Abstract

Business enterprises are required to adopt new economic models and business strategies in line with global trends such as the green agenda, the shortening of innovation cycles, digitalization (networking platforms) and socio-economic security. The models of network integrations (clusters, industrial symbioses, innovation ecosystems, etc.) are developing faster than other business models. Networking allows businesses to synergetically, based on the principles of collaboration, trust and self-organization, increase intellectual, innovative, social, and environmental values, which leads to economic growth and sustainable development. Through networking integration, the business performance of all participants in multi-company projects can be improved, regardless of their size and activities. The purpose of this study is to develop a methodological framework for assessing the synergistic effect and the level of collaborative maturity of participants in network industrial integration. This paper provides a comprehensive analysis and evaluation of network business integration efficiency. The authors’ methodology is based on the AHP hierarchy method, expert evaluation and Harrington’s level of desirability. The methodology is validated on Russian industrial integrations: industrial cluster of Nizhny Novgorod region; pipeline valve manufacturing cluster; South Ural industrial cluster producing spare parts and assembly units for roadbuilding, construction and agricultural vehicles. The results show that the level of collaborative maturity of business partners and the synergies from network integration effect the sustainability of business development. Recommendations for businesses are provided to improve their network integration and collaborative maturity. Furthermore, the findings allow the authors to define directions for further research, considering the interests of the business community, regional authorities, and financial institutions, and provide a framework for researchers to investigate the link between industrial network integration and economic growth.

1. Introduction

The available forms of business enterprise interaction developed historically, starting with concerns and family-owned business groups at the beginning of the 20th century [1,2,3] and developing forward to the strategic alliances of the late 20th century [4,5]. The companies always attempted to resolve their most important, existential question: how does one find the balance between staying competitive and at the same time keeping one’s economic independence [6,7]? Is it feasible for a medium-sized industrial company to cooperate with large players without the risk of becoming an acquisition target [8,9]? At the end of the last century, researchers and businesspeople published their papers on network-based forms of business organization. R. Miles and C. Snow defined network structures as a strategic organizational solution and a new stage in the evolution of companies’ organizational structures [10]. Clusters were one of the most popular network-based forms appearing in the late 20th century. M. Porter introduced the concept of clusters and the Silicon Valley cluster established in California, USA, proved the practical value of the clusters’ innovation efficiency [11].

The global trends of the early 21st century—specifically, the Fourth Industrial Revolution related to digitalization and the sustainable development goals as a global strategy for achieving a better future—stimulated the development of evolutionary network-based forms of business interaction. Clusters, technoparks and eco-industrial parks, centers for technology transfer, industrial symbioses and industrial ecosystems are all forms of collaborative interaction [12,13,14,15,16].

Viewing a region’s sustainable development as a system consisting of enterprises and organizations, stakeholders and infrastructure, we must note that the relations between the components of such a system develop much faster than the components themselves. Therefore, the driving force behind changes taking place in a system of sustainable development would be centered primarily on the relations or linkages between the system’s components. According to K. Kelly, “a dynamic network is the symbol of science for the next century. The network is the sole organization capable of self-learning and of growth that is not encumbered with biases” [17,18]. One of the first papers reviewing sustainable network interaction between companies and the network externalities stemming from that is A. Marshall’s study of “Sustainable network interactions of economic agents located in close proximity to one another, performing joint activities and obtaining positive externalities” [19]. The positive effects mentioned by A. Marshall include accelerated exchange of important information, access to specialized vendors of goods and services as well as access to skilled workforce. “Forming the network as a method of achieving cost savings and related justification of choosing the network as a preferred alternative” is covered in the works of Fisher, Koller and Langmann [20,21]. J. Lipnack and J. Stamps defined the network as “a system of formal and informal contracts servicing the sustainable relations between the organizations, where the latter are formally independent but can pool their resources to lower the costs, mitigate the risks and create additional competencies required to create value and achieve the participants’ joint goals” [12]. The key prerequisites for the sustainability of a certain organizational model are the dependence of an individual network participant on the resources controlled by the other participants and the feasibility of combining the participants’ resources with a view to achieving a synergetic effect. According to the definition provided by M. Castells, a network structure consists of a set of mutually related nodes [22]. The integration of businesses and organizations based on network principles forms a special type of cognitive environment, allowing an interchange of “innovation energy” between the network participants through the generation of knowledge and ideas and through the implementation of novel, creative and efficient technology and environmental solutions. This affects the development of the economy by changing the existing markets or facilitating the formation of new ones. It is difficult for a single enterprise with limited resources to achieve economic growth in the context of systemic crises while implementing a sustainable development strategy. Therefore, it is necessary to search for business models that provide a synergistic combination of innovative potentials, new technologies, knowledge, competencies and unique resources. The authors believe that the assessment of the collaborative maturity and the effect of the industrial integration of enterprises can serve as a tool to ensure the readiness of companies to interact and the ability to adapt to the challenges of sustainable development. Such adaptation will help companies to better manage their resources and accelerate the development of new technologies.

The authors’ hypothesis is that to ensure the sustainable development of companies and regions, it is necessary to create a partnership-based intellectual technology environment, which will use the collaboration principles to combine the integration of participants’ capabilities for an adequate coordination of goals and resources in resolving the global strategic challenges.

The possible contributions of this research are as follows. (1) Network integration is more effective for sustainable business development, as it allows businesses to obtain synergetic economic, environmental, technological and social effects. (2) The authors developed a system of indicators and an evaluation scale for assessing the impact of network industrial integration. (3) A proprietary methodology has been developed by the authors that allows estimation of the network integration efficiency of companies. AHP methods, expert estimates and the Harrington’s desirability function form the foundation of this methodology.

This paper has five main sections. Section 1 is an introduction that outlines the paper’s purpose, the current state of the research, the primary contributions, and the hypotheses. Section 2 provides a review of publications covering network forms of integration and cluster models. In Section 3, we present the research methodology, including the proprietary system of metrics (developed by the authors) for the estimation of the network integration effects and the level of collaborative maturity. The evaluation results concerning the efficiency of operation of three industrial clusters and the analysis of those results are contained in Section 4. Section 5 contains the discussion on the most significant findings and recommendations for further research.

2. Theoretical Framework and Hypotheses Development

2.1. Network Industrial Integrations

The significant acceleration and increased complexity of economic processes led to emergence of network models of interaction between economic agents. Development of these models led to the transformation of the structure of the economy: the networks became the most productive and promising forms of interaction between the economic agents [23]. Presently, the “network interaction is the dominant form of integration with complete coverage. At the same time, the undisputed advantages of the networks provide grounds for forecasting of further expansion of this form of integrative interaction” [24,25]. Julia Planko and Jacqueline Cramer believe that “to realize sustainability transitions, firms need to collaborate in networks and carry out system-changing activities. In this way, they pro-actively build a more sustainable system and change the environment in which they operate. The networked business model feeds into each network member’s individual firm-centric business model and vice versa” [26]. The use of integration-based models of interaction allows companies to pool all types of resources, including those used for the implementation of environmental, technical and social projects for achieving the sustainable development goals [27]. The relations between the parties arising in the course of asset integration are beyond the framework of existing theories and require additional research.

Network-based horizontal integration is attractive because it achieves high economic performance levels that are unattainable in a standalone business process. In a horizontal integration, the whole value creation chain provides a set of services [28]. A group of researchers, including Wang, J.; Zhang, X.; and Sun, C., study the network-based integrative interaction in agriculture. The authors believe that the formation and development of an innovation-prone environment in industrial integrations is the foundation for the high-technology modernization of agriculture [29,30,31]. In his paper [32], Bryan J Weiner estimates companies’ readiness for integration as seen through the maturity of governance viewpoint and as a measure of readiness for change. In his opinion, “organizational readiness for change is a multi-level, multi-faceted construct. Organizational readiness for change is a function of how much the organization’s members value the change and how favorably they appraise the three key determinants of implementation capability: task demands, resource availability, and situational factors. When organizational readiness for change is high, organizational members are more likely to initiate change and display more cooperative behavior”. The authors define collaborative maturity as the level of development of informal institutions, such as cultural values, trust, reputation, etc., required for effective network integration and playing a crucial role in technological interaction between companies. Thomas Llewellyn and Autio Erkko offer a typology of different integration concepts, thereby “helping to re-organize this proliferating domain”. The typology consists of three distinct system-level outputs—value propositions, business model innovations, and knowledge [33].

