Abstract

Waste prevention is at the top of the EU Waste Framework directive hierarchy. With this in mind, this article considers the application of novel technologies in the Cultural Heritage Restoration and Conservation field through environmental and circular economy principles. While previous research has explored the use of wood waste for composite materials such as building insulation and concrete additives, the suitability of degraded historical wood waste for filament production and 3D printing has not yet been addressed. This article contributes to this topic by studying the PLA/wood composite, material composed of a polylactic acid (PLA) polymer matrix reinforced with wood particles, produced from degraded historical construction materials. The paper describes the process of producing filament from bio- and moisture-damaged pine beam and oak parquet, followed by the 3D printing of historical platband replica. Research methods include photogrammetry, filament machine construction, filament production and 3D printing. The machines settings used in the process: heater temperatures were set to 140 °C, 90 °C and 105 °C; servo speed was 33 s; spool tension was 12.5; winding speed was 24 RPM; and screw speed was 9.2 RPM. For material preparation, a mixture containing 25% pine and oak sawdust and PLA dust was processed to achieve particle sizes of 312 μm, 471 μm, and 432 μm, respectively. Filament production was carried out with diameters of 2.85 mm for the pine/PLA composite and 1.75 mm for the oak/PLA composite. Finally, replica samples were fabricated using 3D printing. The dual objective of this research was to develop the method of 3D printing from degraded historical materials and introduce it to restoration practice as a wood waste minimization technique. Perspectives for further study include the testing of 3D-printed construction materials in outdoor conditions, and pellet production to achieve a higher wood content, compared to the filament thread. The processes described are adaptable to a variety of materials and disciplines.

1. Introduction

1.1. Problem Statement

Architectural elements and traditional carpentry practices of historical value are increasingly at risk of being lost due to material degradation, insufficient documentation, and limited preservation efforts. Wood waste is typically either recycled or incinerated for energy production. Regardless of the historical value, construction wood waste is generally divided into two groups according to chemical features: (a) impregnated or heavily covered or painted, for example, lacquered wooden boards, is milled and burned for energy production; and (b) uncovered or lightly covered is milled to sawdust and used for particle boards production [1]. This paper also contributes to the EU construction waste directive fulfilment [2] by offering a prevention approach to avoid wood waste. This study shows that sawdust consisting of century-old historical deteriorated wood waste (pine beam and oak parquet) are suitable for PLA/wood 3D-printed composite of a replication of an historical element. This article aims to raise environmental awareness and promote sustainable technologies for waste reduction.

1.2. Literature Context

Additive manufacturing (AM), particularly 3D printing [3], offers new approaches to wood waste treatment [4,5]. Fused deposition modeling (FDM) and fused filament fabrication (FFF) are extrusion-based 3D printing technologies widely studied for their cost efficiency and compatibility with PLA [6,7].

The topic is studied worldwide; for example, the Australian wood furniture sector [8] and in Nigeria, a new solution was proposed instead of burning residue sawdust [9]; in Hong Kong, three scenarios of greener products such organic polymer particleboard as were offered as an alternative solution for landfill disposal of wood waste [10]; in Poland, the rational way of using raw wood instead of burning (more than 61% of harvested timber in Europe) studied, as well as sawmills wood waste adaptation for wood-based panel production [11]. The variety of fabrication technologies, especially 3D printing, has developed in the past decade [12]. A critical issue concerning accuracy of scanning, 3D modelling, and the 3D printing of replicas of cultural heritage objects is studied in Italy [13]. The environmental impact of 3D-printed renewable PLA–wood composites compared to conventional products was previously investigated [14].

The biodegradation and application of PLA (polylactic acid) [15] in different disciplines is widely researched [16,17]. PLA is usually chosen as binder in PLA/wood composites for its low cost and low melting temperature [18]. Previously studied PLA/wood composites mechanical properties [19,20,21,22,23] made a good base for a current study. Despite these advances, most studies consider industrial wood residues or furniture waste rather than degraded historic wood, and they prioritize mechanical characterization over aesthetic authenticity and replication fidelity.

1.3. Research Gap

A summary of previous composite filament studies is presented in Table 1. Unlike previous studies that primarily investigate the mechanical or environmental performance of PLA/wood composites, this work focuses on their application in replicating structurally compromised historical artefacts, with particular attention to unique surface patterns in replication and replication accuracy fidelity in heritage contexts. The investigation of cost and EI of wood waste/PLA replica fabrication versus wood workshop replica production from new wood was carried out.

Table 1.

Summary of previous composite filaments from upcycled wood waste research.

2. Research Aim

The innovation of this work offers a new point of view on how the life cycle of a one-hundred-year-old platband could be extended in its 3D-printed prototype. The present research enlightens the way of fulfilment of the EU directive by reducing construction waste [2], and making restoration and conservation more sustainable. This paper investigates the suitability of historical wood waste which is in degraded for the filament production and 3D printing of PLA/wood waste composite. Calculation of prototype production cost, duration, and energy consumption added a strong argument to the investigation. Previous studies concerning PLA/wood composites, photogrammetry, and 3D printing have built a good base for this paper’s methodology.

3. Materials and Methods

3.1. Object Selection

This study investigated the suitability of degraded historical wood waste for producing a 3D prototype of a facade decoration element. To achieve the results, the selection of analytical techniques was combined with photogrammetry; filament machine design; construction and testing; grinding sawdust and PLA for filament production; and 3D printing.

The objective of this study was to select a facade decoration element in deteriorated condition, regarded as waste material. In further work, suitability of produced filament for 3D printing was investigated. The primary criterion for selecting the object was its complex cross-sectional shape, which posed challenges for both 3D modeling and 3D printing. A suitable spruce door platband was found amongst old construction material [31]. The platband source material is Spruce (Picea Abies), which refers to a mature wood group [32]. The platband was found in a waste container and collected by SRIK (SRIK—Säästva Renoveerimise keskus (Center of Sustainbale restoration)) personnel, which limited the possibility of conducting contextual or site-based analyses. The analysis of the platband cross-section revealed the absence of key criteria for dendrochronological dating: (a) a sufficient number of annual rings, and (b) the presence of bark or sapwood to determine the year the tree was felled. As the object had already been dismantled and showed no evidence of its origin, no further techniques were applied to investigate its origin. Similar elements related to the construction period of the first quarter of the twentieth century [33] are found in Tallinn city Nõmme district [34]. The platband (Figure 1) was covered with multiple paint layers, and had signs of moisture damage and plenty of nail holes.

Figure 1.

The door platband and its cross-section (a,b).

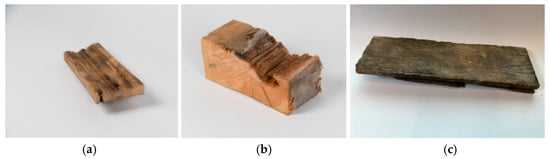

To address the size limitations of the 3D printer and photogrammetric modeling, the 1.5 m platband was cut into ~0.2 m sections. One section was then selected for 3D modelling. After being cleaned of paint layers and sanded (Figure 2), the sample showed significantly better condition than proposed. To achieve this study criteria of preparing filament from structurally compromised old wood, pine beam (Pinus sylvestris) (Figure 2) and oak parquet (Figure 2) with moisture and bio damage from the same construction period were added [35]. The physical properties of the chosen materials are shown in Table 2.

Figure 2.

Platband after cleaning (a), pine beam (b), and oak parquet piece (c).

Table 2.

