Abstract

The sustainable development and operation of mining enterprises as major sources of economic growth in many countries is determined by a balance of economic, environmental, and social objectives and the resources required to achieve these objectives. Transportation is one of the main equipment at open pits. It accounts for up to 70% of open pit operating expenses. Various parameters of transportation means should be coordinated both with the parameters of the open pit and meet the conditions of its operation. The authors have developed a universal system of criteria for selecting a dump truck model for open pit conditions. The novelty of the proposed system lies in the complex consideration of all known factors to date and criteria of dump truck selection and the allocation of four groups of criteria: technical, technological, environmental, economic, and organizational. The groups of criteria and specific criteria in each group were ranked by the degree of importance using the multi-criteria decision-making method FUCOM (Full Consistency Method). The methodology of creating criteria systems in conditions of influence on the choice of alternatives of a set of interrelated factors is presented. The peculiarity of the methodology is the evaluation of different sets of criteria by several groups of experts with different competencies. The obtained criterion ranks are recommended to be used by managers of mining enterprises to choose a dump truck model. The presented methodology is suitable for the development of new systems of criteria, considering significant changes in operating conditions or the emergence of factors not considered in this study. Evaluation of all models of dump trucks on the market using the developed system of criteria is envisaged by the authors in a future study.

1. Introduction

The largest volume of transportation of rock mass in open pits is carried out all over the world by dump-trucks of various carrying capacities [1,2]. The cost of transporting rock mass increases by 20–30% on average for every 100 m of depth in deep pits. The share of these costs reaches 70% or more of field development total cost [3,4,5]. At the same time, the maximum transportation distance is 10 km for deep open pits. Cost reduction is achieved by combining modes of transport. The combination of automobile and conveyor transport or cyclical-and-continuous method is the most common in open pits [6,7]. Most researchers consider this method promising for deep open pits [8,9]. The implementation of this method requires the creation of transshipment points. The effectiveness of schemes with combined transport depends on the depth of the transshipment points in the open pit. Nevertheless, the share of transportation by dump trucks remains considerable in this case [10,11].

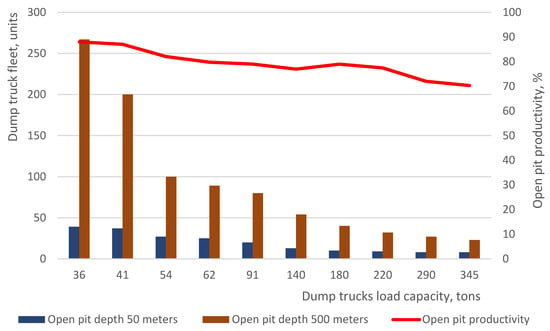

Many alternative options for the layout of the open pit transport system have appeared in mining enterprises currently. This is due to both an increase in the carrying capacity of new models of mining dump trucks and the number of dump truck manufacturers. The tendency to increase the carrying capacity of dump trucks to ensure the required cargo turnover is especially relevant for large and deep open pits [12,13]. The maximum carrying capacity of modern mining dump trucks has reached 450 tones [3]. According to [14], nine major manufacturers of mining dump trucks are represented on the world market. However, their number tends to increase. In addition, the range of mining equipment is constantly expanding. These factors are the reason for a significant variety of applied technical and technological solutions. The results of 13 open pit projects carried out by the authors show that the most common differences are the following: the load capacity of dump truck models in the same open pit—5 times; the estimated width of the transport berm—1.5–3 times; the depth, and angles of the conveyor in different open pits—2–4 times; the number of dump trucks for various transport complex layout options, but for the same open pits depth and productivity—up to 10 times [10] (Figure 1).

Figure 1.

Change in the number of dump truck fleets of the depth and productivity of the open pit.

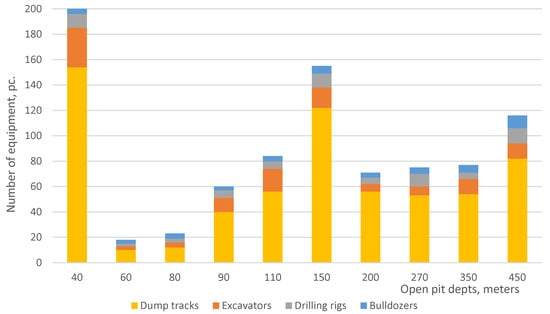

The number of equipment pieces in the open pit increases as it deepens. At least 3–4 dump trucks account for one mining excavator at a depth of open pits up to 200 m and at a depth of 200–600 m—10 or more dump trucks. Moreover, open pit transport constitutes the bulk of the equipment and is 2.1–3.7 times higher than the number of all other types of equipment for the main technological processes (Figure 2).

Figure 2.

The amount of equipment in different depths of open pits.

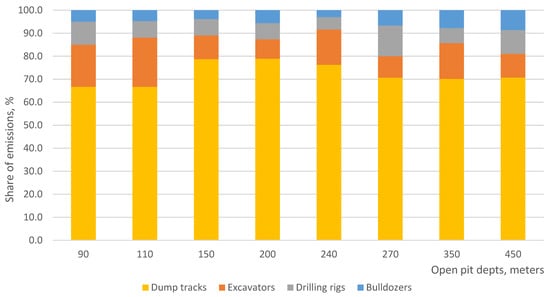

The negative impact of a mining company on the environment increases with the increase in the amount of equipment. Especially relevant are the issues of the negative impact of equipment operation on the atmosphere in deep open pits. The main negative impacts of open pit equipment are emissions from the operation of dump truck engines and dust during the transportation of rocks [15]. Dump trucks account for 60% to 75% of emissions (Figure 3). The results of these authors’ studies do not consider the volume of emissions during the production of blasting. These emissions are not permanent and do not affect the work of personnel and equipment in the open pit since until the complete dispersion of the dust-gas cloud, after blasting, the resumption of work in the open pit is not allowed.

Figure 3.

Contribution of different types of equipment to open pit emissions.

In this regard, environmental issues have a significant influence on the design decisions for deep open pits [16,17,18,19]. The paper [20] shows the influence of different subsystems—the opening-up of an opencast system, opencast development system, transportation system, and others—on the sustainability of a mining enterprise. The importance of the transportation system as a connecting link of all subsystems of a mining enterprise is proved. In the review [21], the authors show that fleet management contributes to the creation of a green and climate-smart open pit mine. Improving the efficiency of deep open pits operations requires the consideration of many alternative solutions in such conditions. One of the most important decisions is the selection of a specific dump truck model. The presence of numerous factors and options makes the selection issue complex and multi-criteria.

The main contributions are:

- (1)

- A novel universal system of criteria for selecting a dump truck model for open pit conditions. The two-level system of criteria is a ranked and grouped list of all criteria known today.

- (2)

- The methodology of development and adjustment of such a system is based on the use of multi-criteria decision-making method FUCOM (Full Consistency Method). The peculiarity of the methodology is the evaluation of the degree of importance of different sets of criteria by groups of experts competent in different fields.

The remainder of this paper is organized as follows. Section 2 presents a literature review on the study of factors, methods, and criteria for selecting a dump truck model. Section 3 presents the methodology of criteria system formation using the FUCOM multi-criteria method. Section 4 contains the result of the systematization and ranking of criteria for selecting a dump truck model using the developed methodology. Finally, the conclusion section presents conclusions and recommendations on the application of the proposed methodology and future research.

2. Literature Review

2.1. Factors for Selecting a Dump Truck Model

One of the main factors is the excavator model, the choice of which, in turn, depends on the height of the ledge, the physical and mechanical properties of the rocks, and the required productivity of the open pit [22]. However, numerous variants of dump truck models are possible for the same excavator model.

The authors [23] propose to consider the properties of rocks, the distance of transportation, the amount of work, and the rate of deposit development when selecting a dump truck model. The authors of the study [24] consider the ratio of the dump truck body capacity to the capacity of the excavator bucket, which should be in the range from 4–6 to 7–8, to be the most important factor. In addition, they suggest selecting higher capacity models as the open pit deepens, transport distances increase, and rock mass transport volumes increase. Three factors are proposed to be considered in the paper [25]. The first factor is the maneuverability of the dump truck, which depends on its technical characteristics, including the load capacity and size of the dump truck. The second factor is the carrying capacity, which must correspond to the transportation volumes. Finally, the third factor is safe working conditions. In [26], research proposes a performance measure for dump trucks which is derived from the overall equipment effectiveness through modification of performance metrics.

