Abstract

The viability of supply chains is a central challenge in environments marked by frequent disruptions, extreme uncertainty, and rising sustainability requirements. While literature has advanced in integrating resilience and sustainability, predominant methods—mainly robust or stochastic optimization—focus on predefined scenarios and offer only a partial view of adaptive capacity. This emphasis on known–unknowns leaves unresolved how to ensure continuity, efficient recovery, and organizational learning under unexpected or unknown–unknown events. A methodological gap therefore persists in evaluating and designing supply chains that not only withstand disruptions but also retain essential goals, autonomously activate responses, and reorganize with acceptable costs and times. This study introduces the Immune-Structural Adaptive Response (RAIE) methodology, inspired by the human immune system. RAIE provides an evaluation framework combining properties such as early detection, minimal redundancy, adaptive memory, and structural reconfiguration, operationalized through dynamic metrics: goal retention, autonomous activation, adaptation cost, recovery time, and service loss. Applied to Carbon Capture, Utilization, and Storage (CCUS) supply chains, RAIE reduced service-loss area (Rₐᵣₑₐ) by 40–65% and recovery time (TTR) by 30–45%, while keeping adaptation costs below 2% of total expenditures. Unlike traditional stochastic or robust models, RAIE explicitly embeds endogenous responses and post-shock reorganization, producing more viable configurations that balance efficiency and resilience. The results deliver actionable guidance for strategic and tactical decision-making in highly uncertain environments.

1. Introduction

The challenges of contemporary supply chains are increasingly shaped by turbulence, uncertainty, and the urgent demand for sustainable transitions. Over the past two decades, supply chain management has expanded from focusing primarily on efficiency and cost minimization to addressing broader dimensions such as resilience, viability, and sustainability [1,2]. Viability has emerged as a meta-capability that integrates economic, environmental, and social objectives, while also emphasizing the long-term ability of supply chains to sustain their identity under continuous disruptions [3]. This perspective is particularly relevant in contexts where uncertainty cannot be reduced to probabilistic terms, as networks are increasingly exposed to unknown-unknown events such as pandemics, geopolitical shocks, or regulatory shifts [4]. Despite conceptual advances, much of the existing literature continues to operationalize resilience through simplified scenarios or static analyses, leaving limited room for adaptive responses [5]. As a result, the need for frameworks that combine robustness, adaptability, and circularity in supply chain design has become a central concern for both researchers and practitioners [6].

Recent scholarship has further emphasized that traditional optimization methods often fall short in addressing the multidimensional requirements of viable supply chains [7,8]. Classical stochastic and robust optimization approaches are effective in handling known-unknown uncertainties but are less suited to dynamic environments characterized by structural uncertainties [9,10]. This gap has prompted the exploration of biologically inspired paradigms, particularly analogies from the human immune system, which is inherently capable of rapid response and adaptive learning [11,12]. Immune-inspired frameworks highlight mechanisms such as sentinel nodes, redundancy, and memory as design principles for adaptive supply chains [13]. By translating these metaphors into mathematical constraints and indicators, immune-inspired approaches offer promising pathways for embedding adaptation into optimization-based models. Nevertheless, the integration of immune system principles with rigorous mathematical programming remains incipient, especially in applied contexts such as agro-industrial or energy-intensive supply chains. Addressing this gap requires models that simultaneously capture efficiency, resilience, and adaptability, thereby enabling decision-makers to anticipate disruptions while ensuring long-term viability. In particular, existing optimization approaches for supply chain design insufficiently operationalize adaptive viability—the ability to sustain objectives under deep uncertainty by combining robustness, autonomous response, and controlled recovery costs—pointing to the need for a modeling framework that embeds these properties within a rigorous mathematical program.

Within this broader landscape, carbon capture, utilization, and storage (CCUS) supply chains stand out as a domain where the interplay between viability and resilience is particularly critical. CCUS systems involve complex networks that encompass CO2 capture from industrial and energy sources, conditioning and liquefaction, transportation through pipelines or ships, and final storage or utilization in industrial applications [14,15]. Their viability depends not only on economic factors such as the levelized cost of CO2 capture and transport, but also on safety, environmental performance, and social acceptance [16,17]. Existing models tend to prioritize cost minimization and techno-economic assessments, often oversimplifying operational risks, multimodal transport thresholds, and the resilience of storage hubs [18,19,20]. Moreover, the integration of CCU pathways within CCUS supply chains, such as the production of methanol, urea, or building materials, has been insufficiently addressed from a systemic perspective [20,21,22]. This lack of comprehensive frameworks restricts the capacity to evaluate trade-offs between storage, utilization, and long-term adaptation [23]. Consequently, the design of CCUS supply chains represents a fertile ground to operationalize viability as a systemic property that balances efficiency, resilience, and circularity.

The Colombian context exemplifies both the urgency and the opportunity to advance CCUS supply chain design [24]. Studies highlight significant geological potential for CO2 storage in offshore basins such as Guajira and Sinú [25], and in onshore formations including Cesar-Ranchería and Middle Magdalena [26]. Mid-century decarbonization pathways confirm that without CCUS, Colombia is unlikely to achieve its deep decarbonization goals, particularly in hard-to-abate sectors like cement, steel, and thermal power generation [27]. Offshore logistics models indicate that cryogenic shipping may be competitive with pipelines for flows above 2–3 MtCO2 per year and distances greater than 400 km, closely aligning with Colombian industrial clusters [25]. However, national research also reveals institutional and regulatory barriers, limited integration of digital monitoring systems, and scarce empirical calibration of supply chain models with local data [28]. These constraints underscore the need for methodological frameworks that embed adaptive robustness and digital traceability, ensuring that CCUS networks can withstand unexpected disruptions while aligning with Colombia’s long-term decarbonization strategies.

This paper develops and tests an immune-inspired, goal-programming MILP framework to design viable CCUS supply chains that remain effective under both known and unknown uncertainties. We address the question: How can the viability of CCUS networks be quantified and strengthened by embedding adaptive responses—detection, redundancy, and memory—directly in the optimization model? We introduce the Immune-Structural Adaptive Response (RAIE) methodology, inspired by principles of the human immune system. This framework translates properties such as early detection (sentinel nodes), functional redundancy, adaptive memory, and structural reorganization into the design and evaluation of supply chains facing unexpected disruptions. Unlike classical approaches, RAIE does not rely solely on optimization under predefined scenarios but introduces dynamic metrics that assess the network’s ability to retain objectives, autonomously activate responses, adapt with controlled costs, and recover within acceptable timeframes. The application of this framework to the design of CCUS supply chains, particularly in the Colombian context, demonstrates how an immune-inspired perspective can contribute to building viable and resilient networks under conditions of profound uncertainty. In doing so, this research addresses critical gaps identified in the literature and positions RAIE as an original contribution for the analysis and design of supply chains in highly uncertain environments. We formalize the Immune-Structural Adaptive Response (RAIE) as a set of metrics and constraints—goal retention, autonomous activation, adaptation cost, recovery time, and service loss—and integrate them with multimodal CCUS logistics (capture, compression, liquefaction, pipelines/shipping, storage, and utilization). The formulation is instantiated for Colombia to demonstrate policy-relevant trade-offs.

Below we outline the structure of the paper. Section 2 synthesizes prior work on supply chain viability and resilience—with emphasis on CCUS networks—and distills the specific gaps that motivate our immune-inspired approach. Section 3 formalizes the problem setting and presents the RAIE methodology, detailing its metrics (goal retention, autonomous activation, adaptation cost, recovery time, and service loss) and how these are embedded in network design and evaluation. Section 4 describes the experimental setup, data and parameterization and reports the results of applying RAIE to CCUS supply chains, including sensitivity analyses to stressors and design levers. Section 5 interprets the findings, connects them to the identified gaps, and derives actionable guidance for practitioners and policy makers on designing viable, resilient CCUS networks under deep uncertainty. Section 6 summarizes the main contributions, acknowledges limitations, and outlines avenues for future research on immune-inspired, adaptability-centric supply chain design.

2. Literature Review

2.1. Supply Chain Viability

The concept of viability in supply chains has emerged as a central theme in recent operations and supply chain management research, reflecting the necessity of developing networks capable of withstanding turbulence while maintaining long-term operational and strategic integrity [29,30]. Unlike resilience, which focuses primarily on short-term recovery, viability refers to the systemic property of sustaining identity and functionality across dynamic and often unstable environments [31,32]. This perspective introduces viability as a meta-capability that integrates resilience, adaptability, and sustainability into a coherent framework [7,30]. It encompasses not only the capacity to absorb shocks but also the ability to adapt to evolving conditions such as market volatility, regulatory changes, or resource scarcity [33,34]. In this sense, viable supply chains are not merely reactive systems, but adaptive entities designed to perform under continuous uncertainty [35]. The notion of viability has also been linked to the ability of supply chains to balance efficiency with redundancy, demonstrating that long-term performance cannot rely solely on cost minimization but requires flexible structures and alternative configurations to remain feasible in diverse contexts [36].

Building on these conceptual foundations, scholars have proposed quantitative approaches to evaluate and operationalize viability in supply chain design [37]. Scenario-based stochastic programming has been employed to assess performance under multiple potential futures, highlighting how viability requires considering both expected and extreme-case outcomes [38]. Robust optimization methods also contribute by ensuring that feasible solutions persist across a wide range of uncertainties, thus guaranteeing continuity under disruptions [10,39]. In agro-industrial and energy-intensive supply chains, the incorporation of viability indicators has been critical, as perishability, seasonality, and technological constraints introduce unique vulnerabilities [40,41]. These contexts demonstrate that viability is not a universal or static concept but is shaped by the specific characteristics of products, processes, and infrastructure. Furthermore, researchers have emphasized the role of decision-support systems and digital technologies, such as digital twins and predictive analytics, in enhancing viability through real-time monitoring and adaptive response mechanisms [35,42,43]. This technological dimension reflects the growing consensus that viability requires both structural and informational robustness.

Literature underscores the multidimensional nature of viability, positioning it as a holistic framework that integrates economic, environmental, and social objectives while ensuring long-term feasibility [44]. For instance, studies highlight how viable supply chains must align with sustainability goals without compromising adaptability, thereby contributing to broader agendas such as climate resilience and social welfare [45]. The link between viability and resilience is particularly critical: while resilience emphasizes recovery after disruption, viability stresses sustained operation under persistent instability [30]. This distinction has important implications for mathematical modeling, as it necessitates performance indicators that go beyond efficiency metrics to capture adaptability, feasibility, and continuity [38]. The integration of these elements into supply chain optimization models marks a paradigm shift, moving from deterministic efficiency-oriented approaches to frameworks that value systemic endurance and adaptability [2]. As a result, the concept of viability provides not only a theoretical foundation but also a practical lens for guiding the design of robust, adaptive, and sustainable supply chain networks capable of navigating uncertain futures.

Supply chain viability requires distinguishing two uncertainty regimes with distinct instruments: known-unknowns, which can be modelled probabilistically (e.g., scenario-based stochastic programming), and unknown-unknowns or deep uncertainty, which call for non-parametric hedges (robust or distributionally robust optimization). Unified formulations integrate both regimes within a single decision problem and report feasibility/performance gains without permanent oversizing [46,47]. Complementarily, disaster-management studies propose phase-specific policies that “convert” unknown-unknowns into known-unknowns over the disaster cycle, reducing losses [48]. From complex systems, adaptive topological mechanisms (edge growth versus rewiring) yield quantified robustness improvements, though operational instrumentation remains limited [49]. Methodologically, pattern-oriented modelling advocates calibrating against multiple empirical patterns to move from known to unknown unknowns [50] and event-triggered designs when inputs are partly unknown [51]. Because CCUS risk frameworks remain fragmented and largely imported from general supply-chain studies [20], we subsequently validate these viability principles in a CCUS case.

2.2. Resilient Supply Chain Optimization

Resilience has been at the core of supply chain research for more than two decades, but recent studies increasingly focus on embedding resilience directly into optimization frameworks [52]. Traditionally, resilience has been conceptualized as the ability to resist, absorb, and recover from disruptions, often evaluated ex post through case studies or qualitative assessments [53]. However, with the growing frequency of global crises such as the COVID-19 pandemic, natural disasters, and geopolitical conflicts, scholars argue that resilience must become a built-in property of supply chain design rather than an afterthought [53]. Optimization-based approaches provide an avenue to formalize resilience, incorporating mechanisms such as redundancy, flexibility, and multi-sourcing into mathematical models [54]. For example, resilient supply chain optimization explicitly accounts for trade-offs between cost efficiency and preparedness, recognizing that short-term cost savings may undermine long-term continuity [55]. This shift also introduces resilience as a quantifiable design criterion, allowing decision-makers to systematically evaluate how alternative configurations perform under disruption scenarios [56]. As such, resilient optimization moves beyond descriptive analysis, creating actionable strategies that can be implemented in real-world supply chains.

One critical development in this area is the use of stochastic and robust optimization models to manage uncertainty in supply chain planning [52]. Stochastic programming allows supply chains to consider multiple potential futures and optimize for expected performance while hedging against adverse conditions [57]. Robust optimization, on the other hand, ensures feasibility across predefined uncertainty sets, creating supply chain configurations that can withstand variability in demand, supply, and transportation [58]. Hybrid models combining stochastic and robust approaches have also been proposed, offering flexibility in managing both probabilistic and non-probabilistic uncertainties [59]. Moreover, resilience has been linked to network topology, where structural properties such as connectivity, modularity, and clustering determine the ability to absorb shocks [60]. Mathematical models incorporating these structural dynamics show how supply chains can reconfigure routes and reallocate resources autonomously when nodes or links fail [61]. This highlights resilience not only as a functional property but as an emergent capability of network design.

Furthermore, resilient supply chain optimization has expanded to integrate sustainability and digitalization, reflecting the interconnected challenges of modern global networks [62]. Several studies show that resilience and sustainability are not mutually exclusive; rather, resilience mechanisms often enhance environmental and social outcomes by reducing waste, ensuring fair access, and stabilizing employment [63,64]. Digital technologies such as digital twins, artificial intelligence, and blockchain further augment resilience by enabling real-time visibility and predictive analytics [65]. These tools allow supply chains to anticipate disruptions and implement corrective measures proactively, thereby shortening recovery times and reducing vulnerability [66]. At the same time, researchers caution that resilience must not be equated with redundancy alone, as excessive buffers can generate inefficiencies and environmental burdens [67]. Instead, optimization models highlight the importance of balance, ensuring that resilience is achieved through intelligent design rather than excessive resource allocation [68]. Collectively, this body of work underscores the evolution of resilience from a reactive capacity to a strategic, quantifiable, and integrative component of supply chain optimization.