Physical properties of platband, pine beam, and oak parquet pieces.

3.2. Three-Dimensional Modeling: Photogrammetry

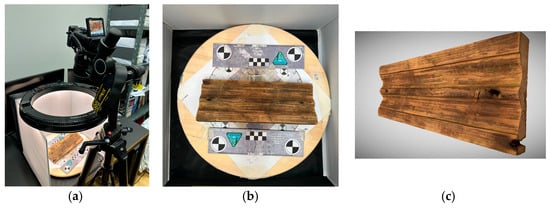

Object selection and preparation continued with 3D modeling (Figure 3). The following equipment was used: photo camera Nikon D850 with objective Nikon 150 mm micro tripod (Nikon Corporation, Shinagawa, Tokyo, Japan), LED ring light FalconEyes DVR-512DVC (FalconEyes, Shenzhen, China), tape measure, Adobe Lightroom (Version Classic 13.0), Agisoft Metashape Professional (Version 1.8.5), calibrated scale bars and markers, and a manual turntable.

Figure 3.

Photogrammetry imaging campaign (a,b) and platband 3D model (c).

The preparation of the captured image sets was a crucial step in the photogrammetric surveying workflow prior to high-accuracy 3D modeling. The use of Adobe Lightroom or comparable applications enabled the control and quality assessment of the image sets, representing an essential step in the workflow, especially when a macro lens was utilized. During the imaging campaign, capturing nail holes in the 3D models proved difficult, as their visibility in photographs depended on diameter, angle, and shape. The required shooting angles did not always guarantee their detection. In addition, nail holes on the sample were made with different angles, which made their reproduction more effort-demanding. All different positions of the wooden sample were processed separately, masked and arranged into one set. The workflow used Agisoft Metashape Professional to process photographs into a 3D model, and Blender 3.2.2 to manually add two nail holes.

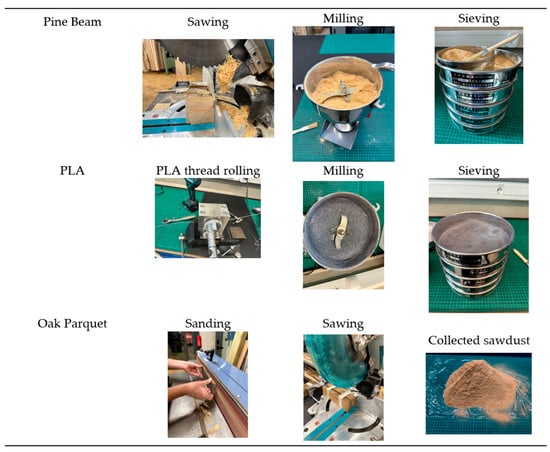

3.3. Sawdust and PLA Preparation

While PLA was melting during filament production and 3D printing, wood sawdust was ground to a particle size smaller than the printer nozzle diameter of 0.4 mm to avoid plumbing during 3D printing. For this study, eSUN PLA+ filament (Shenzhen eSUN Industrial Co., Ltd., Shenzhen, Guangdong, China) [36] was selected as a binder for sawdust due to its environmental friendliness, high-impact resistance, elongation at break, and toughness. Before milling, PLA was rolled to achieve a flat cross section for faster milling, sieved with 0.75 mm mesh for better mixing with sawdust. Pine beam and oak parquet were sawed into shaving and sawdust, which were collected with a previously cleaned vacuum cleaner installed with the saw.

For filament preparation, representative types of wood waste were selected based on their classification: impregnated (a piece of parquet with previous surface coating) and non-impregnated (an uncovered pine beam). To remove dirt and existing coatings, eight pieces of parquet were sanded before being sawn. Additionally, three pieces of pine timber beam were processed into shavings (Table 2). The second stage, milling sessions, were held with Hoapin electric grain mill (2000 g, 4000 W) and took place from February to April 2024. The mill was cooled for 15 min after every 30 s milling session to avoid the mill motor overheating.

After milling, the pine beam and oak parquet sawdust was sifted through the sieve with mesh sizes 24 (0.75 mm) and 100 (0.015 mm). The average particle size of pine, oak sawdust and PLA dust after sieving was 312 µm, 471 µm, and 432 µm, respectively, measured with microscope (Evident Scientific, Austin, TX, USA) [37]. The structure of the sawdust at 200 µm magnification is shown in Figure 4 and sawdust preparation stages in the Figure 5.

Figure 4.

Pine beam, and oak sawdust and PLA dust with a 200 µm extension.

Figure 5.

Sawdust and PLA preparation.

3.4. Determination of Printing Parameters

Previous studies have examined the auxetic characteristics of Laywood filament to assess its suitability for producing construction materials such as sandwich boards [38]. Its color changes to a darker shade at higher printing temperatures, an effect that can reproduce the appearance of natural wood growth rings [39]. The swelling behavior of its components—recycled wood and PLA—has also been investigated under varying temperature and humidity conditions. Moreover, printed copies have been shown to retain their shape in outdoor environments [40].

Laywood-D3 Flex and Laywood meta 5 (Lay-Filaments, Germany) recycled wood/PLA-based filaments were chosen for this study stage to determine Raise 3D Pro2 printer (Raise3D, Irvine, CA, USA) properties for subsequent wood waste/PLA composite 3D printing [41]. The objective of this stage was to determine optimal printing parameters—including temperature, speed, nozzle diameter, bed temperature, layer height, and interior pattern—for using wood-based filaments with the Raise 3D Pro2 printer. Future stage of this study is climate resistance testing of wood waste/PLA composites. Therefore, cold-sensitive materials were excluded entirely, even at the stage of preliminary printing trials or parameter determination. Laywood-D3 filament was excluded from this study due to cracking in temperatures below zero [42]. Therefore, composites printed with Laywood-D3 filament are unsuitable for outdoor applications.

4. Results

4.1. Filament Preparation

This research is novel in its investigation of the suitability of deteriorated historical construction materials for filament production and 3D printing.

This study accounts for differences in the densities of PLA dust, pine beam sawdust, and oak parquet sawdust by calculating proportions by volume rather than by weight, ensuring consistent composition between the two wood species.

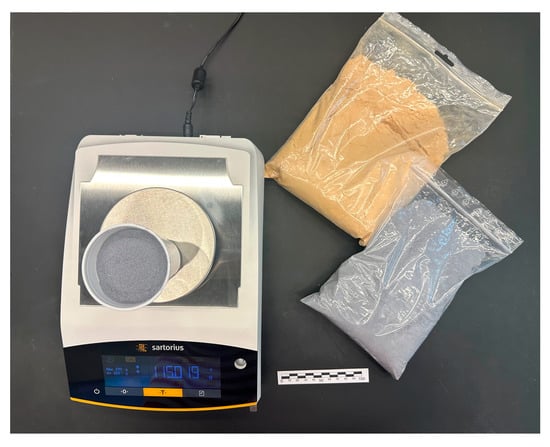

The workflow included calculation of the compression coefficient for PLA dust, pine beam sawdust, and oak parquet sawdust to account for the sensitivity of bulk materials to volume compression. Weighing employed an Entris Santorius BCE223-1S (Sartorius, Göttingen, Germany) [43].

