Abstract

Using construction waste materials as substrates can reduce the resource consumption of minerals and provide sustainability benefits in green roofs. This research examined the viability of crushed bricks and crushed concrete with varying particle sizes as substrates by conducting a simulated drought experiment and roof experiment. Six composite substrates were prepared, respectively, by mixing peat with small-, medium-, and large-sized crushed bricks and crushed concrete particles (peat-to-inorganic-particle volume ratio of 1:2). The properties of each group were within acceptable parameters, with the crushed brick substrates displaying lower bulk density and higher porosity compared to the crushed concrete substrates. Seldom lineare was selected for the experiments, and the substrate thickness was set at 10 cm. Under the simulated drought conditions, the growth and stress resistance of Seldom lineare in the crushed brick substrates was similar to that in the conventional substrates and poorer in the crushed concrete substrates. Seldom lineare in medium-particle-size brick substrates performed the best, surpassing the traditional group. The growth of Seldom lineare in the small-particle-size concrete substrates was the worst. In the rooftop environment, all groups could support Seldom lineare over 180 days without maintenance, with an overall coverage of more than 60%. The plants in the medium-particle-size brick substrates exhibited the highest cover. In conclusion, the medium-particle-size brick substrate exhibits ideal characteristics in terms of substrate physical properties and plant growth, making it a favorable option.

1. Introduction

Green roof technology has been widely applied in urban areas. Builders favor extensive green roofs due to their simplified construction process, low maintenance requirements, and cost-effectiveness [1,2]. The substrate is the fundamental medium for green roofs and plays a crucial role in facilitating plant growth [2,3]. It should meet the criteria of supporting vegetation growth, possessing a lightweight structure, exhibiting high water retention capacity, providing thermal insulation, and being cost-effective [4,5,6].

Green roof substrate is typically composed of a mixture of inorganic and organic materials to achieve the desired properties. Traditional organic components usually include grass charcoal, peat, and loam [7,8,9], provide nutrients to plants, act as water storage, and contribute to increased biodiversity [5,10]. However, it is essential to maintain the specific gravity of the organic matter at appropriate levels to prevent increasing nutrient loads in stormwater runoff and to avoid any adverse effects on plant growth for its unstable characteristics [11,12]. The inorganic component forms the majority of substrate [13], providing physical support for plant growth and protecting them from adverse environmental and climatic influences. The inorganic materials should have low bulk weight and appropriate pore size to reduce their weight while enhancing porosity and drainage capacity [14,15,16]. Minerals that are both lightweight and porous [17,18], including vermiculite, perlite, gravel, and pumice, serve as the primary sources of inorganic components [19,20,21].

The extraction, production, and transportation of natural ores and peat soils, which have long been utilized as traditional substrates materials, exert pressure on resources and the environment [22], making the cost of building green roofs higher and less environmentally friendly. Recycled waste is a widely available material that is relatively easy to process, transport, and use [23]. This alternative meets the requirements for green roof substrates and plant growth conditions while reducing energy consumption and construction costs [14,24]. Moreover, incorporating waste materials in green roof substrates helps alleviate the burden of waste disposal, effectively conserves resources, and minimizes adverse environmental impacts [25,26].

Sources of recycled materials for green roof research include construction, industry, and agroforestry. Industrial recycled materials, such as slag, incinerator ash, and fly ash, have primarily been utilized as replacements for inorganic components, whereas stabilized sludge from sewage plants can serve as an alternative to organic ingredients [27,28,29]. Agroforestry renewable resources, such as treated fruit shells, cultivation waste, and compost, have also been considered potential substitutes for peat or loam soil [15,30,31]. Construction waste materials, typically comprising 10–30% of total waste in municipal landfills [32], can be pulverized and utilized as substrate components [33], such as concrete, bricks, tiles, and recycled glass [14,16,34].

A comprehensive understanding of the properties of substrates and their relationships with plants can play a crucial role in promoting the sustainability of green roofs [35]. Previous research has shown that construction waste substrates exhibit desirable traits, such as appropriate bulk density and sufficient aeration [36,37,38], and are characterized by moderate pH [34]. Therefore, it may have equivalent or better properties than sand and gravel [39,40]. Evaluating the suitability of recycled construction materials substrates by assessing plant growth can effectively demonstrate their functional effectiveness. Plants like turfgrasses and Sedum varieties were successfully established and grown in mixed substrates comprising recycled construction waste materials [41]. Crushed brick substrates have been found to enhance plant growth and promote biodiversity, making them a promising option for sustainable landscaping practices [42]. In other studies, substrates containing crushed concrete materials were applied and resulted in the development of abundant vascular plants, moss, and potted plant communities on the roof after three years [43]. Achieving the appropriate ratio between construction waste and organic materials can efficiently retain the water of the substrate and provide a suitable basis for plant growth, such as crushed bricks or tiles combined with loam [24,44], and crushed concrete or bricks with compost [34,39,40].

Furthermore, some investigations specifically examine the influence of construction waste substrates on the ecological benefits of green roofs and the potential risks associated with environmental contamination. The application of crushed bricks can enhance the rainwater retention in green roof systems [37,41]. Research has also shown that crushed bricks significantly reduced the presence of metal ions in storm water runoff [45]. However, adding substantial quantities of construction waste into the substrate may result in phosphorus contamination and the release of higher concentrations of nickel [46]. Nevertheless, some studies have shown that the levels of pollutant elements released from construction waste substrate were lower in the actual green roof environment compared to the laboratory testing conditions [47].

The key to adopting extensive green roofs widely relies on the excellent properties of the substrate during periods of high temperature and drought stress in the summer [19]. Previous research has primarily concentrated on the effect of different types and proportions of construction waste materials in substrates performance and plant growth. Nevertheless, there remains to be more in-depth exploration regarding the impact of material particle size on substrate properties and plant growth and the adaptability of plants to construction waste substrates under drought conditions. Therefore, based on an extensive green roof application scenario, the main objectives of this study were as follows: (1) to measure the physical and chemical properties of construction waste substrates composed of different materials and particle sizes, providing a reference for their application in roof greening; (2) to combine indoor simulated drought conditions and the outdoor rooftop environment, observing and analyzing the growth and stress resistance response of plants to different substrates treatments, therefore providing a reference concerning the stability of both the substrate and the plants.

