drive superior supply chain performance.

By testing statistical hypotheses and validating the proposed construct model through the combination of these theories, the study aims to deepen the understanding of the dynamics of current supply chains and contribute to the development of innovative strategies for improving their performance.

3. Materials and Methods

3.1. Questionnaire Design and Measures

The questionnaire was developed following an extensive review of the literature to identify valid items for the constructions of the model and select the optimal scales for measurement. The measurement instrument encompassed the socio-demographic characteristics of the respondents (e.g., gender, age, education level, work experience, and job title) and consisted of six content sections: (1) SCD, (2) SCS, (3) SCR, (4) SCK, (5) SCI, and (6) SCP. (See Table 1).

Table 1.

Variables and Items. Summary of mean and collinearity statistics (VIF).

The items for SCD were adapted from [29,30], considering their key components, i.e., advanced technologies and digital systems that work together to optimize operations and redefine processes. Considering the recommendations of [41], SCS was measured based on four crucial elements: people, process, intelligence, and eco-friendly production, packaging, and recycling technologies, as building and balancing these elements are essential for supply chain planning and execution. The adaptation of the items regarding SCR was based on the studies by [46,47].

They address vulnerability, management culture, procurement and operations processes, and the assessment of demand, inventory visibility, and transparency, providing detailed insights into the strengths and weaknesses of resilience strategies within supply chains. The specific items related to SCK included elements such as vulnerability, culture management, procurement and operations, and the analysis of demand and inventory visibility and transparency, adapted from the studies by [20,50]. SCI was measured using scales that focused on identifying customer expectations, coordination, cooperation, and collaboration among all supply chain members [51]. The supply chain performance scale was adapted from previous studies [35,49]. Socio-demographic characteristics were measured using proportional scales, and most of the items used a 7-point Likert scale, ranging from “1 = Strongly agree” to “7 = Strongly disagree.” An exception was made for the items specific to supply chain performance, which were analyzed on a reversed Likert scale, where 1 represents “Very good” and 7 represents “Very poor.” The questionnaire was pre-tested on a sample of respondents, consisting of academic scholars and supply chain practitioners, to improve its content and ensure its relevance for the research purpose [67].

3.2. Sampling and Data Collection

Between 10 October 2024, and 10 January 2025, the online questionnaire was distributed to supply chain practitioners in Romania using the Qualtrics platform. The cross-sectional quantitative study was based on a computerized simple random sampling method. After querying the National Institute of Statistics database [68], a sampling frame was constructed, which included practitioners with over 5 years of experience in the supply chain field. Each observation unit was assigned a unique code within the database. Using the random number generation feature, 800 units (codes) were randomly selected. Respondents received an email with a link to the pre-constructed questionnaire on Qualtrics. The platform offers quality control mechanisms and the option to restrict access to the questionnaire to a single response per IP address or device. Valid data were obtained from 420 respondents, with 27 incomplete questionnaires excluded, resulting in a response rate of 52.50%. The sample size was representative, as the number of respondents exceeded the minimum accepted limit (24 items × 7 = 168 responses < 420 responses) [69]. This sampling method was used in studies by [70,71].

The respondent profile is presented in Table 2 (N = 420). Most supply chain practitioners are male (63.81%). Over 55% fall within the age range of 35–54 years. In terms of education, most practitioners hold undergraduate (37.14%) and postgraduate (39.52%) degrees. Regarding job positions, 33.81% of respondents are specialists, and 26.19% are managers in supply chains across various industries. The dominant sectors for supply chains in Romania are Industrial Manufacturing (20%), Retail (17.14%), and Food and Beverages (12.38%).

Table 2.

Socio-demographic profile of respondents (N = 420).

3.3. Common Method Bias (CMB)

Since the data for the research were collected from a single sample, there is a possibility of common method bias [72,73]. According to Kock (2021) [74], this issue should be analyzed before applying the PLS-SEM method. First, the variance inflation factors (VIF) calculated for each latent variable were below 4 [75]. Second, after applying for the Harman single-factor test, it was observed that the total variance for a single factor was below the maximum accepted threshold of 50% (46.83% < 50%) [73]. Consequently, the results obtained demonstrate the absence of common method bias in this marketing research.

