Abstract

This study aims to investigate researchers’ interest in the topic of integrated life cycle design in the context of geotechnical works (ground improvement and piling solutions). In the first part, the authors conducted a literature review to assess the popularity of sustainable development themes in research related to the aforementioned topics using the VOSviewer software. Several main categories were then identified, such as environmental aspects, noise, vibrations, economic aspects, process efficiency, and the most frequently addressed issues were highlighted for each category. The conclusions drawn from the review were used to conduct a decision-making trial and evaluation laboratory (DEMATEL) analysis to investigate the inter-relationships between the identified factors and their impact on the implementation of integrated design principles in the relevant technologies. Analysis carried out using the VOSviewer program revealed that publications on ground improvement and piling solutions mainly focus on two thematic areas: design and the broadly understood materials used in these methods. A more in-depth review confirms the scarcity of publications addressing the technology selection process from a multi-aspect perspective, particularly in terms of sustainable development criteria and the assessment/characterization of individual technologies. This highlights a significant research gap. This study notes the promising potential of new, green materials in sustainable geoengineering and the need for comprehensive tools to assess their sustainability. It also acknowledges the potential cost savings offered by sustainable technologies, while discussing the challenges in their adoption due to resistance to new technologies, the lack of consistent emissions data, and the absence of uniform standards. These factors contribute to difficulties in comparing and implementing sustainable solutions effectively.

1. Introduction

Integrated design in geotechnical engineering is a key element of civil and geotechnical engineering aimed at providing a comprehensive approach to projects related to soils and foundations. In today’s world, where the demand for new buildings and infrastructure is rapidly increasing, proper management and design in the geotechnical area are extremely important. The drive to utilize previously deemed unsuitable areas for construction purposes has led to the development of foundational technologies and ground improvement solutions (GI) [1]. Unfortunately, in many countries, geotechnical concepts with significantly different meanings still exist, which affects the feasibility of applying various technologies.

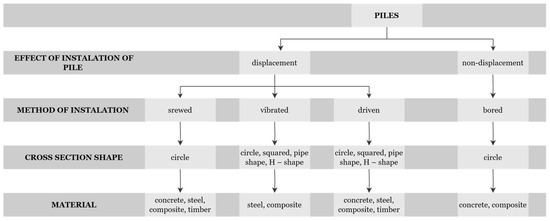

A pile, according to ISO 6707-1:2017 [2], is defined as a “slender structural member, substantially underground, intended to transmit forces into load-bearing strata below the surface of the ground”. The classification of piles is shown in Figure 1.

Figure 1.

Pile classification. Own elaboration based on [3].

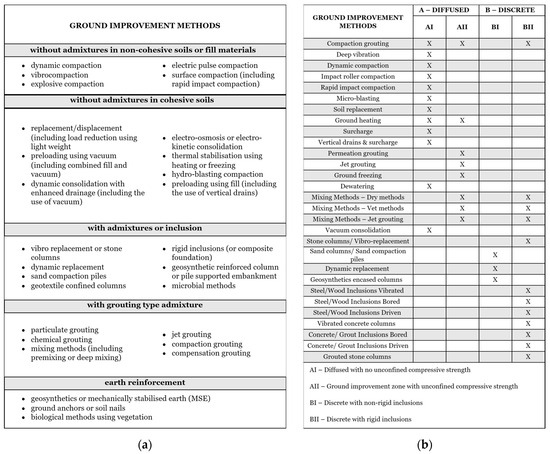

However, according to prEN 1997-3:202x [4], the ground improvement is defined as “modification of the ground or its hydraulic conductivity in order to bring the effects of actions within ultimate and serviceability requirements. Ground improvement can be achieved by reducing or increasing hydraulic conductivity, binding, or densifying the ground, filling voids, or creating inclusions in the ground” [5]. Several classifications of subsoil improvement methods can be found in scientific studies. A frequently used one is that from [6], which divides methods according to the materials used for reinforcement purposes (Figure 2a). A new classification for the design of ground improvement methods can be found in the draft standard [4] (Figure 2b).

Figure 2.

Ground improvement classification: (a) based on [6]; (b) based on [4]. Own elaboration.

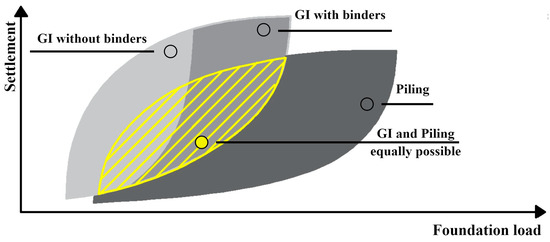

The range of options is so extensive that in many cases, it is possible to employ more than one solution. Figure 3 illustrates an approximate area where, while maintaining the same load range and without compromising functional design criteria, both ground improvement and piling solutions can be used interchangeably [7].

Figure 3.

Variants of piling and ground improvement methods. Own elaboration based on [7].

The diversity of solutions is evidenced by publications that include comparisons and suggestions of alternative methods for specific projects. Examples of such comparisons are presented in Table 1.

Table 1.

Alternatives presented in publications. Own elaboration.

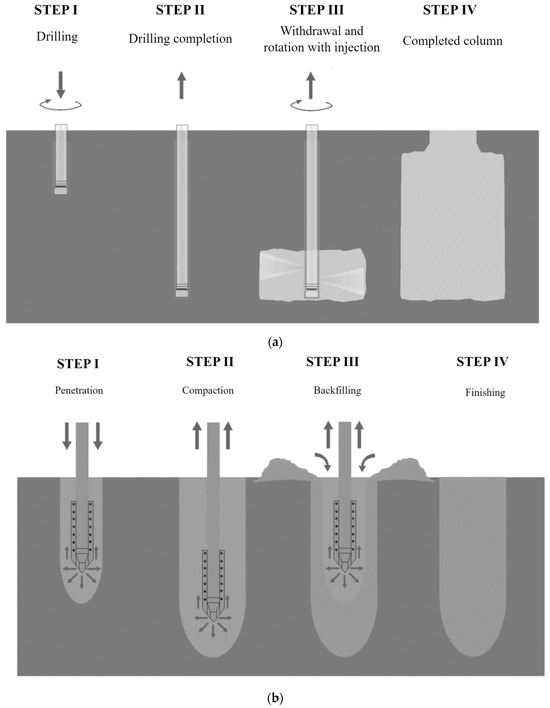

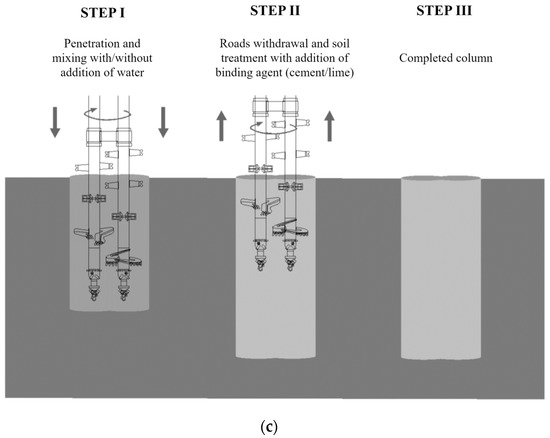

Figure 4.

Ground improvement: (a) jet grounding based on [16]; (b) VR based on [11]; (c) DSM based on [12]. Own elaboration.

Table 1.

Alternatives presented in publications. Own elaboration.

| Project | Analyzed/Proposed Solutions | Source | Description of Methods |

|---|---|---|---|

| Building construction project with problematic ground conditions |

| [8] | Jet Grouting: A method involving the disruption of in situ soil using a high-speed fluid jet from a slender nozzle on a monitor. In this process, the disrupted soil mixes with an injected fluid, usually a cement slurry, forming a blend that eventually hardens. Depending on the injection method and the number of fluids used, jet grouting is categorized into three main systems: mono-fluid, bi-fluid, and tri-fluid [9,10]. VR: A method involving the penetration of a vibroflot to the designated depth, aided by water jetting from the nose cone. Once the target depth is reached, the water jetting is reduced, and the vibroflot is gradually withdrawn, ensuring adequate compaction at each depth. This process forms a compacted ground zone around the insertion point, with the optional addition of site-sourced sand to fill any resulting depression. The extraction rate is adjusted according to site conditions to achieve the desired densification for the project [11]. DSM: This method involves inserting a mixing tool, into the soil. Cement slurry flows from nozzles on the tool, thoroughly mixing with the soil to create a homogenous blend. The slurry composition is tailored to achieve the desired soil properties. Additionally, a dry version of this method is feasible (without water) [12]. |

| High-rise building |

| [13] | |

| Large residential and commercial complex |

| [13] | |

| Residential multi-family building with an underground garage |

| [14] | |

| Iron ore storage facility |

| [15] |

The selection among such a wide range of available methods can pose a challenge which requires consideration of various factors, as emphasized by Gomes Correia et al. in [17]. Onyelowe et al., in the paper [18], present an analysis of seven solutions for slope stabilization. Criteria considered included cost, constructability, reliability, and environmental impact.