The matters of corporate culture that impact the efficiency of network-based industrial integrations were studied by Arellano, M.C., Sancha, C., and Netland, T. [34]. In the paper by Trusova, N. and Oleksenko, R. [35], the synergy of managing the intellectual potential of an enterprise within business networks is reviewed. The synergy of network interaction is a joint action of various actors. This creates qualitatively new (innovative, technological, ecological, etc.) results through the interaction between the participants in an integration.

The paradigm of development of a company’s intellectual potential within network-based systems is presented, and a methodology-based approach for managing the efficient interaction of companies is proposed. This approach defines the entropy shift of the observed companies’ intellectual potential value and determines the impact on a business system given the limited duration of the network’s operation.

Therefore, the first hypothesis is as follows:

Hypothesis 1.

Formation of common corporate values, governance maturity, partnership culture and readiness for change in network-based integrations facilitate the creation of an intellectual technology environment.

2.2. Cluster-Based Forms of Interaction

In recent decades, scientific publications saw active discussions on various forms of network-based industrial integrations (including clusters). M. Porter, a US economist, introduced the term “cluster” in 1990 to define groups of competitively viable related industry sectors of a country’s economy. A distinctive feature of this network-based interaction is the geographic concentration and operation of actors in the same sector of the economy [36]. A sufficiently complete definition of industrial clusters as an economic model of interacting actors is provided in the paper by Tkacheva, A. and Saginova, S. [37]. A cluster is understood to mean an industrial-manufacturing complex implemented based on a geographic combination of major producers, general suppliers and end consumers, having a common process flow chain and representing a competitive alternative to a sector-based approach. In the authors’ opinion, the process of actors’ interaction includes cooperation for the sake of common goals, mutual development of unique competencies while preserving internal competition.

McPhillips conceptually linked open innovation and clusters, proposing and categorizing the roles of clusters as open innovation intermediaries. This author also indicated factors that might influence the successful adoption of this role. “Clusters could not only manage and mediate their network of members, but also shape and co-create a broader open innovation ecosystem” [38]. The transition to a “cluster management organization” as a new and advanced form of organization of the innovation process was described by Maracha, V. [39]. According to the results of a conceptual analysis [40], an unbalanced focus on the complementarities, collaboration, and actors in the received definitions was identified, and “among other things proposes the additional inclusion of competition, substitutes, and artifacts in conceptualizations of innovation ecosystems”.

The macroeconomic role of clusters is provided in the paper by Mendes, T.; Silva, C.; and Braga, A. [41]. Clusters may facilitate the access of domestically produced goods to international markets. Derlukiewicz and Mempel-Śnieżyk believed that such forms of interaction are the most productive and flexible ones from the viewpoint of overcoming external and internal challenges [42]. Clusters are one of the generally recognized methods for achieving sustainable development goals [43,44,45] and the ESG agenda [46,47]. Clusters become points of economic growth. The implementation of cluster technologies contributes to the growth of business activity and the improvement of the investment climate in the region. Clustering based on the ESG concept fosters sustainable economic growth, as clusters allow participants to create jobs, increase labor productivity, enhance innovation, and develop cooperation and partnerships between cluster actors. Adherence to ESG principles enables cluster participants to increase their investment attractiveness for responsible investors, improve the image and reputation of cluster organizations, and provide comfortable conditions for employees. Teams of authors conducted research and proved the important role of clusters in the economy’s transition to a closed-cycle model [48,49]. Clusters facilitate stimulation of the development of high-tech sectors of the economy while bearing in mind the orientation toward national development goals. Creation of a biomedical cluster in Norway and development of a biomedical cluster in Ireland stand as examples of the above [50].

A contribution toward the development of the concept of clusters has been made by the authors whose research was aimed at studying the interaction of clusters with the regional infrastructure for governance and development of innovations [51,52,53,54,55]. Zeng, S.; Wang, T.; and Lin, W proved that the development of clusters requires the interaction of enterprises belonging to the same sector of the economy with scientific research institutions—this facilitates the permeation of innovations into the industry. In addition, the use of multilateral technical services platforms for information interchange is required [56]. In addition to playing a significant role in the national economy, clusters are also an important factor in the development of the regions of their presence. Chen, X.; Wang, E.; Miao, C.; Ji, L.; and Pan, S. studied the impact of automotive industry clusters on the regional economic development in three areas: industrial, technological and social development [57]. Christopoulos, G., and Wintjes, R. proposed an indicator for identifying innovation clusters transcending traditional sectoral taxonomies and integrating the creation and use of knowledge into regional economic systems [58].

Mercado-Caruso, N. and Segarra-Oña, M. studied the organizational structure of clusters and their lifecycle; these researchers presented a role-based model for cluster participants [59]. According to the findings of the research conducted by Tong, T. and Zainudin, N.B. [60], enterprises within sector-specific clusters are interrelated and interact with one another in order to obtain an economic benefit from such a combination, to decrease manufacturing costs and to maximize the profit. It was proven that the participation of small and medium-sized high-tech companies favorably affects the metrics of an industrial cluster. This matter was also researched in detail in the following papers [61,62,63]. Publications devoted to the development of clusters in a digital economy environment [64,65] studied the integration of small and medium-sized business into industrial clusters via the use of digital platforms acting as a tool for both internal and external communication.

In conjunction with the above, we present Hypotheses 2a and 2b.

Hypothesis 2a.

Clusterization as a form of network-based integration allows participants to obtain synergies stemming from the combination of every type of resource.

Hypothesis 2b.

Setting up an integration-specific KPI for the business partners (with such a KPI serving as a measure of collaborative maturity) allows assessment of every participant’s contribution toward the execution of the industrial cluster’s strategic objectives.

3. Materials and Methods

The authors believe that an overall effect of industrial integration could be presented as a function of five independent variables (effects), with each effect occurring whenever a partnership-based interaction is established:

- where —Effect from the creation of industrial integrations;

- —Economic effect;

- —Social effect;

- —Environmental effect;

- —Innovation and technological effect;

- Entrepreneurial effect;

- and where all of , , , , > 0.

Economic effect reflects the economic impact of the combination of participants in an integration. It includes (in monetary terms) the aggregate volume of goods produced and services rendered by the participants in a network-based industrial integration. In order to estimate the economic effect, the production costs (raw materials, semi-finished goods and spare parts) are studied over a period to form the trends. Additionally, the financial performance and financial condition of the integration participants impact the amount of economic effect obtained. Social effect includes metrics reflecting the positive impact of the integration on the population, region and employees of the enterprise. Measuring the contribution toward the regional infrastructure helps in assessing the social effect of the creation of an integration. Environmental effect reflects the benefits from preventing a negative impact on the environment. This component is assessed using the metrics of resource use efficiency, contribution of the integration toward the decreased environmental burden suffered by natural ecosystems, and the environmental awareness of the employees. Environmental efficiency is linked to minimizing the negative environmental impact of manufacturing activities. Innovation and technological effect quantifies the market participants’ capability to modernize their fixed assets and use modern equipment and technologies. This component is characterized by the level of investment in innovations and technological development. Finally, entrepreneurial effect assesses the functioning of the integration through the availability of developed sales channels, positive business reputation and level of entrepreneurial activity. Obtaining a synergetic effect from the interaction is possible when a positive value is achieved for every one of the above-mentioned effect components.

This condition is the minimal and sufficient one for an efficient interaction. We should also mention here that for different types of integration, the ratio of the effect component values achieved may differ.

In compliance with the decision-making theory, assessment of the level of interaction between business partners is included in the group of so-called partially structured problems. Building quantitative models for such problems is virtually impossible as not all the linkages between the potential participants in the network-based industrial integration could be quantified due to the lack of the required volume of information. In such cases, these linkages are quantified using expert estimates. Decisions in such cases are reduced to selecting one of several alternatives created during the previous stages of the process. However, the distinctive feature of multiple-criteria problems is that there is no single alternative presenting the best values for all the criteria. “One of the tools for solving multi-criteria problems is the analytic hierarchy process (AHP) developed by T. Saaty. The AHP method is relevant for group decision-making and is aimed at solving practice-oriented multi-criteria optimization problems. The advantage of the method is the possibility to justifiably compare heterogeneous factors and to take into account both quantitative and qualitative criteria of optimality. AHP allows evaluation of alternatives based on calculated priorities (measure of relative importance) using the procedure of pairwise comparisons” [66]. AHP is widely used in practical applications and is actively developed by researchers from all over the world. For example, AHP was used for the analysis and estimation of linkages in biological ecosystems by Baodi Sun, Jingchao Tang, and Rongqun Zhang; for the assessment of the sustainable development of territories, cities and industry by Xu, Shuobo; Xu, Dishi and Liu, Lele; to determine the level of environmental risks for urban ecosystems by Dong, R., and Cai, Y.; for the evaluation of city–industry integration in industrial parks by Xu, M., Luo, Y., and Li, D.; and to analyze reverse logistics practices associated with the concept of circular economy, comparing studies conducted before and after the implementation of the National Solid Waste Policy (NSWP) in Brazil, by Aguirre Rodríguez [67,68,69,70,71].