Many studies are devoted to the choice of a rational model of a dump truck based on economic factors. The competitiveness coefficient, which considers the prices of compared models, as well as several technical characteristics, was proposed in [27]. The indicator of the efficiency of transport work is studied in [28]. This indicator considers changes in mining conditions and the economic situation. The value of the total discounted costs for the acquisition and operation of dump trucks [3] is one of the common indicators for evaluating dump truck models. Economic losses from downtime of dump trucks [29], including because of their breakdowns [30], are considered when choosing dump trucks. Options for using fuel [31] and other energy sources [15,32] are determining the amount of operating expenses for various models of dump trucks. Researchers in [33,34,35] suggest considering the possibility of using conveyors in an open pit when selecting dump truck models. The choice is also made based on an economic comparison of the options in these studies.

The cost of buying dump trucks and subsequent operating expenses are major factors in business practice. To perform the corresponding calculations, various software tools are used, for example, PTV Vissim [36] in the method [37].

However, the emphasis mainly on economic indicators does not allow the consideration ofthe environmental friendliness and safety of the operation of dump trucks. Progressive mining enterprises are beginning to shape their mission in accordance with the concept of sustainable development. Social and environmental factors, as well as factors of automation of transportation and production processes, begin to influence decision making [38,39,40] at such enterprises. The systematic consideration of these factors is especially difficult when selecting a model of dump trucks for deep open pit conditions. This is because the fleet of dump trucks is completely replaced as the open pit deepens. Thus, technical, technological, economic, environmental, geological, and organizational factors must be considered when selecting dump truck models to ensure the efficient operation of deep open pits. The present study summarizes the factors and criteria for dump truck selection presented in previous studies. A list of all known criteria is compiled based on the analyzed works and the analysis of open pit practices.

2.2. Multi-Criteria Decision-Making Methods

The specifics of work at great depth predetermine the need for a multifactorial and multi-criteria approach to solving the problem of selecting mining dump trucks. Therefore, the study proposes the use of multi-criteria methods to select the dump truck model. These methods are based on expert ranking of criteria for evaluating alternatives, followed by ranking of alternatives in accordance with the rank of criteria. This approach allows for considering many conflicting factors and requirements. Currently, such methods are widely used in mining and in the choice of transport and handling systems for open-pit mining. An analysis of the experience of using MCDM (Multi-Criteria Decision-Making) was performed to identify the most used methods. The result of the analysis is presented in Table 1.

Table 1.

MCDM for the selection of transportation and loading-handling systems in mining.

The AHP or fuzzy AHP method, as well as its combinations with other methods (TOPSIS, PROMETHEE, ELECTRE) is used most often for the selection of dump trucks and loading and unloading systems in open pits. The analyzed methods (Table 1) are widely used in various research areas, use both quantitative and qualitative evaluation criteria, are relatively simple, and are also implemented in convenient software.

The main disadvantage of the considered methods is many pairwise comparisons of criteria. This makes the procedure of multi-criteria evaluation time-consuming with numerous criteria. Several researchers in the field of MCDM have proposed more efficient methods for multi-criteria evaluation [60,61,62]. FUCOM [63,64] is the most promising, according to the authors. However, we were unable to find studies on the application of this method in mining. Considering the large number of factors influencing the selection of dump trucks for open pit mines, the study proposes the use of FUCOM.

This study is a continuation of a series of our previous articles. First, we drew attention to the need to consider additional criteria when selecting dump trucks [65]. Then it was established that the opening-up of an opencast system is the main subsystem of the mining and technical system that determines its efficiency. The main element of the opening-up of an opencast system is dump trucks [20]. Finally, the necessity to consider the sustainable development goals when selecting the parameters of the opening-up of an opencast system was established. This requires considering many different factors and criteria based on MCDM [19]. This paper continues the previous research and focuses on the development of a system of universal criteria for selecting dump trucks using MCDM. The developed system of criteria will harmonize the parameters of the opening-up of an opencast system for the sustainable development of the whole mining and technical system.

3. Models and Methods

3.1. Methodology of Forming a System of Criteria for Dump Tracks Selecting Model

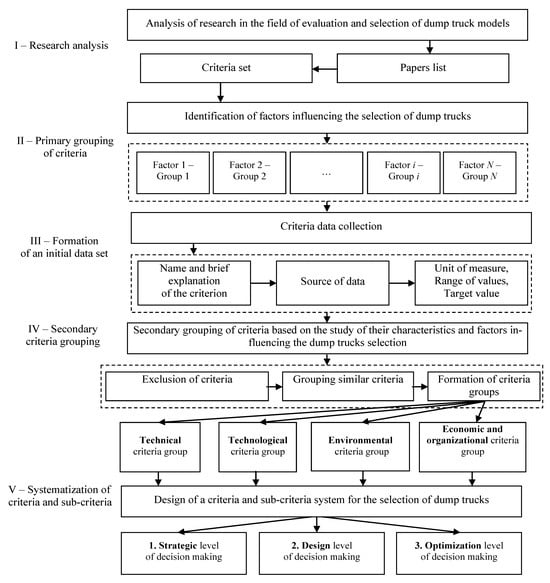

The section presents a new methodology resulting in an original universal system of criteria for selecting a dump truck model. The methodology consists of the following five stages.

Stage I. Analysis of research in the field of selecting mining equipment, dump trucks, and optimizing the operation of mining vehicles. Identification of factors and formation of a list of selection criteria.

Stage II. Primary grouping of criteria according to factors influencing the selection of dump trucks. Grouping is done by establishing relationships between factors and criteria.

Stage III. Formation of an initial data set. We suggest the following list of data: the range of values, the unit of measure, and the target value of the criterion. In addition, the description of the criterion should contain its name, a brief explanation, the name of the corresponding group of criteria, and an indication of the source of data on the range of quantitative values of the criterion.

Stage IV. Secondary criteria grouping. This grouping is recommended to equalize the number of criteria in the groups. Such adjustment is necessary for the correct ranking of criteria by the FUCOM method. Secondary grouping is carried out by combining similar criteria in terms of meaning, units of measurement, range of acceptable values, and target values. In addition, it is allowed to combine groups of criteria according to the similarity of the relevant factors. In addition, we recommend excluding conditionally constant parameters, as well as dependent parameters, from consideration. For example, the technical indicator “duration of unloading a dump truck” is excluded since it is conditionally the same for all mining dump trucks, and the time spent on unloading does not exceed 1% of the total duration of the trip. Another technical indicator, “average rolling resistance”, is also excluded since its value depends on other criteria already included in the group of technical criteria.

As a result, four groups of criteria are obtained: technical, technological, environmental, and economic and organizational. In addition, we recommend excluding conditionally constant parameters, as well as dependent parameters, from consideration. For example, the technical parameter “duration of unloading a dump truck” is excluded since it is conditionally the same for all mining dump trucks, and the time spent on unloading does not exceed 1% of the total duration of the trip. Another technical parameter, “average rolling resistance”, is also excluded since its value depends on other parameters already included in the group of technical criteria.

Stage V. Distribution of criteria by expert competence levels for further ranking of criteria by the FUCOM method. Such a distribution is necessary to obtain the most objective and qualitative assessment of the criteria. We proceeded from the assumption that the most qualitative assessment of the criteria can be given by experts with competencies that best match the content of the criterion. It is proposed to distinguish three levels of expert competencies: strategic, project, and optimization.

Level 1—Strategic: Experts of this level have competencies in the field of strategic management of a mining enterprise. These experts evaluate the criteria that determine the company’s financial performance and reputation. We classified owners or presidents of companies, key executives, general, commercial, and technical directors, as well as their deputies, as first-level experts.

Level 2—Design: The second-level experts evaluate the criteria that are used in making design decisions. The experts at this level are the heads and specialists of the design and engineering department, chief engineers, miners, geologists, mine surveyors, heads and specialists of planning and economic departments, and heads of labor protection and environmental departments.