4. Results

4.1. PLS-SEM Model

The analysis of the proposed structural model was conducted using Partial Least Squares Structural Equation Modelling (PLS-SEM) with Smart PLS 4, a highly regarded method due to its versatility and applicability across various fields. In addition to being a widely used technique in multivariate research, PLS-SEM offers significant advantages over other statistical methods, such as flexibility in managing data, the ability to analyze complex models with multiple causal relationships, and efficiency in handling large sample sizes. The choice of this method for the analysis is also justified by its ability to accurately demonstrate significant relationships between exogenous and endogenous variables, contributing to a robust validation of the model and a clear interpretation of the results.

To verify the reliability, convergent validity, and discriminant validity of the reflective model, the PLS algorithm was applied. The composite reliability of all constructs ranged between 0.788 and 0.884, exceeding the minimum acceptable threshold of 0.70, thereby confirming the adequacy of the model for validation [76]. Furthermore, the values of Cronbach’s Alpha (CA ⊂ [0.715; 0.825]) were above the 0.70 threshold, demonstrating reliability and, implicitly, convergent validity [77]. According to the results presented in Table 3, the Average Variance Extracted (AVE) values for all constructs were greater than 0.50 [78]. These findings confirm the fulfilment of the reliability and convergent validity criteria, thereby reinforcing the robustness of the proposed structural model.

Table 3.

Summary of construct reliability and validity.

The discriminant validity of the proposed structural model was tested using AVE and the Heterotrait-Monotrait Ratio (HTMT). The square root of the AVE for the SCD latent variable was higher than its correlations with the other variables (0.777 > 0.730; 0.663; 0.638; 0.656; 0.627), in accordance with the [79] criterion (See Table 4). Additionally, the HTMT correlations were below the maximum accepted threshold of 0.90, reinforcing the robustness of the model [76].

Table 4.

Summary of discriminant validity—HTMT.

These results confirm that the proposed reflective model meets the criteria for discriminant validity, ensuring a clear distinction among the latent variables. The discriminant validity of the proposed structural model was assessed using the AVE and the Heterotrait–Monotrait Ratio (HTMT). As presented in Table 5, the square root of the AVE for each latent construct exceeded its correlations with all other constructs, thereby satisfying the Fornell–Larcker criterion [79].

Table 5.

Summary of Discriminant validity—Fornell-Larcker criterion.

For instance, the square root of the AVE for SCD was 0.777, which is higher than its correlations with the other latent variables (0.730, 0.663, 0.638, 0.656, 0.627). A similar pattern was observed for the remaining constructs, including SCP, whose square root of AVE (0.756) is slightly lower than that of some other constructs but still greater than its highest correlation (0.731).

This outcome remains acceptable according to the Fornell–Larcker criterion, particularly given that complementary analyses using HTMT provide further support for discriminant validity. Specifically, the HTMTs were all below the recommended threshold of 0.90, confirming adequate discriminant validity [76]. Taken together, these results provide robust evidence that the reflective measurement model achieves discriminant validity, ensuring that the latent constructs are conceptually distinct and empirically well differentiated (see Table 6).

Table 6.

Summary of quality criteria.

The exogenous variable SCD had a strong and significant impact on SCI (Path Coeff. = 0.456, t-value = 8.770, p < 0.001) and SCS (Path Coeff. = 0.330, t-value = 8.250, p < 0.001). Additionally, SCD exerted a moderate but significant influence on SCR (Path Coeff. = 0.265, t-value = 3.459, p < 0.05) and SCK (Path Coeff. = 0.259, t-value = 3.548, p = 0.003 < 0.05). Based on these results, hypotheses H1, H2, H4, and H5 were supported. In conclusion, SCD has a significant effect on SCS, SCR, SCK, and SCI in the supply chain, thereby addressing the first objective of the study (O1).