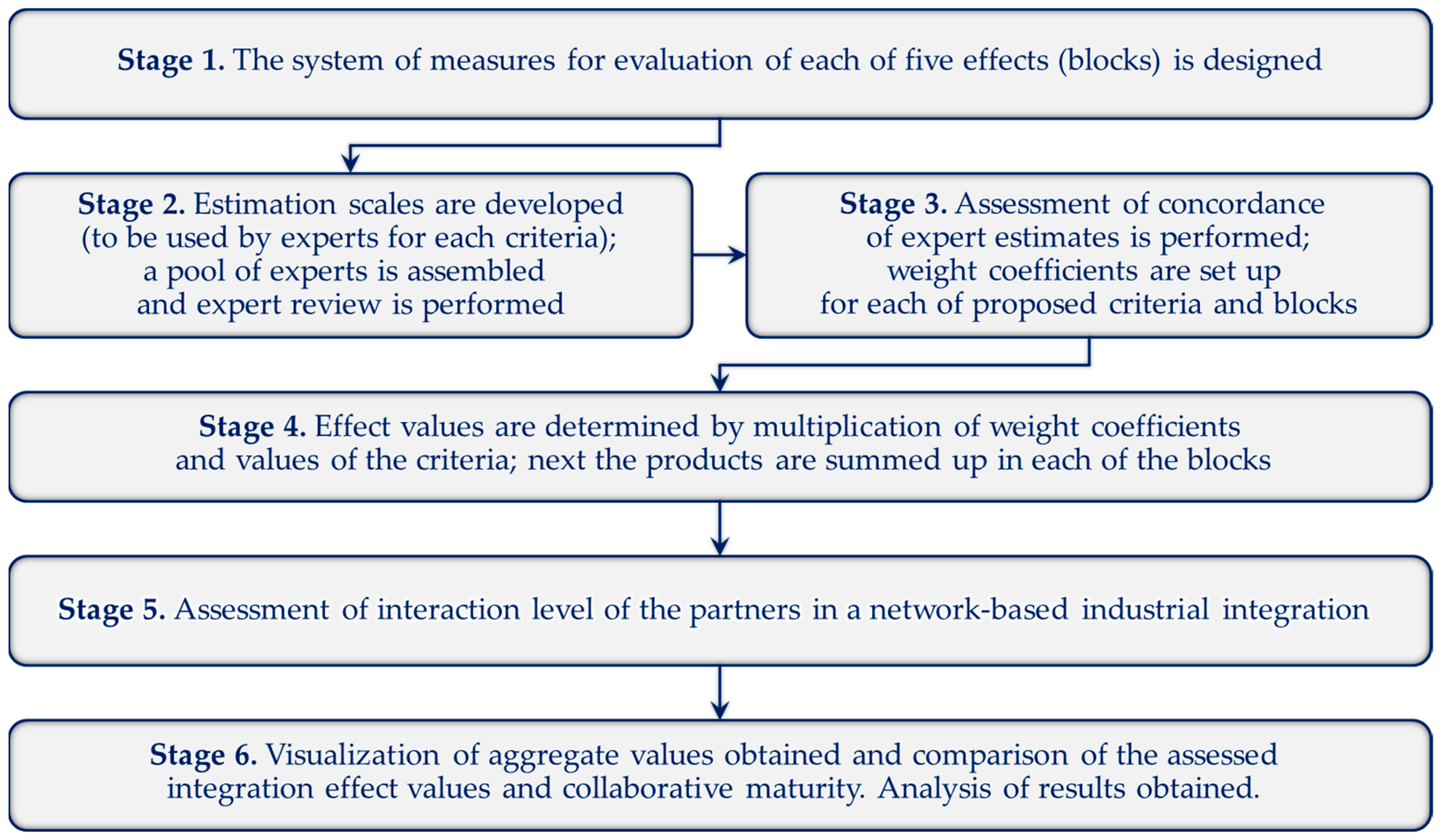

However, AHP has a few limitations and assumptions that include, among others, the following: the approach is highly labor-intensive, especially in situations requiring a large number of pairwise comparisons; significant variance of the estimated values (affected, in part, by the experts’ personal prejudice and preferences); variability of the results based on the method of ranking used and on the assigned parameter values. The AHP method may be inefficient for problems with a few criteria or alternatives, or for very complex problems with a high degree of indetermination. The implementation stages for the method of assessment of the interaction level of the business partners in creating a network-based industrial integration are provided in Figure 1.

Figure 1.

AHP methodology flowchart. Source: authors’ own elaboration.

At the first preparatory stage, a system of measures for the assessment of each of the five effects (blocks) is set up. This includes economic, social, environmental, innovation-technological and entrepreneurial effects. Table 1 shows the elements of the matrix of values for each type of effect occurring in the course of the integration process. The proposed system of measures contains a relatively large number of criteria, with these criteria having different levels of importance.

Table 1.

System of measures for assessing the effect of network-based industrial integration.

C1.1 This criterion reflects the stability of the manufacturing and sales processes. In a successful case of integration, this metric for integration participants should not decrease, and its relative change in percent should increase.

C2.3 This metric estimates the social responsibility of the cluster participants. The available data are quantified using expert estimates. The factors considered are participation in the implementation of social projects, corporate social responsibility and labor conditions.

C3.1 This criterion estimates the degree of usage of secondary (recycled) resources in the manufacturing processes of the industrial integration (Are all types of recycled resources used? What is the consumption volume of recycled resources?). This metric is a qualitative one and is estimated by the experts.

C4.1 Defined through estimation of the integration participants’ investment amounts in the modernization of the manufacturing processes and technologies allowing transition to best practices or creation of own leading-edge technologies.

C5.4 Estimates the reputation of the industrial integration participants in such areas as image, reliability of information, personnel policy, uninterrupted operations, timely fulfillment of contractual obligations, customer reviews, procedure for mitigation of violations (and the number of such incidents), etc.

Indicators C1.1, C1.2, C1.3, C1.4, C1.5, C2.1, C2.2, C2.4, C4.2, C4.3, C4.4, C5.1, and C5.2 are quantitative, and their values are available from the regional statistical databases. For the assessment of other qualitative indicators, it is necessary to involve experts.

During the second stage, evaluation scales are developed for the experts’ use of each of the criteria; a pool of experts is assembled, and the expert review is performed (Table 2). The experts were chosen according to the following criteria: professional experience of more than 5 years; work in industry or research institutes; have expertise in the field of sustainable development assessment, network integration, circular economy; development of environmental regulations. The experts representing the business community live in the regions where the clusters under study are located. The experts are between 30 and 65 years of age. To estimate the weight coefficients using an expert estimate, the authors developed a questionnaire. Sixty experts received the questionnaire. Feedback was received from 32 of those experts. The questionnaire requested the experts to evaluate the qualitative indicators in Table 1 using the scales developed by the authors. The experts could evaluate the contribution of various metrics to the aggregate final score based on their prior experience. The sum of the coefficients had to be equal to 1.

Table 2.

Details of the experts.

A scale of 0 to 5 is used to evaluate the criteria. Examples of such scales developed by the authors for the expert estimation are provided in Table 3, Table 4 and Table 5. For all the scales, the threshold values are developed for the average annual change over the last 3 years. The threshold values of the indicators’ growth metrics are presented on an annual basis. Also, the change in the number of participants is considered in the estimation. For all the proposed scales, the value of 3.0 is taken as the normal value.

Table 3.

Evaluation scale for the C1.5 criterion.

Table 4.

Evaluation scale for C2.3.

Table 5.

Evaluation scale for C5.2.

At the third stage, the consistency of the expert estimates is verified, and the weight coefficients are set for each of the proposed criteria based on the priorities in accordance with the AHP method. Similar to probabilities, priorities are dimensionless values that can take values from zero to one. The larger the value of the priority, the more significant the element corresponding to it. The sum of the priorities of elements subordinated to one element of the higher level of the hierarchy is equal to one. The priority of the goal is equal to 1.0 by definition. Determination of the priorities of the elements of each level is based on the method of pairwise comparisons [72].