2. Materials and Methods

2.1. Experimental Site

The experimental site was in the Fengxian Campus of the Shanghai Institute of Technology in the southern part of Fengxian District, Shanghai, which belongs to the area of northern subtropical monsoon climate. Based on the information provided by the Shanghai Meteorological Bureau, the start of the summer season in Shanghai for 2021 was documented on 7 May, lasting 162 days. Most precipitation was concentrated during the East Asian rainy season and typhoon events, with the remaining rainfall occurring as scattered afternoon convective showers. During September and October, the region experienced hot weather and low precipitation due to the influence of the subtropical high-pressure system (Table 1). This study involved two testing locations, one indoors and one outdoors. The indoor site was situated within the greenhouse in the botanical garden of the Shanghai Institute of Technology (30°50′37.29″ N, 121°31′4.44″ E). The green roof test experiment was installed atop The Third Canteen on campus (30°50′31.60″ N and 121°30′45.78″ E).

Table 1.

Temperature data for Fengxian District, May–October 2021.

2.2. Experimental Materials

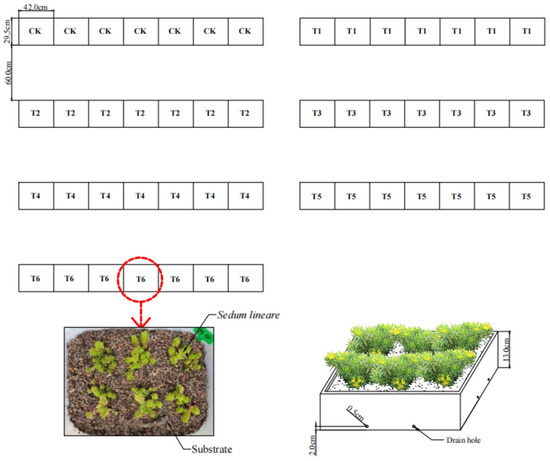

Previous studies have demonstrated that substrate thicknesses of 10–25 cm can support the growth of green roof plants [48,49]. Hence, the experiment set the substrate thickness at 12 cm. Construction waste materials, including crushed bricks (Br) and crushed concrete (Co), were sourced from Shanghai Pudong Xingsheng Road Base Material Co. (Shanghai, China). Three particle sizes—small (less than 3 mm), medium (between 3–5 mm), and large (between 5–8 mm)—were acquired through the removal of impurities and sieving. The abbreviations S, M, and L were employed to denote the three sizes of particles, respectively. Peat (Pe) and perlite were purchased from Shanghai Dingze Horticultural Co. (Shanghai, China ) The substrate composition was set as a ratio of peat to inorganic particles at 1:2 (v/v), whereas inorganic composition in group CK (the volume ratio of vermiculite to perlite was 1:1) was denoted by IP. The ratio of each substrate treatment is presented in Table 2. T1–T3 represent crushed brick substrates; T4–T6 represent crushed concrete substrates. Each group of substrates was packed in a rectangular plastic container, with a size of 42.0 × 29.5 × 13.0 cm. Two drainage holes with a diameter of 1.0 cm were, respectively, located on each side of the container and 1.5 cm away from the bottom of the container. Water storage space can be formed below the drainage holes.

Table 2.

Ratio of selected materials for substrate treatments.

Sedum lineare was used in the experiment. Through extensive research and industry experiences, Sedum species has been widely utilized in the context of extensive green roof substrate for their high adaptability and minimal maintenance requirement [50], and they exhibit excellent coverage even in challenging roof environments [51]. The plants were purchased from Shanghai JiuXin Flower Market. When selecting seedlings, the plant height was controlled at 5–10 cm, and the fresh weight was controlled at 10–20 g. Prior to being transplanted into the plastic container, we removed the original soil carried by the root of Sedum Sedum and cleaned the plants with pure water to remove impurities attached to the plants. Each container was planted with a total of 6 bushes.

2.3. Simulated Drought Experiment

The experiment was conducted from April to September 2021. The experiment included seven test groups, each with 8 replicates and a total of 56 containers. Among these, 3 containers in each group were exclusively used for measuring the relative water content of leaves. After planting, there was a 30-day maintenance period during which the plants were watered once a week and a small amount of nutrient was applied. The observation period for simulated drought conditions started from 1 May 2021. Throughout this period, a small amount of water was supplied to the water storage space of the substrate every 30 days. The coverage, leaf chlorophyll content, and relative water content were measured every 10 days.

2.4. Roof Experiment

The experiment was conducted from April to November 2021, with seven replicates for each test group, as shown in Table 2. Six of the containers in each group were planted with vegetation, and one was not planted to assess substrate properties (Figure 1). The plant containers were initially placed in the greenhouse for 30 days for maintenance. After the maintenance period, the containers were transferred to the roof of The Third Canteen on 30 April 2021. The measurement of plant coverage was conducted at 10-day intervals over a period of 6 months.

Figure 1.

Layout of roof environmental experiment substrate.

2.5. Data Collection

2.5.1. Substrate Physical and Chemical Properties

The physical and chemical properties assessed included bulk density, overall porosity, pH, and electrical conductivity (EC), which were measured on three replicates of each substrate. A ring knife with a volume V of 100 cm3 and mass M1 was used to extract the substrate sample from the container. The sample was dried at 80 °C in the oven until a constant mass was achieved, and the resulting mass was recorded as M2. Bulk density (g/cm3) = (M2 − M1)/V. To measure the porosity, the dried substrate sample was put into a specific gravity bottle with volume V, and the specific gravity of the substrate sample was determined via the drainage weighing principle. Porosity (%) = (1 − bulk density/specific gravity) × 100% [52,53].

To measure pH and EC, the air-dried substrate samples from each group were mixed with deionized water in a ratio of 1:5 (v/v), followed by a 10-min standing period for filtration [54,55]. The pH and EC of the filtrate from substrate-saturated leaching were measured, respectively, using the REX pH300F pH meter and REX EC100B conductivity meter.

2.5.2. Plant Growth and Physiological Data

The vegetation coverage was captured through vertical downward photography from a height of 25 cm above the plant surface, avoiding the influence of shadows when collecting images [33]. Auto-CAD 2021 software was utilized to calculate the plants’ vertical projected area S1 and statistical area S2. Coverage (%) = S1/S2 × 100%.