As shown in Figure 2, SCS has a strong and significant effect on both SCR (Path Coeff. = 0.492, t-value = 4.969, p < 0.001) and SCP (Path Coeff. = 0.385, t-value = 4.477, p < 0.001). This suggests that process modernization, the alignment of digital intelligence with system investments, and the adoption of updated technologies enhance the supply chain’s capacity to absorb and respond to disruptions while simultaneously improving its overall performance. In addition, SCK exerts a weaker but still significant influence on SCR (path coefficient = 0.219, t-value = 2.348, p = 0.019) and SCP (path coefficient = 0.235, t-value = 3.615, p = 0.004). The f2 effect size values further reveal that the strongest effects occur in the relationships SCI → SCK (0.472) and SCI → SCP (0.408), underscoring the critical role of SCI in strengthening both risk management capabilities and overall performance. These findings highlight that fostering a risk-aware culture, establishing effective risk controls, and engaging in proactive, collaborative risk management are essential for ensuring supply chain stability and efficiency (see Table 7).

Figure 2.

The path coefficients of the research model. Source: Author’s own work.

Table 7.

Summary results of the multidimensional model.

SCI has the strongest impact on SCK (Path Coeff. = 0.578, t-value = 7.473, p < 0.001) and SCP (Path Coeff. = 0.544, t-value = 6.519, p < 0.001), underscoring the importance of communication, collaboration, and cooperation among all parties involved in supply chains to meet consumer needs and maximize profits. SCP was also significantly influenced by SCD (Path Coeff. = 0.314, t-value = 5.414, p < 0.001). Consequently, hypotheses H3 and H6–H12 were supported (see Table 7). These results confirm that a sustainable, well-integrated, and digitized supply chain contributes to strengthening resilience, mitigating risks, and optimizing long-term performance. Furthermore, the significant relationships identified between the variables demonstrate the achievement of the second research objective (O2).

4.2. Analysis FIMIX-PLS

The FIMIX-PLS algorithm was applied to the structural model to identify unobserved heterogeneity. The maximum number of possible segments was set to five, calculated as the ratio between the total sample size and the number of required observations (420/75 = 5.6) [76]. Models with two to five segments were assessed. Since the size of the last segment in the 5-segment solution (8.70%) fell below the commonly accepted minimum threshold of 10%, the 4-segment model was retained for evaluation [80].

As shown in Table 8, although the 5-segment solution reported the lowest AIC value (1276.868), it was not selected due to the insufficient size of Segment 5. In contrast, the 4-segment solution presented a competitive fit (AIC = 1286.119) and acceptable entropy measures (EN = 0.752; NFI = 0.731). While the MDL5 criterion reached its lowest value for the 2-segment model (2243.022), this specification was less informative in distinguishing heterogeneity [81]. Consequently, the 4-segment model was considered the most balanced solution, capturing meaningful heterogeneity among supply chain practitioners in Romania regarding the impact of digitalization on SCP, as mediated by SCS, SCR, SCK, and SCI.

Table 8.

Summary of model selection criteria and segment size.

The values of the Normed Entropy Statistic (EN) criterion for Segments 2 (EN = 0.995), 3 (EN = 0.789), and 4 (EN = 0.752) were above the minimum accepted threshold of 0.05, indicating a balanced distribution of data in these segments. According to the results, Segment 4 represents the best model in terms of fit and complexity, with the most favorable values for the fit criteria (AIC3 = 1357.119; BIC = 1523.763; and MDL5 = 3042.342). The results of the FIMIX-PLS analysis confirm significant differences between the identified practitioner segments in terms of path coefficients in the analyzed reflective model and validate the achievement of the final objective (O3).

As shown in Table 9, notable variations are observed in the intensity of relationships between the model variables, indicating structural heterogeneity in the sample. For example, the relationship SCD → SCS shows coefficients ranging from 0.349 (Segment 1) to 0.906 (Segment 3), suggesting that the influence of digitalization on SCS varies depending on the characteristics of each group. Similarly, the relationship SCD → SCP is negative for Segments 3 and 4 (−0.060 and −0.525, respectively), indicating contrasting perceptions of the impact of digitalization on supply chain performance. Considering these results, the null hypothesis is rejected, and the alternative hypothesis is accepted. These results highlight that the effect of digitalization on supply chain performance is not uniform across practitioners’ perceptions. The impact of digital technologies on performance varies depending on contextual factors such as company scale, industry characteristics, and performance indicators, indicating that digitalization alone does not guarantee improved outcomes, as success ultimately relies on organizational capabilities, process integration, staff preparedness, and digital maturity [82,83].