To date, design has focused on functional and structural issues, with minimal capital expenditure. Nowadays, integrated life cycle design (ILCD), which considers the principles of sustainability, is becoming increasingly important [19].

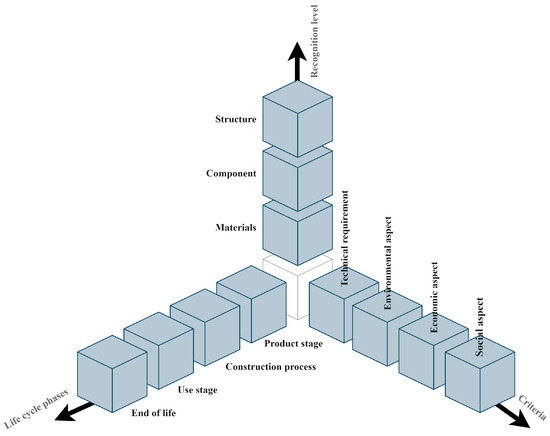

Integrated life cycle design involves combining the various stages of design, such as the design of materials, structural elements, and the entire building. During this process, not only technical requirements but also economic efficiency, environmental impact, and social aspects must be taken into account. The introduction of all these elements makes the design of buildings a more complex and interdisciplinary process. The basis of this approach is the division of the life cycle of a building into modules and the subsequent evaluation of the design solutions on three successive levels. This makes the design process three-dimensional, allowing for better consideration of the various factors and their interactions (Figure 5).

Figure 5.

Three-dimensional model of integrated design. Own elaboration.

The life cycle of a construction project includes stages such as the product stage, the construction process stage, the use stage, and the end-of-life stage. In the context of foundation piles and ground improvement techniques, the product stage and the construction process stage are predominant. The use stage is typically non-existent or involves minimal processes, and during the end-of-life stage, most underground structures usually remain as an integral part of the ground. However, there are options for reuse, particularly in projects on demolition sites with existing underground infrastructure, where reuse can lead to significant savings in terms of costs, construction time, and materials [20]. These include replacing existing foundations with new ones (piles are re-drilled and re-concreted), reusing existing foundations to bear some of the new load, or fully utilizing existing foundations in new structures, especially when the load of the new building closely aligns with the original [21].

In summary, the following groups can be singled out as sources of environmentally harmful emissions for ground improvement and pilings investments:

- Materials—all processes related to the production of materials needed in the construction process;

- Transport—the transport of, e.g., materials to the construction site (freight), equipment (mobilization), and workers (transportation);

- Energy—related to the energy used on a construction site, e.g., fuel for construction equipment, operation of construction facilities, etc.;

- Waste.

Decision-making according to the principles of integrated design involves complex interactions between environmental, economic, and social aspects [22,23]. The need to take them into account is emphasized by researchers [24,25,26] but also in the legal framework of EU policy, among which are the European Green Deal (a set of policy initiatives from the European Commission with the overarching goal of achieving climate neutrality in Europe by 2050) [27] and the Fit for 55 package (specific legislation aimed at reducing greenhouse gas emissions by at least 55% by 2030) [28]. The regulations being introduced also affect the construction sector. They include the updating of existing regulations and the introduction of new guidelines related to the energy efficiency of buildings, the use of renewable raw materials, and GHGs emissions. As a result, participants in the building process are required not only to adapt their activities to environmental requirements but also to comply with new guidelines and re-strategies that shape technical standards. In turn, this affects the entire dynamics of the construction industry, forcing innovative approaches, new technologies, and more sustainable working methods. As a result, the sector can not only voluntarily undertake integrated development measures; they are becoming a necessity.

In line with the idea of sustainable development, an initiative for green public procurement [29] has emerged, i.e., where public entities integrate environmental criteria and/or requirements into their procurement procedures. Such measures may contribute not only to environmental protection but also to financial savings for contracting authorities, especially by taking into account the costs of products or services over their entire life cycle. According to data for Poland [30] in 2021, the share of green public procurement in the total number of public contracts was 1.5%, and its total value accounted for 4.1% of the total value of public contracts awarded, which is still low.

The decision-making process can be divided into two stages: the first stage involves the selection of technologies that can be applied based on specific ground/technical conditions (e.g., soil type, soil parameters, depth, groundwater level), i.e., design criteria; the subsequent step, and ultimately the choice of the final solution from the narrowed pool, can be dependent on sustainable criteria. Within this group, the following aspects can be distinguished [31]:

- Economic aspects (cost-effective, performance);

- Environmental aspects;

- Social aspects and requirements depending on the project location (noise, vibrations, material availability, and trained personnel).

Although noise and vibration are often included in environmental categories, this publication examines them separately to pay particular attention to their impact on the comfort of residents or workers in the vicinity of the project. In addition to the introduction of more environmentally friendly techniques, the reduction of noise and vibration during construction work can help to reduce nuisance for residents and workers in the vicinity of the site and improve working conditions on site.

Such a process can help in selecting the most sustainable solution [17]. For example, a model was developed to assess the sustainability index of technically feasible reinforcement alternatives for CFA piles [32].

The aim of this study is to investigate researchers’ interest in the topic of integrated life cycle design in the context of ground improvement and piling methods. By analyzing existing research, this study aims to comprehend the current state of knowledge, key areas of investigation, and future trends in this field.

The paper consists of the following parts. A description of the research methodology is presented in Section 2. Section 3.1 includes the results of a literature review assessing the popularity of integrated design issues in research related to ground reinforcement methods and piling techniques, utilizing the VOSviewer software. Section 3.2 presents an analysis of the most frequently discussed issues in geotechnical engineering technologies, categorized into areas such as environmental aspects, noise, vibrations, economic factors, and process efficiency. Meanwhile, Section 3.3 contains a decision-making trial and evaluation laboratory (DEMATEL) analysis, evaluating the interrelations among identified factors and their impact on the implementation of integrated design principles in these technologies, while also identifying key determinants crucial for achieving sustainable development goals in the studied area. A summary and discussion are presented in Section 4.

2. Materials and Methods

In the first part of the study, the VOSviewer software (version 1.6.19) [33] was used to identify areas of research interest related to ground improvement and piling solutions. This tool allows for the analysis of a large number of scientific publications to identify patterns and trends in research. The software allows for the visualization and analysis of data such as scientific articles, authors, affiliations, keywords, and citations [34]. In this study, a concerted keyword analysis was performed based on the Web of Science Core Collection (WoSCC) database. The WoSCC distinguishes itself in the realm of academic databases by offering an expansive spectrum of data, making it a preferred choice among many [35]. The format of the WoSCC’s data is notably compatible with bibliometric tools, facilitating direct analysis. Compatibility and breadth of data were key factors in selecting WoSCC as the primary data source for this study, following a thorough comparative review of outputs from several databases. The search was limited by the following parameters:

- Topic: “ground improvement” OR “soil improvement” OR “DSM” OR “jet grouting” OR “piling” OR “piles”;

- Year published: 2013–2023;

- Web of Science Categories: Engineering, Civil.

For the given restrictions, 4897 articles were obtained. The datasets for this study were compiled by extracting information in plain text format, including elements like titles, authors, abstracts, and source from the articles. The study performs a keyword co-occurrence analysis to identify common words or phrases across academic articles in geotechnical engineering. It aims to reveal key research themes by creating a network based on term frequency. Utilization of VOSviewer facilitates the generation of graphical representations, elucidating the primary thematic concentrations within the field.

Then, using the same parameters, the number of publications focusing on specific non-design criteria was analyzed, adding a restriction (in the topic group) relevant to the aspect studied:

- Environment—“LCA” OR “life cycle assessment” OR “carbon footprint” OR “environmental impact”, “sustainability”;

- Noise—“noise”;

- Vibration—“vibration”;

- Time-efficient—“time analysis” OR “construction time” OR “effective” OR “time efficient”;

- Cost-effective—“LCC” OR “life cycle cost” OR “cost analysis” OR “cost” OR “cost-effective”.

The selection of keywords was based on a previous preliminary literature review of the areas under study.

The obtained research results were subjected to analysis in terms of issues related to the topic of integrated design. The conclusions of the analysis were used to extract 16 factors, which were used to develop the DEMATEL [36] analysis. The aim of this analysis was to investigate the interrelationships between the identified factors and their impact on the implementation of the principles of integrated design in the area related to geoengineering technologies. This method is widely applied in the analysis of economic processes, as well as environmental aspects [37,38,39]. DEMATEL analysis enables the determination of causal relationships among the components of the system under consideration and the resulting roles of individual elements within the system. To achieve this, it is necessary to determine the direct influence of each element on the others within the considered system. The network of all interconnections and interactions among the elements is referred to as the structure of direct influence. Based on this, the structure of indirect influence (exerted through other elements of the system) is determined, followed by the structure of total influence, encompassing both direct and indirect influences of the elements.