At the fourth stage, the effect values are determined by multiplying the weight coefficients by the values of the criteria and summing up the resulting products in each of the blocks. Then, the integral value of an effect of network-based industrial integration is calculated. For this, an additive convolution is used with the following formula:

where K(x) is the common criterion for alternative x, indicating its applicability for the purpose of achieving the goal; Ki(x) is the set of initial criteria; n is the number of initial criteria; and ai is the priority of a partial criterion Ki.

Consistent execution of all the AHP steps provides the possibility of changing the structure of the hierarchy to include newly appeared criteria and alternatives, or those criteria and alternatives previously considered not important. If the calculated values of the indicators of individual integration effects do not reach the desired value (thereby reducing the aggregate value), it is possible to develop recommendations for the integration participants, allowing them to restructure business processes in such a way as to increase the value of the relevant indicator.

At stage five, the expert assessment method is used to quantify the level of interaction between the partners in an industrial integration based on the criteria provided in Table 6.

Table 6.

Evaluation criteria for the level of interaction in an industrial integration.

Upon receipt of the expert evaluations (in points), coded values for the control points are set, taking into account the upper and lower limits of the range of allowed values based on the generalized Harrington’s desirability function [73]. The closer the value of the level of interaction gets to 1.0, the higher the efficiency of the integration. Values quantifying the project’s potential in the range between 0 and 1 match the corresponding levels on the Harrington scale—“very bad” (0.2 to 0); values between 1 and 2 receive the grade of “bad” (0.37 to 0.2); between 2 and 3—“satisfactory” (0.67–0.37); between 3 and 4—“good” (0.8–0.63); and values between 4 and 5 are graded as “very good” (1.00–0.80).

In stage six, the aggregate values obtained are visualized and matched to metrics for the assessment of the integration effect and collaborative maturity. The final results are also analyzed.

Limitations of the methodology: the results of the expert review depend on the completeness and availability of the database on integration, since expert assessment is subjective; the availability of experts with relevant experience and competencies; the development of criteria for integration in the given field of industry; data on the evaluated clusters should be available for 3 or more years.

Use of the proposed methodology for modeling lets the user determine and forecast the parameters of enterprises that would make such enterprises fit for participation in industrial integration and where such integration would create a synergetic effect. The methodology proposed by the authors was tested on the data for three Russian clusters: a cluster for pipeline valve production (Chelyabinsk region); an industrial cluster in Nizhny Novgorod region; and the South Ural industrial cluster.

4. Results

4.1. Description of Clusters and the Regions of Their Presence

Nizhny Novgorod region, a subject of the Russian Federation, is located in the center of the European part of Russia. It is Russia’s 14th largest subject in terms of the gross regional product (GRP). The largest sector of the regional economy is manufacturing—it accounts for 31% of the GRP [74]. General statistical data characterizing the development of business in Nizhny Novgorod region are provided in Table 7.

Table 7.

Statistical data for the Nizhny Novgorod region.

Statistical data show the low level of involvement of the regional businesses in network-based industrial integration. To increase the level of clusterization in the Nizhny Novgorod region since 2022, the state provides the following support measures to cluster participants: development of business plans; organization of employee training; assistance in document processing, certification and licensing; provision of legal, patent, financial and accounting services; conducting marketing research aimed at analyzing various markets based on the needs of territorial cluster participants; preparation and placement of press releases in the media covering the activities of the cluster participants; organization of press conferences; presentation of the cluster participants’ products at exhibitions and forums.

Chelyabinsk region is one of the core industrialized, dynamically developing regions of the Russian Federation. Chelyabinsk region is part of the Urals Federal District, located on the border between Europe and Asia. The largest share of the GRP is created by the following types of activities: manufacturing (37.2%), wholesale and retail trade, repair of motor vehicles, motorcycles, household goods and personal items (9.4%), transactions with real estate (8.2%), mining of minerals (6.5%), transportation and storage (6.1%) [76]. With the clear predominance of industry, the region has well-developed agriculture, especially in the area of black earth soils, and has a rich and diverse natural resource base. According to the Unified Register of the Federal Tax Service, Chelyabinsk region has over 155,000 small and medium-sized enterprises (SMEs) [77]. In the year 2020, every third ruble of economic turnover and every third employee in the region came from the SME sector. General statistical data characterizing the development of business in Chelyabinsk region are shown in Table 8.

Table 8.

Statistical data for Chelyabinsk region.

A Foundation for the Development of Industry operates in the Chelyabinsk region [77]. The purpose of the Foundation’s activity is to create conditions for efficient interaction between industrial enterprises, investors, educational establishments, scientific and research facilities, non-governmental organizations and bodies of state power in the interests of implementing the program of development of industrial clusters. The main areas of the Foundation’s operations include the execution of the cluster-centered policy in the region; development of manufacturing and cooperation chains with participation of large businesses and SMEs; and organization of efficient interaction between the industry, science and education.

An industrial cluster may include enterprises belonging to different sectors of the economy, different forms of ownership (private enterprises; state-owned enterprises and organizations; enterprises and organizations established in the process of public–private partnership) and different size (SMEs and large companies). The limitation of the cluster-based model is the assumption that the cluster under review is insulated from the external economic environment (i.e., from companies that are not members of said cluster). Information on the clusters analyzed in this paper is provided in Table 9.

Table 9.

Brief description of the clusters being studied.

The pipeline valve manufacturing cluster (Chelyabinsk region) combines three types of participants: a plant performing the preparatory stages of production; several SMEs manufacturing pipeline valves and valve spare parts; companies performing the final assembly. This cluster also includes a company for recycling and utilization of waste materials and interacts with the national research university in the areas of educating potential future employees for the cluster participants and transfers of technology.

The industrial cluster of Nizhny Novgorod region specializes in car-making, production of spare parts and car components. In Nizhny Novgorod region, car-making is one of the key sectors of the economy. Through interaction with adjacent industrial sectors, the economic and social impact of the car-making sector is significant at the regional level. The cluster includes industrial enterprises producing finished goods (motor vehicles) and spare parts; and enterprises organizing a full-cycle production process, from design to manufacturing of high-tech products. Cluster participants interact based on joint R&D and socio-economic projects. The R&D and educational interactions within the cluster are organized jointly with the Nizhny Novgorod State Technical University.

The South Ural industrial cluster includes several groups of participants: manufacturers of finished goods (motor vehicles, components and spare parts, assembly units); service providers (assembly, treatment of parts, servicing); manufacturers of semi-finished goods, custom equipment and blanks for further processing. The cluster interacts with the South Ural State Technical College for employee training and related matters. The cluster also interacts with organizations providing technology and industrial infrastructure.

The main results of the clusters’ performance between 2017 and 2022 are provided in Table 10.

Table 10.

Results of the clusters’ economic activity.

The analyzed clusters demonstrate positive trends for such indicators as the volume of manufacturing output, amounts of capital investment and tax disbursements to budgets of various levels.

4.2. Estimation of the Integral Effect of Integration and the Level of Collaborative Maturity Within the Clusters

The assessment is carried out sequentially, in accordance with the flowchart presented in Figure 1. At the preparatory stage, a system of indicators is formed to assess five types of effects (blocks): economic, social, environmental, innovation and technological and entrepreneurial for each of the three industrial clusters. Then, based on the proposed evaluation scales, experts grade the clusters according to 25 criteria. A five-point grading scale is used for the evaluation of the criteria. A total of 47 experts from research institutes, government agencies and business representatives were involved in this study. At the next stage, the consistency of the expert evaluations is assessed and the weight coefficients for each of the proposed criteria are set on the basis of the priorities (NPV, normalized priority vector) in accordance with the AHP methodology. The results of these expert assessments are provided in Table 11 and Table 12.

Table 11.

Priority-based ranking of the blocks and criteria.

Table 12.

Calculation results for the effect of network-based integration for the three clusters.