To measure chlorophyll content, 5–10 leaves with normal growth were picked in each container and were thoroughly ground with 95% high-concentration ethanol and a small quantity of quartz sand. The homogenate was subsequently transferred to a centrifuge tube, while the mortar and pestle underwent rinsing twice with a solution of 95% ethanol. The liquid resulting from the rinsing process was carefully introduced into the same centrifuge tube. The homogenate was subjected to centrifugation at a speed of 3000 revolutions per minute for a duration of 8 min, following which the clear supernatant was collected [56]. The supernatant from each group was measured via chromometry at two different wavelengths (663 nm and 645 nm). The content of chlorophyll a and b was calculated using the following formula [5]:

The absorbance of the extract was measured at wavelengths 663 nm and 645 nm, denoted as D663 and D645, respectively. V represents the volume of leaching liquid, while w indicates the weight of the leaf sample.

To measure the relative water content of leaves, we regularly harvested 15–20 vigorously growing leaves from the designated plants and promptly preserved them in a laboratory setting. They were immediately weighed and recorded as initial fresh weight M1. Then, the leaves were immersed in distilled water for a duration of 6 h. Sterile filter paper was used to absorb the moisture present on the leaf surface after taking them out, followed by determination of the saturated fresh weight M2. The leaves were placed in the oven at a temperature of 80 °C until the constant weight M3 was achieved. RWC = (M1 − M3)/(M2 − M3) × 100% [57].

Following completion of the simulated drought experiment, the above-ground part of plants from each group were harvested and subjected to oven drying at 80 °C until a constant weight was achieved. The final biomass was measured by recording the dry weight [58].

2.6. Data Analysis

In the experiment, each planting container is an experimental unit, and data were collected using Microsoft Excel. All statistical analyses were conducted using SPSS software (version 26.0). The normality of the data was assessed using the description statistics procedure in SPSS. Significance of the data between each group was analyzed using one-way analysis of variance. Least significant difference (LSD) statistics were used to examine the mean value differences within the groups. The relationship between the physical and chemical properties of the substrate and the physiological indexes of plant growth was examined using the correlation analysis procedure in SPSS. The statistical charts were plotted by Origin software (version 2021).

3. Results

3.1. Substrate Physical and Chemical Properties

According to Table 3, the bulk density of construction waste substrates varied from 0.61 to 0.91 g·cm−3, which was higher than that of the control group. The crushed brick substrates exhibited a lower bulk density than the crushed concrete substrates, and the bulk density of the T3 substrate (0.61 g·cm−3) had the smallest difference to that of the control group.

Table 3.

Substrate physical and chemical properties.

The total porosity of the crushed brick substrates was higher than that of the control group, while the total porosity of the crushed concrete substrates fell below that of the control group. However, the minimum value of 36.37% still exceeds the minimum value of 10% recommended in the FLL guidelines. Moreover, as the particle size of the construction waste increases, the total porosity demonstrates a corresponding increase.

Regarding the chemical properties of the substrates, the pH of the construction waste materials displayed a mild alkalinity, with the collective pH being higher than 7.00 for each group except for the T3 group. This pH level met the range values recommended by the FLL guidelines. The electrical conductivity values ranged from 0.58 to 0.75 ms/cm for all groups within the appropriate range of values.

3.2. Effects of Construction Waste Substrate with Different Compositions and Particle Sizes on Sedum lineare Growth under Simulated Drought Stress

3.2.1. Coverage

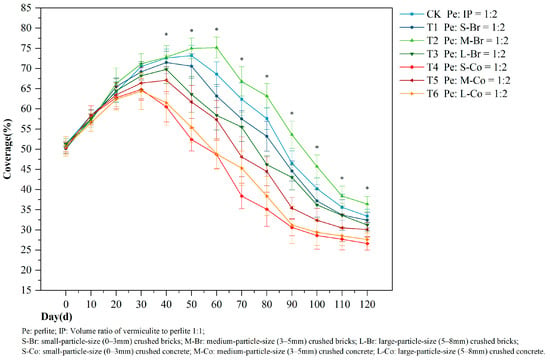

As shown in Figure 2, during the simulated drought stress test, the coverage of Sedum lineare growth in all groups demonstrated a trend of an initial increase followed by a decline. In the control group, the maximum coverage (73.2%) was reached on the 40th–50th days. The T2 group had the most extended duration of the increasing trend in coverage, reaching the highest value (75.2%) within the 50th–60th days, which is higher than that of the control group. Regarding the crushed concrete substrates, maximum coverage occurred in T5 at 67%; the upward trend in coverage was lower compared to the control group and the crushed brick substrates. In terms of particle size of the substrate, community coverage was higher in medium-particle-sized substrates than in both small- and large-particle-size substrates of the same composition.

Figure 2.

The change in coverage of Sedum lineare in each group (mean ± SE; n = 5) with time in the simulated drought stress experiment. The asterisk indicates a significant difference among the seven groups (p < 0.05).

3.2.2. Biomass

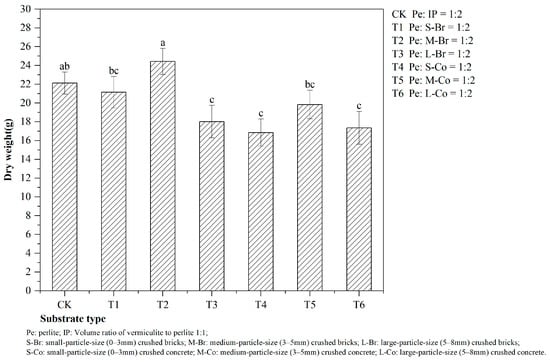

As illustrated in Figure 3, there were differences in biomass of Sedum lineare across different groups after 120 days of the simulated drought stress experiment. The total dry weight of Sedum lineare growing in the crushed brick substrate was larger than that in the crushed concrete substrates. The biomass of Sedum lineare in T2 exhibited the highest value, demonstrating an increase of 10.93% in comparison to the control group. In the crushed concrete substrate group, the biomass of Sedum lineare cultivated in T5 was slightly higher than that of T4 and T6. The differences between the T3, T4, and T6 treatments were not significant.

Figure 3.

Dry weight biomass of Sedum lineare in each group (mean ± SE; n = 5) after the simulated drought stress experiment. Analysis of variance showed a significant difference among the treatments (p < 0.05). LSD was used to separate the mean values. Different lowercase letters indicate significant differences among the treatments (p < 0.05).