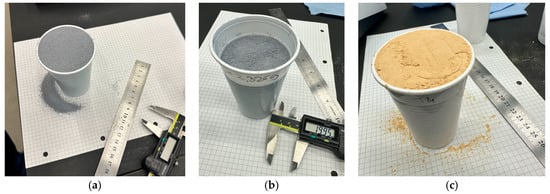

The workflow measured volumes before and after compression using a plastic cup with a calculated volume of 0.00023 m3, based on a water weight of 0.230 kg and a density of 1000 kg/m3. The procedure determined compaction coefficients for PLA dust, pine beam sawdust, and oak parquet sawdust by weighing each material under normal compression, applying additional compression, and weighing again. The calculation of the released volumes used these measurements and a 3D model for verification:

where V = released volume of the plastic cup, π ≈ 3.1416, r = radius of the plastic cup, h = height of the plastic cup, inner diameters of released volume of the plastic cup: D1 = 69.01 mm and D2 = 56.55 mm; height of volume: h = 19.96 mm; substituting with values:

where m normal compression = mass of bulk material in plastic cup with normal compression; m maximum compression = mass of bulk material in plastic cup with maximum compressed; V = volume of plastic cup. Normal compression of sawdust was measured without any mechanical compaction or shaking, reflecting its natural, loosely packed state. The maximum compression of sawdust in the plastic cup was obtained after constant shaking and mechanical pressure, until the volume was constant.

The same measurement and calculation were conducted with pine beam and oak parquet sawdust and compression coefficient calculated. The results are shown in Table 3 and Figure 6.

Table 3.

Results of the calculation of compression coefficient.

Figure 6.

PLA dust before and after maximum compression (a,b), and oak parquet sawdust before compression (c).

In the final stage sawdust and PLA proportions in future filament thread calculated. The volume and mass of the filled plastic cup was taken as 100%. To mix 30% of pine beam sawdust, the following formula was applied:

where V = volume of the plastic cup, pine beam sawdust m n.c. = pine beam sawdust mass with normal compression, pine beam sawdust c.c. = pine beam sawdust compression coefficient; substituting with values

(0.000231 × 0.3) × 0.043/0.000231/0.624 = 0.021 [kg]

(0.000231 × 0.7) × 0.122/0.000231/0.740 = 0.083 [kg].

Calculations were conducted for other percentages for pine beam and oak parquet sawdusts, and is presented in Table 4. Measuring the mass of PLA before mixing with sawdust is presented in Figure 7.

Table 4.

Results of wood sawdust and PLA percentage and its’ mass in the filament.

Figure 7.

Measuring the mass of PLA and sawdust before mixing.

The percentage of wood sawdust affects the flexibility of the filament thread. Filament containing 50% wood content cracked easily and could not be wound onto the bobbin. Filament with wood content of 30% was chosen as the most suitable for 3D printing.

4.2. Filament Thread

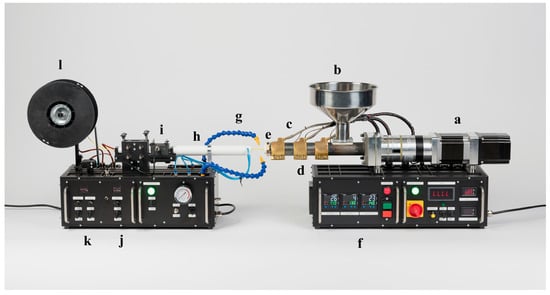

Especially for this study, the filament and winding machines were designed and constructed in the 3D Prototyping lab of Estonian Academy of Arts (Figure 8). The filament machine consisted of two Nema 34 stepper motors with digital stepper drivers and switching power supply (350 W, 60 V, 115/230 V) (a), funnel (b), three brass heaters (max 350 °C, 220 V, 210 W) (c), screw (vacuum quenching, diameter 20 mm, length 305 mm) in drilled barrel (290 mm) (d) with nozzle 1.75 mm (carbon steel) (e), three thread thermocouples (0.5 mm, M6, K-Type), and Nema 34 gear reducer.

Figure 8.

Filament and winding machines.

The process was as follows: after the machine was turned on and the heaters (f) reach the required temperature, the screw rotation was activated. The wood and PLA mixture were placed into the funnel and tamped to ensure even distribution, preventing empty spaces that could cause thread breaks. The process extruded the wood/PLA mixture at the required temperature, cooled the thread (g,h), and guided it through the winding system. A magnet sensor (i) monitored the filament diameter (1.75 mm), and the setup regulated drawing speed (j,k) to ensure consistent quality before winding the filament onto the bobbin (l) for 3D printer [44].

The first testing of the filament machine conducted in May 2024 with recycled PLA. The best thread production was defined at a 165 °C for all three heaters and 5.6 RPM rotating speed. Laboratory temperature during machine testing was 23° C and 45% of RH.

After successful machine tests with 100% recycled PLA and producing a suitable 3D printing filament thread, this study moved to adding sawdust and PLA mixture. For a wood/PLA filament, new PLA was used. Filament production was held in several stages, with the duration of each at approx. 1.5 h. The results of filament production with machine properties are shown in Table 5.

Table 5.

Results of the filament thread production and filament and winding machines’ settings.

Different materials pass through the nozzle at varying rates, each with its own optimal drawing speed. To ensure consistent filament winding, the spool speed were manually adjusted—either increased or decreased—so that the filament winds evenly. Additionally, as filament accumulated and the spool diameter grew, the winding speed is further modified to compensate. In the case of oak, its greater fragility necessitated slower processing speeds to maintain filament continuity and quality.

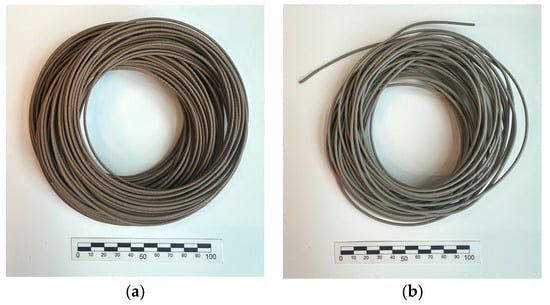

After 13 series of filament thread production, the most suitable proportion of 30% pine beam or 30% oak parquet sawdust (measured by volume with compression coefficient) and 70% PLA has achieved, shown in Figure 9. The best filament and winding machines settings for oak/PLA filament fabrication were determined. The heaters were set to temperature of 140/90/105 °C, servo speed was 33 s, spool tension was 12.5, winding machine spinning speed was 23 RPM; and filament machine screw spinning speed was 9.2 RPM.

Figure 9.

Filaments: (a) 30% oak/70% PLA, (b) 30% pine/70% PLA.

4.3. Three-Dimensional Printing with Wood-Based Filaments

Laywood filaments consist of apr. 35% recycled wood and 65% PLA [45], which is comparable to the wood waste/PLA filament chosen for 3D printing. This part of this study was required to determine printer parameters with the similar filament. During this part of this study, thread diameter reduction of 8.58% (average 0.0016 m, manufacturer’s 0.00175 m) was detected on a Laywood meta5 filament coil. To detect if the overdrying of filament caused thread diameter reduction, part of filament thread for S3 sample printing was moisturized (S3M).

This stage showed that Laywood filament is fragile, and the Raise 3D Pro 2 printer extruder was not suitable for this type of filament. Artillery Sidewinder SW-X2 3D Printer (Artillery3D, Shenzhen, China) was chosen for wood waste/PLA composite printing instead. Table 6 presents the printing parameters for wood waste/PLA composites.

Table 6.

Three-dimensional printer settings for the platband replica 3D printing.