The numeric value of each of the five effects is obtained by multiplying the criteria values obtained through an expert evaluation by the weight coefficient (relevance) of each criterion. An integral metric–aggregate effect of the network-based industrial integration (Ei) is calculated using the geometric progression formula:

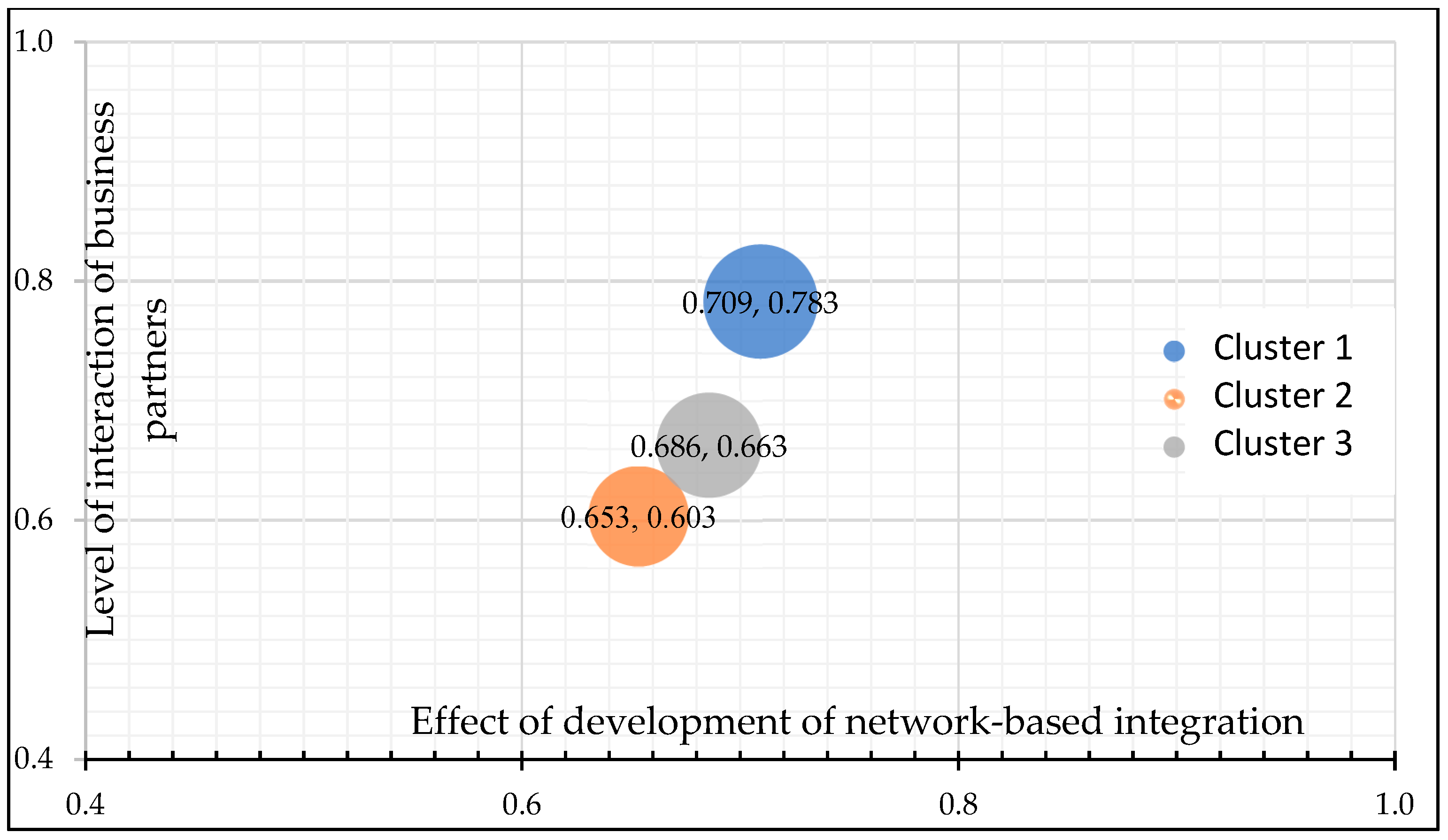

Based on the analysis performed, it was determined that the best value of the effect from the development of network-based integration is shown by Cluster 1 (Ei = 0.709); this result was achieved through the entrepreneurial and environmental effects. Cluster 3 is in second place, with an integral effect value of 0.686 delivered predominantly through the economic and social effects. Cluster 2 is in third place (Ei = 0.653). For Cluster 3, the innovation and technology effects play the most important role.

Similarly, we have calculated the integral estimates quantifying the degree of interaction between the business partners within a cluster (Table 13); however, the calculation was performed using the values of the metrics, not the blocks:

Table 13.

Results of the evaluation of the cluster participants’ interaction levels.

According to the results obtained, Cluster 1 is the leader of the list based on the level of interaction of the industrial cluster participants (Di = 0.783). Cluster 3 is in second place (Di = 0.663) and Cluster 2 is in third place (Di = 0.603).

At the next stage, all the integral values obtained are measured against the threshold values within the 0 to 1 range in accordance with Harrington’s desirability scale (Table 14).

Table 14.

Final aggregate metrics.

Thus, for the clusters reviewed in our study, for both assessment dimensions, we obtain matching interpretation of results: for Cluster 1, we have a “High” grade for both assessment dimensions; for Cluster 2, both grades are “Average”; and for Cluster 3, it is “high” for both assessment dimensions. In the final stage of our research, visualization of the assessment results is performed (Figure 2). The horizontal axis shows the integral values of the effect of the development of network-based integration, and the vertical axis shows the level of interaction of the business partners in the clusters.

Figure 2.

Visualization of the integral estimates obtained and their relative positioning on the Harrington scale.

Visualization of the results obtained demonstrates that there is a positive dependency between the effect of the development of network integration and the level of interaction between business partners within the cluster. To verify the existence of this dependency, the values obtained were sorted in ascending order and the trend line equation was determined to be y = 3.1342*x − 1.4569. The approximation of the confidence level for this trend line equation is 0.9225. This indicates a highly accurate description of the distribution of the source data. It is proven that positive correlation exists between integral values Ei and Di.

The proposed KPI can be applied by the Ministry of Industry and Trade of the Russian Federation to decide whether to include the cluster in the program of state support (subsidies) or to continue its participation in it. Based on the KPI, cluster participants may estimate their contribution to the cluster development, economic efficiency, and innovation potential, and they may adjust the sustainable development strategy.

5. Discussion and Conclusions

Network-based industrial integrations are an effective tool for the sustainable development of the industrial sector and for the implementation of industrial policy in the modern environment. The systemic approach toward the formation of clusters based on the principles of network integration and partnership provides technological interaction between companies, optimizes the methods and forms of their economic activities, and allows integration participants to achieve their strategic goals. In this paper, we have confirmed the research hypothesis that the sustainable development of companies and regions requires the formation of a partnership-based intellectual environment, where the individual capabilities of integration participants are pooled together based on the principles of collaboration for the adequate harmonization of goals and resources in solving global strategic tasks.

Various methods and approaches have been developed to assess the performance of industrial integrations [78,79,80]. In particular, our results are consistent with the findings of Frunze, I. and Mikhaylik, D. These authors believe that “the efficiency assessment of economic units must be carried out through synergy effect, which comes along with integration processes and has been the integral goal of their performance. Usage of system dynamics for assessment of efficiency integration of economic objects will provide organizational and quantitative basis for optimal management of the integrated formation” [81]. We also confirm the conclusions of Schardosin, F., and De Rolt, C. [82], namely that the methodology for assessing the efficiency of network-based industrial integrations should take into account the type of integration, industry affiliation, level of collaborative maturity, strategy and economic characteristics of the participants in the integration.

The principal difference between the present study and prior research lies in the use of a system of indicators characterizing five types of integration effects, economic, social, environmental, innovation and technological, and entrepreneurial, to assess the effectiveness of industrial clusters. The authors’ methodology consists of a set of methods and approaches, including AHP, expert assessment using evaluation scales developed by the authors, and Harrington’s desirability functions. However, our study has a number of limitations that could be mitigated in the future. The collection of baseline data is a resource-intensive process due to the limited access to primary information on the industrial cluster activities and to further validation of these data. The proposed methodology is tested on three industrial clusters. Expanding the geographical coverage by including clusters from other regions of the Russian Federation can provide additional results to those of our study.

According to prior research [83,84,85], the balancing of the social, environmental and economic interests of integration participants allows for leveling out the imbalances and disproportions within the system, ensuring its sustainability and ability to withstand external and internal threats. As a further direction of research, it is possible to develop approaches for the design of KPIs (key performance indicators) for network-based integration. For example, the following indicators could be included in the relevant KPIs:

- Resources and manufacturing infrastructure. KPIs from this area are required to assess each participant’s potential in terms of the manufacturing, infrastructure, transportation and logistics resources required to achieve the strategic goals of each integration participant individually and of the region as a whole.

- Intellectual resource maturity. KPIs covering this direction provide qualitative and quantitative analysis of the intellectual competencies of integration participants’ employees as seen from the viewpoint of the strategic goals of integration and the goals of the region as a whole.

- The level of development of operational management. These KPIs determine the ability of integration participants to respond flexibly to challenges in the external and internal environment and to promptly adapt business processes during the implementation of joint innovative technological and (or) environmental projects.