2.3. Immune-Inspired Approaches

An emerging strand of research introduces immune-inspired analogies as a novel lens to understand and design resilient supply chains [69]. The human immune system is often cited as one of the most robust adaptive systems in nature, capable of mounting immediate responses to pathogens through innate mechanisms while simultaneously developing long-term memory through adaptive processes [70]. Translating these principles to supply chains, researchers argue that networks should incorporate both rapid-response mechanisms and adaptive learning capabilities to survive in volatile environments [71]. For example, the concept of sentinel nodes, inspired by immune sentinels, can be applied to critical facilities that monitor and detect disruptions early, enabling proactive interventions [72]. Similarly, redundancy and degeneracy in supply chains resemble immune system properties, where multiple pathways and overlapping functionalities ensure continuity even when individual components fail [71]. These analogies provide powerful metaphors for embedding adaptive and self-organizing features into mathematical models of supply chain design.

From a methodological perspective, immune-inspired approaches have been operationalized through algorithms and optimization frameworks that mimic biological processes [73,74]. Clonal selection, immune memory, and negative selection algorithms have been adapted to solve complex logistics problems under uncertainty, demonstrating superior performance in dynamic environments [75]. These methods allow supply chains to autonomously explore solution spaces, adapt to new constraints, and refine responses as disruptions unfold [13]. Beyond computational heuristics, immune-inspired principles have been integrated into conceptual models of viability, emphasizing adaptability as a systemic property rather than a situational response. This perspective suggests that supply chains should not only anticipate known risks but also evolve mechanisms to handle “unknown unknowns,” a challenge that traditional robust and stochastic optimization struggles to address [76]. Thus, immune-inspired approaches complement existing optimization paradigms by introducing endogenous adaptation and learning capabilities.

Finally, the immune-inspired perspective contributes to bridging the gap between resilience and viability in supply chains [71]. While resilience emphasizes recovery and robustness, immune analogies highlight the importance of continuous monitoring, adaptation, and memory as critical elements for long-term viability [77]. For instance, immune memory translates into the ability of supply chains to learn from past disruptions, embedding adaptive rules that guide future decision-making [75]. Similarly, the immune system’s balance between attack and tolerance mirrors the trade-offs that supply chains face between redundancy and efficiency, or between flexibility and cost [13]. These insights have been particularly relevant in energy-intensive and CCUS-related contexts, where uncertainty is structural, and adaptive responses are essential for maintaining service continuity [74]. By formalizing immune-inspired mechanisms within optimization models, scholars propose a pathway toward supply chains that are not only resilient to disruptions but also viable in the long term, capable of evolving alongside changing technological, environmental, and societal demands [11,71,78].

2.4. CCUS Supply Chains

The design and operation of carbon capture, utilization, and storage (CCUS) supply chains have become a critical area of research for ensuring the viability and resilience of low-carbon energy transitions. Early studies emphasized the importance of integrated modeling approaches to address the multistage complexity of CCUS systems, which encompass capture, conditioning, compression, transport, utilization, and long-term storage [79,80,81]. Optimization-based frameworks have proven essential to support infrastructure design under uncertainty, particularly when evaluating multimodal transport options, diverse geological formations, and heterogeneous industrial utilization routes [82,83]. In recent years, research has increasingly focused on multi-objective optimization, seeking to balance economic, environmental, and social dimensions of feasibility [84,85].

From a viability perspective, techno-economic optimization studies have been central in evaluating when CCUS deployment can be competitive compared to alternative mitigation strategies [86]. Extensive research in Europe and Asia explored synergies among CO2 liquefaction plants, pipeline networks, and shipping routes, demonstrating that transport cost structures and hub configurations are decisive for overall feasibility [87,88]. More recent models have expanded toward safety-driven or robust optimization, incorporating probabilistic risk parameters and failure modes in capture or storage facilities [20,89,90]. However, these formulations remain largely static, where uncertainty is exogenous and no endogenous mechanisms allow the system to adapt to perturbations.

Table 1 provides a comparative synthesis of representative studies on CCUS supply chain optimization, encompassing various formulations such as deterministic, stochastic, and hybrid models. Around 80% of studies use mathematical programming methods—mainly MILP and MINLP—to tackle network design and infrastructure configuration issues in CCUS supply chains. These approaches primarily focus on optimizing economic and environmental objectives, supporting the development of efficient and sustainable CCUS systems [91,92,93,94]. Among these, multi-objective models dominate, typically combining cost and emission minimization, as observed in Ostovari et al. [90], Nguyen et al. [95], and Koketsu et al. [96]. However, only a few studies explicitly treat uncertainty beyond deterministic assumptions through inexact or stochastic formulations [97,98,99].

Table 1.

Comparative review of CCUS supply chain optimization studies.

Incorporation of adaptive or recovery-oriented capacities remains limited, appearing marginally in safety-driven [22] or in frameworks that address operational resilience conceptually [99]. Likewise, viability-oriented dimensions, such as the inclusion of social, regulatory, or policy instruments, are rarely integrated; Liu [100] and Koketsu [96] constitute exceptions by linking CCUS deployment to carbon taxation and national decarbonization pathways. Only two works [22,85] quantitatively assess risk or safety, while LCA-based indicators are explicitly modeled in Ostovari et al. [90] and Nie et al. [16].

Furthermore, despite increasing sophistication in spatial and temporal modeling—e.g., the multi-period frameworks by Nguyen [95] and Jones et al. [85]—the literature still conceptualizes resilience and viability largely as ex-post evaluations rather than embedded system properties. In summary, although the reviewed studies collectively advance the techno-economic understanding of CCUS networks, none operate adaptive or viability metrics as endogenous components of the optimization process. This gap underscores the need for integrated frameworks capable of evaluating adaptive, viable, and learning-oriented network behaviors, such as the one developed in this study.

In addition to the optimization-focused studies summarized above, Kabir et al. [103] provide a systematic review and a conceptual risk-management framework for CCUS supply chains that links functions → risk factors → mitigation strategies. Their analysis highlights the scarcity of supply-chain-specific CCUS models and the need to integrate regulatory/traceability requirements and monitoring, reporting, and verification (MRV) practices into design decisions, rather than treating them as ex-post considerations. This aligns with our framing of viability dimensions as part of the optimization problem, and it justifies the inclusion of policy and interoperability constraints alongside economic and environmental objectives in CCUS network design. Similarly, Rajabi et al. [104] demonstrate, in a different domain, how bi-objective network design can incorporate adaptive levers—such as temporary distribution nodes and precautionary inventories—to mitigate sudden demand shocks. Although sector-specific, this study is instructive for CCUS because analogous endogenous responses (e.g., surge storage, temporary hubs, and rerouting policies) can be encoded within the decision space and evaluated through adaptive/recovery capacity metrics, moving resilience from a post hoc assessment to an intrinsic property of the optimization model.

At the regional level, research in Latin America—and particularly in Colombia—is gaining momentum within national decarbonization frameworks. Studies employing the Global Change Analysis Model (GCAM) indicate that achieving mid-century carbon neutrality requires maintaining natural gas and bioenergy systems coupled with CCUS to ensure energy security under stringent emission targets [24,25]. Geological assessments have identified significant storage potential in offshore basins such as Guajira and Sinú, and in onshore formations like Cesar–Ranchería and Middle Magdalena, positioning Colombia as one of the few South American countries with viable CO2 storage capacity [105]. These formations, together with the concentration of industrial sources along the Caribbean coast, make offshore shipping-based logistics an efficient configuration for transporting captured CO2 to saline aquifers or depleted hydrocarbon reservoirs [106,107]. Comparative analyses further suggest that maritime transport becomes cost-competitive with pipelines beyond approximately 400 km and for annual CO2 flows of 2–3 Mt, a condition consistent with Colombia’s emission clusters and regional industrial hubs [25].

From a strategic standpoint, CCUS deployment in Colombia supports deep decarbonization while preserving the competitiveness of sectors such as cement, oil, gas, and refining [108]. The integration of enhanced oil recovery (EOR), emerging CO2 utilization technologies, and digital traceability systems—including blockchain and AI-based monitoring—has been highlighted as essential for environmental integrity and public confidence [109]. Consequently, Colombia represents a relevant testbed for advancing models that capture adaptive, viable, and policy-coherent CCUS networks in geologically diverse and socio-economically sensitive contexts.

In summary, the reviewed literature reveals three dominant characteristics of current CCUS supply chain modeling: (i) a technically robust but behaviorally static optimization structure, (ii) a persistent gap in quantifying adaptive and recovery capacities, and (iii) a limited incorporation of regulatory, interoperability, and social viability dimensions. Addressing these limitations, therefore, requires a modeling framework capable of embedding endogenous responses—such as rerouting, surge storage activation, and recovery cost evaluation—directly within the optimization problem. The model developed in this study advances in that direction by integrating economic, environmental, safety, and regulatory criteria within a dynamic optimization structure that evaluates system continuity and viability under both known and unforeseen disruptions. The following subsection consolidates these insights, outlining the specific methodological gaps that motivate the proposed immune-inspired viability framework.

2.5. Research Gaps and Contributions

Despite the considerable progress achieved in modeling resilient and sustainable CCUS networks, several methodological challenges remain unresolved. Most existing frameworks emphasize cost efficiency and static feasibility, while the system’s ability to reorganize and recover from disruptions—especially under unknown–unknown conditions—remains unmodeled. Few studies quantify indicators that jointly assess goal retention, recovery time, and adaptation cost, and no study operationalizes these within an optimization environment. Additionally, the interplay between technical resilience and socio-institutional viability, including interoperability, traceability, and regulatory adaptability, continues to be underexplored.

This research addresses these gaps by introducing a viability-oriented optimization framework that integrates endogenous adaptive responses directly into the mathematical structure of a CCUS supply chain model. The framework combines multi-objective optimization, uncertainty treatment, and safety-driven constraints with dynamic indicators that capture system recovery, continuity, and reorganization efficiency. Unlike prior works that externalize uncertainty, this approach embeds it as part of the decision space—allowing the network to self-adjust under perturbations. In doing so, the study provides a comprehensive methodology for assessing technical, economic, and organizational viability in CCUS networks, with direct applicability to the Colombian context.

3. Proposed Methodology and Optimization Model

The design of RAIE is inspired by the human immune system (SIH) and its response to pathogens. The innate component is fast, local, and non-specific (analogous to minimum inventories and operational safeguards that stabilize the affected node during a crisis). The adaptive component coordinates a systemic response that redistributes functions to healthy organs (surge capacity and alternate routing to sustain throughput during the disruption). Finally, immune memory reduces convalescence time upon repeated exposures (recovery mechanisms that shorten the TTR once the shock ends). From an operational perspective, this analogy is implemented through scenario parameters acting on effective capacities, minimum inventory, and temporary losses, without altering the underlying optimization model structure. The analysis systematically compares ω across three severity levels (high, medium, low) and under two regimes (RAIE–ON vs. non-SIH), reporting both absolute and relative differences. Anchored in the immune metaphor, this reading enables attribution of RAIE’s benefits—backlog reduction, service-level enhancement, and TTR shortening—while also prioritizing critical corridors and nodes in the design. The results thus provide practical guidelines for reinforcing the CCUS network against plausible disruptions.

The methodological contribution of this study does not lie in the deterministic mixed-integer linear programming (MILP) model itself, which serves only as the structural backbone, but in the integration of RAIE framework as an analytical layer to evaluate network viability and resilience. The model is subjected to perturbations that represent known–unknown risks, that is, disruptions that are plausible and well recognized in the supply chain literature but uncertain in their magnitude or timing. These are operationalized through four scenarios: (i) disruption of a port infrastructure, (ii) performance degradation in a line to enhance oil recovery fields, (iii) temporary shutdown of a specific port infrastructure, and (iv) temporary shutdown of a specific line to enhance oil recovery fields. Each scenario is characterized by affected nodes, time windows, and severity parameters, which allows a systematic exploration of controlled failures and their impact on supply chain performance.