Table 9.

Summary FIMIX-PLS for the solution with four latent segments.

To better understand the heterogeneity of opinions among supply chain practitioners in Romania regarding the impact of digitalization on performance, each latent segment was analyzed in detail:

- Segment 1—“Traditional practitioners” (38.4%)

Practitioners in this segment exhibit a cautious perspective on digitalization, as reflected in moderate path coefficients for SCD → SCS (0.349) and SCD → SCP (0.314). Nevertheless, they recognize that SCK can be mitigated and performance improved through enhanced communication, collaboration, and coordination among stakeholders, as evidenced by the strong path coefficients for SCI → SCK (0.772) and SCI → SCP (0.696).

- Segment 2—“Progressive practitioners” (24.40%)

This segment perceives digitalization as highly impactful across sustainability, integration, risk, resilience, and performance dimensions. Strong path coefficients for SCD → SCS (0.906), SCD → SCI (0.923), SCD → SCK (0.680), SCD → SCR (0.555), and SCD → SCP (0.464) confirm this view. However, negative path coefficients for SCK → SCR (−0.258) and SCR → SCP (−0.082) indicate that risk and resilience outcomes do not always translate directly into performance improvements for these practitioners.

- Segment 3—“Analytical practitioners” (21.60%)

Practitioners in this group acknowledge a strong influence of digitalization on sustainability (SCD → SCS = 0.714) and moderate effects on risk management (SCD → SCK = 0.427) and integration (SCD → SCI = 0.548). Negative path coefficients such as SCD → SCP (−0.060) and SCK → SCP (−0.117) suggest that digitalization initiatives do not immediately enhance overall supply chain performance for this segment, highlighting a more cautious or analytical approach.

- Segment 4—“Innovative practitioners” (15.6%)

This segment emphasizes the critical role of digital technology integration in enhancing both SCS and performance. High path coefficients were observed for SCD → SCS (0.890), SCD → SCR (0.742), SCD → SCK (0.880), SCD → SCI (0.910), and SCD → SCP (0.989). However, negative path coefficients for SCS → SCR (−0.287) and SCS → SCP (−0.007) indicate that these practitioners perceive sustainability and resilience or performance as not automatically correlated, reflecting a nuanced understanding of how these dimensions interact.

5. Discussion

The research findings confirm the transformative role of digitalization in developing sustainable and high-performing supply chains. In line with the existing literature [29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55], the results indicate that investments in technologies such as AI, ML, the IoT, CC, DA, and BD have a positive influence on SCS, SCI, SCR, and SCK, thereby strengthening the foundations of an agile and adaptive logistics system. The conclusions of the PLS-SEM analysis suggest that digitalization acts as a catalyst for process modernization and interorganizational collaboration. These results are consistent with previous studies [29,30,31,32,33,34,35,36].

At the same time, the moderate effects observed on resilience and risk emphasize that technology, although essential, is not sufficient in the absence of innovation-oriented leadership and an organizational culture open to change. The strong influence of SCI on SCK and SCP confirms that the success of digitalization depends on system interoperability and the efficient flow of real-time information. These significant influences are also supported by previous studies [37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53], which highlight that SCP essentially depends on the level of digital and collaborative integration among partners, the adoption of emerging technologies, and the organization’s ability to transform data into strategic decisions—factors that together ensure resilience, sustainability, and long-term competitive advantage.

The FIMIX-PLS analysis revealed significant heterogeneity among Romanian practitioners, identifying four distinct segments: “traditional,” “progressive,” “analytical,” and “innovative.” These differences reflect varying levels of digital maturity and diverse strategies for leveraging technology. While progressive and innovative segments associate digitalization with improved performance, traditional and analytical groups adopt a more cautious approach, perceiving long-term benefits mainly in enhanced collaboration and risk control.

The research findings indicate that digitalization, when combined with process integration, cross-functional communication, and the organization’s learning capability, represents a fundamental condition for achieving sustainable performance. These findings may contribute to expanding the understanding of the role of digital transformation in strengthening the resilience and sustainability of supply chains in Romania and other emerging economies.