The 3D printing sessions began with 1:1 scale platband prototypes, and Table 6 presents the Laywood replica results. The temperature-induced darkening of wood-containing filaments [46] is significant for historical prototypes, where visual similarity to the original is essential.

The pine/PLA prototype (h = 0.03 m) did not show significant shade differences with printing temperatures 220/230/240/250/260 °C in every 0.006 m layer, unlike the oak/PLA printed prototype, when gradient change to darker with printing temperature increase (Figure 10a,b).

Figure 10.

Three-dimensional-printed platband replicas showing shade variations with temperature for (a) oak/PLA and (b) pine/PLA composites.

The main difficulty during 3D-printed sessions of the both pine beam and oak parquet wood waste filaments was non-constant thread diameter. Thick thread got stuck in the printer extruders; on contrary, printer extruder was not able to roll thin thread to the nozzle.

Due to the higher oak parquet wood/PLA filament thread fragility, lower printing speed was applied during replica 3D printing. On the contrary, pine beam wood/PLA filament with diameter of 2.85 mm melted faster in the printer head and was not fragile, which allowed for printing with a higher speed (Table 6, sample S7). The findings showed that pine beam wood containing filament was not significantly sensitive to printing temperature increase, unlike the oak/PLA filament, which significantly changed shades to darker. Filament with diameter 2.85 mm (pine beam wood/PLA) allows for faster printing with the same printing quality as 1.75 (oak/PLA) filament. This study demonstrates that using a filament of larger diameter increases printing speed without compromising print quality.

4.4. Cost, Energy Consumption, and Environmental Impact

The Life Cycle Assessment (LCA) describes the environmental impact (EI) of all stages of the product life cycle from extraction of natural resources to disposal or recycling [47]. The LCA of historical wood waste could not be calculated, but LCA of PLA lifecycle environmental loadings could be researched. The eSUN PLA, used in this research as binder for wood sawdust, is produced from the corn grains, renewable and responsible material. Compared to PE and PP, which complete decomposition could last centuries and remain as a microplastic [48]. However, a broader EI of starch-based PLA products could even exceed the fossil-based analogs, mostly in eutrophication [49]. Previous research found out that the most energy-consuming part of PLA LCA stage is conversion, the optimization of which could decrease PLA EI [50].

This study compares the energy consumption and EI of wood waste–PLA composite production (length 0.2 m, 1:1 scale) to the replicas of new wood (Table 7).

Firstly, the electricity consumption (GreenBlue, Tarnowskie Góry, Poland) [51] and duration for all used equipment was measured or taken according to the device technical data. Then, EI was calculated according to energy consumption and consumed electricity cost calculated according to average electricity price in the process conduction moment. HVAC (HVAC systems = Heating, Ventilation, Air Conditioning. In this study, HVAC-related energy consumption (building-level climate control) were excluded from the reported values to focus on process-specific costs and energy use.) systems and indoor lighting were not taken into account.

Table 7.

Comparison of cost, duration, electricity consumption and EI.

Table 7.

Comparison of cost, duration, electricity consumption and EI.

| Nr. | Process/Devices That Consume Electricity | Power [W] | Duration [h] | Electric Consumption [kWh] | CO2 Emission [kgCO2] | Remuneration of Personnel [€/hour] | Remuneration of Personnel [€] | Av. * Electricity Price During Process Conduction [s/kWh] | Consumed Electricity Cost [s/kWh] |

|---|---|---|---|---|---|---|---|---|---|

| Wood waste/PLA composite, total | - | 42 | 8 | 6 | - | 648 | - | 77 | |

| 1 | Cleaning of platband [52] | 1000 | 0.167 | 0.167 | 0.116 | 13.371 | 2.233 | 11.36 | 1.898 |

| 2 | Sandpaper cleaning | - | 0.500 | - | - | 13.371 | 6.686 | - | - |

| 3 | Photogrammetry | - | 4.500 | - | - | 50.000 * | 225 | - | - |

| 4 | Photo camera Nikon D850 battery [53] | 7 | 0.667 | 0.005 | 0.004 | - | - | 11.36 | 0.057 |

| 5 | LED ring light FalconEyes [54] | 32 | 0.667 | 0.022 | 0.016 | - | - | 11.36 | 0.250 |

| 6 | Desktop computer [55], monitor [56] | 850 + 28.8 | 4.000 | 3.516 | 2.427 | - | - | 11.36 | 39.942 |

| 7 | Machine sanding (oak) [57] | 2200 | 0.250 | 0.550 | 0.38 | 13.371 | 3.343 | 8.25 | 4.538 |

| 8 | Sawing [58], vacuum cleaner [59] | 1800 + 1000 | 0.333 | 0.933 | 0.644 | 13.371 | 4.450 | 8.25 | 7.698 |

| 9 | Wood sawdust milling | 1468 | 0.010 | 0.015 | 0.011 | - | - | 8.25 | 0.124 |

| 10 | Wood sawdust milling | - | 4.51 | - | - | 13.371 | 60.303 | - | - |

| 11 | Wood sawdust sieving | - | 3.00 | - | - | 13.371 | 40.120 | - | - |

| 12 | PLA thread rolling with cordless drill [60,61] | 270 | 0.333 | 0.09 | 0.063 | 13.371 | 4.453 | 9.20 | 0.828 |

| 13 | PLA milling | 1468 | 0.010 | 0.015 | 0.011 | - | - | 9.20 | 0.138 |

| 14 | PLA milling | - | 4.510 | - | - | 13.371 | 60.303 | - | - |

| 15 | PLA sieving | - | 3.00 | - | - | 13.371 | 40.113 | - | - |

| 16 | Weighing and mixing | 1.5 | 0.083 | 0.001 | 0.001 | 13.371 | 1.114 | 9.20 | 0.010 |

| 17 | Filament machine | 838.1 | 1.500 | 1.258 | 0.869 | 13.371 | 20.057 | 9.20 | 11.574 |

| 18 | Winding machine | 31 | 1.500 | 0.047 | 0.033 | 13.371 | 20.057 | 9.20 | 0.433 |

| 19 | 3D printing | 100 | 11.889 | 1.189 | 0.821 | 13.371 | 158.968 | 7.52 | 8.942 |

| Platband replica, new wood, total | - | 3 | 3 | 2 | - | 95 | - | 30 | |

| 20 | Blades’ production with profiling machine [62] | 1500 | 1.333 | 2.000 | 1.38 | 48.243 * | 64.165 | 12.65 | 25.300 |

| 21 | Blades’ template [63] | 400 | 0.333 | 0.134 | 0.093 | 48.243 * | 16.065 | 12.65 | 1.696 |

| 22 | Thicknessing of blank [64] | 5500 | 0.017 | 0.094 | 0.065 | 13.371 | 0.228 | 12.65 | 1.190 |

| 23 | Plaining of the blank [65] | 3000 | 0.001 | 0.003 | 0.003 | 13.371 | 0.014 | 12.65 | 0.038 |

| 24 | Sliding table saw [66] | 4000 | 0.017 | 0.068 | 0.047 | 13.371 | 0.228 | 12.65 | 0.861 |

| 25 | Table miller [67] | 5000 | 0.008 | 0.040 | 0.0028 | 13.371 | 0.107 | 12.65 | 0.506 |

| 26 | Machine operation | - | 1 | - | - | 13.371 | 13.371 | - | - |

* Av.—average.