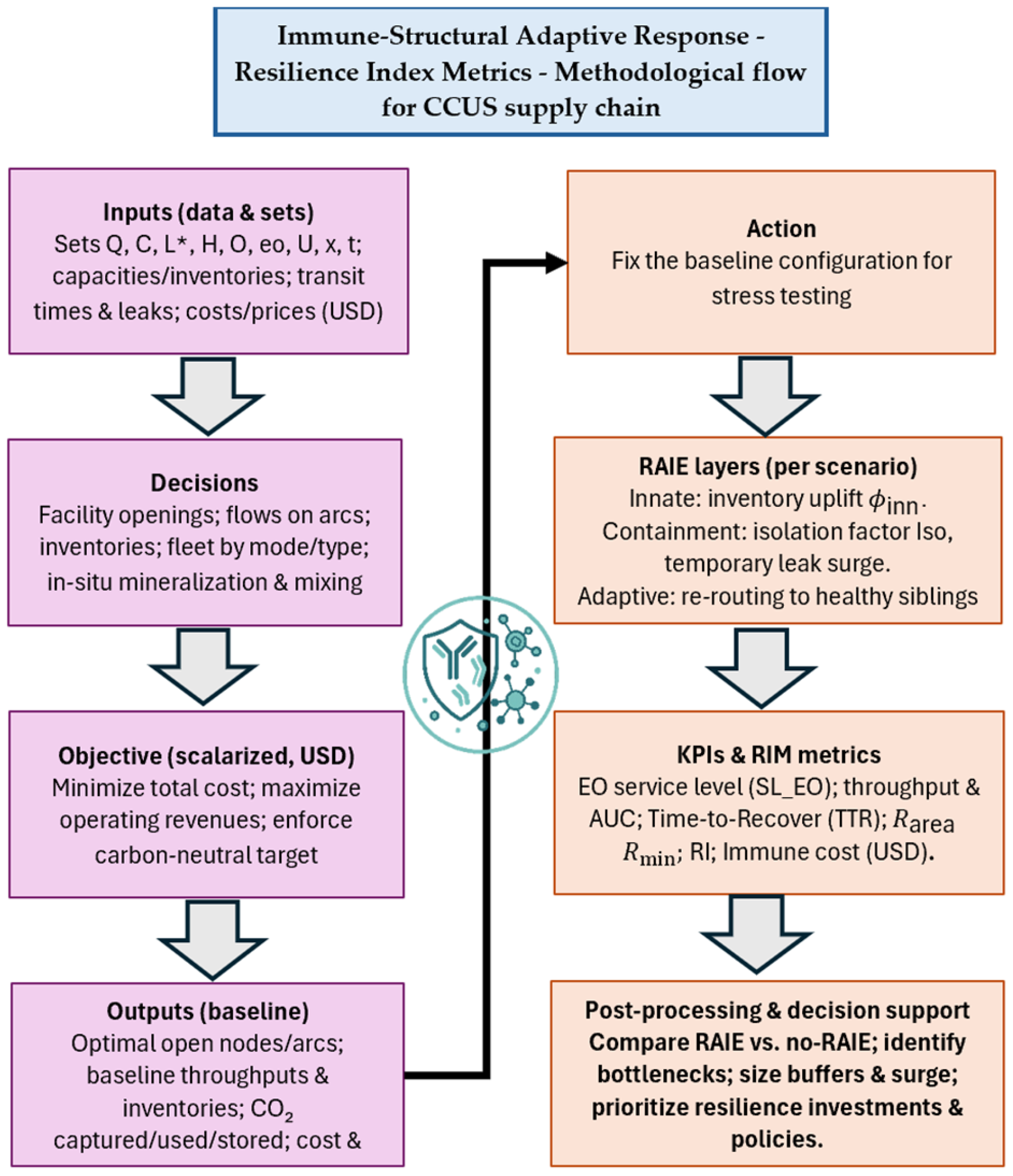

However, the methodology also seeks to transcend parametrized perturbations by addressing unknown–unknown risks, namely unexpected shocks that cannot be anticipated in the experimental design. To this end, RAIE incorporates an adaptive layer inspired by immunological principles, enabling the evaluation of the system’s capacity to: (i) retain essential goals under adverse conditions, (ii) autonomously activate alternative nodes or routes, (iii) temporarily reorganize inventories and flows, and (iv) explicitly measure costs and recovery times after disruption. The inputs of the methodology include structural data of the network, perturbation parameters, and indicators, while the outputs encompass not only optimal baseline configurations but also immune-inspired performance metrics RIM (Resilience Index Metrics), which quantify adaptive resilience beyond predefined scenarios. In this way, RAIE extends a deterministic MILP into a decision-support framework capable of analyzing operational continuity and structural reorganization under deep uncertainty.

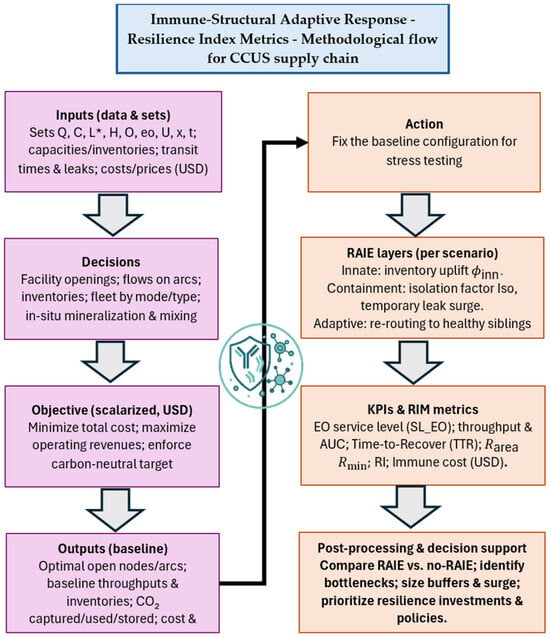

3.1. Proposed Methodology

We introduce RAIE (Immune-Structural Adaptive Response) as an immunology-inspired methodological layer that complements a deterministic MILP model to evaluate supply chain viability and resilience under disruptions without relying on stochastic assumptions. Unlike robust or probabilistic formulations, RAIE establishes a mechanism-based response framework that specifies how the network reorganizes under deterministic stress tests (known–unknowns) and how it preserves essential goals when facing unanticipated shocks (unknown–unknowns). The inputs include structural data of the network (nodes, arcs, capacities, and costs), disruption parameters (affected node or arc, time window, and severity), and target levels for viability and resilience. The outputs comprise baseline configurations and flows, feasible reconfigurations after disruptions, and a set of immune-inspired indicators (RIM) that quantify goal retention, autonomous activation, adaptation cost, recovery time, and demand loss. RAIE operates through three complementary mechanisms: the homeostatic mechanism, which safeguards essential goals under stress through viability constraints; the adaptive mechanism, which activates backup capacity at healthy nodes and redistributes flows through alternative routes within deterministic bounds; and the memory mechanism, which maintains temporary overcapacity or additional inventories after a shock to accelerate recovery. The disruption scenarios implemented correspond to known–unknowns: they are plausible and documented but uncertain in timing and severity, modeled as parameterized shutdowns or degradations. The unknown–unknowns are not represented as explicit scenarios; instead, they are assessed indirectly through the system’s ability to retain goals, activate alternatives, and recover baseline performance with transient reinforcement, as captured by the RIM indicators. The innovative contribution of RAIE lies in shifting the focus from probability-dependent robustness to mechanism-driven adaptiveness: it makes explicit which elements are activated, which reinforcements are maintained, and for how long, thereby generating quantitative evidence of viability and resilience under deep uncertainty within a deterministic and reproducible framework.

The proposed framework unfolds in two complementary phases. Phase I (baseline design and operation): the multi-period design–operation problem is solved, determining which facilities and corridors are activated and how flows are scheduled on a quarterly basis. The outcome is a feasible configuration that maximizes net economic performance subject to mass balances, capacity limits, injectivity, mode-specific losses, and inventory constraints. This phase provides baseline series (e.g., throughput and capture per period) along with associated costs and revenues, which serve as quantitative references. Phase II (viability and resilience with RAIE): building on the frozen baseline design, disruption scenarios are introduced, parameterized by temporal window, severity, and location. In each ω, RAIE modulates the system’s response through three mechanisms: (i) innate, local elevation of minimum inventories during the shock; (ii) adaptive, surge capacity in healthy nodes to absorb deviations; and (iii) memory, transient post-shock reinforcement that accelerates recovery. For causal quantification, each scenario is executed under two conditions: RAIE–ON (with innate, adaptive, and memory mechanisms activated) and the counterfactual non-SIH condition (RAIE–OFF), maintaining identical severity and shock window. This symmetry allows isolating the contribution of RAIE to performance. Figure 1 illustrates the flow diagram of the proposed methodology.

Figure 1.

The flow diagram of the proposed methodology. Model sets. : capture sources; : compression and gathering stations; : liquefaction plants partitioned as (offshore), (onshore), (EOR), and (industrial); : offshore storage hubs; : onshore storage hubs; : EOR fields; : industrial utilization sites; : mixing centers for mineralization; : discrete time periods (quarters).

The design of RAIE is inspired by the human immune system and its response to pathogens. The innate component is fast, local, and non-specific (analogous to minimum inventories and operational safeguards that stabilize the affected node during a crisis). The adaptive component coordinates a systemic response that redistributes functions to healthy organs (surge capacity and alternate routing to sustain throughput during the disruption). Finally, immune memory reduces convalescence time upon repeated exposures (recovery mechanisms that shorten the TTR once the shock ends).

From an operational perspective, this analogy is implemented through scenario parameters acting on effective capacities, minimum inventory, and temporary losses, without altering the underlying optimization model structure. The analysis systematically compares ω across three severity levels (high, medium, low) and under two regimes (RAIE–ON vs. non-SIH), reporting both absolute and relative differences. Anchored in the immune metaphor, this reading enables attribution of RAIE’s benefits—backlog reduction, service-level enhancement, and TTR shortening—while also prioritizing critical corridors and nodes in the design. The results thus provide practical guidelines for reinforcing the CCUS network against plausible disruptions.

3.1.1. RAIE Layer (Innate–Adaptive–Memory) as a Control Policy

RAIE layer (Adaptive, Innate, and Memory-based Resilience) is implemented as a “response module” that acts on the baseline design of the CCUS chain for each scenario and each period t. Computation-wise, RAIE takes as input the shock masks (e.g., node shutdowns or degradations) and, without altering the network structure, temporarily adjusts the relevant operating parameters. The innate response is triggered immediately by raising minimum inventories and, where applicable, introducing a leakage/stress surcharge; in this way, it cushions the interruption prior to any tactical decisions. Containment partially isolates the affected node via an isolation factor () that reduces its operational contribution to prevent failure contagion, while a stress term captures transient losses or inefficiencies. The adaptive response reinforces “sibling” nodes—unaffected assets within the same functional family (e.g., other liquefaction plants)—through a bounded overcapacity, enabling flow diversion without reconfiguring the network. After the event, memory enhances effective capacity/inventory over a post-shock window, reflecting operational learning and enabling faster recovery. To ensure comparability across scenarios, nominal parameters are restored at the start of each ω\omegaω and only then are the RAIE layers applied, following mutually consistent and bound rules. The output of this sequence is a set of effective per-node, per-period parameters (e.g., capacities, leakage rates, and inventories) that feed the same original flow problem. In the next subsection, we formalize these adjustments and show how they translate into ω and t-dependent effective capacities, leakage rates, and inventory floors. Let denote the quarterly horizon, and let be the shock window of scenario ω. Define as the shock indicator for family if a disruption is active at time t, and 0 otherwise.

For a node in family , with nominal capacity , the effective capacity under scenario ω is modeled as

where

is the containment or isolation (loss).

is the system’s adaptive capacity.

. is the fraction isolated during the shock (loss of capacity).

while a shock is active.

The innate layer is implemented as a minimum inventory buffer—or operational ‘slack’—at affected nodes:

where raises the inventory floor during the shock.

Stress-induced leakage/shrinkage is modeled as a temporary increase in the loss coefficient:

Memory (2): post-shock recovery via W periods:

These rules act parametrically on capacity and loss terms within the constraints, enabling a RAIE–ON versus non-SIH comparison under identical severity.

3.1.2. RIM Metrics (Resilience–Viability–Performance) and Computation

To objectively evaluate performance under disruptions, we employ a set of RIM (Resilience Impact Metrics) designed to quantify the viability and resilience of the CCUS chain in each scenario ω and period t. The central idea is to compare, for key operating curves (e.g., total throughput and EO service), the scenario trajectory with its disruption-free baseline and to summarize the impact using normalized, interpretable indicators. Specifically, we use: (i) a viability flag ΩOK(ω) indicating whether the model satisfies all constraints; (ii) service-level metrics (e.g., EO service) and the area under the capture/throughput curve over the horizon; and three strict resilience metrics: (integrated performance loss during and after the shock), (maximum relative pointwise drop), and TTR (time-to-recover), i.e., the first post-shock period in which the deviation falls below a technical tolerance. All metrics are constructed from the baseline curve ybase(t) and the scenario curve (e.g., total throughput), such that ∈ [0, 1] and ∈ [0, 1] higher values imply greater resilience, while TTR is expressed in quarters. The area metric captures the accumulated severity of the impact (depth × duration), the minimum metric captures the worst instantaneous drop, and TTR captures the speed of recovery; together they provide a complementary view of dynamic behavior. To maintain comparability across scenarios and severity levels, we normalize by the area and maxima of the baseline curve and use a fixed tolerance (e.g., 3–5%) to declare recovery. Finally, we report these metrics by functional module (LP and LEO) and for the entire system, thereby linking the RIM results to the RAIE layers (innate, adaptive, memory) and to the design’s economic–environmental trade-offs.

We next define the observable time series for scenario ω.

- Total throughput .

- Captura .

- Backlog EO ).

- Baseline series .

- Area Under the Curve (AUC) and normalization:

- Normalized indices (relative to the baseline):

- EO service level and backlog: Let be the quarterly EO demand (or requirement):with to quantify peak severity.

- Area-based resilience (resilience triangle). Define the per-period performance loss as . La resiliencia agregada (8) (más cercano a 1 es mejor) es:

- Robustness over the window and vulnerability (9): Let be the shock window. The minimum instantaneous robustness:captures the relative performance floor during the disruption.

- Time to recover (TTR) (10): Let with tolerance and persistence m (quarters), the TTR is:

It is worth clarifying that the effective-capacity formulation is not a standard equation in the optimization literature; rather, it is derived from the immunological logic that underpins the RAIE methodology. The term represents the system’s innate response, modeling isolation and the temporary loss of capacity at an affected node. The term corresponds to the adaptive response, in which backup capacity is enabled at healthy nodes of the same family to compensate for the disruption. Finally, the memory mechanism is incorporated via the transient persistence of overcapacity or additional inventories after the shock. This mathematical formalism is justified by the analogy with the human immune system [13], where processes of containment, compensation, and reinforcement are essential for the viability of complex systems. In this sense, the equations are not arbitrary; they constitute a translation of immunological principles into a deterministic MILP framework designed to capture the network’s dynamics of isolation, adaptation, and recovery.

The metrics employed in this study are drawn from the existing literature on supply chain viability and resilience (e.g., service level, capacity utilization, costs, recovery times) and therefore do not constitute new indicators by themselves. However, their integration into an immune-inspired system metrics (RIM) represents the methodological contribution, as they are reorganized according to the mechanisms of the RAIE framework (homeostasis, adaptation, and memory). This articulation enables the interpretation of network performance under disruptions not only in operational terms but also as quantifiable immune-like responses.

3.2. Proposed MIP Approach

3.2.1. Model Overview

We formulate an optimization model for a CCUS network (capture–conditioning–transport–use/storage) over a tactical, discrete eight-quarter horizon, whose objective is to size and operate a physically viable, economically attractive, and carbon-neutral configuration (see Appendix B). The chain integrates 12 capture sources (with a cement sub-set), 7 compression and collection stations , liquefaction plants ll structured into destination-based subsets —ports/offshore— onshore geologic, — EOR fields, and — industrial uses), storage hubs offshore and onshore , 5 production fields with enhanced recovery , and 3 industrial-use nodes . Between and , we model mixing centers co-located with each source, which homogenize qualities and allow diversion without reprocessing when technically feasible. Transport combines existing pipelines along four corridors (), road modes (cryogenic fleets differentiated by type: ), and maritime shipping (). The model is multi-objective with an aggregated objective in monetary units (US$) that internalizes three goals: total costs, revenues from CO2 use, and a penalty on residual emissions to achieve carbon neutrality. The formulation is mixed-integer at the structural level and linear in operations; it is solved in GAMS Release 51.3.0/CPLEX, reporting CPU times compatible with tactical, meso-scale studies.