To evaluate the relationships among the factors, a direct influence matrix Z (Equation (1)) was formulated to determine the presence of influence and its direction. The assessment employed the following impact scale: 0—no influence; 1—weak influence; 2—influence, 3—strong influence. The authors determined the strength of the impact by drawing on the literature review and their own knowledge and observations.

where:

- i, j = 1, 2, …, n;

- n × n—matrix dimension.

Subsequently, the normalization of grade values and the establishment of the direct influence matrix X (Equations (2) and (3)) were undertaken, followed by the computation of the total influence matrix T (according to Equation (4)).

where:

- s—scaling factor.

Based on the aforementioned matrices, the computation of vectors R and C (Equation (6)) was performed, involving the summation of rows and columns from the total-influence matrix tij.

The vectors mentioned above represent the components of “prominence” (R + C) and “relation” (C − R), sequentially showcasing the magnitude of influences exerted by the factor and the impact the factor imparts on the system [36].

3. Results

3.1. Main Research Areas on Ground Improvement and Piling Solutions: Keywords Co-Occurrence Analysis

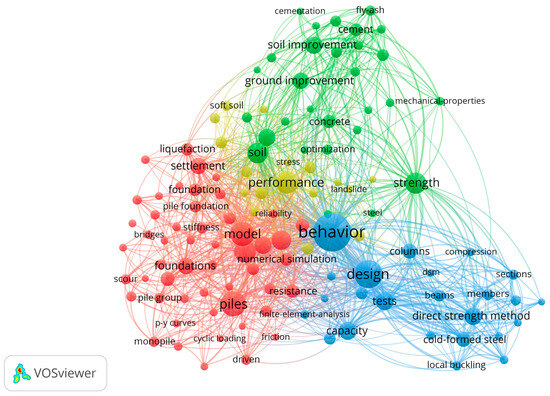

Figure 6 presents the results of an analysis conducted using VOSviewer. The analysis revealed four main thematic clusters representing distinct areas of research. The first cluster, depicted in green, focuses on the application of materials in ground improvement and piling solutions, evident by the presence of terms such as “concrete”, “cement”, and “fly ash”. The red and blue clusters primarily explore the design and behavior of structures in the context of interactions with the ground, covering topics such as “numerical simulation”, “local buckling”, “reliability”, “tests”, and “design”.

Figure 6.

Map of related topics. Own elaboration.

A significant conclusion drawn from the analysis is the absence of explicit keywords indicating the presence of sustainable development themes, indicating a research gap in this area. However, the presence of the term “performance” (yellow cluster) suggests a focus on project optimization, leading to reduced investment costs and environmental impact. Additionally, considering the widespread use of fly ash (green cluster) as a substitute for cement to reduce emissions, it can be inferred that there is an interest in addressing environmental impact reduction.

3.2. Sustainable Development Criteria

3.2.1. Environmental

The environmental aspect is gaining increasing importance, especially in the context of ground improvement works, which are an integral part of construction and infrastructure. In particular, the issue of greenhouse gas emissions contributing to global warming has become one of the priority aspects to consider. Statistics clearly indicate that the construction sector is responsible for approximately 40% of total greenhouse gas emissions [40]. Therefore, it is crucial not to overlook this issue in the context of such construction works [41].

Studies concentrate on cement substitutes, as well as the utilization of waste and recycled materials or reinforcement modifications [42]. Among the new or “greener” materials, the following groups can be distinguished:

- Portland cement substitutes: calcium sulfoaluminate (CSA) cement [43,44], biocement [45,46], fly ash (FA) [47], ground granulated blast furnace slag (GGBS) [48], and bottom ash [49];

- Waste materials: xanthan gum [50], natural rubber latex [51], waste marble dust [52], paper fibre from the cement bag [53], glass manufacturing waste (GMW) [54], recycled construction sludge [55], bagasse ash, and stone dust [56];

- Recycled aggregate: brick, recycled concrete aggregate, sandstone, granite, limestone, and marble [57,58].

The use of life cycle assessment (LCA) is recommended to accurately assess the environmental impact. Within such studies, a comparative analysis of the environmental impact and cost effectiveness of different alkali-activated binder (AAB) concrete mixes has been carried out using industrial waste materials [59]. Increasing the amount of bottom ash in the concrete mix relative to the amount of cement leads to a reduction in eCO2 emissions [60]. A comparison of different recycled aggregates showed that the carbon footprint was highest for crushed brick and lowest for sandstone [57]. The addition of 0.5% by dry mass of polypropylene fibers to the cutter soil mix (CSM) wall results in a reduction in emissions compared to the CSM wall without fibers (reduction embodied carbon from 929 kgCO2e/m3 to 755 kgCO2e/m3) [61].

Chang, in study [62], presents greenhouse gas (GHG) emissions for different projects. However, the lack of presentation of the results per functional unit (different investments), and the absence of an indication of the specific technologies used, makes it impossible to clearly identify the least-emitting technology. Nevertheless, the data indicate the contribution of individual emission sources for piles and ground improvement methods. For the various investments where foundation piles were used, the largest share of the carbon footprint is accounted for by GHG emissions related to the materials used. In contrast, for ground improvement methods, the main source of GHG emissions was the energy used. Similarly, a carbon footprint analysis conducted for piles showed that approximately 90% of emissions are related to the materials used [63]. Based on LCA analysis conducted by Lee and Basu, it was found that driven piles have a lower environmental impact compared to drilled shafts [64].

A computational model was developed to assess the carbon footprint of precast concrete piles during the construction phase. The GHG emissions from construction machinery accounted for 73% of the total CO2e emissions during the construction of precast concrete piles [65]. A comparison between ground improvement techniques and CFA piles for two projects indicated that GI solutions (VR and DSM) lead to a significant reduction in CO2e emissions (−16% for DSM) compared to the standard piling design [7].

To summarize the research on environmental aspects, the following can be concluded:

- There are limited comparative studies; the literature to date mainly focuses on the analysis of individual materials used in the ground improvement process;

- Insufficient/partial LCA analysis;

- The literature currently focuses primarily on the carbon footprint; most analyses concentrate on greenhouse gas emissions as the main indicator of environmental impact; however, a more holistic approach that also takes into account other aspects, such as water consumption, which is missing.

3.2.2. Noise

Noise generated during construction activities affects the natural environment, nearby residents, users of other facilities, and workers involved in the construction project. According to the survey, about 41% of complaints from people living near construction sites relate to noise and vibration caused by the operation of diesel hammers, and 17% of complaints relate to the operation of jackhammers of drilling devices [66]. Noise assessment is prescribed by law, e.g., the EU directive on the assessment and management of environmental noise [67].

Some ground improvement solutions, particularly those based on driving piles into the ground, generate significant noise emissions. Reference [66] presents average noise levels for the following pile methods:

- Pile driving with diesel hammers—100–120 dB;

- Vibration loading of piles by vibration loaders and vibrohammering of piles with vibrohammers—80–100 dB.

Many of the publications on construction noise focused on the development of methods to reduce the level of this factor. Examples of mitigation measures include the use of damping materials or special pile designs such as double-shell pipe, which can reduce noise by an average of 20 dB [68], or the use of alternative installation technologies such as PHC (pretensioned spun high-strength concrete) screw piles [69] or the NB system [70]. PHC piles are inserted into the ground using the pile driving method, which involves penetrating the soil by rotating and compressing the pile to minimize noise and vibration. The NB system is a method of installing steel piles and cofferdams in an internal excavation using vibrating equipment. The NB system increases the speed of pile installation because the vibratory movement temporarily reduces the frictional resistance between the pile surface and the surrounding soil. This is the method used in Japan.

Predictive models are particularly useful in forecasting noise levels as they allow for the consideration of multiple influencing parameters, such as the equipment used, pile geometry, possible noise-reducing measures (e.g., avoiding multiple operations at the same time), and variations in sound wave propagation depending on the medium [71]. Numerical models are being developed to predict noise and ground vibration in buildings caused by pile driving [72].

A significant portion of the research focuses on the noise generated during underwater construction, which is supported by numerous reports addressing this issue, e.g., [73,74,75]. Jiang et al. [68] have developed a model to predict the effect of pile driving noise on the underwater environment. In contrast, noise mitigation measures in this context have been described in [76,77]. This work does not focus on methods used in subsea investments, so this aspect was not analyzed in more detail.

While many publications claim that a particular technology has low noise levels, these figures are rarely supported by concrete on-site analyses. Despite the rather long studies in reference [78], Kang et al. show that certain technologies that are described as low-noise-emitting can produce noise levels that exceed the legal limits. It therefore seems important to carry out such tests for the available technologies so that decision-makers have the opportunity to take this criterion into account when choosing a particular solution. Such analyses have been carried out for the PHC piles mentioned above [69]. The results showed sound levels of 65.9 and 61.1 dB at 10 and 30 m from the source, respectively, and a vibration level of 55.9 dB measured at 10 m distance. These values were all lower than other low-noise and low-vibration pile construction methods.