The calculation in Table 7 for the process Nr 1 was as follows: a heat gun (Stanley Black & Decker, New Britain, CT, USA) worked in several sessions on low heat with a total duration of 10 min (10/60 = 0.167 h), assuming the half of maximum possible electricity: 2000/2 = 1000 [W]. Electricity consumption is 1000 × 0.167/1000 = 0.167 [kWh]. Electricity price according to the weighted stock exchange price in September 2023 was 11.36 [s/kWh] [68]. Therefore, the consumed electricity cost was 11.36 × 0.167 = 1.898 [s/kWh].

According to the EU Environmental Agency greenhouse emission intensity of energy generation in Estonia in 2023 was 690 [g] = 0.690 [kg] of CO2e/kWh [69]. EI for the platband cleaning with heat gun is 0.167 × 0.690 = 0.116 [CO2e/kWh].

The remuneration of academic personnel was taken according to the Estonian Ministry of Finance salary survey held in 2024 [70]. The average gross hour salary for academic staff, junior researchers, in the amount of 25 671 [EUR] (13.371 EUR per hour) was multiplied with duration of every presented process. To calculate heat gun platband cleaning, the duration of 0.167 [h] was multiplied with 13.371 [EUR/hour]. The exception is photogrammetry and blade production, of which the hourly salaries were taken according to the invoice. The same calculation was conducted to the other positions.

During photogrammetry, 421 pictures were taken with use of 50% of battery storage (14 W), therefore 14 W/2 = 7 [W] was taken for calculation. The photo session lasted 40 min, converted into hours: 40/60 = 0.667 [h].

Milling with an electric mill was held for a total of 18 of 33 [s] long sessions, converting to the hours: 33 [s]/3600 [s/hour] = 0.01 [h]. The PLA thread rolling machine used the energy of the cordless drill, of which the battery lasts for 20 min of constant work: 20/60 = 0.333 [h], 90 [Wh]/0.333 = 270 [W].

According to the presented calculation, replica preparation from a new wood is much faster 3 [h], then production of PLA/wood waste composite 42 [h] with energy consumption of 8 [kWh] with total cost of 77 [s/kWh] and 3 [kWh] and 30 [s/kWh], respectively. The production of wood waste/PLA composite was three times higher than production of replica from the new wood.

For this calculation, only processes held in Prototyping lab or Wood Workshop were taken into consideration; therefore, the EI and energy consumption of production and transportation of PLA, new wood, devices and machines was not taken into account in this study stage.

5. Discussion and Conclusions

5.1. Key Findings and Interpretation

This study shows that bio-degraded historic wood waste (pine beam and oak parquet) can be compounded with PLA into printable filaments. The average particle sizes of pine, oak, and PLA dust after sieving are 312 µm, 471 µm, and 432 µm, respectively, confirming compatibility with 3D printer nozzle diameters of 1 mm and 0.8 mm. Sawdust losses occurred during sawing, milling, and sieving, as well as during filament fabrication. The best filament fabrication performance was detected with 30% wood waste content by mass. Consistent with prior reports, higher wood fractions increased brittleness and diameter variability. Printability windows of 220–260 °C and printing speed 2000–2400 mm/min with 0.2 mm layers were robust for the studied filaments. Notably, oak/PLA exhibited clear temperature-dependent shade darkening, which can be exploited to emulate growth-ring contrast and patination effects. Whereas pine/PLA showed less pronounced shade gradation under equivalent settings, a difference plausibly tied to species-specific extractives and thermal response [43]. The 2.85 mm pine/PLA filament—despite diameter variability—enabled a higher throughput at comparable surface quality, suggesting that larger-diameter feedstocks may partially mitigate filament fragility when printer hardware permits. Cost and environmental impact analyses showed that wood waste/PLA composites are more resource-intensive to produce than new wood replicas. This additional resource is balanced by sustainability benefits such as wood waste mitigation, circularity and potential EI reduction through wood materials’ life cycle prolonging.

5.2. Comparison with Prior Work

The finding that 30% of wood content is printable aligns with previous reports for wood-filled PLA in FDM/FFF, where 10–30% wood content is typically printable before embrittlement and feed failures occur [5,24,25,26,27,28,29,30]. The observed increase in fragility with a higher wood content is consistent with previous findings, which report increased hardness but reduced ductility and greater sensitivity to defects as wood loading rises [30]. The visual control (temperature-induced shading) parallels recent advancements in temperature-programmed “3D pyrography,” which embed tonal variation in printed wood composites. This supports its relevance for heritage replication, where aesthetic fidelity may take precedence over mechanical strength [12,13]. At the process level, our cost and energy comparison highlights that composite-based approaches can be more resource-intensive than traditional woodworking for small components, under the defined boundary conditions. This finding aligns with existing literature on the life cycle sensitivity of PLA to processing stages and system limitations [7,50].

Conversely, Fico et al. show environmental improvement at ~20% wood in specific scenarios [26,27]; together, these findings indicate that context and parameterization are decisive, and that AM routes may excel where geometric complexity, documentation scarcity, or material identity goals dominate [8,9,28,50].

This study aligns with recent zero-waste approaches in AM, such as those demonstrated previously [17] by highlighting how recycled plastic materials can be successfully integrated as a raw material into future filament fabrication supporting circular economy and sustainable practices [48,49,50]. The review on circular use of the market-available filaments produced from recycled plastic waste with self-production option was previously studied [49].

5.3. Implications for Heritage Practices

For small-to-medium architectural details with complex profiles, AM with PLA/wood composites sourced from the original element can deliver replication fidelity and stylistic control (e.g., tuned shade gradients) not easily achieved by substitution materials. The approach additionally preserves material identity by reintegrating the historic substance in altered form, an argument that may carry weight in interpretation and engagement, although it requires transparent documentation. However, the measured energy and time required (42 h; 8 kWh) compared to that of a workshop-made replica (3 kWh; 3 h) highlights the need for caution when making sustainability claims. These must be balanced against process intensification, and decision frameworks—combining significance assessment, aesthetic targets, and process impacts—are essential [48,49,50]. In the previous case study held in Piraeus Archaeological Museum, sustainably fabricated PLA replicas enriched the museum experience for visitors with disabilities. This study showed the challenges in determining the most effective 3D printing parameters for replicas optimal quality [48].

The technologies examined support sustainable restoration by preserving cultural traditions and reducing wood waste. Beyond material conservation, this study contributes to education and ethics in cultural heritage preservation, raising sustainability awareness across disciplines [71,72].

5.4. Limitations

Several constraints delimit inference:

- Mechanical performance was not measured; thus, structural claims are out of scope. The results target visual and geometric fidelity rather than load-bearing service.

- Moisture content of sawdust/filament was controlled procedurally (drying steps) but not reported numerically; moisture–printability links remain to be modeled.

- Filament diameter control exhibited variability that affected feeding; no closed-loop diameter feedback was implemented.

- Process-level comparison excluded upstream material production and facility HVAC/lighting; it is not a full LCA and should be read as a bounded operational comparison [50].

- Health-related risks: Strong allergic reactions were observed during sawing, milling, and sieving, highlighting the need for improved safety measures and protective protocols in future work.

- Ethical/interpretive considerations (e.g., authenticity, reversibility, and labeling of replicas) are context-dependent and require curatorial oversight beyond the technical scope.

5.5. Future Work

- Diameter control: Implement closed-loop laser micrometry with feedback to winding speed for diameter tolerance.

- Higher wood content via pellets: The highest wood content achieved (50% old wood/50% PLA) in filament thread was not suitable for printing, due to easy cracking. Achieving higher wood waste content may be possible with pellet-based extrusion. The design and construction of a pellet machine is planned for future research.