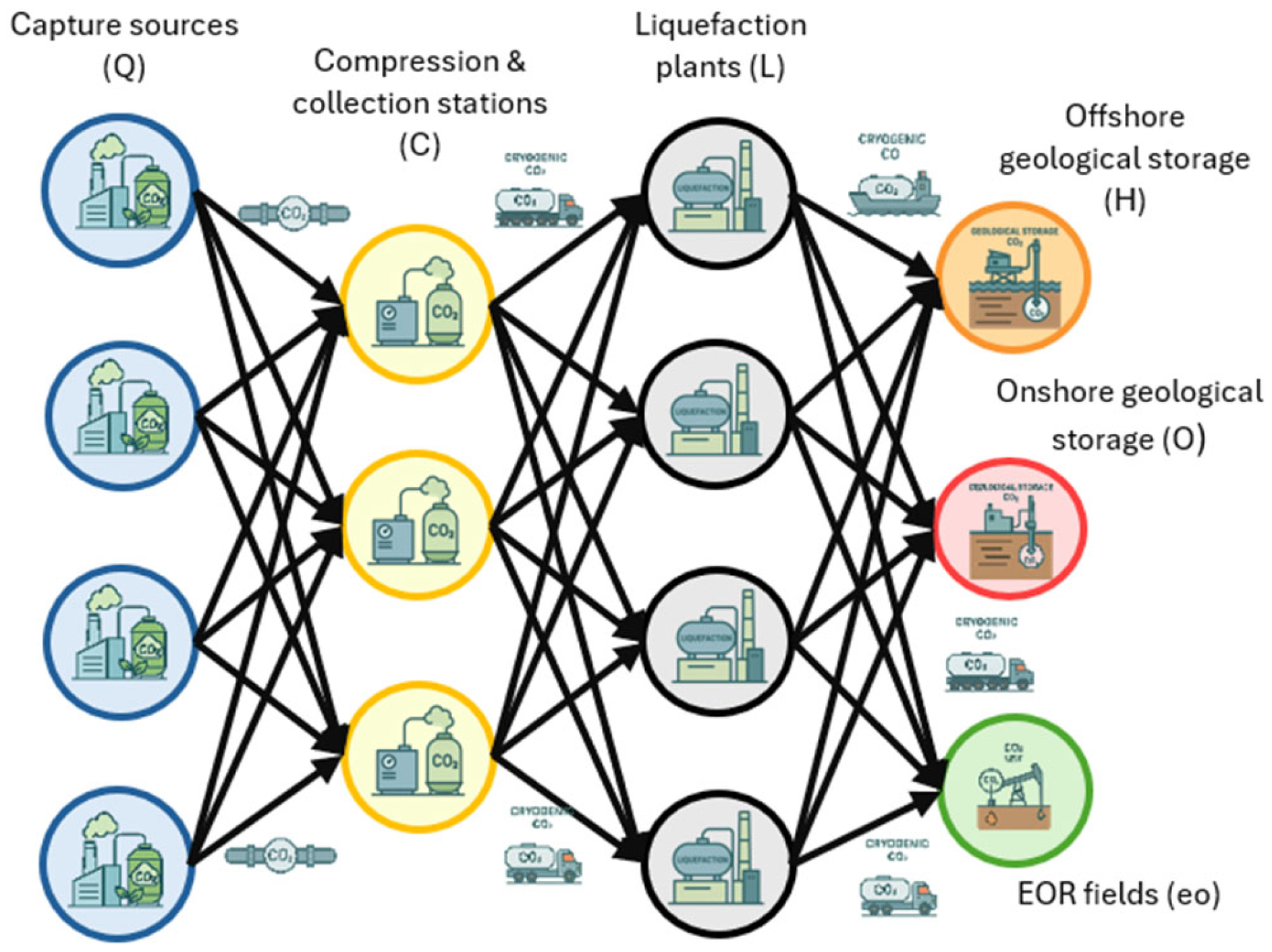

The CCUS network can be conceptualized as a multi-echelon system comprising interdependent upstream, midstream, and downstream layers. The upstream segment includes industrial emitters such as cement, steel, and power plants, which act as CO2 sources feeding the capture subsystem. The midstream layer encompasses compression and liquefaction facilities—often managed by energy operators or service providers—responsible for conditioning CO2 for multimodal transport via pipelines, cryogenic trucks, or ships. The downstream layer integrates storage and utilization pathways: offshore and onshore geological reservoirs managed by energy agencies, enhanced-oil-recovery (EOR) fields operated by petroleum companies, and industrial users that convert CO2 into chemicals or construction materials. Cross-cutting stakeholders such as regulators, port authorities, and digital-monitoring providers ensure traceability, safety, and carbon-neutral compliance across the chain. This layered configuration establishes the physical and institutional backbone on which the RAIE-based MILP model operates, allowing the analysis of both logistical and adaptive dynamics in an integrated manner.

Model Logic and Data Sources

The MILP model follows a hierarchical logic that combines strategic and tactical decisions within a unified optimization framework. It simultaneously determines (i) the activation of facilities, (ii) multimodal transport flows, (iii) storage and inventory levels, and (iv) carbon use and storage decisions, subject to cost, emission, and capacity constraints. Each decision variable and equation corresponds directly to a physical or operational process in the CCUS network—capture, compression, liquefaction, transport (pipeline, ship, or truck), injection, and mineralization—ensuring transparent interpretability between mathematical entities and engineering actions.

The parameter database was compiled from three complementary sources:

- (1)

- Scientific literature, including techno-economic and geospatial data for CO2 capture, transport, and storage (DOE/NETL CO2 Transport Cost Model);

- (2)

- Industrial specifications, such as cryogenic truck and ship performance (Northern Lights, Mitsubishi, FIBA, Chart Industries), and Geological and territorial data from the Colombian Geological Survey and the National Hydrocarbons Agency (ANH).

- (3)

- All parameters were standardized to consistent units (USD/tCO2, tCO2/km, USD/t·km) and verified through dimensional consistency checks.

Calibration was conducted through internal consistency tests and sensitivity analysis on key parameters (capture efficiency, injectivity, leak rate). The entire dataset is traceable and publicly reproducible, as summarized in Appendix B (Table A4). This guarantees that the optimization results are not parameter-dependent artifacts but a coherent representation of CCUS network behavior under realistic industrial and territorial conditions.

Network Structure and Destination-Based Partitioning of Liquefaction Plants

A central feature of the case is the functional partitioning of the liquefaction plants into four mutually exclusive subsets, defined by the final destination and the quality/treatment-time requirements of the compressed CO2:

- (6 alternatives): Liquefaction with maritime shipment to offshore hubs ; requires high purity and robust cryogenic conditions for marine carriage, with longer processing times (dehydration, impurity polishing, phase stabilization).

- (4 alternatives): Liquefaction with road dispatch to onshore storage complexes ; permits somewhat shorter operating windows than and purity specifications compatible with saline injection (water NOₓ/SOₓ limits).

- (4 alternatives): Oriented to production fields with enhanced oil recovery (EOR use); they require tighter pressure/temperature windows and bounded impurity levels (for reservoir compatibility), which translate into longer residence times and higher capacity consumption per metric ton treated.

- (3 alternatives): Supply to industrial uses; these allow industry-specific specifications (beverages, chemicals, materials), with differentiated treatments that the model represents as process coefficients and specific costs. This segmentation is not cosmetic: it translates into routing constraints (which destinations each effective-capacity coefficients (hour-equivalents per tCO2), and quality/impurity limits, so that the decision to activate and allocate flows entails measurable operational trade-offs.

Quality Treatment, Specifications, and Processing Times

Post-compression conditioning is modeled using quality balances at the route and destination levels:

- Purity and moisture: Each arc from to enforces a minimum quality. If the blend via the mixing center contains impurities above thresholds, polishing modules are activated, incurring additional costs and processing-time adders.

- NOₓ/SOₓ/trace-compound risks: Stricter limits are enforced for EOR than for , industrial-use specifications are parameterized by subsector.

- Processing–time coefficients (): The processing time per metric ton depends on the liquefaction subset () and on inlet quality; the plant’s equivalent capacity is computed as = thus linking quality to productivity, where τ is the processing time per ton.

- Mode- and segment-specific losses/leakage (pipeline, cryogenic road, maritime) are included in the mass balances and in the objective function’s emissions accounting.

CO2 Mineralization: In Situ and Ex Situ

The model considers CO2 utilization via mineralization under two complementary schemes:

- In situ mineralization: Modeled at specific nodes co-located with capture centers. At these nodes, a fraction of the CO2_22 is fixed directly into nearby minerals via mineral carbonation reactions in suitable formations (ultramafic/saline), represented in aggregate through stoichiometric yields and per-period injectivity limits.

- Ex situ mineralization: Reaction of CO2 with carbonateable solids (slag, ashes, Ca/Mg-rich residues, quarry fines) under processing platforms co-located with cement plants . We model an eligibility matrix and stoichiometric coefficients () that convert tCO2 into tonnes of carbonated mineral, with energy consumption and curing/process-time cycles that limit throughput. Both pathways compete for utilizable CO2 and therefore enter the economic objective (product/service revenues) and the environmental objective (credits for durable fixation), while preserving mass and quality consistency.

Decision Variables

Binary–type variables select the activation of nodes and modular capacity blocks; continuous variables determine arc-by-period flows , inventory levels at , fleet allocation by vehicle type, and blending at . ey decisions include (i) which plants to open and which destinations to serve; (ii) how to blend streams to meet minimum quality at the lowest processing cost; (iii) multimodal routing subject to capacities, transit times, and losses; (iv) inventory policies at (safety stock, technical maxima); and (v) the allocation of CO2 among EOR, mineralization, and other uses, maximizing economic value while achieving carbon neutrality.

Objective Function and Carbon Accounting (Values in USD)

The objective function is multi-objective and expressed entirely in USD, thereby placing economic and environmental performance on a common, commensurate scale:

Net emissions account for compression/liquefaction energy, transport losses, maritime/road transits, and credits from geological storage and mineralization (in situ/ex situ). Carbon neutrality is enforced either as a hard constraint or as a penalized term, depending on the experimental design.

3.2.2. Main Constraints

- Mass and quality balance at each node and period (includes impurities and minimum purity by route/destination).

- Nominal and effective capacities in liquefaction (via τ\tauτ), compression, geological storage, and injectivity.

- Inventories: Min/max bounds, inter-period carryover, and leakage.

- Multimodal transport: Pipeline limits (by corridor and direction), fleets (number/type, shifts), barges (time windows, minimum lot sizes), and transit times.

- Routing compatibility: Each serves only authorized destinations (port/geo/eor/ind).

- Mineralization: Stoichiometric yields, processing times, capacity curves, and energy consumption by (carbonateable solids set).

- Environmental: Neutrality (or emissions budget), regulatory limits (e.g., NOₓ/SOₓ, water), maximum leakage per link.

- Operational rules: Technical start-up minima, lot sizes, blending ratios, and dispatch priorities.

Key Assumptions

- Deterministic data for Phase I (design): Capacities, costs, yields, routes, and specifications are taken from industrial sources and literature; Phase II (RAIE) introduces the perturbations ω

- Intra-period homogeneity: Parameters and decisions are constant within each quarter; processing times are aggregated into τ

- Quality bounding: Thresholds (purity/impurities) and treatment coefficients are used; no detailed thermodynamic model is solved.

- Given topology: Pre-existing pipeline corridors and a plausible geometry for road and maritime routes.

- Markets: EOR/industrial prices are exogenous by scenario; energy costs and CO2 shadow prices are consistent with the context.

- Operational safety: Pressure/temperature and leakage limits are incorporated as bounds and specific loss factors.

Although the model is subjected to deterministic disruption scenarios (known–unknowns), the treatment of unknown–unknowns is not based on the direct simulation of hypothetical events, as in traditional stochastic models. Instead, it relies on the RAIE methodology, which translates immunological principles into network analysis: goal retention, autonomous activation, adaptive reorganization, and transient reinforcement. In this sense, the scenarios function solely as stress tests that reveal the system’s response capacity. The extrapolation toward unknown–unknowns arises from observing whether the network preserves its essential properties under disruptions not explicitly modeled, which is assessed through immune-inspired metrics.

The extrapolation toward unknown–unknowns arises from observing whether the network preserves its essential properties under disruptions not explicitly modeled, which is assessed through immune-inspired metrics. The mathematical formulation of these post-optimization dynamics—including the interaction between goal retention, adaptive activation, and recovery trajectories—is detailed in Appendix C (RAIE Post-Optimization Dynamics). This Appendix formalizes how the immune-inspired metrics evolve beyond the deterministic optimization stage, capturing transient recovery processes and adaptive reconfigurations that ensure network viability over time.