In conclusion, noise during construction works is an important factor affecting the environment, the comfort of residents and workers, and the quality of the investments carried out. Studies show that many construction techniques, especially those based on driving piles into the ground, generate significant noise emissions. Existing regulations and predictive models help to assess and minimize the noise impact.

3.2.3. Vibration

Construction equipment and operations generate ground vibrations that can affect nearby structures. The effects of vibration can manifest as the disruption of operating conditions for sensitive equipment and processes, damage to nearby structures, and inconvenience to residents [79,80].

Many researchers are carrying out work to develop predictive models or to determine safe distances of the work being carried out from neighboring structures so that those structures are not affected. Study [81] by Vytiniotis, Casey, and Sykora describes the observation, measurement, and analysis of lateral ground displacement during the driving of “displacement” piles in soft clays in East Baton Rouge, Louisiana. The piles were driven in close proximity to a newly constructed concrete retaining wall. As a result of the analyses, it was shown that pile driving, even at distances greater than 50 times their diameter, should not be overlooked.

Liang et al., in study [82], confirmed the consistency of the vibration monitoring with the results of earlier simulations. Their research also revealed that significant vibrations affecting a nearby bridge occur within a distance of up to 50 m from the construction site. The recommended minimum distance for conducting works depending on the structure is provided in [83]:

- Buildings in sound construction—4 m;

- Buildings in poor condition—7 m;

- Buildings in very poor condition—15 m;

- Visibly damaged buildings—30 m.

Musir and Ghani, in [84], carried out a study on the effect of vibrations on a building, considering the reference level inside the building, the distance, and the size of the pile. The results indicate that vibrations have a greater effect on the lower floors of the building, and that closer proximity to the construction site and smaller pile size result in higher vibrations. The relationship between vibrations and distance was also investigated in the study [85].

Vibration monitoring was conducted for various technologies, including driving sheet piles, Franki piles, and prefabricated piles. The results showed that in 95% of the cases, the vibration levels were within the limits prescribed by the [86]. Similarly, in [87], studies carried out by Vavrina and Windeln on precast reinforced concrete piles indicated that vibrations did not exceed permissible standards. There are measures that can help to reduce vibrations, such as reducing the drop height (to reduce the impact velocity), minimizing the area of contact between the pile and the ground, and using pre-drilling techniques.

Summarizing the vibration aspect, the conclusions are similar to those concerning noise. Emerging new technologies require additional studies and research so that decision-makers can also take this aspect into account when making their choice.

3.2.4. Economic

Several strategies to reduce costs and improve the efficiency of projects have been presented in the literature. Among the reviewed publications, many focus on project modification using asymmetric reinforcement [42], the use of waste materials [60], or the optimization of pile designs in terms of reinforcement, quantity, spacing, and/or diameter [88,89,90,91,92].

The literature reviewed also include several studies that consider time–cost analysis, such as risk analyses including time, cost, and quality throughout the project life cycle [93] as well as a model incorporating time, cost, and quality aspects [94]. Mata, Silva, and Pinho, in [95], proposed a risk-management methodology based on the probability of specific events occurring, and their economic consequences were proposed, which are applicable to drilled shafts.

Comparative analyses can also be found among the studies. For example, a comparison between post-tensioned piles (PTPs) and reinforced concrete piles (RCP) showed that PTPs were more economical in terms of resources, costs, and construction time [96]. The cost of the piled foundation was compared with the piled raft foundation, resulting in a cost reduction of 49.61% compared to the conventional design [97]. Another study focused on the life cycle cost analysis (LCC) of landslide stabilization piles [98]. Among the cited analyses, there is a predominant focus on piling techniques, with a few dealing with ground improvement solutions, such as [99]. The aforementioned study evaluates various options for the implementation of soil reinforcement during the remediation of a site for the construction of a petrochemical plant on highly compressible ground. Among the methodologies considered were the excavation of the clay layer and replacing it with sand fill, deep soil mixing, jet grouting, prefabricated vertical drains (PVDs) with preload fill, and sand drains with preload fill.

When analyzing the economic aspects in the field of geoengineering, there are several important shortcomings. First, we need more comprehensive optimization analyses that take into account different ground reinforcement techniques. Second, life-cycle analyses are becoming increasingly popular, but there is still a need for in-depth research on their application to the project. New technologies represent another area which is lacking in the research, especially in terms of their impact on project costs and efficiency. Cost comparisons between different regions and the analysis of the long-term costs of innovation are some other important areas for further research.

3.2.5. Summary

Table 2 summarizes the research and analysis carried out for the different ground improvement methods depending on the criterion examined.

Table 2.

Summary of the research carried out for ground improvement methods and piling by different analysis criteria. Own elaboration.

3.3. DEMATEL Analysis

Table 3 presents the criteria utilized in the DEMATEL analysis along with brief explanations.

Table 3.

The criteria utilized in the DEMATEL analysis. Own elaboration.

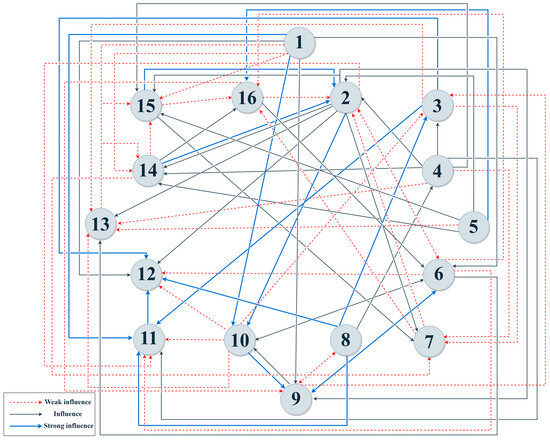

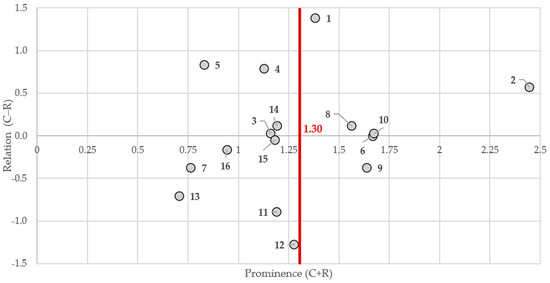

The cause-and-effect diagram shown is in Figure 7, and the influence relationship map is shown in Figure 8. The relationships between the factors, as well as the magnitude of the relationship, can be found in the direct influence matrix (Appendix A). The values of “Prominence” (R + C) and the “Relation” (C − R) are shown in Table 4.

Figure 7.

Direct influence graph. Own elaboration.

Figure 8.

Influential relation map. Own elaboration.

Table 4.

“Prominence” (R + C) and the “Relation” (C − R). Own elaboration.

The DEMATEL method provides a way to understand the cause-and-effect relationships among factors in a complex system. From Table 4, we can discern the most influential factors based on the “C + R” (Prominence) and “C − R” (Relation) values:

- New technologies based on the use of eco-friendly materials (2): This factor has the highest “C + R” value, indicating its significant prominence. This suggests that integrating eco-friendly materials into new technologies is a key driver for sustainability in ground improvement methods.

- Lack of standards/guidelines for new technologies (10): This also has a high “C + R” value, implying that it is a prominent issue that affects many other factors. The “C − R” value being close to zero indicates that it is a central issue that influences others as much as it is influenced by them.

- Strong position of well-known technologies (9): Although this has a negative “C − R” value, indicating that it is more of an effect than a cause. Its high “C + R” value signifies that it is an important factor to consider. The industry’s preference for established technologies can hinder the adoption of newer, more sustainable options.

- Reluctance to adopt new and lesser-known technologies (6): With a “C − R” value of zero, this factor stands exactly at the threshold between cause and effect, showing that it is a critical pivot point in the system. This indicates that the geoengineering sector’s hesitancy to adopt new technologies is as much a result of other factors as it is a contributing factor to the system.

- Insufficiently detailed analyses considering multiple aspects (11): Despite a low “C + R” value, the “C − R” value is highly negative, suggesting that this is predominantly an effect of other factors, but it is a significant one that shows the need for more comprehensive sustainability analyses.

- Difficulties in comparing technologies with each other (12): This has the most negative “C − R” value, making it the strongest effect factor. It underscores the challenge in evaluating different technologies against each other, which is a significant barrier to the adoption of sustainable methods.

These factors are crucial in understanding the dynamics of sustainable practices in ground improvement and piling methods. Addressing these issues could facilitate the implementation of integrated life cycle design principles in the sector.

From the data, the factors that appear to be the least significant are as follows:

- Potential cost savings through the implementation of sustainable technologies (7): This factor has one of the lower “C + R” values, suggesting that while cost savings are recognized, they might not be the primary motivator or the most pressing concern within the system.

- Insufficiently detailed analyses considering multiple aspects (11): Despite its importance for sustainability, this factor has a lower “C + R” value in the analysis, indicating that it is not perceived as a leading influence in the current landscape of the industry.

