Effect of Hydrogen Injection Strategy on Combustion and Emissions of Ammonia–Hydrogen Sustainable Engines

Abstract

1. Introduction

2. Test Methods

2.1. Engine Test Platform

2.2. Fuel and Experiment Method

2.3. Definition of Test-Related Parameters

3. Analysis of Results

3.1. Hydrogen Injection Timing

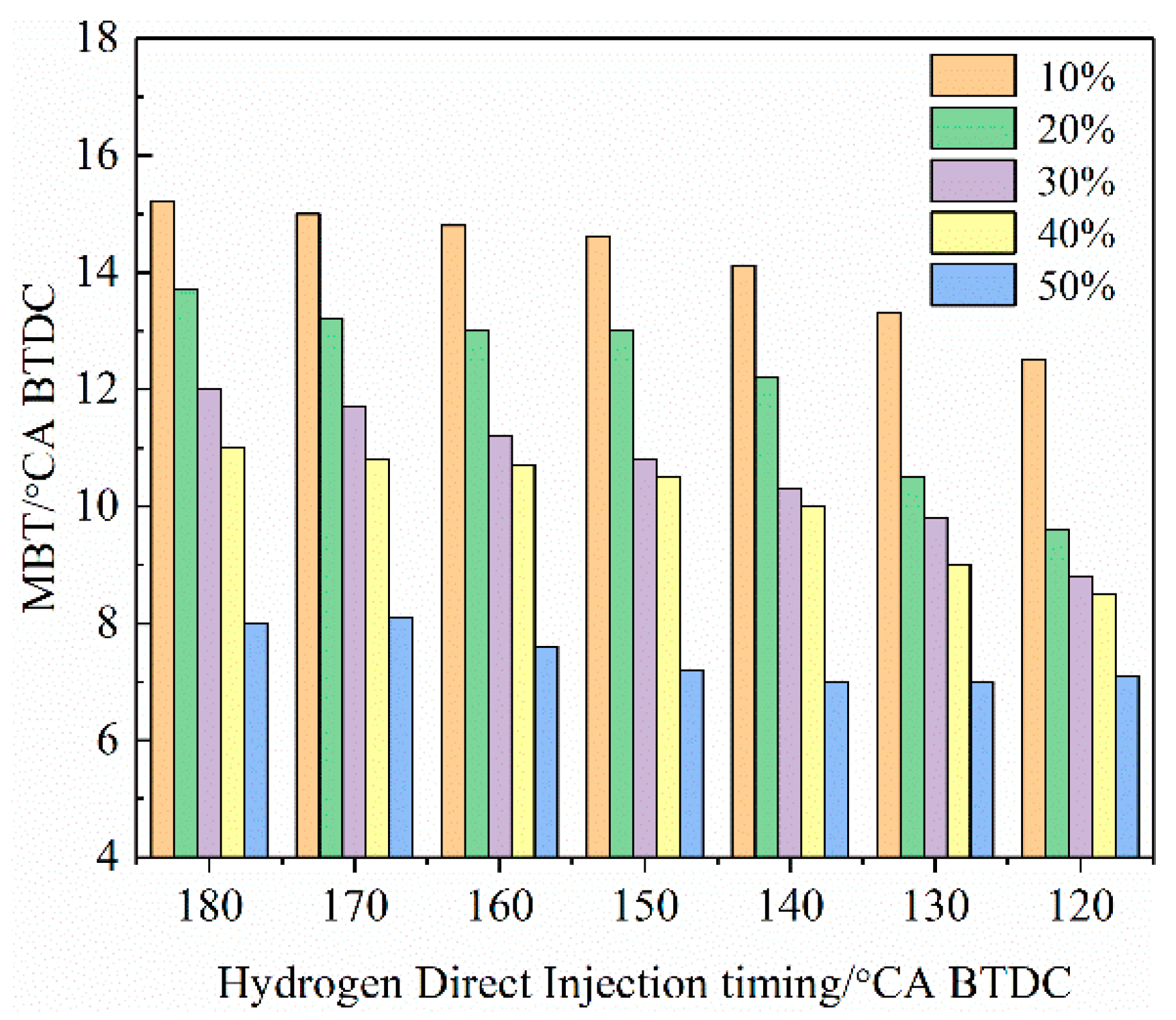

3.1.1. MBT

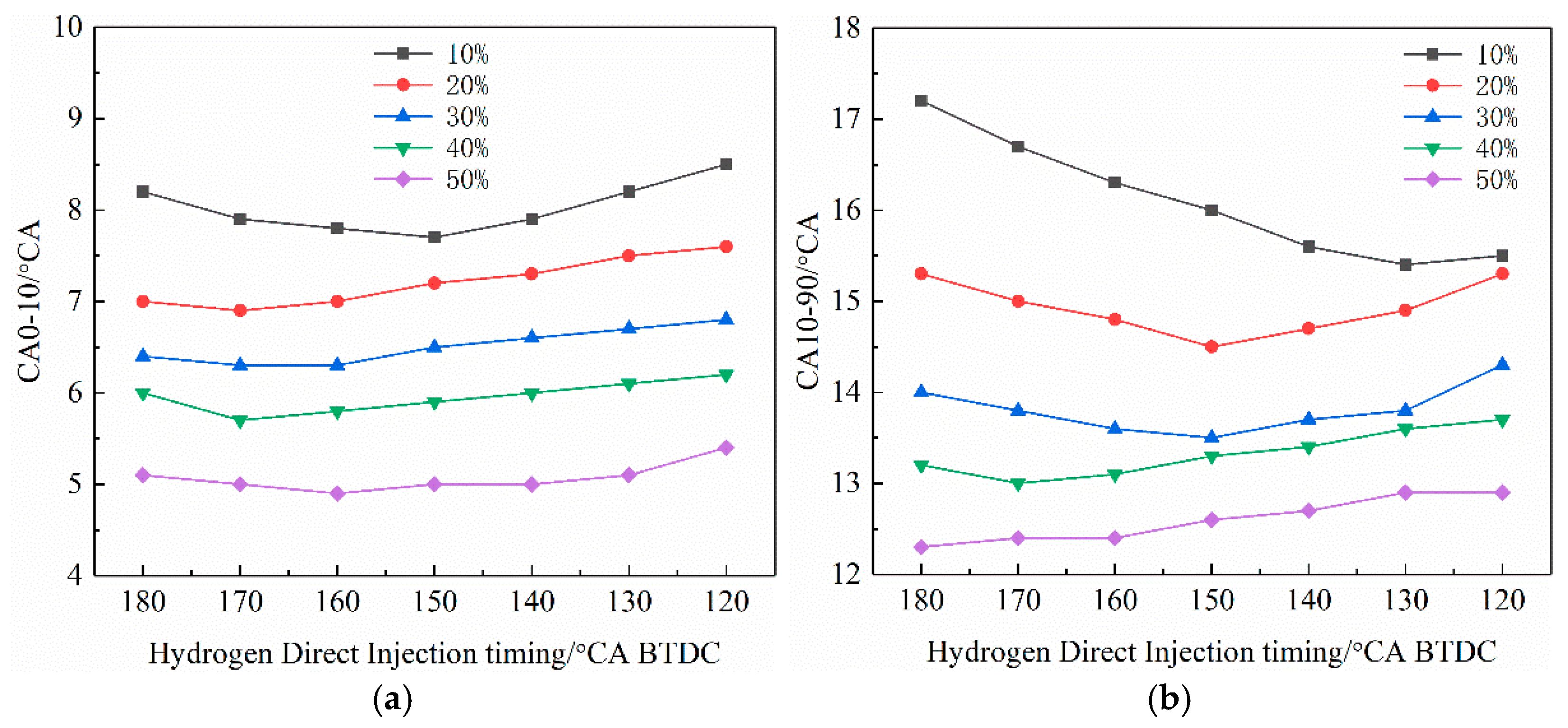

3.1.2. CA0-10 and CA10-90

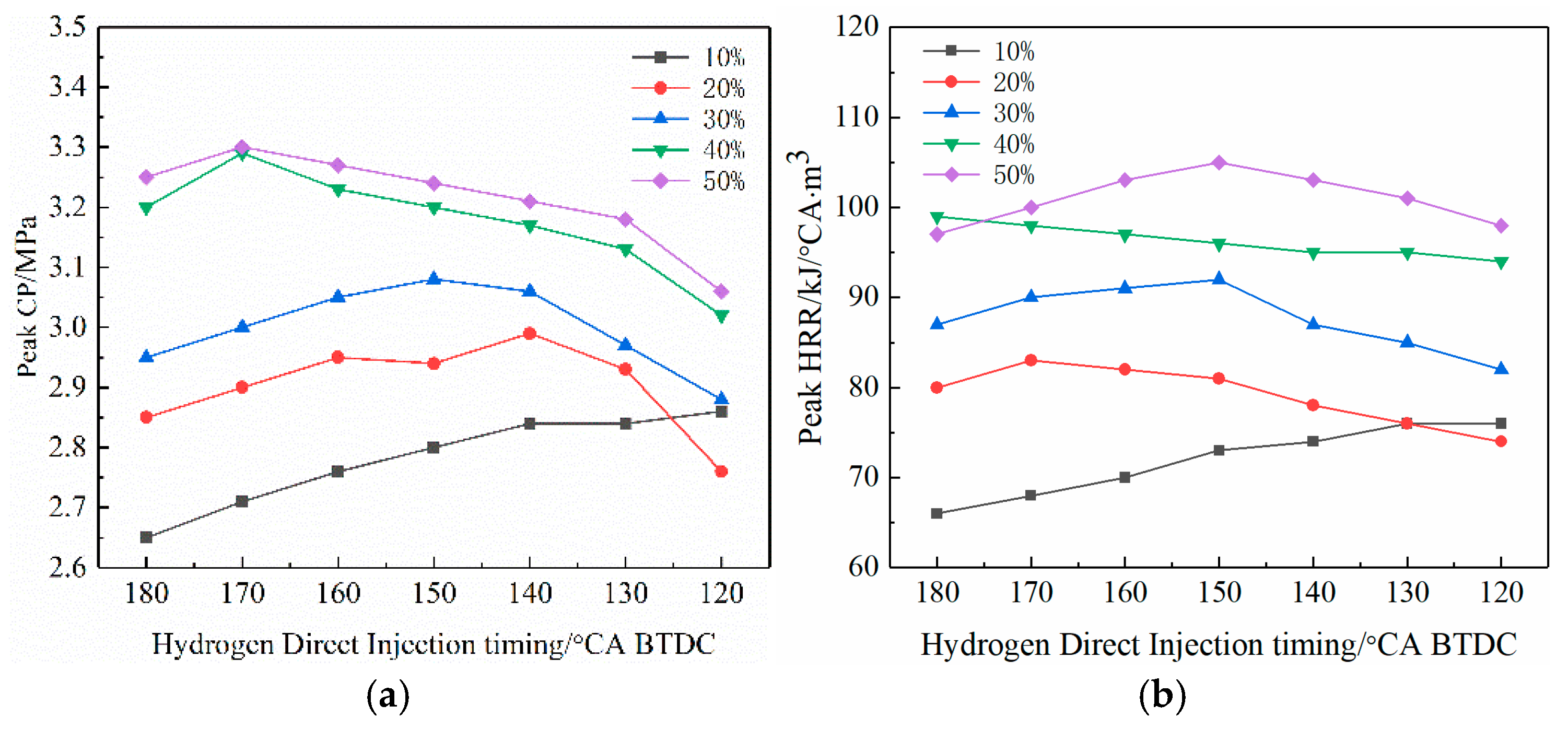

3.1.3. Peak CP and Peak HRR

3.1.4. COVIMEP

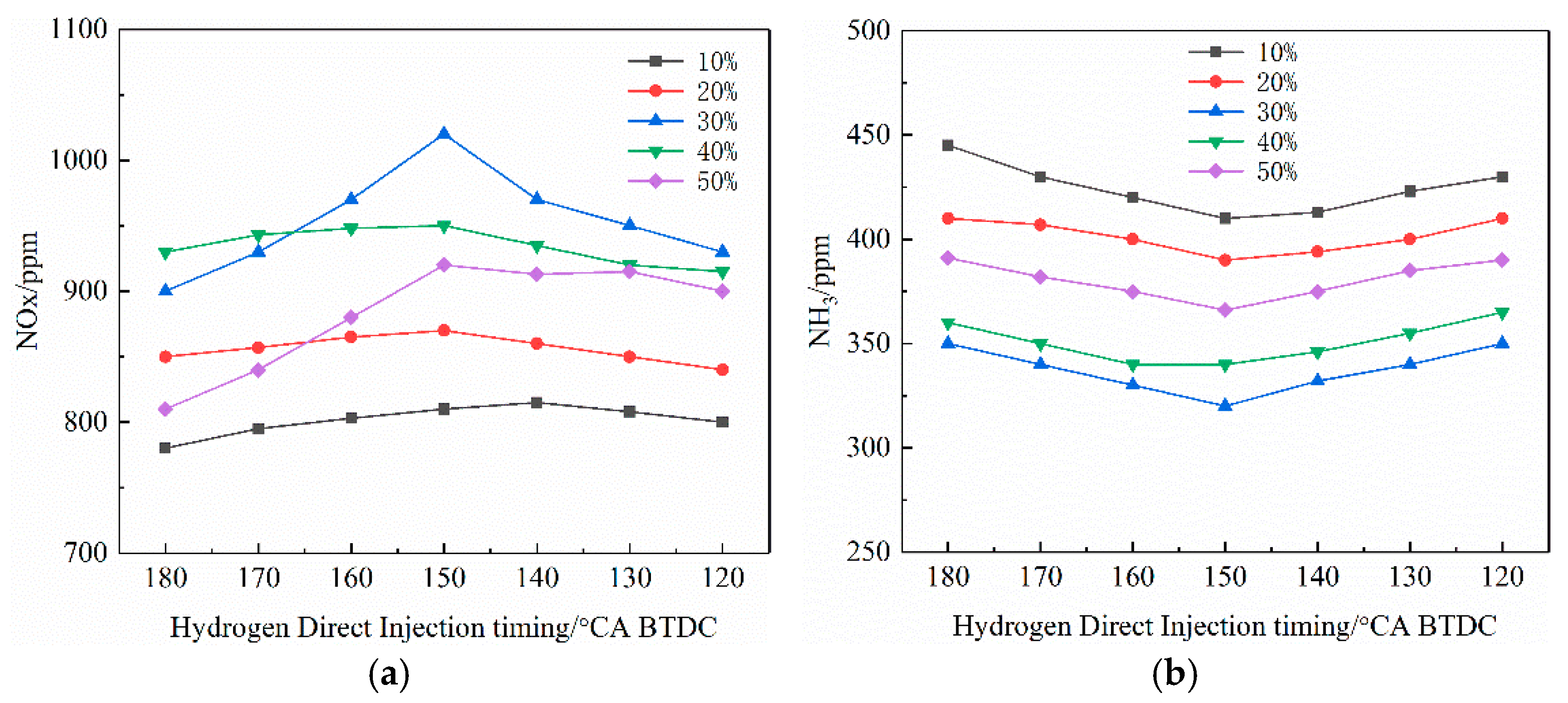

3.1.5. NOx and NH3