4. Computational Analysis

4.1. Background of Real Application Case

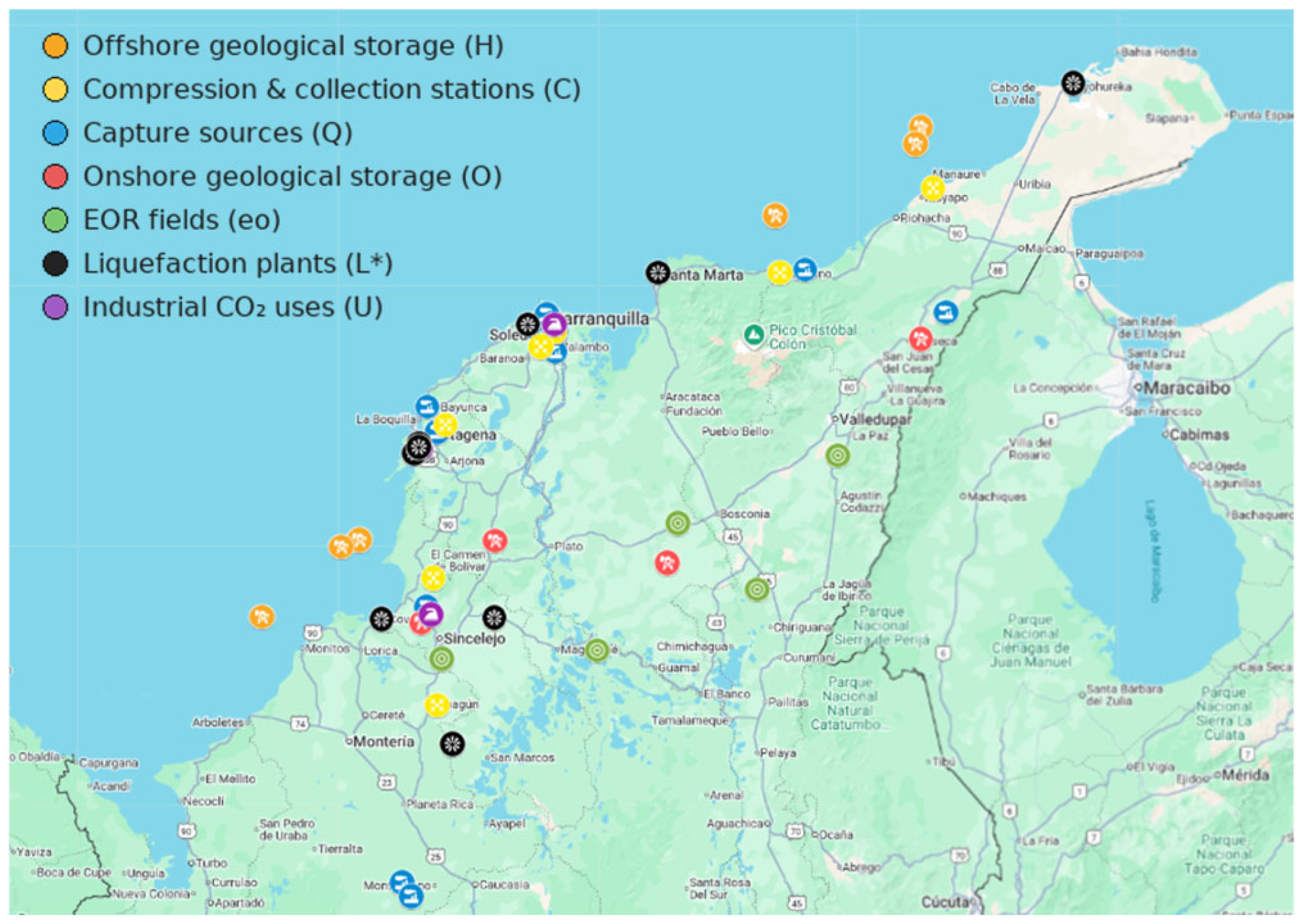

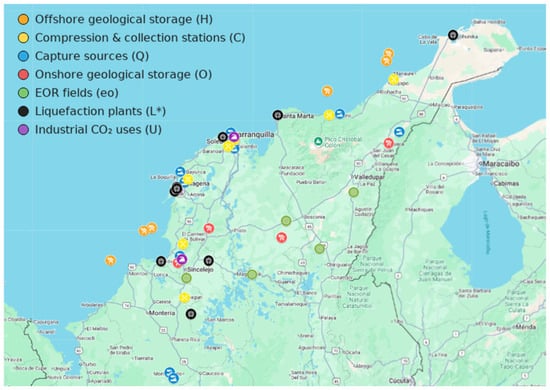

The application of the proposed model to the robust design of a CCUS supply chain (capture, transport, utilization, and storage of CO2) along Colombia’s Atlantic coastal zone is illustrated through a case study based on real-world data. The chain undertakes tactical planning over an eight-quarter horizon and must assess its network structure to select a configuration that jointly delivers operational viability and resilience to perturbations, while simultaneously optimizing economic and environmental performance. The practical interest is twofold: to ensure compliance with decarbonization commitments and, at the same time, to make CO2 utilization in industrial and enhanced oil recovery (EOR) applications viable.

The physical network considered integrates the key links of a multimodal CCUS chain. At the origin there are 12 capture sources, including a subset of cement plants that enable comparison of alternative capture-and-use routes. Captured CO2 is conditioned at 7 candidate compression and buffer stations and then feeds four families of liquefaction plants: (i) six candidate plants that liquefy CO2 at port complexes for offshore dispatch; (ii) four plants that liquefy for onshore hubs; (iii) four liquefaction plants supplying EOR fields; and (iv) three plants that connect liquefied gas to industrial uses. The system also comprises six offshore storage hubs and four onshore hubs, three industrial-use nodes, and five EOR fields. To increase operational flexibility, mixing centers co-located with each capture source are modeled; these homogenize qualities and enable diversions without additional reprocessing when technically feasible. Figure 2 shows the potential locations of the nodes in the CCUS logistics network under analysis.

Figure 2.

Node locations in the CCUS network approximation.

Transport combines existing pipelines along four main corridors, road modes with different types of cryogenic trucks, and the maritime mode for port connections to offshore hubs. All arcs are subject to per-period capacity limits, transit times, and mode-specific losses/leakage, while storage/use nodes carry inventory limits and injectivity/substitution bounds where applicable (e.g., in EOR). Model decisions are taken quarterly and include the assignment of flows on each arc, inventory levels at liquefaction plants and mixing centers, fleet utilization by type and mode, and the activation of redundancy and rerouting mechanisms. All physical quantities are expressed in tonnes of CO2 (tCO2).

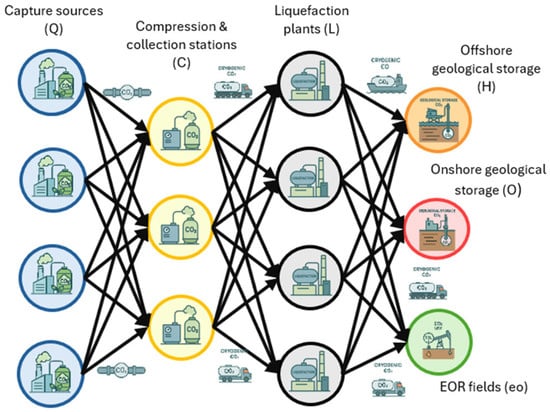

The Carbon Capture, Utilization, and Storage (CCUS) process, oriented toward carbon neutrality, integrates multiple technological and logistics links whose purpose is to reduce net CO2 emissions through a cycle of capture, transformation, and geological or mineral fixation. First, carbon dioxide is captured at large stationary industrial sources—such as cement plants, thermal power stations, or refineries—using cryogenic separation, adsorption, or membrane systems. This CO2 is subsequently compressed at compression centers to reach the pressures required for safe transport. The transport infrastructure includes cryogenic trucks, specialized vessels, and high-pressure pipeline networks, enabling movement of CO2 to liquefaction plants, intermediate hubs, or directly to storage and end-use sites. Once liquefied in cryogenic plants, CO2 attains temperature and pressure conditions that optimize both fluid density and logistics efficiency. In this state, the gas can be directed to: (i) deep geological storage in saline formations, saline aquifers, or depleted reservoirs, both offshore and onshore; (ii) industrial uses such as beverage carbonation, chemical processes, or materials synthesis; and (iii) enhanced oil recovery (EOR) operations, where injected CO2 increases the recovery factor while simultaneously becoming stably confined within the porous rock. Figure 3 presents the CO2 capture and storage network.

Figure 3.

CCS Net.

A distinctive feature of a carbon-neutral CCUS chain is the inclusion of both in situ and ex situ mineralization processes. In the in situ case, CO2 is injected directly into geologic formations rich in magnesium- and calcium-silicate minerals, where it reacts with subsurface minerals to form stable carbonates (CaCO3, MgCO3). This mechanism emulates natural mineral carbonation that occurs over geologic timescales, but is accelerated by controlling pressures, flow rates, and geochemical conditions. By contrast, in ex situ mineralization at mixing centers, CO2 is combined with industrial residues (e.g., steel slag, fly ash, or cement dust) in reactors engineered to promote the formation of solid carbonates, which can be reintegrated into value chains as additives in cement production or construction materials (Figure 4). Integrating both mineralization pathways ensures not only permanent carbon capture but also the generation of value-added by-products, thereby strengthening the chain’s economic viability. This holistic approach yields a CCUS network with adaptive resilience to operational disruptions and aligns the system with carbon-neutrality objectives set by international sustainability commitments.

Figure 4.

CCU Net.

4.2. Experimental Settings

The computational evaluation is structured in two phases. First, the network design problem (eight-quarter horizon) is solved once, and the optimal configuration of nodes and arcs is fixed. On this fixed network, we run a scenario-based design of experiments over Ω with three severity levels (low, medium, high). Each scenario represents an operationally plausible event in the CCUS chain: (i) an interruption at a port liquefaction plant (LP); (ii) degradation at a liquefaction plant meeting CO2 treatment specification for EOR (LEO); (iii) temporary shutdown of a specific LP; and (iv) temporary shutdown of a specific LEO. All experiments are executed with the RAIE layer active (innate, adaptive, and memory); for sensitivity analysis, non-SIH variants with RAIE disabled are considered where appropriate. Performance metrics include economic/environmental KPIs and the RIM metrics (Rmin, Rarea, TTR), reported by scenario and severity. The planning horizon is quarterly (). Flows and inventories are expressed in tons of CO2 (tCO2); costs/benefits are in USD. Geographic locations and nominal capacities are taken from the node dataset (map in Figure 2) and from the transport cost/time bases described in the data section. All models are solved in GAMS/CPLEX and run on a desktop PC (Windows 10, Intel® Core™ i5, 16 GB RAM). The experimental design uses batch runs (a loop over Ω × severity), storing KPIs and RIM outputs per run for subsequent graphical and tabular analysis.

Table 2 summarizes the scenarios considered and the temporal window during which each disruption is activated (for high severity). Medium and low severities reduce the window length by 1 and 2 periods, respectively, while keeping the start time fixed. In a CCUS chain, the critical points—liquefaction plants with CO2 treatment specifications for geological storage and EOR—concentrate: (i) the CO2 state conversion, (ii) multimodal coupling (road–maritime–pipeline), and (iii) injectivity/storage constraints. Accordingly, the most plausible disruptions with the greatest systemic impact are:

- LP shutdown/degradation (operational failures, corrective maintenance, port/energy constraints).

- LEO degradation/shutdown (EOR injectivity limitations, geomechanical or regulatory constraints).

Table 2.

Summary of the scenarios considered.

Table 2.

Summary of the scenarios considered.

| Scenario ω | Description | Affected Node | Window (t) |

|---|---|---|---|

| ω1: LP-disruption | Port LP shutdown | lP3 | t3–t6 |

| ω2: LEO-degradation | LEO degradation | leor1 | t4–t7 |

| ω3: LP-shutdown | Temporary shutdown of a specific LP | lP1 | t1–t5 |

| ω4: LEO-shutdown | Temporary shutdown of a specific LEO | leor4 | t2–t6 |

The process of modelling shutdowns and degradations using temporal windows and severity levels is commonly employed in robust design and stress testing focused on system viability. During these assessments, performance is measured under various perturbation parameters, and the system’s response —such as changes in flow, temporary losses, and recovery—is observed. Theoretically, this aligns with viability (the ability to sustain and adapt in a changing environment) and resilience (absorb–recover), both of which call for scenario analysis and parameter sensitivity when uncertainty spans the known-unknown and the unknown-unknown.

Each severity level is characterized by (i) the window duration and (ii) a set of parameters that operationalize the RAIE ‘arms’ in the model: Innate (φ: temporary inventory floor), Containment (Iso: fraction of capacity isolated at the affected node; the operable share is 1-Iso), Leakage/Stress (), and rerouting load (Σ: temporary overcost/penalty factor for deviations). Distinct levels are used for LP and LEO, consistent with their roles in the network. Setting three severity levels (high–medium–low) yields an experimental design comparable to orthogonal arrays or batteries of cases that explore ‘types’ and ‘magnitudes’ of uncertainty—a common practice for policy validation and sensitivity analysis (including Taguchi arrays where appropriate).

The specific parameterization of each severity level is summarized in Table 3. For every disruption archetype—LP (liquefaction–port), LEO (liquefaction–EOR), and their corresponding onshore counterparts—the parameters define the intensity of the RAIE response “arms”: φ (temporary inventory-floor increase), Iso (isolation share at the affected node), LeakSurge (transient throughput loss), and Σ (adaptive slack coefficient). These values were calibrated through pilot runs to ensure consistent stress magnitudes across experiments and to preserve model feasibility while enabling comparative analysis between RAIE-ON and non-SIH configurations.

Table 3.

Severity-level parameters.

For each (ω, severidad) the model is solved on the fixed network of the optimal design. We collect (i) KPIs (Z, Total cost, Income, Emisiones, AUCCapture, AUCThru, SL_EO) and (ii) RIM metrics (Rmin, Rarea, TTR along with throughput and inventory time series for visualization. The Tables/Figures in Section 4.3.2. report comparisons by scenario and severity, as well as the effect of RAIE versus non-SIH. By targeting shocks at these propagation bottlenecks, the experiment captures both local failures (shutdowns/degradations) and systemic effects (constraints toward EOR)—the two risk classes with the greatest potential to compromise CCUS network viability. The parametric representation of each shock—via capacity isolation (Iso), transient stress losses (LeakSurge) and temporary inventory-floor increases (φ)—reflects operational mechanisms observable in practice (derating, pressure-induced inefficiencies, and safety buffers), while the adaptive surge (Σ) captures the temporary availability of slack at healthy facilities without altering topology. This direct correspondence between parameters and operational decisions confers construct validity on the disruption treatment.

Recent literature distinguishes viability (sustain/adapt over time) from resilience, understood narrowly as stability–recovery, and advocates systematic stress testing to evaluate policies and their associated costs. In parallel, the immune analogy for supply chains (innate–adaptive–memory) supports the use of operational layers that modulate effective capacities, buffers, and recovery without redesigning topology at each shock. Our set (LP-disruption, LEO-degradation, LP-shutdown, LEO-shutdown) covers local failures and systemic bottlenecks (EOR/LEO), the two risk archetypes with the greatest propagation (“ripple”) in CCUS. Testing each at three severity levels and with/without RAIE (RAIE–ON vs. non-SIH) enables causal attribution of RAIE’s contribution to SL, backlog, Rarea, Rmin and TTR—precisely the kind of evidence called for by contemporary viability and robustness approaches.