- Socioeconomic trends (16): With a “C + R” value on the lower end of the spectrum, socioeconomic trends are seen as having less immediate influence on the decision-making processes within the sector, according to the DEMATEL analysis.

It is important to note that while these factors may have lower “C + R” values, they are still critical pieces of the puzzle. Their lower relative importance does not negate their absolute importance in achieving sustainability goals; rather, it suggests that they may not be the current focal points of action or the most influential factors in the system according to this particular analysis.

Among the remaining factors, the following is also worth highlighting:

- Lack of unified databases on emissions (8): With a “C + R” value indicating its prominence, this factor reflects the need for a centralized repository of information on emissions related to ground improvement technologies. The relatively low “C − R” value suggests that it is slightly more of a cause than an effect within the system. The absence of such a database is likely impeding the ability of stakeholders to make informed decisions regarding the environmental impact of different technologies. By establishing unified databases, practitioners could more easily comply with regulations, compare the sustainability of various methods, and identify areas for improvement.

- A large number of potential technologies available for utilization (1): This factor has a moderate “C + R” value and a “C − R” value suggesting that it is predominantly a cause within the system. It indicates that while there is a wealth of potential technologies that can be utilized, this abundance itself may be causing confusion or paralysis in decision-making. This could be due to the challenges of adequately comparing and assessing the wide array of options, potentially leading to decision fatigue or a preference for sticking with familiar technologies.

- Lack of comprehensive tools for assessing the sustainability of solutions (3): This factor has a relatively low “C + R” value, but its “C − R” value is almost neutral, hinting that it is both influenced by and influencing other factors almost equally. It points to a gap in the methodological framework used to evaluate the sustainability of ground improvement solutions. Without comprehensive tools, the assessment of such solutions may not fully capture their lifecycle impacts, leading to suboptimal decision-making that does not favor the most sustainable options.

- Legislative changes (5): It is a strong cause in the system (“C − R” value is high). Legislative changes are typically external drivers that can force significant shifts in industry practices. For example, the “Fit for 55” package in the EU aims to align policies with the goal of reducing net greenhouse gas emissions by at least 55% by 2030. Such legislative changes can catalyze the adoption of sustainable technologies by creating a regulatory environment that necessitates or incentivizes their implementation. The analysis implies that keeping abreast of, and complying with, legislative changes is a major driver for the industry to move towards sustainable practices.

Together, these factors highlight the complexities and interdependencies within the system that affect the implementation of sustainable ground improvement methods. There is an interplay between the availability of options, the tools for assessing them, the need for centralized information, and the external push from legislation that shapes the sector’s approach to sustainability. Addressing these factors holistically is key to advancing the adoption of integrated life cycle design principles in ground improvement and piling methods.

4. Summary and Discussion

The analysis, conducted using VOSviewer software, revealed that publications on ground improvement and piling solutions primarily focus on two thematic areas: design and materials used in these methods. This finding was further supported by a more detailed literature review. The popularity of sustainable development-related topics is relatively low. If addressed, research mainly revolves around the exploration and analysis of potential materials that align with the principles of sustainable development, as confirmed by Puppala and Pedarla in [100]. Research focuses on analyzing the impact of the materials used on soil parameters or their properties, but not all analyses consider the environmental impact of a given material.

The DEMATEL analysis, focusing on the implementation of sustainable principles in geoengineering technologies, isolates several key findings. First, the wide range of available technologies can make it difficult to choose the most suitable solutions, which makes the implementation process challenging. New technologies based on green materials show promising potential for sustainable geoengineering, which should be an incentive for their implementation. However, the lack of comprehensive tools to assess the sustainability of solutions may reduce the efficiency of the implementation process.

In light of the increasing number of new technologies, it is important that the research on noise and vibration impacts continues and expands. These activities will allow for a better understanding of the scale of the challenge and the development of appropriate strategies and regulations to minimize the negative impact of noise and vibration on the environment, working comfort, and human health. Conducting comprehensive field studies that take into account the noise charts of new developments will help decision-makers in making choices. It is also worth noting that reducing noise and vibration impacts can be a key element in the public acceptance of new developments.

However, resistance to the adoption of new and less-well-known technologies, as well as the lack of consistent emissions databases, can challenge the effective implementation of sustainable solutions. Also, the lack of uniform standards and guidelines for new technologies and difficulties in comparing different options affect the selection and implementation process.

It is worth noting that there are few publications that focus on the process of technology selection through a multi-criteria approach, considering sustainable development criteria as well as the assessment/characterization of individual technologies in relation to these aspects. Additionally, it should be noted that none of the technologies have been fully characterized in terms of the factors analyzed in the publication, such as the environment, noise, vibrations, cost-effectiveness, and process efficiency, which precludes a comprehensive comparison of these technologies against one another. There is a noticeable absence of comparative studies focusing on various technologies for a single project, including a specific indication of unit emissions. Supporting the selection process of ground improvement and piling solutions in accordance with the principles of sustainable development may involve the development of environmental, social, and economic criteria. To achieve this, specific technologies need to be examined to estimate factors such as their material consumption, labor requirements, energy consumption, and harmful emissions. Establishing a database on greenhouse gas emissions is crucial for optimizing construction projects, enabling accurate calculations [63]. The developed parameters can be implemented into design software programs, thereby facilitating the analysis at an early stage of the design process [104]. Moreover, such data and the developed decision-making model based on them can be considered in making decisions regarding the selection of specific technologies and public procurement procedures. This approach would promote innovative and environmentally friendly projects, while also supporting transparency and competitive balance in the bidding process. Despite researchers primarily focusing on the environmental impact of construction processes, particularly the carbon footprint, it is important to consider other impact categories such as the water footprint, which will become increasingly significant as GHG emissions are reduced. Although life cycle analyses are key to assessing the environmental impact of a technology, detailed LCA analyses for different ground improvement methods, which take into account many factors over the entire life cycle (e.g., energy, transport), are missing in the literature. Decision-making models have already been developed for many building components and construction projects, such as [105]. In order to achieve sustainable development goals and emission reductions within the context of the entire investment, it is important to analyze the works related to ground improvement and pile as well. The advantage of such tools is that they can consider all the criteria related to sustainable development rather than just one aspect [106].

Taking these arguments into account, the authors see a research gap in the area of ground improvement methods and piling in terms of the following:

- Evaluation/characterization of individual technologies in terms of sustainability criteria (mainly, relatively new technologies);

- Development of tools that would support the technology selection process regarding sustainability criteria.

In conclusion, the lack of comprehensive research and tools in the above areas provides an opportunity for future research work that will strengthen the capacity of the geoengineering industry to implement more sustainable and efficient ground improvement and pilings solutions.

Author Contributions

Conceptualization, A.M. and D.W.; methodology, A.M. and D.W.; validation, A.M. and D.W. formal analysis, A.M. and D.W.; investigation, A.M. and D.W.; resources, A.M. and D.W.; data curation, A.M. and D.W.; writing—original draft preparation, A.M. and D.W.; writing—review and editing, A.M. and D.W.; visualization, A.M. and D.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Direct influence matrix Z. Own elaboration.

Table A1.

Direct influence matrix Z. Own elaboration.

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 3 | 2 | 3 | 3 | 2 | 1 | 1 | 1 | 0 |

| 2 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 3 | 2 | 3 | 1 | 2 | 2 | 2 | 2 | 0 |

| 3 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 3 | 3 | 1 | 1 | 1 | 0 |

| 4 | 0 | 2 | 2 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 2 | 0 | 1 | 2 | 2 | 0 |

| 5 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 2 | 3 |

| 6 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 2 | 1 | 1 | 2 | 0 | 0 | 1 |

| 7 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 8 | 0 | 0 | 3 | 2 | 0 | 0 | 0 | 0 | 1 | 0 | 3 | 3 | 0 | 0 | 0 | 0 |

| 9 | 0 | 0 | 1 | 0 | 0 | 3 | 0 | 1 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 |

| 10 | 0 | 0 | 1 | 0 | 0 | 2 | 0 | 2 | 3 | 0 | 1 | 1 | 1 | 0 | 0 | 0 |

| 11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 0 | 0 | 0 | 0 |

| 12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 14 | 0 | 3 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 |

| 15 | 0 | 3 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 16 | 0 | 1 | 0 | 0 | 0 | 2 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

References

- Amarakoon, G.G.N.N. Development of Sustainable Ground Improvement Methods Using Biochemical Techniques. Ph.D. Thesis, Hokkaido University, Sapporo, Japan, 2016. [Google Scholar]

- ISO 6707-1:2017; Buildings and Civil Engineering Works—Vocabulary—Part 1: General Terms. ISO (International Organization for Standardization): Geneva, Switzerland, 2017.

- Hoffmann, M.; Żarkiewicz, K.; Zieliński, A.; Skibicki, S.; Marchewka, Ł. Foundation Piles—A New Feature for Concrete 3d Printers. Materials 2021, 14, 2545. [Google Scholar] [CrossRef] [PubMed]

- PrEN 1997-3:202x; Eurocode 7: Geotechnical Design—Part 3: Geotechnical Structures. European Standard: Brussels, Belgium, 2021.