3.2.3. Relative Water Content

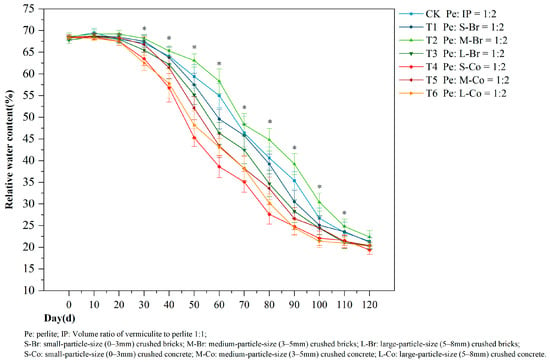

As depicted in Figure 4, the relative water content (RWC) of the leaves within each group remained relatively stable during the initial 20 days of the simulated drought stress experiment. After that, a trend of consistent decline was observed. The RWC of the leaves in T2 was higher than that of other groups and showed a relatively large downward trend after day 50th. The RWC in the T1 and T3 groups decreased after day 30th–40th, and was lower than that of the control group. The overall RWC in the crushed concrete substrates was lower than that in the crushed brick substrates and lowest in T4.

Figure 4.

The change in relative water content (RWC) of Sedum lineare in each group (mean ± SE; n = 3) with time in the simulated drought stress experiment. The asterisk indicates a significant difference among the seven groups (p < 0.05).

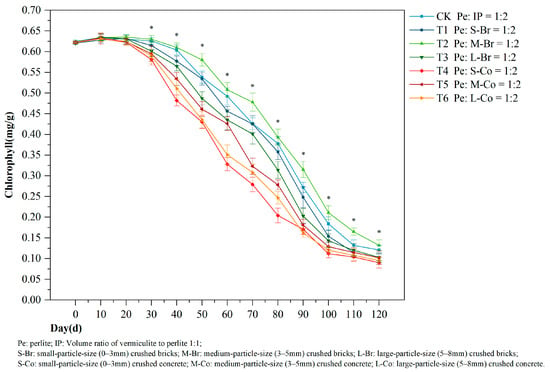

3.2.4. Chlorophyll Content

Under drought stress, the chlorophyll content of each group remained relatively stable, followed by a continuous decline. The chlorophyllin content of Sedum lineare in the crushed brick substrates was generally higher than that in the crushed concrete substrates. In addition, the chlorophyll content of Sedum lineare growing in T2 showed a significant decreased trend at the latest point, with the inflection point occurring on the 50th day. In the crushed concrete substrate, the chlorophyll levels in T4 and T6 treatments were lower than in the T5 treatment during the mid-term of the experiment (Figure 5).

Figure 5.

The change in chlorophyll content of Sedum lineare in each group (mean ± SE; n = 5) with time in the simulated drought stress experiment. The asterisk indicates a significant difference among the seven groups (p < 0.05).

3.3. Correlation Analysis between Growth Indexes of Sedum lineare and Properties of Substrates under Simulated Drought Stress

From Table 4, a significant positive correlation was determined between the total porosity of the substrates and the test indicators of plants, suggesting a direct impact of total porosity on plant growth. Conversely, there was an inverse correlation between the bulk weight and the growth index of the plant. This could be attributed to an increase in bulk density leading to a tighter composition of the substrate and less porosity, which are unfavorable for root respiration and growth. The change in pH level within the substrate demonstrated a negative correlation with the indexes of plant growth but not significant. The EC value had a significant positive correlation with the chlorophyll content of the leaves, suggesting that the soluble salt ions in the substrates had a certain effect on plant growth.

Table 4.

Correlation coefficient between properties of substrates and growth indexes of Sedum lineare in the simulated drought stress experiment.

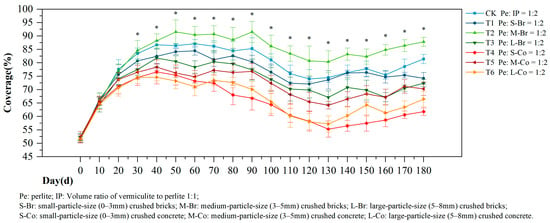

3.4. Effects of Construction Waste Substrates with Different Composition and Particle Sizes on Sedum lineare Growth in Outdoor Roof Environment

Under outdoor roof conditions, all the treatments demonstrated an adaptation to the roof environment. Initially, the vegetation coverage displayed an upward trend, which later stabilized or experienced minor variations in response to changes in temperature and rainfall. When comparing crushed brick and crushed concrete substrates, Sedum lineare exhibited a greater overall coverage in the former. Moreover, the coverage of Sedum lineare in medium-particle-size substrates (T2 and T5) reached the highest level, respectively, among different substrate types, with the T2 treatment reaching approximately 90% during the middle stage, surpassing the control group (Figure 6).

Figure 6.

The change in coverage of Sedum lineare in each group (mean ± SE; n = 6) with time in the roof environment. The asterisk indicates a significant difference among the seven groups (p < 0.05).

4. Discussion

4.1. The Adaptability of the Green Roof Plants to the Construction Waste Substrate

The substrate is the primary source of water and nutrients for green roof plant growth due to a lack of sustained supply and regulation from ground conditions. The exposure of the roof to more light and higher wind speeds compared to the ground leads to increased water evaporation from the substrate [13]. Consequently, selecting a suitable growing substrate is crucial for roof greening [59]. In the simulated drought environment, Sedum lineare exhibited the capacity to adapt to this type of substrate during the initial stage of the experiment, as substantiated by the attained levels of coverage, chlorophyll content, and relative water content in all groups [60,61]. As drought stress intensified, plants experienced a continuous loss of water content, leading to impaired cell membrane structure and function, blocked chlorophyll synthesis, and increased decomposition [62,63]. The stress resistance of Sedum lineare in the crushed brick substrates was better than that in the broken concrete substrates during the stage. Previous studies have shown that water stress is a common limitation of plant growth on green roofs [40,64]. Therefore, the stress resistance of Sedum lineare to construction waste substrates with varying compositions and particle sizes may depend on the characteristics of the substrate [65].

In addition, it has been observed that construction waste substrates could support plant growth under outdoor temperature and precipitation conditions, maintaining a coverage of at least 60% of Sedum lineare, which was similar to previous findings [42,43,60]. Some industry standards advocate for sustaining vegetation coverage on green roofs above 60% [66], and Sedum lineare communities can achieve this goal within a shorter duration, thereby resulting in cost reductions associated with maintenance.