Level 3—Optimization: At the third level, experts evaluate the criteria directly related to the process of operation and maintenance of dump trucks in an open pit. Such experts include mechanics, power engineers, heads of open pits, transport departments, and shift supervisors.

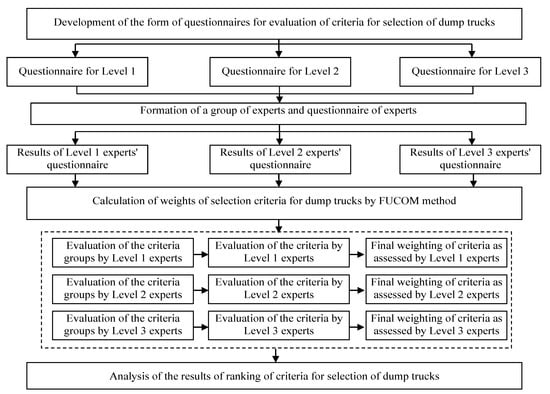

A flowchart of the proposed methodology for systematizing the selection criteria for dump trucks is shown in Figure 4.

Figure 4.

Methodology of the criteria system design for the dump truck selection.

The presented methodology is general for solving the criteria system design problem. The initial data are scientific publications and the results of surveys of industrial experts. Nevertheless, the authors propose to use the developed system of criteria (see Section 4) as a base one, since it is the result of an analysis of all currently known factors considered when choosing models of dump trucks.

3.2. FUCOM Method for Calculating Criterion Weights

The FUCOM [43] method was chosen to calculate the weight of the criteria that determine the selection of dump trucks. The choice of the FUCOM method is justified by the fact that in comparison with AHP, ANP, and BWM (Best-Worst Method), it provides the following advantages [63,66,67]:

- -

- Minimum number of pairwise comparisons of criteria equal to (n − 1), compared to AHP (n(n − 1)/2), and to BWM (2n − 3).

- -

- Simple algorithm is used for the prioritization of criteria by decision makers.

- -

- High reliability of the result.

- -

- Allows obtaining optimal weighting factors with the possibility of validating them, showing the consistency of the results.

Thus, the FUCOM method, unlike AHP and BWM, provides an opportunity to perform model checking by calculating the error size for the obtained criterion weight vectors to determine the degree of consistency and thus adequately reflect errors in expert judgments.

The FUCOM method has been used in transportation to evaluate and select alternative fuel vehicles [68], human resources of a transportation company [69], and others [70,71]. In the mining industry, additionally, it is used to assess the mineral potential of new deposits [67].

The basic steps of the FUCOM method are [71]:

Step 1. Ranking of criteria from a predefined set of evaluation criteria C = {C1, C2, …, Cn} is performed:

where k is a rank of the criterion considered.

Step 2. The ranked criteria are mutually compared, and comparative importance, , is identified:

where k is a rank of the evaluation criteria.

Step 3. The final values of the weighting coefficients of the evaluation criteria are calculated. The final values should meet two conditions:

- (a)

- The ratio of the weighting coefficients is equivalent to the comparative importance among the criteria considered , as determined in Step 2, more specifically, that the following condition is met:

- (b)

- The condition of mathematical transitivity, i.e., that should be met by the final values of the weighting coefficients. Since and , then . So, the final values of the weighting coefficients of the evaluation criteria should fulfill the second condition, which is as follows:

Based on the above, a final model for determining the final values of the weighting coefficients of the evaluation criteria can be created.

The proposed methodology for determining the weights of criterion groups and criteria for selecting dump trucks using the FUCOM method is presented in Figure 5.

Figure 5.

Methodology for ranking criteria for selection of dump trucks.

4. Results

4.1. Data Collection and Formation of a Universal System of Dump Truck Selection Criteria

The selection of a dump truck model using multi-criteria methods requires the definition of a criterion set for evaluating various models. Fifty studies were analyzed to identify the criteria used to address this question. We analyzed studies on the selection of dump trucks and equipment complexes for open pits, as well as studies on the features of transport operation in deep open pits. The results of the analysis are presented in Table 2.

Table 2.

The result of criteria data collection for selecting dump trucks *.

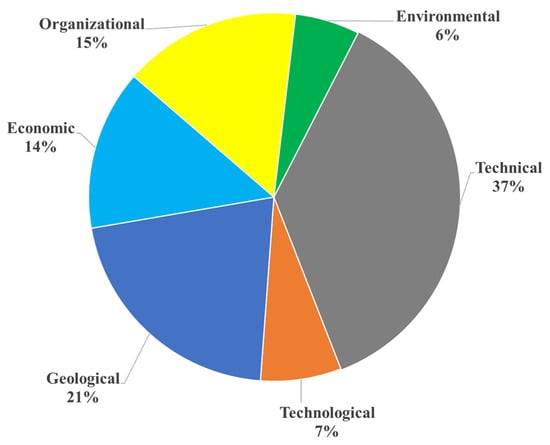

Six groups of criteria (Stage 2) were initially identified: technical, technological, geological, economic, environmental, and organizational (Figure 6). The number of criteria in the initial groups turned out to be uneven, from 4 to 26.

Figure 6.

Distribution of the number of criteria in predefined groups.

The authors in the referred literature defined the following features of the use of dump truck selection criteria in the analyzed studies:

- A total of 71 different criteria were identified.

- Significant variation in the number of criteria used by different authors. The minimum number of criteria is 2, and the maximum is 26.

- Differences in the understanding of the criteria by different authors.

- The predominance of criteria that we previously attributed to the group of economic criteria. 58% of the authors consider only capital and operating expenses.

- 25% of the total number of criteria are unique; that is, they are mentioned in only one study.

- 51% of the total number of criteria used in no more than three studies. We characterized such criteria as rarely used.

- 19% of the total number of criteria is used most frequently, that is, in ten or more studies.

- Some researchers use the criteria to select not only dump trucks but also other equipment, for example, when justifying excavator-and-dump truck complex options.

- A different number of levels of the criteria hierarchy—from 1 to 2. In the latter case, the level of criteria and subcriteria is distinguished.

- A variety of ways and systems for grouping criteria are used.

- 57% of the criteria are quantitative; for the remaining criteria, qualitative assessments are used.

- We have not identified studies that systematically use the entire set of known criteria for selecting dump trucks.

The variety and large number of criteria for choosing dump trucks motivate us to develop a universal system of criteria.

The sources of data on the criteria, as well as the units of measurement, ranges of values, and target values of each criterion, are defined in Stage 3 of the methodology.

A secondary grouping of criteria was carried out in accordance with the recommendations of Stage 4 of the methodology. This resulted in 4 groups of criteria. This allowed the elimination of the imbalance of the number of criteria in separate groups, which made further calculations difficult, as well as reduced the number of criteria under consideration by 36%—from 71 to 43 criteria.

Finally, the criteria were regrouped by competence levels and areas of responsibility of different mining specialists (Stage 5). We assigned 13 criteria to the Strategic level, 18 criteria to the Constructive level, and 15 criteria to the Optimization level. Some criteria were assigned to the areas of responsibility of specialists of several levels.

The system of dump truck selection criteria was formed because of the developed methodology (Table 3). The authors propose to use the developed system of criteria as a universal one because it includes all currently known factors influencing decision making on the choice of dump truck model.

Table 3.

Universal system of criteria for selection of dump trucks.

The panel of experts to determine the weighting of the criteria consisted of managers and specialists from various mining companies. Such enterprises were open pit mining iron ore, copper ore, gold ore, construction rocks, and raw materials for chemical and metallurgical industries. The composition of the expert group is presented in Table 4.

Table 4.

Composition of the expert group.

Experts completed questionnaires, the form of which differed for different levels of expert competence. The questionnaires consisted of the following sections: selection of the expert’s competence level (Appendix A), instruction (Appendix B), and questionnaire to assess the importance of criteria groups (Appendix C). The questionnaires for assessing specific criteria by experts of different levels have a form like Table A2. The difference lies in the set of specific criteria evaluated (Table 5, Table 6 and Table 7). The names of the group of criteria are present in all questionnaires, while the composition of criteria in the questionnaire depends on the expert’s level of competence (Table 3). The combinations of parameters and indicators depending on the level of competence are presented in Table 5, Table 6 and Table 7.