- Indicators for assessing the management tools used. These KPIs illustrate whether management methods are “progressive” in terms of the readiness for transformation, partnership and cooperation; these KPIs also quantify the achieved speed and quality of the tactical and strategic decision-making of each of the integration participants.

- Corporate culture and institutions. KPIs from this section should send a clear message to all the integration participants about the level of loyalty of each participant’s personnel and their involvement in the process of implementing partnership projects.

The synergetic interaction of companies in a network-based integration should result in a variety of technological and environmental projects aimed at the sustainable development of both individual companies, their integration, and the whole territory of their operation. The interaction between companies in a network-based integration (as a partnership model based on collaborative knowledge exchange) should be based not only on the synergies of the environmental and technological benefits derived by the participants in the partnership but such interaction must also provide self-evident benefits for society.

The papers by the following researchers are devoted to the environmental aspects of network integration [86,87,88]. Leonie Schlüter and Lone Kørnøv developed guidelines for embedding systems thinking principles into tools for sustainability assessment for use in the early stages of sustainable business model (SBM) innovation [89]. The network analysis [90] revealed five emerging areas: SBM strategies, challenges in developing SBMs, drivers of SBMs, the role of innovation in SBMs, and digital technologies in the SBM. Furthermore, this review indicates that most studies on SBM are quantitative, focusing on the manufacturing industry.

The results and findings of our research could prove useful for enterprises, business entities, scientific, research and educational organizations and bodies of state authority in performing the following tasks of sustainable development:

- -

- Increasing the efficiency of the strategic management of enterprises and their interactions.

- -

- Boosting technological processes promoting innovation and integration.

- -

- Acceleration of technological and environmental development through the introduction of environmental and technological projects of enterprise development.

Scaling up sustainable business models of network integration will allow enterprises to increase their resource efficiency and ensure the necessary volume of investment to produce high-value-added products. Businesses can improve their network integration and collaborative maturity by considering such recommendations as implementing external collaboration and joint business planning, forming industrial symbioses, creating cyclical production models, and using digital platforms for the mutual interaction of industrial network integration participants.

In conclusion, the authors would like to emphasize that modern realities require a holistic approach to the management of industrial production. This requires linking the goals, strategies, development tools at the level of individual industrial enterprises, clusters, symbioses and regions, thus combining the efforts of all stakeholders, ensuring synergy and sustainable development of the economy as a whole [91,92,93,94]. Further research should consider that the effective integration of industry, science, education and business is possible when the vertical and horizontal links are balanced.

This study contributes to a better understanding of the formation and operation of network-based industrial integrations in line with the global trends such as sustainable development and digitalization.

Author Contributions

Methodology, V.K. and N.S.; validation, T.T. and D.B.; resources, D.L.; data curation, D.B., V.K. and D.L.; writing—original draft, N.S., T.T., V.K. and D.B.; writing—review and editing, T.T. and N.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Khan, S. A Comprehensive Dataset of the Family Business Groups Firms. Available online: https://ssrn.com/abstract=4866450 (accessed on 3 June 2022).

- Samphantharak, K. Family Business Groups and Economic Development in Southeast Asia. Available online: https://ssrn.com/abstract=3328861 (accessed on 4 February 2019).

- Kinger Hans, L.; Chittoor, R.; Vissa, B.; Chen, G. Family-Controlled Business Groups: An In-Depth Review and a Micro-Foundations Based Research Agenda. INSEAD Working Paper No. 2023/22/EFE/STR. Available online: https://ssrn.com/abstract=4459012 (accessed on 25 May 2023).

- Chemmanur, T.J.; Shen, Y.; Xie, J. Unlocking Strategic Alliances: The Role of Common Institutional Blockholders in Promoting Collaboration and Trust. 11 July 2023. Available online: https://ssrn.com/abstract=4509164 (accessed on 11 July 2023).

- Oliveira, N.; Ariño, A.; Lumineau, F. Time in international strategic alliances: Progress and prospect. J. World Bus. 2023, 58, 101456. [Google Scholar] [CrossRef]

- Veljanovski, C. Hayek’s Meaning of Competition and Antitrust in a Digital Age. Available online: https://ssrn.com/abstract=3965633 (accessed on 10 December 2021).

- Tirole, J. Competition and industrial policy in the 21st century. Oxf. Open Econ. 2024, 3 (Suppl. S1), i983–i1001. [Google Scholar] [CrossRef]

- Giglio, C.; Corvello, V.; Coniglio, I.M.; Kraus, S.; Gastf, J. Cooperation between large companies and start-ups: An overview of the current state of research. Eur. Manag. J. 2023, in press. [CrossRef]

- Audretsch, D.B.; Belitski, M.; Caiazza, R.; Phan, P. Collaboration strategies and SME innovation performance. J. Bus. Res. 2023, 164, 114018. [Google Scholar] [CrossRef]

- Miles, R.E.; Snow, C.C. Causes of failure in network organizations. Calif. Manag. Rev. 1992, 34, 53–72. [Google Scholar] [CrossRef]

- Porter, M.E. On Competition; Harvard Business School Press: Boston, MA, USA, 1998; pp. 120–128. [Google Scholar]

- Lipnack, J.; Stamps, J. The Age of the Network: Organizing Principles for the 21st Century; OMNEO: Essex Junction, VT, USA, 1994; pp. 85–89. [Google Scholar]

- von Kardorff, E. Castells (1996): The Rise of the Network Society. In Schlüsselwerke der Netzwerkforschung; Holzer, B., Stegbauer, C., Eds.; Netzwerkforschung; Springer VS: Wiesbaden, Germany, 2019; pp. 105–109. [Google Scholar] [CrossRef]

- Angelis-Dimakis, A.; Arampatzis, G.; Alexopoulos, A.; Vyrkou, A.; Pantazopoulos, A.; Angelis, V. Industrial Symbiosis in the Balkan-Mediterranean Region: The Case of Solid Waste. Environments 2023, 10, 1. [Google Scholar] [CrossRef]

- Tsujimoto, M.; Kajikawa, Y.; Tomita, J.; Matsumoto, Y. A review of the ecosystem concept—Towards coherent ecosystem design. Technol. Forecast. Soc. Chang. 2018, 136, 49–58. [Google Scholar] [CrossRef]

- UNIDO. «Eco-Industrial Parks—Achievements and Key Insights from the Global RECP Programme». Swiss Confederation. 2019. Available online: https://downloads.unido.org/ot/33/32/33320314/Evaluation%20report%20on%20Global%20Eco-Industrial%20Parks%20Programme%20(GEIPP).pdf (accessed on 10 August 2024).

- Shmeleva, N.; Tolstykh, T.; Gamidullaeva, L.; Lazarenko, D. Challenges and Opportunities for Technology Transfer Networks in the Context of Open Innovation: Russian Experience. J. Open Innov. Technol. Mark. Complex. 2021, 7, 197. [Google Scholar] [CrossRef]

- Parman, J.J. The Inevitable: Understanding the 12 Technological Forces That Will Shape Our Future: Kevin Kelly, Viking, 2016, 336 Pages, $28.00 (paperback). Technol. Archit. Des. 2017, 1, 114–115. [Google Scholar] [CrossRef]

- Marshall, A. Principles of Economics; The Macmillan Press Ltd.: New York, NY, USA, 1983; 638p. [Google Scholar]

- Fischer, M.M. The innovation process and network activities of manufacturing firms. In Innovation, Networks, and Knowledge Spillovers: Selected Essays; Springer: Berlin/Heidelberg, Germany, 2006; pp. 117–133. [Google Scholar]

- Koller, H.; Langmann, C. Das Management von Innovationsnetzwerken in verschiedenen Phasen. In Innovative Kooperationsnetzwerke; Wojda, F., Barth, A., Eds.; Deutscher Universitätsverlag: Wiesbaden, Germany, 2006; pp. 27–80. [Google Scholar]

- Castells, M. The Rise of the Network Society: The Information Age: Economy, Society, and Culture; Wiley: Hoboken, NJ, USA, 2010; 597p. [Google Scholar]

- Tolstykh, T.; Shmeleva, N.; Boev, A.; Guseva, T.; Panova, S. System Approach to the Process of Institutional Transformation for Industrial Integrations in the Digital Era. Systems 2024, 12, 120. [Google Scholar] [CrossRef]

- Rossignoli, F.; Lionzo, A. Network impact on business models for sustainability: Case study in the energy sector. J. Clean. Prod. 2018, 182, 694–704. [Google Scholar] [CrossRef]