4.2. The Relationship between the Characteristics of Construction Waste Substrate and the Growth of Green Roof Plants

The physical characteristics of roof greening substrates are crucial in assessing their performance [67]. Bulk density is a critical parameter to consider, as an excessively high density can potentially compromise the load-bearing capacity of the roof, while a density that is too low may not offer sufficient support for plant growth [3,52]. Overall, substrates using crushed bricks and crushed concrete have a bulk density range of 0.6–0.8 g/cm−3, allowing them to be used in green roofs without causing harm to the building structure. This density range is comparable to that of substrates utilizing heat-expanded slate and composted waste as their base materials [68].

The porosity enhancement promotes the substrates’ aeration efficiency, providing adequate transfer channels for gas- and liquid-phase substances within the medium [37,69]. Correlation analysis showed a significant positive relationship between the total porosity of substrates and the growth indicators of Sedum lineare, which suggests that substrates’ porosity is a critical factor influencing the growth of roof greening plants [31,70]. The abundant distribution of tiny pores also facilitates water retention and creates sufficient breathing space for root growth [55], benefiting overall plant development. As for the materials tested in this study, crushed bricks are formed through high-temperature clay sintering, resulting in a substantial amount of pore space internally and on the surface. Therefore, crushed bricks have a higher water retention capacity, typically 20% to 25% [71,72]. Due to the performance of crushed bricks in improving substrate porosity and water retention, Sedum lineare growing in crushed brick substrates exhibited a better growth state and drought resistance, as previously observed by Bates et al. and Mickovski et al. [41,42]. Consequently, applying crushed bricks in roof greening substrate materials offers more advantages, particularly in areas with prolonged periods of low rainfall, as it presents a convenient means of enhancing water-holding capacity.

The particle size significantly influences the pore distribution between particles and within particles, and is crucial in determining the water-holding capacity [73,74]. The growth of Sedum lineare in the medium-particle-size brick substrate was optimal and better than in the conventional substrate used as a control. The results indicate that the pore size and distribution between particles reach equilibrium, thereby improving the water retention and permeability of the substrate [37,75]. Appropriate particle size could provide superior moisture support and create better conditions for plant root growth by promoting effective air exchange [70,76]. Similar results have also been found in other studies; for example, Graceson et al. [37] demonstrated that a substrate composed of rough and fine crushed brick exhibited superior water retention capacity to one composed solely of rough crushed tiles. Young et al. [77] found that the water-holding capacity of the larger brick substrate decreased by 35% in comparision to the smaller brick substrate, resulting in a decline in plant growth. Excessive gaps between large-sized particles greatly reduce capillary action and hinder moisture retention, while small particles (e.g., the small-particle-size concrete substrate in this study) result in excessively small pore size and aeration decline, which may damage the root system of plants [68,78,79]. Therefore, manipulating the particle size of the substrate to an optimal level is the most cost-effective approach to enhancing water retention capacity. Comparative studies on substrate particle size can serve as valuable references for most substrate producers.

4.3. Potential of Construction Waste Substrate Applied to Extensive Green Roof

A considerable amount of construction waste is generated annually, offering a promising avenue for developing roof greening substrate materials. Several studies propose the increased utilization of locally sourced recycled construction waste in future green roof construction [44,60,76]. Crushed brick and other materials possess inherent stability, enabling them to withstand the erosive impact of strong winds on roofs effectively [41], thus providing a solid basis for plant growth. Crushed brick is recommended as a substrate for roof greening due to its higher water retention and lower bulk density than other recycled building materials [60,77]. In addition to improving the properties of the substrate itself, the ecological benefits of reducing the rainwater runoff of the roof can be well-exerted by bricks [45]. In addition, our study exclusively focused on inert building waste and did not evaluate potential chemical contamination, such as heavy metals. Therefore, in practical applications, the potential environmental impact of construction waste cannot be disregarded. Establishing robust quality control and monitoring systems is imperative to ensuring environmentally friendly sourcing, handling, and utilization practices [47].

5. Conclusions

This study focused on using environmentally friendly construction waste materials as green roof substrates. These materials’ stable physical and chemical properties enhance the overall performance of extensive roof green substrates. Crushed brick substrates were found to have lower bulk density and higher porosity than crushed concrete substrates, making them suitable for green roof substrates. According to the observation and measurement of the growth of Sedum lineare, the plant coverage value in the medium-particle-sized brick group was the highest, accompanied by optimal chlorophyll content and relative water retention. Consequently, this study concludes that medium-sized crushed brick particles (3–5 mm) exhibit the most significant potential for enhancing the functionality of green roof substrates and facilitating plant growth, while construction waste particles that are either too large or too small are deemed unsuitable for use in green roof substrates.

In this study, Sedum lineare only grew in experimental containers. Therefore, the exploration of plant growth in construction waste substrates can be extended to roof greening projects in practice. By refining the classification of construction waste particle size and selecting other plant species based on specific conditions, further examination can be conducted to determine the practical application efficacy of construction waste substrates and gradually promote the use of construction waste substrates.

Author Contributions

Conceptualization, N.J. and W.Z.; Methodology, W.Z., N.J. and Y.L.; investigation, Y.L., Z.L. and L.W.; Validation, N.J., Y.L., Z.L. and L.W.; Data analysis, N.J. and Z.L.; Writing—original draft preparation, N.J.; Writing—review and editing, N.J. and W.Z.; supervision, W.Z.; Funding acquisition, W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Shanghai Science and Technology Innovation Action Plan Project (Project Number 19DZ1204006) and the University Think Tank Connotation Construction Project of Shanghai (Project Number 2022ZKNH063).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data in this study are available within the the article. More detailed data is not publicly available for the privacy reasons.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Blank, L.; Vasl, A.; Levy, S.; Grant, G.; Kadas, G.; Dafni, A.; Blaustein, L. Directions in green roof research: A bibliometric study. Build. Environ. 2013, 66, 23–28. [Google Scholar] [CrossRef]

- Shafique, M.; Kim, R.; Rafiq, M. Green roof benefits, opportunities and challenges–A review. Renew. Sustain. Energy Rev. 2018, 90, 757–773. [Google Scholar] [CrossRef]

- Ampim, P.A.; Sloan, J.J.; Cabrera, R.I.; Harp, D.A.; Jaber, F.H. Green roof growing substrates: Types, ingredients, composition and properties. J. Environ. Hortic. 2010, 28, 244–252. [Google Scholar] [CrossRef]

- Bisceglie, F.; Gigante, E.; Bergonzoni, M. Utilization of waste Autoclaved Aerated Concrete as lighting material in the structure of a green roof. Constr. Build. Mater. 2014, 69, 351–361. [Google Scholar] [CrossRef]