- Mitchell, J.M.; Jardine, F.M. A Guide to Ground Treatment; CIRIA: London, UK, 2002; ISBN 0860175731. [Google Scholar]

- Chu, J.; Varaksin, S.; Klotz, U.; Mengé, P. Construction Processes. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering (Volumes 1, 2, 3 and 4), Alexandria, Egypt, 5–9 October 2009; pp. 3006–3135. [Google Scholar]

- Topolnicki, M. Ground Improvement Instead of Piling—Effective Design Solutions for Heavily Loaded Structures. In Proceedings of the International Conference on Deep Foundations and Ground Improvement, Rome, Italy, 5–8 June 2018; pp. 1128–1137. [Google Scholar]

- Aydinli, S.; Bağriaçik, B.; Oral, E.L. Comparison of Construction Costs of Piled Raft Foundations and Jet GroutingSystems. In Proceedings of the 13th International Congress on Advances in Civil Engineering, İzmir, Turkey, 12–14 September 2018; pp. 1–8. [Google Scholar]

- Njock, P.G.A.; Chen, J.; Modoni, G.; Arulrajah, A.; Kim, Y.H. A Review of Jet Grouting Practice and Development. Arab. J. Geosci. 2018, 11, 1–31. [Google Scholar] [CrossRef]

- Dybeł, P.; Wałach, D.; Jaskowska-Lemańska, J. Technical Note: Example of the Application of Jet Grouting to the Neutralisation of Geotechnical Hazard in Shaft Structures. Studia Geotech. Mech. 2015, 37, 95–99. [Google Scholar] [CrossRef]

- Balfour Beatty. Vibro Compaction. Available online: https://www.balfourbeatty.com/ (accessed on 31 August 2023). (In Polish).

- Keller Polska. Soil Mixing-Ground Improvement by Soil Mixing Method. Available online: https://www.keller.com.pl/czym-sie-zajmujemy/technologie/kolumny-dsm (accessed on 31 August 2023).

- Topolnicki, M.; Chang, H.N. Ground Improvement, an Alternative to Pile Foundations. In Proceedings of the 17th African Regional Conference on Soil Mechanics and Geotechnical Engineering, Cape Town, South Africa, 7–9 October 2019. [Google Scholar]

- Polańska, B.; Rainer, J. Rigid Inclusion Ground Improvements as an Alternative to Pile Foundation. IOP Conf. Ser. Mater. Sci. Eng. 2020, 869, 052080. [Google Scholar] [CrossRef]

- Sondermann, W. Ground Improvement as Alternative to Piling—Effective Design Solutions for Heavily Loaded Structures. In Latest Thoughts on Ground Improvement Techniques; Shehata, H., Poulos, H., Eds.; Springer Nature: Cham, Switzerland, 2019. [Google Scholar]

- SOILMEC Spa. Jet Grouting. Available online: https://www.soilmec.com/en/ (accessed on 31 August 2023).

- Gomes Correia, A.; Winter, M.G.; Puppala, A.J. A Review of Sustainable Approaches in Transport Infrastructure Geotechnics. Transp. Geotech. 2016, 7, 21–28. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ebid, A.M.; Mahdi, H.A.; Baldovino, J.A. Selecting the Safety and Cost Optimized Geo-Stabilization Technique for Soft Clay Slopes. Civ. Eng. J. 2023, 9, 453–464. [Google Scholar] [CrossRef]

- Wałach, D. Economic and Environmental Assessment of New Generation Concretes. IOP Conf. Ser. Mater. Sci. Eng. 2020, 960, 042013. [Google Scholar] [CrossRef]

- Tayler, H. A Short Guide to reusing Foundations. J. Struct. Eng. 2020, 98, 20–23. [Google Scholar] [CrossRef]

- Valenta, J.; Vanícek, I. Reuse of Foundation. Construction on Brownfields 155–160. Available online: http://www.udrzitelnavystavba.cz/WP1_papers/17_Valenta.pdf (accessed on 24 November 2023).

- Dos Santos, P.H.; Neves, S.M.; Sant’Anna, D.O.; de Oliveira, C.H.; Carvalho, H.D. The Analytic Hierarchy Process Supporting Decision Making for Sustainable Development: An Overview of Applications. J. Clean. Prod. 2019, 212, 119–138. [Google Scholar] [CrossRef]

- Ziemba, P. Application Framework of Multi-Criteria Methods in Sustainability Assessment. Energies 2022, 15, 9201. [Google Scholar] [CrossRef]

- Czajkowska, A. The Role of Sustainable Construction in Sustainable Development. MATEC Web. Conf. 2018, 174, 01027. [Google Scholar] [CrossRef]

- Sobotka, A.; Sagan, J.; Gicala, M. Sustainability of Construction Processes—Requirements, Criteria, Evaluation Concep. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 112051. [Google Scholar] [CrossRef]

- Wałach, D.; Sagan, J.; Gicala, M. Assessment of Material Solutions of Multi-Level Garage Structure within Integrated Life Cycle Design Process. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 072027. [Google Scholar] [CrossRef]

- COM/2019/640 Final. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions—The European Green Deal. Brussels. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52019DC0640 (accessed on 24 November 2023).

- European Council. Council of the European Union. Fit for 55 Package. Available online: https://www.consilium.europa.eu/en/policies/green-deal/fit-for-55-the-eu-plan-for-a-green-transition/ (accessed on 14 April 2023).

- European Commission Buying Green! A Handbook on Green Public Procurement 3rd Edition. Available online: https://ec.europa.eu/environment/gpp/pdf/Buying-Green-Handbook-3rd-Edition.pdf (accessed on 17 May 2023).

- Główny Urząd Statystyczny; Urząd Statystyczny w Białymstoku. Green Economy Indicators for Poland. 2022. Available online: https://stat.gov.pl/obszary-tematyczne/srodowisko-energia/srodowisko/wskazniki-zielonej-gospodarki-w-polsce-2022,10,3.html (accessed on 6 June 2023). (In Polish)

- Nicholson, P.G. Chapter 2—Ground Improvement Techniques and Applications. In Soil Improvement and Ground Modification Methods; Nicholson, P.G., Ed.; Butterworth-Heinemann: Boston, MA, USA, 2015; pp. 9–17. ISBN 978-0-12-408076-8. [Google Scholar]

- Pons, O.; Casanovas-Rubio, M.M.; Armengou, J.; de la Fuente, A. Sustainability-Driven Decision-Making Model: Case Study of Fiber-Reinforced Concrete Foundation Piles. J. Constr. Eng. Manag. 2021, 147, 04021116. [Google Scholar] [CrossRef]

- VOSviewer—Visualizing Scientific Landscapes. Available online: https://www.vosviewer.com/ (accessed on 24 April 2023).

- van Eck, N.J.; Waltman, L. Visualizing Bibliometric Networks. In Measuring Scholarly Impact; Ding, Y., Rousseau, R., Wolfram, D., Eds.; Springer: Cham, Switzerland, 2014; pp. 285–320. ISBN 19103778_13. [Google Scholar]

- Ji, W.; Yu, S.; Shen, Z.; Wang, M.; Cheng, G.; Yang, T.; Yuan, Q. Knowledge Mapping with CiteSpace, VOSviewer, and SciMAT on Intelligent Connected Vehicles: Road Safety Issue. Sustainability 2023, 15, 12003. [Google Scholar] [CrossRef]

- Si, S.-L.; You, X.-Y.; Liu, H.-C.; Zhang, P. DEMATEL Technique: A Systematic Review of the State-of-the-Art Literature on Methodologies and Applications. Math. Probl. Eng. 2018, 2018, 3696457. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Connecting Circular Economy and Industry 4.0. Int. J. Inf. Manag. 2019, 49, 98–113. [Google Scholar] [CrossRef]

- Lee, H.S.; Tzeng, G.H.; Yeih, W.; Wang, Y.J.; Yang, S.C. Revised DEMATEL: Resolving the Infeasibility of DEMATEL. Appl. Math. Model. 2013, 37, 6746–6757. [Google Scholar] [CrossRef]

- Hsu, C.-W.; Kuo, T.-C.; Chen, S.-H.; Hu, A.H. Using DEMATEL to Develop a Carbon Management Model of Supplier Selection in Green Supply Chain Management. J. Clean. Prod. 2013, 56, 164–172. [Google Scholar] [CrossRef]

- United Nations Environment Programme. 2021 Global Status Report for Buildings and Construction Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector. Available online: https://globalabc.org/sites/default/files/2021-10/GABC_Buildings-GSR-2021_BOOK.pdf (accessed on 16 January 2023).