Table 5.

Composition of criteria assessed by experts of Level 1.

Table 6.

Composition of criteria assessed by experts of Level 2.

Table 7.

Composition of criteria assessed by experts of Level 3.

4.2. Results of Expert Evaluation of Criteria Groups and Criteria for Selection of Dump Trucks

The results of the evaluation of criteria groups for the selection of dump trucks by experts of different levels of competence are presented in Table 8, Table 9 and Table 10. For example, the first row of Table 8 presents the results of the evaluation of groups of criteria by the Level 1 experts. The evaluation was carried out in accordance with the instructions presented in Appendix B. A nine-point scale was used to assess the significance of the criteria.

Table 8.

Results of evaluation of the criteria groups by Level 1 experts.

Table 9.

Results of evaluation of the criteria groups by Level 2 experts.

Table 10.

Results of evaluation of the criteria groups by Level 3 experts.

The results of expert evaluation of the selection criteria for dump trucks are presented in Table 11, Table 12 and Table 13.

Table 11.

Results of criteria evaluation by Level 1 experts.

Table 12.

Results of criteria evaluation by Level 2 experts.

Table 13.

Results of criteria evaluation by Level 3 experts.

4.3. Results of Ranking the Criteria Groups and Criteria of the FUCOM Method

Below is an example of calculating the weighting coefficients of a group of criteria using the FUCOM method. As an example, the group of criteria of the first level (Table 8, assessment by expert DM1) is taken as follows: Technical (C1), Technological (C2), Environmental (C3), and Economic and organizational (C4). The expert ranks the group of criteria according to Formula (1): C2 > C1 > C4 > C3.

The decision maker performs a pairwise comparison of the ranked criteria. The comparison was performed with respect to criterion C2, which took the first place. As a result, the priorities of criteria are determined for all criteria under consideration (Table 8): , , , .

Based on the obtained criteria priorities, the comparative priorities of the criteria are calculated in accordance with Formula (2):

The final values of weighting factors are checked using Formulas (3) and (4).

Formula (3): ; ; .

Formula (4): ; .

Considering expression (5), a model for determining the values of criteria weighting coefficients is obtained:

The solution of this model results in the values of weight coefficients of the groups of criteria C1–C4 (0.1818; 0.5455; 0.0909; 0.1818) (Table 14). The value of the deviation value from the full consistency of the results is = 0.00, which indicates the objectivity of the obtained results.

Table 14.

The results of calculating the weights of the criteria groups for selecting dump trucks.

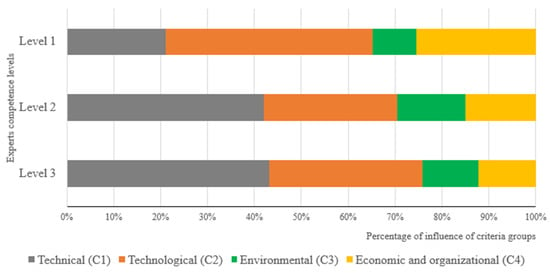

The results of calculating the weights of the groups of criteria for selecting dump trucks in accordance with the FUCOM methodology (Section 2.2) are presented in Table 14 and Figure 7. The value of deviation for all criteria groups and for all experts is equal to 0.

Figure 7.

Results of assessment of criteria groups weights by experts of different competence levels.

The analysis of the results of the assessment of criterion group weights confirmed the hypothesis about differences in these assessments by experts of different competence levels.

Level 1 experts gave the highest priority to the group of Technological criteria (C2)—the weight coefficient of this group is 0.4416. The Technical (C1) and Economic–Organizational (C4) groups of criteria have almost the same weight, 0.211 and 0.2548, respectively. The lowest priority is given to the group of Environmental criteria (C3), with a weight coefficient of 0.0926.

Level 2 and 3 experts give the highest priority to the group of Technical (C1) criteria, the weight coefficients for which are 0.4202 and 0.4320, respectively. This is followed by Technological (C2)—0.2842 and 0.3263 and Economic–Organizational (C4)—0.1499 and 0.1229. These experts also put the Environmental (C3) group in last place—0.1457 and 0.1188.

The group of Environmental (C3) criteria received the least weight according to the assessments of experts of all levels.

This result indicates the insufficient state regulation of environmental problems at the studied mining enterprises. On the other hand, modern research proves the necessity to revise priorities in decision making for mining enterprises towards environmental aspects [16]. For example, studies [38,39,40] show the effectiveness of excluding economic criteria at the stage of preliminary assessment of criteria since economic criteria, in most cases, are evaluated by experts according to the highest priority.

The results of calculating the weights of the selection criteria for dump trucks are presented in Table 15, Table 16 and Table 17. The value of deviation for all groups of criteria and for all experts, as well as in the case of groups of criteria, is equal to 0.

Table 15.

Results of criteria for selection of dump trucks evaluation by Level 1 experts.

Table 16.

Results of criteria for selection of dump trucks evaluation by Level 2 experts.

Table 17.

Results of criteria for selection of dump trucks evaluation by Level 3 experts.

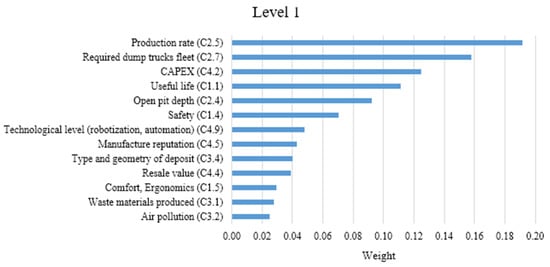

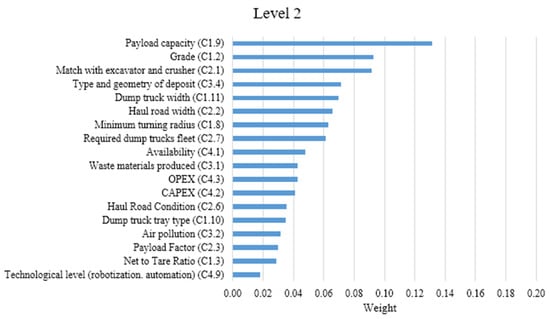

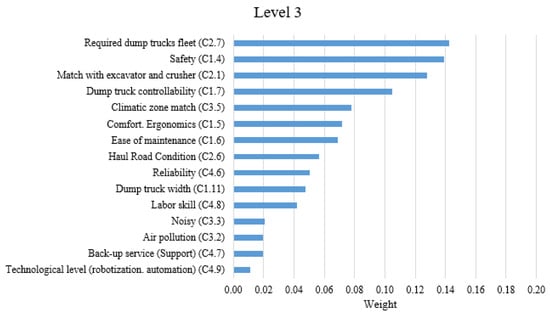

The results of the evaluation of the weighting of the selection criteria for dump trucks, performed by the FUCOM method, are presented in Table 18, Table 19 and Table 20. The results of criteria ranking (Global weight) by expert competence levels are presented in Figure 8, Figure 9 and Figure 10. The criterion groups and the criteria that received the highest weight values are in bold.

Table 18.

Results of evaluation of the weighting of selection criteria for dump trucks by Level 1 experts *.

Table 19.

Results of evaluation of the weighting of selection criteria for dump trucks by Level 2 experts *.

Table 20.

Results of evaluation of the weighting of selection criteria for dump trucks by Level 3 experts *.

Figure 8.

Result of ranking of criteria for selection of dump trucks by Level 1 competence experts.

Figure 9.

Result of ranking of criteria for selection of dump trucks by Level 2 competence experts.

Figure 10.

Result of ranking of criteria for selection of dump trucks by Level 3 competence experts.

Estimates of dump truck selection criteria significance differ according to experts of different levels of expertise. The same situation is observed here as in the case of criteria groups.