- Nektarios, P.A.; Amountzias, I.; Kokkinou, I.; Ntoulas, N. Green roof substrate type and depth affect the growth of the native species Dianthus fruticosus under reduced irrigation regimens. HortScience 2011, 46, 1208–1216. [Google Scholar] [CrossRef]

- Manso, M.; Teotónio, I.; Silva, C.M.; Cruz, C.O. Green roof and green wall benefits and costs: A review of the quantitative evidence. Renew. Sustain. Energy Rev. 2021, 135, 110111. [Google Scholar] [CrossRef]

- Ntoulas, N.; Nektarios, P.A.; Kapsali, T.-E.; Kaltsidi, M.-P.; Han, L.; Yin, S. Determination of the physical, chemical, and hydraulic characteristics of locally available materials for formulating extensive green roof substrates. Horttechnology 2015, 25, 774–784. [Google Scholar] [CrossRef]

- Papafotiou, M.; Pergialioti, N.; Tassoula, L.; Massas, I.; Kargas, G. Growth of native aromatic xerophytes in an extensive Mediterranean green roof as affected by substrate type and depth and irrigation frequency. HortScience 2013, 48, 1327–1333. [Google Scholar] [CrossRef]

- Monteiro, C.M.; Calheiros, C.S.; Palha, P.; Castro, P.M. Growing substrates for aromatic plant species in green roofs and water runoff quality: Pilot experiments in a Mediterranean climate. Water Sci. Technol. 2017, 76, 1081–1089. [Google Scholar] [CrossRef]

- Fassman, E.; Simcock, R. Moisture measurements as performance criteria for extensive living roof substrates. J. Environ. Eng. 2012, 138, 841–851. [Google Scholar] [CrossRef]

- Emilsson, T.; Rolf, K. Comparison of establishment methods for extensive green roofs in southern Sweden. Urban For. Urban Green. 2005, 3, 103–111. [Google Scholar] [CrossRef]

- Rowe, D.B. Green roofs as a means of pollution abatement. Environ. Pollut. 2011, 159, 2100–2110. [Google Scholar] [CrossRef] [PubMed]

- Lata, J.C.; Dusza, Y.; Abbadie, L.; Barot, S.; Carmignac, D.; Gendreau, E.; Kraepiel, Y.; Mériguet, J.; Motard, E.; Raynaud, X. Role of substrate properties in the provision of multifunctional green roof ecosystem services. Appl. Soil Ecol. 2018, 123, 464–468. [Google Scholar] [CrossRef]

- Fan, L.; Wang, J.; Liu, X.; Luo, H.; Zhang, K.; Fu, X.; Li, M.; Li, X.; Jiang, B.; Chen, J. Whether the carbon emission from green roofs can be effectively mitigated by recycling waste building material as green roof substrate during five-year operation? Environ. Sci. Pollut. Res. 2020, 27, 40893–40906. [Google Scholar] [CrossRef] [PubMed]

- Xue, M.; Farrell, C. Use of organic wastes to create lightweight green roof substrates with increased plant-available water. Urban For. Urban Green. 2020, 48, 126569. [Google Scholar] [CrossRef]

- Vijayaraghavan, K. Green roofs: A critical review on the role of components, benefits, limitations and trends. Renew. Sustain. Energy Rev. 2016, 57, 740–752. [Google Scholar] [CrossRef]

- Oberndorfer, E.; Lundholm, J.; Bass, B.; Coffman, R.R.; Doshi, H.; Dunnett, N.; Gaffin, S.; Köhler, M.; Liu, K.K.; Rowe, B. Green roofs as urban ecosystems: Ecological structures, functions, and services. Bioscience 2007, 57, 823–833. [Google Scholar] [CrossRef]

- Ondoño, S.; Martínez-Sánchez, J.; Moreno, J. Evaluating the growth of several Mediterranean endemic species in artificial substrates: Are these species suitable for their future use in green roofs? Ecol. Eng. 2015, 81, 405–417. [Google Scholar] [CrossRef]

- Farrell, C.; Ang, X.Q.; Rayner, J.P. Water-retention additives increase plant available water in green roof substrates. Ecol. Eng. 2013, 52, 112–118. [Google Scholar] [CrossRef]

- Fassman-Beck, E.; Voyde, E.; Simcock, R.; Hong, Y.S. 4 Living roofs in 3 locations: Does configuration affect runoff mitigation? J. Hydrol. 2013, 490, 11–20. [Google Scholar] [CrossRef]

- Schindler, B.Y.; Blaustein, L.; Vasl, A.; Kadas, G.J.; Seifan, M. Cooling effect of Sedum sediforme and annual plants on green roofs in a Mediterranean climate. Urban For. Urban Green. 2019, 38, 392–396. [Google Scholar] [CrossRef]

- Peri, G.; Traverso, M.; Finkbeiner, M.; Rizzo, G. Embedding “substrate” in environmental assessment of green roofs life cycle: Evidences from an application to the whole chain in a Mediterranean site. J. Clean. Prod. 2012, 35, 274–287. [Google Scholar] [CrossRef]

- Kazemi, F.; Mohorko, R. Review on the roles and effects of growing media on plant performance in green roofs in world climates. Urban For. Urban Green. 2017, 23, 13–26. [Google Scholar] [CrossRef]

- Molineux, C.J.; Fentiman, C.H.; Gange, A.C. Characterising alternative recycled waste materials for use as green roof growing media in the UK. Ecol. Eng. 2009, 35, 1507–1513. [Google Scholar] [CrossRef]

- Tams, L.; Nehls, T.; Calheiros, C.S.C. Rethinking green roofs-natural and recycled materials improve their carbon footprint. Build. Environ. 2022, 219, 109122. [Google Scholar] [CrossRef]

- Bhairappanavar, S.; Liu, R.; Coffman, R. Beneficial uses of dredged material in green infrastructure and living architecture to improve resilience of lake erie. Infrastructures 2018, 3, 42. [Google Scholar] [CrossRef]

- Coelho, K.; Almeida, J.; Castro, F.; Ribeiro, A.; Teixeira, T.; Palha, P.; Simões, N. Experimental characterisation of different ecological substrates for use in green roof systems. Sustainability 2022, 15, 575. [Google Scholar] [CrossRef]