- Sadjadi, M.; Nikooee, E.; Habibagahi, G. Biological Treatment of Swelling Soils Using Microbial Calcite Precipitation. In Unsaturated Soils: Research & Applications; Springer: Berlin/Heidelberg, Germany, 2014; pp. 917–922. [Google Scholar]

- Pop, I.; Wan-Wendner, L.; Vits, W. Optimized Structural Design of Concrete Pile Plug in Steel Pipe Piles. Struct. J. 2022, 119, 153–163. [Google Scholar] [CrossRef]

- Pooni, J.; Robert, D.; Giustozzi, F.; Setunge, S.; Xie, Y.M.; Xia, J. Novel Use of Calcium Sulfoaluminate (CSA) Cement for Treating Problematic Soils. Constr. Build. Mater. 2020, 260, 120433. [Google Scholar] [CrossRef]

- Subramanian, S.; Tee, W.Z.; Moon, J.; Ku, T. Sustainable Use of OPC-CSA Blend for Artificial Cementation of Sand: A Dosage Optimization Study. Geomech. Eng. 2022, 31, 409. [Google Scholar] [CrossRef]

- Chu, J. Solutions to Sustainability in Construction: Some Examples. Procedia Eng. 2016, 145, 1127–1134. [Google Scholar] [CrossRef]

- Naeimi, M.; Haddad, A. Investigation on the Environmental Impact of Soil Improvement Techniques: Comparison of Cement Grouting and Biocement. In Proceedings of the GeoShanghai 2018 International Conference: Geoenvironment and Geohazard; Springer: Singapore, 2018; pp. 483–490. [Google Scholar]

- Bačić, M.; Marčić, D.; Peršun, T. Application of Industrial Waste Materials in Sustainable Ground Improvement. In Proceedings of the International Conference on Road and Rail Infrastructure CETRA, Spilt Dalmatia, Croatia, 28–30 April 2014; University of Zagreb: Spilt Dalmatia, Croatia, 2014; pp. 609–615. [Google Scholar]

- Bhavita Chowdary, V.; Ramanamurty, V.; Pillai, R.J. Experimental Evaluation of Strength and Durability Characteristics of Geopolymer Stabilised Soft Soil for Deep Mixing Applications. Innov. Infrastruct. Solut. 2021, 6, 1–10. [Google Scholar] [CrossRef]

- Kaczmarczyk, G. Application of Fluidized Bed Furnance Bottom Ash in Civil Engineering—A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1203, 032013. [Google Scholar] [CrossRef]

- Bağrıaçık, B.; Mahmutluoğlu, B. Conducting Large-Scale Model Experiments on Xanthan Gum Treated Clay as an Eco-Friendly Approach to Soil Improvement. KSCE J. Civ. Eng. 2023, 27, 1480–1489. [Google Scholar] [CrossRef]

- Burrows, V.K.; Watson, E. Advancing Net Zero Whole Life Carbon Offsetting Residual Emissions from the Building and Construction Sector. Available online: https://worldgbc.org/advancing-net-zero/advancing-net-zero-whole-life-carbon/ (accessed on 12 April 2022).

- Hamdy, D.B. A Sustainable Approach for Improving the Behavior of Collapsible Soil Using Marble Dust. Innov. Infrastruct. Solut. 2022, 7, 260. [Google Scholar] [CrossRef]

- de Albuquerque, P.J.R.; León-Mogrovejo, D.R. A Laboratory Investigation on a Mechanical Behavior of Sandy and Clayey Soils with Kraft Paper Fiber. Transp. Infrastruct. Geotech. 2021, 8, 12–36. [Google Scholar] [CrossRef]

- Mahmutluoglu, B.; Bagriacik, B. Sustainable Implementation of Glass Manufacturing Waste and Geogrids in the Improvement of Fine-Grained Soils. KSCE J. Civ. Eng. 2021, 25, 1295–1307. [Google Scholar] [CrossRef]

- Mochida, Y.; Olabamiji, O.J.; Kasahara, K. Study on Development of Soil Improvement Pile Method Using Recycled Soil. Int. J. GEOMATE 2021, 20, 28–33. [Google Scholar] [CrossRef]

- Basack, S.; Goswami, G.; Khabbaz, H.; Karakouzian, M.; Baruah, P.; Kalita, N. A Comparative Study on Soil Stabilization Relevant to Transport Infrastructure Using Bagasse Ash and Stone Dust and Cost Effectiveness. Civ. Eng. J. 2021, 7, 1947–1963. [Google Scholar] [CrossRef]

- Pradhan, B.; Tiwari, S.K. FEM Analysis of Granular Pile Made with Alternate Materials. Transp. Infrastruct. Geotech. 2022, 10, 1284–1320. [Google Scholar] [CrossRef]

- Sobotka, A.; Radziejowska, A.; Czaja, J. Tasks and Problems in the Buildings Demolition Works: A Case Study. Arch. Civ. Eng. 2015, 61, 3–18. [Google Scholar] [CrossRef]

- Zahmak, A.; Abdallah, M.; Jarah, B.; Arab, M.G. Environmental Performance of Alkali-Activated Binders for Ground Improvement. Transp. Geotech. 2021, 31, 100631. [Google Scholar] [CrossRef]

- Hanafi, M.; Ekinci, A.; Aydin, E. Engineering and Microstructural Properties of Alluvium Clay Stabilized with Portland Cement and Coal Bottom Ash for Sustainable Future. KSCE J. Civ. Eng. 2022, 26, 5049–5066. [Google Scholar] [CrossRef]

- Russell, A.R.; Chapman, M.; Teh, S.H.; Wiedmann, T. Cost and Embodied Carbon Reductions in Cutter Soil Mix Walls through Fibre Reinforcement. Geosynth. Int. 2017, 24, 280–292. [Google Scholar] [CrossRef]

- Chang, N. Sustainability in Geotechnical Construction. Available online: https://www.keller-africa.co.za/news/sustainability-geotechnical-construction (accessed on 12 June 2023).

- Fan-Ren, L.Y.U.; Hong-Cai, S.; Wen, Z. A Contrastive Analysis of Carbon Emissions in Different Solutions to Battered Piles. IOP Conf. Ser. Earth. Environ. Sci. 2021, 634, 012007. [Google Scholar] [CrossRef]

- Lee, M.; Basu, D. Environmental Impacts of Drilled Shafts and Driven Piles in Sand. In Proceedings of the IFCEE 2018, Orlando, FL, USA, 5–10 March 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 643–652. [Google Scholar]

- Li, X.J.; dan Zheng, Y. Using LCA to Research Carbon Footprint for Precast Concrete Piles during the Building Construction Stage: A China Study. J. Clean. Prod. 2020, 245, 118754. [Google Scholar] [CrossRef]

- Chernyuk, V.; Semenyuk, S.; Yuskovich, V. Effective Low-Noise Technologies for the Production of Pile Works in Construction. In Proceedings of the MATEC Web of Conferences; EDP Sciences, Sibiu, Romania, 2–4 June 2021; Volume 350. [Google Scholar]

- European Commission. Directive 2002/49/EC of the European Parliament and of the Council of 25 June 2002 Relating to the Assessment and Management of Environmental Noise. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02002L0049-20210729 (accessed on 14 June 2023).

- Jiang, Q.; Wang, X.; Yu, M.; Tang, M.; Zhang, H.; Wu, J. Theoretical Study of Vibro-Acoustics of Fluid-Pile-Soil Coupled System and Experimental Research of Noise Reduction of Small-Scale Pile Driving. Ocean Eng. 2022, 252, 110997. [Google Scholar] [CrossRef]

- Choi, Y.; Kim, D.-C.; Kim, S.-S.; Nam, M.S.; Kim, T.-H. Implementation of Noise-Free and Vibration-Free PHC Screw Piles on the Basis of Full-Scale Tests. J. Constr. Eng. Manag. 2013, 139, 960–967. [Google Scholar] [CrossRef]

- Komazawa, T.; Harada, O.; Inazumi, K. Installation of Steel Pipe Piles and Steel Pipe Sheet Pile for Bridge Foundation Using Vibratory Inner-Excavation Method (NB SYSTEM). In Geotechnics for Sustainable Infrastructure Development. Lecture Notes in Civil Engineering; Duc Long, P., Dung, N., Eds.; Springer: Singapore, 2020; Volume 62, pp. 451–458. [Google Scholar]

- Zingoni, A. Advances in Engineering Materials, Structures and Systems: Innovations, Mechanics and Applications. In Proceedings of the 7th International Conference on Structural Engineering, Mechanics and Computation (SEMC 2019), Cape Town, South Africa, 2–4 September 2019; CRC Press LLC: Cape Town, South Africa, 2020. [Google Scholar]

- Colaço, A.; Alves Costa, P.; Mont’Alverne Parente, C.; Silva Cardoso, A. Ground-Borne Noise and Vibrations in Buildings Induced by Pile Driving: An Integrated Approach. Appl. Acoust. 2021, 179, 108059. [Google Scholar] [CrossRef]

- Dahl, P.H.; Dall’osto, D.R.; Laughlin, J. Measurements of Pile Driving Noise from Control Piles and Noise-Reduced Piles at the Vashon Island Ferry Dock. Available online: https://wsdot.wa.gov/sites/default/files/2021-10/Env-Noise-MonRpt-VashonControlNoiseReducedPiles.pdf (accessed on 13 June 2023).