- Natural binder exploration: Evaluate pine–resin derivatives as bio-binders or co-binders to improve interfacial adhesion and recyclability of all-biogenic composites, building on evidence of resin improving thermal/mechanical behavior in bioplastics and cementitious composites [73,74,75]; position this as a controlled experiment, not as a claim from the present data. Pine–resin has already been studied as a sustainable additive to improve the thermal properties of thermoplastic starch as well as mechanical, thermal and structural properties of bioplastic [70] and pumice–cement composites [72], pine resin biodegradability [73]. The pine–resin application instead of PLA as binder could allow for 3D-printed wood waste composite recycling as a whole substance. Historical decoration element replicas produced with pine–resin instead of PLA have more advantages on the cultural heritage sites.

- Outdoor performance: We conducted accelerated weathering and natural exposure for climate resistance, biodegradability, water absorption, occurrence of patina to validate facade applicability.

- Mechanical and fracture testing of wood waste/composite replicas: Tensile and flexural properties and fracture behavior against prior PLA/wood studies inform the limits of use where incidental stresses occur [7,18,19,20,21,22,23,25,27].

- Decision frameworks ana LCA boundary expansion: Extend assessment to cradle-to-gate (or gate-to-gate) scenarios, incorporate energy mix sensitivities, and codify heritage-specific decision criteria (significance, material identity, aesthetics, interventions).

5.6. Concluding Synthesis

This study demonstrated that filaments with a content of 30% wood waste/70% PLA filaments produced from bio-degraded historic wood waste can be printed into visually faithful replicas of architectural elements, with tunable shading that supports appearance matching. While process burdens can exceed those of a conventional workshop replica for small parts under our boundary conditions, the heritage value proposition—preserving material identity, enabling complex geometries, and controlling surface aesthetics—justifies the method in selected cases. The approach complements, rather than replaces, traditional practice. Advancing process control, bio-based binders, and outdoor validation will be pivotal to responsible, scalable adoption in conservation workflows [12,21,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,71,72]. This study also demonstrated educational value, as the methodology was applied by a Master’s student in the Design Department at the Estonian Academy of Arts to assess sustainable practices in fashion design. The broader societal relevance of this research has been recognized through public science communication initiatives [74,75].

Funding

This research is funded by the LIFE IP BuildEST project (LIFE20 IPC/EE/000010, Pursuing Estonian national climate ambition through smart and resilient renovation); and the Estonian Academy of Arts.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

Conflicts of Interest

The author declares that she has no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Abbreviations

The following abbreviations are used in this manuscript:

| FDM | Fused deposition modeling |

| LCA | Life Cycle Assessment |

| PE | Polyethylene |

| PP | Polypropylene |

| EI | Environmental impact |

| PLA | Polylactic acid |

| FFF | Fused filament fabrication |

References

- Gineiko, A. Representative of Estonian Environmental Services AS. Phone Interview, 22 January 2024. [Google Scholar]

- European Commission. Waste Framework Directive. Energy, Climate Change, Environment. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en (accessed on 1 April 2025).

- What Is Additive Manufacturing. Built In. Available online: https://builtin.com/3d-printing/additive-manufacturing (accessed on 7 March 2024).

- Löschke, K.S.; Mai, J.; Proust, G.; Brambilla, A. Microtimber: The Development of a 3D Printed Composite Panel Made from Waste Wood and Recycled Plastics. In Digital Wood Design; Bianconi, F., Filippucci, M., Eds.; E-Publishing Inc.: Cham, Switzerland, 2019; pp. 827–848. [Google Scholar]

- Pringle, A.M.; Rudnicki, M.; Pearce, J.M. Wood Furniture Waste—Based Recycled 3-D Printing Filament. For. Prod. J. 2017, 68, 86–95. [Google Scholar] [CrossRef]

- Divakaran, N.; Das, J.P.; PV, A.K.; Mohanty, S.; Ramadoss, A.; Nayak, S.K. Comprehensive review on various additive manufacturing techniques and its implementation in electronic devices. J. Manuf. Syst. 2022, 62, 477–502. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef]

- Daian, G.; Ozarska, B. Wood waste management practices and strategies to increase sustainability standards in the Australian wooden furniture manufacturing sector. J. Clean. Prod. 2009, 17, 1594–1602. [Google Scholar] [CrossRef]

- Owoyemi, J.M.; Zakariya, H.O.; Elegbede, I.O. Sustainable wood waste management in Nigeria. Environ. Socio-Econ. Stud. 2016, 4, 1–9. [Google Scholar] [CrossRef]

- Hossain, U.; Poon, C.S. Comparative LCA of wood waste management strategies generated from building construction activities. J. Clean. Prod. 2017, 177, 387–397. [Google Scholar] [CrossRef]

- Zbieć, M.; Franc-Dąbrowska, J.; Drejerska, N. Wood Waste Management in Europe through the Lens of the Circular Bioeconomy. Energies 2022, 15, 4352. [Google Scholar] [CrossRef]

- Balletti, C.; Ballarin, M.; Guerra, F. 3D printing: State of the art and future perspectives. J. Cult. Heritage 2017, 26, 172–182. [Google Scholar] [CrossRef]

- Balletti, C.; Ballarin, M. An application of integrated 3D technologies for replicas in cultural heritage. ISPRS Int. J. Geo-Information 2019, 8, 285. [Google Scholar] [CrossRef]

- Govedič, T.B.; Tomec, D.K.; Kuzman, M.K.; Oblak, L.; Glavonjic, B. Environmental assessment/evaluation of 3D printing and 3D printing with wood-PLA composites—Case study. Drv. Ind. 2024, 75, 49–58. [Google Scholar] [CrossRef]

- McKeown, P.; Jones, M.D. The Chemical Recycling of PLA: A Review. Sustain. Chem. 2020, 1, 1–22. [Google Scholar] [CrossRef]

- Hussain, M.; Khan, S.M.; Shafiq, M.; Abbas, N. A review on PLA-based biodegradable materials for biomedical applications. Giant 2024, 18, 100261. [Google Scholar] [CrossRef]

- Kantaros, A.; Laskaris, N.; Piromalis, D.; Ganetsos, T. Manufacturing Zero-Waste COVID-19 Personal Protection Equipment: A Case Study of Utilizing 3D Printing While Employing Waste Material Recycling. Circ. Econ. Sustain. 2021, 1, 851–869. [Google Scholar] [CrossRef]

- Bhayana, M.; Singh, J.; Sharma, A.; Gupta, M. A review on optimized FDM 3D printed Wood/PLA bio composite material characteristics. Mater. Today Proc. 2023, 63, 311–318. [Google Scholar] [CrossRef]

- Bhagia, S.; Lowden, R.R.; Erdman, D., III; Rodriguez, M., Jr.; Haga, B.A.; Solano, I.R.M.; Gallego, N.C.; Pu, Y.; Muchero, W.; Kunc, V.; et al. Tensile properties of 3D-printed wood-filled PLA materials using poplar trees. Appl. Mater. Today 2020, 21, 100832. [Google Scholar] [CrossRef]

- Siddiqui, V.U.; Yusuf, J.; Sapuan, S.; Hasan, M.Z.; Bistari, M.M.M.; Mohammadsalih, Z.G. Mechanical Properties and Flammability Analysis of Wood Fiber Filled PLA Composites Using Additive Manufacturing. J. Nat. Fibers 2024, 21, 2409868. [Google Scholar] [CrossRef]

