Abstract

Since the pandemic first appeared in early 2020, the manufacturing industry across the globe has experienced a decline. Concerns regarding public health were present at the start of the new decade, and as the pandemic reached its peak in March 2020, manufacturers all over the world were forced to contend with high demand, reduced workforce requirements, subsequent lockdowns, and major disruptions to their supply chains to prevent the global spread of the pandemic. No research has been done on the interaction of these variables because the idea of VSCM is still relatively new, particularly in Malaysia’s manufacturing industry. The purpose of this study is to present management researchers with a novel idea for coping with a pandemic situation in today’s business environment. Furthermore, the purpose of this research is to determine VSCM practices that contribute to company sustainability so that such future incidents can be controlled and revamped. The report also advocated a VSCM framework to improve supply chain resilience and sustainability. This study’s objective is to analyze the relationship between viable supply chain management (VSCM) practices and company sustainability for manufacturing companies in Malaysia during the COVID-19 pandemic. 197 respondents from Malaysian manufacturing companies were surveyed using a quantitative approach. Using PLS-SEM analysis, all surveys are examined. As a result, the direct relationship between VSCM and company sustainability has demonstrated a significant positive effect. The implication of this study is to strengthen the viability and reliability of viable supply chain management and contribute further to the COVID-19 outbreak’s impact on company sustainability. Moreover, a successful supply chain model would guarantee that manufacturers are compelled to respond swiftly to safeguard and support their employees and maintain operations that are critical lifelines for consumers and communities.

1. Introduction

COVID-19 impacts a new normal way of life, including social activities, health, education, economic activities in the business sector, medicine, transportation, and telecommunications. The manufacturing industry is also vulnerable to the impacts of COVID-19 [1]. Since the manufacturing sector is a contributor to Malaysia’s economic development, the negative effects of COVID-19 have impacted the nation’s economic growth, for example, supply chain disruptions, demand uncertainty, country border restrictions, and others [2]. The impact of economic disruptions caused by lockdowns such as Movement Control Order (MCO) during this period weighed heavily on Malaysian manufacturers’ businesses during the first half of 2020. The COVID-19 pandemic and subsequent lockdowns have resulted in major disruptions to business activities, the global supply chain, and world trade. Lockdown reduces the spread of the virus. However, simultaneously, the country’s economy was also affected by the move. Malaysia’s former Prime Minister, Tan Sri Muhyiddin Yassin, stated that the government has suffered a total loss of MYR64.6 billion in the first 14 days of MCO since 18 March 2020 [3]. If the MCO is continued, the potential losses will be higher, and more people will lose their jobs. The situation faced by the government right now is likened between the devil and the deep sea. Thus, it can be avoided by implementing a good strategy in company management, especially in supply chain management. One of the strategies is to determine which viable supply chain management factors will impact the company’s sustainability. As a result, the business can be sustained and survive during this pandemic.

The Purchasing Managers’ Index (PMI) is a useful tool for determining the direction of economic trends in manufacturing and for providing information about present and future business conditions to firm executives, analysts, and investors. The PMI is a numeric number between 0 and 100. A PMI value greater than 50 indicates that the economy has grown in comparison to the previous month, while a value less than 50 indicates that the economy has contracted. The more one deviates from 50, the bigger the magnitude of change [4]. The PMI is intended to give an advanced signal of what is really happening in the economy. The PMI is based on responses from manufacturers about new orders from customers, production rate, employment rate, supplier deliveries, inventories, and import and export activities. Malaysia’s PMI continues to decline, falling to 48.4 points in March 2020 from 48.5 points in February 2020. The greatest slump was in April 2020, which was 31.3 from 48.4 in March 2020. The sector is contracting as a result of the negative economic impact of the COVID-19 outbreak. The PMI for the majority of countries involved in the MCO of COVID-19 is below 50. The fall in PMI can be attributed to a lack of new demand (new orders) from importing countries, a shortage of supply, and a slowdown in export and import activity [5]. In Malaysia, the movement control order implementation at the end of March 2020 contributed to a negative impact on demand, buying levels shrank the most on record and employment declined modestly [6]. Problems related to the supply chain have occurred again due to the emergence of new variants of COVID-19. In January 2021, Malaysian manufacturers reported more drops as the Omicron variant hit manufacturers all over the world, hurting demand and making supply chain delays worse than ever before. Malaysia’s PMI eased to 50.5 in January from 52.8 recorded in December 2021 [7].

There is a lack of research on the relationship between VSCM practices and business sustainability in developing countries [8,9]. The studies on COVID-19’s impact on supply chain management and sustainability are also very limited [10], especially in the manufacturing industry in Malaysia during the COVID-19 pandemic [11]. In the published studies on the COVID-19 pandemic, however, little is known about the effectiveness of any particular supply chain reconfiguration and the severity of the negative impact of the COVID-19 pandemic on supply chain operations [12]. Moreover, most of COVID-19 is focused on the medical science perspective, while the sustainable supply chain perspective is absent [13]. The literature on viability and adaptation, on the other hand, is still fragmented, and little has been done to standardize current methods and adaptation strategies [14]. Therefore, this study will help ascertain the practices of VSCM that contribute to the long-term viability of the business during the COVID-19 pandemic in Malaysia. Moreover, this study is expected to increase the number of studies regarding the impact of COVID-19 on supply chain management and company sustainability, since most of the COVID-19 studies right now are more focused on a medical science perspective.

According to [14], the pandemic situation is unique in several ways. To begin, a pandemic is defined as a long-term disturbance whose dynamics must be anticipated. It entails not just preparing the supply chain for a pandemic but also rethinking supply chain operations for an extended period. Second, pandemic features include simultaneous interruptions at many supply chain echelons, as well as concurrent and sequential supplier, facility, and market openings and closures. Finally, in the event of an interruption, recovery procedures must be developed and implemented. As a result, supply chain management requires a more effective strategy to ensure that all aspects of its management can resist all threats and hence survive for an incredibly long time. Therefore, this study will look into the viability of supply chain management.

For now, the topic related to a viable supply chain is still new but has attracted the interest of researchers and academics to explore it in more depth. According to a study by [15], he has assessed the impact of the COVID-19 pandemic on environmental sustainability and social sustainability in Brazil and Portugal. To measure these sustainability indicators, three dependent variables are used: environmental awareness, sustainable consumption, and social responsibility. However, this study focuses exclusively on the impact of COVID-19 with little emphasis on strategies or methods for improving supply chain management’s resilience toward company sustainability. A study by [16] discusses only a few ways for strengthening supply chain viability through the combination of agility, resilience, and a sustainability viewpoint. However, this model has not been validated in practice, and the resulting consequences have not been seen and must be validated in real-time. This study has not yet been validated empirically, and this paradigm has not yet demonstrated its efficacy. Additionally, these five recommended variables have not been demonstrated to be associated with corporate sustainability. Although the author mentions the importance of paying special attention to these five variables to promote agility, viability, and resilience, their relevance to the company’s sustainability is not explored in detail or explicitly. Ref. [17] has also identified 13 sustainable supply chain drivers based on the findings of 30 experts in the process of selecting sustainable supply chains. The limitations of this study include the acquisition of only 13 sustainable supply chain drivers, and this validation may be biased. This research also recommended that this theoretical framework be examined in further detail, employing statistical approaches like structural equation modeling and focusing on the sustainability of companies. [18] has identified the main parameters that contribute to the survivability of SSCs. However, the factors affecting the supply chain are evaluated by a decision panel comprised of experts who may be biased. Additionally, only 18 experts are picked, which is insufficient to generalize the results to the entire population. This study advises using sensitivity analysis to determine the results’ robustness. Customers were excluded from this investigation under this scope. Thus, the expert group’s legitimacy might be questioned, as the customer is the primary party in the supply chain system. As a result of the current COVID-19 epidemic, practically all supply chains have been severely damaged, highlighting the need for stronger supply chain resilience techniques. There is still a need for more investigation into the effectiveness of prior studies’ COVID-19-related methods as well as the best mix of tactics to combat the pandemic’s negative impacts [19]. Other studies have identified a variety of risk-reduction methods that may be used in the supply chain. However, the measures are more narrowly focused on a single party, namely the supplier or manufacturer, than on the entire supply chain. Moreover, single disruptions were more common than multiple disruptions in these studies, such as supply or demand, production, or transportation [20]. Even though these steps are being taken, they are still considered insufficient because a complete supply chain involves three dominant parties: suppliers, manufacturers, and customers.