The authors made several assumptions at the initial stage of the study. These assumptions are related to the orientation of experts of a certain level of competence to the criteria corresponding to their field of activity. The hypothesis that Level 1 experts prioritize economic and environmental criteria was that these experts are oriented toward strategic decisions. Such decisions include, for example, maximizing the financial results of the whole company, as well as strengthening the company’s reputation by implementing various environmental and social measures. Emphasis on technological criteria was expected in the Level 2 experts, as these experts are responsible for operational planning. Finally, prioritization of technical criteria was expected in the assessments of Level 3 experts, as they directly operate dump trucks and are interested in their reliability and safety. However, all the above hypotheses were not confirmed. A detailed analysis of the results obtained allowed us to find explanations for the differences between the actual results and the expected ones.

The assessments of criteria groups and local criteria did not coincide among experts of all competence levels. Discussion of the obtained results with experts allowed to establish the reason for such differences. It was found that experts perceive groups of criteria as target criteria and local criteria as constraints to be observed in the process of achieving target criteria.

For example, Level 1 experts prioritized the group of Technological criteria (C2) as target criteria, but the technical criterion “Useful life of dump trucks” (C1.1) was selected by them as a priority local criterion. Level 2 experts chose the group of Technical criteria (C1) as the target criteria, as they are oriented in their activities towards the most efficient operation of machinery. However, the same experts prioritized the local criterion “Type and geometry of deposit” (C3.4) from the Environmental criteria group. This is because the operational decisions of these experts are determined by the actual configuration of the ore body, which may differ significantly from the design configuration. Operational adjustments complicate current and operational planning and are therefore perceived as constraints by this group of experts. Although the Level 3 experts expectedly prioritized their target group of technical criteria (C1), they selected “Climatic zone match” (C3.5) from the Environmental criteria group as the priority local criterion. The main reason for this discrepancy was explained by the fact that the mining enterprises where the interviewed experts work are located in the harsh climatic conditions of the Russian Federation and the Republic of Kazakhstan. Therefore, the influence of climatic conditions, in particular, sharp fluctuations in ambient air temperature is perceived by experts of this level as factors complicating the operation of the mining enterprise and reducing the reliability and safety of dump trucks.

The values of global criteria weights for each group of experts are the result of striving for a balance between target and local criteria—constraints. For example, the technological criterion “Production rate” (C2.5) received the maximum weight from the Level 1 experts because the achievement of the target values of this criterion is the main indicator of the efficiency of experts from this group. We make a similar explanation for the results of other groups of experts. The criterion “Payload capacity” (C1.9) received the maximum global weight in the group of Level 2 experts, and the criterion “Required dump trucks fleet” (C2.7)—in the experts of Level 3.

The findings also explain the non-confirmation of the hypothesis about the priority of certain criteria among experts of certain levels. There are two reasons for this. The first reason is the selection of specific experts. For example, experts who are not owners of mining enterprises or top managers formed the composition of the Level 1 expert group in our case study. Therefore, they selected the technological group of criteria as the target criteria rather than the expected group of economic or environmental criteria. The second reason is the two-tiered nature of our proposed criteria system. The criteria with the highest local weight do not belong to the group of criteria also with the highest weight among experts of all levels. This also indicates differences in the evaluation of target criteria—groups and limiting criteria. Criteria with maximum global weight are defined as compromise criteria, compliance with which allows achieving the target criteria while meeting the limiting local criteria.

We compared the results of averaging the weights of the criteria groups with the assessments of experts of different levels. The average values almost completely coincide with the results of Level 3 experts’ assessments. However, Level 1 and Level 2 experts evaluated the groups of technical and technological criteria differently. Level 1 experts gave priority to the group of Technological criteria (weight C2 = 0.5528), while Level 2 experts most highly evaluated the significance of the Technical criteria (weight C1 = 0.5861). The obtained result is explained by the peculiarity of work organization at the studied open pits when direct executors (Level 3) are oriented to the requirements of managers pursuing different, often opposite goals.

The analysis of the obtained results allowed us to conclude about the productivity of the proposed methodology of forming a system of criteria for selecting dump trucks. The dump truck fleet is a critical element of a complex mining and technical system. The main feature of the methodology is a two-level system of criteria, the weight of which is determined by experts of three different levels of competence. The two levels of the criteria system include the level of target and common criteria for all experts, as well as the level of criteria specific to different experts. The application of the proposed methodology for the conditions of a particular mining enterprise will allow the determination of the criteria for selecting the dump truck model considering the existing conditions.

The proposed approach to selecting a dump truck model for an open pit has two main differences from the traditional technical and economic comparison of options. Firstly, in the traditional method, economic criteria have the highest priority. Social and environmental indicators of the options are considered as limitations. Secondly, a limited number of technical and technological criteria are considered. The set of such criteria in each specific case is subjective. The proposed universal system of criteria and the methodology of development and adjustment of such a system take into account all criteria known today and factors determining the choice of dump truck model for an open pit. Moreover, the use of criteria ranks substantiated in the paper allows for minimizing the influence of subjectivism in the evaluation of dump truck models.

5. Conclusions

A universal system of criteria for selecting a dump truck model for open pit conditions is presented. The novelty of the system of criteria consists of considering a set of all known criteria today, which are mentioned in the scientific literature and used in practice by engineers and managers of mining enterprises. We have identified 71 criteria, which are summarized and combined into four groups of criteria: technical, technological, environmental, and economic and organizational. Both groups and specific criteria in each group were ranked. The FUCOM multi-criteria decision-making method was chosen for ranking.

The methodology of construction of universal systems of criteria for conditions of many heterogeneous criteria and influencing factors is proposed. The distinctive feature of the methodology is the division of experts by competence levels and the evaluation of criteria in accordance with the competence area of each expert. For the problem to be solved, it is proposed to divide experts into three levels of competence: Strategic Level—the experts of this level have competencies in the field of strategic management of a mining enterprise; Design Level—the experts at this level are the heads and specialists of the design and engineering department, chief engineers, miners, geologists, mine surveyors, heads and specialists of planning and economic departments, heads of labor protection and environmental departments; and Optimization Level—such experts include mechanics, power engineers, heads of mining enterprises, transport departments and shift supervisors. In addition, the method of criteria grouping and the procedure of forming sets of criteria for experts of different levels in accordance with their competencies are proposed. The criteria with the highest weights according to experts of different competence areas were identified: “Production rate” (according to Level 1 experts), “Payload capacity” (Level 2), and “Required dump trucks fleet” (Level 3). The division of experts by levels of competence allows for increasing the accuracy of assessments.

The analysis of the practice of thirteen real open pits and the results of fifty scientific studies allowed us to conclude that today, there is no systematic approach to solving the problem of dump truck model selection for open pits in the conditions of the necessity to consider a multitude of interrelated factors. The importance of the task of creating a universal system of criteria for the reasonable choice of dump truck model is to a significant share of transportation costs in the operating expenses of open pits.

We recommend using the proposed methodology of criteria system development in case it is necessary to consider specific factors and adjust the developed system.

In future studies, the authors will present a methodology for selecting a specific dump truck model using the developed system of criteria. We also intend to rank all dump truck models available on the market today for a particular deep pit. Finally, we plan to develop a methodology to summarize the evaluations of experts of different competencies to obtain integral ranks of criterion groups and individual criteria in each group.

The use of the developed system of criteria will ensure the objectivity of the choice of the dump truck model, improve not only the economic performance of the mining enterprise but also reduce the harmful impact on the environment, and improve the safety and comfort of the personnel.

Author Contributions

Conceptualization, A.R., K.B. and N.O.; methodology, A.R., K.B. and N.O.; validation, A.R., K.B. and N.O.; formal analysis, K.B. and N.O.; investigation, K.B. and N.O.; data curation, K.B.; writing—original draft preparation, K.B. and N.O.; writing—review and editing, A.R.; visualization, A.R., K.B. and N.O.; project administration, A.R.; All authors have read and agreed to the published version of the manuscript.

Funding

The work was carried out with the financial support of the Russian Science Foundation No. 23-21-10040, https://rscf.ru/en/project/23-21-10040/ (accessed on 12 December 2023) and Russian Science Foundation No. 23-21-10038, https://rscf.ru/en/project/23-21-10038/ (accessed on 12 December 2023).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Expert level selection form.

Table A1.