Finally, the RIM metrics employed—area and relative-minimum indices, service level, and time-to-recover (TTR)—provide an integrated reading of dynamic performance (depth, temporal extent, and speed of return), ensuring reproducibility and transferability of the protocol to other geographies or CCUS configurations with minimal parameter adjustments. Taken together, the experimental plan combines operational realism, statistical control, and traceability of effects, meeting the validity criteria required for the scientific evaluation of viability and resilience in CCUS networks.

4.3. Computational Results

4.3.1. CCUS Supply Chain Design

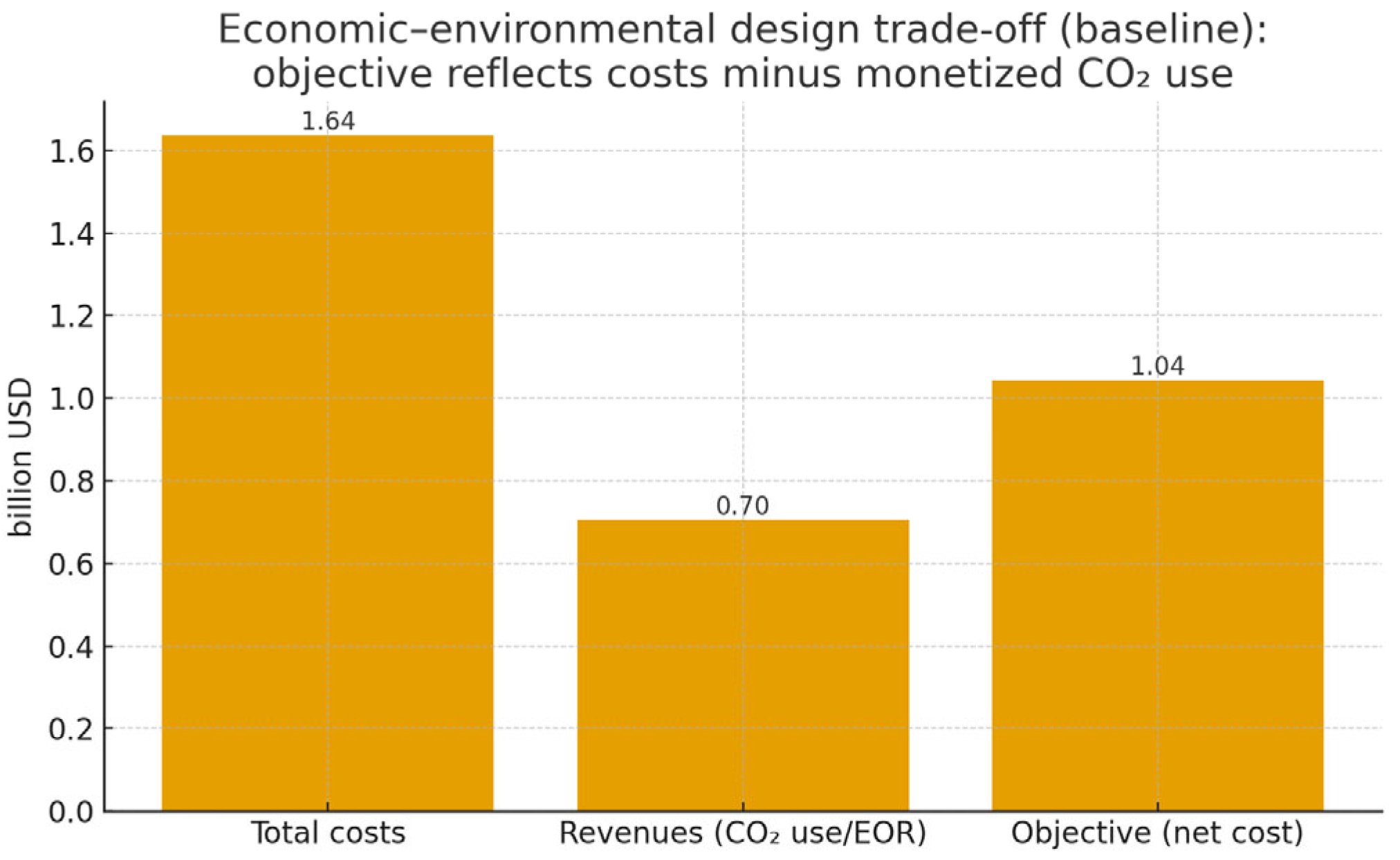

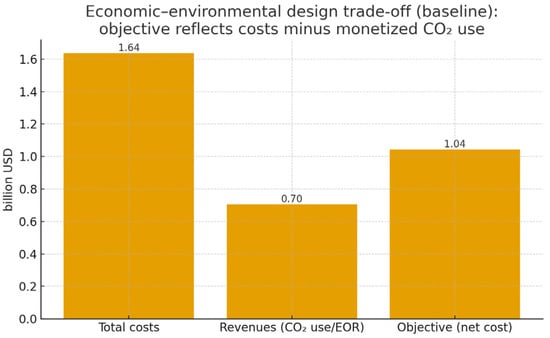

The solution to the design problem yields a CCUS network with all capture sources active (12/12); four compression and buffer stations (c1, c3, c5, c7); three port-based liquefaction plants for shipments to offshore geological storage (lP1, lP3, lP6); three liquefaction plants for shipments to onshore geological storage (lgeo1–lgeo3); two liquefaction plants supplying CO2 for EOR uses (leor1 and leor4); three liquefaction plants for industrial CO2 use (lind1–lind3); and one CO2–minerals mixing center (x8) for cement plants. This configuration—fixed for the scenario evaluation—achieves an objective value of 1.043 × 109 USD, with total costs of 1.635 × 109 USD and system revenues of 7.043 × 108 USD (see Table 4).

Table 4.

Baseline CCUS network design and performance summary (Phase I).

Solving the design problem delivers a network configuration that maximizes net economic performance (USD) while, in parallel, internalizing the carbon-neutrality target through the corresponding term in the objective function. The baseline result (Ω°) exhibits full service to EOR and no backlog, with stable throughput trajectories along the network’s two technological corridors (C-L-H/LP and C-L-EO/LEO). In aggregate terms, the indicators AUCCapt and AUCThru reach, respectively, on the order of 3.69 × 106 tCO2 y 3.55 × 106 tCO2 over the eight quarters, providing a robust baseline for subsequent experiments (Table 1). Convergence to this design confirms the system’s techno-economic viability under realistic assumptions on capacities, transit times, and losses, and satisfies the net-emissions constraint required by the carbon-neutrality target.

From an environmental sustainability perspective, the design functions as a verifiable abatement mechanism: capture at emitting sources is coupled with compression, liquefaction, and multimodal transport (pipeline, road, maritime) to onshore/offshore geological storage nodes and industrial uses. In the baseline, CO2 utilization for EOR is fully satisfied (SL_EO = 1.000), while storage trajectories at onshore/offshore hubs keep inventories within safety bounds, reducing risks of venting and leakage. The fact that AUCCapt ≈ AUCThru over the horizon (with marginal differences attributable to mode-specific losses) is consistent with a mass balance conducive to carbon neutrality, while also evidencing efficient infrastructure utilization without unnecessary oversizing (Figure 2).

From an economic and social sustainability standpoint, the baseline solution integrates utilization revenues (e.g., from EOR and industrial applications) that co-finance operations, thereby reducing reliance on subsidies and improving the bankability of the CCUS scheme. In terms of social impact, the proposed network links industrial clusters with port logistics corridors, generating positive externalities: (i) measurable emissions reductions in hard-to-abate sectors; (ii) preservation of jobs and value chains by avoiding prolonged shutdowns due to regulatory emissions limits; and (iii) the development of local technical capabilities in capture, liquefaction, and storage (aligned with a just transition).

Finally, the design’s economic–environmental trade-off is transparent: the objective function, in USD, simultaneously reflects logistics and processing costs, revenues from CO2 utilization, and penalties associated with the carbon-neutrality target. The baseline result confirms that, under current parameters, the system monetizes a significant fraction of the captured CO2 (via EOR/industrial use) while keeping residual net emissions negligible, positioning the network as a cost-effective decarbonization solution for the regional context (Figure 5).

Figure 5.

Economics trade-off.