This study contributes to empirical research on the value of VSCM in Malaysia’s manufacturing industries. The primary contribution of this study is to provide management researchers with a ground-breaking idea for dealing with a pandemic situation in the current business environment. Furthermore, the goal of this research is to identify VSCM practices that contribute to company sustainability to control and revamp such future events. Also, the study recommended a VSCM framework that would enhance supply chain resilience and sustainability. This study also aims to persuade organizations and managers to invest time and resources in developing and implementing effective VSCM practices such as top management support, integration, digital technologies, information sharing, and customer focus. Effective VSCM implementation will contribute to the company’s sustainability, including social, economic, and environmental performance during the COVID-19 pandemic. Similarly, this study will assist businesses in enhancing the resilience and viability of their supply chains to ensure long-term survival during a pandemic.

2. Literature Review

This section will discuss more details about viable supply chain management (independent variable) and company sustainability (dependent variable).

2.1. Viable Supply Chain Management (VSCM) Practices

The pandemic of COVID-19 has altered how people work and how supply chains operate. As a result, businesses must prioritize developing long-term resilience in their value chains to address future challenges [21]. The COVID-19 pandemic has exposed the inadequacy of many supply chains, as complex networks collapsed as a consequence of disturbances at local nodes, their spread, and the resultant loss of connection [14]. Supply chain viability stresses the supply chain’s capacity to adapt to changing environmental conditions over time through the development of several strategies focused not only on the incidence of disruption, but also on the aftermath of such disruption [14,22]. As happened in March 2020 during the Movement Control Order (MCO) implementation, the COVID-19 pandemic has revealed the lack of viability in many supply chains. It is unsurprising that the country’s economy in general, and the manufacturing sector in particular, have performed poorly, as no one anticipated the severity of the impact of an unprecedented occurrence such as COVID-19. The question is whether the same consequence must be faced each time this calamity occurs, regardless of supply chain management changes.

Supply chain viability is defined as the ability to withstand and succeed in a changing environment through the implementation of restructuring and strategic rethinking of economic performance with long-term consequences [23,24]. If companies are to survive and continue to offer important goods and services to society during long-term crises, they must build and run supply chains that are not just efficient and robust but also viable [22]. A supply chain is considered viable if it is capable of satisfying three feedback cycles associated with ecosystem balance: the positive feedback cycle (innovation, profitability, efficiency, investments, agility, and responsiveness), the volatile feedback (sustainability and recovery from disruptions); and the survivability cycle (economic and social security) [16,24]. The visible supply chain incorporates perspectives on sustainability, resilience, and survivability [16]. Resilience and viability are inextricably linked because they both refer to the supply chain’s level of survivability. Increasing the viability of supply chains is critical to maintaining and strengthening regional economic competitiveness during and after the COVID-19 epidemic. The ability to quickly alter the shares of trade with their consumers and suppliers across borders has been shown to improve company performance in the past, including during the first year of the COVID-19 epidemic, as previously indicated. This demonstrates that companies that demonstrated greater supply chain viability and flexibility in the face of the COVID-19 problem were able to maintain a higher level of business sustainability [25]. The process to obtain the five factors of VSCM begins with the synthesis of data from previous studies in the field of supply chain management as well. It is just that the concept of VSCM is still new because traditional SCM practices only add elements of viability, resilience, and agility to ensure that the company’s resilience can be increased in facing the challenges of the COVID-19 pandemic. For example, top management support before the outbreak of the COVID-19 pandemic is different from top management support during the outbreak of the COVID-19 pandemic. In fact, SCM practices are the same as VSCM; only VSCM adds the elements of viability, resilience, and agility so that the company can survive and continue to operate without any problems related to the supply chain in the long term. The author has identified five critical success factors for SCM based on previous studies and a review and synthesis of SCM literature: (1) Top Management Support; (2) Integration/Partnership; (3) Digital Technologies; (4) Information Sharing; and (5) Customer Focus.

2.1.1. Top Management Support

Top management commitment is crucial to fostering a supportive atmosphere, employee ownership and responsibility, continual quality improvement, and an organized and successful change management process [26]. During the COVID-19 pandemic, the demands and resource trends are not stable and fluctuating due to global market uncertainty. With many manufacturers having to rethink the number of employees physically present in their plant at any one time, organizations are finding creative ways to stay productive and meet social distancing requirements, as well as to leverage on adjusting to less manual-intensive work-flows [27]. Additionally, top-level management support is required for the implementation of strategies to minimize supply chain risk exposure and increase the agility of the supply chain, such as ensuring effective communication with employees, implementing flexible and remote work options, sharing information about company-wide standard operating procedures (SOPs), establishing rules and regulations, organizing a safe working environment, and providing motivating work environments [28,29].

2.1.2. Integration/Partnership

To reduce the disruptions of a changing environment such as COVID-19, the role of the supplier is very important to manage capacity and demand, avoid the bullwhip effect, and manage inventory reservations. Besides that, [20] finds that integration with key supply chain members, such as suppliers, can aid in rapid recovery and increase the viability of the supply chain. Aside from that, the goal of the collaboration is to develop a shared understanding to make relationships meaningful [30]. The level of trust must be higher so that the collaborative relationship will be better and supply chain performance can be higher [31]. Supply chain integration can provide firms with access to specific resources that can help them increase their resilience and ultimately achieve higher performance. In other words, rather than focusing exclusively on performance enhancement, firms must leverage their integration to foster resilience to succeed in today’s changing business climate. This will eventually provide them with a competitive advantage by allowing them to maintain high-performance levels amid periods of market instability [32].

2.1.3. Digital Technologies

The COVID-19 epidemic serves as a sharp reminder to local firms that they must expedite their digital transformation [33]. The rise of Industry 4.0 has been utilized in a supply chain viability study to emphasize the benefits of digital technology in demand forecasting, production flexibility, and supply chain visibility [10,23,34]. Digital technologies play a critical role in helping businesses become more resilient and agile, in assisting businesses in surviving, shortening the recovery phase, and assisting businesses in returning to normal operations as quickly as possible [33]. Common digital technology qualities demonstrate a manufacturer’s ability to use real-time information, new technology, and agility to respond quickly and effectively to disturbances without sacrificing productivity or quality, while maintaining efficiency and profitability [18].

2.1.4. Information Sharing

In the current changing environment, information sharing is critical to ensuring continuity in the supply chain. It will not only reduce the risk due to COVID-19, but in the long run, companies will continue to survive [35]. The exchange of information during the negotiating process is critical to the management of manufacturer-supplier relationships. Additionally, internal communication fosters improved communication between suppliers, manufacturers, and customers [36]. According to [37], velocities, visibility, and flexibility in the supply chain can be increased by sharing information among all key members of the organization. Moreover, risks in the supply chain can be reduced [30]. Practicing this will improve supply chain collaboration and response to disruptions.

2.1.5. Customer Focus

Due to the pandemic, supply and demand instability has become a significant issue for supply chain viability management [38]. This is because large-scale manufacturing companies, particularly those considered to be critical service providers, have been forced to reduce production capacity, while all others have been forced to temporarily shut down. As a result of these factors, businesses that have not been able to fully integrate technology into all aspects of their manufacturing and supply chain operations will see a decrease in their ability to provide consistent goods and services, which will lead to lower levels of customer satisfaction, revenue, and profit [39]. Firms can take steps to strengthen their supply chain’s viability by fulfilling unanticipated customer demands. They can gain competitive advantages in this way by developing plans to respond quickly to and recover from supply chain interruptions [40]. To maintain a pleasant customer experience during times of crisis, rapid research is required to discover shifting dynamics and new pain points, as well as agile innovation to solve them [41].