- Molina, A.; Panetto, H.; Chen, D.; Whitman, L.; Chapurlat, V.; Vernadat, F.B. EnterpriseIntegration and Networking: Challenges and trends. Stud. Inform. Control 2007, 16, 353–368. [Google Scholar]

- Planko, J.; Cramer, J. The Networked Business Model for Systems Change: Integrating a Systems Perspective in Business Model Development for Sustainability Transitions. In Business Models for Sustainability Transitions; Aagaard, A., Lüdeke-Freund, F., Wells, P., Eds.; Palgrave Macmillan: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Wang, Y.; Sheng, X.; Gong, X. Evaluation and Spatial Correlation Analysis of Rural Industry Integration Development from an Ecological Niche Perspective: A Case Study of Three Prefectures in Southern Xinjiang. China Agric. Resour. Reg. Plan. 2023, 44, 242–252. [Google Scholar]

- Plotnikov, V.; Vertakova, Y. Formation of Networks as a Form of Busi-ness Integration. Procedia Econ. Financ. 2015, 24, 511–518. [Google Scholar] [CrossRef]

- Wang, J.; Peng, L.; Chen, J.; Deng, X. Impact of Rural Industrial Integration on Farmers’ Income: Evidence from Agricultural Counties in China. J. Asian Econ. 2024, 93, 101761. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, X. Paths and Development of Rural Industry Integration in China from the Perspective of Six Industries: Insights from Japan’s Six Industry Integration. Guizhou Soc. Sci. 2023, 1, 152–160. [Google Scholar]

- Zhang, Z.; Sun, C.; Wang, J. How Can the Digital Economy Promote the Integration of Rural Industries—Taking China as an Example. Agriculture 2023, 13, 2023. [Google Scholar] [CrossRef]

- Weiner, B.J. A theory of organizational readiness for change. Implement. Sci. 2009, 4, 67. [Google Scholar] [CrossRef]

- Thomas, L.; Autio, E. Innovation Ecosystems. Available online: https://ssrn.com/abstract=3476925 (accessed on 28 October 2019).

- Arellano, M.C.; Sancha, C.; Netland, T.; Gimenez Thomsen, C. Manufacturing network integration and culture: An institution-based view. J. Manuf. Technol. Manag. 2021, 32, 1121–1143. [Google Scholar] [CrossRef]

- Trusova, N.V.; Oleksenko, R.I.; Kalchenko, S.V.; Yeremenko, D.V.; Pasieka, S.R.; Moroz, S.A. Managing the Intellectual Potential in the Business-Network of Innovative Digital Technologies. Stud. Appl. Econ. 2021, 39, 1–15. [Google Scholar] [CrossRef]

- Porter, M.; Delgado, M.; Ketels, C.; Stern, S. Moving to a New Global Competitiveness Index. In The Global Competitiveness Report 2008–2009; World Economic Forum: Geneva, Switzerland, 2008; pp. 43–63. [Google Scholar]

- Tkacheva, A.; Saginova, S.; Karimbergenova, M.; Taipov, T.; Saparova, G. Problems and Prospects for the Development of Cluster Structuring in the Economy of Kazakhstan’s Agricultural Sector: Theory and Practice. Economies 2024, 12, 185. [Google Scholar] [CrossRef]

- McPhillips, M. Innovation by proxy—Clusters as ecosystems facilitating open in-novation. J. Entrep. Manag. Innov. 2020, 16, 101–128. [Google Scholar] [CrossRef]

- Maracha, V. The Relationship Between Government and Business in the Context of the Formation of Innovation Clusters and Ecosystems in Russia. Available online: https://ssrn.com/abstract=3392337 (accessed on 7 May 2019).

- Granstrand, O.; Holgersson, M. Innovation ecosystems: A conceptual review and a new definition. Technovation 2020, 90–91, 102098. [Google Scholar] [CrossRef]

- Mendes, T.; Silva, C.; Braga, A. Dancing with Giants: A Unified Framework for Cooperation Networks, Speed of Internationalisation, and Performance. Sustainability 2023, 15, 2003. [Google Scholar] [CrossRef]

- Derlukiewicz, N.; Mempel-Śnieżyk, A.; Mankowska, D.; Dyjakon, A.; Minta, S.; Pilawka, T. How do Clusters Foster Sustainable Development? An Analysis of EU Policies. Sustainability 2020, 12, 1297. [Google Scholar] [CrossRef]

- Huang, Y.; Hong, T.; Ma, T. Urban network externalities, agglomeration economies and urban economic growth. Cities 2020, 107, 102882. [Google Scholar] [CrossRef]

- Bărbulescu, O.; Nicolau, C.; Munteanu, D. Within the Entrepreneurship Ecosystem: Is Innovation Clusters’ Strategic Approach Boosting Businesses’ Sustainable Development? Sustainability 2021, 13, 11762. [Google Scholar] [CrossRef]

- Zhu, J.-G.; Li, X.-J. The Effect of Industrial Agglomeration on High-quality Regional Economic Growth: From the Perspective of Spatial Spillover Effect. Econ. Geogr. 2022, 42, 1–9. [Google Scholar]

- Ju, X.; Zhou, X.; Zhang, L.; Ma, C.-A.; Zhang, Y. Evaluation of Low-Carbon Economic Efficiency under Industrial Clustering and Study of Regional Differences, Taking Xinjiang as an Example. Sustainability 2024, 16, 2008. [Google Scholar] [CrossRef]

- Bezerra, R.R.R.; Martins, V.W.B.; Macedo, A.N. Validation of Challenges for Implementing ESG in the Construction Industry Considering the Context of an Emerging Economy Country. Appl. Sci. 2024, 14, 6024. [Google Scholar] [CrossRef]

- Mazzoni, F. Circular economy and eco-innovation in Italian industrial clusters. Best practices from Prato textile cluster. Insights Reg. Dev. 2020, 2, 661–676. [Google Scholar] [CrossRef]

- Razminienė, K.; Vinogradova-Zinkevič, I.; Tvaronavičienė, M. Tracing Relationship between Cluster’s Performance and Transition to the Circular Economy. Sustainability 2021, 13, 13933. [Google Scholar] [CrossRef]

- Perez-Valdes, G.A.; Nørstebø, V.S.; Ellingsen, M.-B.; Teräs, J.; Werner, A.T. Bioeconomic Clusters—Background, Emergence, Localization and Modelling. Sustainability 2019, 11, 4611. [Google Scholar] [CrossRef]

- McKernan, D.; McDermott, O. The Evolution of Ireland’s Medical Device Cluster and Its Future Direction. Sustainability 2022, 14, 10166. [Google Scholar] [CrossRef]

- Zhuang, T.; Zhao, S.L. Collaborative innovation relationship in Yangtze River Delta of China: Subjects collaboration and spatial correlation. Technol. Soc. 2022, 69, 101974. [Google Scholar]

- Dimos, C.; Fai, F.M.; Tomlinson, P.R. The attractiveness of university and corporate anchor tenants in the conception of a new cluster. Reg. Stud. 2021, 55, 1473–1486. [Google Scholar] [CrossRef]

- Xiong, W.; Li, J. The Knowledge Spillover Effect of Multi-Scale Urban Innovation Networks on Industrial Development: Evidence from the Automobile Manufacturing Industry in China. Systems 2024, 12, 5. [Google Scholar] [CrossRef]

- Xu, Y.; Li, X.; Tao, C.; Zhou, X. Connected knowledge spillovers, technological cluster innovation and efficient industrial structure. J. Innov. Knowl. 2022, 7, 100195. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, T.; Lin, W.; Chen, Z.; Xiao, R. A Patent Mining Approach to Accurately Identifying Innovative Industrial Clusters Based on the Multivariate DBSCAN Algorithm. Systems 2024, 12, 321. [Google Scholar] [CrossRef]

- Chen, X.; Wang, E.; Miao, C.; Ji, L.; Pan, S. Industrial Clusters as Drivers of Sustainable Regional Economic Development? An Analysis of an Automotive Cluster from the Perspective of Firms’ Role. Sustainability 2020, 12, 2848. [Google Scholar] [CrossRef]

- Christopoulos, G.; Wintjes, R. Identifying Clusters as Local Innovation Systems. J. Knowl. Econ. 2024, 15, 9784–9823. [Google Scholar] [CrossRef]

- Mercado-Caruso, N.; Segarra-Oña, M.; Ovallos-Gazabon, D.; Peiró-Signes, A. Identifying Endogenous and Exogenous Indicators to Measure Eco-Innovation within Clusters. Sustainability 2020, 12, 6088. [Google Scholar] [CrossRef]