- Beach, V. Pile Driving Noise Measurements at Atlantic Fleet Naval Installations: 28 May 2013–28 April 2016; HDR: Virginia Beach, VA, USA, 2017. [Google Scholar]

- Bellmann, M.A.; May, A.; Wendt, T.; Gerlach, S.; Remmers, P.; Brinkmann, J. Underwater Noise Duringthe Impulse Pile-Driving Procedure: Influencing Factors on Pile-Driving Noiseand Technical Possibilities to Comply with Noise Mitigation Values; Institute of Technical and Applied Physics (itap) GmbH: Oldenburg, Germany; German Ministry for the Environment, Nature Conservation, Building and Nuclear Safety (BMUB): Berlin, Germany, 2020.

- Juretzek, C.; Schmidt, B.; Boethling, M. Turning Scientific Knowledge into Regulation: Effective Measures for Noise Mitigation of Pile Driving. J. Mar. Sci. Eng. 2021, 9, 819. [Google Scholar] [CrossRef]

- Wagenknecht, F. Assessment of Noise Mitigation Measures during Pile Driving of Larger Offshore Wind Foundations. EGU J. Ren. En. Rev. 2021, 19–23. [Google Scholar] [CrossRef]

- Kang, D.; Lee, W.S.; Hong, J.K. Characteristics of Construction Machinery Noise and Vibration. Trans. Korean Soc. Noise Vib. Eng. 2005, 15, 645–651. [Google Scholar] [CrossRef]

- Svinkin, M.R. Forensic Engineering of Construction Vibrations. Proc. Inst. Civ. Eng. Forensic. Eng. 2013, 166, 81–93. [Google Scholar] [CrossRef]

- Grizi, A.; Athanasopoulos-Zekkos, A.; Woods, R.D. H-Pile Driving Induced Vibrations: Reduced-Scale Laboratory Testing and Numerical Analysis. In IFCEE 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 165–175. [Google Scholar]

- Vytiniotis, A.; Casey, B.; Sykora, D.W. Lateral Soil Movements Due to Pile Driving: A Case Study in Soft Clays. In IFCEE 2018; American Society of Civil Engineers: Reston, VA, USA, 2018. [Google Scholar]

- Liang, Y.; Feng, Q.; Fu, M.; Wu, B.; Lu, J.; Tang, G. Prediction and Monitoring of the Construction Vibration Effect on an Adjacent Old Long Span Double-Convex Arch Bridge. KSCE J. Civ. Eng. 2022, 26, 2183–2201. [Google Scholar] [CrossRef]

- Chang, H.N.; Markides, B.D. Vibration Associated with Construction of DCIS Enlarged-Base Piles. In Proceedings of the First Southern African Geotechnical Conference, Sun City, South Africa, 5–6 May 2016; pp. 53–58. [Google Scholar]

- Musir, A.A.; Ghani, A.N.A. A Study of Pile Driving Effects on Nearby Building. Int. J. Geomate 2014, 6, 806–810. [Google Scholar]

- Cleary, J.C.; Gillis, A.S.; Steward, E.J. A Case Study of Ground Vibrations Due to Pile Driving in Mobile, Alabama. In Forensic Engineering 2015; American Society of Civil Engineers: Reston, VA, USA, 2015; pp. 132–142. ISBN 9780784479711. [Google Scholar]

- Wojtowicz, A.; Michałek, J.; Ubysz, A. Range of Dynamic Impact of Geotechnical Works on Reinforced Concrete Structures. E3S Web Conf. 2019, 97, 03026. [Google Scholar] [CrossRef]

- Vavrina, L.; Windeln, D. Example of a Low Vibration Deep Foundation with Precast Driven Piles. Bautechnik 2017, 94, 661–666. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, K.H.; Jamin, J.C.; Mission, J.L.C. Stochastic Cost Optimization of Ground Improvement with Prefabricated Vertical Drains and Surcharge Preloading. Geomech. Eng. 2014, 7, 525–537. [Google Scholar] [CrossRef]

- Abu-Farsakh, M.Y.; Haque, M.N.; Tavera, E.; Zhang, Z. Evaluation of Pile Setup from Osterberg Cell Load Tests and Its Cost–Benefit Analysis. Transp. Res. Rec. 2017, 2656, 61–70. [Google Scholar] [CrossRef]

- Gong, W.; Tang, H.; Juang, C.H.; Martin, J.R.; Wang, L. Optimization-Based Design of Stabilizing Piles. In Proceedings of the GeoShanghai 2018 International Conference: Geoenvironment and Geohazard; Farid, A., Chen, H., Eds.; Springer: Singapore, 2018; pp. 45–53. [Google Scholar]

- Hernández-Montes, E.; Alameda-Hernández, P.; Gil-Martín, L.M. Strength Design Criterion for Asymmetrically Reinforced RC Circular Cross-Sections in Bending. Comput. Concr. 2013, 11, 571–585. [Google Scholar] [CrossRef]

- Sales, M.M.; Lima, B.S.; Almeida, S.R.M.; Farias, M.M. Automatic Optimization of Piled Raft Design Based on Branch and Bound Method. Struct. Des. Tall Special Build. 2015, 24, 351–365. [Google Scholar] [CrossRef]

- Mozakka, I.; Zeynalian, M.; Hashemi, M. A Feasibility Study on Construction Methods of High Voltage Transmission Towers’ Foundations. Archiv. Civ. Mech. Eng. 2021, 21, 1–15. [Google Scholar] [CrossRef]

- Lateef, H.H.; Burhan, A.M. Time-Cost-Quality Trade-off Model for Optimal Pile Type Selection Using Discrete Particle Swarm Optimization Algorithm. Civ. Eng. J. 2019, 5, 2461–2471. [Google Scholar] [CrossRef]

- Mata, P.; Silva, P.F.; Pinho, F.F.S. Risk Management of Bored Piling Construction on Sandy Soils with Real-Time Cost Control. Infrastructures 2021, 6, 77. [Google Scholar] [CrossRef]

- Mekdash, H.; Jaber, L.; Temsah, Y.; Sadek, M. Reinforcement of Concrete Shoring Systems by Prestressing. Adv. Civ. Eng. 2022, 2022, 2383781. [Google Scholar] [CrossRef]

- Amornfa, K.; Quang, H.T.; Tuan, T.V.; Amornfa, K.; Quang, H.T.; Tuan, T.V. 3D Numerical Analysis of Piled Raft Foundation for Ho Chi Minh City Subsoil Conditions. Geomech. Eng. 2022, 29, 183–192. [Google Scholar] [CrossRef]

- Yao, W.; Li, C.; Zhan, H.; Zhang, H.; Chen, W. Probabilistic Multi-Objective Optimization for Landslide Reinforcement with Stabilizing Piles in Zigui Basin of Three Gorges Reservoir Region, China. Stoch. Environ. Res. Risk Assess. 2020, 34, 807–824. [Google Scholar] [CrossRef]

- Hazirbaba, K.; Mughieda, O. A Comparative Study of Targeted Ground Improvement Alternatives during Site Reclamation. Jordan J. Civ. Eng. 2019, 13, 180–196. [Google Scholar]

- Puppala, A.J.; Pedarla, A. Innovative Ground Improvement Techniques for Expansive Soils. Innov. Infrastruct. Solut. 2017, 2, 1–15. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Lam, C.G.Y.; Skitmore, M.; Talebian, N. Barriers To The Adoption Of New Safety Technologies In Construction: A Developing Country Context. J. Civ. Eng. Manag. 2022, 28, 120–133. [Google Scholar] [CrossRef]

- Thomas, T.; Praveen, A. Regulating Natural Resource Consumption in the Construction Sector Using Emergy Model. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1114, 012033. [Google Scholar] [CrossRef]

- Atradius, N.V. Industry Trends Construction Credit Risk Outlook Clouded by High Levels of Uncertainty. Available online: www.atradius.com (accessed on 2 January 2024).

- Mowafy, N.; El Zayat, M.; Marzouk, M. Parametric BIM-Based Life Cycle Assessment Framework for Optimal Sustainable Design. J. Build. Eng. 2023, 75, 106898. [Google Scholar] [CrossRef]

- Gilani, G.; Hosseini, S.M.A.; Pons-Valladares, O.; de la Fuente, A. An Enhanced Multi-Criteria Decision-Making Approach Oriented to Sustainability Analysis of Building Facades: A Case Study of Barcelona. J. Build. Eng. 2022, 54, 104630. [Google Scholar] [CrossRef]

- Bhyan, P.; Shrivastava, B.; Kumar, N. Allocating Weightage to Sustainability Criteria’s for Performance Assessment of Group Housing Developments: Using Fuzzy Analytic Hierarchy Process. J. Build. Eng. 2023, 65, 105684. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).