2.2. Company Sustainability

According to [42], corporate sustainability is described as the process of maximizing long-term shareholder value via the identification and management of opportunities and hazards related to social, environmental, and economic aspects. It is an effective tool for enhancing the corporate image by assessing the capabilities and effectiveness of business management, focusing on long-term benefits, and increasing transparency. To ensure long-term viability and sustainability, management should strike a balance between social, economic, and environmental performance. Businesses with a strong commitment to corporate sustainability view social and environmental issues as business opportunities. They will not regard these issues as burdensome but will work to resolve them with genuine commitment [43]. According to [44], an ideal supply chain design should take into account not just sustainability considerations such as environmentalism and social concerns, but also proactive and reactive resilience techniques in the event of disruptions. Due to the fact that business operations are sustainable as long as their core activities are resistant to disruptive occurrences, it is critical to consider the organization’s condition. To put it another way, if a system is not resilient enough, it will be extremely prone to interruption [15]. In this study, the company’s sustainability will be measured by its economic, social, and environmental performance.

2.3. Theoretical Research Framework

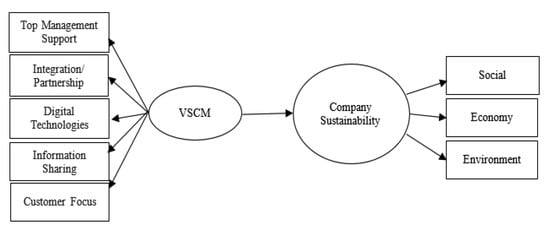

This research led to the development of a theoretical framework, which is depicted in Figure 1 below. The framework is supported by the premise that a high level of VSCM practices will result in greater company sustainability. Therefore, VSCM practices are conceptualized using five components, while firm sustainability is conceptualized using three constructs. Then, a hypothesis is formulated to assess the connection between VSCM and company sustainability.

Figure 1.

VSCM Theoretical Framework.

The hypothesis of this study is that VSCM practices have a positive and direct effect on company sustainability. According to a study done by [25], to maintain and increase regional industrial competitiveness in the wake of the COVID-19 epidemic, supply chain viability is essential. Even during the first year of the COVID-19 epidemic, companies that were able to quickly modify the shares of trade with their customers and suppliers across borders had better business results, as previously indicated. This shows that the businesses that demonstrated viability and flexibility in the face of the COVID-19 situation had a better chance of surviving. According to [17], supply chain practices aimed at minimizing supply chain disruptions are evaluated solely in terms of their economic performance. For the COVID-19 outbreak, [45] proposed VSCM strategies for containment that were exclusively focused on economic and social performance. However, the studies conducted by [46,47] only looked at the economy and environmental performance. Health and safety have traditionally been seen as critical components of running a business, but lately, due to advances in technology, this has started to change. COVID-19 has completely altered this perception [22].

2.4. Underpinning Theory

Theoretical application is important to identify related variables to enhance company sustainability. In this study, the author has identified a theory, namely the Resource-Based View (RBV) theory, that has been combined in a conceptual framework that shows the relationship among the variables. According to the resource-based view (RBV) theory, a business must possess valuable, unique, and non-substitutable resources to achieve competitive advantages [48,49]. RBV emphasizes the importance of internal and external resources such as knowledge, assets, capabilities, firm operations, firm attributes, and information in determining an organization’s performance [48]. The competitiveness of any company is based on the resources it masters to develop competitive advantages or core competencies [50]. This research investigates VSCM skills (an organization’s capacity to recognize, utilize, and integrate information and resources to enable corporate sustainability) and how these capabilities are implemented by businesses. A successful supply chain management strategy encompasses multiple critical success factors, which are essential for increasing a company’s competitiveness as well as contributing to its long-term sustainability. Such cooperative behaviors of companies provide effective top management, successful partnerships, rapid access to required information, advanced use of information technology, accurate forecasting with strategic planning, and faster response times to customer demand. These factors will be the competitive advantages of the companies. Moreover, the practices of visible supply chain management are difficult to imitate by competitors as they are based on experience and knowledge [51]. The VSCM practices used in this study are top management support, integration/partnership, digital technologies, information sharing, and customer focus, as shown in the theoretical framework. These practices are improved with the elements of agility, resilience, and viability, which will be the competitive advantage of the company. Furthermore, if these five practices are successfully improved in the aspects of resilience, agility, and viability, it will certainly have a positive effect on company sustainability.

3. Research Methodology

A quantitative approach is utilized in this study. The sample was chosen from among the manufacturing companies in Malaysia that are members of the Federation of Malaysian Manufacturers (FMM). The sampling approach that will be used in this study is stratified random sampling. This study requires a total of 200 samples from the population of Malaysian manufacturing companies. The questionnaire is constructed based on a comprehensive review of previous VSCM literature, as shown in Table 1. The questionnaire is divided into three parts: demographics, VSCM practices, and company sustainability. The questionnaire will employ a five-point Likert scale (1 = Strongly Disagree, 2 = Disagree, 3 = Natural, 4 = Agree, 5 = Strongly Agree) to measure responses. Only 197 of the initial 488 surveys were returned with complete responses.

Table 1.

Number of Items in the Research Instruments.

4. Results

4.1. Analysis of Response Rate

To achieve an adequate response rate, around 488 questionnaires were distributed to the selected manufacturing companies in Malaysia. Of the 488 questionnaires distributed, only 239 were returned, yielding a 49% response rate. In consideration of [65]’s argument that a response rate of 30% is sufficient for surveys, a response rate of 49% is found acceptable. In addition, a response rate of 49% is appropriate for supply chain management research, as indicated by previous studies that indicated response rates of 20% or higher are acceptable [47,66,67,68]. However, after the data screening procedure, around 42 questionnaires had to be discarded due to missing data, suspicious response patterns, and outlier cases, resulting in only 197 usable questionnaires.

Data were analyzed in this study using Partial Least Squares Structural Equation Modeling (PLS-SEM). A measurement model is used to measure validity and reliability values. To measure the reliability of the constructs, construct reliability (CR), Cronbach’s alpha, and average variance extracted (AVE) were used. For measuring construct validity, convergent validity and discriminant validity were used. The structural measurement model assessment is the next step after the measurement model evaluation that was just completed.

4.2. Findings of Measurement Model

In this study, PLS-SEM analysis was used to obtain the results of the measurement model. In this research, because the research model contains multidimensional latent variables, the variables were modeled as second-order constructs. The hierarchical component model (HCM) is another name for the measurement model with second-order constructs [69]. HCM is a higher-order structure that consists of many construction layers and a greater level of abstraction [70]. This study assessed the reliability and validity of higher-order components (HOC) in a PLS-SEM path model using the “embedded two-stage approach” technique [70].

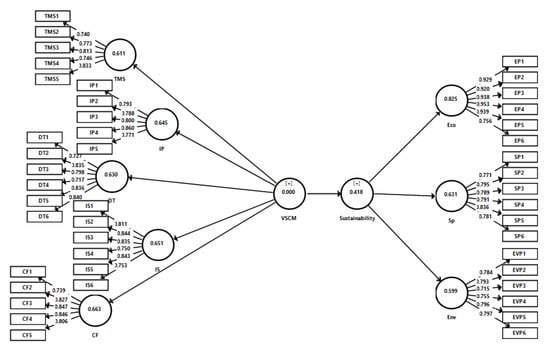

Figure 2 illustrates the first stage of measurement model assessment, whereby there are 10 latent variables with two higher order constructs (HOC): 1. viable supply chain management (VSCM); 2. company sustainability; and eight lower order constructs (LOC): 1. top management support (TMS); 2. integration/partnership (IP); 3. digital technologies (DT); 4. information sharing (IS); 5. customer focus (CF); 6. economy performance (Eco); 7. social performance (Sp); and 8. environment performance (Env). LOCs represent the dimensions of HOCs.

Figure 2.

The First Stage of Measurement Model Assessment.