- Chien, Y.C.; Wu, J.H.; Shu, C.H.; Lo, J.T.; Yang, T.C. Closed-Loop Recycling of 3D-Printed Wood–PLA Composite Parts: Effects on Mechanical and Structural Properties via Fused Filament Fabrication. Polymers 2024, 16, 3002. [Google Scholar] [CrossRef]

- Ecker, J.V.; Haider, A.; Burzic, I.; Huber, A.; Eder, G.; Hild, S. Mechanical properties and water absorption behaviour of PLA and PLA/wood composites prepared by 3D printing and injection moulding. Rapid Prototyp. J. 2019, 25, 672–678. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. Fracture studies of 3D-printed PLA-wood composite. Procedia Struct. Integr. 2022, 37, 97–104. [Google Scholar] [CrossRef]

- Keerthana, M.; Reddy, V.D.; Nayak, B.R.P. Study and investigation on 3D printed wastewood and walnut filament with epoxy resin LY566 by using FDM. Int. J. Multidiscip. Res. 2024, 6, 1–9. [Google Scholar] [CrossRef]

- Maslej, M.; Wojnowska, M.; Peliński, K.; Słonina, M.; Smardzewski, J. Experimental Testing of Elastic Properties of LayWood Pyramidal Cores, BioResources. Available online: https://bioresources.cnr.ncsu.edu/resources/experimental-testing-of-elastic-properties-of-laywood-pyramidal-cores/ (accessed on 25 June 2025).

- Fico, D.; Rizzo, D.; Malinconico, F.; Corcione, C.E. A sustainable approach to recycling waste: Examples of the application of 3D printing to extend the life cycle of materials. Detritus 2024, 28, 60–69. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Palumbo, E.; Corcione, C.E. Development and characterization of sustainable PLA/Olive wood waste composites for rehabilitation applications using Fused Filament Fabrication (FFF). J. Build. Eng. 2022, 56, 104673. [Google Scholar] [CrossRef]

- Cengiz, Ö.; Aktepe, Ş. Evaluation of the Potentiality of Wood and Processing Dust as Sustainable Raw Materials for 3 Dimensional (3D) Printers. Eur. J. Sci. Technol. 2022, 38, 143–150. [Google Scholar] [CrossRef]

- Narlıoğlu, N.; Salan, T.; Alma, M.H. Properties of 3D-Printed Wood Sawdust-Reinforced PLA Composites. BioResources 2021, 16, 5467–5480. [Google Scholar] [CrossRef]

- Spohr, D.L.; Sánchez, F.A.L.; Marques, A.C. Estudo da viabilidade de fabricação de filamentos compósitos sustentáveis para impressão 3D a partir de uma matriz PLA reforçada com resíduos de fibras de madeira. Mix. Sustentável 2021, 7, 115–126. [Google Scholar] [CrossRef]

- Information Centre for Sustainable Renovation (ING). Available online: https://renoveeri.net/about-us (accessed on 12 December 2023).

- Veski, A. Carpenter’s and Furniture Maker’s Handbook; Estonian National Publishing House: Tallinn, Estonia, 1962; pp. 7–8. [Google Scholar]

- Private House Is Located on Lauliku 48, Nõmme District, Tallinn. The Same Original Wooden Door Platband Is Found on the Facade. According to the Estonian Construction Register, the First Information About This Building Is from 1923. (Building code 101005249). Available online: https://livekluster.ehr.ee/ui/ehr/v1/building/101005249 (accessed on 12 December 2023).

- Nõmme Self-Management Started to Be a Part of Tallinn City Since 1940. Source: Pöördeline 1940—Nõmme Museum. Available online: https://www.nommemuuseum.ee/artikkel/poordeline-1940/ (accessed on 23 January 2024).

- Gineiko, A. Supplementary Materials “Herne Street Residential Housing Construction Project with Construction Permission (2024)”; Zenodo: Geneva, Switzerland, 2025. [Google Scholar] [CrossRef]

- eSUN. eSUN PLA Pro Filament 3D Printer PLA Plus Filament PLA Pro. eSUN. Available online: https://www.esun3d.com/pla-pro-product/ (accessed on 24 April 2025).

- Olympus. BX53M Upright Microscope. Evident Scientific. Available online: https://evidentscientific.com/en/products/upright/bx53m (accessed on 23 September 2025).

- Smardzewski, J.; Wojciechowski, K.W.; Poźniak, A. Auxetic Lattice Truss Cores Fabricated by Laywood. BioResources 2018, 13, 8714–8727. [Google Scholar] [CrossRef]

- Molitch-Hou, M. An Interview with Wood Filament Inventor Kai Parthy, 3D Printing Industry. 14 February 2014. Available online: https://3dprintingindustry.com/news/journey-laywoo-d3-interview-wood-filament-inventor-kai-parthy-23357/ (accessed on 14 December 2023).

- Kliem, S.; Tahouni, Y.; Cheng, T.; Menges, A.; Bonten, C. Biobased Smart Materials for Processing via Fused Layer Modeling. AIP Conf. Proc. 2020, 2289, 020034. [Google Scholar] [CrossRef]

- Raise3D Pro2 3D Printer, Raise3D. Available online: https://www.raise3d.com/products/raise3d-pro2-3d-printer/ (accessed on 25 June 2025).

- 3Dfilamenten.nl, LayWoo-d3 Filament—1.75 mm—0.25kg. Available online: https://www.3dprima.com/filaments/special-filament-1-75mm/laywoo-d3-filament-1-75-mm-0-25kg_20285_1063 (accessed on 14 December 2023).

- Entris® II Essential Line Milligram Balance 220 g|1 mg|Sartorius. Available online: https://shop.sartorius.com/ww/p/entris-ii-essential-line-milligram-balance-220-g1-mg-external-adjustment/BCE223-1S#documentsTabHeader (accessed on 22 April 2025).

- Artillery Sidewinder SW-X2 3D Printer. Artillery3d. Available online: https://eu.artillery3d.com/products/artillery-sw-x2-fdm-3d-printer-larger-printed-size-300x300x400mm?shpxid=584d9c74-b3fa-4e6a-91bf-549e7864aaf2 (accessed on 22 April 2025).

- The Last Wood Bender: Kai Flexes His New Wood 3D Printing Filament, 3D Printing Industry. 2020. Available online: https://3dprintingindustry.com/news/the-last-wood-bender-kai-flexes-his-new-wood-3d-printing-filament-49540/ (accessed on 25 June 2025).

- Moon, K.J.; Yi, J.; Savage, V.; Bianchi, A. 3D printed pyrography: Using wood filament and dynamic control of nozzle temperature for embedding shades of color in objects. Addit. Manuf. 2024, 83, 104064. [Google Scholar] [CrossRef]

- Finnveden, G.; Potting, J. Life cycle assessment. In Encyclopedia of Toxicology, 3rd ed.; Wexler, P., Ed.; E-Publishing Inc.: Amsterdam, The Netherlands, 2014; pp. 74–77. [Google Scholar] [CrossRef]

- Mosomi, E.K.; Olanrewaju, O.A.; Adeosun, S.O. Pivotal role of polylactide in carbon emission reduction: A comprehensive review. Eng. Rep. 2024, 6, e12909. [Google Scholar] [CrossRef]

- Forfora, N.; Azuaje, I.; Kanipe, T.; Gonzalez, J.A.; Lendewig, M.; Urdaneta, I.; Venditti, R.; Gonzalez, R.; Argyropoulos, D. Argyropoulos, Are starch-based materials more eco-friendly than fossil-based? A critical assessment. Clean. Environ. Syst. 2024, 13, 100177. [Google Scholar] [CrossRef]

- Ghomi, E.R.; Khosravi, F.; Ardahaei, A.S.; Dai, Y.; Neisiany, R.E.; Foroughi, F.; Wu, M.; Das, O.; Ramakrishna, S. The life cycle assessment for polylactic acid (PLA) to make it a low-carbon material. Polymers 2021, 13, 1854. [Google Scholar] [CrossRef]

- Energy Meter 7-Mode 230VAC 16A White 3680W—Oomipood. Available online: https://www.oomipood.ee/en/product/GB350F_energiakulu_mootja_7_reziimi_230vac_16a_valge_3680w (accessed on 30 April 2025).