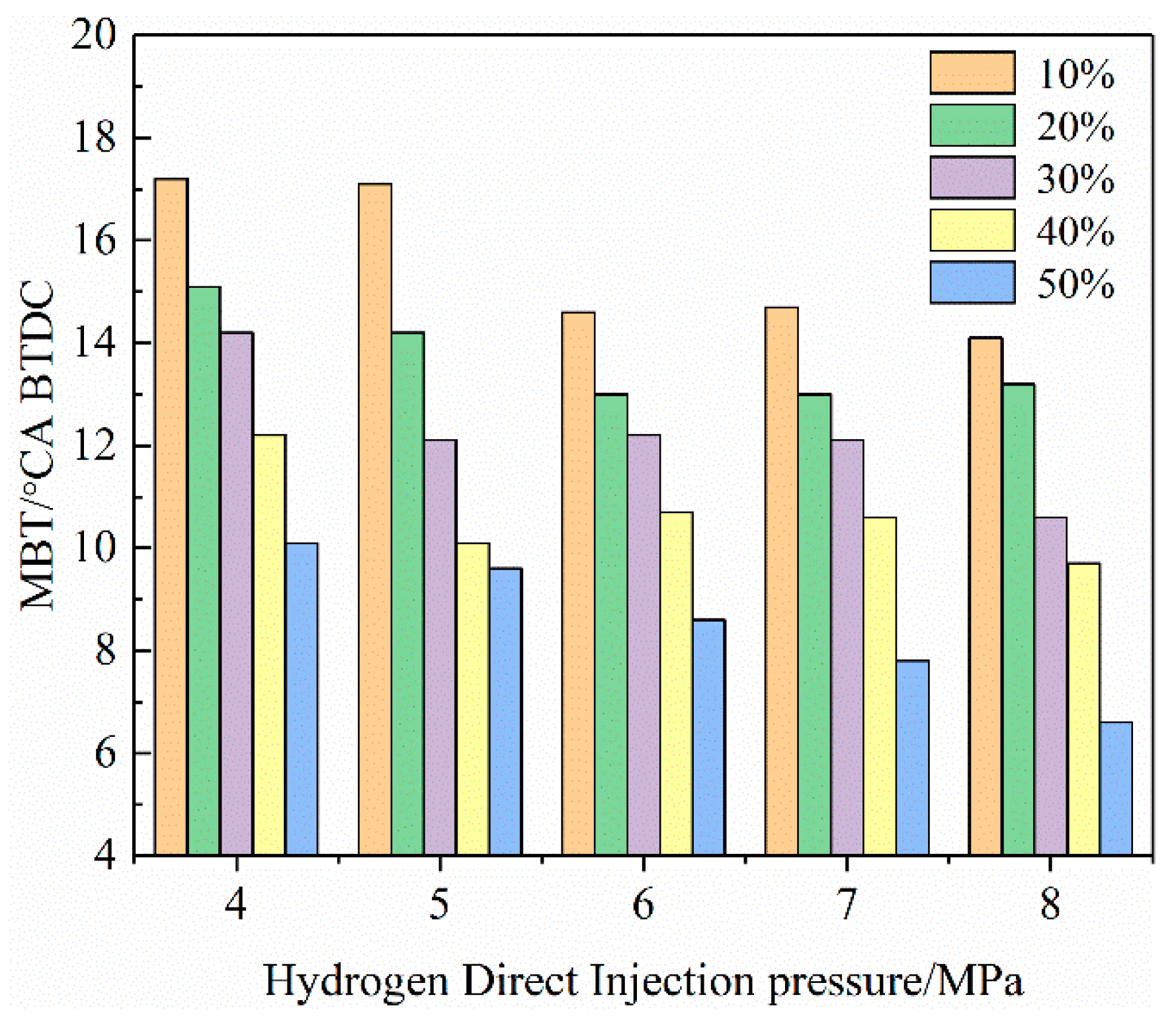

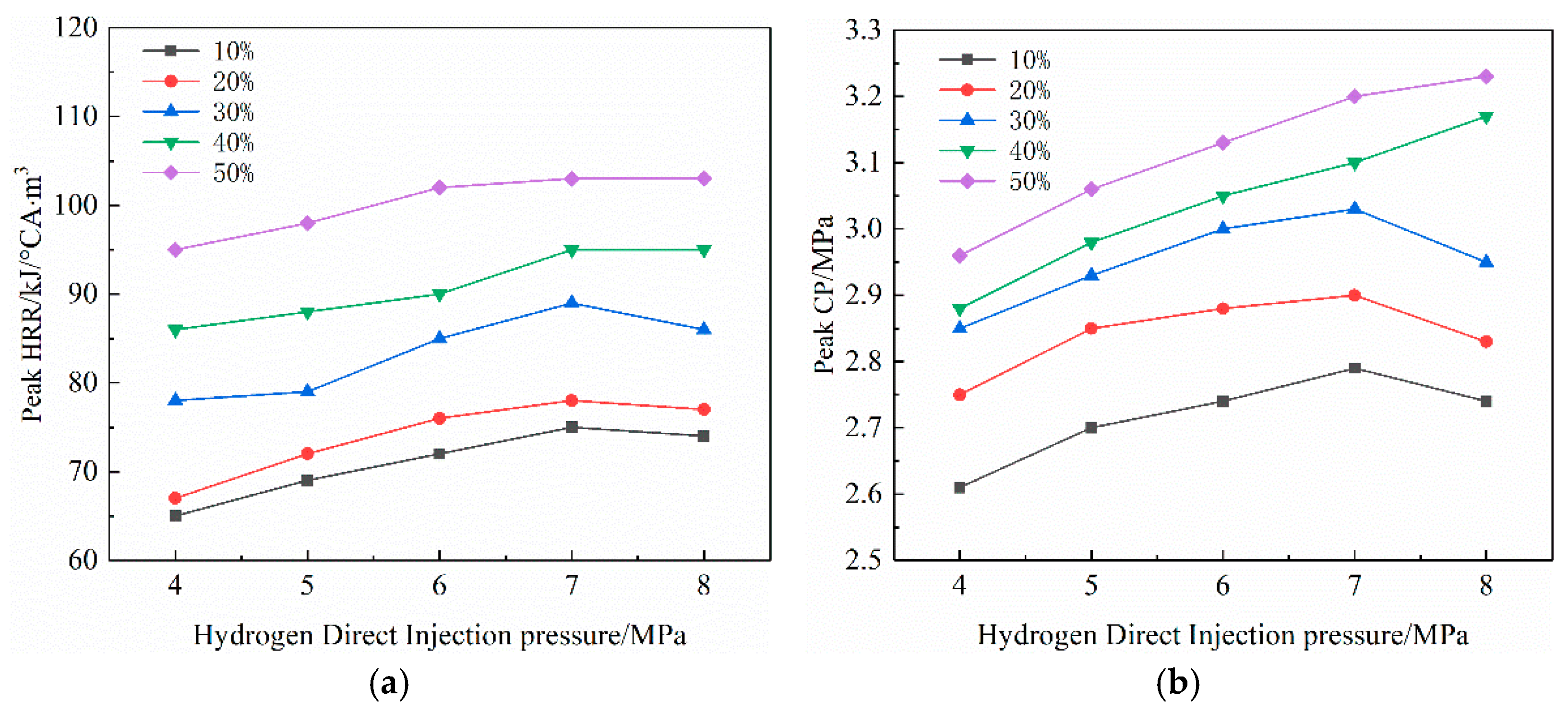

3.2. Hydrogen Injection Pressure

3.2.1. MBT

3.2.2. Peak CP and Peak HRR

3.2.3. COVIMEP

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MBT | minimum advance for best torque |

| COV | coefficient of variations |

| CA0-10 | flame development period |

| CA10-90 | rapid combustion period |

| IMEP | indicated mean effective pressure |

| HRR | heat release rate |

| CP | cylinder pressure |

References

- Sun, X.; Jiang, Y.C.; Zhao, P.; Jing, G.; Ma, T. Effect of ammonia/hydrogen blending and injection modes on combustion emission and performance of marine engine. Fuel 2024, 371, 131894. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, J.; Wang, S.; Zhang, Y. Ammonia-hydrogen direct injection in a rotary engine: A pathway to cleaner combustion. Energy 2025, 324, 135968. [Google Scholar] [CrossRef]