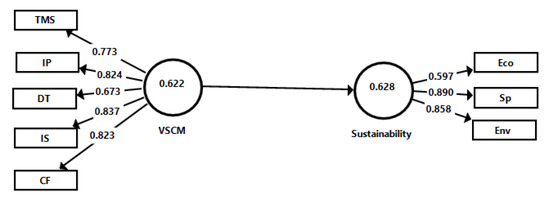

In the second stage, LOC latent variable scores serve as the indicator for determining HOC. Here, the reliability and validity of HOC are evaluated as shown in Figure 3. The value inside constructs is AVE, and the value on arrows is factor loading. Figure 3 shows the second stage of measurement model evaluation, wherein only two latent variables exist: 1. VSCM and 2. sustainability. Using the latent variable scores of each respective dimension, the dimensions of 1. VSCM (TMS, IP, DT, IS, and CF) and 2. sustainability (sp, eco, and env) were turned into indicators (items) at this stage. In PLS-SEM, construct reliability and validity tests include internal consistency reliability, convergent validity, and discriminant validity.

Figure 3.

The Second Stage of Measurement Model Assessment.

4.3. Internal Consistency Reliability

In this study, composite reliability is employed to examine internal consistency. Acceptable composite reliability ratings should be greater than or equal to 0.60 or between 0.70 and 0.90. For the examination of composite reliability, a cut-off value of 0.70 or higher was utilized to indicate good convergent or internal consistency [71]. The Cronbach’s alpha must be greater than 0.7 to measure the reliability of the constructs [72]. The values of composite reliability and Cronbach’s alpha for each construct in this study are presented in Table 2.

Table 2.

Internal Consistency Reliability Result.

The PLS-SEM analysis of the measurement model revealed that the composite reliability (CR) values obtained for each construct ranged from 0.887 to 0.966, with economic performance contributing the greatest CR value (0.966) and top management support scoring the lowest (0.887). Moreover, Cronbach’s alpha values obtained for each construct ranged from 0.840 to 1.0. Therefore, all constructs in this measurement model achieved indicator reliability because the values obtained are greater than 0.7.

4.4. Convergent Validity Assessment

The study also used convergent validity to find out how well a single item measures similar concepts. Convergent validity analysis can be checked with the outer loading assessment, the composite reliability (CR), and the average variance extracted (AVE) tests. The outer loading values must be greater than 0.708 [73]. AVE must have a value larger than 0.5, and CR must be greater than 0.7. Table 3 summarized the result of outer loadings, CR, and AVE for lower-order constructs (LOC) and higher-order constructs (HOC). For outer loadings for lower order constructs (LOC), all items exceeded 0.708 except items TMS6, IP6, and CF6 which have been deleted due to lower values. For higher order constructs (HOC), all items exceeded 0.708 except items DT and Eco. However, according to [73], when a minimum AVE result of 0.5 is reached, indicators with loadings lower than 0.708 may be retained. Consequently, no item is deleted. The composite reliability (CR) for LOC and HOC is greater than 0.7 which means all the items showed good reliability. For AVE, all the values obtained for each construct ranged from 0.599 to 0.825 which means all the values exceed the minimum value of AVE.

Table 3.

Convergent Validity Result.

4.5. Discriminant Validity

An analysis of discriminant validity is used to prove that a set of indicators are different across different constructs. It looks at the correlations between the measurements to see if there are any overlaps and checks that the things being studied are really different from each other [70,73]. Fornell and Larcker’s criteria and the Heterotrait Monotrait Ratio (HTMT) were used in this study to test the discriminant validity.

The Fornell and Larcker criteria is an analysis that compares the square root of the AVE value to the correlations between latent variables. The value should be larger than any other construct’s value. The evaluation is predicated on the notion that a construct has a greater variation with its own indicators than with those of any other construct. Table 4 shows that Fornell and Larcker’s criterion with the correlation value for each construct was higher than other constructs, indicating adequate discriminant validity.

Table 4.

Fornell and Larcker’s Criteria Result.

Cross-loading and Fornell-criteria Larcker’s have been criticized for not being able to find out if a trait is discriminant, so this Heterotrait Monotrait Ratio (HTMT) was made [73]. The projected value should be less than 1 since a score closer to 1 means there is not enough discriminant validity. The HTMT value must fall below 0.9 [74]. Table 5 shows that the value of HTMT was all below the threshold value of 0.9, indicating that the discriminant validity had been met.

Table 5.

HTMT Result.

4.6. Hypothesis Testing

For structural model analysis, 5000 bootstrap samples were selected for a one-tailed test with a significance level of 0.01 to investigate the path coefficient [69]. This bootstrapping procedure was applied to examine the relationship between an independent variable (VSCM) and a dependent variable (company sustainability). The critical values for one-tailed t-tests are 1.645 at a 5 percent significance level [73]. If the t-value of the hypothesis is larger than 1.64 at a significance level of 5%, the hypothesis is accepted. The significance level was set at p < 0.05 [73]. The initial part of the test for statistical significance was based on the analysis that was carried out to examine the direct relationships. There is a direct relationship in this structural model, which is the relationship between VSCM and company sustainability. The full significance test findings for this structural model are presented in Table 6.

Table 6.

Result of Significance Testing.

Based on the results above, the relationship between VSCM and company sustainability is supported. The t-values are greater than 1.645, thus the relationship is significant. Moreover, the p-value is significant because the value is lower than 0.05. Based on the research objectives, the hypothesis is accepted.

5. Discussion

The findings of this study have demonstrated that viable supply chain management has a positive impact on the sustainability of companies. The direct relationship between VSCM and company sustainability has demonstrated a significant positive effect. The critical values for one-tailed t-tests are 1.645 at the 5 percent significance level [73]. If the t-value of the hypothesis is larger than 1.64 at a significance level of 5%, the hypothesis is accepted. The t-value is 22.447, which is greater than 1.645, and the p-value is 0.000, which is lower than 0.05. Thus, the hypothesis is supported and can be interpreted as saying that companies with VSCM practices will have better company sustainability during the COVID-19 pandemic.

A supply chain that can continue operating normally after a disturbance like the COVID-19 pandemic is an indicator of a viable supply chain. Based on the findings of this study, the results obtained are significant and are in line with previous studies. According to [16], viability is the capacity to endure environmental change. It adds additional characteristics to the behavior and performance of the supply chain. The supply chain’s resilience to interruptions demonstrates its ability to prevent market collapse and continue supplying products and services. It assists the supply chain in maintaining itself and surviving a calamity of this nature [14]. This study is in line with the findings of the study by [75], who also stated that the supply chain in the pandemic era indeed needs elements of agility, resilience, and viability to ensure that company sustainability can be achieved. According to research findings from [76] implementing viable and resilient supply chain strategies can help avoid long-term repercussions while coping with pandemic threats. This will help the business remain sustainable and last for a very long time. [25] claims that supply chain viability is crucial for preserving and boosting regional industrial competitiveness in the wake of the COVID-19 epidemic. Companies that were able to quickly change the shares of trade with their suppliers and customers across borders had greater business outcomes even during the first year of the COVID-19 outbreak. This demonstrates that companies with a higher probability of survival were those that showed their viability and flexibility in the face of the COVID-19 crisis.

Because this viable supply chain is a subset of the new supply chain field, there are not many empirical studies on it. According to earlier studies, less attention is placed on the three sustainability-related factors. Most studies only focus on one or two of the three sustainability factors [46,47]. Moreover, according to [77], issues with supply chain management will worsen during the pandemic due to factors such as forced production halts, erratic demand, inventory issues, increased logistics costs, postponed industrial operations, and issues with imports and exports. The sustainability of companies will be affected by all of these issues. In this research, five viable supply chain management practices influence the company’s sustainability during the COVID-19 pandemic, which are top management support, integration/partnership, digital technologies, information sharing, and customer focus. This study also shows that the five factors of VSCM have a positive impact on company sustainability.