Expert level selection form.

| Level | Description | Choosing Level |

|---|---|---|

| 1 | Strategic: company owner; company president; key executives; general, commercial, and technical directors; etc. | |

| 2 | Design: heads and specialists of the design and engineering department; chief engineers; miners; geologists; mine surveyors; heads and specialists of planning and economic departments; heads of labor protection and environmental departments; etc. | |

| 3 | Optimization: mechanics, power engineers, head of transport departments, shift supervisors, etc. |

Appendix B. Instruction for Experts

Dear Expert, please give your opinion on the importance of selection criteria for dump trucks.

You form your opinion in two stages:

First stage. Give your opinion on the importance of four criteria groups: technical, technological, environmental, and economic and organizational. Your opinion is expressed by assigning a certain place to each group of criteria. The first place will go to the most important group of parameters; the second place—less important; the third place—the even less important group; and the fourth place—the least important group of parameters of the four. In the “Score” line, enter a score from “1” to “9”. A score of “1” indicates the absolute superiority of the first-ranked criterion group over the second-, third-, or fourth-ranked group. Note that the first-ranked group will always have a score of “1”. The scores of the other groups should be greater than or equal to “1”. Furthermore, check that the score of the lower-ranked group is greater than or equal to the score of the higher-ranked group.

Second stage. Rank the specific criteria in each group in the same way as in the first stage. A description of each specific criterion is provided to the experts in the form of Table 4.

Appendix C

Table A2.

Questionnaire to assess the importance of criteria groups.

Table A2.

Questionnaire to assess the importance of criteria groups.

| Criteria Groups | First Place | Second Place | Third Place | Fourth Place |

|---|---|---|---|---|

| Write the designation of only one group of criteria, C1, C2, C3, or C4 * | ||||

| Scores from 1 to 9 | 1 |

* C1—technical, C2—technological, C3—environmental, C4—economic and organizational.

References

- Evseev, V.N.; Varenichev, A.A. Auto dump quarries. Min. Informational Anal. Bull. 2017, 8, 30–36. [Google Scholar] [CrossRef]

- Rudenko, Y.F.; Opanasenko, P.I.; Mishin, Y.M.; Isajchenkov, A.B.; Anistratov, K.Y. Research of laws of change of parameters of work of career dumpers during term of their operation. Ugol 2008, 7, 58–63. [Google Scholar]

- Kuznetsov, D.V.; Odaev, D.G.; Linkov, Y.E. Peculiarities of technological motor transport selection used for deep north open pits operation. Min. Informational Anal. Bull. Sci. Tech. J. 2017, 5, 54–65. [Google Scholar]

- Kuznetsov, D.V.; Kosolapov, A.I. Justification criteria for open pit mine depth and mining/haulage machinery parameters. IOP Conf. Ser. Earth Environ. Sci. 2019, 262, 12038. [Google Scholar] [CrossRef]

- Paricheh, M.; Osanloo, M. Determination of the optimum in-pit crusher location in open-pit mining under production and operating cost uncertainties. In Proceedings of the 16th International Conference on Computer Applications in the Mineral Industries (CAMI 2916), Istanbul, Turkey, 5–7 October 2016; AGRO ARGE Danışmanlık San. ve Tic. A.Ş.: Istanbul, Turkey, 2016. ISBN 978-605-66638-1-9. [Google Scholar]

- Yakovlev, V.L.; Karmaev, G.D.; Bersenev, V.A.; Glebov, A.V.; Semenkin, A.V.; Sumina, I.G. Efficiency of cyclical-and-continuous method in open pit mining. J. Min. Sci. 2016, 52, 102–109. [Google Scholar] [CrossRef]

- Burchett, T.; Young, B. Optimizing an engineered slope conveyor system; An OEM/operator collaboration. Min. Eng. 2013, 65, 18. [Google Scholar]

- Braun, T.; Hennig, A.; Lottermoser, B.G. The need for sustainable technology diffusion in mining: Achieving the use of belt conveyor systems in the German hard-rock quarrying industry. J. Sustain. Min. 2017, 16, 24–30. [Google Scholar] [CrossRef]

- Velikanov, V.S.; Dyorina, N.V.; Kocherzhinskaya, Y.; Mamay, N.V.; Logunova, T.V. The brachistochrone problem applied in the study on a conveyance descending trajectory in open pit mining. Vestn. Nosov Magnitogorsk State Tech. Univ. 2022, 20, 5–14. [Google Scholar] [CrossRef]

- Zimmermann, E.; Kruse, W. Mobile Crushing and Conveying in Quarries Cheaper Production! Available online: https://www.911metallurgist.com/blog/wp-content/uploads/2015/12/mobile-crushing.pdf (accessed on 28 May 2023).

- Kolga, A.; Rakhmangulov, A.; Osintsev, N.; Sładkowski, A.; Stolpovskikh, I. Robotic transport complex of automotive vehicles for handling of rock mass at the process of open cast mining. Transp. Probl. 2015, 10, 109–116. [Google Scholar] [CrossRef]

- Kuleshov, A.A. Ways to improve the quality of operation of quarry road transport systems in modern conditions. J. Min. Inst. 2004, 157, 181–185. [Google Scholar]

- Yakovlev, V.L.; Kornilkov, S.V. Technological problems and features of conducting mining operations in deep open pits. Min. Informational Anal. Bull. Sci. Tech. J. 2015, S56, 54–66. [Google Scholar]

- Anistratov, K.; Borshch-Komponiets, L.V. Research into the performance of mine dump trucks for the substantiation of the fleet structure and performance standards. Russ. Min. Ind. 2011, 4, 38–49. [Google Scholar]

- Khazin, M.; Tarasov, A. Ecological and economic evaluation of quarry trolley trucks. Perm. J. Pet. Min. Eng. 2018, 17, 166–180. [Google Scholar] [CrossRef]

- Xu, X.; Gu, X.; Wang, Q.; Zhao, Y.; Zhu, Z.; Wang, F.; Zhang, Z. Ultimate pit optimization with environmental problem for open-pit coal mine. Process Saf. Environ. Prot. 2023, 173, 366–372. [Google Scholar] [CrossRef]

- Golik, V.I.; Polovneva, S.I.; Turluyev, R.R. Processing and use of waste from the mining industry. IOP Conf. Ser. Earth Environ. Sci. 2022, 1021, 12004. [Google Scholar] [CrossRef]

- Argimbaev, K.R. Investigations of the deposit geological structure impact on the technogenic accident risk at the mining plant. J. Eng. Appl. Sci. 2018, 18, 1713–1717. [Google Scholar]

- Rakhmangulov, A.; Burmistrov, K.; Osintsev, N. Selection of open-pit mining and technical system’s sustainable development strategies based on MCDM. Sustainability 2022, 14, 8003. [Google Scholar] [CrossRef]

- Rakhmangulov, A.; Burmistrov, K.; Osintsev, N. Sustainable open pit mining and technical systems: Concept, principles, and indicators. Sustainability 2021, 13, 1101. [Google Scholar] [CrossRef]

- Wang, Q.; Gu, Q.; Li, X.; Xiong, N. Comprehensive overview: Fleet management drives green and climate-smart open pit mine. Renew. Sustain. Energy Rev. 2024, 189, 113942. [Google Scholar] [CrossRef]

- Lashgari, A.; Yazdani–Chamzini, A.; Fouladgar, M.M.; Zavadskas, E.K.; Shafiee, S.; Abbate, N. Equipment selection using fuzzy multi criteria decision making model: Key study of Gole Gohar Iron Min. Eng. Econ. 2012, 23, 125–136. [Google Scholar] [CrossRef]

- Panachev, I.; Shirokolobov, G.; Kuznetsov, I.; Shirokolobova, A. Justification of efficiency of heavy dump trucks effectiveness in open pit mines according to operating life criterion of the back axle. In Proceedings of the 8th Russian-Chinese Symposium “Coal in the 21st Century: Mining, Processing, Safety”, Kemerovo, Russia, 10 January–12 October 2016; Atlantis Press: Paris, France, 2016; pp. 144–148, ISBN 978-94-6252-233-6. [Google Scholar]

- 8 Q&A You Need to Know about Dump Truck. Available online: https://www.miningpedia.cn/mining/8-Q-A-You-Need-to-Know-about-Dump-Truck.html#section7 (accessed on 20 April 2023).