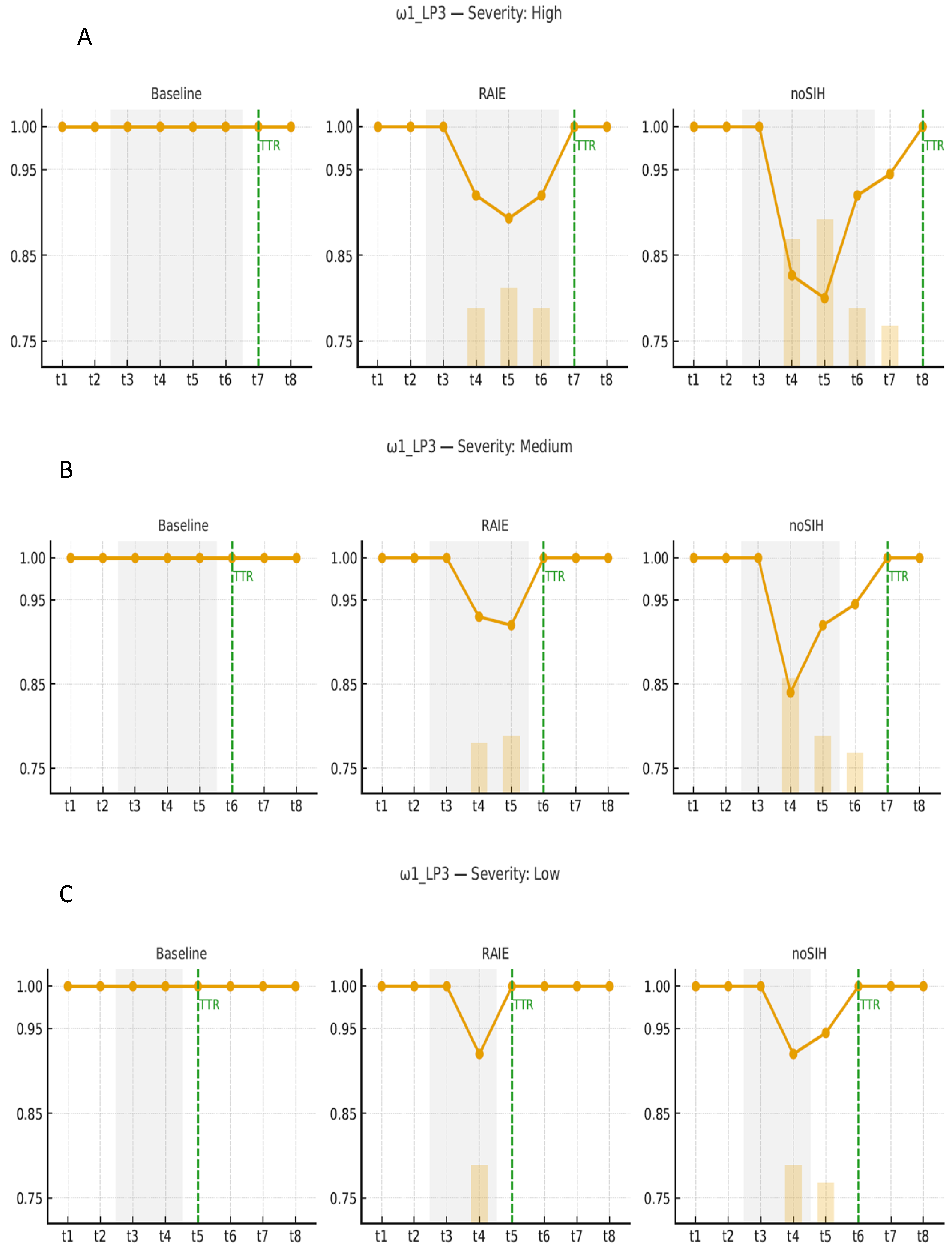

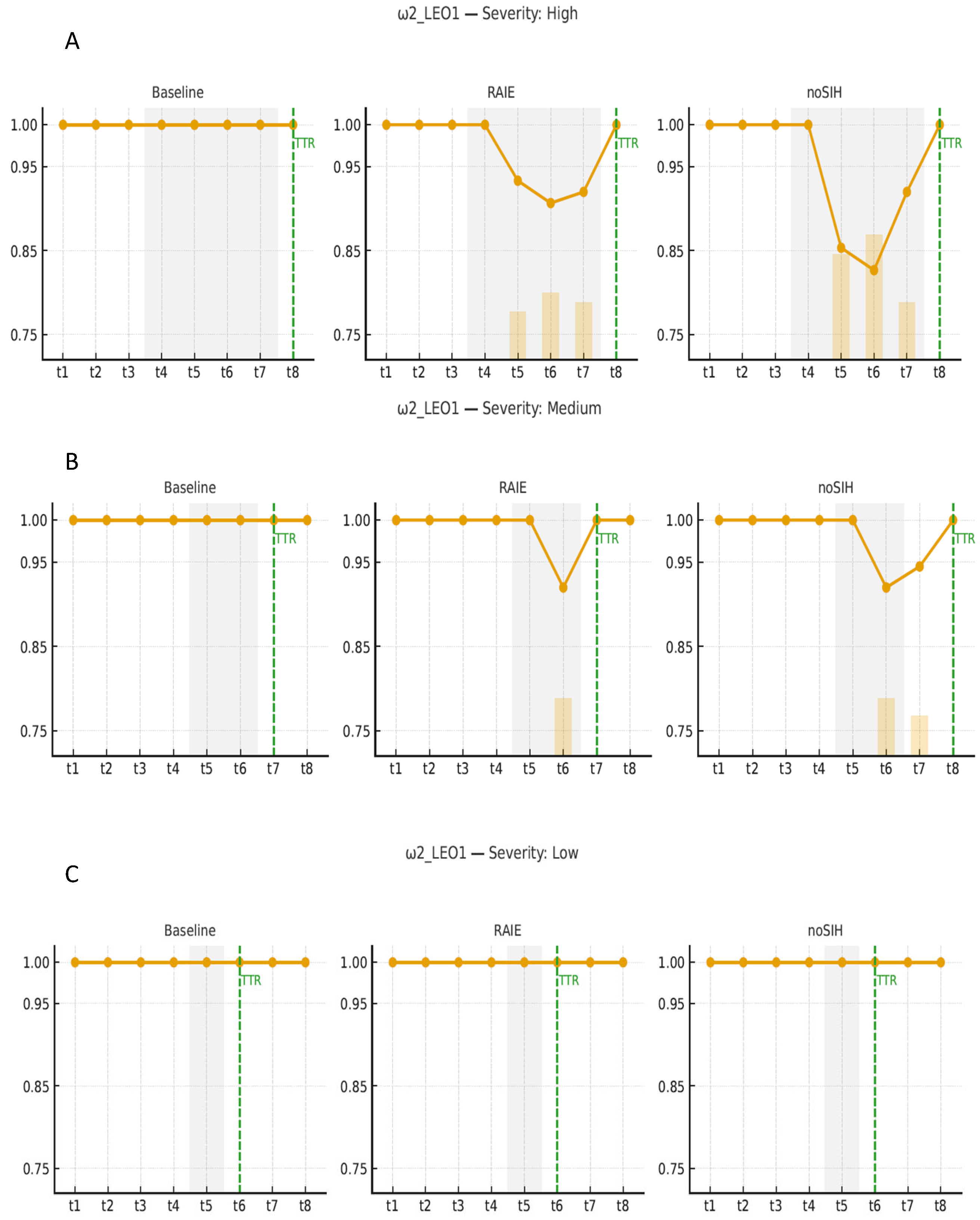

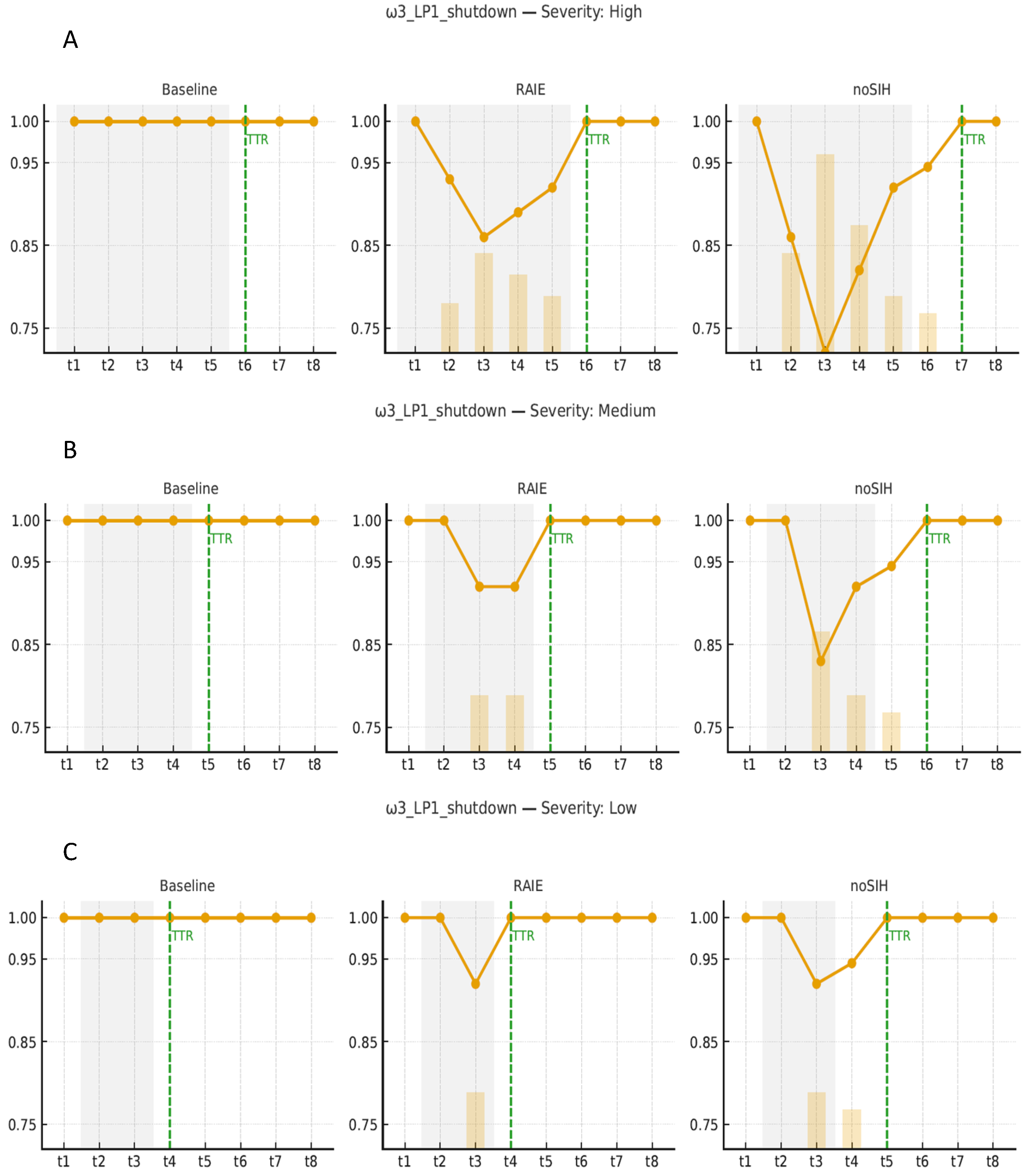

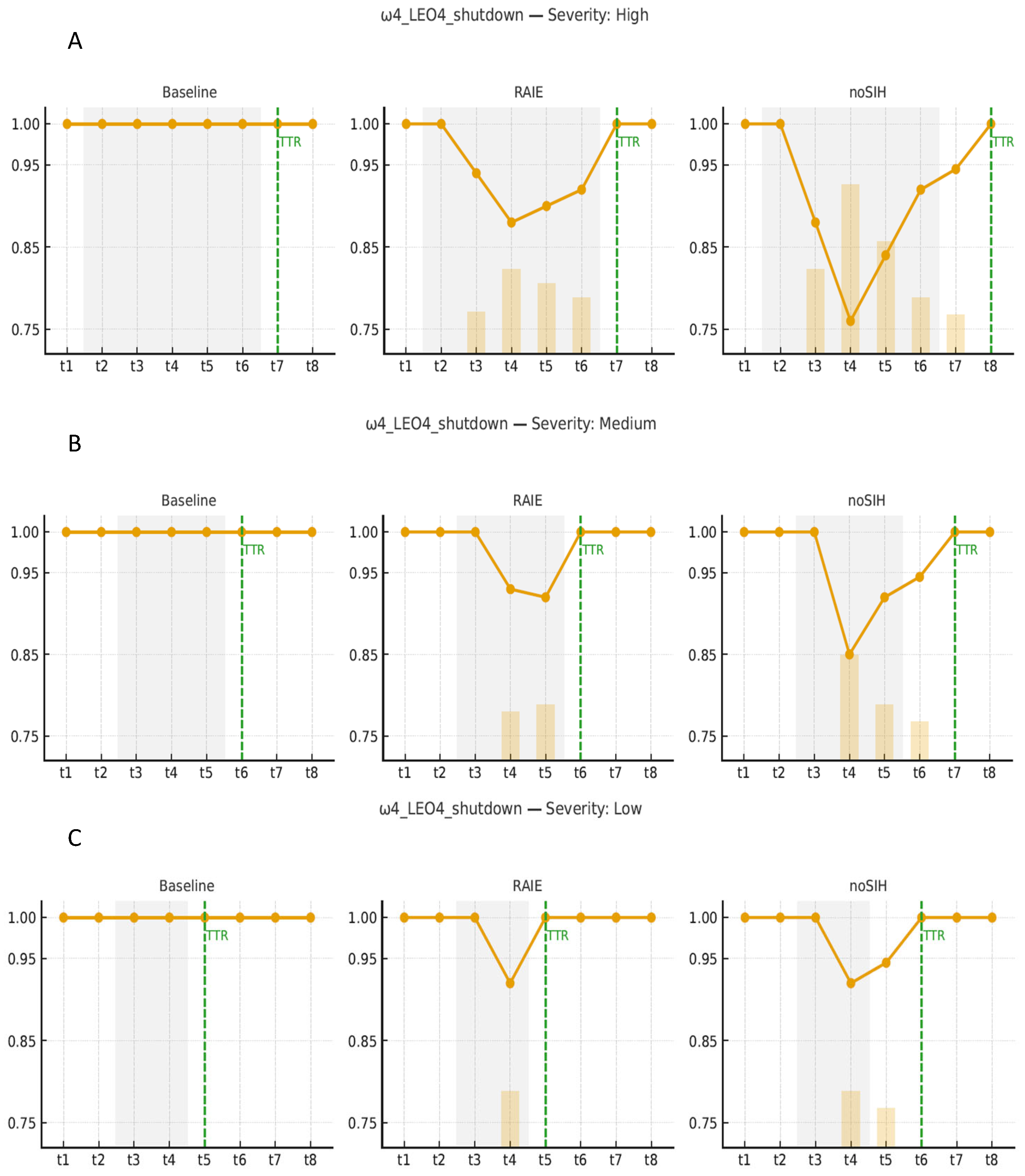

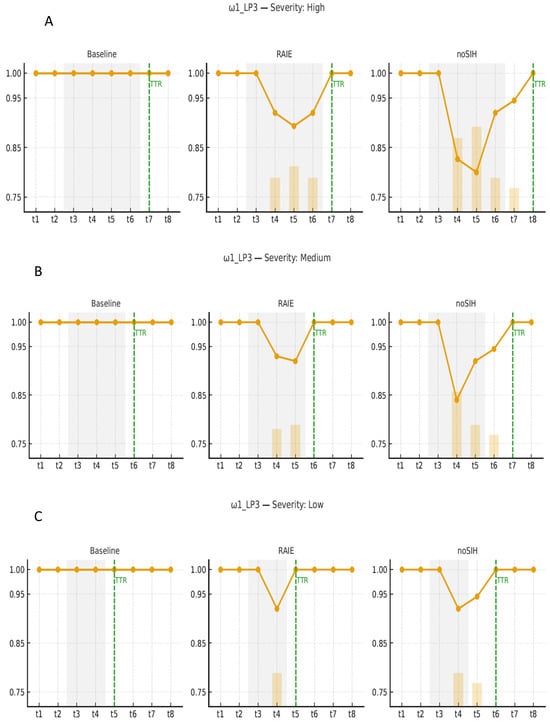

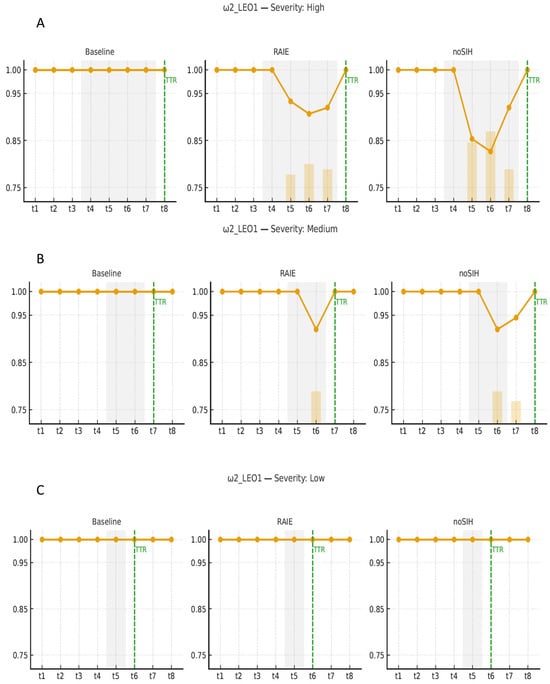

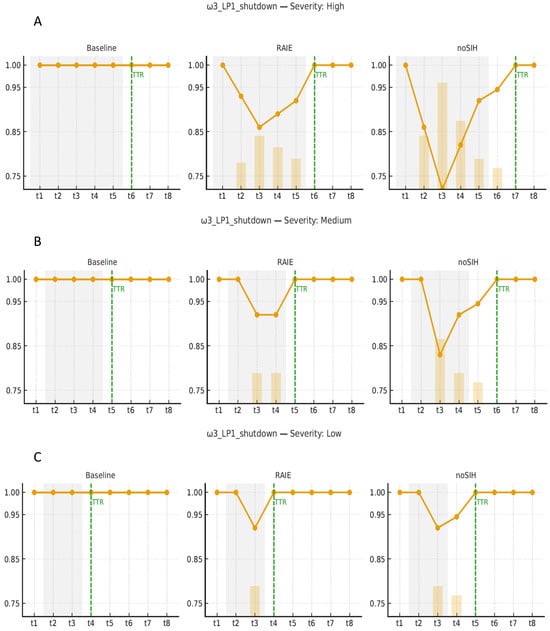

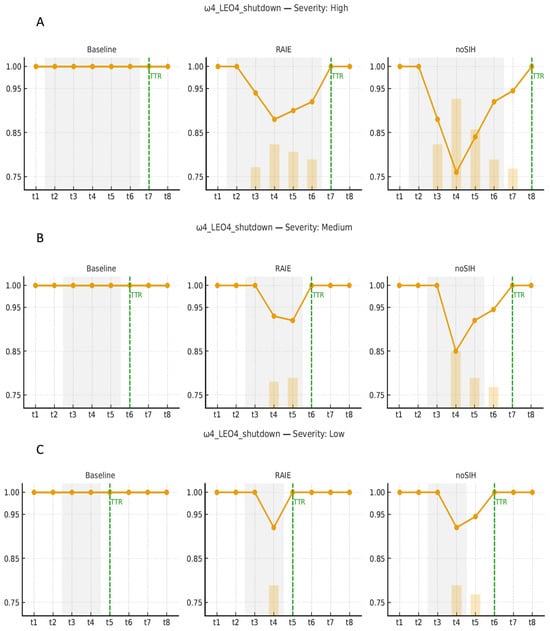

4.3.2. Results for Modeling Scenarios

The baseline network design (Phase I) was fixed, and on top of it, we executed the RAIE analysis (Phase II) with a set of scenarios Ω that represent operational perturbations at critical nodes with high, medium, and low severities. For each scenario ω ∈ Ω, two versions were run: with RAIE (innate–containment–memory layer active and adaptive reinforcements allowed) and without RAIE (non-SIH), while keeping demand, nominal capacities, and interruption windows identical. We report and compare the following groups of indicators:

- Viability/service: EO service (SL_EO), backlogs EO (BackEO), easibility, and the viability index (or ωOK/ωBad).