The responsibility of top management in ensuring the company’s continued viability is critical. COVID-19 has compelled several companies to leave their comfort zones. Top management of the companies had to run the company despite limits in manpower, resources, and safety standards, such as the implementation of SOP [78]. Ref. [24] stated that the top management needs to put more effort into operational planning, such as manpower planning and production planning, by incorporating principles of agility and viability. This is due to how drastically different supply chain management was during the COVID-19 pandemic outbreak compared to supply chain management prior to the occurrence of this disruption. [22] agreed that due to the fluctuating global economic climate and the unpredictability of client demand, they must make critical decisions more quickly based on actual information. To build resilience against potential threats, they also need to maximize the use of technology, such as virtual meetings, robotics, information technology, and so on [55]. According to [79], if the top management does not really implement any significant improvements in supply chain management, there is a very high likelihood that the business will fail. This is due to the company’s inability to attain sustainability. For example, the business encountered significant financial difficulties, a failure to control unpredictable customer demand, a shortage of raw resources, and workforce issues.

According to [80], supply chain integration will enable operations to be flexible, allowing the participating supply chain partners to quickly and easily adapt to changing conditions with minimal cost. This integration is important to share accurate and detailed information with all supply chain partners [9]. Ref. [81] in their research, they stated that collaboration in the supply chain can reduce the bullwhip effect, since it increases visibility, which impacts inventory levels and company performance. To plan a more flexible and profitable supply chain management, effective integration must be done directly with suppliers, customers, and other stakeholders while considering the current constraints that impose pressure on manufacturers. Moreover, due to the fact that stakeholder groups either directly or indirectly impact the sustainability of a company, it is considered corporate suicide for a company to neglect sustainability [82]. It is supported by the research findings of [18], who identified integration as a significant tool to enhance the sustainability of the companies and the survivability of the supply chain. [32] concluded that supply chain integration can give businesses access to particular resources that will help them become more resilient and ultimately perform better. To put it another way, companies must use their integration to promote resilience rather than solely concentrating on performance development if they want to succeed in the dynamic business environment of today. Eventually, this will give companies a competitive edge by enabling businesses to keep up their performance standards even during times of market uncertainty.

Ref. [19] claimed that digital technology, in the pandemic era, has a very significant role to play in the execution of recovery strategies and plans. For instance, data analytics and blockchain can be utilized to gain real-time data analysis to enhance supply chain operations. As a result, these data enable top management to put the developed recovery strategy into action. Recent empirical research conducted by [83] lends support to the idea that boosting recovery capabilities in the recovery window can be accomplished with the use of digital technologies such as Industry 4.0, blockchain, the Internet of Things (IoT), and digital manufacturing. Digital technologies play a critical role in helping businesses become more resilient and agile, in assisting businesses in surviving, shortening the recovery phase, and assisting businesses in returning to normal operations as quickly as possible [33]. According to [84], firms that use new digital technology quickly, as well as their employees’ flexibility and ingenuity, might come out of the crisis with safer, more productive, and more viable manufacturing processes, thus improving the company’s sustainability.

The integration of the supply chain is made possible through the sharing of information, which is crucial to the continued existence of businesses. These days, information sharing is more feasible than ever thanks to developments in information and communication technology [85]. According to [37], velocity, visibility, and flexibility in the supply chain can be increased by sharing information among all key members of the organization. Due to the possibility of suppliers and customers being located all over the world, especially during pandemics where travel restrictions are in place, it is absolutely necessary to integrate all activities in organizations [86]. Realizing how important information sharing is, [14] has listed this factor as one of the important factors in a viable supply chain management practice.

Almost all companies have had supply chain problems due to unexpectedly high or low demand. To face and conquer these obstacles, demand planning is essential. Companies are scrambling to figure out how to predict consumer demand in the wake of the epidemic, and they are searching for a more sophisticated approach to sales forecasting. According to a study by [87], customer focus is an important element in supply chain management because it determines the level of sustainability of a company. Customer focus refers to efforts that are made to align and integrate a company’s supply chain with its most important customers. These efforts include things like integrating market information and developing common ordering processes via an existing shared network or information system [55].

This study previously identified the Resource-Based View theory as the fundamental underpinning theory to reinforce a better understanding of viable supply chain management practices. According to the Resource-Based View (RBV) theory, a business must possess valuable, unique, and non-substitutable resources to achieve competitive advantages. RBV emphasizes the importance of internal and external resources such as knowledge, assets, capabilities, firm operations, firm attributes, and information in determining an organization’s performance. This study employs the following VSCM practices as internal and external resources: top management support, integration/partnership, digital technology, information sharing, customer focus, and CPFR. These practices, enhanced with the elements of agility, resilience, and viability, will become the company’s competitive advantage, especially during the COVID-19 pandemic. The coordination of these factors has the potential to significantly improve the performance and sustainability of the company. The underpinning theory in this study also provides a new contribution, especially when the results of this study can be seen in the context of the COVID-19 pandemic.

6. Conclusions

This research focuses on two key constructs: viable supply chain management and company sustainability. The measurement of VSCM is based on five dimensions: top management support, integration/partnership, digital technologies, information sharing, and customer focus. In the meantime, the sustainability of a company is assessed across three dimensions: economic performance, social performance, and environmental performance. To meet the challenge of COVID-19, supply chain management must undergo severe adjustments. COVID-19 has introduced a new dimension in which this supply chain must be enhanced by incorporating aspects of viability and durability into all supply chain management practices. There is always the risk that raw material supplies could abruptly decrease or that product demand will spike dramatically. Due to these disruptions, planning has become increasingly challenging. Supply chains need to be viable and robust so that they can withstand unexpected changes and adapt quickly to new circumstances. This study will continue by examining structural modeling in order to investigate the relationship between VSCM and company sustainability. The findings of this structural modeling investigation will assist the Malaysian manufacturing industry in fending off challenges such as COVID-19 and others.

Managers can decide on new solutions and conduct frequent evaluations of supply chain management’s resilience. These evaluations enable more effective and well-planned solutions for risk management. Additionally, they must be more sensitive to the most recent scenario and capable of making quicker and more precise decisions. In addition, they must develop a more complete strategy for dealing with issues such as lack of raw materials, production disruptions, limited workforce issues, lack of demand, etc. The majority of companies that incur losses do so due to a failure to structure their strategies and a reluctance to make decisions. In addition, they do not develop an alternative plan of action in case the initial strategy fails. So, this study has shown that there are a number of important supply chain management factors that need more attention if the company is to be more sustainable.

These five practices also include the SCM system’s three most crucial parties: suppliers, manufacturers, and customers. This study also answers the question of which supply chain management factors should be prioritized to increase the survivability and sustainability of companies during pandemics such as COVID-19. Moreover, this study is needed to determine the extent to which and how the strategies provided in previous studies aided supply chains in addressing COVID-19-related issues such as the bullwhip effect, increased demand, labor shortages, supply constraints, rapid technology transition, and global logistic constraints, as well as the optimal combination of strategies to address the pandemic’s effects. By using quantitative techniques to analyze the data, this study has also been empirically conducted. This empirical research on supply chain resilience and viability is done to better understand how businesses confronted with COVID-19 threats develop survival mechanisms to mitigate the pandemic’s threat. By incorporating viable supply chain management practices, this study will aid in mitigating the impact of COVID-19 disruptions on supply chain viability and resilience.

The reviewed literature has confirmed that past studies over the period have seen the important relationship that exists between these factors: viable supply chain management practices (top management support, integration/partnership, digital technologies, information sharing, and customer focus), collaborative planning (flexibility and responsiveness), and company sustainability (social, economic, and environmental) in the manufacturing industry during the COVID-19 pandemic. Previous studies have also demonstrated that the majority of studies conducted assessed these elements independently or individually in their research. To the best of the researcher’s knowledge, no research has been done on the interaction of these variables because the idea of VSCM is still relatively new, particularly in Malaysia’s manufacturing industry. To close this identified gap in the current literature, the researcher understudied by integrating all of the aforementioned factors to examine how they can work in one model. Hence, this piece of work adds to existing knowledge by positively validating the effect of VSCM practices on company sustainability in the manufacturing industry in Malaysia. The contribution has emphasized VSCM practices as a very important factor that could significantly influence company sustainability in the manufacturing industry.