- 3 Factors to Consider When Choosing Dump Trucks for Your Project. Available online: https://connect2local.com/l/48162/c/163549/3-factors-to-consider-when-choosing-dump-trucks-for-your-project (accessed on 20 April 2023).

- Kumar, D.; Yadav, P.K.; Gupta, S. Measurement and analysis of performance of mining dump trucks. Int. J. Veh. Perform. 2020, 6, 129. [Google Scholar] [CrossRef]

- Sisin, A.G.; Glebov, A.V. Evaluation of Technical and Economic Level and Open Pit Dump Track Rational Model Selection; Ural Department of Russian Academy of Sciences: Ekaterinburg, Russia, 2001. [Google Scholar]

- Koptev, V. Justification of the choice of effective model of career dump. Mod. Tech. Technol. 2014, 5, 3850. [Google Scholar]

- Andreeva, L.I.; Ushakov, Y.Y. Research of operational reliability of quarry dump trucks. News Ural State Min. Univ. 2016, 43, 74–77. [Google Scholar] [CrossRef]

- Bochkarev, Y.S.; Vikulov, M.A.; Ishkov, A.M.; Sedalishchev, I.I. Research of the exploitation of dump trucks BELAZ-7540 in conditions of the North. Min. Informational Anal. Bull. Sci. Tech. J. 2015, 7, 151–157. [Google Scholar]

- Gupta, P.; Mehlawat, M.K.; Aggarwal, U.; Charles, V. An integrated AHP-DEA multi-objective optimization model for sustainable transportation in mining industry. Resour. Policy 2021, 71, 101180. [Google Scholar] [CrossRef]

- Khazin, M.L.; Shtykov, S.O. Electric mining trucks. Vestn. Nosov Magnitogorsk State Tech. Univ. 2018, 16, 11–18. [Google Scholar] [CrossRef]

- Despodov, Z.; Mirakovski, D.; Mijalkovski, S. Methodology for selection of the most convenient ore transportation system in regard to the environmental protection. Int. J. Transp. Logist. 2013, 13, 1. [Google Scholar]

- Owusu-Mensah, F.; Musingwini, C. Evaluation of ore transport options from Kwesi Mensah Shaft to the mill at the Obuasi mine. Int. J. Min. Reclam. Environ. 2011, 25, 109–125. [Google Scholar] [CrossRef]

- Yazdani-Chamzini, A. An integrated fuzzy multi criteria group decision making model for handling equipment selection. J. Civ. Eng. Manag. 2014, 20, 660–673. [Google Scholar] [CrossRef]

- PTV Vissim. Available online: https://ptv-vision.ru/ (accessed on 10 October 2023).

- Rakishev, B.R.; Begalinov, A.B.; Lukin, I.V. Determination of limits of using of wheeled transport different types at open pits. Min. Informational Anal. Bull. Sci. Tech. J. 2002, 10, 150–152. [Google Scholar]

- Blagojevic, A.; Veskovic, S.; Kasalica, S.; Gojic, A.; Allamani, A. The application of the fuzzy AHP and DEA for measuring the efficiency of freight transport railway undertakings. Oper. Res. Eng. Sci. Theor. Appl. 2020, 3, 1–23. [Google Scholar] [CrossRef]

- Liachovičius, E.; Skrickij, V.; Podviezko, A. MCDM Evaluation of Asset-Based Road Freight Transport Companies Using Key Drivers That Influence the Enterprise Value. Sustainability 2020, 12, 7259. [Google Scholar] [CrossRef]

- Anysz, H.; Nicał, A.; Stević, Ž.; Grzegorzewski, M.; Sikora, K. Pareto optimal decisions in multi-criteria decision making explained with construction cost cases. Symmetry 2021, 13, 46. [Google Scholar] [CrossRef]

- Patyk, M.; Bodziony, P.; Krysa, Z. A multiple criteria decision making method to weight the sustainability criteria of equipment selection for surface mining. Energies 2021, 14, 3066. [Google Scholar] [CrossRef]

- Komljenovic, D.; Kecojevic, V. Multi-attribute selection method for mining trucks. Soc. Min. Metall. Explor. 2006, 320, 94–104. [Google Scholar]

- Bodziony, P.; Kasztelewicz, Z.; Sawicki, P. The problem of multiple criteria selection of the surface mining haul trucks. Arch. Min. Sci. 2016, 61, 223–243. [Google Scholar] [CrossRef]

- Patyk, M.; Bodziony, P.; Przylibski, T.A.; Kasza, D. Analysis of multiple criteria selection and application of APEKS method in haul truck mining transport process. E3S Web Conf. 2018, 71, 3. [Google Scholar] [CrossRef]

- de Sousa, W.T., Jr.; Souza, M.J.F.; Cabral, I.E.; Diniz, M.E. Multi-Criteria Decision Aid methodology applied to highway truck selection at a mining company. Rem Rev. Esc. Minas 2014, 67, 285–290. [Google Scholar] [CrossRef]

- Malli, T.; Mizrak Ozfirat, P.; Yetkin, M.E.; Ozfirat, M.K. Truck selection with the fuzzy-WSM method in transportation systems of open pit mines. Teh. Vjesn. Tech. Gaz. 2021, 28, 58–64. [Google Scholar] [CrossRef]

- Yavuz, M. Equipment selection by using fuzzy TOPSIS method. IOP Conf. Ser. Earth Environ. Sci. 2016, 44, 42040. [Google Scholar] [CrossRef]

- Ghasvareh, M.A.; Safari, M.; Nikkhah, M. Haulage system selection for Parvadeh coal mine using multi-criteria decision making Methods. Min. Sci. 2019, 26, 69–89. [Google Scholar] [CrossRef]

- Samimi Namin, F.; Ghasemzadeh, H.; Aghajari, A.M. A comprehensive approach to selecting mine transportation system using AHP and FUZZY-TOPSIS. Decis. Mak. Anal. 2023, 1, 23–39. [Google Scholar] [CrossRef]

- Bascetin, A. The study of decision making tools for equipment selection in mining engineering operations. Gospod. Surowcami Miner. Miner. Resour. Manag. 2009, 25, 37–56. [Google Scholar]

- Samanta, B.; Sarkar, B.; Mukherjee, S.K. Selection of opencast mining equipment by a multi-criteria decision-making process. Min. Technol. 2013, 111, 136–142. [Google Scholar] [CrossRef]

- Adebimpe, R.A.; Akande, J.; Arum, C. Mine equipment selection for Ajabanoko Iron Ore Deposit, Kogi State, Nigeria. Sci. Res. 2013, 1, 25–30. [Google Scholar] [CrossRef]

- Bazzazi, A.A.; Osanloo, M.; Karimi, B. A new fuzzy multi criteria decision making model for open pit mines equipment selection. Asia-Pac. J. Oper. Res. 2011, 28, 279–300. [Google Scholar] [CrossRef]

- Bazzazi, A.A.; Osanloo, M.; Karimi, B. Optimal open pit mining equipment selection using fuzzy multiple attribute decision making approach. Arch. Min. Sci. 2009, 54, 301–320. [Google Scholar]

- Bascetin, A. A decision support system for optimal equipment selection in open pit mining: Analytical hierarchy process. J. Earth Sci. 2003, 16, 1–11. [Google Scholar]

- Yazdani-Chamzini, A.; Shariati, S. Selection of material handing equipment system for surface mines by using a combination of fuzzy MCDM models. Int. Res. J. Appl. Basic. Sci. 2013, 5, 1501–1511. [Google Scholar]

- Tuzkaya, G.; Gülsün, B.; Kahraman, C.; Özgen, D. An integrated fuzzy multi-criteria decision making methodology for material handling equipment selection problem and an application. Expert. Syst. Appl. 2010, 37, 2853–2863. [Google Scholar] [CrossRef]

- Patyk, M.; Bodziony, P. Application of the analytical hierarchy process to select the most appropriate mining equipment for the exploitation of secondary deposits. Energies 2022, 15, 5979. [Google Scholar] [CrossRef]