- Li, P.Z.; Pan, J.; Fan, B.; Qin, M.; Nauman, M.; Yang, W. Effects of injection timing and rotating speed on combustion and emissions in an Ammonia/Hydrogen rotary engine. Appl. Therm. Eng. 2025, 262, 125172. [Google Scholar] [CrossRef]

- Wang, B.; Wang, H.; Duan, B.; Yang, C.; Hu, D.; Wang, Y. Effect of ammonia/hydrogen mixture ratio on engine combustion and emission performance at different inlet temperatures. Energy 2023, 272, 127110. [Google Scholar] [CrossRef]

- Yu, Z.; Zhao, J.; Markov, V.; Han, D. Effects of hydrogen addition on ignition characteristics and engine performance of ammonia-hydrogen blended fuel: A kinetic analysis. Int. J. Hydrogen Energy 2024, 87, 722–735. [Google Scholar] [CrossRef]

- Yu, X.; Li, Y.; Zhang, J.; Guo, Z.; Du, Y.; Li, D.; Wang, T.; Shang, Z.; Zhao, Z.; Zhang, J. Effects of hydrogen blending ratio on combustion and emission characteristics of an ammonia/hydrogen compound injection engine under different excess air coefficients. Int. J. Hydrogen Energy 2024, 49, 1033–1047. [Google Scholar] [CrossRef]

- Ji, C.; Xin, G.; Wang, S.; Cong, X.; Meng, H.; Chang, K.; Yang, J. Effect of ammonia addition on combustion and emissions performance of a hydrogen engine at part load and stoichiometric conditions. Int. J. Hydrogen Energy 2021, 46, 40143–40153. [Google Scholar] [CrossRef]

- Xin, G.; Ji, C.; Wang, S.; Hong, C.; Meng, H.; Yang, J. Experimental study on the effect of hydrogen substitution rate on combustion and emission characteristics of ammonia internal combustion engine under different excess air ratio. Fuel 2023, 343, 127992. [Google Scholar] [CrossRef]

- Ji, C.; Qiang, Y.; Wang, S.; Xin, G.; Wang, Z.; Hong, C.; Yang, J. Numerical investigation on the combustion performance of ammonia-hydrogen spark-ignition engine under various high compression ratios and different spark-ignition timings. Int. J. Hydrogen Energy 2024, 56, 817–827. [Google Scholar] [CrossRef]

- Hong, C.; Ji, C.; Wang, S.; Xin, G.; Wang, Z.; Meng, H.; Yang, J. An experimental study of various load control strategies for an ammonia/hydrogen dual-fuel engine with the Miller cycle. Fuel Process. Technol. 2023, 247, 107780. [Google Scholar] [CrossRef]

- Sharma, G.; Dewangan, A.K.; Yadav, A.K.; Ahmad, A. Effect of hydrogen enrichment strategy on performance, combustion and emission characteristics of dual-fuel diesel engine: Recent progress, challenges and opportunities. J. Therm. Anal. Calorim 2025, 150, 10659–10679. [Google Scholar] [CrossRef]

- Khalid, A.H.; Said, M.F.M.; Veza, I.; Abas, M.A.; Roslan, M.F.; Abubaker, S.; Jalal, M.R. Hydrogen port fuel injection: Review of fuel injection control strategies to mitigate backfire in internal combustion engine fuelled with hydrogen. Int. J. Hydrogen Energy 2024, 66, 571–581. [Google Scholar] [CrossRef]

- Akhtar, M.U.S.; Asfand, F.; Khan, M.I.; Mishra, R.; Ball, A. Comparative analysis to assess the effects of hydrogen injection techniques on performance and emission characteristics of a compression-ignition engine. Case Stud Therm Eng 2025, 73, 106724. [Google Scholar] [CrossRef]

- Aboujafari, M. Numerical investigation of the effects of adding different gases on the performance and emissions of an ammonia-hydrogen dual-fuel engine. J. Environ. Manage 2024, 368, 122189. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, B.; Yang, C.; Hu, D.; Duan, B.; Wang, Y. Study on dual injection strategy of diesel ignition ammonia/hydrogen mixture fuel engine. Fuel 2023, 348, 128526. [Google Scholar] [CrossRef]