- Operational performance: Throughput by family (THR_LP, THR_LEO), aggregate capture (), nd average utilization at L-nodes.

- Resilience: (area under the normalized curve relative to baseline), (post-shock relative minimum), and TTR (time-to-recover to 95–100% of baseline, per tolerance).

- Immune cost: Penalty “overcost” of activating buffers, containment, stress-induced leakage, and adaptive reinforcements, in USD.

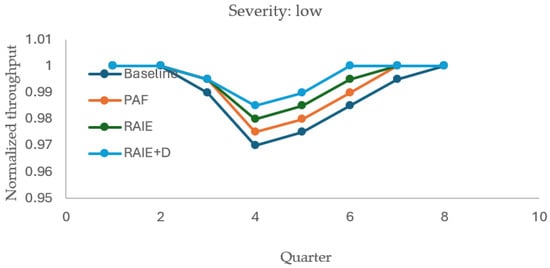

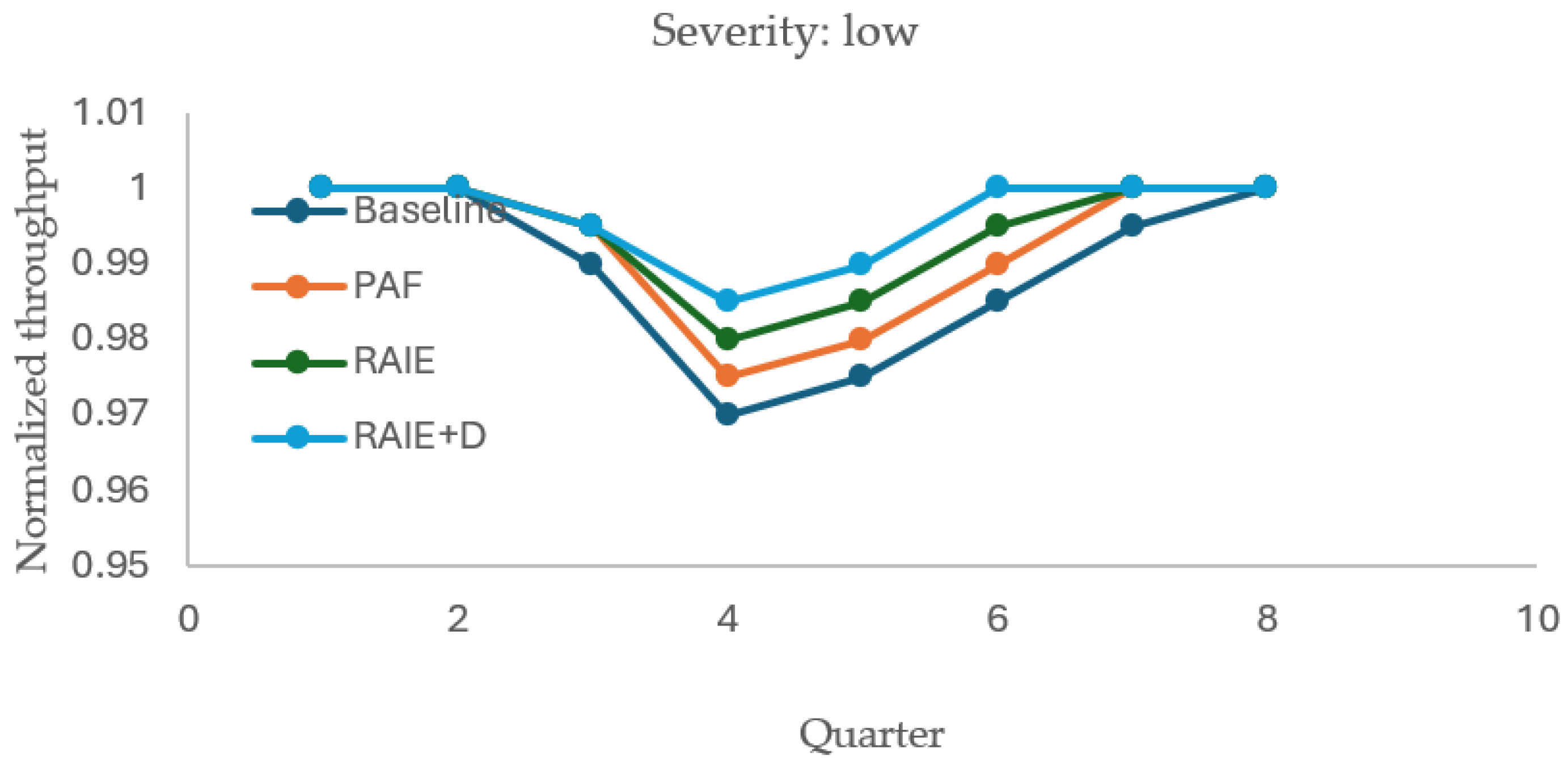

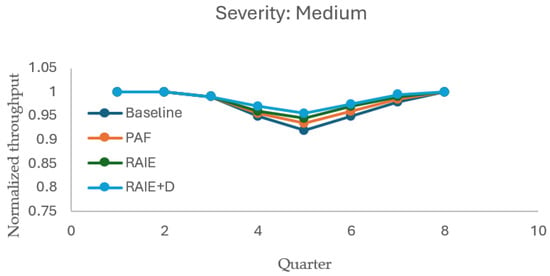

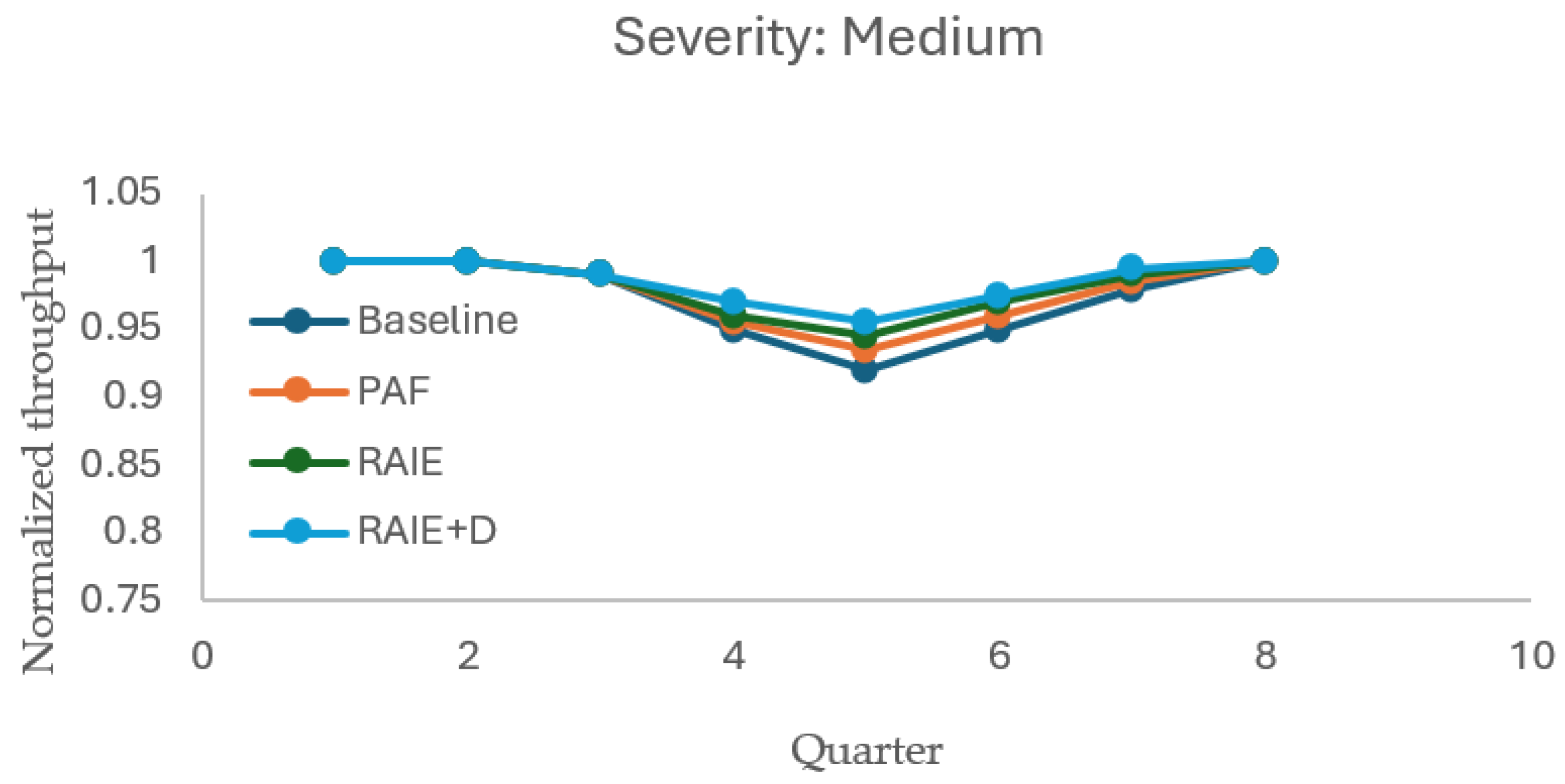

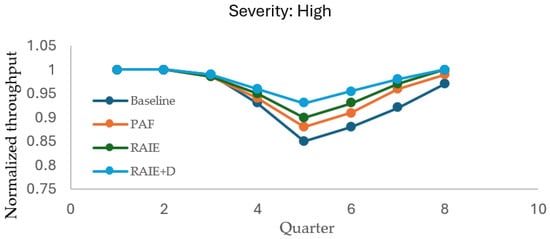

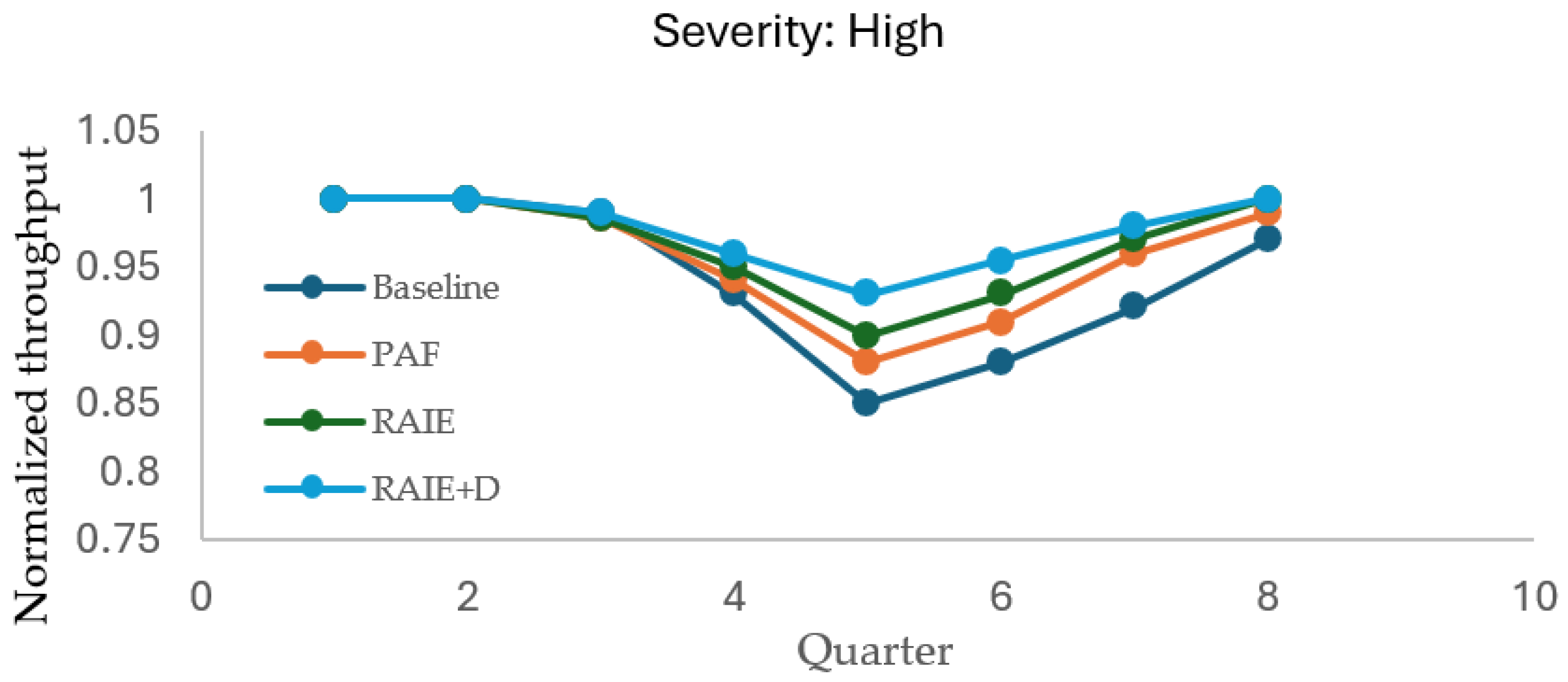

Qualitatively, the results exhibit a consistent pattern: RAIE stabilizes service and shortens TTR, at the expense of a moderate immune cost that is lower than both the economic cost of backlog and the capture/revenue losses observed when RAIE is disabled (Table 5).

Table 5.

Global KPIs (RAIE) across scenarios (Phase II).

Table 5 consolidates the quantitative comparison between RAIE-enabled and non-SIH configurations, showing how adaptive mechanisms influence the network’s response under equivalent disturbance conditions. For each scenario ω, matched values of , , TTR, and Immune Cost were obtained from RAIE-ON and non-SIH runs. Normality was verified through Shapiro–Wilk tests (p > 0.1 for all metrics). Paired t-tests at α = 0.05 were then applied, and when normality was not met, Wilcoxon signed-rank tests were used. Effect sizes (Cohen’s d = 0.8–1.1 for and TTR) denote large improvements, confirming the robustness of the adaptive response in the CCUS network.