- Liu, S.Q.; Lin, Z.; Li, D.; Li, X.; Kozan, E.; Masoud, M. Recent research agendas in mining equipment management: A review. Mining 2022, 2, 769–790. [Google Scholar] [CrossRef]

- Mardani, A.; Jusoh, A.; Nor, K.M.D.; Khalifah, Z.; Zakwan, N.; Valipour, A. Multiple criteria decision-making techniques and their applications—A review of the literature from 2000 to 2014. Econ. Res. Ekon. Istraživanja 2015, 28, 516–571. [Google Scholar] [CrossRef]

- Namin, F.S.; Ghadi, A.; Saki, F. A literature review of Multi Criteria Decision-Making (MCDM) towards mining method selection (MMS). Resour. Policy 2022, 77, 102676. [Google Scholar] [CrossRef]

- Taherdoost, H.; Madanchian, M. Multi-Criteria Decision Making (MCDM) Methods and Concepts. Encyclopedia 2023, 3, 77–87. [Google Scholar] [CrossRef]

- Pamučar, D.; Stević, Ž.; Sremac, S. A New Model for Determining Weight Coefficients of Criteria in MCDM Models: Full Consistency Method (FUCOM). Symmetry 2018, 10, 393. [Google Scholar] [CrossRef]

- Stević, Ž.; Mujaković, N.; Goli, A.; Moslem, S. Selection of logistics distribution channels for final product delivery: FUCOM-MARCOS Model. J. Intell. Manag. Decis. 2023, 2, 172–178. [Google Scholar] [CrossRef]

- Burmistrov, K.V.; Osintsev, N.A.; Shakshakpaev, A.N. Selection of open-pit dump trucks during quarry reconstruction. Procedia Eng. 2017, 206, 1696–1702. [Google Scholar] [CrossRef]

- Ayadi, H.; Hamani, N.; Kermad, L.; Benaissa, M. Novel fuzzy composite indicators for locating a logistics platform under sustainability perspectives. Sustainability 2021, 13, 3891. [Google Scholar] [CrossRef]

- Feizi, F.; Karbalaei-Ramezanali, A.A.; Farhadi, S. FUCOM-MOORA and FUCOM-MOOSRA: New MCDM-based knowledge-driven procedures for mineral potential mapping in greenfields. SN Appl. Sci. 2021, 3, 255. [Google Scholar] [CrossRef]

- Pamucar, D.; Ecer, F.; Deveci, M. Assessment of alternative fuel vehicles for sustainable road transportation of United States using integrated fuzzy FUCOM and neutrosophic fuzzy MARCOS methodology. Sci. Total Environ. 2021, 788, 147763. [Google Scholar] [CrossRef]

- Stević, Ž.; Brković, N. A Novel Integrated FUCOM-MARCOS Model for Evaluation of Human Resources in a Transport Company. Logistics 2020, 4, 4. [Google Scholar] [CrossRef]

- Badi, I.; Jibril, M.L.; Bakır, M. A composite approach for site optimization of fire stations. J. Intell. Manag. Decis. 2022, 1, 28–35. [Google Scholar] [CrossRef]

- Stević, Ž.; Bašić, A.; Moslem, S.; Zhong, K. An integrated ABC-FUCOM model for product classification. Spectr. Eng. Manag. Sci. 2023, 1, 83–91. [Google Scholar]

- Rayan, K. Differentiation of open pit dump trucks operating conditions. Gorn. Delo 2015, 4, 66–72. [Google Scholar]

- Tarasop, P.I.; Zyryanov, I.V.; Fefelov, E.V. Differentiation of operating conditions for mining dump trucks. Russ. Min. Ind. 2016, 127, 51–53. [Google Scholar]

- Fefelov, E.V. Systematization of mining conditions for operating of run-of-bank motor transport. Min. Informational Anal. Bull. Sci. Tech. J. 2012, 7, 207–211. [Google Scholar]

- Soofastaei, A.; Aminossadati, S.M.; Kizil, M.; Knights, P. Reducing fuel consumption of haul trucks in surface mines using artificial intelligence models. In Proceedings of the 16th Coal Operators’ Conference. Coal Operators’ Conference, Dubai, United Arab Emirates, 10–12 February 2016; Aziz, N., Kininmonth, B., Eds.; University of Wollongong: Wollongong, Australia, 2016. [Google Scholar]

- Panachev, I.A.; Kuznetsov, I.V. Analysis of the impact angle on the energy consumption of road transportation of rocks by heavy auto-tippers. Bull. Kuzbass State Tech. Univ. 2013, 100, 67–70. [Google Scholar]

- Cardu, M.; Lovera, E.; Patrucco, M. Loading and haulage in quarries: Criteria for the selection of excavator-dumper system. In Proceedings of the Fourteenth International Symposium on Mine Planning and Equipment Selection (MPES), Banff, AB, Canada, 31 October–3 November 2005; pp. 1594–1606. [Google Scholar]

- Lel’, Y.; Il’bul’din, D.H. Justification of the open pit depth for transition to new models of dump trucks in the process of deep open pit reworking. Min. Inf. Anal. Bull. Sci. Tech. J. 2009, S6, 313–319. [Google Scholar]

- Peralta, S.; Sasmito, A.P.; Kumral, M. Reliability effect on energy consumption and greenhouse gas emissions of mining hauling fleet towards sustainable mining. J. Sustain. Min. 2016, 15, 85–94. [Google Scholar] [CrossRef]

- Soltanmohammadi, H.; Aghajani Bazzazi, A.; Osanloo, M. Loading-haulage equipment selection in open pit mines based on fuzzy-TOPSIS method. Gospod. Surowcami Miner. 2008, 24, 87–102. [Google Scholar]

- Kartashov, A.; Harutyunyan, G.; Kosolapov, A.; Shkarupelov, E. Justification of the concept of creating a perspective dump truck. IOP Conf. Ser. Mater. Sci. Eng. 2020, 779, 12028. [Google Scholar] [CrossRef]

- Hardy, R.J. Selection Criteria for Loading and Hauling Equipment—Open Pit Mining Applications. Ph.D. Thesis, Curtin University of Technology, Bentley, Australia, 2007. [Google Scholar]

- Ta, C.H.; Ingolfsson, A.; Doucette, J. A linear model for surface mining haul truck allocation incorporating shovel idle probabilities. Eur. J. Oper. Res. 2013, 231, 770–778. [Google Scholar] [CrossRef]

- Özfirat, P.M.; Özfirat, M.K.; Malli, T. Selection of coal transportation mode from the open pit mine to the thermic power plant using fuzzy Analytic Hierarchy Process. Transport 2018, 33, 502–509. [Google Scholar] [CrossRef]

- Glebov, A.V. Technological peculiar features in deposit opening of solid minerals while using articulated dump trucks. Sci. Tech. 2018, 17, 238–245. [Google Scholar] [CrossRef]

- Khazin, M.L. Robotic Equipment for Mining Operations. Vestn. Nosov Magnitogorsk State Tech. Univ. 2020, 18, 4–15. [Google Scholar] [CrossRef]

- Ashihmin, V.E.; Furman, A.S.; Shadrin, V.N. Speedy and working modes of open pit dump trucks. Bull. Kuzbass State Tech. Univ. 2012, 92, 123–125. [Google Scholar]

- Voronov, Y.; Basmanov, S.V. Directions of technical conditions increasing for open pit dump trucks. Bull. Kuzbass State Tech. Univ. 2007, 59, 37–40. [Google Scholar]

- Glebov, A.V.; Zhuravlev, A.G. Formation of an open pit dump trucks fleet for Elga coal deposit. Min. Informational Anal. Bull. Sci. Tech. J. 2010, S4, 69–82. [Google Scholar]

- Kuznetsov, S.R.; Vasil’eva, M.A. The parameters defining power efficiency of dump trucks in opencast mine. J. Min. Inst. 2014, 209, 185–188. [Google Scholar]

- Savchenko, V.V. Development of systems for support of open-cast dump truck drivers’ fitness to work. Sci. Tech. 2006, 6, 57–61. [Google Scholar]

- Glebov, A.V. Formation of a park of dump trucks for open pit mining. Asp. Min. Miner. Sci. 2019, 3, 401–403. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).