- Kuoppamäki, K.; Setälä, H.; Hagner, M. Nutrient dynamics and development of soil fauna in vegetated roofs with the focus on biochar amendment. Nat.-Based Solut. 2021, 1, 100001. [Google Scholar] [CrossRef]

- Pérez, G.; Vila, A.; Rincón, L.; Solé, C.; Cabeza, L.F. Use of rubber crumbs as drainage layer in green roofs as potential energy improvement material. Appl. Energy 2012, 97, 347–354. [Google Scholar] [CrossRef]

- Araújo de Almeida, M.; Colombo, R. Construction of green roofs via using the substrates made from humus and green coconut fiber or sugarcane bagasse. Sustain. Chem. Pharm. 2021, 22, 100477. [Google Scholar] [CrossRef]

- Liberalesso, T.; Tassi, R.; Ceconi, D.E.; Allasia, D.G.; Arboit, N.K.S. Effect of rice husk addition on the physicochemical and hydrological properties on green roof substrates under subtropical climate conditions. J. Clean. Prod. 2021, 315, 128133. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Ding, G.; Feng, Z. Developing a quantitative construction waste estimation model for building construction projects. Resour. Conserv. Recycl. 2016, 106, 9–20. [Google Scholar] [CrossRef]

- Chen, C.F.; Kang, S.F.; Lin, J.H. Effects of recycled glass and different substrate materials on the leachate quality and plant growth of green roofs. Ecol. Eng. 2018, 112, 10–20. [Google Scholar] [CrossRef]

- Eksi, M.; Sevgi, O.; Akburak, S.; Yurtseven, H.; Esin, I. Assessment of recycled or locally available materials as green roof substrates. Ecol. Eng. 2020, 156, 105966. [Google Scholar] [CrossRef]

- Dvorak, B.D.; Volder, A. Plant establishment on unirrigated green roof modules in a subtropical climate. AoB Plants 2013, 5, pls049. [Google Scholar] [CrossRef]

- Schröder, R.; Kiehl, K. Testing standard growth substrates for establishing native dry sandy grassland species on extensive green roofs in Northern Germany. Basic Appl. Ecol. 2021, 56, 181–191. [Google Scholar] [CrossRef]

- Graceson, A.; Hare, M.; Monaghan, J.; Hall, N. The water retention capabilities of growing media for green roofs. Ecol. Eng. 2013, 61, 328–334. [Google Scholar] [CrossRef]

- Nehls, T.; Rokia, S.; Mekiffer, B.; Schwartz, C.; Wessolek, G. Contribution of bricks to urban soil properties. J. Soils Sed. 2013, 13, 575–584. [Google Scholar] [CrossRef]

- Razzaghmanesh, M.; Beecham, S.; Kazemi, F. The growth and survival of plants in urban green roofs in a dry climate. Sci. Total Environ. 2014, 476, 288–297. [Google Scholar] [CrossRef]

- Nagase, A.; Dunnett, N. The relationship between percentage of organic matter in substrate and plant growth in extensive green roofs. Landsc. Urban Plann. 2011, 103, 230–236. [Google Scholar] [CrossRef]

- Mickovski, S.B.; Buss, K.; McKenzie, B.M.; Sökmener, B. Laboratory study on the potential use of recycled inert construction waste material in the substrate mix for extensive green roofs. Ecol. Eng. 2013, 61, 706–714. [Google Scholar] [CrossRef]

- Bates, A.J.; Sadler, J.P.; Greswell, R.B.; Mackay, R. Effects of recycled aggregate growth substrate on green roof vegetation development: A six year experiment. Landsc. Urban Plann. 2015, 135, 22–31. [Google Scholar] [CrossRef]

- Jauni, M.; Kuoppamäki, K.; Hagner, M.; Prass, M.; Suonio, T.; Fransson, A.M.; Lehvävirta, S. Alkaline habitat for vegetated roofs? Ecosystem dynamics in a vegetated roof with crushed concrete-based substrate. Ecol. Eng. 2020, 157, 105970. [Google Scholar] [CrossRef]

- Molineux, C.J.; Gange, A.C.; Connop, S.P.; Newport, D.J. Using recycled aggregates in green roof substrates for plant diversity. Ecol. Eng. 2015, 82, 596–604. [Google Scholar] [CrossRef]

- Vijayaraghavan, K.; Joshi, U. Application of seaweed as substrate additive in green roofs: Enhancement of water retention and sorption capacity. Landsc. Urban Plann. 2015, 143, 25–32. [Google Scholar] [CrossRef]

- Karczmarczyk, A.; Baryła, A.; Fronczyk, J.; Bus, A.; Mosiej, J. Phosphorus and metals leaching from green roof substrates and aggregates used in their composition. Minerals 2020, 10, 112. [Google Scholar] [CrossRef]

- López-Uceda, A.; Galvín, A.P.; Ayuso, J.; Jiménez, J.R.; Vanwalleghem, T.; Peña, A. Risk assessment by percolation leaching tests of extensive green roofs with fine fraction of mixed recycled aggregates from construction and demolition waste. Environ. Sci. Pollut. Res. 2018, 25, 36024–36034. [Google Scholar] [CrossRef] [PubMed]

- Brown, C.; Lundholm, J. Microclimate and substrate depth influence green roof plant community dynamics. Landsc. Urban Plann. 2015, 143, 134–142. [Google Scholar] [CrossRef]

- Eksi, M.; Rowe, D.B. Effect of substrate depth and type on plant growth for extensive green roofs in a Mediterranean climate. J. Green Build. 2019, 14, 29–44. [Google Scholar] [CrossRef]

- Monteiro, M.V.; Blanuša, T.; Verhoef, A.; Richardson, M.; Hadley, P.; Cameron, R. Functional green roofs: Importance of plant choice in maximising summertime environmental cooling and substrate insulation potential. Energy Build. 2017, 141, 56–68. [Google Scholar] [CrossRef]

- Schrieke, D.; Farrell, C. Trait-based green roof plant selection: Water use and drought response of nine common spontaneous plants. Urban For. Urban Green. 2021, 65, 127368. [Google Scholar] [CrossRef]

- Tala, S.; Al-Ajlouni, M.G.; Ayad, J.Y.; Othman, Y.A.; Hilaire, R.S. Performance of six different soilless green roof substrates for the Mediterranean region. Sci. Total Environ. 2020, 730, 139182. [Google Scholar]