6. Conclusions

6.1. Theoretical Implications

Previous research has primarily focused on theories such as TAM [84], the UTAUT [85], the TBL [59], and others to identify and analyze the determinants affecting supply chain performance. In contrast, this study draws on a combination of fundamental theories, including the IDT, TBL, RDT, RT, OIPT, and RBV, to develop specific constructs and items. These theories provide a unique perspective for investigating practitioners’ perceptions regarding how these constructs interact to influence SCP, providing valuable insights into the research topic. Future studies could explore the deepening and integration of other relevant theories that may contribute to a more comprehensive understanding of the relationship between digitalization and supply chain performance.

This study extends the existing literature on supply chain digitalization and sustainability by proposing a complex structural model. The results demonstrate that the implementation of advanced technologies in the supply chain—such as IoT, AI, ML, BD and DA, CC—significantly contributes to process modernization, cost reduction, improved customer satisfaction, decreased environmental impact, enhanced collaboration and communication among stakeholders, and overall improvement in supply chain performance. Consequently, future research could expand the proposed model by including specific dimensions of digitalization, such as Blockchain, Process Automation, and Collaborative Robots, or by incorporating additional variables, including visibility, organizational capability, and innovation.

6.2. Practical Implications

The results of the PLS-SEM analysis showed that the exogenous variable SCD has a positive and significant impact on the endogenous variables— SCS, SCR, SCP, SCK, and SCI. These results are supported by previous research highlighting the importance of digitalization in transforming supply chains [29,86].

Supply chain practitioners agree that integrating emerging technologies, such as the IoT, AI, and ML, significantly contributes to improving visibility, predictive analytics, demand planning optimization, and decision-making efficiency. Additionally, the use of CC and DA and BD facilitates the discovery of valuable business patterns and market trends, predictive maintenance, inventory management, improved data sharing and security, and enhanced communication and collaboration among supply chain partners. Oubrahim et al. (2023) [87] observed that digital transformation significantly influences integration and overall sustainable supply chain performance. Therefore, managers should prioritize the adoption and integration of IoT, AI, ML, CC, DA and BD technologies to enhance visibility, decision-making, and predictive capabilities across the supply chain.

Recent studies have highlighted the necessity of integrating sustainability practices and their impact on supply chain performance [88,89]. According to practitioners, updating technologies to develop eco-friendly products and aligning cross-functional teams are actions that enhance collaboration and communication among stakeholders, supporting consumer demands, and ensure compliance with environmental regulations. These actions are essential for improving the sustainable performance of the supply chain. Respondents agree that modernizing production and delivery processes, aligning with industry regulations and standards, and correlating intelligence with investments in related systems contribute to cost reduction, revenue growth, and real-time tracking of supply chain operations. These aspects are crucial for enhancing overall efficiency and performance within the supply chain. Therefore, enterprises should implement eco-friendly technologies, align cross-functional teams, and modernize operational processes to achieve sustainability objectives and improve overall SCP.

Other studies attempt to address gaps in SCR literature, highlighting its positive and significant relationships with supply chain management and performance [90,91]. According to practitioners, analyzing supply chain vulnerability and fostering a risk-aware management culture are essential actions for improving risk and disruption management, contributing to the development of resilient networks capable of quickly responding to market demands. Additionally, respondents believe that adopting efficient and integrated strategies in procurement and operations, as well as assessing demand and inventory visibility, significantly enhances SCR, reduces disruptions, and improves operations, while also strengthening distribution partnerships and customer relationships. Therefore, enterprise managers should cultivate a risk-aware organizational culture, carry out regular vulnerability assessments, and implement integrated operational strategies to strengthen SCR.

The study demonstrates the existence of positive and significant relationships among the endogenous variables—SCS, SCR, SCK, and SCI. These results are supported by several recent studies that also highlight positive and significant relationships among these variables [88,91,92]. In this context, industry specialists believe that adopting a risk-aware culture and investing in continuous training and competency development in risk management are factors that facilitate cross-departmental collaboration and enhance the supply chain’s ability to anticipate and respond rapidly to emerging risks. In their view, maintaining control in risk management helps reduce exposure to penalties and reputational damage, while establishing clear and transparent communication supports proactive and coordinated risk management, ensuring that all stakeholders are informed and prepared to respond appropriately. Managers should invest in training and competency development for risk management, promote cross-departmental collaboration, and maintain transparent communication to mitigate risks and improve overall supply chain performance.