- Tong, T.; Zainudin, N.B.; Yan, J.; Rahman, A.A. The Impact of Industry Clusters on the Performance of High Technology Small and Middle Size Enterprises. Sustainability 2023, 15, 9333. [Google Scholar] [CrossRef]

- Venugopal, P.; Malhotra, R.; Annamalai, B. The determinants for sustainability in a low-technology SME textile cluster in an emerging economy. Int. J. Bus. Innov. Res. 2018, 15, 340–356. [Google Scholar] [CrossRef]

- Kong, M.; Wang, X.; Wu, Q. The development efficiency of China’s innovative industrial clusters-based on the DEA-Malmquist model. Arab. J. Geosci. 2021, 14, 638. [Google Scholar] [CrossRef]

- Millers, M.; Gaile-Sarkane, E. Management Practice in Small and Medium-Sized Enterprises: Problems and Solutions from the Perspective of Open Innovation. J. Open Innov. Technol. Mark. Complex. 2021, 7, 214. [Google Scholar] [CrossRef]

- Domański, R.; Wojciechowski, H.; Lewandowicz, J.; Hadaś, Ł. Digitalization of Management Processes in Small and Medium-Sized Enterprises—An Overview of Low-Code and No-Code Platforms. Appl. Sci. 2023, 13, 13078. [Google Scholar] [CrossRef]

- Holzmann, P.; Gregori, P. The Promise of Digital Technologies for Sustainable Entrepreneurship: A Systematic Literature Review and Research Agenda. Int. J. Inf. Manag. 2023, 68, 102593. [Google Scholar] [CrossRef]

- Saaty, T.L. Relative measurement and its generalization in decision making why pairwise comparisons are central in mathematics for the measurement of intangible factors the analytic hierarchy/network process. Rev. R. Acad. Cien. Ser. A. Mat. 2008, 102, 251–318. [Google Scholar] [CrossRef]

- Sun, B.; Tang, J.; Yu, D.; Song, Z.; Wang, P. Ecosystem health assessment: A PSR analysis combining AHP and FCE methods for Jiaozhou Bay, China. Ocean Coast. Manag. 2019, 168, 41–50. [Google Scholar] [CrossRef]

- Xu, S.; Xu, D.; Liu, L. Construction of Regional Informatization Ecological Environment Based on the Entropy Weight Modified AHP Hierarchy Model. Sustain. Comput. Inform. Syst. 2019, 22, 26–31. [Google Scholar] [CrossRef]

- Dong, R.; Cai, Y.; Chen, X.; Wang, C.; Lian, A. Ecological Risk Assess-ment of Saltwater Intrusion and Urban Ecosystem Management in Shenzhen City. Land 2024, 13, 1338. [Google Scholar] [CrossRef]

- Xu, M.; Luo, Y.; Li, D. Research on Evaluation of City–Industry Integration in Industrial Parks. Sustainability 2024, 16, 6906. [Google Scholar] [CrossRef]

- Aguirre Rodríguez, E.C.; Hernández, C.T.; Aguirre-Rodríguez, E.Y.; da Silva, A.F.; Marins, F.A.S. Reverse Logistics and the Circular Economy: A Study before and after the Implementation of the National Solid Waste Policy in Brazil. Recycling 2024, 9, 64. [Google Scholar] [CrossRef]

- Tolstykh, T.; Gamidullaeva, L.; Shmeleva, N. Elaboration of a Mechanism for Sustainable Enterprise Development in Innovation Ecosystems. J. Open Innov. Technol. Mark. Complex. 2020, 6, 95. [Google Scholar] [CrossRef]

- Harrington, E. The desirability function. Ind. Qual. Control 1965, 21, 494–498. [Google Scholar]

- Strategies of Socio-Economic Development of Nizhny Novgorod Region Until 2035. Available online: https://strategy.nobl.ru/assets/ (accessed on 29 July 2024).

- State Information System of Industry. Available online: https://gisp.gov.ru/mainpage/ (accessed on 20 July 2024).

- Federal Tax Service of Russia. Available online: https://www.nalog.gov.ru/eng/ (accessed on 20 July 2024).

- Industrial Development Fund Chelyabinsk Region. Available online: https://frp74.ru/klastery (accessed on 25 July 2024).

- Garzella, S.; Fiorentino, R. Inside Synergy Assessment: Towards the Real Value of M&As. In Synergy Value and Strategic Management; Contributions to Management Science; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Oparin, S.G. Sinergy in integrated systems of risk management and its accounting in the digital economy. Issues Risk Anal. 2020, 17, 50–61. [Google Scholar] [CrossRef]

- Polednáková, A. Synergistic effect of joining process and its measurement. SHS Web Conf. 2020, 83, 01051. [Google Scholar] [CrossRef]

- Frunze, I.; Mikhaylik, D.; Levytskyi, S. Assessment techniques for integration efficiency of economic objects. Int. J. Econ. Commer. Manag. 2014, II, 143–158. [Google Scholar]

- Schardosin, F.Z.; De Rolt, C.R. Organizational Maturity Assessment Model for Collaborative Networks. In Smart and Sustainable Collaborative Networks 4.0. PRO-VE 2021, Saint-Étienne, France, 22–24 November 2021; Camarinha-Matos, L.M., Boucher, X., Afsarmanesh, H., Eds.; IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2021; Volume 629. [Google Scholar] [CrossRef]

- Schaltegger, S.; Wagner, M. Managing the Business Case for Sustainability: The Integration of Social, Environmental and Economic Performance; Routledge: London, UK, 2017; 626p. [Google Scholar] [CrossRef]

- Oertwig, N.; Galeitzke, M.; Schmieg, H.-G.; Kohl, H.; Jochem, R.; Orth, R.; Knothe, T. Integration of Sustainability into the Corporate Strategy. In Sustainable Manufacturing; Stark, R., Seliger, G., Bonvoisin, J., Eds.; Sustainable Production, Life Cycle Engineering and Management; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Zhukov, R.; Kuznetsov, G.; Manokhin, E.; Gorodnichev, S.; Plinskaya, M. Balanced Functioning of Socio-Economic Systems: Regional Perspective. J. Law Sustain. Dev. 2023, 11, e1922. [Google Scholar] [CrossRef]

- Gamidullaeva, L.A.; Tolstykh, T.O.; Shmeleva, N.V. Environmental and technological projects as an instrument of industrial policy in Industry 5.0 conditions. Vestn. Samara State Univ. Econ. 2024, 231, 24–37. (In Russian) [Google Scholar]

- Karuppiah, K.; Sankaranarayanan, B.; Lo, H.-W. A systematic literature review on the evolution of sustainable manufacturing practices: Key findings and implications. Clean. Eng. Technol. 2024, 22, 100798. [Google Scholar] [CrossRef]

- Aagaard, A.; Saari, U.A.; Mäkinen, S.J. Mapping the types of business experimentation in creating sustainable value: A case study of cleantech start-ups. J. Clean. Prod. 2021, 279, 123182. [Google Scholar] [CrossRef]

- Schlüter, L.; Kørnøv, L.; Mortensen, L.; Løkke, S.; Storrs, K.; Lyhne, I.; Nors, B. Sustainable business model innovation: Design guidelines for integrating systems thinking principles in tools for early-stage sustainability assessment. J. Clean. Prod. 2023, 387, 135776. [Google Scholar] [CrossRef]

- Karuppiah, K.; Sankaranarayanan, B.; Ali, S.M. A systematic review of sustainable business models: Opportunities, challenges, and future research directions. Decis. Anal. J. 2023, 8, 100272. [Google Scholar] [CrossRef]

- Thomson, L.; Kamalaldin, A.; Sjödin, D.; Parida, V. A maturity framework for autonomous solutions in manufacturing firms: The interplay of technology, ecosystem, and business model. Int. Entrep. Manag. J. 2022, 18, 125–152. [Google Scholar] [CrossRef]

- Paiola, M.; Schiavone, F.; Grandinetti, R.; Chen, J. Digital servitization and sustainability through networking: Some evidences from IoT-based business models. J. Bus. Res. 2021, 132, 507–516. [Google Scholar] [CrossRef]

- Aldowaish, A.; Kokuryo, J.; Almazyad, O.; Goi, H.C. Environmental, Social, and Governance Integration into the Business Model: Literature Review and Research Agenda. Sustainability 2022, 14, 2959. [Google Scholar] [CrossRef]

- Rubio-Andrés, M.; Abril, C. Sustainability oriented innovation and organizational values: A cluster analysis. J. Technol. Transf. 2024, 49, 1–18. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).