- Verheijen, F.G.; Zhuravel, A.; Silva, F.C.; Amaro, A.; Ben-Hur, M.; Keizer, J.J. The influence of biochar particle size and concentration on bulk density and maximum water holding capacity of sandy vs sandy loam soil in a column experiment. Geoderma 2019, 347, 194–202. [Google Scholar] [CrossRef]

- Liao, W.; Thomas, S.C. Biochar particle size and post-pyrolysis mechanical processing affect soil pH, water retention capacity, and plant performance. Soil Syst. 2019, 3, 14. [Google Scholar] [CrossRef]

- Liao, W.; Drake, J.; Thomas, S.C. Biochar granulation enhances plant performance on a green roof substrate. Sci. Total Environ. 2022, 813, 152638. [Google Scholar] [CrossRef] [PubMed]

- Harmut, A. Chlorophylls and carotenoids: Pigments of photosynthetic membranes. Methods Enzymol. 1987, 148, 350–383. [Google Scholar]

- Liu, F.; Stützel, H. Leaf water relations of vegetable amaranth (Amaranthus spp.) in response to soil drying. Eur. J. Agron. 2002, 16, 137–150. [Google Scholar] [CrossRef]

- Cao, C.T.; Farrell, C.; Kristiansen, P.E.; Rayner, J.P. Biochar makes green roof substrates lighter and improves water supply to plants. Ecol. Eng. 2014, 71, 368–374. [Google Scholar] [CrossRef]

- Lamera, C.; Becciu, G.; Rulli, M.C.; Rosso, R. Green roofs effects on the urban water cycle components. Procedia Eng. 2014, 70, 988–997. [Google Scholar] [CrossRef]

- Graceson, A.; Monaghan, J.; Hall, N.; Hare, M. Plant growth responses to different growing media for green roofs. Ecol. Eng. 2014, 69, 196–200. [Google Scholar] [CrossRef]

- Nektarios, P.A.; Ntoulas, N.; Nydrioti, E.; Kokkinou, I.; Bali, E.-M.; Amountzias, I. Drought stress response of Sedum sediforme grown in extensive green roof systems with different substrate types and depths. Sci. Hortic. 2015, 181, 52–61. [Google Scholar] [CrossRef]

- Basu, S.; Ramegowda, V.; Kumar, A.; Pereira, A. Plant adaptation to drought stress. F1000Research 2016, 5, 1554. [Google Scholar] [CrossRef] [PubMed]

- Koźmińska, A.; Al Hassan, M.; Wiszniewska, A.; Hanus-Fajerska, E.; Boscaiu, M.; Vicente, O. Responses of succulents to drought: Comparative analysis of four Sedum (Crassulaceae) species. Sci. Hortic. 2019, 243, 235–242. [Google Scholar] [CrossRef]

- Monterusso, M.A.; Rowe, D.B.; Rugh, C.L. Establishment and persistence of Sedum spp. and native taxa for green roof applications. HortScience 2005, 40, 391–396. [Google Scholar] [CrossRef]

- Vijayaraghavan, K.; Badavane, A. Preparation of growth substrate to improve runoff quality from green roofs: Physico-chemical characterization, sorption and plant-support experiments. Urban Water J. 2017, 14, 804–810. [Google Scholar] [CrossRef]

- Cascone, S. Green roof design: State of the art on technology and materials. Sustainability 2019, 11, 3020. [Google Scholar] [CrossRef]

- Zhao, M.; Tabares-Velasco, P.C.; Srebric, J.; Komarneni, S.; Berghage, R. Effects of plant and substrate selection on thermal performance of green roofs during the summer. Build. Environ. 2014, 78, 199–211. [Google Scholar] [CrossRef]

- Olszewski, M.W.; Young, C.A. Physical and chemical properties of green roof media and their effect on plant establishment. J. Environ. Hortic. 2011, 29, 81–86. [Google Scholar] [CrossRef]

- Hill, J.; Drake, J.; Sleep, B. Comparisons of extensive green roof media in southern Ontario. Ecol. Eng. 2016, 94, 418–426. [Google Scholar] [CrossRef]

- Ondoño, S.; Martínez-Sánchez, J.; Moreno, J. The inorganic component of green roof substrates impacts the growth of Mediterranean plant species as well as the C and N sequestration potential. Ecol. Indic. 2016, 61, 739–752. [Google Scholar] [CrossRef]

- Bauer, M.; Krause, M.; Heizinger, V.; Kollmann, J. Increased brick ratio in urban substrates has a marginal effect on tree saplings. Trees 2023, 37, 875–889. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. Feasible use of recycled concrete aggregates and crushed clay brick as unbound road sub-base. Constr. Build. Mater. 2006, 20, 578–585. [Google Scholar] [CrossRef]

- Abad, M.; Fornes, F.; Carrión, C.; Noguera, V.; Noguera, P.; Maquieira, Á.; Puchades, R. Physical properties of various coconut coir dusts compared to peat. HortScience 2005, 40, 2138–2144. [Google Scholar] [CrossRef]

- Werdin, J.; Conn, R.; Fletcher, T.D.; Rayner, J.P.; Williams, N.S.; Farrell, C. Biochar particle size and amendment rate are more important for water retention and weight of green roof substrates than differences in feedstock type. Ecol. Eng. 2021, 171, 106391. [Google Scholar] [CrossRef]

- Pettersson, K.; Maggiolo, D.; Sasic, S.; Johansson, P.; Sasic-Kalagasidis, A. On the impact of porous media microstructure on rainfall infiltration of thin homogeneous green roof growth substrates. J. Hydrol. 2020, 582, 124286. [Google Scholar] [CrossRef]

- Eksi, M.; Rowe, D.B. Green roof substrates: Effect of recycled crushed porcelain and foamed glass on plant growth and water retention. Urban For. Urban Green. 2016, 20, 81–88. [Google Scholar] [CrossRef]

- Young, T.; Cameron, D.D.; Sorrill, J.; Edwards, T.; Phoenix, G.K. Importance of different components of green roof substrate on plant growth and physiological performance. Urban For. Urban Green. 2014, 13, 507–516. [Google Scholar] [CrossRef]

- Emilsson, T. Vegetation development on extensive vegetated green roofs: Influence of substrate composition, establishment method and species mix. Ecol. Eng. 2008, 33, 265–277. [Google Scholar] [CrossRef]

- Olszewski, M.W.; Holmes, M.H.; Young, C.A. Assessment of physical properties and stonecrop growth in green roof substrates amended with compost and hydrogel. HortTechnology 2010, 20, 438–444. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).