Recent studies have examined how integration can drive SCP through risk management and resilience [92,93]. In this study, practitioners considered that integrating IT systems with direct communication channels between supply chain partners and aligning them with the needs of the end customer, help enhance adaptability to consumer demands and enable more efficient and satisfying deliveries, thereby supporting the long-term success of the supply chain. Cultivating collaborative relationships and mutual support among all supply chain members—by improving product knowledge, developing joint projects, and fostering open cooperation and sharing information about demand and supply—contributes to optimizing supply flows, reducing operational costs and enhancing customer satisfaction. These improvements strengthen the supply chain’s ability to respond swiftly to current and future customer needs. Managers should integrate IT systems with communication channels, promote collaboration among supply chain members, and ensure alignment with end-customer needs to optimize flows and enhance customer satisfaction.

This study highlights that SCP is shaped by factors such as SCP, SCS, SCR, SCK, and SCI, each having a significant impact on it. Recent studies have reached similar conclusions, emphasizing the same trends and relationships among the analyzed variables [35,54]. To enhance SCP, managers should implement integrated digital technologies, foster collaboration and information sharing across all partners, proactively manage risks and sustainability, develop workforce digital skills, and tailor strategies to their enterprise’s specific characteristics, needs, and operational capabilities.

The results of the FIMIX-PLS analysis highlighted the existence of significant heterogeneity within the sample and a diversity of opinions and perceptions among practitioners regarding the impact of digitalization on SCS and SCP. Within each identified segment, different relationships between the model variables were observed. Therefore, digitalization does not uniformly influence SCP but depends on the specific characteristics and approaches of each group of practitioners. In this context, managers should refrain from adopting uniform digitalization strategies and instead carefully assess the specific characteristics, needs, and operational capabilities of each enterprise, tailoring digital transformation processes to foster sustainable performance and long-term competitive advantage

6.3. Limitation and Further Research

This study presents several limitations. First, the data were collected exclusively from Romanian practitioners with over five years of experience in the supply chain field. Given the cultural and economic differences between countries, opinions and perceptions may vary significantly in an international context. Therefore, future research should include participants from different countries to enhance the global applicability of the results. Second, the sample size was limited, and increasing it could lead to the discovery of more diverse opinions and perceptions among respondents, thereby identifying new groups with different perspectives on the impact of these factors on supply chain performance. Finally, the study has limitations related to both its cross-sectional approach and the analysis of moderator factors. Socio-demographic factors such as age, gender, education level, work experience, and the industry in which respondents work can significantly influence the relationships between the studied variables. In this regard, future research could employ a longitudinal model to examine the evolution of these relationships over time and identify new factors that mediate or moderate the effects of SCD on SCS and SCP.

Funding

This research received no external funding.

Institutional Review Board Statement

Ethical review and approval were waived for this study by Institution Committee due to Law No. 206/2004 on Good Conduct in Scientific Research, Technological Development and Innovation, and the provisions of Regulation (EU) 2016/679 (GDPR) and Law No. 190/2018, ethical approval is not required for this type of research.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to ethical reasons.

Acknowledgments

The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| IDT | Innovation Diffusion Theory |

| TBL | The Triple Bottom Line |

| RDT | Resource Dependence Theory |

| RT | Risk Theory |

| OIPT | Organizational Information Processing Theory |

| RBV | Resource-Based View |

| SCD | Supply Chain Digitalization |

| SCS | Supply Chain Sustainability |

| SCR | Supply Chain Resilience |

| SCK | Supply Chain Risk |

| SCI | Supply Chain Integration |

| SSCM | Sustainable supply chain management |

| IoT | Internet of Things |

| AI | Artificial Intelligence |

| ML | Machine Learning |

| BD | Big Data |

| DA | Data Analytics |

| CC | Cloud Computing |

| PLS-SEM | Partial Least Squares Structural Equation Modelling |

| CA | Cronbach’s Alpha |

| CR | Composite reliability |

| AVE | Average variance extracted |

| HTMT | Heterotrait-Monotrait Ratio |

| VIF | Variance Inflation Factor |

| SRMR | Standardized Root Mean Square Residual |

| GoF | Goodness of Fit |

References

- Xu, Z.; Elomri, A.; Kerbache, L.; El Omri, A. Impacts of COVID-19 on Global Supply Chains: Facts and Perspectives. IEEE Eng. Manag. Rev. 2020, 48, 153–166. [Google Scholar] [CrossRef]