- Stanley Heat Gun: 2000W Heat Gun with Kitbox|STANLEY. Available online: https://cee.stanleytools.global/product/fme670k-qs/2000w-heat-gun-kitbox (accessed on 30 April 2025).

- Support Articles. Available online: https://www.nikonimgsupport.com/eu/BV_article?articleNo=000044904&configured=1&lang=en_GB (accessed on 30 April 2025).

- DVR-512DVC Bi-Color Dimmable LED Ring Light. Falcon Eyes. Available online: https://www.falconeyeshk.com/product-page/dvr-512dvc?srsltid=AfmBOorTJzwQ9hpo7Q_3z2BDI_VVo7zEGOXAGldjs08ebVhAFWkVPOVY (accessed on 9 May 2025).

- Computer Power Supply: EVGA Corporation, Brea, CA, USA, SuperNOVA 650W/750W/850W/1000W P5 Platinum Power Supply User Manual. EVGA (2021). Available online: https://www.evga.com/support/manuals/files/220-P5-1000-X1.pdf (accessed on 12 May 2025).

- Dell 27inch 4K UHD Computer Monitor—S2721QS|Dell Technologies, Round Rock, TX, USA. Dell. Available online: https://www.dell.com/en-us/shop/dell-27-4k-uhd-monitor-s2721qs/apd/210-axlg/monitors-monitor-accessories#techspecs_section (accessed on 12 May 2025).

- HV 80 OSZI|Bernardo Maschinen GmbH, Mudersbach, Germany. Available online: https://www.bernardo.at/en/shop/Edge-sanding-machine-with-oscillation-HV-80-OSZI--400-V~p86347 (accessed on 14 May 2025).

- LS1219L—Chopping and Miter Sa. Makita Corporation, Anjo, Japan. Available online: https://www.makita.ee/product/ls1219l.html (accessed on 14 May 2025).

- WD 2 Plus Wet and Dry Vacuum Cleaner. Alfred Kärcher GmbH & Co. KG, Winnenden, Germany. [Video]. Alfred Kärcher GmbH & Co. KG. Available online: https://www.kaercher.com/ee/home-garden/vee-ja-tolmuimejad/wd-2-plus-v-12-4-18-16280000.html (accessed on 14 May 2025).

- Makita. DDF083—Cordless Drill. Makita Corporation, Anjo, Japan. Available online: https://www.makita.ee/product/ddf083.html (accessed on 14 May 2025).

- Makita. BL1850B—18V LXT® Lithium-Ion 5.0Ah Battery. Makita Corporation, Anjo, Japan. Available online: https://www.makitatools.com/products/details/BL1850B (accessed on 14 May 2025).

- UT.MA SRL—Construction of Grinders and Sharpening Machines and Accessories for Sharpening Operations—Model P20 CNC. UT.MA SRL, Barberino Tavarnelle, Tuscany, Italy. Available online: https://www.utma.it/english/utma-profiling-machines-p20-cnc.html (accessed on 13 May 2025).

- Blade Template Produced with Contour Motion. Schneeberger, Rapperswil-Jona, Switzerland (2 April 2025). Schneeberger—Contour Motion. Available online: https://www.contourmotion.com/suppliers/schneeberger/ (accessed on 13 May 2025).

- Griggio. PSA 520 Thicknessing Machine User Manual. Griggio SpA, San Vendemiano, Italy. Available online: https://wtp.hoechsmann.com/en/lexikon/16464/psa_520 (accessed on 14 May 2025).

- Griggio. PF 310 Surface Planer User Manual. Griggio SpA, San Vendemiano, Italy. Available online: https://www.griggiomachinery.com/en/product/classic-machine/serie-pf/ (accessed on 14 May 2025).

- Altendorf Group. Altendorf WA 80—Altendorf Group. Altendorf GmbH & Co. KG, Minden, Germany. 2024. Available online: https://www.altendorfgroup.com/en/machines/altendorf-wa-80/ (accessed on 14 May 2025).

- Klipphausen, H.G.D. MINI-MAX T 45 CLASSIC—WOOD TEC PEDIA. SCM Group, Rimini, Italy. Available online: https://wtp.hoechsmann.com/en/lexikon/26959/mini-max_t_45_classic (accessed on 14 May 2025).

- Weighted Average Stock Exchange Prices over the Last 12 Months. Alexela. Available online: https://www.alexela.ee/en/viimase-12-kuu-kaalutud-keskmised-borsihinnad (accessed on 13 May 2025).

- Greenhouse Gas Emission Intensity of Electricity Generation in Europe. European Environment Agency’s Home Page. 2024. Available online: https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emission-intensity-of-1 (accessed on 12 May 2025).

- Ministry of Finance. Salary Survey of State Administrative and Administrative Institutions, State-Established Foundations and Public Institutions 2024. 2024. Available online: https://www.fin.ee/sites/default/files/documents/2024-09/Riigi%20ameti-%20ja%20hallatavate%20asutuste%2C%20riigi%20asutatud%20sihtasutuste%20ning%20avalik-%C3%B5iguslike%20asutuste%20palgauuring%202024.pdf (accessed on 12 May 2025).

- Aldas, M.; Ferri, J.M.; Lopez-Martinez, J.; Samper, M.D.; Arrieta, M.P. Effect of pine resin derivatives on the structural, thermal, and mechanical properties of Mater-Bi type bioplastic. Appl. Polym. Sci. 2019, 137, 48236. [Google Scholar] [CrossRef]

- Bicer, A.; Celik, N. Influence of pine resin on thermo-mechanical properties of pumice-cement composites. Cem. Concr. Compos. 2020, 112, 103668. [Google Scholar] [CrossRef]

- Jutila, L.; Layek, R.; Javanshour, F.; George, L.; Sarlin, E.; Kanerva, M. Effects of Pine Rosin on the Degradation of Mechanical Performance in Flax-Reinforced Polymeric Composites after Soil Burial at Low Temperatures. BioResources 2023, 18, 899–925. [Google Scholar] [CrossRef]

- Estonian Academy of Sciences. Winners of the Best Young Researchers in the “Science in Three Minutes” Competition Announced. Estonian Academy of Sciences. 2023. Available online: https://www.akadeemia.ee/selgusid-parimad-noorteadlased-kolme-minuti-loengutes-2/ (accessed on 17 September 2025). (In Estonian).

- Gineiko, A. 3D Printing Gives New Life to Historical Materials. Novaator. 2023. Available online: https://novaator.err.ee/1609602935/3d-printimine-annab-ajaloolistele-materjalidele-uue-elu (accessed on 17 September 2025). (In Estonian).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).