The Resource-Based View Theory was chosen as the fundamental theory for this study to strengthen our grasp of the model for viable supply chain management practices. The resource-based view (RBV) idea states that for a company to have a competitive advantage, its resources must be valuable, unique, and non-replaceable. RBV emphasizes the significance of both internal and external resources in determining an organization’s success, including knowledge, assets, capabilities, firm operations, firm attributes, and information. As both internal and external resources, this study makes use of the VSCM practices of top management support, integration/partnership, digital technology, information sharing, and customer focus. In particular, during the COVID-19 pandemic, these practices, strengthened with the components of agility, resilience, and viability, will become the company’s competitive advantage. The performance and the company’s sustainability could be greatly enhanced via the coordination of these elements. The use of RBV theory in this study also provides a new contribution, especially when the results of this study can be seen in the context of the COVID-19 pandemic. The contribution refers to the theoretical grounding of the study within the RBV theory to better appreciate the viable supply chain management methods within the industry as well as the related behaviors of the variables participating in the study.

The limitation of this study is that the scale proposed in this study was only investigated in the context of supply chain management in the manufacturing industries, since the current scenario calls for unprecedented approaches to address the supply chain management issues caused by COVID-19. If this study is conducted in other industries, such as service, construction, or retail, the results will undoubtedly differ. Since the idea of effective supply chain management is fairly new in relation to the COVID-19 epidemic, more research is needed in this area so that more strategies can be used to deal with long-term interruptions.

Author Contributions

Conceptualization, M.K.Z. and N.Z.; Data curation, M.K.Z.; Formal analysis, M.K.Z., M.E.Y. and M.Z.M.S.; Funding acquisition, N.Z., M.E.Y., M.Z.M.S., M.N.A.A.K., F.M.M. and T.Z.Y.; Investigation, M.K.Z.; Methodology, M.K.Z., N.Z. and T.Z.Y.; Project administration, M.K.Z.; Resources, M.K.Z., M.N.A.A.K. and F.M.M.; Software, M.K.Z., T.Z.Y. and M.N.A.A.K.; Supervision, N.Z.; Validation, M.K.Z. and N.Z.; Visualization, M.K.Z., M.E.Y., M.Z.M.S. and F.M.M.; Writing—original draft, M.K.Z.; Writing—review & editing, M.K.Z. and N.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Malaysian Ministry of Education (MOE), Universiti Malaysia Perlis, Faculty of Management, Universiti Teknologi Malaysia (UTM), and Research Management Centre (RMC) through grants funding numbers 20H76 and 31J18.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The author would like to express his gratitude to his supervisor, Norhayati Zakuan for her guidance and Research Management Centre (RMC), UTM for financial support through VOT: Q.J130000.2555.20H76 and VOT: Q.J130000.3829.31J18. He also wishes to thank his study sponsor, the Ministry of Higher Education Malaysia and Universiti Malaysia Perlis.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chatterjee, S.; Chaudhuri, R. Supply chain sustainability during turbulent environment: Examining the role of firm capabilities and government regulation. Oper. Manag. Res. 2021, 15, 1081–1095. [Google Scholar] [CrossRef]

- Nguyen, V.K.L.; Le, T.M.H.; Tran, T.M.C.; Duong, T.N.M.; Nguyen, T.S.; Vo, N.H. Exploring The Impact of Pandemic on Global Economy: Perspective from Literature Review. Pertanika J. Soc. Sci. Humanit. 2021, 29, 2033–2087. [Google Scholar] [CrossRef]

- Hasimi, M. Negara rugi RM2.4 bilion sehari sepanjang PKP-Perdana Menteri. Berita Harian, 30 April 2020. [Google Scholar]

- Investopedia, Purchasing Managers’ Index (PMI). 2020. Available online: https://www.investopedia.com/terms/p/pmi.asp (accessed on 1 April 2021).

- Mohamad, A.R. Kajian Kes Impak PKP Terhadap Sektor Pembuatan. 2020. Available online: https://www.dosm.gov.my/v1/uploads/files/6_Newsletter/Newsletter%202020/DOSM_BPPIB_1-2020_Siri-19.pdf (accessed on 1 April 2021).

- Trading Economics, Malaysia Manufacturing PMI. 2020. Available online: https://tradingeconomics.com/malaysia/manufacturing-pmi (accessed on 1 April 2021).

- Bernama. Omicron: Indeks pembelian pengilang Malaysia merosot pada Januari. Berita Harian, 2 February 2022.

- Sánchez-Flores, R.B.; Cruz-Sotelo, S.E.; Ojeda-Benitez, S.; Ramírez-Barreto, M.E. Sustainable supply chain management-A literature review on emerging economies. Sustainability 2020, 12, 6972. [Google Scholar] [CrossRef]

- Subramanian, L.; Alexiou, C.; Steele, P.; Tolani, F. Developing a sustainability index for public health supply chains. Sustain. Futur. 2020, 2, 100019. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Ivanov, D.; Dolgui, A.; Wamba, S.F. Impacts of epidemic outbreaks on supply chains: Mapping a research agenda amid the COVID-19 pandemic through a structured literature review. Ann. Oper. Res. 2020, 319, 1159–1196. [Google Scholar] [CrossRef]

- Sundram, V.P.K.; Chhetri, P.; Bahrin, A.S. The Consequences of Information Technology, Information Sharing and Supply Chain Integration, towards Supply Chain Performance and Firm Performance. J. Int. Logist. Trade 2020, 18, 15–31. [Google Scholar] [CrossRef]

- Min, H. Assessing the impact of a COVID-19 pandemic on supply chain transformation: An exploratory analysis. Benchmarking: Int. J. 2022. [Google Scholar] [CrossRef]

- Kumar, A.; Luthra, S.; Mangla, S.K.; Kazançoğlu, Y. COVID-19 impact on sustainable production and operations management. Sustain. Oper. Comput. 2020, 1, 1–7. [Google Scholar] [CrossRef]

- Ivanov, D. Supply Chain Viability and the COVID-19 pandemic: A conceptual and formal generalisation of four major adaptation strategies. Int. J. Prod. Res. 2021, 59, 3535–3552. [Google Scholar] [CrossRef]

- Severo, E.A.; De Guimarães, J.C.F.; Dellarmelin, M.L. Impact of the COVID-19 pandemic on environmental awareness, sustainable consumption and social responsibility: Evidence from generations in Brazil and Portugal. J. Clean. Prod. 2020, 286, 124947. [Google Scholar] [CrossRef]

- Ivanov, D. Viable supply chain model: Integrating agility, resilience and sustainability perspectives—Lessons from and thinking beyond the COVID-19 pandemic. Ann. Oper. Res. 2020, 319, 1411–1431. [Google Scholar] [CrossRef]

- Karmaker, C.L.; Ahmed, T.; Ahmed, S.; Ali, S.M.; Moktadir, M.A.; Kabir, G. Improving supply chain sustainability in the context of COVID-19 pandemic in an emerging economy: Exploring drivers using an integrated model. Sustain. Prod. Consum. 2021, 26, 411–427. [Google Scholar] [CrossRef]

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A. Developing a framework for enhancing survivability of sustainable supply chains during and post-COVID-19 pandemic. Int. J. Logist. Res. Appl. 2020, 25, 433–453. [Google Scholar] [CrossRef]

- Chowdhury, P.; Paul, S.K.; Kaisar, S.; Moktadir, M.A. COVID-19 pandemic related supply chain studies: A systematic review. Transp. Res. Part E Logist. Transp. Rev. 2021, 148, 102271. [Google Scholar] [CrossRef]

- Paul, S.K.; Chowdhury, P. Strategies for Managing the Impacts of Disruptions During COVID-19: An Example of Toilet Paper. Glob. J. Flex. Syst. Manag. 2020, 21, 283–293. [Google Scholar] [CrossRef]

- Accenture. Supply Chain Disruption. 2020. Available online: https://www.accenture.com/my-en/insights/consulting/coronavirus-supply-chain-disruption (accessed on 10 July 2021).