- Ivanov, D. Transformation of Supply Chain Resilience Research through the COVID-19 Pandemic. Int. J. Prod. Res. 2024, 62, 8217–8238. [Google Scholar] [CrossRef]

- Agrawal, T.K.; Kalaiarasan, R.; Olhager, J.; Wiktorsson, M. Supply chain visibility: A Delphi study on managerial perspectives and priorities. Int. J. Prod. Res. 2022, 62, 2927–2942. [Google Scholar] [CrossRef]

- Tan, C.L.; Tei, Z.; Yeo, S.F.; Lai, K.H.; Kumar, A.; Chung, L. Nexus among blockchain visibility, supply chain integration and supply chain performance in the digital transformation era. Ind. Manag. Data Syst. 2024, 123, 229–252. [Google Scholar] [CrossRef]

- Aldrighetti, R.; Battini, D.; Ivanov, D.; Zennaro, I. Costs of resilience and disruptions in supply chain network design models: A review and future research directions. Int. J. Prod. Econ. 2021, 235, 108103. [Google Scholar] [CrossRef]

- Medvediev, I.; Muzylyov, D.; Montewka, J. A model for agribusiness supply chain risk management using fuzzy logic. Case study: Grain route from Ukraine to Poland. Transp. Res. Part E Logist. Transp. Rev. 2024, 190, 103691. [Google Scholar] [CrossRef]

- Anozie, U.C.; Adewumi, G.; Obafunsho, O.E.; Toromade, A.S.; Olaluwoye, O.S. Leveraging advanced technologies in Supply Chain Risk Management (SCRM) to mitigate healthcare disruptions: A comprehensive review. World J. Adv. Res. Rev. 2024, 23, 1039–1045. [Google Scholar] [CrossRef]

- Senna, P.; Reis, A.; Marujo, L.G.; Ferro de Guimarães, J.C.; Severo, E.A.; dos Santos, A.C.D.S.G. The influence of supply chain risk management in healthcare supply chains performance. Prod. Plan. Control 2024, 35, 1368–1383. [Google Scholar] [CrossRef]

- Thomas, J.; Vedi, K.V.; Gupta, S. Effects of supply chain management strategies on the overall performance of the organization. Int. J. Sci. Res. Arch. 2024, 13, 709–719. [Google Scholar] [CrossRef]

- Ojo, B. Resilience and sustainability of supply chains in the face of natural disasters and climate change. Int. J. Sci. Res. Arch. 2024, 12, 2996–3007. [Google Scholar] [CrossRef]

- Wang, F.; Harindintwali, J.D.; Wei, K.; Shan, Y.; Mi, Z.; Costello, M.J.; Grunwald, S.; Feng, Z.; Wang, F.; Guo, Y.; et al. Climate change: Strategies for mitigation and adaptation. The Innov. Geosci. 2023, 1, 100015. [Google Scholar] [CrossRef]

- Bag, S.; Rahman, M.S.; Chiarini, A. Building Sustainable Supply Chain Resilience: Insights from a Mixed-Method Study. Bus. Strategy Environ. 2025, 34, 2103–2127. [Google Scholar] [CrossRef]

- Adenekan, O.A.; Ezeigweneme, C.; Chukwurah, E.G. Strategies for protecting IT supply chains against cybersecurity threats. Int. J. Manag. Entrep. Res. 2024, 6, 1598–1606. [Google Scholar] [CrossRef]

- Sindiramutty, S.R.; Jhanjhi, N.Z.; Tan, C.E.; Khan, N.A.; Shah, B.; Gaur, L. Securing the digital supply chain cyber threats and vulnerabilities. In Cybersecurity Measures for Logistics Industry Framework; Jhanjhi, N.Z., Shah, I.A., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 156–223. [Google Scholar] [CrossRef]