- Qi, Y.; Liu, W.; Liu, S.; Wang, W.; Peng, Y.; Wang, Z. A review on ammonia-hydrogen fueled internal combustion engines. eTrans 2023, 18, 100288. [Google Scholar] [CrossRef]

- Aboujafari, M. Numerical Investigation of the Effects of the Ammonia Injection Rate Shape and Timing on the Performance of an Ammonia-Hydrogen Dual-Fuel Engine. Emiss. Control Sci. Technol. 2025, 11, 4. [Google Scholar] [CrossRef]

- Lin, Z.; Liu, S.; Sun, Q.; Qi, Y.; Wang, Z.; Li, J. Effect of injection and ignition strategy on an ammonia direct injection–Hydrogen jet ignition (ADI-HJI) engine. Energy 2024, 306, 132502. [Google Scholar] [CrossRef]

- Rueda-Vázquez, J.M.; Serrano, J.; Pinzi, S.; Jiménez-Espadafor, F.J.; Dorado, M.P. A review of the use of hydrogen in compression ignition engines with dual-fuel technology and techniques for reducing Nox emissions. Sustainability 2024, 16, 3462. [Google Scholar] [CrossRef]

- Hong, C.; Ji, C.; Wang, S.; Xin, G.; Meng, H.; Yang, J.; Ma, T. An experimental study of a strategy to improve the combustion process of a hydrogen-blended ammonia engine under lean and WOT conditions. Int. J. Hydrogen Energy 2023, 48, 33719–33731. [Google Scholar] [CrossRef]

- Bakir, A.H.; Ge, H.; Zhang, Z.; Zhao, P. Computational investigation on spray autoignition of liquid ammonia with dissolved hydrogen in Spray D configuration. Fuel 2024, 371, 132124. [Google Scholar] [CrossRef]

- Dinesh, M.H.; Kumar, G.N. Experimental investigation of variable compression ratio and ignition timing effects on performance, combustion, and Nox emission of an ammonia/hydrogen-fuelled Si engine. Int. J. Hydrogen Energy 2023, 48, 35139–35152. [Google Scholar] [CrossRef]

- Yang, R.; Yu, Z.; Yue, Z.; Yao, M. Effect of fuel injection spatial and temporal arrangement on high-pressure direct-injection ammonia/diesel dual-fuel combustion. Fuel 2025, 387, 134409. [Google Scholar] [CrossRef]

- Yang, R.; Yue, Z.; Zhang, S.; Yu, Z.; Wang, H.; Liu, H.; Yao, M. A novel approach of in-cylinder NOx control by inner selective non-catalytic reduction effect for high-pressure direct-injection ammonia engine. Fuel 2025, 381, 133349. [Google Scholar] [CrossRef]

- Lu, C.; Chen, W.; Zuo, Q.; Kou, C.; Wang, H.; Zhu, G.; Ma, Y. Numerical investigation on gaseous fuel injection strategies on combustion characteristics and NO emission performance in a pure hydrogen engine. Fuel 2024, 363, 130911. [Google Scholar] [CrossRef]

- Pan, S.; Wang, J.; Huang, Z. Effects of hydrogen injection strategy on the hydrogen mixture distribution and combustion of a gasoline/hydrogen SI engine under lean burn condition. Int. J. Hydrogen Energy 2022, 47, 24069–24079. [Google Scholar] [CrossRef]

- Luo, H.; Yu, M.; Zhai, C.; An, Y.; Wang, C.; Nishida, K. Study on fermentation gas combustion with hydrogen addition under various throttle openings. Green Energy Resour. 2023, 1, 100003. [Google Scholar] [CrossRef]

- Luo, H.; Zhou, B.; Liu, Y.; Yu, J.; Zhai, C.; Nishida, K.; Ge, J. Characteristics of hydrogen enrichment on RNG combustion under various engine speeds in a retrofitted gas engine. Process Saf. Environ. Prot 2024, 188, 629–642. [Google Scholar] [CrossRef]

- Chen, W.; Lu, C.; Zuo, Q.; Kou, C.; Shi, R.; Wang, H.; Ning, D.; Shen, Z.; Zhu, G. Combustion characteristics analysis and performance evaluation of a hydrogen engine under direct injection plus lean burn mode. J. Cleaner Prod. 2024, 470, 143323. [Google Scholar] [CrossRef]