- Ruel, S.; El Baz, J.; Ivanov, D.; Das, A. Supply chain viability: Conceptualization, measurement, and nomological validation. Ann. Oper. Res. 2021. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D.; Rozhkov, M. Does the ripple effect influence the bullwhip effect? An integrated analysis of structural and operational dynamics in the supply chain. Int. J. Prod. Res. 2020, 58, 1285–1301. [Google Scholar] [CrossRef]

- Oikawa, K.; Todo, Y.; Ambashi, M.; Kimura, F.; Urata, S. The Impact of COVID-19 on Business Activities and Supply Chains in the ASEAN Member States and India. ERIA Discuss. Pap. Ser. 2021, 384, 40–59. [Google Scholar]

- Mohammad Mosadeghrad, A. Essentials of total quality management: A meta analysis. J. Health Care Qual. Assur. 2014, 27, 544–558. [Google Scholar] [CrossRef]

- Robinson, J. What is the Future for Industry 4.0 in the Post COVID-19 Paradigm? 2020. Available online: https://www.themanufacturer.com/articles/what-is-the-future-for-industry-4-0-in-the-post-covid-19-paradigm/ (accessed on 10 July 2021).

- Boichenko, O.; Tymchenko, N. How to reduce the pandemic impact on employees: A guide for company leaders. 2020. Available online: https://www2.deloitte.com/ua/en/pages/human-capital/articles/impact-of-covid-19.html (accessed on 10 April 2021).

- Leksono, F.D.; Siagian, H.; Oei, S.J. The Effects of Top Management Commitment on Operational Performance Through the Use of Information Technology and Supply Chain Management Practices. SHS Web Conf. 2020, 76, 01009. [Google Scholar] [CrossRef]

- de Sousa Jabbour, B.L.; Jabbour, C.J.C.; Hingley, M.; Vilalta-Perdomo, E.L.; Ramsden, G.; Twigg, D. Sustainability of supply chains in the wake of the coronavirus (COVID-19/SARS-CoV-2) pandemic: Lessons and trends. Mod. Supply Chain Res. Appl. 2020, 2, 117–122. [Google Scholar] [CrossRef]

- Eftekhar, M.; Li, H.; Van Wassenhove, L.N.; Webster, S. The Role of Media Exposure on Coordination in the Humanitarian Setting. Prod. Oper. Manag. 2017, 26, 802–816. [Google Scholar] [CrossRef]

- Barakat, M.; Ali, A.; Abdelbary, I.; Haroun, M. The impact of supply chain integration on operational performance through resilience under COVID-19 pandemic. In Proceedings of the International Conference on Advanced Materials and Systems—ICAMS, Alkharj, Saudi Arabia, 2–4 November 2020. [Google Scholar]

- Javaid, M.; Haleem, A.; Vaishya, R.; Bahl, S.; Suman, R.; Vaish, A. Industry 4.0 technologies and their applications in fighting COVID-19 pandemic. Diabetes Metab. Syndr. Clin. Res. Rev. 2020, 14, 419–422. [Google Scholar] [CrossRef] [PubMed]

- Wamba, S.F.; Dubey, R.; Gunasekaran, A.; Akter, S. The performance effects of big data analytics and supply chain ambidexterity: The moderating effect of environmental dynamism. Int. J. Prod. Econ. 2020, 222, 107498. [Google Scholar] [CrossRef]

- Nasir, S.B.; Ahmed, T.; Karmaker, C.L.; Ali, S.M.; Paul, S.K.; Majumdar, A. Supply chain viability in the context of COVID-19 pandemic in small and medium-sized enterprises: Implications for sustainable development goals. J. Enterp. Inf. Manag. 2021, 35, 100–124. [Google Scholar] [CrossRef]

- Pulles, N.J.; Hartman, P. Likeability and its effect on outcomes of interpersonal interaction. Ind. Mark. Manag. 2017, 66, 56–63. [Google Scholar] [CrossRef]

- Scholten, K.; Schilder, S. The role of collaboration in supply chain resilience. Supply Chain Manag. Int. J. 2015, 20, 471–484. [Google Scholar] [CrossRef]

- Linton, T.; Vakil, B. Coronavirus Is Proving We Need More Resilient Supply Chains. Glob. J. Flex. Syst. Manag. 2020, 21, 113–133. [Google Scholar]

- Nkengasong, J.N.; Mankoula, W. Looming threat of COVID-19 infection in Africa: Act collectively, and fast. Lancet 2020, 395, 841–842. [Google Scholar] [CrossRef]

- Wicaksono, T.; Illés, C.B. From resilience to satisfaction: Defining supply chain solutions for agri-food SMEs through quality approach. PLoS ONE 2022, 7, e0263393. [Google Scholar] [CrossRef]

- Madsen, S.M.; Petermans, A. Exploring the system of digitised retail design—Flattening the ontology. J. Retail. Consum. Serv. 2020, 54, 102053. [Google Scholar] [CrossRef]

- Mays, S. Corporate Sustainability—An Investor Perspective The Mays Report. 2003. Available online: https://onesearch.library.uwa.edu.au/discovery/fulldisplay/alma9997089702101/61UWA_INST:UWA (accessed on 15 March 2021).

- Robinson, D.; Boulle, M. Overcoming organizational impediments to strong sustainability management. Bus. Rev. Cambridge. 2012. Available online: https://www.researchgate.net/profile/David-Robinson-51/publication/348420470_Overcoming_Organizational_Impediments_to_Strong_Sustainability_Management/links/5ffe5020a6fdccdcb84d7590/Overcoming-Organizational-Impediments-to-Strong-Sustainability-Management.pdf (accessed on 10 February 2021).

- Hosseini, S.; Ivanov, D.; Dolgui, A. Review of quantitative methods for supply chain resilience analysis. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 285–307. [Google Scholar] [CrossRef]

- Taqi, H.M.M.; Ahmed, H.N.; Paul, S.; Garshasbi, M.; Ali, S.M.; Kabir, G.; Paul, S.K. Strategies to Manage the Impacts of the COVID-19 Pandemic in the Supply Chain: Implications for Improving Economic and Social Sustainability. Sustainability 2020, 12, 9483. [Google Scholar] [CrossRef]

- Habib, A.; Bao, Y.; Nabi, N.; Dulal, M.; Asha, A.; Islam, M. Impact of Strategic Orientations on the Implementation of Green Supply Chain Management Practices and Sustainable Firm Performance. Sustainability 2021, 13, 340. [Google Scholar] [CrossRef]

- Çankaya, S.Y.; Sezen, B. Effects of green supply chain management practices on sustainability performance. J. Manuf. Technol. Manag. 2019, 30, 98–121. [Google Scholar] [CrossRef]

- Borchert, O. Resource-Based Theory: Creating and Sustaining Competitive Advantage. J. Mark. Manag. 2008. [Google Scholar] [CrossRef]

- Hart, S.L. A natural-resource-based view of the firm. In Corporate Environmental Responsibility; Academy of Management: Briarcliff Manor, NY, USA, 2017. [Google Scholar]

- Akhtar, P.; Frynas, J.G.; Mellahi, K.; Ullah, S. Big Data-Savvy Teams’ Skills, Big Data-Driven Actions and Business Performance. Br. J. Manag. 2019, 30, 252–271. [Google Scholar] [CrossRef]

- Choi, D.; Hwang, T. The impact of green supply chain management practices on firm performance: The role of collaborative capability. Oper. Manag. Res. 2015, 8, 69–83. [Google Scholar] [CrossRef]

- Ifinedo, P. Impacts of business vision, top management support, and external expertise on ERP success. Bus. Process. Manag. J. 2008, 14, 551–568. [Google Scholar] [CrossRef]

- Baah, C.; Acquah, I.S.K.; Ofori, D. Exploring the influence of supply chain collaboration on supply chain visibility, stakeholder trust, environmental and financial performances: A partial least square approach. Benchmarking 2022, 29, 172–193. [Google Scholar] [CrossRef]