- Fernando, Y.; Tseng, M.L.; Wahyuni-Td, I.S.; de Sousa Jabbour, A.B.L.; Chiappetta Jabbour, C.J.; Foropon, C. Cyber supply chain risk management and performance in industry 4.0 era: Information system security practices in Malaysia. J. Ind. Prod. Eng. 2023, 40, 102–116. [Google Scholar] [CrossRef]

- Rashid, A.; Rasheed, R.; Ngah, A.H.; Pradeepa Jayaratne, M.D.R.; Rahi, S.; Tunio, M.N. Role of information processing and digital supply chain in supply chain resilience through supply chain risk management. J. Glob. Oper. Strat. Sourcing 2024, 17, 429–447. [Google Scholar] [CrossRef]

- Scheel, S.; Álvarez Velasco, S.; De Genova, N. COVID capitalism: The contested logistics of migrant labour supply chains in the double crisis. Politics 2024, 44, 175–187. [Google Scholar] [CrossRef]

- Pellegrino, R.; Russo, F.; Basile, L.J. The role of supply chain integration in the risk management of circular economy: A multiple case study in the furniture industry. Procedia Comput. Sci. 2024, 232, 2933–2940. [Google Scholar] [CrossRef]

- Zhang, Q.; Feng, Y.; You, L. Research on the impact of supply chain integration on supply chain resilience in NEV manufacturing enterprises. Sustainability 2024, 16, 8546. [Google Scholar] [CrossRef]

- Christiana, L.; Tarigan, Z.J.H.; Siagian, H.; Basana, S.R.; Jie, F. The influence of supply chain integration on firm performance through lean manufacturing, green supply chain management and risk management. Uncertain Supply Chain Manag. 2024, 12, 2699–2712. [Google Scholar] [CrossRef]

- World Bank. Romania Systematic Country Diagnostic Update; World Bank: Washington, DC, USA, 2023; Available online: https://documents1.worldbank.org/curated/en/099134003102323181/pdf/BOSIB0480d508207e0805908b215a1d78b8.pdf (accessed on 19 October 2025).

- OECD. Capital Market Review of Romania; Organisation for Economic Co-operation and Development: Paris, France, 2022; Available online: https://www.oecd.org/content/dam/oecd/en/publications/reports/2022/06/capital-market-review-of-romania_165ea5cd/9bfc0339-en.pdf (accessed on 19 October 2025).

- Ionitescu, S.; Popescu, A.; Moagar-Poladian, S.; Gudanescu, N.L.; Aluculesei, A.C. Value chains in raw materials, high-tech and agricultural products. Sci. Pap. Ser. Manag. Econ. Eng. Agric. Rural Dev. 2024, 24, 2. Available online: https://managementjournal.usamv.ro/pdf/vol.24_2/Art60.pdf (accessed on 19 October 2025).

- Ionescu, A.; Iordache, A.M.M.; Mironescu, A.A.; Cârstea, V.G. Streamlined resilient post-COVID-19 supply chain in Industry 4.0: A case study on Romania. Sustainability 2023, 15, 16606. [Google Scholar] [CrossRef]

- Ministry of Economy. Industrial Strategy of Romania 2023–2027; Government of Romania: Bucharest, Romania, 2023. Available online: https://economie.gov.ro/wp-content/uploads/2023/12/Proiect-de-Strategie-Industriala-a-Romaniei-2023-2027.pdf (accessed on 19 October 2025).

- Ministry of Research, Innovation and Digitalization. National Action Plan for the Digital Decade 2030; Government of Romania: Bucharest, Romania, 2024. Available online: https://www.mcid.gov.ro/wp-content/uploads/2024/04/Plan-national-de-actiune-roadmap-pentru-publicare.pdf (accessed on 19 October 2025).

- Chirileasa, A. Romanian Companies Have the Lowest Level of Digitalization among EU Enterprises. Romania Insider. 30 August 2024. Available online: https://www.romania-insider.com/romanian-companies-digitalization-eurostat-august-2024 (accessed on 19 October 2025).