- Ramsay, C.J.; Dinesh, K.K.J.R.; Fairney, W.; Vaughan, N. A numerical study on the effects of constant volume combustion phase on performance and emissions characteristics of a diesel-hydrogen dual-fuel engine. Int. J. Hydrogen Energy 2020, 45, 32598–32618. [Google Scholar] [CrossRef]

- Liang, Z.; Xie, F.; Lai, K.; Chen, H.; Du, J.; Li, X. Study of single and split injection strategies on combustion and emissions of hydrogen DISI engine. Int. J. Hydrogen Energy 2024, 49, 1087–1099. [Google Scholar] [CrossRef]

- Chu, W.; Li, H.; Liu, Y.; Zhou, B.; Lou, H.; Kim, W. Three-dimensional simulation analysis of in-cylinder combustion in space in-orbit hydrogen–oxygen internal combustion engine. Appl. Therm. Eng. 2025, 263, 125391. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, B.; Luo, Q.; Bao, L.; Li, X.; Leach, F. Experimental multiple parameters optimization of the injection strategies for a turbocharged direct injection hydrogen engine to achieve highly efficient and clean performance. Energy 2024, 312, 133592. [Google Scholar] [CrossRef]

- Shi, C.; Ji, C.; Ge, Y.; Wang, S.; Yang, J.; Wang, H. Effects of split direct-injected hydrogen strategies on combustion and emissions performance of a small-scale rotary engine. Energy 2021, 215, 119124. [Google Scholar] [CrossRef]

- Bao, L.; Sun, B.; Luo, Q. Optimal control strategy of the turbocharged direct-injection hydrogen engine to achieve near-zero emissions with large power and high brake thermal efficiency. Fuel 2022, 325, 124913. [Google Scholar]

- Mi, S.; Wu, H.; Pei, X.; Liu, C.; Zheng, L.; Zhao, W.; Qian, Y.; Lu, X. Potential of ammonia energy fraction and diesel pilot-injection strategy on improving combustion and emission performance in an ammonia-diesel dual fuel engine. Fuel 2023, 343, 127889. [Google Scholar] [CrossRef]

| Fuel Characteristics | NH3 | H2 [15] |

|---|---|---|

| Calorific value (MJ/kg) | 18.8 | 120 |

| Density (g/L) | 0.771 | 0.089 |

| Octane rating | 130 | 105 |

| Minimum ignition energy (mJ) | 8 | 0.02 |

| Stoichiometric air–fuel ratio | 6.05 | 34.6 |

| Laminar combustion velocity (m/s) | 0.07 | 3.51 |

| Adiabatic flame temperature (°C) | 2110 | 1800 |

| Autoignition Temperature (°C) | 930 | 858 |

| Flame propagation speed (cm/s) | 7 | 291 |

| Engine-Related Parameters | Parameter Settings |

|---|---|

| Excess air ratio (λ) | 1 |

| RPM (r/min) | 1500 |

| Air intake flow rate (kg/h) | 66 |

| Hydrogen direct injection ratio (%) | 10, 20, 30, 40, 50 |

| First hydrogen direct injection timing (°CA BTDC) | 180, 170, 160, 150, 140, 130, 120 |

| Hydrogen direct injection pressure (MPa) | 4 |

| Ignition timing (°CA BTDC) | MBT |

| Hydrogen injection frequency | Single |

| Engine-Related Parameters | Parameter Settings |

|---|---|

| Excess air ratio (λ) | 1 |

| RPM (r/min) | 1500 |

| Air intake flow rate (kg/h) | 66 |

| Hydrogen direct injection ratio (%) | 10, 20, 30, 40, 50 |

| First hydrogen direct injection timing (°CA BTDC) | 180 |

| injection pressure (MPa) | 4, 5, 6, 7, 8 |

| Hydrogen injection frequency | Single |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, K.; Wu, H. Effect of Hydrogen Injection Strategy on Combustion and Emissions of Ammonia–Hydrogen Sustainable Engines. Sustainability 2025, 17, 9403. https://doi.org/10.3390/su17219403

Shao K, Wu H. Effect of Hydrogen Injection Strategy on Combustion and Emissions of Ammonia–Hydrogen Sustainable Engines. Sustainability. 2025; 17(21):9403. https://doi.org/10.3390/su17219403

Chicago/Turabian StyleShao, Kun, and Heng Wu. 2025. "Effect of Hydrogen Injection Strategy on Combustion and Emissions of Ammonia–Hydrogen Sustainable Engines" Sustainability 17, no. 21: 9403. https://doi.org/10.3390/su17219403

APA StyleShao, K., & Wu, H. (2025). Effect of Hydrogen Injection Strategy on Combustion and Emissions of Ammonia–Hydrogen Sustainable Engines. Sustainability, 17(21), 9403. https://doi.org/10.3390/su17219403