- Shukor, A.A.A.; Newaz, S.; Rahman, M.K.; Taha, A.Z. Supply chain integration and its impact on supply chain agility and organizational flexibility in manufacturing firms. Int. J. Emerg. Mark. 2020, 16, 1721–1744. [Google Scholar] [CrossRef]

- Ajmal, M.M.; Khan, M.; Shad, M.K.; AlKatheeri, H.; Jabeen, F. Socio-economic and technological new normal in supply chain management: Lessons from COVID-19 pandemic. Int. J. Logist. Manag. 2021, 33, 1474–1499. [Google Scholar] [CrossRef]

- Khin, S.; Ho, T.C.F. Digital technology, digital capability and organizational performance: A mediating role of digital innovation. Int. J. Innov. Sci. 2019, 11, 177–195. [Google Scholar] [CrossRef]

- Omar, R. Information sharing, information quality and usage of information technology (IT) tools in Malaysian organizations. African J. Bus. Manag. 2010, 4, 2486–2499. [Google Scholar]

- Baah, C.; Opoku Agyeman, D.; Acquah, I.S.; Agyabeng-Mensah, Y.; Afum, E.; Issau, K.; Ofori, D.; Faibil, D. Effect of information sharing in supply chains: Understanding the roles of supply chain visibility, agility, collaboration on supply chain performance. Benchmarking 2021, 29, 434–455. [Google Scholar] [CrossRef]

- Li, S.; Rao, S.S.; Ragu-Nathan, T.; Ragu-Nathan, B. Development and validation of a measurement instrument for studying supply chain management practices. J. Oper. Manag. 2005, 23, 618–641. [Google Scholar] [CrossRef]

- Al-Shboul, M.A.R.; Barber, K.D.; Garza-Reyes, J.A.; Kumar, V.; Abdi, M.R. The effect of supply chain management practices on supply chain and manufacturing firms’ performance. J. Manuf. Technol. Manag. 2017, 28, 577–609. [Google Scholar] [CrossRef]

- Sin, L.Y.; Tse, A.C.; Yim, F.H. CRM: Conceptualization and scale development. Eur. J. Mark. 2005, 39, 1264–1290. [Google Scholar] [CrossRef]

- Eltayeb, T.K.; Zailani, S.; Ramayah, T. Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: Investigating the outcomes. Resour. Conserv. Recycl. 2011, 55, 495–506. [Google Scholar] [CrossRef]

- Paulraj, A. Understanding the relationships between internal resources and capabilities, sustainable supply management and organizational sustainability. J. Supply Chain Manag. 2011, 47, 19–37. [Google Scholar] [CrossRef]

- Suprawan, L. Does CSR Branding Matter to the Young Consumers in Thailand: The Mediation Effect of Product Brand Attitudes. ASEAN J. Manag. Innov. 2015, 2, 73–85. [Google Scholar]

- Sekaran, U.; Bougie, R. Research Methods for Business: A Skill-Building Approach/Uma Sekaran and Roger Bougie; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Darnall, N.; Henriques, I.; Sadorsky, P. Adopting Proactive Environmental Strategy: The Influence of Stakeholders and Firm Size. J. Manag. Stud. 2009, 47, 1072–1094. [Google Scholar] [CrossRef]

- Pagell, M.; Yang, C.-L.; Krumwiede, D.W.; Sheu, C. Does the Competitive Environment Influence the Efficacy of Investments in Environmental Management? J. Supply Chain Manag. 2004, 40, 30–39. [Google Scholar] [CrossRef]

- Prahinski, C.; Benton, W. Supplier evaluations: Communication strategies to improve supplier performance. J. Oper. Manag. 2004, 22, 39–62. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis. Polymers 2020, 12, 834. [Google Scholar]

- Sarstedt, M.; Hair, J.F., Jr.; Cheah, J.-H.; Becker, J.-M.; Ringle, C.M. How to Specify, Estimate, and Validate Higher-Order Constructs in PLS-SEM. Australas. Mark. J. 2019, 27, 197–211. [Google Scholar] [CrossRef]

- Gefen, D.; Straub, D.; Boudreau, M.-C. Structural equation modeling and regression: Guidelines for research practice. Commun. Assoc. Inf. Syst. 2000, 4, 1–70. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 6th ed.; Analysis: Boston, MA, USA, 2006. [Google Scholar]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Gold, A.H.; Malhotra, A.; Segars, A.H. Knowledge Management: An Organizational Capabilities Perspective. J. Manag. Inf. Syst. 2001, 18, 185–214. [Google Scholar] [CrossRef]

- Sarkis, J. Supply chain sustainability: Learning from the COVID-19 pandemic. Int. J. Oper. Prod. Manag. 2020, 41, 63–73. [Google Scholar] [CrossRef]

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A. Accelerating retail supply chain performance against pandemic disruption: Adopting resilient strategies to mitigate the long-term effects. J. Enterp. Inf. Manag. 2021, 34, 1844–1873. [Google Scholar] [CrossRef]

- Bak, O.; Shaw, S.; Colicchia, C.; Kumar, V. A Systematic Literature Review of Supply Chain Resilience in Small–Medium Enterprises (SMEs): A Call for Further Research. IEEE Trans. Eng. Manag. 2020, 70, 328–341. [Google Scholar] [CrossRef]

- Deliotte. Addressing the Impact of COVID-19 Navigating Your Organization through Uncharted Territory. 2020. Available online: https://www2.deloitte.com/content/dam/Deloitte/global/Documents/About-Deloitte/RECOVER-TAL-STRAT-Reimagine-talent-strategy-op-modelPDF1.pdf (accessed on 25 June 2020).

- Mollenkopf, D.A.; Ozanne, L.K.; Stolze, H.J. A transformative supply chain response to COVID-19. J. Serv. Manag. 2020, 32, 190–202. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, X.; Tang, O.; Price, L.; Zhang, S.; Zhu, W. Supply chain collaboration for sustainability: A literature review and future research agenda. Int. J. Prod. Econ. 2017, 194, 73–87. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Helo, P. Supplier relationship management for circular economy: Influence of external pressures and top management commitment. Manag. Decis. 2019, 57, 767–790. [Google Scholar] [CrossRef]

- Agyabeng-Mensah, Y.; Afum, E.; Acquah, I.S.K.; Dacosta, E.; Baah, C.; Ahenkorah, E. The role of green logistics management practices, supply chain traceability and logistics ecocentricity in sustainability performance. Int. J. Logist. Manag. 2020, 32, 538–566. [Google Scholar] [CrossRef]

- Das, A.; Gottlieb, S.; Ivanov, D. Managing Disruptions and the Ripple Effect in Digital Supply Chains: Empirical Case Studies. In International Series in Operations Research and Management Science; Springer: Berlin/Heidelberg, Germany, 2019; Volume 276. [Google Scholar]

- Furtado, V.; Kolaja, T.; Mueller, C.; Salguero, J. Managing a Manufacturing Plant through the Coronavirus Crisis. McKinsey Co. Insights. 2020. Available online: https://www.mckinsey.com/capabilities/operations/our-insights/managing-a-manufacturing-plant-through-the-coronavirus-crisis (accessed on 20 June 2021).

- Lotfi, Z.; Mukhtar, M.; Sahran, S.; Zadeh, A.T. Information Sharing in Supply Chain Management. Procedia Technol. 2013, 11, 298–304. [Google Scholar] [CrossRef]

- Nikolopoulos, K.; Punia, S.; Schäfers, A.; Tsinopoulos, C.; Vasilakis, C. Forecasting and planning during a pandemic: COVID-19 growth rates, supply chain disruptions, and governmental decisions. Eur. J. Oper. Res. 2021, 290, 99–115. [Google Scholar] [CrossRef]

- Diebner, R.; Silliman, E.; Ungerman, K.; Vancauwenberghe, M. Adapting Customer Experience in the Time of Coronavirus. 2020. Available online: https://www.mckinsey.com/business-functions/marketing-and-sales/our-insights/adapting-customer-experience-in-the-time-of-coronavirus# (accessed on 20 February 2021).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).